Table of Contents Section-Page

Table of Contents SW-07doc0801131

Wood-Mizer

!

®

Sawmill

Safety, Setup, Operation

& Maintenance Manual

LT10S3 E7,5S rev. A5.00

Safety is our #1 concern! Read and understand

all safety information and instructions before operating, setting up or maintaining this machine.

December 2006

Form #794

This is the original language

for the manual.

Table of Contents Section-Page

General Contact Information

Branches & Authorized Sales Centers

SECTION 1 SAFETY 1-1

1.1 Safety Symbols...................................................... ..... ............................1-1

1.2 Blade Handling.......................................................................................1-2

1.3 Sawmill Setup.........................................................................................1-2

1.4 Sawmill Operation..................................................................................1-2

1.5 Sawmill Maintenance.............................................................................1-4

1.6 Belt Sizes................................................................................................1-8

1.7 Blade Sizes .............................................................................................1-9

1.8 Cutting Capacity.....................................................................................1-9

1.9 Engine/Motor Specifications..................................................................1-9

1.10 Noise Level...........................................................................................1-10

1.11 Sawdust Extractor Specifications.........................................................1-10

1.12 Overall Dimensions..............................................................................1-11

1.13 Components..........................................................................................1-12

SECTION 2 SAWMILL ASSEMBLY 2-1

2.1 Mounting Parts of LT10 Sawmills with Electric Motors.......................2-1

Parts Specifications

Specifications of Fasteners

Tools Necessary for Assembling the Sawmill

2.2 Unpacking the Sawmill ..........................................................................2-5

2.3 Bed Frame Assembly .............................................................................2-7

2.4 Frame Leg Adjustment.........................................................................2-12

2.5 Saw Head Assembly .............................................................................2-13

2.6 Log Loading Ramp (Option)................................................................2-19

SECTION 3 SETUP & OPERATION 3-1

3.1 Sawmill Setup.........................................................................................3-1

3.2 Replacing The Blade ..............................................................................3-9

3.3 Tensioning The Blade...........................................................................3-10

3.4 Tracking The Blade..............................................................................3-11

3.5 Starting The Motor...............................................................................3-12

3.6 Loading, Turning, And Clamping Logs...............................................3-13

3.7 Up/Down Operation .............................................................................3-15

3.8 Blade Guide Arm Operation.................................................................3-17

3.9 Blade Drive Operation..........................................................................3-18

3.10 Feed Operation .....................................................................................3-20

3.11 Cutting The Log ...................................................................................3-20

2 SW-07doc080113Table of Contents

Table of Contents Section-Page

3.12 Edging...................................................................................................3-21

3.13 Blade Height Scale...............................................................................3-22

3.14 Water Lube Operation..........................................................................3-24

3.15 Transporting the Sawmill.....................................................................3-25

SECTION 4 MAINTENANCE 4-1

4.1 Wear Life................................................................................................4-1

4.2 Sawdust Removal...................................................................................4-1

4.3 Carriage Track & Rollers .......................................................................4-1

4.4 Vertical Mast Rails....................................................................... .... ..... .4-2

4.5 Miscellaneous Lubrication ........................................................... .... ..... .4-2

4.6 Blade Wheel Belts..................................................................................4-3

4.7 Up/Down System....................................................................................4-3

4.8 Miscellaneous Maintenance ...................................................................4-4

4.9 Safety Devices Inspection ....................................................... ...............4-4

SECTION 5 TROUBLESHOOTING GUIDE 5-1

5.1 Sawing Problems....................................................................................5-1

SECTION 6 SAWMILL ALIGNMENT 6-1

6.1 Pre-Alignment Procedures......................................................................6-1

6.2 Preparing The Sawmill For Alignment ..................................................6-1

6.3 Blade Installation and Alignment...........................................................6-2

6.4 Blade Wheel Alignment.........................................................................6-3

6.5 Blade Guide Arm Alignment..................................................................6-8

6.6 Aligning The Blade Guides..................................................................6-10

6.7 Blade Deflection...................................................................................6-10

6.8 Blade Guide Vertical Tilt Adjustment..................................................6-11

6.9 Blade Guide Flange Spacing................................................................6-13

6.10 Horizontal Tilt Adjustment...................................................................6-14

6.11 Side Supports........................................................................................6-14

6.12 Blade Height Scale Adjustment............................................................6-16

6.13 Motor Drive Belt Adjustment...............................................................6-18

6.14 Safety Handle Linkage Adjustment......................................................6-19

6.15 Track Roller Distance Adjustment.......................................................6-20

Table of Contents SW-07doc0801133

Sawmill and Customer Identification

LT10

Basic Sawmill I.D.

E7,5

Motor/Engine

A1.

Major “Revision” Code

00

Minor ”Revision”

Typ e

Revision Number

Code

S3

Bed Frame Type

Each Wood-Mizer LT10 sawmill is identified with a revision and VIN numbers.

REVISION AND VIN NUMBERS

See the chart for VIN description.

456=Wood-Mizer Indiana

Company Identification Number

456 A 4 24 1 X H P A F9 017 F9 .01

When you pick up your mill, you will receive a customer number. The VIN number,

revision, and your customer number expedite our service to you. Please write these

numbers below so you have quick, easy access to them.

-i G24doc080113

Length of the Trailer;

C=1814-2268 kg, D=2269-3000kg

Weight Class; A=Under 1361 kg, B=1361-1814 kg,

4=LT40 Series, 7=LT70 Series

Product No.; 1=LT10/15, 2=LT20 Series,

Check Digit

Number of axles on the trailer

Add all the number and divide by 11

20= 20’ (6 m), 24=24’ (7 m), 35=35’ (11 m)

Year of Manufacture;

State of Manufacture

N=Indiana, P=Poland

Month of Manufacture

G=2009, H=2010, J=2011, K=2012, L=2013, M=2014

Revision Level

Sequence Number

Ranging from 000-999

A=January, B=February, C=March, etc...

End of 17-Digit VIN

Revision Level (Repeated)

Two-Digit Minor Revision Level

V.I.N. DESCRIPTION

Customer No. Type VIN No. Revision No.

!

IIMPORTANT! Read the entire Operator's Manual before

operating the sawmill. Take notice of all safety warnings

throughout this manual and those posted on the machine.

Keep this manual with this machine at all times, regardless

of ownership.

G24doc080113 ii

Introduction

1

General Contact Information

Getting Service

Wood-Mizer is committed to providing you with the latest technology, best quality and

strongest customer service available on the market today. We continually evaluate our

customers’ needs to ensure we’re meeting current wood-processing demands. Your comments and suggestions are welcome.

General Contact Information

From Europe call your local distributor or our European Headquarters and Manufacturing

Facility in Kolo, Nagórna 114 St, Poland at +48-63-2626000. From the continental U.S.,

call our U.S. Headquarter 8180 West 10th St.Indianapolis, IN 46214, toll-free at

1-800-525-8100.

your machine identification number and your customer number ready when you call. The

Service Representative can help you with questions about the operation and

maintenance of your machine. He also can schedule you for a service call.

Office Hours:

Ask to speak with a Customer Service Representative. Please have

Country Monday - Friday Saturday Sunday

Poland

US

Please have your vehicle identification number and your customer number ready when

you call.

Wood-Mizer will accept these methods of payment:

Visa, Mastercard, or Discover

COD

Prepayment

Net 15 (with approved credit)

Be aware that shipping and handling charges may apply. Handling charges are based on

size and quantity of order.

7 a.m.- 3 p.m.

8 a.m.- 5 p.m. 8 a.m.- 12 p.m

Closed Closed

Closed

1-iii 1005doc080113 Introduction

Branches & Authorized Sales Centers

Introduction

Branches & Authorized Sales Centers

1

European Headquarters

Wood-Mizer Industries Sp. z o.o.

Nagórna 114, 62-600 Koło, Poland

Tel.: +48-63-26-26-000

Fax: +48-63-27-22-327

www.woodmizer.eu

BELARUS

MOST-GRUPP

Siemashko 15, k.3

Minsk 2200116

Tel.: +375-17-270-90-08

Fax: +375-17-270-90-08

GSM: +375-29-649-90-80

e-mail: most-by@mail.ru

EUROPE UNITED STATES

World Headquarters

Wood-Mizer LLC

8180 West 10th Street

Indianapolis,Indiana 46214-2400,

USA

Tel.: +1-317-271-1542

Fax: +1-317-273-1011

www.woodmizer.com

SWITZERLAND Bruno Steiner

Striegelgasse 2

CH-6214 Schenkon

Tel.: +41-41-921-13-01

Fax: +41-41-922-18-87

e-mail: info@mobilsaegen.ch

RUSSIA Dariusz Mikołajewski

OOO WOOD-MIZER INDUSTRIES

141031, Moscow

Reg., Mytishenski raj., pos. Veshki,

Zavodskaja str., 3B

Tel.Fax: +7(495) 788-72-35

Tel.Fax: +7(495) 641-51-60

e-mail: dariuszm@woodmizer-moscow.ru

Introduction 1005doc080113 1-iv

Introduction

1

Branches & Authorized Sales Centers

BULGARIA Kalin Simeonov

Ecotechproduct

38 Star Lozenski pat str.

Sofia 1186

Tel.: +359-2-462-7035

Tel.: +359-2-963-1656

Tel:/Fax

: +359-2-979-1710

Kalin Simeonov

GSM: +3592-963-2559

e-mail: office@ecotechproduct.com

CROATIA Krešimir Pregernik

Pregimex d.o.o.

S. Batušiæa 31, 10090 Zagreb

Tel.:/Fax: +3851-38-94-668

Krešimir Pregernik

GSM: +3851-98-207-106

e-mail: Kresimir.Pregernik@gmail.com

CZECH REPUBLIC Miroslaw Greill

Wood-Mizer CZ s.r.o.

