Wood-Mizer

MP360 Planer Moulder

USER MANUAL

Read through the user manual carefully and make sure you understand its

contents before you use the planer/moulder.

This user manual contains important safety instructions.

WARNING! Incorrect use can result in serious personal injury or even death to

the operator or others.

© 2018

Printed in the United States of America. All rights reserved. No part of this manual may be

reproduced in any form by any photographic, electronic, mechanical or other means or

used in any information storage and retrieval system without written permission from

Wood-Mizer

8180 West 10th Street

Indianapolis, Indiana 46214

Wood-Mizer

from forest to final form

®

Table of contents

Getting started 2

Warranty 3

Safety instructions 6

Tools required 8

Machine description 8

Preparations 9

Setup 10

Chip management 10

In and outfeed table 11

Starting the planer 11

Control panel 12

Bottom cutter 13

Top cutter 15

Molding knife in bottom and

top cutter 17

Side cutters 18

Variable Feed Motor 22

Maintenance 23

Setting the upper chassis' plan 24

Planing tips 24

MP360 Profile knives 25

Electrical schematic 28

Technical data 31

List of components 32

Overview Images 34

Wood-Mizer

2

®

from forest to final form

GETTING STARTED

Wood-Mizer is committed to providing you with the latest technology, best quality, and

strongest customer service available on the market today. We continually evaluate our

customers’ needs to ensure we

comments and suggestions are welcome.

Read this manual completely before starting!!

General Contact Information

Toll free phone numbers are listed below for the continental U.S.

and Canada. See the next page for contact information for more

Wood-Mizer locations.

are meeting current wood-processing demands. Your

United States Canada

Sales 1-800-553-0182

Service

Website www.woodmizer.com

E-mail woodmizer@woodmizer.com oninfo@woodmizer.c

1-800-525-8100

Office Hours: All times are Eastern Standard

Monday - Friday Saturday

(Indianapolis Office Only)

8 a.m. to 5 p.m. 8 a.m. to

Time.

12 p.m.

1-877-866-0667

1-877-866-0667

www.woodmizer.ca

om

Sunday

Closed

Please have your vehicle identification number and your customer number ready when you call.

Wood-Mizer will accept these methods of payment:

Visa, Mastercard, or Discover

COD

Prepayment

Net 15 (with approved credit)

Be aware that shipping and handling charges may apply. Handling charges are

based on size

and quantity of order. In most cases, items will ship on the day they are ordered. Second Day

and Next Day shipping ar

If your equipment was purchased

e available at additional cost.

outside the United States or Canada, contact the distributor

for service.

Wood-Mizer Locations

3

USA World Headquarters Canadian Headquarters

Wood-Mizer MP360

Serving North & South America, Oceania, East

Asia

Wood-Mizer LLC 8180

West 10th Street

Indianapolis, IN 46214

Phone: 317.271.1542 or 800.553.0182

Customer Service: 800.525.8100 Fax:

317.273.1011

Email: infocenter@woodmizer.com

Serving Canada

Wood-Mizer Canada

396 County Road 36, Unit B

Lindsay, ON K9V 4R3

Phone: 705.878.5255 or 877.357.3373

Fax: 705.878.5355

Email:

ContactCanada@woodmizer.com

Brazil Headquarters Europe Headquarters

Serving Brazil

Wood-Mizer do Brasil

Rua Dom Pedro 1, No: 205 Bairro: Sao Jose

Ivoti/RS CEP:93.900-000

Tel: +55 51 9894-6461/ +55 21 8030-3338/ +55

51 3563-4784

Email: info@woodmizer.com.br

Serving Europe, Africa, West Asia

Wood-Mizer Industries Sp z

o.o. Nagorna 114

62-600 Kolo, Poland

Phone: +48.63.26.26.000

Fax: +48.63.27.22.327

Branches & Authorized Sales Centers

For a complete list of dealers, visit www.woodmizer.com

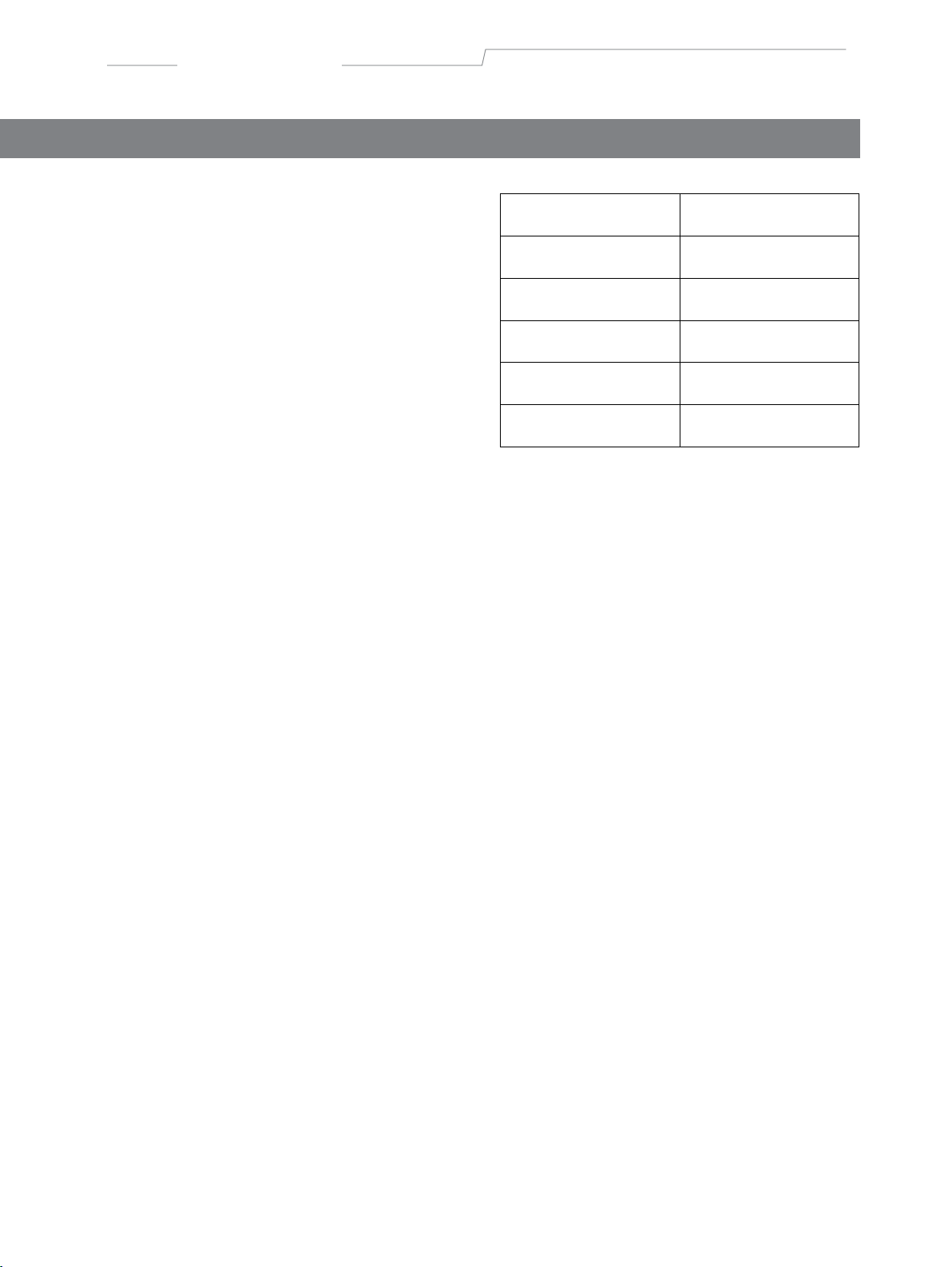

WARRANTY

Wood-Mizer® LLC

Limited Product Warranty

Wood-Mizer LLC (“Warrantor”), an Indiana corporation with its principal place of business at 8180 West

Tenth Street, Indianapolis, IN 46214-2400 USA, warrants to the purchaser (“Purchaser”) that for the time

periods specifically stated herein and subject to the terms, conditions and limitations stated herein, the

equipment manufactured by the Warrantor will be free from defects in material and workmanship

attributable to Warrantor so long as, during the warranty periods stated herein, the equipment is installed,

operated and maintained in accordance with the instructions provided by Warrantor.

Wood-Mizer

4

PRODUCT

Portable Sawmills,

Resaws, Edgers

Portable Sawmills

with Chassis

from forest to final form

MODEL CLASS

LT, LX, HR, EG

LT28, LT35, LT40,

LT50, LT70, LX450

®

LENGTH OF WARRANTY

USA&CANADA

Two years

Two years, excluding

the chassis, which

chassis shall have a five

year warranty

NON USA &

CANADA

One year

One year

EFFECTIVE DATE

Date of purchase

Industrial Sawmills,

Resaws, Edgers

TITAN Industrial

Material Handling

Blade Maintenance

Options and Accessories

Moulders, Kilns

WM, HR, EG, TVS, SVS

WB, TV, HR, EG, EA, MR

TWC, IC, TD, LD,

GC, CR, CB, CC

One year One year

One year One year

One year One year

BMS, BMT, BMST One year One year

Various

MP, KS, KD

One year* One year*

One year One year

Date of purchase or

date of installation /

training (if applicable),

whichever occurs first,

not to exceed 6

months from date of

purchase

Date of purchase

Pallet Dismantlers

Log Splitters

Replacement Parts

PD One year One year

FS One year One year

Various

90 days 90 days

* Warranty on Options will match the warranty on the primary equipment when purchased on same invoice.

Exclusions from 90 Day, Limited One Year and Two Year Warranty

Warrantor shall have no responsibility under this warranty for any wear components, including, but not limited to: belts,

blade guides, blades, electric motor brushes, drum switches, filters, fuses, hoses, bearings (excluding cylindrical drive

bearings), bushings, cable carriers, and spark plugs. All wear components are furnished “as is”, without any warranty

from Warrantor. This limited warranty does not cover any defects caused by misuse, negligence, alterations, damage

due to overload, abnormal conditions, excessive operation, accident, or lack of performance of normal maintenance

services.

Several components which are used in the manufacture of the equipment but not manufactured by Warrantor such as

cant hooks, power plants, laser sights, batteries, tires, and trailer axles have warranties provided by the original

equipment manufacturer (written copies available upon request). Warrantor does not separately warrant such items.

