Horizontal Resaw HR700

!

Safety, Operation,

Maintenance & Parts Manual

HR700E15S -1/6 rev. A4.00

HR700E20S -1/6 rev. A4.00

HR700E25S -1/6 rev. A4.00

HR700E30S -1/6 rev. A4.00

Safety is our #1 concern! Read and understand

all safety information and instructions before

operating, setting up or maintaining this machine.

Form #1007

This is the original language

for the manual.

Table of Contents Section-Page

General Contact Information

Branches & Authorized Sales CentersWood-Mizer Locations (North and South America)

SECTION 1 SAFETY 1-1

1.1 Safety Symbols.......................................................................................1-1

1.2 Safety Instructions..................................................................................1-2

Observe Safety Instructions

Wear Safety Clothing

Keep Resaw And Area Around Resaw Clean

Dispose Of Sawing By-Products Properly

Check Resaw Before Operation

Keep Persons Away

Keep Hands Away

Use Proper Maintenance Procedures

Keep Safety Labels In Good Condition

SECTION 2 OPERATION 2-1

2.1 Control Overview ...................................................................................2-1

2.2 Resaw Setup ...........................................................................................2-3

Electrical Requirements (US Version Only)

2.3 Replacing the Blade..............................................................................2-15

2.4 Using the Blade Tensioner Pump.........................................................2-17

2.5 Tensioning the Blade............................................................................2-18

2.6 Tracking the Blade ...............................................................................2-20

2.7 Saw Head Height Adjustment ..............................................................2-21

2.8 Guide Fence Adjustment ......................................................................2-24

2.9 Blade Guide Arm Adjustment..............................................................2-25

2.10 Machine Start........................................................................................2-26

2.11 Water Lube Operation ..........................................................................2-29

Standard Lube System (Supplied from a Water Supply Network)

Optional Lube System (Supplied from Water Tanks)

2.12 Operation Procedure.............................................................................2-32

SECTION 3 MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT) 3-1

3.1 General Information ...............................................................................3-1

3.2 Functions ................................................................................................3-1

3.3 Start-up ...................................................................................................3-2

Calibration

3.4 Manual Mode..........................................................................................3-4

3.5 X-Board Mode........................................................................................3-7

4 SW-07doc012819 Table of Contents

Table of Contents Section-Page

3.6 Diagnostic.............................................................................................3-10

Calibration

Diagnostic I/O

Tuning

3.7 Errors ....................................................................................................3-18

Impulses are not counted.