Osvaldova 91

339 01 Klatovy-Luby

Tel.:/Fax: +420-376-312-220

Fax: +420-376-319-011

Miroslaw Greill

GSM: +420-723-580-799

e-mail: greill@woodmizer.cz

CZECH REPUBLIC Lubomir Kudlik

Wood-Mizer Moravia

Sovadinova 6

69002 Breclav

Tel.:/Fax: +420-519-322-443

Lubomir Kudlik

GSM: +420-602-734-792

e-mail: info@wood-mizer.net

HUNGARY Wiktor Turoczy

Wood-Mizer Hungary K.F.T.

Szonyi Ut 67., 2921 Komárom

Tel.:/Fax: +36-34-346-255

e-mail: woodmizer@woodmizer.hu

ITALY Felice Pasquale

Wood-Mizer Italia Srl

Cda. Capoiaccio SN

86012 Cercemaggiore

Campobasso

Tel.:/Fax: +39-0874-798-357

GSM: +39-333-281-03-79

e-mail: wmitaliasrl@gmail.com

Subagent:

ITALY Franz Josef Reichsigl

Muls 21, 39058 Sarnthein

Tel.:/Fax: +39-471-627-264

GSM: +39-335-824-88-05

LATVIA Vilmars Jansons

OBERTS Ltd

Gaujas str. 32/2

LV-2167 Marupe, Rigas Raj.

Tel.: +371-7-810-666

Fax: +371-7-810-655

Vilmars Jansons

GSM: +371-92-06-966

Andris Orols

GSM: +371-28-33-07-90

e-mail: andris@oberts.lv

RUSSIA Far East Wladimir Głazaczew

“WM Service”

Krasnoretchenskaya Str.111

680006 Khabarovsk

Tel.:/Fax: +7-914-541-1183

e-mail: wms-khv@mail.ru

SERBIA Dragan Markov

Wood-Mizer Balkan d.o.o.

Svetosavska GA 3/3; P. Fah 25

23 300 Kikinda

Tel.:/Fax: +381-230-25-754

Tel.:/Fax: +381-230-23-567

GSM: +381-63-568-658

e-mail: office@woodmizer.co.yu

SLOVAKIA Wiktor Turoczy

Wood-Mizer Danubia s.r.o.

Hadovce 5, 94501 Komárno

Tel.: +421-35-77-40-316

Fax: +421-35-7740-326

GSM: +421-905-930-972

e-mail: woodmizer@woodmizer.sk

TURKEY

Er-Ka Ahsap Profil Kerestecilik San.

ve Tic. Ltd. Sti.

Adana Keresteciler Sitesi 191 sk No.41

ADANA

Tel.: +90-322-346-15-86

Fax: +90-322-345-17-07

GSM: +90-533-363-18-44

e-mail: info@erkaahsap.com.tr

FINLAND Howard Blackbourn

Oy Falkberg Jordbruk Ab

Falkintie 220

25610 Ylonkyla

Tel.: +358-2732-2253

Fax: +358-2732-2263

Howard Blackbourn

GSM: +358-440-424-339

e-mail: falkberg@woodmizer.fi

LITHUANIA Andrius Zuzevicius

UAB Singlis

Savanoriu pr. 187, 2053 Vilnius

Tel.: +370-5-2-32-22-44

Fax: +370-5-2-64-84-15

GSM: +370-620-28-645

e-mail: andrius.z@singlis.lt

Dmitrij Gaiduk

GSM: +370-69-84-51-91

e-mail: dmitrijus.g@singlis.lt

UKRAINE Ivan Vi nnicki

MOST UKRAINA

bul. Myru 3, Bajkivtsi Ternoplskyj r-j

Ternopolska oblast

47711 Ukraine

Tel/Fax: +38 (0352) 52 37 74

GSM: +38 (067) 352 54 34

GSM: +38 (067) 674 50 68

E-mail: most-ukraina@ukr.net

1-v 1005doc080113 Introduction

Introduction

Branches & Authorized Sales Centers

1

FRANCE Laurence Serrurier

Wood-Mizer France

Zac du Prѐ Marechal Route de Fruges

62560 Fauquembergues

Tel: +33-321-930-544

Fax: +33-321-930-990

GSM: +33-607-025-282

Mail: lserrurier@woodmizer.fr

SLOVENIA Jan Fale

FAMTEH d.o.o.

Gacnikova pot 2,

2390 Ravne na Koroskem

Tel.: +386-2-62-04-232

Fax: +386-2-62-04-231

Jan Fale

GSM: +386-2-62-04-230

e-mail: jan.fale@famteh.si

Matjaz Kolar

Tel.: +386-2-62-04-232

GSM: +386-31-775-999

e-mail: matjaz.kolar@famteh.si

GERMANY Klaus Longmuss

Wood-Mizer Sägewerke GmbH

Dorfstraße 5, 29485 Schletau

Tel.: +49-5883-9880-10

Fax: +49-5883-9880-20

e-mail: info@woodmizer.de

Klaus Longmuss

Tel.: +49-5883-9880-12

GSM: +49-17-298-55-892

e-mail: KLongmuss@woodmizer.de

NORWAY Odd Edvoll

Wood-Mizer Nordic AS

Vardelia 17, 2020 Skedsmokorset

Tel.: +47-63-87-49-89

Fax: +47-63-87-37-66

GSM: +47-930-42-335

e-mail: odd.edvoll@woodmizer.no

e-mail: firmapost@woodmizer.no

Subagent:

SWEDEN Kjell Larsson

Mekwood AB

Slingan 14, 812 41 Gästrike-Hammarby

Tel.: +46-290-515-65

Kjell Larsson

GSM: +46-706-797-965

e-mail: kjell.larsson@mekwood.se

UNITED KINGDOM & IRELAND

Wood-Mizer UK

Hopfield Barn

Kenward Road, Yalding

Kent ME18 6JP, UK

Tel.: +44-1622-813-201

Fax: +44-1622-815-534

e-mail: info@

David Darnell

10 Tennyson Avenue

Southend on Sea

Essex, SS2 5HD

David Darnell GSM: +44 7799 063 497

Stephan Cull

Cembrandy Gardens, Manorwen

Fishguard, Pembrokeshire SA659PT

Tel.: +44-1348-873-179

GSM: +44-7887-544-333

IRELAND

Wood-Mizer Ireland

Stephen Brennan

Cum Lahardane Ballina County Mayo

Tel:+353 96 51345

E-mail: brennanmill@ericom.net

woodmizer.co.uk

Subagents:

DENMARK Brian Jensen

Arnborgvej 9, 7330 Brande- Fasterholt

Tel.: +45-971-88-265

Fax: +45-971-88-266

Brian Jensen

GSM: +45-23-49-5828

e-mail: Fasterholt-Savvaerk@Mail.Tele.dk

Netherlands Chris Dragt

Lange Brink 77d,

7317 BD Apeldoorn

Tel.: +31-55312-1833

Fax: +31-55312-2042

e-mail: Info@dragtbosbouw.nl

ROMANIA Adrian Echert

SC WOOD-MIZER RO SRL

TRANSILVANIEI Nr. 5

Sibiu, Cisnadie 555300

Tel.:/Fax: : +40-369-405-433

GSM: +40-745-707-323

e-mail: aechert@woodmizer.ro

Subagent:

ROMANIA M. Echert

S.C. Echert Comprod s.r.l

Str. Schitului Nr. 6, Apt.7 etajul-1

725 70 Vatra Dornei, Romania

Tel.:/Fax: +40-230-374-235

Tel. : +40-740-35-35-74

Regional Manager - Asia

Wood-Mizer Asia Pte Ltd.

James Wong

Tel: +65 81216910

Fax: +65 6283 8636

WWW: www.woodmizerasia.com

E-mail: jwong@woodmizerasia.com

Regional Manager - Africa

Wood-Mizer Africa

Jean-Jacques Oelofse

UNIT 3, LEADER PARK, NO: 20 CHARIOT

ROAD

STORMILL, EXT 5, Roodepoort,

Johannesburg

Tel: +27 011 473 1313

Fax: +27 011 473 2005

Jean-Jacques Oelofse E-mail:

jjoelofse@woodmizerafrica.com

Jean-Jacques Oelofse

Skype:jean.jacques.pierre.oelofse

Introduction 1005doc080113 1-vi

Safety

1

SECTION 1 SAFETY

1.1 Safety Symbols

This symbol calls your attention to instructions concerning your personal safety. Be sure to observe

and follow these instructions.

The word DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING suggests a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION refers to potentially hazardous situations which, if not

avoided, may result in minor or moderate injury to persons or

equipment.

Warning stripes are placed on areas where a single decal would be

insufficient. To avoid serious injury, keep out of the path of any

equipment marked with warning stripes.

Read and observe all safety instructions before operating this equipment! Also read any additional

manufacturer’s manuals and observe any applicable safety instructions including dangers, warnings,

and cautions.

Always be sure that all safety decals are clean and readable. Replace all damaged safety decals to

prevent personal injury or damage to the equipment. Contact your local distributor, or call your

Customer Service Representative to order more decals.

IMPORTANT! It is always the owner's responsibility to comply with all applicable federal, state and

local laws, rules and regulations regarding the ownership, operation and towing of your Wood-Mizer

sawmill. All Wood-Mizer mill owners are encouraged to become thoroughly familiar with these

applicable laws and comply with them fully while using the mill.

Always properly dispose of all sawing by-products, including sawdust and other debris, coolant, oil,

fuel, oil filters and fuel filters.

Safety instructions are listed in this section by the following operations:

Blade Handling,

Sawmill Setup

Sawmill Operation

Sawmill Maintenance

1-1 15doc080113 Safety

1.2 Blade Handling

!

DANGER! Always disengage the blade and shut off the sawmill engine

before changing the blade. Failure to do so will result in serious injury.

WARNING! Always wear gloves and eye protection when handling

bandsaw blades. Changing blades is safest when done by one person!

Keep all other persons away from area when coiling, carrying or

changing a blade. Failure to do so may result in serious injury.