Components or equipment manufactured by third parties are not covered by this warranty. Warrantor, however, will

provide reasonable assistance to the Purchaser to make claims against any warranties applicable to such component

parts as provided by such original equipment manufacturers. Components or equipment manufactured by third parties

are not covered by this Warranty.

Five Year Limited Chassis Warranty

The limited five year chassis warranty described above, DOES NOT extend to (a) any damage stemming from

accident, improper towing, overload, abuse, misuse, abnormal conditions, negligence, excessive operation, or lack of

maintenance, (b) rust caused by exposure to corrosive atmospheric conditions, or (c) the sawmill head, carriage, axle,

brakes, or any hydraulic or electrical components attached to the chassis.

Wood-Mizer MP360

5

Warrantor’s Obligations as To Defects

In the event that the equipment fails to perform due to defective materials or workmanship attributable to Warrantor

under normal use and service within the established warranty period, Purchaser’s sole and exclusive remedy and

Warrantor’s sole liability shall be to replace or repair, in Warrantor’s sole and subjective discretion, any defective part

at Warrantor’s principal place of business without cost to the Purchaser if such defect exists. The determination of

whether a product is defective shall be made by Warrantor in Warrantor’s sole and subjective discretion. The

Purchaser must notify Warrantor prior to shipping any defective part. Warrantor, at its sole discretion, may cover

expenses incurred in shipping the defective part to Warrantor for evaluation; provided, however, that Warrantor will not

be responsible for labor, travel time, mileage, removal, installation or incidental or consequential damages. However,

any part in excess of 140 pounds must be returned by the Purchaser, to the Warrantor’s nearest authorized facility at

the Purchaser’s expense, if return is requested by Warrantor. Warrantor shall have a reasonable time within which to

replace or repair the defective part. If Warrantor determines that the product is not defective under the terms of this

warranty in Warrantor’s sole and subjective discretion, then Purchaser shall be responsible for any expenses incurred

by Warrantor in returning the equipment to the Purchaser.

Limitations and Disclaimers of Other Warranties

EXCEPT FOR THE EXPRESS WARRANTY PROVISIONS STATED ABOVE, WARRANTOR DISCLAIMS ALL

WARRANTIES, EXPRESS AND/OR IMPLIED, INCLUDING WITHOUT LIMITATION, THE IMPLIED WARRANTIES

OF MERCHANTABILITY, AND FITNESS FOR A PARTICULAR PURPOSE, NONINFRINGEMENT AND TITLE. No

representation or other affirmation of fact by representatives of Warrantor, whether verbal or in writing, including

photographs, brochures, samples, models, or other sales aids, shall constitute a warranty or other basis for any legal

action against Warrantor. There are no other representations, promises, agreements, covenants, warranties,

guarantees, stipulations or conditions, express or implied, by Warrantor except as expressly set forth herein. THE

ORIGINAL PURCHASER AND ANY INTENDED USER OR BENEFICIARY OF THIS EQUIPMENT, SHALL NOT BE

ENTITLED TO RECOVER ANY INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY, CONSEQUENTIAL, SPECIAL,

OR INCIDENTIAL DAMAGES OR LOSES, INCLUDING BUT NOT LIMITED TO, DAMAGES OF LOST

PRODUCTION, LOST REVENUE, LOST PRODUCT, LOST PROFITS, LOST BUSINESS, LOSS OF USE, LOSS

OF GOODWILL, OR BUSINESS INTERRUPTION, FROM WARRANTOR FOR ANY REASON WHATSOEVER

INCLUDING WITHOUT LIMITATION WARRANTY OR DEFECT IN THE PRODUCT REGARDLESS OF THE SOLE,

JOINT AND/OR CONCURRENT NEGLIGENCE, BREACH OF CONTRACT, BREACH OF WARRANTY, STRICT

LIABILITY IN TORT OR STATUTORY CLAIMS OR OTHER LEGAL FAULT OR RESPONSIBILITY OF EITHER

WARRANTOR OR PURCHASER OR ITS EMPLOYEES OR AGENTS. Warrantor does not warrant that its

equipment meets or complies with the requirements of any particular safety code or governmental requirements.

Defective items replaced under the terms of this warranty become the property of Warrantor.

Design Changes

Warrantor reserves the right to change the design of its products from time to time without notice and without

obligation to make corresponding changes in or to its products previously manufactured.

Rights of Purchasers

The validity and effect of this limited warranty as well as its interpretation, operation and effect, shall be determined

exclusively by the principles of law and equity of the State of Indiana, USA. This limited warranty gives Purchaser

specific legal rights. Purchaser may also have other rights, which may vary from state to state. Some states may not

allow limitations as to the duration of implied warranties or to the exclusion or limitation of incidental or consequential

damages, so some of the limitations and exclusions detailed set forth above may not apply. In the event that any one

or more of the provisions of this warranty shall be or become invalid, illegal or unenforceable in any respect, the

validity, legality and enforceability of the remaining provisions of this warranty shall not be affected thereby.

Interpretations

This Warranty constitutes the entire warranty agreement between Warrantor and Purchaser and supersedes any prior

understandings or agreements pertaining to the same subject matter. This warranty cannot be amended except in

writing which refers to this warranty which is signed by both Warrantor and Purchaser.

© 2018 Wood-Mizer LLC – 8180 West 10th Street, Indianapolis, IN 46214

FORM#1814ENG

Wood-Mizer

6

®

from forest to final form

SAFETY INSTRUCTIONS

• Make sure that all warning and information

stickers are in place, and that they are clean

and legible. Any damaged stickers must be

replaced immediately.

• Persons who do not have the necessary

knowledge or experience of planers must not

use this planer/moulder. This instructions do

not constitute training in machine planing.

Contact Wood-Mizer for information regarding

training in machine planing.

• Ensure that non-authorized persons do not

use this moulder.

• All protection must be assembled before

the molder is used.

• Always use protective goggles and ear

protection.

• Never use the molder if you are under the

influence of strong medication, alcohol or any

other strong drugs.

• Always check that knobs, screws, nuts,

fences, sleeves, planing cutters, planing

knives, etc. are properly tightened. Also

check that the cutter can rotate freely and that

there are no tools in or on the planer/moulder

before it is started.

• Never use the planer/moulder in poor

visual conditions such as bad lighting.

• Small dimensions must be planed using

fixtures, e.g. a piece of wood with a

customized groove that extends along the full

length of the table.

• Never stand along the workpiece's extension

line as kickback can occur, and bits of the

workpiece can be thrown out of the planer/

moulder. This applies to both the in and

outfeed sides, although the risk is greater on

the infeed side.

KEY TO SYMBOLS

For your own safety, read the entire

instruction manual carefully and do not

start the planer/moulder before you have

understood everything.

Use approved ear protection and

protective goggles. Hearing can be

damaged after only a short exposure

Sharp rotating tools. Be careful not to

let your fingers get near the cutter.

This symbol means "WARNING!". Be

extra vigilant when this symbol appears

in the manual text.

This symbol is followed by a prompt. Be

extra vigilant when this symbol appears

in the manual text.

• Never place tools or hands into the in or

outfeed areas when the planer/moulder is

running.

• Never intervene in the planer/moulder

before you have ensured that the power is

switched off and the planer/moulder cannot

be started accidentally.

PLANING/MOULDING

• Always measure the workpiece and set

suitable thickness and width before planing.

• There is a high risk of accident if you feed in

a workpiece that is not high enough for the

feed rollers to get hold of the workpiece.

GENERAL

Wood-Mizer MP360

7

SAFETY DISTANCE

• Check the molder/planer as soon as you

receive it. Report any transport damage to the

transport company immediately.

• LIFT THE PLANER/MOULDER using a forklift or pallet jack.

• When replacing spare parts, use only original

parts and note that anything electrical must

be assembled by a qualified electrician.

APPLICATIONS

The planer/moulder can be used for planing/

molding and planing wood, chipboard, board, etc.

Hard materials such as chipboard, teak, MDF,

etc. require hard carbide tools.

The planer/moulder is designed for indoor use,

with temporary outdoor use.

ENVIRONMENTAL REQUIREMENTS

The temperature in the premises should be above

freezing, unless special measures are taken.

Other than the operator, no one should

be within 3 meters (10 foot) of the

planer/moulder's sides or 8 meters (26

foot) from the in and outfeed sides

during operation. Mark a limit that

prevents anyone accidentally wandering

into the risk area.

TIPS: An extended infeed table is practical to

use, and prevents anyone coming into the risk

area.

Ventilation in the premises must be mechanical,

and of a good standard.

The planer/moulder must be connected to a

chip extractor.

Wood-Mizer

8

from forest to final form

TOOLS REQUIRED

®

A LIST OF THE TOOLS REQUIRED TO BE

ABLE TO WORK WITH THE PLANER/

MOULDER:

Hex key 4 mm (supplied)

Hex key 5 mm

Hex key 6 mm

Open ended wrench 10 mm

(supplied) Wrench 10 mm

Ring wrench 13 mm

Open ended wrench 30 mm

(supplied)(for milling spindle)

Adjustable wrench 8" or 10"

(for milling spindle)

Sliding caliper

Measuring tape or ruler

Paraffin oil for the table

Whetstone

THE FOLLOWING SPACER RINGERS

ARE SUPPLIED:

3 x 40 mm height

2 x 20 mm height

2 x 10 mm height

1 x 5 mm height

2 x 2 mm height

1 x 1 mm height

1 x 0.5 mm height

1 x 0.3 mm height

1 x 0.2 mm height

1 x 0.1 mm height per cutter

These spacer rings allow you to set the required height.

MACHINE DESCRIPTION

The MP360 is a planer/moulder that can work four

sides of a workpiece in one action. The planer/

moulder is contained in a stable and strong

chassis. The planer/moulder table and slide for

the moving cutter are made of planed cast iron.

The workpiece is fed, lying on the planer table,

through the planer by four feed rollers as well as

an outfeed roller. The rollers are driven by a

chain transmission with separate motor. The

workpiece is controlled laterally with adjustable

fences and pressure rollers.

The work is done using a top cutter and a bottom

cutter, that are hung at both ends, as well as two

side cutters which are fixed to the planer table.