Incorrect up/down movement direction

Limit switches

Positioning error

SECTION 4 MAINTENANCE 4-1

4.1 Wear Life................................................................................................4-1

4.2 Blade Guides ..........................................................................................4-2

4.3 Sawdust Removal ...................................................................................4-2

4.4 Vertical Mast ..........................................................................................4-2

4.5 Miscellaneous Lubrication .....................................................................4-3

4.6 Belts........................................................................................................4-4

4.7 Drive Belt Adjustment............................................................................4-5

4.8 Feed Track Chain Adjustments ..............................................................4-8

4.9 Optional Hold-Down Arm Adjustment................................................4-10

4.10 Up/Down System..................................................................................4-12

4.11 Long-Term Storage ..............................................................................4-13

4.12 End of the life cycle..............................................................................4-13

4.13 Safety Devices Inspection ....................................................................4-14

SECTION 5 ALIGNMENT 5-1

5.1 Alignment Procedures ............................................................................5-1

5.2 Blade Installation And Tracking ............................................................5-2

5.3 Blade Wheel Alignment .........................................................................5-4

5.4 Saw Head Adjustment ..........................................................................5-10

5.5 Blade Guide Arm Vertical Adjustment ................................................5-11

5.6 Blade Guide Arm Horizontal Adjustment............................................5-12

5.7 Aligning the Blade Guides ...................................................................5-14

5.8 Blade Deflection...................................................................................5-15

5.9 Blade Guide Vertical Tilt Adjustment..................................................5-16

5.10 Blade Guide Spacing ............................................................................5-18

5.11 Blade Guide Horizontal Tilt Adjustment .............................................5-19

5.12 Blade Height Scale Adjustment............................................................5-20

5.13 Adjustment of the Sensor Activating the Air Cylinder ........................5-21

SECTION 6 SPECIFICATIONS 6-1

6.1 Overall Dimensions ................................................................................6-1

6.2 Cutting Capacity.....................................................................................6-6

Table of Contents SW-07doc0128195

Table of Contents Section-Page

6.3 Blade Motor Specifications ....................................................................6-7

6.4 Noise Level.............................................................................................6-7

6.5 V-Belt Sizes............................................................................................6-8

6.6 Air Supply Specifications.......................................................................6-8

6.7 Dust Extractor Specifications.................................................................6-8

SECTION 7 MOTOR BRAKE 7-1

7.1 Motor Brake Maintenance......................................................................7-1

Maintenance intervals

Checking the rotor thickness

Check the air gap

6 SW-07doc012819 Table of Contents

General Contact Information

Getting Service

Wood-Mizer is committed to providing you with the latest technology, best quality and strongest

customer service available on the market today. We continually evaluate our customers’ needs to

ensure we’re meeting current wood-processing demands. Your comments and suggestions are

welcome.

General Contact Information

From Europe call your local distributor or our European Headquarters and Manufacturing Facility in

Koło, Nagórna 114 St, Poland at +48-63-2626000. From the continental U.S., call our U.S.

Headquarter 8180 West 10th St.Indianapolis, IN 46214, toll-free at 1-800-525-8100.

with a Customer Service Representative. Please have your machine identification number and your

customer number ready when you call. The Service Representative can help you with questions

about the operation and maintenance of your machine. He also can schedule you for a service call.

Office Hours:

Country Monday - Friday Saturday Sunday

Poland

US

7 a.m.- 3 p.m.

8 a.m.- 5 p.m. 8 a.m.- 12 p.m

Closed Closed

Closed

Ask to speak

Please have your vehicle identification number and your customer number ready when you call.

Wood-Mizer will accept these methods of payment:

Visa, Mastercard, or Discover

COD

Prepayment

Net 15 (with approved credit)

Be aware that shipping and handling charges may apply. Handling charges are based on size and

quantity of order.

Technical data are subject to change without prior notice.

Actual product may differ from product images. Some illustrations show machines with optional

equipment.

doc012819 -7

Branches & Authorized Sales CentersWood-Mizer Locations (North and South America)

Branches & Authorized Sales CentersWood-Mizer Locations (North and South America)

European Headquarters

Wood-Mizer Industries Sp. z o.o.

Nagórna 114, 62-600 Koło, Poland

Tel.: +48-63-26-26-000

Fax: +48-63-27-22-327

www.woodmizer.eu

BELARUS

MOST-GRUPP

Siemashko 15, k.3

Minsk 2200116

Tel.: +375-17-270-90-08

Fax: +375-17-270-90-08

GSM: +375-29-649-90-80

e-mail: most-by@mail.ru

BULGARIA Kalin Simeonov

Ecotechproduct

38 Star Lozenski pat str.

Sofia 1186

Tel.: +359-2-462-7035

Tel.: +359-2-963-1656

Tel:/Fax

: +359-2-979-1710

Kalin Simeonov

GSM: +3592-963-2559

e-mail: office@ecotechproduct.com

EUROPE UNITED STATES

World Headquarters

Wood-Mizer LLC

8180 West 10th Street

Indianapolis,Indiana 46214-2400,

USA

Tel.: +1-317-271-1542

Fax: +1-317-273-1011

www.woodmizer.com

SWITZERLAND Stefan Wespi

Maschinen u. Geräte

Spezialarbeiten GmbH

Eichistraße 4

6353 Weggis

Tel.: +41-(0)41 - 3900312

GSM: +41-(0)79 - 9643594

info@mobilsaegen.ch

HUNGARY Wiktor Turoczy

Wood-Mizer Hungary K.F.T.