1.3 Sawmill Setup

WARNING! Do not set up the mill on ground with more than a 10

degree incline. If setup on an incline is necessary, put blocks under

one side of the mill or dig out areas for the legs to keep mill level.

Setting up the mill on an incline could cause it to tip over, resulting in

serious personal injury.

Safety

Blade Handling

1

WARNING! Keep all persons out of the path of the saw head while

loading and unloading the sawmill. Failure to do so may result in

serious injury or death.

1.4 Sawmill Operation

IMPORTANT! The sawmill is intended for sawing wood only.

See Section Cutting Capacity

IMPORTANT! The operator of the sawmill should get adequate

training in the operation and adjustment of the machine.

DANGER! Make sure all guards and covers are in place and secured

before operating or towing the sawmill. Failure to do so may result in

serious injury.

DANGER! Be sure the blade housing cover is in place and secured.

Do not open the blade housing when the blade is engaged.

DANGER! Always keep hands away from moving bandsaw blade.

Failure to do so may result in serious injury.

for log size capacities of the machine.

DANGER! Keep all persons out of the path of moving equipment and

logs when operating sawmill or loading and turning logs. Failure to do

so may result in serious injury.

DANGER! Maintain a clean and clear path for all necessary movement

around the mill and lumber stacking areas. Failure to do so may result

in serious injury.

Safety 15doc080113 1-2

Safety

1

Sawmill Operation

WARNING! Always wear eye, ear, respiration and foot protection as

well as safety clothing when operating the sawmill. Failure to do so

may result in serious injury.

WARNING! Secure all loose clothing and jewelry before operating the

sawmill. Failure to do so will result in serious injury or death.

WARNING! Always make sure log is clamped securely before sawing.

Failure to do so will result in serious injury or death.

WARNING! Use ONLY water or alcohol solution with the water lube

accessory. Never use flammable fuels or liquids. If these types of

liquids are necessary to clean the blade, remove it and clean with a

rag. Failure to do so will result in serious injury or death.

CAUTION! Be sure the log clamps are all the way down before loading

a log onto the bed. Failure to do so may result in machine damage.

CAUTION! Before loading a log, be sure the cutting head is moved far

enough forward so the log does not hit it. Failure to do so may result in

machine damage.

CAUTION! Do not try to force the saw head beyond its upper and

lower travel limits. Damage to the up/down system may result.

CAUTION! Be sure to stop the blade when returning the carriage.

This will not only prevent the blade from being pulled off and ruined by

a wood sliver, but also will increase the life of the blade.

CAUTION! Remove the optional loading ramps before sawing.

CAUTION! Never clean the blade or the blade wheels with a brush

or a scraper during sawmill operation.

CAUTION! Before installation of the blade, inspect it for damage and

cracks. Use only properly sharpened blades. Always handle the blade

with extreme caution. Use suitable carrier equipment for transporting

the blades.

CAUTION! Always wear gloves when handling the blade. Never grab

the blade with bare hands!

CAUTION! If the blade breaks during sawmill operation, push the

EMERGENCY STOP button to stop the blade motor and wait

10 seconds before you open the blade housing cover.

CAUTION! The sawmill’s work-stand should be equipped with a 4 kg

or bigger dry powder extinguisher.

1-3 15doc080113 Safety

1.5 Sawmill Maintenance

099220

CAUTION! Reinstall the track wiper so that it lightly touches the track

bar. If the wiper presses too firmly against the bar, it can cause the

power feed to bind.

CAUTION! Never use grease on the mast rails as it will collect

sawdust.

See Table 1-1. Pictogram decals used to warn and inform the user about danger in the LT10.

Decal View W-M No. Description

Sawmill Maintenance

TABLE 1-1

096317 CAUTION! Read thoroughly the manual

before operating the machine. Observe all

safety instructions and rules when

operating the sawmill.

Safety

1

099220 CAUTION! Close all guards and covers

before starting the machine.

Safety 15doc080113 1-4

Safety

099219

+

099221

1

Sawmill Maintenance

TABLE 1-1

099219 Blade tension. Turning the bolt clockwise

will increase the blade tension and turning

the bolt counterclockwise will decrease the

tension.

099221 CAUTION! Keep all persons a safe

distance away from work area when

operating the machine.

096316 CAUTION! Do not open or close the

electric box when the switch is not in the

“0” position.

096319 CAUTION! Disconnect power supply

before opening the box.

1-5 15doc080113 Safety

Sawmill Maintenance

TABLE 1-1

096321 Blade movement direction

S12004G CAUTION! Always wear safety goggles

when operating the sawmill!

S12005G CAUTION! Always wear protective ear

muffs when operating the sawmill!

Safety

1

501465 CAUTION! Always wear safety boots when

operating the sawmill!

501467 Lubrication Point

Safety 15doc080113 1-6

Safety

099226

092597

099401

1

Sawmill Maintenance

TABLE 1-1

P11789 Aligning the blade on the wheels

099226 Power feed system engagement

092597 Setting the blade tension indicator

P85070 CE safety certification

099401 Russian safety certification

1-7 15doc080113 Safety

TABLE 1-1

S20097F

2925 RPM

P85066

3-4 mm

S20097F 2925 RPM - Motor rotation direction

P85066 Blade positioning

501477 Safety handle. The blade is stopped when

the handle is released.

Safety

Belt Sizes

1

1.6 Belt Sizes

See Table 1-2. Belt sizes for the LT10 are shown.

Description Belt Size Wood-Mizer

Part #

Motor Drive Belt E7.5 B81 014819

Blade Pulley Belts

B57

1

P04185

TABLE 1-2

1

To insure proper blade tracking, use Goodyear, Dayco Super II, or Browning belts

only.

Safety 15doc080113 1-8

Safety

1

Blade Sizes

1.7 Blade Sizes

See Table 1-3. Wood-Mizer TRU•SHARP™ offers three types of blades to provide efficient sawing

for all models of sawmills. The engine/motor size of your sawmill and the type of wood you saw

should determine which blade you choose for optimum performance.

Engine/Motor Size Recommended Blade For Sawing:

5 hp - 15hp B275IH1030

16hp or more B376IH1030

Electric Motor B376IH1030

Softwood Hardwood Frozen or Hard-to-Cut

Wood

B275IH741030

B376IH741030

B376IH741030

B375IH929

B275IH1030

B275IH741030

B376IH1030

B376IH741030

B275IH1030

B275IH741030

B376IH1030

B376IH741030

2

2

B375IH929

B375IH929

B375IH929

1

1

1

1

TRU•SHARP™ “F” blades use a 9/29 profile (9° hook angle and 29° back angle) and are designed to cut frozen and/or

extremely dense, hard-to-cut wood.

Standard TRU•SHARP™ blades use a 10/30 profile.

2

Customer may choose preferred blade.

See The Blade Handbook for blade hook angle, tooth height, and tooth set specifications.

1.8 Cutting Capacity

See Table 1-4. The log size capacities of the LT10 sawmills are listed below.

LT10 S 3 70 cm 5,4 m

LT10 S 4 70 cm 7,3 m

1

Each additional bed frame segment adds approximately 195

cm ( 6’ 5” ) to length capacity.

1.9 Engine/Motor Specifications

Max. Diameter

Max. Length

TABLE 1-4

TABLE 1-3

1

See Table 1-5. The power options available for the LT10 sawmill are listed below.

Engine/Motor Type Manufacturer Model Number Specifications

5.5 kW Electric Motor Siemens, Germany 1LA7130-2AA60-2 3 x 400V, 50 Hz

TABLE 1-5

1-9 15doc080113 Safety

1.10 Noise Level

See Table 1-6. The average level of noise is given in table below12.

LT10 E 7,5 83,3 dB (A)

1.11 Sawdust Extractor Specifications

CAUTION! Always turn on the dust extractor before starting the

machine.

See Table 1-7. The dust extractor specifications are given below.

Noise Level

TABLE 1-6

Safety

Noise Level

1

Maximum Capacity

C o l l e c t o r I n l e t D i a m e t e r s

(in front of fan)

Motor Power 1,5 kW

Number of Sacks for Waste 1 pcs

Total Capacity of Sacks

Weight 110 kg

Conveying Speed When 10m

Long Hose is Used

1200 m

150 mm

0,25 m

20 m/s

3

/h

3

TABLE 1-7

1. The noise level measurement was taken in accordance with PN-EN ISO 3746 Standard.

The noise exposure level given above concerns an 8-hour work day.

2. The figures quoted are emission levels and are not necessarily s af e w or k in g l ev e ls . W hi l s t t h e re i s

a correlation between the emission and exposure levels, this cannot be used reliably to determine

whether or not further precautions are required. Factors that influence the actual level of

exposure of the workforce include the characteristics of the work room and the other sources of

noise etc. i.e. the number of machines and other adjacent processes. Also the permissible exposure

level can vary from country to country. This information, however, will enable the user of the machine

to make a better evaluation of the hazard and risk.

Safety 15doc080113 1-10

Safety

2186

967

2

2

8

0

1

7

0

4

10_002d

1

Overall Dimensions

1.12 Overall Dimensions

See Figure 1-1. The overall dimensions of the LT10 sawmills are shown below.

FIG. 1-1

1-11 15doc080113 Safety

1.13 Components

10_001_E

Water Tank

Blade Tensioner

Up/Down Crank Handle

Sawmill Frame

Log

Clamp

Blade Guide Arm Handle

Blade Drive Motor

Electric Box

See Figure 1-2. The major components of the Wood-Mizer LT10 are shown below.

Safety

Components

1

FIG. 1-2

Safety 15doc080113 1-12

SAWMILL ASSEMBLY

510720-1

2

Mounting Parts of LT10 Sawmills with Electric Motors

SECTION 2 SAWMILL ASSEMBLY

2.1 Mounting Parts of LT10 Sawmills with Electric Motors

2.1.1 Pa rt s Sp ec if ic at ion s

Table 1:

Sawmill Mounting Parts

Fig. Wood-Mizer No. Description Qty.