All the cutters are driven by separate motors, via

a belt transmission.

The cutters and feed rollers are covered by a

foldable protective cover plate with window. The

cover plate is supplied with a safety switch.

Another safety switch sits behind the top edge of

the cover plate on the infeed side. A 100 mm (4”)

hose is connected to the bottom and side cutters

and a 125 mm (5”) hose is connected to the top

cutter with the option of an additional 100 mm (4”)

for connection to the chip extractor.

TABLE SURFACE

The table is cast in the highest quality. The table surface is specially processed for the highest

precision and the best anti-friction qualities. When

the planer/moulder is new, it requires a breaking-in

period until the table gets a slightly shinier surface to

optimize the anti-friction qualities. During this period,

we recommend that you use a lubricant or wax on

the table.

PREPARATIONS

Stål Blankförzinkad

Bricka 11x22x3

Automatstål

Stång D30 L11

360-342

1312

Plåt 4mm

360-167-2

Automatstål

Stång D30 L25

360-134-1

Oljebrons

Lager d12 D18 L25

360-125-1

AL

AL-profil:360-325

40x30x800

360-329

Mutter M12

9

Wood-Mizer MP360

Certain parts are not assembled on delivery for

transport and packaging reasons.

Part number references are found in the

exploded views in the back of this manual.

1.

Assemble the control panel in place with the

arm where the cabling goes, (232), (251).

2. Assemble all safety doors.

3. Assemble the infeed table (212). [Figure 1]

• Screw down all adjustable screws (B) in the

bottom.

• Insert all screws (A) tighten by hand.

• Insert the adjustment screws (C) and adjust

the table so it is straight.

• Adjust exactly: The highest position of the

infeed table must be on the same level as

the cast machine table. Check with a long,

straight fence rail.

• Adjust the height of the table so that it

touches the cast iron table with the

adjustment screws (B) and tighten the

holding screws (A).

Check the table angle and table height

•

and

insert the table fixture’s bottom lock

screws (D) which are fastened using nuts on

the inside of the chassis.

4. Assemble the outfeed table (253). [Figure 2]

5. Assemble the side fences [Figure 3]

6. Connect the planer/moulder to the chip

extractor.

7. Before the planer/moulder is connected to the

electrical circuit, check that all cutters can

rotate freely, and that all parts are fixed.

Figure 2.

M10-25mm

M10-25mm

M10-30mm

Figure 1.

Hole pattern key:

A: Holding screws for the infeed table.

B: Holes for accessing the adjusting screws where the screw

head lies under the table fixture.

C: Threaded hole for adjustment screws for setting the table

angle.

D: Hole for lock screws.

E: Fixing point for adjustable side fence. A double hole pattern

means that the fence can be placed in an outer or inner position

Figure 3.

41

25

42

24

16

16

14

17

15

22

M10

42

26

42

43

27

16

23

13

22

39

16

19

14

22

38

M10-25mm

M10-25mm

M10-30mm

M10

Wood-Mizer

10

from forest to final form

SETUP

®

Check your MP360 as soon as you receive it.

Any transport damage must be reported to

the transport company immediately.

Most of the planer/moulder is protected against

rust, but it will require extra maintenance in the

form of lubrication for all the parts not protected

against rust. See the Maintenance section.

• Place the planer on a stable and flat base.

Preferably screw the planer down using the

holes in the base, if the castor set is not used.

• Ensure that there is enough space for the

longest boards you want to plane at the in

and outfeed sides, and that there is enough

space for maintenance and timber stocks.

• Connect the chip hoses and fix using the

hose clips on the planer and fan.

• Hang the planer's electrical cable on the

ceiling or protect it in another way. Never step

on the cable. The planer/moulder should be

connected via an earth-fault protection switch.

• Ensure that lighting is good. There should

also be good general lighting. Also set up a

strong lamp directly over the planer. Ensure

that there is no risk of glare.

SPACE REQUIREMENTS

The planer/moulder needs a space of at least 2

m (6 1/2 ft) wide. The length required depends on

the length of the workpieces you want to plane.

The minimum length is 4 m (13 ft).

ANCHORING

For the highest safety, the planer/moulder must

be anchored to the floor using screws. Screw

diameter 8-10 mm (3/10"- 4/10").

CHIP MANAGEMENT

The MP360 must be connected to a chip fan

with a capacity of at least 3,000 m3/h (10,000

cubic feet/hr).

Remember that you need an air vent in your chip

container (e.g. a fine net or filter if you carry out

chip collection indoors). Poor suction is often due

to poor airflow from the chip container. If you work

in heated premises, remember that the fan will

quickly cool the space if you do not lead the

filtered air back into the building. Consideration

must be taken for fire risk and dust emissions

(discharge) in connection with chip collection.

Fire risk and dust emission in connection

with chip management.

Contact the local authorities for advice

in designing a chip collection system to

conform with rules in your area.

Chips that are left in the planer/moulder

must be vacuumed up after every work

session.

TECHNICAL REQUIREMENTS

CHIP EXTRACTOR

• The chip extractor must be approved

according to the CE-standard.

• The airflow "without external connection" must

be approx. 4000-5000 m3/hour (13,000-16,500

cubic feet/hour).

• (The manufacturer's standard indication

of airflow.)

• The sleeve diameters for the planer = 100

mm (4”) x 4 and 125 mm (5") x 1.

• The pressure loss in the planer is 26 mm of

water column at 25 m/s (1 inch of water

column at 82 ft/s).

Position the chip fan so that you can

easily reach the switch.

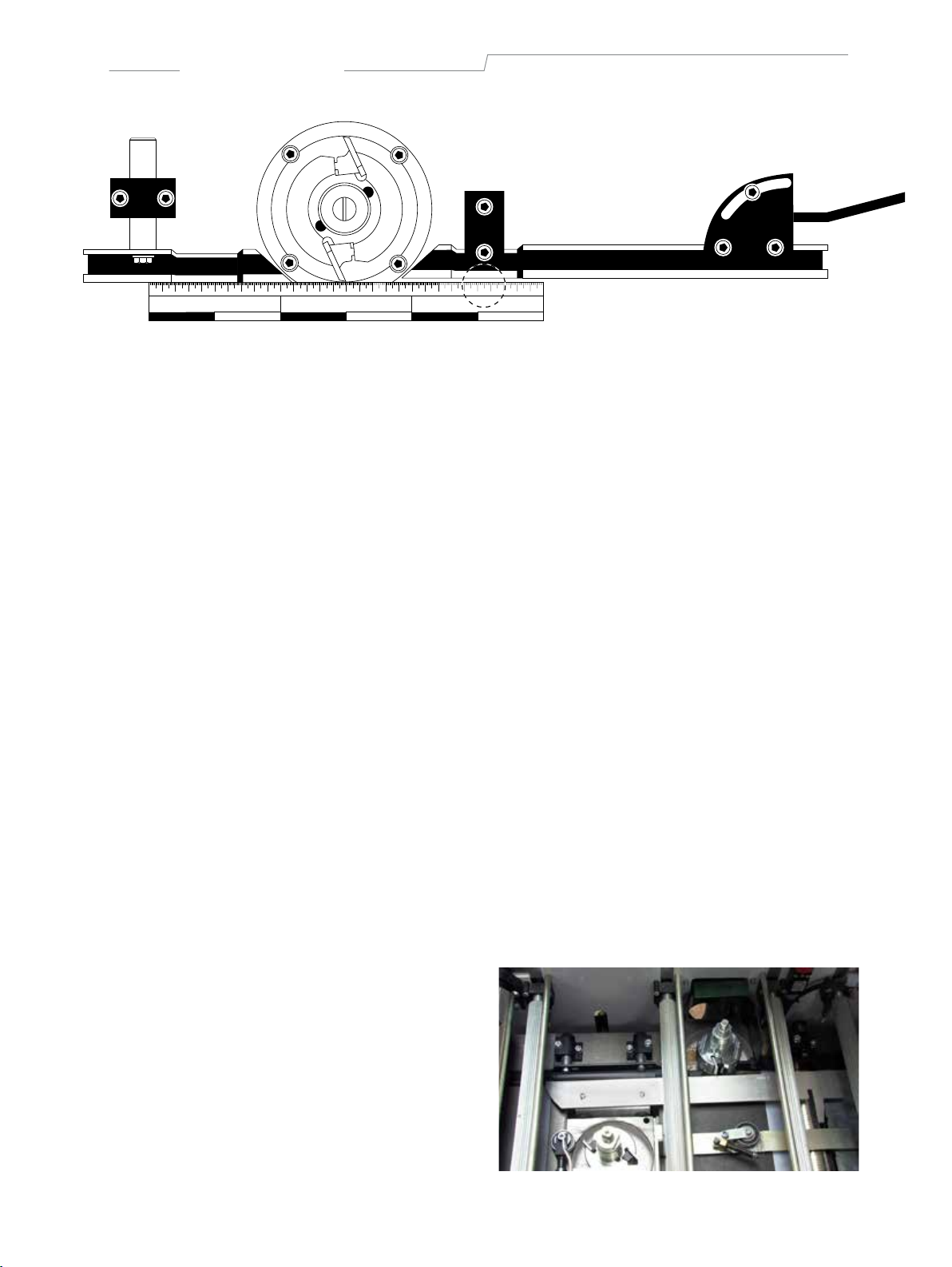

IN AND OUTFEED TABLE

Wood-Mizer MP360

11

Note that the outfeed table can easily be folded

up so you can move around the planer.

The tables must mainly be completely in line with

one another (when the cut in the bottom cutter is

0 mm (0") but in certain cases it can be an

advantage for the ends of the feed table to lie

slightly higher (1-5 mm) than the planer table to

reduce in and

STARTING THE PLANER

Risk of serious damage.

Check that no tools have been left in

the planer.

Check that the cutters can rotate freely

before the safety doors are closed.

Review the safety instructions!

outfeed marks (snipe). This particularly applies

when thin or soft workpieces are being processed.

The outer edges must then always lie slightly

higher than the planer table.

It is extremely important that the infeed table,

planer table and outfeed table are correctly setup

so that there are no cutter marks on the ends of

the object.

Before starting:

• Ensure that all cutters can rotate freely.

• Ensure that the emergency stop (a11) is

pulled out.