Szonyi Ut 67., 2921 Komárom

Tel.:/Fax: +36-34-346-255

e-mail: woodmizer@woodmizer.hu

RUSSIA Dariusz Mikołajewski

OOO WOOD-MIZER INDUSTRIES

141031, Moscow

Reg., Mytishenski raj., pos. Veshki,

Zavodskaja str., 3B

Tel.Fax: +7(495) 788-72-35

Tel.Fax: +7(495) 641-51-60

e-mail: dariuszm@woodmizer-moscow.ru

RUSS IA Fa r Eas t Wladimir Głazaczew

“WM Service”

Krasnoretchenskaya Str.111

680006 Khabarovsk

Tel.:/Fax: +7-914-541-1183

e-mail: wms-khv@mail.ru

-8 doc012819

Branches & Authorized Sales CentersWood-Mizer Locations (North and South America)

CROATIA Krešimir Pregernik

Pregimex d.o.o.

S. Batušiæa 31, 10090 Zagreb

Tel.:/Fax: +3851-38-94-668

Krešimir Pregernik

GSM: +3851-98-207-106

e-mail: Kresimir.Pregernik@gmail.com

CZECH REPUBLIC Miroslaw Greill

Wood-Mizer CZ s.r.o.

Osvaldova 91

339 01 Klatovy-Luby

Tel.:/Fax: +420-376-312-220

Fax: +420-376-319-011

Miroslaw Greill

GSM: +420-723-580-799

e-mail: greill@woodmizer.cz

CZECH REPUBLIC Lubomir Kudlik

Wood-Mizer Moravia

Sovadinova 6

69002 Breclav

Tel.:/Fax: +420-519-322-443

Lubomir Kudlik

GSM: +420-602-734-792

e-mail: info@wood-mizer.net

FINLAND Howard Blackbourn

Oy Falkberg Jordbruk Ab

Falkintie 220

25610 Ylonkyla

Tel.: +358-2732-2253

Fax: +358-2732-2263

Howard Blackbourn

GSM: +358-440-424-339

e-mail: falkberg@woodmizer.fi

ITALY Pasquale Felice

Wood-Mizer Italia Srl

Cda. Capoiaccio SN

86012 Cercemaggiore

Campobasso

Tel.:/Fax: +39-0874-798-357

GSM: +39-333-281-03-79

e-mail: wmitaliasrl@gmail.com

LATVIA Vilmars Jansons

OBERTS Ltd

Gaujas str. 32/2

LV-2167 Marupe, Rigas Raj.

Tel.: +371-7-810-666

Fax: +371-7-810-655

Vilmars Jansons

GSM: +371-92-06-966

Andris Orols

GSM: +371-28-33-07-90

e-mail: andris@oberts.lv

LITHUANIA Andrius Zuzevicius

UAB Singlis

Savanoriu pr. 187, 2053 Vilnius

Tel.: +370-5-2-32-22-44

Fax: +370-5-2-64-84-15

GSM: +370-620-28-645

e-mail: andrius.z@singlis.lt

Dmitrij Gaiduk

GSM: +370-69-84-51-91

e-mail: dmitrijus.g@singlis.lt

SERBIA Dragan Markov

Wood-Mizer Balkan d.o.o.

Svetosavska GA 3/3; P. Fah 25

23 300 Kikinda

Tel.:/Fax: +381-230-25-754

Tel.:/Fax: +381-230-23-567

GSM: +381-63-568-658

e-mail: office@woodmizer.co.yu

SLOVAKIA Wiktor Turoczy

Wood-Mizer Danubia s.r.o.

Hadovce 5, 94501 Komárno

Tel.: +421-35-77-40-316

Fax: +421-35-7740-326

GSM: +421-905-930-972

e-mail: woodmizer@woodmizer.sk

TURKEY

Er-Ka Ahsap Profil Kerestecilik San.

ve Tic. Ltd. Sti.