LT10 S 3 LT10 S 4 LT10 E C

094514 LT15 Bed Section,

Complete (1.95 m)

085981-1 Thick Spacer

Washer

085982-1 Log Side Support,

Complete

085994-1 Bed Leg Mounting

Washer, Painted

510720-1 Leveling Wedge,

Painted

086132-1 Power Cord Bracket 1 1 1

343

68-

68-

12 16 -

1

11

086171-1 Side Bracket 2 2 2

086172-1 Bottom Bracket 1 1 1

086322 Right Track Wiper 2 2 2

086323 Left Track Wiper 2

2-1 15doc080113 SAWMILL ASSEMBLY

22

Table 1:

SAWMILL ASSEMBLY

Parts Specifications

2

086659-1 Frame Mounting

Strap, Zinc-plated

086745 Middle Track Cover

with Felt Wiper

093859 Plate, PC Guard 1

094250-1 Track Rail,

Zinc-plated (Short)

095490-1 Auxiliary Bed Rail 1

100903-1 Sawdust Chute 1

463

1

2

11

11

2-

1-

1-

500844-1 Bed Extension

Tube, Painted

502725-1 Feed Rope Mount

Front Bracket

502726-1 Feed Rope Mount

Rear Bracket

506287-1 PLATE, LT15 BED

SECTION

CONNECTOR

507565 Log Clamp 3

508236-1 Feed Rope Mount

Front Bracket

(LT15-EC)

12

2

1

1

1

2-

1-

1-

16 -

43

-1

508237-1 Feed Rope Mount

Rear Bracket

(LT15-EC)

1

-1

SAWMILL ASSEMBLY 15doc080113 2-2

SAWMILL ASSEMBLY

6

,

5

8

8

,

4

20

1

3

M8 Nut

M8x20 Bolt

8.4 Washer

2

Specifications of Fasteners

Table 1:

094427-1 (LT15S3)

094696-1 (LT15M2)

LTBGAT Tool, Blade, Guide,

R02080 Rope 9

100903-1 Sawdust Chute 1 -

503768-1 Guide Upright - 1

2.1.2 S p ec i f ic at ions of Fasteners

Track Rail 3

Alignment

12 11

Table 2:

Wood-Mizer No. Description Qty. LT10-EC

Sample designations of fasteners:

F81003-17 M10x35 Bolt 1 -

F81030-2 M5 Nut 2

F81000-7 M5x25 Bolt 2

F81001-7 M6x12 Bolt 2

F81054-1 Flat Washer 8.4 264

F81032-2 M8 Nut 127

F81002-5 M8x25 Bolt 118

-

-

2

24

7

7

F81002-4 M8x20 Bolt 5

12

F81055-2 Washer, 10.2 Split Lock 2 6

F81003-11 M10x25 Bolt 4 6

F81003-1 M10x20 Bolt 2 2

2-3 15doc080113 SAWMILL ASSEMBLY

SAWMILL ASSEMBLY

Tools Necessary for Assembling the Sawmill

Table 2:

F81055-1 Flat Washer 10.5 4 8

F81037-1 M20 Nut 28 -

F81032-1 M8 Nut 1 -

F81002-20 M8x16 Bolt 6 -

F81002-23 M8x100 Bolt 12 -

F81059-2 Washer, M20 Flat Zinc 28 -

F81053-1 Washer, M6 Flat Zinc 2 2

095919 Cap, A 50x30 Black 2 -

097480 Pipe Cap 40x40x(3-4) 6 -

F81056-1 13 Flat Washer 2 28

F81034-1 M12 Hex Nut 2 2

F81034-2 M12 Hex Nylon Lock Nut - 14

2

F81004-38 M12x120 Bolt - 12

F81004-12 M12x55 Bolt - 2

F81054-4 Washer, 8.2 Split Lock - 14

F81082-1 Clamp - Plastic Hose 2 -

2.1.3 Tools Necessary for Assembling the Sawmill

Table 3:

Required tools

Flat Wrench #8 1pcs

Flat Wrench #10 2pcs

Flat Wrench #13 2pcs

Flat Wrench #17 2pcs

Flat Wrench #19 2pcs

Ratchet Wrench #30 1pcs

Hammer 1pcs

Allen Wrench #4 1pcs

Allen Wrench #5 1pcs

SAWMILL ASSEMBLY 15doc080113 2-4

SAWMILL ASSEMBLY

2

Unpacking the Sawmill

2.2 Unpacking the Sawmill

FIG. 2-1

1. Cut the bands holding the components together.

2. Remove frame parts from the pallet.

3. Remove up/down crank from the saw head, slide on the up/down handle and secure with the pin

(Part No F81045-1).

2-5 15doc080113 SAWMILL ASSEMBLY

SAWMILL ASSEMBLY

Locking Pin

F81045-1

Unpacking the Sawmill

2

FIG. 2-1

4. Using the up/down crank raise the saw head. Open the box with the sawmill’s equipment.

SAWMILL ASSEMBLY 15doc080113 2-6

SAWMILL ASSEMBLY

!

150158b

M10x75 Bolt

M10 Hex Nylon Lock Nut

10.5 Washer

094427-1 (LT15S3)

094696-1 (LT15M2)

2

Bed Frame Assembly

2.3 Bed Frame Assembly

IMPORTANT! With all screw joints without spring lock washer or lock

nylon nut, use the "LOCTITE 243" (blue, of average durability, for

screw joints).

1. Mount preliminarily the track rail as shown in Figure 2-2. Do not tighten the nuts.

See Figure 2-2.

FIG. 2-2

2. In case of sawmills with non-adjustable legs - Mount four (or six) legs to each bed section. Use two hex

head bolts and lock nuts to secure each leg to the bed section.

2-7 15doc080113 SAWMILL ASSEMBLY

See Figure 2-3.

150185B

M10x75 Bolt

085994-1

100064-1

M10 Hex Nylon

Lock Nut

10.5 Washer

SAWMILL ASSEMBLY

Bed Frame Assembly

2

FIG. 2-3

3. In case of sawmills adjustable legs - Mount four (or six) leg brackets to each bed section. Use two hex head

bolts and lock nuts to secure each leg bracket to the bed section. Be sure the nut on the bracket faces up.

Thread a leg into each bracket.

SAWMILL ASSEMBLY 15doc080113 2-8

SAWMILL ASSEMBLY

150160a

M10x120 Bolt

085994-1

086723-1

M10 Hex Nylon

Lock Nut

10.5 Washer

095745-1

095742-1

M20 Nut

21 Washer

2

Bed Frame Assembly

See Figure 2-4.

FIG. 2-4

4. Lay the frame sections end-to-end so the track portion of each section is on the same side. Slide the sections

together and secure with four hex head bolts and nylon lock nuts.

2-9 15doc080113 SAWMILL ASSEMBLY

See Figure 2-5.

150159F

M6

M6x16

O

\

6.4

A

A

M12

10.2 Split Lock Washer

M10x25 Bolt

Frame Mounting

Strap (086660)

M12 Hex Nylon Lock

Nut

13 Flat Washer

M12x120 Bolt

(4pcs)

M10x30 Bolt

(4pcs)

10.5 Flat Washer

M10 Hex Nylon Lock

Nut

SAWMILL ASSEMBLY

Bed Frame Assembly

2

5. Fasten the track rails together using the frame mounting straps, on the outside of the frame. (See the figure

above.) Secure each strap to the track rail with two hex head bolts. Tighten the track rail mounting nuts.

FIG. 2-5

SAWMILL ASSEMBLY 15doc080113 2-10

SAWMILL ASSEMBLY

M10 Hex Nylon

Lock Nut

13 Flat

Washer

M10x75 Bolt

10.5 Washer

094250-1

M12x120

Bolt

086659-1

M10x30

Bolt

10.2 Split Lock

Washer

M12 Hex Nylon

Lock Nut

2

Bed Frame Assembly

6. Mount a bed extension to the front and the rear ends of the bed frame.

See Figure 2-6.

FIG. 2-6

7. Assemble a log clamp to a bed rail on each bed section using the existing hex head bolts and nylon lock nuts.

8. Install the log side supports as shown in Figure 2-7. Tighten the nuts so that the side supports can be moved

with little resistance. Adjust the side supports. Patrz Rozdzia³ 6.11

.

2-11 15doc080113 SAWMILL ASSEMBLY

See Figure 2-7.

150157b

M10

M12x140 Bolt

100076-1 Bolt

M12 Nut

13 Washer

097224

085981-1

014972

SAWMILL ASSEMBLY

Frame Leg Adjustment

2

FIG. 2-7

2.4 Frame Leg Adjustment

1. Place a foot plate under each bed leg.

2. Using an appropriate wrench, adjust each leg so that the nut is approximately 25mm below the top of the bed

tube

SAWMILL ASSEMBLY 15doc080113 2-12

SAWMILL ASSEMBLY

25mm

(1")

150108b

Foot Plate

2

Saw Head Assembly

See Figure 2-8.

FIG. 2-8

CAUTION! The top of the leg should not be higher than the top surface of

the bed rail.

2.5 Saw Head Assembly

1. Using a forklift truck or a winch with lifting capacity of minimum 500 kg, carefully lift the saw head and

set it aside. Attach the winch hook to the bracket on the saw head.

WARNING! When removing the saw head, use extreme care and keep

all persons at a safe distance. Failure to do so may result in serious

injury or death.

2-13 15doc080113 SAWMILL ASSEMBLY

See Figure 2-9.

500kg

SAWMILL ASSEMBLY

Saw Head Assembly

2

FIG. 2-9

1. Position the saw head at the end of the bed frame assembly. Carefully slide the saw head rollers

onto the bed frame track. Keep the saw head square to the bed to avoid jamming the track rollers.

WARNING! When setting the saw head on the bed frame, use extreme

care and keep all persons at a safe distance. Failure to do so may

result in serious injury or death.