• Ensure that the top door is closed, and

impacts the door switch (179).

• Check that no one other than the operator

is inside the safety distance.

Connect the planer electrically. Watch the

rotational direction. If you are standing by

the feeder gears, the rotational direction

of the top cutter must be

counterclockwise.

Wood-Mizer

12

from forest to final form

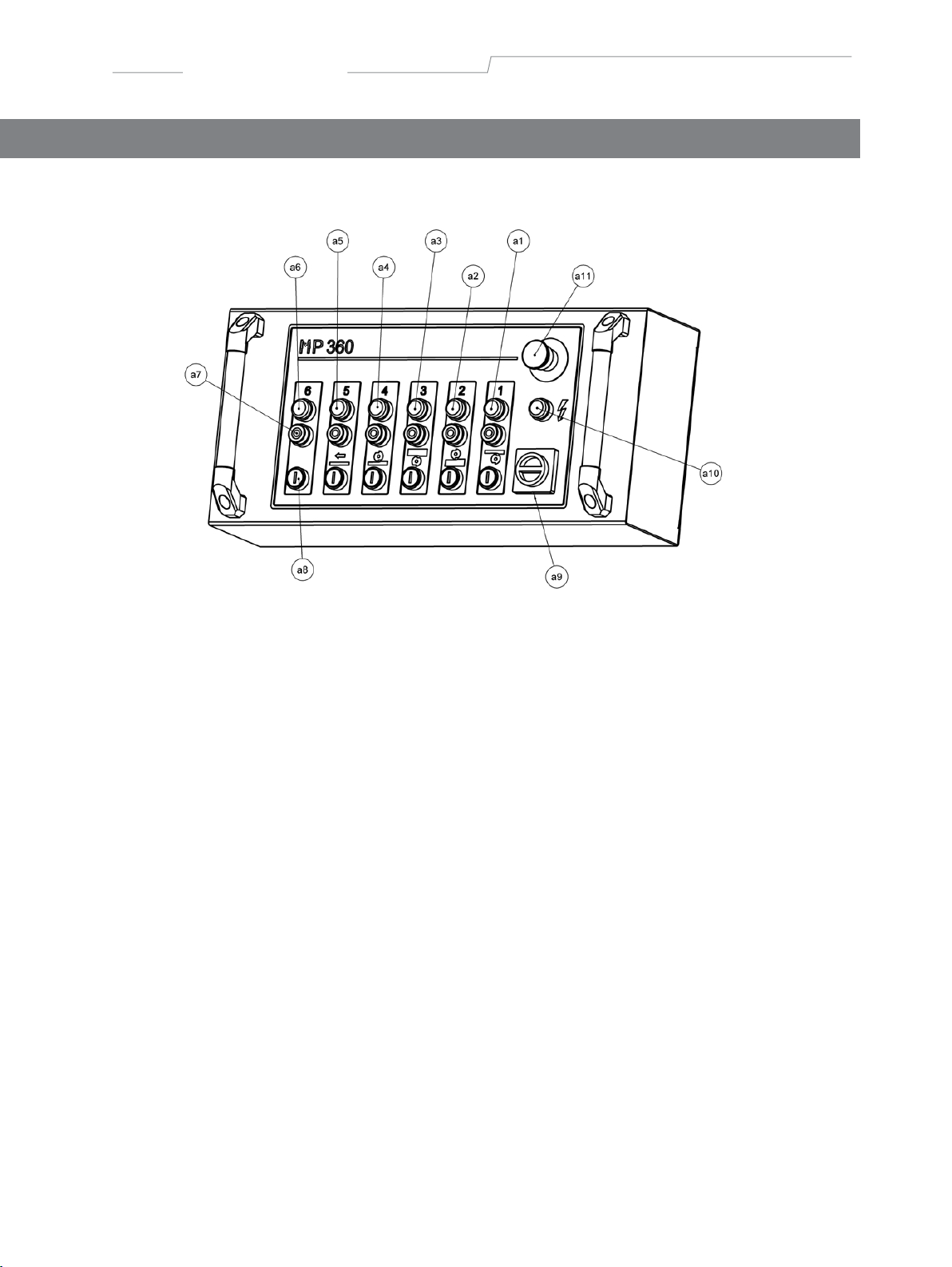

CONTROL PANEL

®

CONTROL PANEL

The top red button (a11) is the emergency stop

and switches off the power to all functions. When

the emergency stop is used, it must be pulled out

again in order for the planer/moulder to be restarted.

Under the emergency stop is a light (a10) which

indicates that the power supply is connected.

When replacing knives and during servicing, for

example, the power switch (a9) must be in the off

position. Check that the light (a10) is not lit.

The bottom white row of buttons (a8) start the

planer's motors. The top black row of buttons (a7)

stops the planer's motors (a7). Above each

button there is a light (a6) which indicates that

the relevant motor is running.

The button's function is from the right:

Starting the planer cutter (lower horizontal cutter)

1.

Starting the side cutter, right

2.

Starting the side cutter, left

3.

Starting the planer cutter (upper horizontal cutter)

4.

Starting the feed

5.

To control extra motors, such as a chip extractor,

6.

or a fifth cutter

BOTTOM CUTTER

Wood-Mizer MP360

13

Before you open the safety doors on the

planer, ensure that the power is switched

off and that the cutters are not rotating. Use

protective gloves, particularly when you

need to loosen screws that are tightly

fastened, or when you are tightening

screws (see warning instructions). Beware

of the planer knives. It is extremely easy to

cut yourself on these, even with the

slightest touch.

The bottom cutter is fixed to the planer table on

the planer's infeed side. Two planer knives are

mounted in two of the bottom cutter's tooling

slots on delivery (planer knife 410 mm (16")

HSS). Another two planer knives, or molding

knives can be mounted in the two empty tooling

slots.

SETTING THE BOTTOM CUTTER'S CUT

The cut of the bottom cutter is set using a

lever. Locking is done using a lever.

The normal cut on the bottom cutter is 2

mm (8/100").

GRINDING THE PLANING KNIFE

Always grind the knives in pairs, so they are the

same height, min. 15 mm (.600"), otherwise

vibrations could occur in the cutter. The

grinding angle must be 38 degrees.

ADJUSTING THE BOTTOM

CUTTER'S PLANING KNIFE

The bottom cutter's planing knife must be set so

that it is on the same level as and in line with the

planer table.

• Loosen the chip breaker's lock screws (B) that

are found in the groove between the chip

breaker (A) and the cutter using a 10 mm

(4/10") key (supplied). After this the knife can

be raised or lowered using the two adjustable

screws (4 mm socket head) (C) that are

recessed by the cutter's keyway. Use a 4 mm

socket head screw (supplied). The knife must

stick out 1 mm (.040") from the cutter body to

align with the molding knife.

DISASSEMBLING THE PLANER KNIFE

The planing knife is disassembled by loosening

the chip breaker's (A) lock screws (B) and then

unscrewing the planing knife with adjuster

screws (C).

B

A

D

C

• Check the level of the knife by placing a bit of

planed edging on the planer table behind the

cutter. The cutter's knife should then touch the

edging (see image below).

F

E

Wood-Mizer

14

®

from forest to final form

• Tighten the screws locking the knife in position

counterclockwise (i.e. out of the keyway). Start

by tightening carefully. Move from the sides

and in towards the middle, retightening them

later.

After adjusting or replacing planing knives:

Check that all screws have

been sufficiently tightened.

Check that the cutters can rotate freely

before the safety doors are closed.

Check that no tools have been left in

the planer.

Review the safety instructions!

TOP CUTTER

Wood-Mizer MP360

15

Before you open the safety doors on the

planer, ensure that the power is switched

off and that the cutters are not rotating. Use

protective gloves, particularly when you

need to loosen screws that are tightly

fastened, or when you are tightening

screws (see safety instructions). Beware of

the planer knives. It is extremely easy to cut

yourself on these, even with the slightest

touch.

SETTING THE CUT OF THE TOP CUTTER

The planer thickness is set using the planing

table crank (189). The set thickness can be read

on the indicator (109) on the machine stand. The

indicator can be calibrated. Plane some wood

and adjust the top cutter until you get the correct

height. Release the cover. The ring above the

indicator has a stop screw. Turn the ring so that

it shows the planing height that has been planed.

The top cutter is fixed to the chassis and hung at

both ends. Two planing knives ar

two of the bottom cutter's tooling slots on delivery

(planer knife 510 mm (20") HSS. Another two

planing knives, or molding knives can be mounted

in the two empty tooling slots.

Always set the top cutter uppermost to reduce

any slack in the threads. If the top cutter needs

to be lowered, lower it half a rotation too low and

then raise it into the correct position. Once you

have the top cutter set at the correct height, you

can lock it in position with the handle to the right

of the feed motor assembly.

DISASSEMBLING, ASSEMBLING AND

GRINDING PLANING KNIVES

S

ee above, under the Bottom cutter section.

Exceptions:

are

different. Make

Setting Block.

After adjusting or replacing planing knives:

The

minimum

Check that no tools have been left

in the planer.

Check that all screws have been

sufficiently tightened.

height

sure

e mounted in

of

you´re

the

planing

using

the

knifes

right

Check that the cutters can rotate freely

before the safety doors are closed.

Review the safety instructions!

ADJUSTING PLANING KNIVES

Adjust the planing knives so that they are the

same level and protrude 1 mm (.040"). This is

done using an aluminum adjustment block, found

in the component packaging on the planer table

when the planer/moulder is delivered.

Loosen the chip breaker's lock screws slightly,

and place the adjustment block over the knife.

Adjust the knife up or down until the knife brushes

against the block when it passes above the knife.

(The planing knife protrusion can also be adjusted

using a magnetic adjuster for the top cutter. See

the instructions enclosed with the magnetic

adjuster.)

Tighten the lock screws that lock the knife,

counterclockwise. Start by tightening carefully. Move from the sides in move towards

the middle, retightening them later.

Wood-Mizer

16

®

from forest to final form

When the top cutter's bearing housing is

adjusted, or when the planing knife's cut is

changed, the counter's pre-set must be

height calibrated.

ADJUSTMENT OF THE TRAPEZOIDAL

THREADED BAR'S CHAIN TRANSMISSION

The chain, which raises and lowers the table,

must not be slack, but needs to be tensioned

enough that teeth bite correctly. The tension is set

using a nut that is located in the chassis under the

planer table on the outfeed side.