Adana Keresteciler Sitesi 191 sk No.41

ADANA

Tel.: +90-322-346-15-86

Fax: +90-322-345-17-07

GSM: +90-533-363-18-44

e-mail: info@erkaahsap.com.tr

UKRAINE Ivan Vinnicki

MOST UKRAINA

bul. Myru 3, Bajkivtsi Ternoplskyj r-j

Ternopolska oblast

47711 Ukraine

Tel/Fax: +38 (0352) 52 37 74

GSM: +38 (067) 352 54 34

GSM: +38 (067) 674 50 68

E-mail: most-ukraina@ukr.net

FRANCE Tizoc Chavez

Wood-Mizer France

556 chemin des Embouffus,

ZAC des Basses Echarrieres

38440 SAINT JEAN DE BOURNAY

Tel: +33-4 74 84 84 44

GSM: +33-607 52 02 82

Mail: tchavez@woodmizer.fr

SLOVENIA Jan Fale

FAMTEH d.o.o.

Gacnikova pot 2,

2390 Ravne na Koroskem

Tel.: +386-2-62-04-232

Fax: +386-2-62-04-231

Jan Fale

GSM: +386-2-62-04-230

e-mail: jan.fale@famteh.si

Matjaz Kolar

Tel.: +386-2-62-04-232

GSM: +386-31-775-999

e-mail: matjaz.kolar@famteh.si

NORWAY Odd Edvoll

Wood-Mizer Nordic AS

Vardelia 17, 2020 Skedsmokorset

Tel.: +47-63-87-49-89

Fax: +47-63-87-37-66

GSM: +47-930-42-335

e-mail: odd.edvoll@woodmizer.no

e-mail: firmapost@woodmizer.no

UNITED KINGDOM & IRELAND

Wood-Mizer UK

Hopfield Barn

Kenward Road, Yalding

Kent ME18 6JP, UK

Tel.: +44-1622-813-201

Fax: +44-1622-815-534

e-mail: info@

woodmizer.co.uk

doc012819 -9

Branches & Authorized Sales CentersWood-Mizer Locations (North and South America)

GERMANY Klaus Longmuss

Wood-Mizer Sägewerke GmbH

Dorfstraße 5, 29485 Schletau

Tel.: +49-5883-9880-10

Fax: +49-5883-9880-20

e-mail: info@woodmizer.de

Klaus Longmuss

Tel.: +49-5883-9880-12

GSM: +49-17-298-55-892

e-mail: KLongmuss@woodmizer.de

Subagents:

DENMARK Brian Jensen

Arnborgvej 9, 7330 Brande- Fasterholt

Tel.: +45-971-88-265

Fax: +45-971-88-266

Brian Jensen

GSM: +45-23-49-5828

e-mail: Fasterholt-Savvaerk@Mail.Tele.dk

Netherlands Chris Dragt

Lange Brink 77d,

7317 BD Apeldoorn

Tel.: +31-55312-1833

Fax: +31-55312-2042

e-mail: Info@dragtbosbouw.nl

Subagent:

SWEDEN Kjell Larsson

Mekwood AB

Slingan 14, 812 41 Gästrike-Hammarby

Tel.: +46-290-515-65

Kjell Larsson

GSM: +46-706-797-965

e-mail: kjell.larsson@mekwood.se

ROMANIA Adrian Echert

SC WOOD-MIZER RO SRL

TRANSILVANIEI Nr. 5

Sibiu, Cisnadie 555300

Tel.:/Fax: : +40-369-405-433

GSM: +40-745-707-323

e-mail: aechert@woodmizer.ro

Subagent:

ROMANIA M. Echert

S.C. Echert Comprod s.r.l

Str. Schitului Nr. 6, Apt.7 etajul-1

725 70 Vatra Dornei, Romania

Tel.:/Fax: +40-230-374-235

Tel. : +40-740-35-35-74

IRELAND

Wood-Mizer Ireland

Stephen Brennan

Cum Lahardane Ballina County Mayo

Tel:+353 96 51345

E-mail: brennanmill@ericom.net

Regional Manager - Asia

Wood-Mizer Asia Pte Ltd.