2. Install a track wiper with a felt strip and to each track roller housing as shown below.

SAWMILL ASSEMBLY 15doc080113 2-14

SAWMILL ASSEMBLY

10_054_A

M8x12 Bolt

M8x12 Bolt

Track Wiper

(086322)

8.4 Washer

Track Wiper

(086322)

M8x12 Bolt

2

Saw Head Assembly

See Figure 2-10.

FIG. 2-10

NOTE: Before installing the track cover and the remaining felt wipers, soak the felt strips with

lubricating fluid (e.g. mineral oil).

3. Assemble the sawdust chute (100903-1).

2-15 15doc080113 SAWMILL ASSEMBLY

See Figure 2-11.

10_052c

100903-1

M8x16 Bolt

8.4 Washer

10_055a

M10x50 Bolt

M8x16 Bolt

M8x25 Bolt

8.4 Washer

Guard (093859)

Nut, M8 Hex Nylon Zinc Lock

10.5 Washer

M8x20 Bolt

SAWMILL ASSEMBLY

Saw Head Assembly

2

4. Install the operator guard.

See Figure 2-12.

FIG. 2-11

FIG. 2-12

SAWMILL ASSEMBLY 15doc080113 2-16

SAWMILL ASSEMBLY

Screw, M10x1x20 (7)

Blade Guide

(094682)

M10x1x25 Bolt

Nut, M10x1 Thin (8)

Blade Guide

(094683)

2

Saw Head Assembly

5. Install the blade guides.

See Figure 2-13.

6. Install the power cord bracket.

FIG. 2-13

2-17 15doc080113 SAWMILL ASSEMBLY

See Figure 2-14.

Power Cord Bracket

086132-1

Holder, Plastic Cable Tie

(F81082-1)

Screw, M4x16

4.3 Washer

M4 Nut

SAWMILL ASSEMBLY

Saw Head Assembly

2

FIG. 2-14

SAWMILL ASSEMBLY 15doc080113 2-18

SAWMILL ASSEMBLY

1

2

3

3

4

150232a

5

2

Log Loading Ramp (Option)

2.6 Log Loading Ramp (Option)

To install the log loading ramp, mount the ramp bracket (1) to the bed frame section tube using two bolts (2),

four washers (3) and two nuts (4) in the place shown below. Insert the ramp assembly (5) into the ramp

bracket.

See Figure 2-15.

1

FIG. 2-15

1. See the Parts List for detailed information about part numbers and mounting hardware dimensions.

2-19 15doc080113 SAWMILL ASSEMBLY

SECTION 3 SETUP & OPERATION

!

150189a

!

3.1 Sawmill Setup

IMPORTANT! Before starting to use the sawmill you have to meet the

following conditions:

Set up the sawmill on firm, level ground and level the sawmill. Secure the sawmill to the

ground to prevent moving during operation. A concrete foundation or pads (rated to support

2

31 T/m

Under roof, the sawmill should always be operated with the sawdust collection system.

The sawmill can be operated under roof only.

at each sawmill foot position) and 16mm anchored bolts are recommended.

Setup & Operation

Sawmill Setup

3

The sawmill can be operated in temperature range from -15

The illumination at the operator's position should be at least 300lx.

The sawmill operator’s position is shown below.

Have a qualified electrician install the power supply (according to EN 60204 Standard).

The power supply must meet the specifications given in the table below.

o

C to 40o C only.

3-Phase

Volt s

400 VAC 16 A

IMPORTANT! When starting the machine for the first time, check that

main motor rotation direction is as indicated by the arrow located on

the motor body (fan guard). If the rotation direction is incorrect, invert

the phases in the phase inverter in the power socket (electric box).

Setting the phases in the phase inverter correctly will ensure correct

rotation directions of all sawmill motors.

Setup & Operation 15doc080113 3-1

Fuse disconnect Suggested Wire Size

2,5 mm

to 15m length

2

TABLE 3-0

Setup & Operation

String across

bed rails

Equal height

object

Equal height

object

Measure distance

between string

and bed rails

150115c

Equal height

object

Measure distance

between string

and bed rails

Equal height

object

String Across

bed rails

3

Sawmill Setup

The LT10 sawmills are only partially aligned at the factory. Some assemblies need to be aligned by the

user before first usage of the sawmill.

Assemblies aligned at the factory:

Blade drive belt tension;

Blade wheels (in vertical and horizontal planes);

Blade guide arm alignment - See Section 6.5;

Blade guides - See Section 6.6;

Blade Height Scale - See Section 6.12;

The following setup procedure should be performed whenever the sawmill is moved or reassembled. If

sawing problems occur and misalignment is suspected, see See SECTION 6

instructions.

1. Adjust the frame legs so the sawmill appears level. If sawmill is on soft ground, use shims under the legs if

necessary.

for complete alignment

2. Run a string from the front bed rail to the rear bed rail near the operator’s side of the frame. Place identical

spacers between the string and the front and rear bed rails. Measure the distance between the string and the

other bed rails. Adjust the frame legs until all bed rails measure the same distance from the string.

3. Loosen the auxiliary bed rail bolts and adjust the rail so it is the same distance from the string as the main bed

rails. Retighten the bolts.

See Figure 3-1.

FIG. 3-1

3-2 15doc080113 Setup & Operation

Setup & Operation

150116D

Roller Bracket

Mounting Bolt (4)

Saw Head

Adjustment Nuts (2)

Lock Nut

Mast Retaining

Bracket Mounting

Bolts (2)

Scraper Mounting

Bolts (2)

4. Repeat the bed rail adjustment with the string at the other side of the sawmill frame.

Sawmill Setup

3

5. Install a blade (See Section 3.2

over the front bed rail.

6. The blade guide rollers should not touch and deflect the blade and the blade guide arm should be adjusted all

the way out, away from the other blade guide.

7. Measure the distance from the bed rail to the bottom of the blade near the inside (fixed) blade guide.

8. Measure the distance from the bed rail to the bottom of the blade near the outside (movable) blade guide.

See Figure 3-2. When the blade is parallel to the bed, it will measure the same distance from the bed rail at the

inside and outside of the saw head. To adjust the saw head tilt, loosen the four mounting bolts of the idle side

roller bracket, the two scraper mounting bolts and the two mounting bolts of the mast retaining bracket. Use the

saw head adjustment nuts to move the outside of the saw head up or down.

through Section 3.4) and move the saw carriage until the blade is positioned

FIG. 3-2

9. Make sure the entire face of each slide pad makes contact with the mast. Use the adjustment nuts

Setup & Operation 15doc080113 3-3

Setup & Operation

Slide Pad Adjustment Nuts

(4)

Clip tool to blade

SM0069

3

Sawmill Setup

shown below to adjust the slide pads if necessary.

FIG. 3-3

10. Check the vertical alignment of each blade wheel using the blade guide alignment tool.

Attach the tool to the blade near the outer blade guide. Be sure the tool does not rest on a tooth

or burr, and is lying flat on the blade.

See Figure 3-4.

FIG. 3-4

3-4 15doc080113 Setup & Operation

Setup & Operation

150075-2_E

To tilt wheel up, tighten top

screw (loosening earlier

bottom screw).

To tilt wheel down, tighten

bottom screw (loosening

earlier top screw).

Sawmill Setup

Move the saw head so the front end of the tool is positioned over the first bed rail. Measure

from the bottom of the tool to the top surface of the bed rail.

Move the saw head so the rear of the tool is positioned over the bed rail. Again, measure from

the bottom of the tool to the bed rail.

If the two measurements differ by more than 1/16” (1.5 mm), adjust the vertical tilt of the

idle-side blade wheel. See Figure 3-5.

Remove the tool from the blade and reattach it near the inner blade guide. Measure from the

tool to the bed rail at both ends of the tool. If the measurements at the front and rear ends of the

tool differ by more than 1/16” (1.5 mm), adjust the vertical tilt of the drive-side blade wheel.

See Figure

See Figure 3-5. To tilt the idle-side blade wheel up, loosen the bottom adjustment screw 1/2 turn.

Loosen the nut on the top adjustment screw and tighten the screw. Tighten the top and bottom nuts.

To tilt the wheel down, loosen the top adjustment screw 1/2 turn. Loosen the nut on the bottom

adjustment screw and tighten the screw. Tighten the top and bottom nuts .

3-6.

3

Setup & Operation 15doc080113 3-5

FIG. 3-5

Setup & Operation

150075-1G

To tilt wheel up, tighten top

screw (loosening earlier

bottom screw).

To tilt wheel down, tighten

bottom screw (loosening

earlier top screw).

Alignment

To ol

3

Sawmill Setup

See Figure 3-6. To tilt the drive-side blade wheel down, loosen the top adjustment screw, loosen the

nut on the bottom adjustment screw and tighten the bottom screw. Tighten the top and bottom nuts.

To tilt the wheel up, loosen the bottom adjustment screw, loosen the nut on the top adjustment screw

and tighten the top screw. Tighten the top and bottom nuts.

Re-check the vertical alignment of each blade wheel. Readjust if necessary.

11. Adjust the spacing between each blade guide roller flange and the back of the blade.

See Section 6.9

12. Adjust the horizontal angle of the blade guides. See Section 6.10

13. Adjust the blade deflection (See Section 6.7

(See Section 6.8

HINT: It is best to preliminarily set the blade deflection so that it is 3 - 4 mm, then adjust the blade

guides in the vertical plane and make the final adjustments to the blade deflection. The proper blade

deflection is 6 mm. After adjusting the blade deflection, recheck the vertical alignment of the blade

3-6 15doc080113 Setup & Operation

.

).

.

) and the vertical angle of the blade guides

FIG. 3-6

Setup & Operation

Sawmill Setup

guides and adjust if necessary.