Do not touch the chain tension as long as

the raising and lowering of the table works,

as an incorrect tension could mean that the

chain disengages.

MOLDING KNIFE IN BOTTOM AND TOP CUTTERS

Wood-Mizer MP360

17

Before you open the safety doors on the

planer, ensure that the power is switched

off and that the cutters are not rotating. Use

protective gloves, particularly when you

need to loosen screws that are tightly

fastened, or when you are tightening

screws (see safety instructions). Beware of

the planer knives. It is extremely easy to cut

yourself on these, even with the slightest

touch.

Molding knives can be assembled in both the top

and bottom cutters. Molding knives must always

be mounted in pairs – opposite each other. A

certain sideways offset of the knife, can however

be accepted, as long as the cutter remains

balanced.

WARNING! Unbalance in the cutter

creates vibrations that can damage the

planer and cause personal injury.

Molding knives must always be mounted

in pairs, so that the cutter remains

balanced.

After assembling the planing knives:

Check that no tools have been left in

the planer.

• To insert knives into the top or bottom cutter

heads, a gib/moulding knife clamp must be

used to hold the knife in the head.

Warning: Do not use any other device to

hold moulding knives in these heads!

• Assemble the Gib (D) and molding knife (E)

as shown. Note: The holes in the bottom of

the knife should fit securely on the pins on

the gib.

• Lower the gib and molding knife to the side of

the cutter where the tooling slots are

extended.

• Insert the knife and gib into the groove. Measure the position using the groove in the

cutter, and fix by tightening the screw (F)

tightly on the back of the gib. (Turning the

screw in the Gib as if to loosen it will tighten

the Gib into the head.)

The lock screw must not be placed over

the area where the tooling slots are

extended.

• Measure the position of the knife laterally

and assemble an identical knife in exactly

the same position on the cutter's opposite

side.

Check that all screws have been

sufficiently tightened.

Check that the cutters can rotate freely

before the safety doors are closed.

Review the safety instructions!

ASSEMBLY

The top and bottom cutter heads have four tooling slots each. As mentioned above, the planer is

delivered with two planing knives assembled in

two of the tooling slots. In the other two tooling

slots, molding knives of different sizes and

profiles can be assembled.

On the front edge of the planer/moulder,

there is a limiting cover that limits the top

cutter's maximum cut when turned. This

must be used when molding knives are

mounted in the top cutter (196).

Knife Gibs

for MP360

lower cutter.

Knife Gibs

for MP360

upper cutter.

Wood-Mizer

18

from forest to final form

Side cutterS

A

C

®

D

8

6

7

B

F

E

Before you open the safety doors on the

planer, ensure that the power is switched

off and that the cutters are not rotating. Use

protective gloves, particularly when you

need to loosen screws that are tightly

fastened, or when you are tightening

screws (see warning instructions).

The side cutters are fixed to the planer table. The

spindles are 30 mm (1 2/10") in diameter, which is

a standard measurement. Upon delivery, the

planer is equipped with two universal cutters with

planing knives, which you can easily replace with

molding knives. For reasons of safety, the cutters

work with conventional milling (the workpiece is

fed towards the molder's cutting motion). This

means that the lock nut and spindle on the

moving side cutter must be left-hand threaded.

The moveable side cutter's lock nut is

left-hand threaded.

After assembling the molding knives:

Check that no tools have been left in the planer.

Check that all screws have been

sufficiently tightened.

Check that the cutters can rotate freely

before the safety doors are closed.

Review the safety instructions!

DISASSEMBLING

Cutter 2 (Right, fixed cutters): Loosen the nut

on the spindle with a 30 mm wrench (supplied)

and a 1/2” or 13 mm wrench or adjustable

wrench. Unscrew the nut and remove the cutter

(A) and any spacing rings under the cutter.

Cutter 3 (left, moveable cutters): Crank the cutters to their previous position. The nut is loosened

in the same way as for cutter 2, with the

difference that the nut for cutter 3 is left-hand

threaded and is therefore screwed in the opposite

direction.

TIP: The side cutter nuts are loosened by turning

them in the same direction as their respective cutter

rotates.

REPLACING KNIVES

Loosen the lock screw (B) with a 4 mm hex

wrench (C) (supplied) and remove the chip

breaker (D). Then remove the knife (E) from the

peg (F). Insert a new wrench and tighten the

locking screw tightly.

Ensure that you turn the knives in the right

Wood-Mizer MP360

19

direction when you assemble them in the

cutter. The cutting edge must be turned

towards the chip breaker. Also check that

the cutter is facing the right direction on

the spindle. All of the planer/moulder's cutters

turn the same way as with conventional

milling.

Check that the non-corrosive spring plate in

front of the moveable cutter is not at risk of

being bent towards the cutter by the

workpiece's unplaned edge. Pay particular

attention when cutting workpieces of different

widths.

Ensure that the cutter can rotate freely and

that the plate working as a chip barrier behind

the moveable cutter is at a distance of approx.

5 mm from the cutter's largest cutting diameter.

HEIGHT SETTING

The side cutter's height is set by adding or removing the spacers that are supplied in the

component package on delivery.

Spacer height:

Spacers 40mm

Spacers 20mm

Spacers 10mm

Spacers 5 mm

Schim set (0.1 – 2.0 mm)

To remove the planing knife from the side

cutters, loosen the knife's lock screws that are

recessed into the cutters. Use a 4 mm hex

wrench

(supplied).

The height settings for tongue and grooves:

When tongues and grooves need to be moulded,

it is important that these are made opposite one

another, i.e. at the same height above the planing

table.Remove the cutter from the spindle (see

above under the Disassembling heading).

• Decide how you want the board to look. E.g. 8

mm above the groove, 6 mm groove and

7 mm under the groove (see image above).

• Assemble the molding knife and screw the

socket head screws that hold the knife properly.

Place the cutter on the spindle completely without

•

spacers. Measure the distance from the top

edge of the knife down to the planer table.

When the cutter is pre-set, the height of the knife

above the table must be 30 mm (7 + 6 + 17 = 30

mm). If, for example, the height of the knife

above the table is measured to 15.2 mm, the

cutter must be raised 14.8 mm (0.58") (15.2 +

14.8 = 30 mm).

Take the following measures:

• Remove the cutter.

• Combine spacers to the calculated

thickness (14.8 mm (0.58") in this example)

and thread them onto the spindle.

• Place the cutter on the spindle, screw on

the lock nut and tighten properly. Check

that the cutter can rotate freely.

• Carry out the points above on the cutter with

the tongue knife, so that it is placed at the

same height above the table.

• Test-plane a small board, and check that

the tongue and groove are at the right

height in relation to one another.

Alternatively, the knife can be set arbitrarily, after

which a test bit is run. Measure the test bit and

correct the knife height.

Spacers must also be placed above the cutter

so that it is fixed on the spindle. Add some of

the distance rings that are not used for height

setting, so that the thickest ring lies highest

and protrudes several millimeters above the

lowest threads on the threaded bar. Then

screw the nuts on the threaded bar and

tighten properly.

GRINDING

To recover the sharpness of the knife, you can

grind the flat side of the knife. Thus retaining the

same profile for the pair of knives. Always grind the

knives in pairs, so that they have the same weight,

other-wise vibrations could occur in the cutter.

If the profile of the knife is damaged, this should

be re-ground by a professional knife sharpener.

This is a service that is normally available locally,

otherwise contact Wood-Mizer.

If the cutter is 40 mm and the groove (6 mm in

this example) is in the middle of the knife, the

height of the knife above the groove is 17 mm.

Wood-Mizer

20

®

from forest to final form

ADJUSTING THE FENCE BY CUTTER 2

In general

The front side fence has a double set of holes for

assembly. It can therefore be assembled in two

basic positions. When the TB90 system is used,

the fence will be fitted in the pair of holes on the

right, as seen from the infeed side (see assembly

of side fence). When cutters with larger

diameters are used, the fence can be moved to

the left pair of holes, so that the stroke length is

sufficient.

The fixed cutter has two fences, the front (62) and

the back fence (54). The front fence controls how

much the cutter cuts, and the back fence works as

a support for the workpiece when it has passed

cutter 2 and is ready to be worked by cutter 3.

Both fences must be in line with one another, but

offset in parallel so that the front fence is slightly

more to the right (see fig.). In this way, the back

fence will support the workpiece once it has been

cut by cutter 2 (the workpiece is slightly smaller

then).

The fence is fixed by socket head screws in the

fence holders (55) according to fig. The screws that

lock the fence in the horizontal direction are 13 mm

(5/10") hexagonal screws and sit in the fence's U

profile. In addition, there are micro adjustments on

the fence. When the hexagonal screws are

loosened slightly, the knob for micro-adjustments

can be turned. If the angle of the fence needs to be

adjusted, both the hexagonal and socket head

screws must be loosened.

INSTALLATION OF SIDE FENCES

Method 1:

• Insert the first fence inwards, for minimal cutting. Add a straight aluminum fence rail tight

against the fence. Adjust the fence using

the lever until the loose fence rail touches

the cutter’s plane diameter (the outer

rotating line) as it lies against the first fence.

• The plane diameter that is inline with the back

fence is where you need to measure to, the

cutter’s plane diameter that is higher than 30

mm above the table height is unimportant

here.

Align the back fence along the guard rail, which

•

is still tight against the first fence and tighten it.

The cut is now 0 mm. The first fence, cutter and

back fence are fully inline, and the first fence

controls the angle through the machine.

• Remove the fence rail and all loose tools

from the machine.

• Move the first fence back to the required cut

and lock it using the tie-back knob. (Around

2 mm is usually a suitable cut for the first

cutter.)

Method 2:

• The back fence is pulled in so that it is not used,

and is fixed there. (Check that the cutter

can rotate freely.)

• Position the front fence so that the required

cut depth is obtained and the fence stands

straight. Tighten the screws that fix the fence.

• Close the safety doors and take the measures

required to start the planer/moulder.

•

Start the bottom cutter, both side cutters and the

feeder and feed in a test piece of approx. 1

meter (3 ft). Stop the planer/moulder just as the

board reaches the moveable cutter (cutter 3).

• Drive the back fence towards the planed part

of the board.