James Wong

Tel: +65 81216910

Fax: +65 6283 8636

WWW: www.woodmizerasia.com

E-mail: jwong@woodmizerasia.com

Regional Manager - Africa

Wood-Mizer Africa

Jean-Jacques Oelofse

UNIT 3, LEADER PARK, NO: 20 CHARIOT

ROAD

STORMILL, EXT 5, Roodepoort,

Johannesburg

Tel: +27 011 473 1313

Fax: +27 011 473 2005

Jean-Jacques Oelofse E-mail:

jjoelofse@woodmizerafrica.com

Jean-Jacques Oelofse

Skype:jean.jacques.pierre.oelofse

USA World Headquarters Canadian Headquarters

Serving North & South America, Oceania, East Asia

Wood-Mizer LLC

8180 West 10th Street

Indianapolis, IN 46214

Phone: 317.271.1542 or 800.553.0182

Customer Service: 800.525.8100

Fax: 317.273.1011

Email: infocenter@woodmizer.com

Serving Canada

Wood-Mizer Canada

396 County Road 36, Unit B

Lindsay, ON K9V 4R3

Phone: 705.878.5255 or 877.357.3373

Fax: 705.878.5355

Email: ContactCanada@woodmizer.com

Brazil Headquarters Europe Headquarters

Serving Brazil

Wood-Mizer do Brasil

Rua Dom Pedro 1, No: 205 Bairro: Sao Jose

Ivoti/RS CEP:93.900-000

Tel: +55 51 9894-6461/ +55 21 8030-3338/ +55 51

3563-4784

Email: info@woodmizer.com.br

Serving Europe, Africa, West Asia

Wood-Mizer Industries Sp z o.o.

Nagorna 114

62-600 Kolo, Poland

Phone: +48.63.26.26.000

Fax: +48.63.27.22.327

Branches & Authorized Sales Centers

For a complete list of dealers, visit www.woodmizer.com

-10 doc012819

SECTION 1 SAFETY

!

1.1 Safety Symbols

The following symbols and signal words call your attention to instructions concerning your personal

safety. Be sure to observe and follow these instructions.

DANGER! indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING! suggests a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION! refers to potentially hazardous situations which, if not

avoided, may result in minor or moderate injury or damage to

equipment.

SAFETY

Safety Symbols

1

IMPORTANT! indicates vital information.

NOTE: gives helpful information.

Warning stripes are placed on areas where a single decal would be

insufficient. To avoid serious injury, keep out of the path of any

equipment marked with warning stripes.

SAFETY Multisetworkdoc012819 1-1

SAFETY

!

!

1

Safety Instructions

1.2 Safety Instructions

IMPORTANT! The Resaw is intended for sawing wood only.

The resaw must not be used for other purposes such as cutting ice,

metal or any other materials. See Section 5.2

the machine.

IMPORTANT! The operator of the resaw should get adequate training

in the operation and adjustment of the machine.

NOTE: ONLY safety instructions regarding personal injury are listed in this section. Caution

statements regarding only equipment damage appear where applicable throughout the manual.

Observe Safety Instructions

IMPORTANT! Read the entire Operator's Manual before operating the

resaw. Take notice of all safety warnings throughout this manual and

those posted on the machine. Keep this manual with this machine at all

times, regardless of ownership.

for log size capacities of

Also read any additional manufacturer’s manuals and observe any

applicable safety instructions including dangers, warnings, and

cautions.

Only adult persons who have read and understood the entire

operator's manual should operate the resaw. The resaw is not

intended for use by or around children.

IMPORTANT! It is always the owner's responsibility to comply with all

applicable federal, state and local laws, rules and regulations

regarding the ownership and operation of your Wood-Mizer resaw.

All Wood-Mizer resaw owners are encouraged to become thoroughly

familiar with these applicable laws and comply with them fully while

using the machine.

1-2 Multisetworkdoc012819 SAFETY

Wear Safety Clothing

!