14. Install the blade height scale. To do that, first measure the distance from the bottom edge on a

down-set tooth of the blade to the top of the bed rail. Then stick the blade height scale on the

mounting bracket so that it indicates the true distance from the blade to the bed. Adjust the scale if

necessary. See Section 6.13

15. Bolt the blade guide guard so that its bottom edge is about 5 mm above the blade.

.

3

FIG. 3-7

Setup & Operation 15doc080113 3-7

Setup & Operation

Loosen the nut and

adjust the stop bolt

3

Sawmill Setup

16. Adjust the cam engaging the limit switch as well as the saw head stop bolt so that the saw head

stops moving at its lower travel limit, i.e. at the height of 25 mm above the bed.

17. Adjust the side bracket. See Section 6.13

WARNING! Adjust the side bracket before first operating the sawmill.

Failure to do so may result in serious injury and machine damage.

FIG. 3-8

.

3-8 15doc080113 Setup & Operation

3.2 Replacing The Blade

DANGER! Always disengage the blade and shut off the sawmill motor

before changing the blade. Disconnect the power supply using the

main switch. Failure to do so will result in serious injury.

WARNING! Always wear gloves and eye protection when handling

bandsaw blades. Changing blades is safest when done by one person!

Keep all other persons away from area when coiling, uncoiling,

carrying or changing a blade. Failure to do so may result in serious

injury.

Adjust the blade guide arm all the way open.

Open the blade housing cover. Turn the blade tension handle to release the blade tension until the

wheel is pulled in and the blade is lying loose in the blade housing. Lift the blade out of the blade

housing.

Setup & Operation

Replacing The Blade

3

Install a new blade on the blade wheels. When installing the blade, make sure the teeth are pointing

the correct direction. The teeth located between the blade guide assemblies should be pointing

toward the sawdust chute.

Position 1 1/4” wide blades on the wheels so the gullet is 1/8" (3.0 mm) out from the front edge of the

wheel. Position 1 1/2” wide blades on the wheels so the gullet is 3/16” (4.5 mm) out from the front

edge of the wheel.

Close the blade housing cover.

Next, turn the tension handle until the blade is tensioned correctly.

Setup & Operation 15doc080113 3-9

Setup & Operation

10_074b

Blade Tensioner

Handle

Cant Control Bolt

Blade Tension

Indicator

3

Tensioning The Blade

3.3 Tensioning The Blade

See Figure 3-9. Turn the blade tension handle clockwise until the tension gauge indicates the

recommended tension. Check the blade tension occasionally when adjusting the cant control or

while cutting. As the blade and belts heat up and stretch, the blade tension will change.

Also, ambient temperature changes can cause tension to change.

FIG. 3-9

CAUTION! Release the blade tension when the mill is not in use.

See Table 3-1. The recommended tension for different blades is shown below.

Blade Type Blade Dimensions Tension range

Width (mm) Height (mm) PSI Bar

275 1.07 32 1015-1088 70-75

375 1.14 32 1088-1160 75-80

2735 1.07 35 1160-1233 80-85

3-10 15doc080113 Setup & Operation

TABLE 3-1

Setup & Operation

150060

1 1/4"

Blade

± 1 mm (0.04”)

3.0 mm (0.12”)

3.4 Tracking The Blade

1. Make sure the blade housing cover is closed and all persons are clear of the blade.

2. Start the motor for a moment until the blade positions itself on the wheels.

WARNING! Do not spin the blade wheels by hand. Spinning the blade

wheels by hand may result in serious injury.

3. Turn off the engine and check the position of the blade on the blade wheels.

See Figure 3-10. Position 1 1/4” wide blades so the gullet is 1/8" (3.0 mm) out from the edge of the

blade wheel (±1/32 [.75 mm]).

Tracking The Blade

3

Setup & Operation 15doc080113 3-11

FIG. 3-10

Setup & Operation

15B017_D

Cant Control Bolt

!

3

Starting The Motor

See Figure 3-11. To adjust where the blade travels on the blade wheels, use the cant control bolt.

FIG. 3-11

If the blade is too far out, back the blade onto the wheel by turning the cant control counterclockwise.

If the blade is too far in, turn the cant control clockwise until the gullet of the blade is the correct

distance from the front edge of the wheel.

4. Adjust the blade tension if necessary to compensate for any changes that may have occurred while

adjusting the cant control.

5. Close the blade housing cover.

DANGER! Make sure all guards and covers are in place and

secured/closed before operating the sawmill. Failure to do so may

result in serious injury.

IMPORTANT! After aligning the blade on the wheels, always double-check the blade guide spacing

and location. (See SECTION 6

for more information.)

3.5 Starting The Motor

See the appropriate manual supplied with your specific motor configuration for starting and operating

instructions.

IMPORTANT! When starting the machine for the first time, check that main

motor rotation direction is as indicated by the arrow located on the motor body

(fan guard). If the rotation direction is incorrect, invert the phases in the phase

inverter located in the power socket (electric box). Setting the phases in the

phase inverter correctly will ensure correct rotation directions of all sawmill

3-12 15doc080113 Setup & Operation

motors.

DANGER! Make sure all guards and covers are in place and secured/closed

before operating the sawmill. Failure to do so may result in serious injury.

DANGER! Always be sure the blade is disengaged and all persons are out

of the path of the blade before starting the engine or motor. Failure to do so

will result in serious injury.

WARNING! Always wear eye, ear, respiration, safety clothing and foot

protection when operating the sawmill. Failure to do so may result in serious

injury.

3.6 Loading, Turning, And Clamping Logs

To Load Logs

Setup & Operation

Loading, Turning, And Clamping Logs

3

1. Move the cutting head to the front end of the frame.

CAUTION! Before loading a log, be sure the cutting head is moved far

enough forward so the log does not hit it. Failure to do so may result in

machine damage.

2. Adjust the log clamps all the way down and move them toward the loading side of the sawmill frame.

CAUTION! Be sure the log clamps are all the way down before loading a log

onto the bed. Failure to do so may result in machine damage.

3. Raise the side supports on the sawmill bed to prevent the log from falling off the side of the bed.

4. Place the optional loading ramps (optional equipment) in the frame brackets that will evenly support the length

of the log.

5. Position the log at the foot of the ramps.

6. Use a cant hook to roll the log up the ramps and onto the sawmill bed. Position the log against the side

supports.

7. Remove the log ramps and set aside.

CAUTION! The saw head will hit the spring-loaded ramp stops when

adjusted for low cuts. Remove the loading ramps before sawing to prevent

damage to the saw head and/or blade guide arm.

If you did not purchase the optional loading ramps, use boards for ramps or use log loading equipment

to load the log on the sawmill bed.

To Turn Logs

1. Use a cant hook to spin the log against the side supports until it is turned the way you want it for the first cut.

To Clamp Logs

Setup & Operation 15doc080113 3-13

Setup & Operation

150117E

sm0379

3

Loading, Turning, And Clamping Logs

1. Position the clamps against the log, far enough down so they are below your cuts on a given side of the log.

Using the clamp handles move the log firmly against the side supports.

See Figure 3-12.

FIG. 3-12

2. Be sure to leave crank in the bottom position to avoid damage to the blade.

See Figure 3-13.

FIG. 3-13

3. Make sure the side supports are positioned low enough for the blade to pass over them. If they are not, back

the clamps off slightly and push the side supports down until they are positioned below the height of your last

cut on a given side of the log.

To Level A Tapered Log

3-14 15doc080113 Setup & Operation

Setup & Operation

150119D

Level log so

heart is same

distance from

bed rails at

both ends

Leveling

Wedge

Up/Down Operation

Use shims or the optional wedge to raise either end of a tapered log, if desired.

Shim one end of the log until the heart of the log measures the same distance from the bed rails at each end of

the log.

3

3.7 Up/Down Operation

1. Install a blade, if needed, and check for correct blade tension. (See Section 3.3)

Set the cutting head to the desired height. (The blade height scale shows the height of the blade

above the bed rails.)

FIG. 3-13

Setup & Operation 15doc080113 3-15

Setup & Operation

To raise the saw head turn the crank

handle clockwise; to lower – turn the

crank handle counterclockwise.

Pull the handle grip, to engage the

up/down drive.