Installation jig for adjusting fences.

21

Wood-Mizer MP360

• Check that the test piece is lying against both

fences and tighten the back fence's lock

screws.

Check that all screws that fix the fences

are properly tightened, and that the cutter

can rotate freely.

TIP: If there is a problem in that the board does

not follow the fences, it could be that the back

fence is not at the right level in relation to the

cutter, that the fences are not completely parallel

to one another, or that the fence does not run

straight through the planer/moulder. If it is difficult

to get the fence to lie perfectly straight through the

planer/moulder, it is better that the fences are

slightly angled to the left, towards cutter 3, as the

feed rollers will then press the workpiece against

the fence. If the fences lie at a slight angle to the

right, away from cutter 3, the feed rollers will pull

the object away from the fence, which will lead to

incorrect measurements and a badly planed

surface.

ADJUSTING THE MOVEABLE

CUTTER (CUTTER 3)

Loosen the lock handle (91) that is located on the

slide under the table and/or the slotted screw that

is located above the slide (38). Then insert the

crank (260) onto the threaded rod on the side of

the planer and move the side cutter head to the

required planing width. One rotation of the crank

is 4 mm.

Measure the distance between the cutter knives

and the back fence with sliding caliper. This

measurement becomes the width of the finished

board. Fix this position with the lock handle under

the table.

INDICATOR

The indicator shows the width measurement in

mm in black, and 1/10 mm in red. Each time,

when setting to a new profile: plane a board,

measure the outer measurements with the sliding

caliper. Turn the small handle to the right of the

indicator so this measurement is shown in the

window.

INSTALLING A PRESSURE ROLLER FOR

MOVEABLE CUTTERS

Two pressure rollers are located in front of the

moveable cutter, to press the workpiece towards

the fence. By adjusting this you can also decide

how wide the workpieces fed into the planer/

moulder can be. These pressure rollers sit on an

arm (77) that is anchored in the moveable cutter's

slide, which

means that they move with the cutter when this

is adjusted.

To set the pressure rollers, loosen the socket head

screws that fix the arm in the moveable cutter's slide

with a 6 mm hex wrench. Adjust the arm so that the

press rollers are pressed in by approx. 5 mm when

the workpiece is fed into the planer.

A spring plate (supplied on delivery) can be mounted

in front of the moveable cutter between the press

rollers' arm and screw plate. The spring plate has

oval holes that allow adjustment in and out from

the workpiece. The spring plate works partly as a

tension control, but also as a fence in front of the

cutter which reduces the risk of long splinters

being knocked out of the workpiece during large

cuts.

Adjust the feather plate so that it is pushed in to a

couple of millimeters from the unplaned edge of

the workpiece.

Check that there is no risk of the spring

plate pushing into the cutter's knife if you

are planing an object of variable width.

Maintain a safety margin of at least one

centimeter in the pressed in position.

After the moveable cutter, there is another

pressure roller (76) which pushes the cut

workpiece towards the back fence. Set the

pressure roller so that it protrudes approx. 1-3 mm

from the cutter's smallest plane diameter, at the

same height as the pressure roller.

The height of the pressure roller can also be set

with washers above or below it. Which may be

required for producing certain profiles.

TEST RUN

Always run a test piece and make subsequent adjustments. Run a piece straight through the planer

at the slowest feed speed. Look through the cover

while it is being planed and check that the board is

lying against the fences in front of and behind

cutter 2.

Then measure the profile, its height and width,

and subsequently adjust the cutters and the

setting for the molding knives if required.

Wood-Mizer

22

®

from forest to final form

VARIABLE FEED MOTOR INSTRUCTION

WARNING! Do not turn the adjustment knob

when the planer/moulder is not running.

AGIP BLASIA 32

ASSEMBLY (IF THE VARIABLE FEED

MOTOR IS ASSEMBLED IN PLACE).

Assemble the feed motor package on the last

feed roller. Make sure that the torque stay is in

place. Lock this with the central screw on the

roller.

SETTING THE FEED SPEED

Turn the wheel clockwise to increase the speed.

INDICATOR DIAL FOR THE FEED SPEED

The indicator dial is/must be mounted in the

hub of the wheel. It works like an indicator that

has a weight in one part, so the indicator

moves. The black indicator shows a figure.

The indicator dial has a relative scale. See

the numbers as an indicator. The higher the

number, the greater the speed.

Start the planer/moulder and turn the wheel so the

planer reaches minimum speed.

Remove the indicator dial and turn it so the

indicator is set to zero. Then press the indicator

dial in with the indicator pointing upwards towards

zero.

SHELL A.T.F DEXRON

ESSO A.T.F DEXRON

MOBIL A.T.F 220

CASTROL DEXTRON II

BP AUTRAN DX

The variator is filled with AGIP BLASIA 32 at the

factory and does not normally require an oil

change during its life.

The worm gear oil does not normally need

changing or topping up during the life of the gear.

Use the indicator dial so that you can return to

the best speed for the profile you are planing.

If you have a 3-15 m/min (10-49 ft/min) gear:

0 on the indicator dial is 3 m/min (10 ft/min)

8 on the indicator dial is 15 m/min (49 ft/min)

MAINTENANCE

Fluid should be visible in the fluid level glass.

The level is checked when the planetary

gear is not running.

Top up if no fluid is visible in the glass. Use oil

for automatic gearboxes according to the table

below, or use compatible oil.

MAINTENANCE

Wood-Mizer MP360

23

The MP360 is easy to maintain as 95% of the

planer/moulder is protected against rust. The

maintenance required, is mentioned below.

Ensure that the power to the planer/moulder

is switched off before beginning maintenance.

After each work session:

• Clean chips from the planer/moulder. Also remove any chips from under the planer/moulder.

• Clean any resin off the table. Use mineral spirit

if necessary. Lubricate the table with paraffin

oil, for example.

MAINTAIN AT REGULAR INTERVALS AS

FOLLOWS

Lubricate these areas regularly:

• Feed roller Bushings.

• Sprockets, including top and bottom layers.

• The chain for setting table height.

• The chain driving the feed rollers.

• The two bars that the moveable slide runs on,

as well as the slide's trapezoidal thread.

• Cast iron table.

USING OR STORING IN COLD OR DAMP

ENVIRONMENTS

If the planer will be stored in a cold or damp environment over a longer period, all corrosive

parts must be treated with a rust inhibitor.

Cover the planer.

Check that all screws and bolt connections

are tightened and that cables and electrical

connectors are in good condition.

Wood-Mizer

24

®

from forest to final form

SETTING THE UPPER CHASSIS' PLAN

FOUNDATIONS

Re-setting the chassis plan requires a serious

intervention in the planer. Ensure that this is

necessary. The planer is set correctly when

leaving the factory, but may have adjusted

due to careless transport or serious impact.

SETTING CUTTERS

1. Loosen the screws to the bearing bracket (4

x M8 on each side)

2. Add a completely level block on the table,

directly under the cutter.

3. Turn the crank so the cutter is lifted

slightly (make sure the knife does not

bite)

4. Lock the screws to the bearing bracket

Setting only the planing table if, for example,

the chain has come loose, or the cutters do

not have enough trimming allowance.

1. Add a completely level block on the table,

directly under the cutter.

2. Crank the planing table so the block is at

a tangent to the cutter

3. Loosen the chain to the planing table via

the chain lock

4. Lift up each threaded sprocket so the cutter is

at a tangent to the block along its entire length.

5. Check the measurement of the front and

back of the table to the stand, adjust the front

or back pair of sprockets

6. Assemble on the chain to the planing table.

7. Before assembly you must check that

each threded rod can be turned by hand.

ADJUSTING THE TOP CUTTER

The top cutter must sit so that it is parallel with

the planer table. This is correctly set in the

factory, but can be adjusted due to careless

transport or serious impact. This is adjusted in

the following way, if necessary:

• Loosen the screws on the bearing housing

several turns (4 x M8 on each side).

• Add a completely level block on the table,

directly under the cutter.

• Turn the cutter so the block does not

press against the planing knife or the

keyway.

• Crank the table up so the block lifts the

cutter slightly.

• Lock the screws to the bearing bracket

PLANING TIPS

1. When you have finished planing a profile that

you know you will be planing again, feed in a

board of approx. 1 m (3 ft) long, then switch

off the planer/moulder when this has been fed

in. Lower the table and remove the board.

Next time the profile needs setting, the board

can be used as a template for both cutters

and fences. Please also note which shims and

knives you used for the test board, as well as

the position of the molding knives in the

horizontal cutters.

2. You can experiment with adjusting the

pressure on the feed rollers yourself. Note the

basic settings before you start, so you can

always return to them. The springs must

normally be tensioned more on the righthand side, particularly if small objects are

planed. The feed rollers must be balanced

on the object, and not press more on either

side.

3. An increased directional function can be

achieved if the first feed roller is set with a

lighter pressure.