WARNING! Secure all loose clothing and jewelry before operating the

resaw. Failure to do so may result in serious injury or death.

WARNING! Always wear gloves and eye protection when handling

bandsaw blades. Changing blades is safest when done by one person!

Keep all other persons away from area when coiling, carrying or

changing a blade. Failure to do so may result in serious injury.

SAFETY

Wear Safety Clothing

1

WARNING! Always wear eye, ear, respiration, and foot protection

when operating or servicing the resaw.

Keep Resaw And Area Around Resaw Clean

DANGER! Maintain a clean and clear path for all necessary movement

around the resaw and lumber stacking areas. Failure to do so will

result in serious injury.

Dispose Of Sawing By-Products Properly

IMPORTANT! Always properly dispose of all sawing by-products,

including sawdust and other debris.

Check Resaw Before Operation

DANGER! Make sure all guards and covers are in place and secured

before operating the resaw. Failure to do so may result in serious

injury.

SAFETY Multisetworkdoc012819 1-3

SAFETY

1

Keep Persons Away

Keep Persons Away

DANGER! Keep all persons out of the path of moving equipment and

lumber when operating the resaw. Failure to do so will result in serious

injury.

DANGER! Always be sure all persons are out of the path of the blade

before starting the motor. Failure to do so will result in serious injury.

WARNING! Allow blade to come to a complete stop before opening

the blade housing cover. Failure to do so will result in serious injury.

Keep Hands Away

DANGER! Always shut off the blade motor before changing the blade.

Failure to do so will result in serious injury.

DANGER! Motor components can become very hot during operation.

Avoid contact with any part of a hot motor. Contact with hot motor

components can cause serious burns. Therefore, never touch or

perform service functions on a hot motor. Allow the motor to cool

sufficiently before beginning any service function.

DANGER! Always keep hands away from moving bandsaw blade.

Failure to do so will result in serious injury.

DANGER! Always be aware of and take proper protective measures

against rotating shafts, pulleys, fans, etc. Always stay a safe distance

from rotating members and make sure that loose clothing or long hair

does not engage rotating members resulting in possible injury.

1-4 Multisetworkdoc012819 SAFETY

WARNING! Use extreme caution when spinning the blade wheels by

hand. Make sure hands are clear of blade and wheel spokes before

spinning. Failure to do so may result in serious injury.

Use Proper Maintenance Procedures

DANGER! Make sure all electrical installation, service and/or

maintenance work is performed by a qualified electrician and is in

accordance with applicable electrical codes.

SAFETY

Use Proper Maintenance Procedures

1

DANGER! Hazardous voltage inside the electric boxes and at the

motor can cause shock, burns, or death. Disconnect and lock out

power supply before servicing! Keep all electrical component covers

closed and securely fastened during resaw operation.

WARNING! Consider all electrical circuits energized and dangerous.

WARNING! Disconnect and lock out power supply before servicing the

resaw! Failure to do so may result in serious injury.

WARNING! Never assume or take the word of another person that the

power is off; check it out and lock it out.

WARNING! Do not wear rings, watches, or other jewelry while working

around an open electrical circuit.

WARNING! Remove the blade before performing any service to the

motor or resaw. Failure to do so may result in serious injury.

SAFETY Multisetworkdoc012819 1-5

SAFETY

!

1

Keep Safety Labels In Good Condition

DANGER! Never clean the blade or blade wheels using the hand-held

brush or scraper whilst the resaw blade is in motion.

CAUTION! Before installation of the blade, inspect it for damage and

cracks. Use only properly sharpened blades. Always handle the blade

with extreme caution. Use suitable carrier equipment for transporting

the blades.

CAUTION! Always wear gloves when handling the blade. Never grab

the blade with bare hands!

CAUTION! If the blade breaks during resaw operation, push the

EMERGENCY STOP button to stop the blade motor and wait

10 seconds before you open the blade housing cover.

CAUTION! The resaw’s work-stand should be equipped with a 4 kg

or bigger dry powder extinguisher.