3

Up/Down Operation

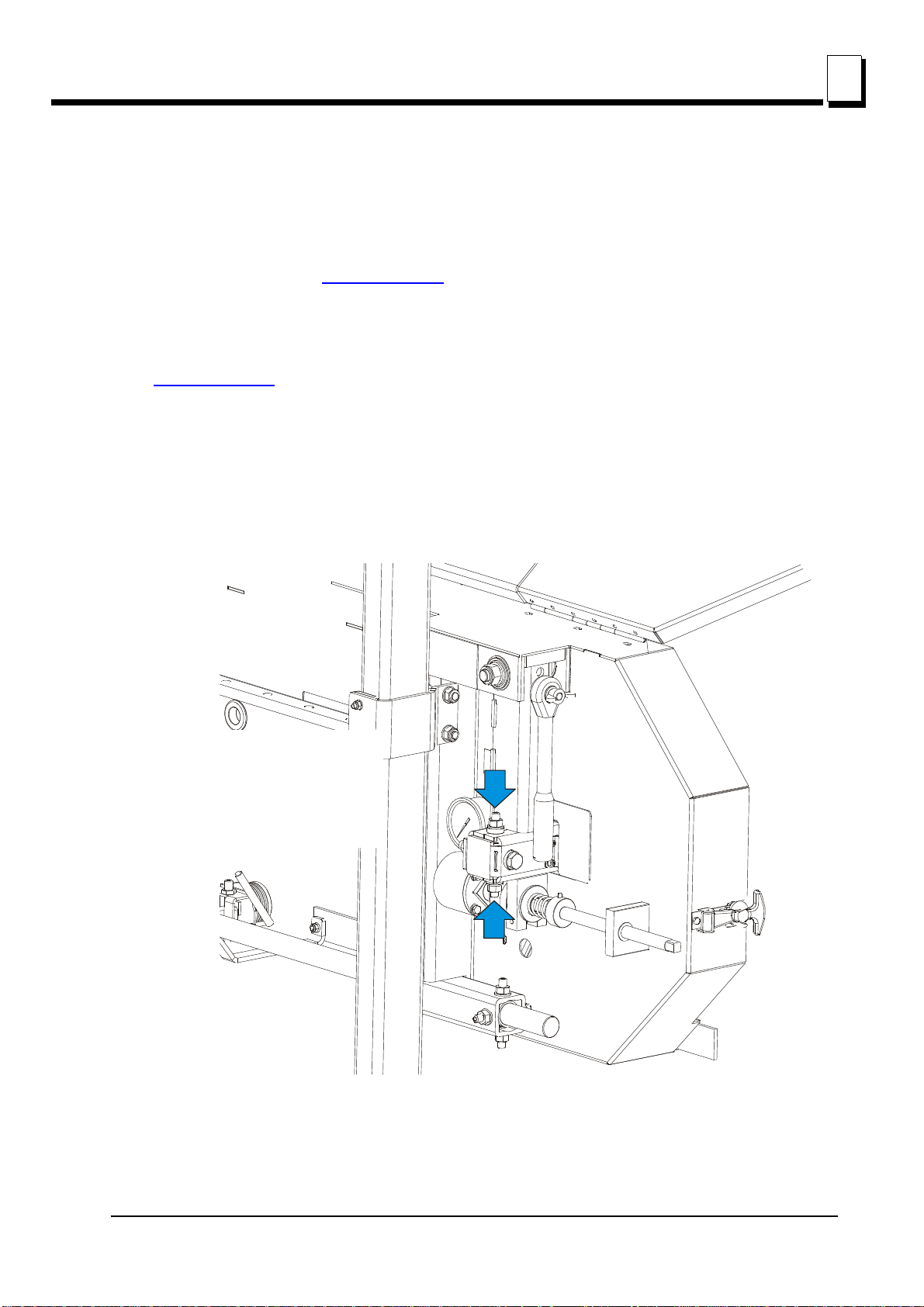

See Figure 3-14. Use the up/down crank to raise or lower the cutting head.

FIG. 3-14

2. Pull the crank grip to lock it in the locking pins.

3. To raise the saw head, turn the up/down crank handle clockwise; to lower – turn the crank handle

counterclockwise.

WARNING! DO NOT try to force the carriage above the 27" (68 cm)

mark or below the 1" (2.54 cm) mark. Damage to the up/down system

may result.

3-16 15doc080113 Setup & Operation

Setup & Operation

150120

Move the handle right

to move the blade arm out.

Move it left to move

the blade guide in.

Blade Guide Arm Operation

3.8 Blade Guide Arm Operation

1. Look down the length of the log to see its maximum width. The outer blade guide roller should be

adjusted to clear the widest section of the log by less than 1" (25.4 mm).

2. Use the blade guide arm handle to adjust the outer blade guide as necessary. Move the blade guide

arm handle right to move the arm out. Move the handle left to move the arm in.

See Figure 3-15.

3

FIG. 3-15

Setup & Operation 15doc080113 3-17

Setup & Operation

!

3

Blade Drive Operation

3.9 Blade Drive Operation

IMPORTANT! When starting the machine for the first time, check that

main motor rotation direction is as indicated by the arrow located on

the motor body (fan guard). If the rotation direction is incorrect, invert

the phases in the phase inverter located in the power socket (electric

box). Correct motor rotation direction is indicated by the arrow located

on the motor body.

DANGER! Make sure all guards and covers are in place and

secured/closed before operating the sawmill. Failure to do so may

result in serious injury.

WARNING! Always wear eye, ear, respiration and foot protection when

operating the sawmill. Failure to do so may result in serious injury.

Be sure the blade housing cover is in place and secured before starting the engine or motor. Use the

rubber latches to fasten the blade housing cover shut. If the blade housing cover is not closed and

secured, the safety switch located on it interrupts the ignition circuit and the motor/engine cannot be

started. If the cover is opened during the mill operation, the engine/motor will be stopped.

To engage the blade, perform the following steps:

1. Clear any loose objects from the area of the blade, motor, and drive belt.

2. Make sure the clamps and side supports are positioned low enough for the blade to pass over them.

Make sure the log is clamped securely.

3. Turn the main switch on the electrical box to the ON position, and check if the red safety button is

released.

4. Press AND HOLD the safety handle on the control box. NOTE: If the safety handle is released, the

blade disengages and stops.

5. Press the START button on the control box to start the motor.

3-18 15doc080113 Setup & Operation

Setup & Operation

Switch,

Emergency

Stop

Switch,

Start-Stop

Safety Handle

Main Switch

Blade Drive Operation

3

CAUTION! If at any time you need to immediately stop the blade

motor, press the emergency stop button located on the electric box.

FIG. 3-15

Setup & Operation 15doc080113 3-19

Setup & Operation

3

Feed Operation

3.10 Feed Operation

To move the saw head, use the two handles located on the electric box bracket.

HINT: To get a straight cut in the first part of the board, feed the blade into the log at a slow speed.

This stops the blade from flexing and dipping up or down. Use a slow speed until the whole width of

the blade has entered the cut. Then increase the feed rate as desired. Maximum feed rate varies

with width and hardness of the wood. Over-feeding results in blade and drive belt wear.

CAUTION! Be sure to stop the blade when returning the cutting head.

This will not only prevent the blade from being pulled off and ruined by

a wood sliver, but also will increase the life of the blade.

HINT: Try to stop the blade while the heel of the blade is still on the log. Then bring the carriage back

without adjusting the blade up. This lets you keep the blade at the current height setting so you can

make the next blade height adjustment more quickly.

IMPORTANT! Secure the saw head when loading, turning or clamping the log. Use the transporting

lock pin as described in Section 3.15

.

3.11 Cutting The Log

The following steps guide you through normal operation of the Wood-Mizer sawmill.

1. Once the log is placed where you want it and clamped firmly, position the blade close to the end of

the log.

2. Use the blade height scale to determine where to make your first cut (See Section 3.13

blade to the desired height with the up/down crank handle. Make sure that the blade will clear all side

supports and clamps. Adjust the outer blade guide (See Section 3.8).

3. Make sure all covers and guards are in place and secured. Start the engine.

4. Start the water lube if necessary to prevent sap buildup on the blade (See Section 3.14

5. Feed the blade into the log slowly. Once the blade completely enters the log, increase the feed rate

as desired. Always try to cut at the fastest speed you can while keeping an accurate cut. Cutting too

slowly will waste blade life and lower production!

6. As you get to the end of the log, slow down the feed rate. When the teeth exit the end of the log,

release the safety handle on the control box. Remove the slab that you have just cut from the log.

). Set the

).

7. Use the feed crank to return the cutting head to the front of the mill. Always disengage the blade

before returning the cutting head for the next cut.

8. Repeat until the first side of the log is cut as desired. Set aside the usable flitches (boards with bark

on one or both sides).You can edge them on the mill later.

9. Remove the leveling wedge if it was used. Release the clamps and turn the log 90 or 180 degrees.

3-20 15doc080113 Setup & Operation

Setup & Operation

Edging

Make sure the flat on the log is placed flat against side supports if turned 90 degrees. Make sure it is

placed on bed rails if turned 180 degrees. If the log was turned 90 degrees and you are using the

wedge to compensate for taper in the log, use the wedge again to adjust the heart of the log parallel

with the bed.

10. Repeat the steps used to cut the first side of the log until the log is square. Cut boards from the

remaining cant.

Example: Remember that the blade cuts a 1/16 - 1/8" (1.6 - 3.2 mm) wide kerf. If you want 1"

(25 mm) thick boards, lower the carriage 1 1/16 - 1 1/8" (27 - 29 mm) for each board.

3.12 Edging

The following steps guide you through edging boards on the Wood-Mizer sawmill.

1. Raise the side supports to 1/2 the height of the flitches, or the boards that need to be edged.

2. Stack the flitches on edge against the side supports.

3

3. Clamp the flitches against the side supports halfway up the flitch height. (Wider flitches should be

placed to the clamp side. When they are edged, flip them over to edge the second side without

disturbing the other flitches.)

4. Adjust the blade height to edge a few of the widest boards.

5. Loosen the clamps and turn the edged boards over to edge the other side.

6. Repeat steps 2-4.

7. Loosen the clamps and remove the boards that have good clean edges on both sides. Clamp the

remaining flitches and repeat steps 2-5.