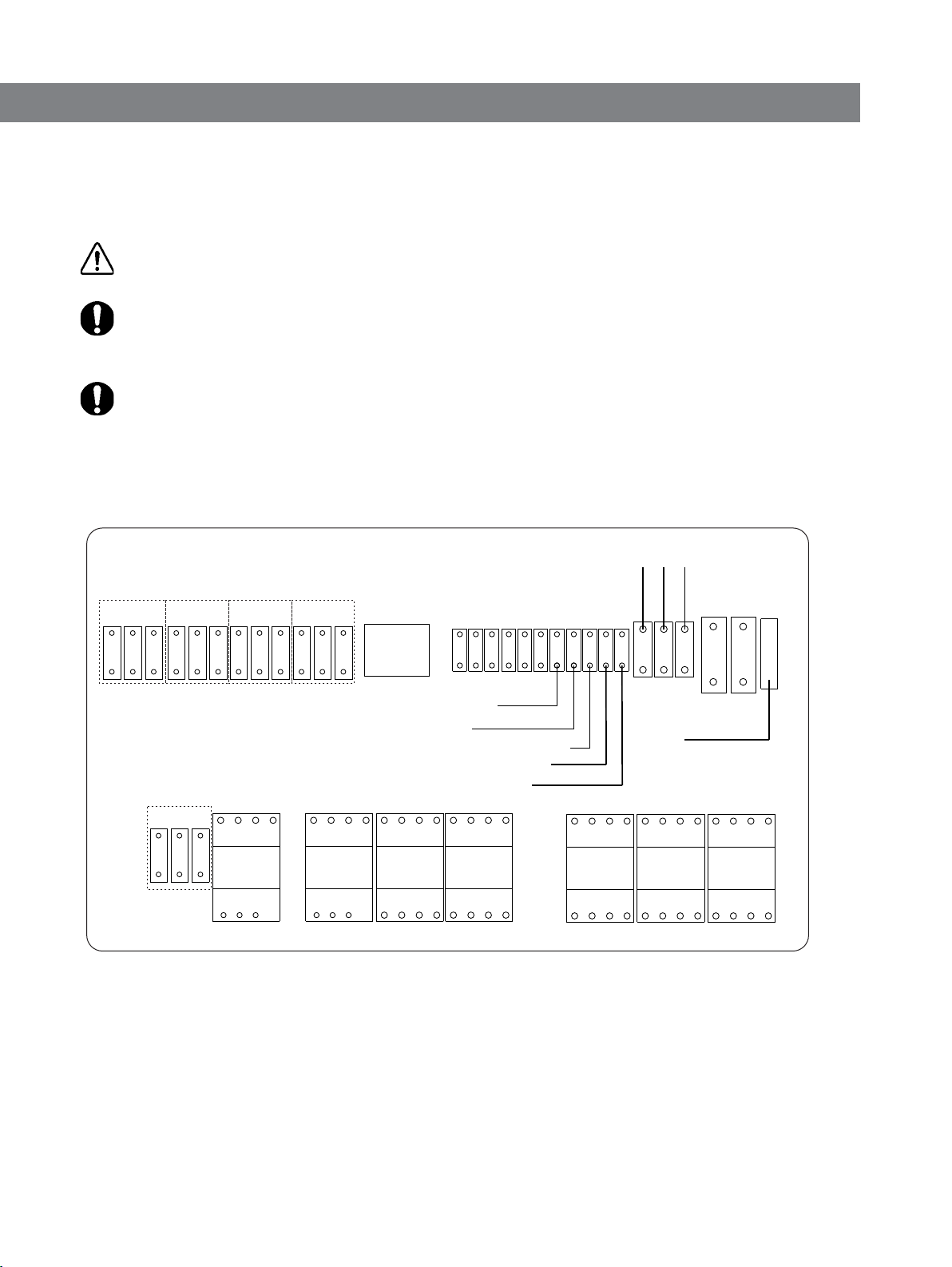

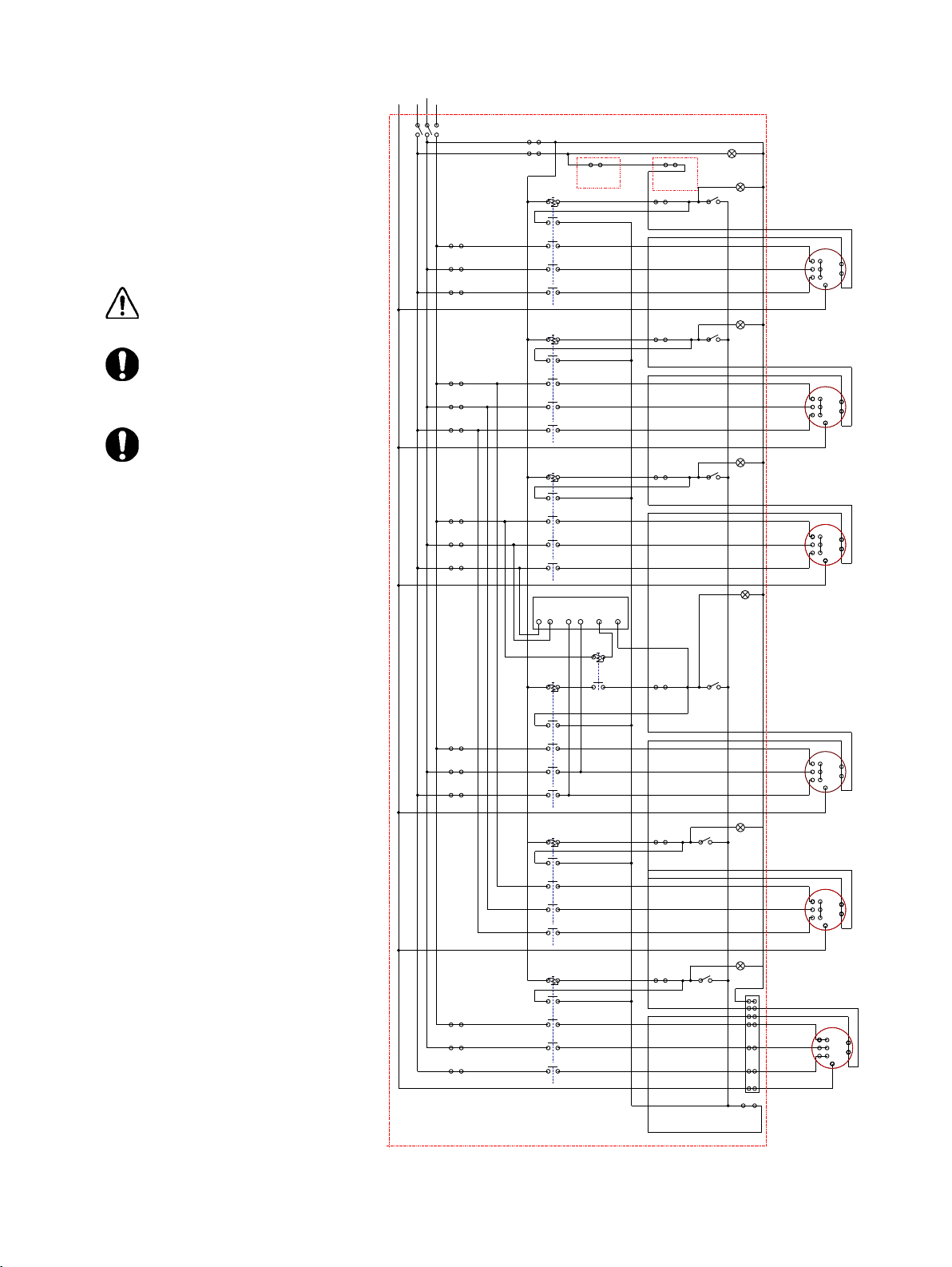

ELECTRICAL SCHEMATIC

ELECTRICAL SCHEMATIC

230 V 3-PHASE, 32-50 A

Lethal voltage! Incorrect

connection is potentially fatal.

Note that you need authorization

to open or intervene in the electrical equipment.

Ensure that the power supply

is switched off before you open

the system.

ELECTRICAL BOX MP360 230 V (North America)

Wood-Mizer MP360

FUSE 25 AMP

MOTOR 4

FUSE 16 AMP

MOTOR 3

FUSE 20 AMP

MOTOR 6

FUSE 16 AMP

MOTOR 2 & 5

Braker upper

cutter K4.1

9

FUSE 20 AMP

MOTOR 1

5th SPINDLE

K6 25

MOTOR BRAKE

UPPER CUTTER

CONNECTION

Extractor or

5th cutter

FEEDING

MOTOR

K5, 9

5

4

UPPER

CUTTER

K4, 25

MAIN

CONNECTION

3-phase

FUSE 1 AMP

FOR CONTROL

CURRENT

L1L1L2

L2

L3

3

L3

YELLOW/GREEN

GND,

EARTH

2

1

LEFT

CUTTER

K3, 18

RIGHT

CUTTER

K2, 18

UNDER

CUTTER

K1, 25

25

Wood-Mizer

from forest to final form

®

GND,

EARTH

L2

L3

L1

MANOUVER BOX

ELECTRICAL SCHEMATIC

230 V, 3-PHASE, 32-50 Aan

version

North American Version

Lethal voltage. Incorrect

connection is potentially fatal.

Note that you need authorization

to open or intervene in the

electrical equipment.

Ensure that the power supply is

switched off before you open

the system.

L1

L2

L3

FUSE 20 A (x3)

FUSE 16 A (x3)

FUSE 16 A (x3)

FUSE 1 A

FUSE 1 A

p2

p1

INFEED

SWITCH

K1

A1

A2

4

3

L3

T3

CONT.

L2

T2

CONT.

L1

T1

CONT.

K2

A1

A2

4

3

L3

T3

CONT.

L2

T2

CONT.

L1

T1

CONT.

K3

A1

A2

4

3

L3

T3

CONT.

L2

T2

CONT.

L1

T1

CONT.

BROMSKORT 230V

L1

L2/N

X1 X2 K

p3

TOP DOOR

SWITCH

OFF

p4

OFF

OFF

SP

WHITE LAMP

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

WHITE LAMP

ON

HORIZONTAL

UNDER CUTTER M1

4

5

1

MOTOR

2

3

YELLOW/GREEN

RIGHT VERTICAL

CUTTER M2

4

5

1

MOTOR

2

3

YELLOW/GREEN

LEFT VERTICAL

CUTTER

4

5

1

MOTOR

2

3

YELLOW/GREEN

1

THERMO

SWITCH

2

THERMO

SWITCH

3

THERMO

SWITCH

A (x3)

FUSE 25

FUSE 20 A (x3)

K4 25 A

L3

CONT.

L2

CONT.

L1

CONT.

K5

A1

4

L3

CONT.

L2

CONT.

L1

CONT.

K5

A1

4

L3

CONT.

L2

CONT.

L1

CONT.

K4.1 9 A

A1A1A2

p11

p10

OFF

OFF

OFF

A2

443

3

T3

T2

T1

A2

3

T3

T2

T1

A2

3

T3

T2

T1

ON

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

TERMINAL

p11

p10

2

p12

EMERGENCY STOP

1

1

2

3

YELLOW/GREEN

1

2

3

YELLOW/GREEN

1

2

3

YELLOW/GREEN

p10

TOP CUTTER

4

5

MOTOR

4

FEED MOTOR

4

5

MOTOR

5

EXTRACTOR

4

5

MOTOR

5

THERMO

SWITCH

THERMO

SWITCH

THERMO

SWITCH

26

ELECTRICAL SCHEMATIC

400-440 V, 3-PHASE, 20-50 A

North American Version

Lethal voltage. Incorrect

connection is potentially fatal.