Keep Safety Labels In Good Condition

IMPORTANT! Always be sure that all safety decals are clean and

readable. Replace all damaged safety decals to prevent personal

injury or damage to the equipment. Contact your local distributor, or

call your Customer Service Representative to order more decals.

IMPORTANT! If replacing a component which has a safety decal

affixed to it, make sure the new component also has the safety decal

affixed.

1-6 Multisetworkdoc012819 SAFETY

SAFETY

099220

099219

+

Keep Safety Labels In Good Condition

See Table 1-1. Pictogram decals used to warn and inform the user about danger in the resaw.

TABLE 1-1

Decal View W-M No. Description

096317 CAUTION! Read thoroughly the manual

before operating the machine. Observe all

safety instructions and rules when

operating the resaw.

099220 CAUTION! Close all guards and covers

before starting the machine.

1

099219 Blade tension. Turning the bolt clockwise

will increase the blade tension and turning

the bolt counterclockwise will decrease the

tension.

SAFETY Multisetworkdoc012819 1-7

SAFETY

099221

1

Keep Safety Labels In Good Condition

TABLE 1-1

099221 CAUTION! Keep all persons a safe

distance away from work area when

operating the machine.

099222 CAUTION! Sawdust outlet. Protect eyes!

096321 Blade movement direction

S12004G CAUTION! Always wear safety goggles

when operating the resaw!

S12005G CAUTION! Always wear protective ear

muffs when operating the resaw!

1-8 Multisetworkdoc012819 SAFETY

SAFETY

Keep Safety Labels In Good Condition

TABLE 1-1

501465 CAUTION! Always wear safety boots when

operating the resaw.

512107 CAUTION! Always wear safety gloves

when operating the resaw.

1

501467 Lubrication Point

P11789 Aligning the blade on the wheels

P85070 CE sign

SAFETY Multisetworkdoc012819 1-9

SAFETY

099401

S20097

d

509025

d

257mm

231mm

197mm

18 m/s

20 m/s

24 m/s

TVS 505346

1

0

505348

Typ e

psi

bar

F[mm] E[mm]

F

E

275

375

376

2735

576

476

1,07

1,14

1,07

1,27

1,40

32

32

38

35

38

830-850

745-765

805-825

715-735

57-59

51-53

55-57

49-51

1

Keep Safety Labels In Good Condition

TABLE 1-1

099401 Russian safety certification sign

S20097 Motor rotation direction

509025 Blade drive wheel diameter-blade linear

speed

505346 TVS Tensioner Valve Handle Positions

505348 Blade Tension Values

1-10 Multisetworkdoc012819 SAFETY

SAFETY

101176

513181

6 bar

0.6 MPa

Keep Safety Labels In Good Condition

TABLE 1-1

101176 CAUTION! Compressed air in the system

even after electric power disconnection

513181 Pressure value of the pneumatic system

1

SAFETY Multisetworkdoc012819 1-11

Operation

Blade Motor

START Buttons

Emergency Stop

Button

Hour

Meter

Feed Track

Switch

Feed Speed

Adjustment

Emergency Stop

Button

Main Power

Switch

Motor/Brake

Switch

Main Power

Indicator

Feed Track

Stop Button

Blade Motor

STOP Button

2

Control Overview

SECTION 2 OPERATION

2.1 Control Overview

See Figure 2-1. The control panel includes switches to start and stop the feed track and

the saw head.

FIG. 2-1 CONTROL PANEL AND MAIN ELECTRIC BOX

Control Panel

1. Blade Drive

To start the blade motor, turn the key switch to the position. Then press the START

button. Each saw head is started with separate START button. To stop the blade motors,

press the STOP switch.

2-1 MHdoc012819 Operation

saw head motor to avoid high peak demand currents.