Setup & Operation 15doc080113 3-21

Setup & Operation

150028C

Scale

Blade Height

Indicator

3

Blade Height Scale

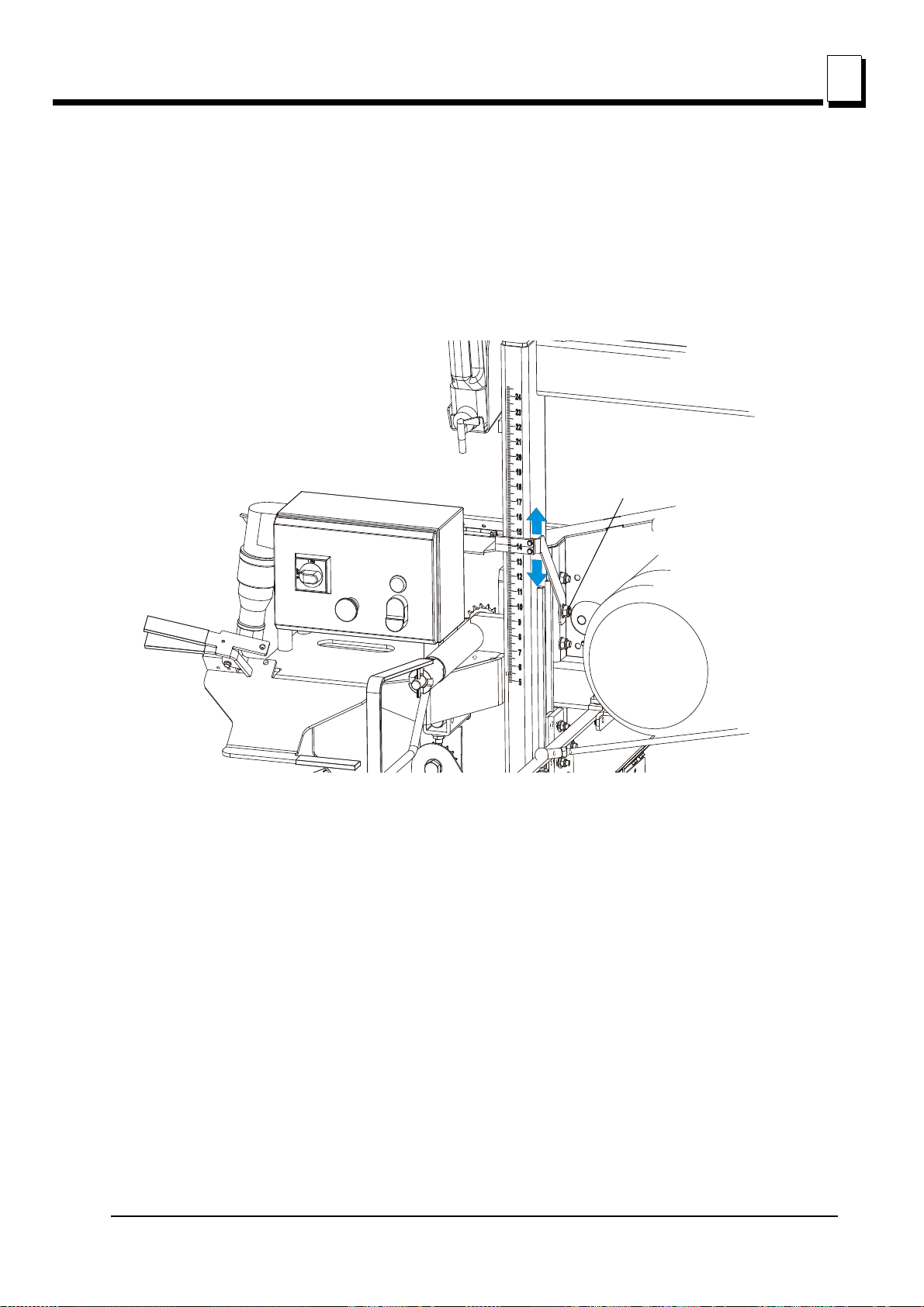

3.13 Blade Height Scale

See Figure 3-16. The blade height scale is mounted on the vertical mast. It includes:

a blade height indicator

centimeter scale (or quarter inch scale)

FIG. 3-16

Blade Height Indicator

The blade height indicator has two horizontal, red lines on both sides. Readings should be taken with

eyes level with the indicator, when the two red lines are in line. This will allow to avoid the parallax

error (different scale readings depending on the angle of vision).

The Scale

The horizontal red line on the blade height indicator shows how many centimeters the bottom of the

blade is above the bed of the mill. If you know the height of your blade at each cut, you can

determine the thickness of lumber you are sawing.

Example: You want to cut 25 mm random width boards from a log. Position the blade for the first cut.

Move the carriage to an even measurement on the scale. Make a trim cut. Return the carriage for the

second cut and lower it 29 mm below the original measurement. (The extra 3 mm allows for saw kerf

and shrinkage of the lumber.)

The yellow area on the scale identifies where the blade could encounter a side support or log clamp.

Check that these items are below the blade level before sawing.

The Quarter Scale

See Table 3-2. The quarter scale contains of four sets of marks. Each set represents a specific

lumber thickness. Saw kerf and shrinkage allowance are included, but actual board thickness will

vary slightly depending on blade thickness and tooth set.

To choose which scale to use, determine what finished thickness you want to end up with. The Grade

Hardwood Quarter Scale provides thicker finished boards usually required by commercial buyers.

3-22 15doc080113 Setup & Operation

Setup & Operation

Blade Height Scale

The Standard Quarter Scale allows for kerf and shrinkage of finished boards suitable for most

custom applications. Always check with your customer before you saw to determine what actual

finished thickness is required.

Standard Quarter Scale Grade Hardwood Quarter Scale

Scale Actual Board Thickness Scale Actual Board Thickness

4/4 25 mm (1") 4/4 29 mm (1 1/8")

5/4 32 mm (1 1/4") 5/4 35 mm (1 3/8")

6/4 38 mm (1 1/2") 6/4 41 mm (1 5/8")

8/4 51 mm (2") 8/4 54 mm (2 1/8")

TABLE 3-0

To use the quarter scale, look at the blade height indicator. Example: You want to cut 1" (25 mm)

(4/4) random width boards from a log. Position the blade for the first cut.

carriage for the second cut. Now, instead of having to measure down 1 1/8" (29 mm) on the inch

scale, you can simply lower the blade so the indicator is aligned with the next 4/4 mark on the quarter

scale. Turn the log 90 degrees and repeat.

Make a trim cut. Return the

3

Setup & Operation 15doc080113 3-23

Setup & Operation

Place water bottle on tray

3

Water Lube Operation

3.14 Water Lube Operation

The Water Lube System keeps the blade clean. Water flows from a 5 liter bottle through a hose to

the blade guide where the blade enters the log. A valve in the bottle cap controls the amount of water

flow.

See Figure 3-17. Install the water bottle at the top of the vertical mast.

3-24 15doc080113 Setup & Operation

FIG. 3-17

Setup & Operation

To close turn valve clockwise; to open

turn valve counterclockwise.

Transporting the Sawmill

See Figure 3-18. Open the valve on the water bottle to start water flow on the blade.

FIG. 3-18

Not all types of wood require the use of the Water Lube System. When it is needed, use just enough

water to keep the blade clean. This saves water, and lowers the risk of staining the boards with

water. Usual flow will be 1-2 gallons (3.8-7.6 liters) per hour. A squirt of liquid dishwashing detergent

in the water bottle will help clean the blade when cutting wood with a high sap content.

3

WARNING! Use ONLY water with the water lube accessory. Never use

flammable fuels or liquids. If these types of liquids are necessary to

clean the blade, remove it and clean with a rag. Failure to do so may

result in serious injury or death.

Before removing the blade, engage blade drive. Let the blade spin with water running on it for about

15 seconds. This will clean the blade of sap buildup. Wipe the blade dry with a rag before storing or

sharpening.

If you are sawing in freezing temperatures, remove the water lube bottle from the sawmill when done

sawing and store it in a warm place. Blow any remaining water from the water lube hose.

3.15 Transporting the Sawmill

The assembled sawmill can be transported in an appropriately equipped pickup truck:

1. Adjust the cutting head up just far enough so it will clear the sides of your truck bed when loaded. Do not adjust

the cutting head so high that the sawmill will tip easily while being loaded.

2. Move the cutting head to one end of the bed frame. Engage the travel lock pin to prevent the cutting head from

moving. Pull the pin and rotate and release so the roll pin seats in the locking position notch.

Setup & Operation 15doc080113 3-25

Setup & Operation

10_079

3

Transporting the Sawmill

See Figure 3-19.

FIG. 3-19

3. Remove the leg assemblies or adjust them above the bottom of the bed frames.

4. Position the bed of the truck at the end of the frame opposite the cutting head.

5. While two people lift the end of the frame without the cutting head, back the truck under the sawmill until the

the end of the frame is resting firmly on the bed of the truck.

6. With a person positioned on either side of the cutting head, disengage the travel lock pin. Push the cutting

head up the bed frame and engage the travel lock pin in the end of the frame in the truck bed.

7. Use two people to lift the end of the mill still on the ground and slide the sawmill into the truck bed.

WARNING! Keep all persons out of the path of the cutting head while

loading and unloading the sawmill. Failure to do so may result in serious injury

or death.

8. Secure the sawmill to the truck bed to prevent the sawmill from shifting while it is being transported.

3-26 15doc080113 Setup & Operation

Wood-Mizer LT10 Short Interval Maintenance Schedule

PROCEDURE MANUAL

REFERENCE

EVERY BLADE CHANGE

Check Blade Guide Roller Performance

Remove Excess Sawdust From Blade Wheel Housings And Sawdust Chute

EVERY 8 HOURS

Clean And Lubricate Track

Remove Sawdust From Upper Cam Housings.

SEE SECTION 4.2

SEE SECTION 4.2

SEE SECTION 4.3

SEE SECTION 4.3

f:\manuals\forms\749 15doc080113

WOOD-MIZER LT10 MAINTENANCE LOG

PROCEDURE MANUAL

REFERENCE

Clean & lubricate mast See Section4.4

Check blade wheel belts for wear. See Section4.6

Lubricate blade tensioner screw. See Section4.5

WOOD-MIZER LT10 MAINTENANCE LOG

PROCEDURE MANUAL

REFERENCE

Clean & lubricate mast See Section4.4

Check blade wheel belts for wear. See Section4.6

Lubricate blade tensioner screw. See Section4.5

TOTAL HOURS OF OPERATION

FILL IN THE DATE AND THE MACHINE HOURS AS YOU PERFORM EACH PROCEDURE.

A SHADED BOX INDICATES MAINTENANCE IS NOT NEEDED AT THIS TIME.

50 HRS 100 HRS 150 HRS 200 HRS 250 HRS 300 HRS 350 HRS 400 HRS 450 HRS 500 HRS

TOTAL HOURS OF OPERATION

FILL IN THE DATE AND THE MACHINE HOURS AS YOU PERFORM EACH PROCEDURE.

A SHADED BOX INDICATES MAINTENANCE IS NOT NEEDED AT THIS TIME.

550 HRS 600 HRS 650 HRS 700 HRS 750 HRS 800 HRS 850 HRS 900 HRS 950 HRS 1000 HRS

f:\manuals\forms\610 15doc080113