Note that you need authorization

to open or intervene in the

electrical equipment.

Ensure that the power supply is

switched off before you open

the system.

GND,

EARTH

L1

L2

L1

L2

L3

FUSE 20 A (x3)

FUSE 16 A (x3)

FUSE 16 A (x3)

L3

FUSE 25 A (x3)

FUSE 16 A (x3)

FUSE 1 A

p2

FUSE 1 A

p1

K1

A1 A2

4 3

L3

T3

CONT.

L2

T2

CONT.

L1

T1

CONT.

K2

A1 A2

4 3

L3

T3

CONT.

L2

T2

CONT.

L1

T1

CONT.

K3

A1 A2

4 3

L3L3

T3

CONT.

L2L2

T2

CONT.

L1L1

T1

CONT.

BRAKE TOP CUTTER

L1 L2/NX1 X2 K

K4 25 A

A2

3

L3

T3

CONT.

L2

T2

CONT.

L1

T1

CONT.

K5

A1A2A2

3

L3T3T3

CONT.

L2T2T2

CONT.

L1T1T1

CONT.

K5

A1

443

L3

CONT.

L2

CONT.

L1

CONT.

Wood-Mizer MP360

MANOUVER BOX

WHITE LAMP

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

WHITE LAMP

ON

ON

p11

p10

p12

2

EMERGENCY STOP

1

HORIZONTAL

UNDER CUTTER M1

1

2

3

YELLOW/GREEN

RIGHT VERTICAL

1

2

3

YELLOW/GREEN

LEFT VERTICAL

CUTTER

1

2

3

YELLOW/GREEN

1

2

3

YELLOW/GREEN

1

2

3

YELLOW/GREEN

4

5

1

2

3

YELLOW/GREEN

INFEED

SWITCH

K4.1 9 A

400V

A1A1A2

443

p3

TOP DOOR

SWITCH

OFF

p4

OFF

OFF

SP

OFF

OFF

OFF

4

5

MOTOR

1

CUTTER M2

4

5

MOTOR

2

4

5

MOTOR

3

TOP CUTTER

4

5

MOTOR

4

FEED MOTOR

4

5

MOTOR

5

Extractor

MOTOR

6

THERMO

SWITCH

THERMO

SWITCH

THERMO

SWITCH

THERMO

SWITCH

THERMO

SWITCH

THERMO

SWITCH

27

Wood-Mizer

®

from forest to final form

TECHNICAL DATA

MP360

Length and width: 2,970 x 1,125 mm (117" x 44")

Height 1,430 mm (56")

Weight 675 kg (1488 lbs)

4-SIDED MOLDING

Width 360 mm (14")

Height 10-130 mm (0.4"-6")

2-SIDED MOLDING

Width 410 mm (16")

Height 10-230 mm (0.4"-9")

PLANING (assembly required)

Width 510 mm (20")

Height 230 mm (9")

TOP HORIZONTAL CUTTER

Diameter 88 mm (3.5")

Width 510 mm (20")

Output 5.5 kW (7.5 Hp)

Rotational speed 6,000 rpm

Cut when planing: 0-8 mm (0-0.3")

Cut when molding Max. 20 mm (0.8")

BOTTOM HORIZONTAL CUTTER

Diameter 72 mm (2.8)

Width 410 mm (16")

Output 4 kW (5.5Hp)

Rotational speed 7,200 rpm

Cut when planing: 0-8 mm (0-0.3")

Cut when molding Max. 10 mm (0.4") (Slot milling: 15 mm (0.6"))

SIDE CUTTERS

Diameter of spindle axel 30 mm (1.2") (with spacers to 1.25")

Cutter height Max. 130 mm (5")

Diameter Max. 140 mm (5.5")

Output 3 kW (Hp)

Rotational speed of side cutters 7,200 rpm

Cutting depth Max. 30 mm (1.2")

SUPPLIED SIDECUTTERS

Type and quantity 2 x TB90

Diameter, body 90 mm (3.5")

Height, body 40 mm (1.6")

Cut, type and width Planing knife HSS, 50 mm (2")

FEED, PLANED VARIATOR

Output 0.75 kW (1 Hp)

Feed rate 3-15 m/min (10-49 ft/min)

ELECTRIC SYSTEM

Total output 16.25 kW (22 hp) All motors are equipped with overheating protection.

Electrical connection 3-phase, 400 V, 32 A, 20A fuses are sufficient for less demanding production.

28

Wood-Mizer MP360

LIST OF COMPONENTS

Refer to the illustrations following this list for locations of parts.

Loc. Description Qty Loc. Description Qty

1 Cast iron table 1 57 Belt Pulley motor, Bottom

Cutter

2 Plastic Slide Strip, Feed

Rollers

3 Plastic Slide Strip, Top

Cutter

8 Chip Duct, Bottom 1 67 Poly-V Beltv, Bottom Cutter, 8

14 Cutter Motor, Bottom

Cutter

21 Belt Pulley, Bottom Cutter 1 1

26 Belt Pulley, Bottom Side

Cutter

27 Poly-V Belt, Side Cutter, 8

tracks

28 Motor, Side Cutter, USA 2 78 Pressure Roller, Front/Back,

29R Spindle, Cutter 1R 1 1

29L Spindle, Cutter I L 1

29L+R Ball Bearing, Side Cutter,

Top Bearing

29L+R Ball Bearing, Side Cutter, 2 1

30 Universal Cutter, TB9092,

2 knives

31R Nut, Spindle 1 R 1 1

31L Nut, Spindle 2 L 1 1

32 Spacer 5 mm 2

32 Spacer 10 mm 2 1

32 Spacer 20 mm 2

32 Spacer 40 mm 2 1

34 Fence 2 1 8

35 Fence Bracket 2 1

36 Micro Adjustment, Side

fence

37 Chip Guard Plate 1 1

38 Locking Screw, Slide 1 1

52 Lock Handle, adjust., M10

Inv. Thread

54 Bottom Cutter 1 2

55 Ball Bearing, Bottom Cutter 2 2

56 Bearing Bracket, Bottom

Cutter

56 Seal O-ring, Bottom Cutter 2 133 Moulding Knife 510mm, HSS,

2 60 Moulding Knife, 410 mm 2

1 61 Chip Breaker, 410 mm 2

tracks

1 70 Bronze Bushing, Slide 1

74 Slide

2

2 77 L Bracket, Complete 1

2 91 Locking Handle, Adjustable,

2

2

2

2

76 Pressure Roller, complete 1

Compl.

90 Bracket, L Bracket

90B Lock Fitting, L Bracket 1

M8x20

94A Chip Duct, Fixed Cutter

94B Chip Duct, Movable Cutter 1

108 Cover Plate, Meter Counter

109A Digital Counter, Side Cutter

109B Meter Counter, Height

Adjustment,

109C Inch Counter, USA

109D Inch Counter, USA 1

122 Chain 1, Feed

123 Chain Sprocket, Rollers

124 Chain M1, M2

125 Chain 3, Feed 1

126 Chain 4, Feed

128 Top Cutter

129 Bearing, Top Cutter 2

130 Bearing Bracket, Top Cutter,

130 O-Ring, Top Cutter

131 Belt Pulley, Top Cutter

Spindle

510x25x3 mm 2

134 Chip Breaker, 410 mm 2

1

1

3

1

1

1

2

2

9

Wood-Mizer

®

from forest to final form

Loc. Description Qty Loc. Description Qty

138 Bear ing Housi ng,

Rollers, Complete

139 Bronze Bushing, Feed

Rollers

143 Fee d Roller, Grooved 4 189 Crank, Height Setting 1

144A Polyurethane Feed

Rollers

144B Shear Pin, Rubber

Roller

148 Motor, Top Cutter, 5.5

KW / 7,5hp

149 Belt Pulley, Motor,

Top Cutter

152 Poly-V Belt, Top

Cutter

153 Cha in, Height

Adjustment

154 Trapezoidal Thread

Bar for Crank table

155 Cha in Sprocket 4 212 In-Feed Table 1

156 Bearing

Washer,Top/Bottom

157 Br onze Bushing,

Bearing Washer,

Top/Bottom

163 Trapezoidal Thread

Bar, Table

165 Re in forcement Plate,

Top Cutter

174 Cov er Pl at e, Sl ide 1 225 Locking

179 Circ uit Breaker 1 232 Electrical Distribution

180 O versize Preventer 1 253 Out-Feed Table 1

181 I nfinit ely Variable

Feed, Complete

182 Wor m Gear 1 260 Crank, Side Cutter,

184 Planetary Gear 1 267 Locking Knob, Door 1

184B Adjustment Knob,

Feed

185 Motor, Feed 400/230V 1 269 Handle, Cover 1

8 185 Motor, Feed, USA 1

14 187 Cover, Worm Gear 1

1 193 Chain Tensioning Arm 3

1 194 Chain Tensioning Wheel 3

1 196 Stop Plate on Infeed

side

1 197 Mount, Plastic, Cover,

Back

1 198 Plastic Cover, Back,

Complete

1 201 Chain Guard Plate 1

1 211 Height Setting Handle,

Feed table

8 216 Adjusting Handle, fence 1

8 220 Fence 1

3 223 Locking

Handle,Adjustable,

M10x20

1 224 Locking

Handle,Adjustable,

M8x25

Handle,Adjustable,

M10x40

Box, USA, Comp

1 259 Trapezoidal Thread Bar

Extender, Slide

Complete

1 268 Cover Plate, Chip Duct 1

272 Chip Duct, Top Cutter 1

1

1

1

1

6

6

2

1

1

1

30

OVERVIEW IMAGES

Wood-Mizer MP360

31

FRONT

Wood-Mizer

®

from forest to final form

32

CROSS-SECTION FRONT

Wood-Mizer MP360

33

BACK

3

4

Wood-Mizer

®

from forest to final form

CROSS-SECTION BACK

35

Wood-Mizer MP360

36

Wood-Mizer

from forest to final form

SKIDS WITH CARRIAGE

®

37

Wood-Mizer MP360

BOTTOM CUTTERS, FIXED SIDE CUTTERS, CONTROL FOR

MOVEABLE CUTTERS, LOCK PLANING TABLE

38

Wood-Mizer

®

from forest to final form

TOP CUTTER, FEED ROLLERS

Loading...

Loading...