CAUTION! Wait five (5) seconds between the start of each

Operation

TRACK FEED

Control Overview

2. Feed Track

To start spinning the feed track forward or backward, turn the switch left or right. To stop

the feed track, press the STOP button

3. Feed Track Speed Adjustment

The feed track speed switch controls the speed at which the feed track moves. Turn the

switch clockwise to increase the speed, counterclockwise to reduce the speed.

4. Emergency Stop

Push the emergency stop button to stop the blades and the track feed motor. Turn the

emergency stop clockwise to release the stop. The resaw will not restart until the

emergency stop is released.

5. Hour Meter

2

Records work hours of the machine.

Main Electric Box

1. Key Switch

The key switch has three positions:

“0” position - all electrical circuits are off,

position - all electrical circuits are on,

position - releases the motor disk brake; the blade and the track feed motors

are off.

2. Emergency Stop

Push the emergency stop button to stop the blades and the track feed motor. Turn the

emergency stop clockwise to release the stop. The resaw will not restart until the

emergency stop is released.

3. Main Power Switch

Disconnects power from all electric circuits of the machine.

Operation MHdoc012819 2-2

Operation

1

2

2

Resaw Setup

2.2 Resaw Setup

The Horizontal Resaw is delivered to the customer place in modules. The HR modules

must be mounted together.

See Figure 2-2. Dismount the electric up/down system assembly (optional equippment)

from the transport bracket (1). Next dismount the transportation bracket form the resaw

base (2). The up/down assembly is heavy (about 90kg). To lift it, use a belt and a winch or

a forklift.

FIG. 2-2

2-3 MHdoc012819 Operation

Operation

1

2

3

Resaw Setup

See Figure 2-3. Mount the up/down assembly in its working position as shown on the

pictures below.

2

Operation MHdoc012819 2-4

FIG. 2-3

Operation

hr023a

hr023a

509666_manuals_oper

2

Resaw Setup

See Figure 2-4. Attach the base to the additional module (or modules).

FIG. 2-4

2-5 MHdoc012819 Operation

Operation

M16x160 Bolt (2)

M12x40 Bolt (2)

Screw, M6x10 Hex

Socket Head Cap

(4)

Washer, 17 (4)

M16 Nut (2)

Resaw Setup

See Figure 2-5. Using the appropriate bolts, washers and nuts, mount the base and the

additional module (modules) together.

2

FIG. 2-5

Operation MHdoc012819 2-6

Operation

M16x160 Bolt(2)

Bolt M6x20 (8)

Washer, 17 (4)

Nut, M16 (2)

Washer, 6.5 (8)

Washer, 8 (16)

M8 Nut (8)

M8x25 Bolt(8)

2

Resaw Setup

See Figure 2-6. Mount the feed chain drive module.

2-7 MHdoc012819 Operation

FIG. 2-6

Operation

HR 700_Oper_005

509661_Manual

Chain Tension

Adjusting Bolts

Link the chain using the

pin

!

!

Resaw Setup

See Figure 2-7. Mount the feed chain and apply proper tension. See Section 4.8

2

FIG. 2-7

IMPORTANT! Before stariting to use any HR resaw

equipped with return tables, move the control panel and the

rear e-stop to the locations shown in the figures 2-9 to 2-12

(depending on the resaw configuration).

IMPORTANT! Before starting to use the resaw, you have to

meet the following conditions:

Set up the resaw on firm and level ground. The machine must be fastened to the

floor. Failure to do so may cause the sawhead to tip, resulting in serious injury or

death. A concrete foundation or pads and anchored bolts are recommended.

The resaw can be operated with the sawdust collection system only.

Operation MHdoc012819 2-8

Operation

2

Resaw Setup

The resaw can’t be operated outdoor when it is raining/snowing and in case of

rain/snow the resaw must be stored under roof or indoor.

The resaw can be operated in temperature range from -15

o

F) only.

104

The illumination at the operator's position must be at least 300lx

Have a qualified electrician install the power supply (according to EN 60204

o

C to 40o C (5oF to

1

.

Standard). The power supply must meet the specifications given in the table

below.

DANGER! It is recommended that a 30mA Ground Fault

Interrupter (GFI) be used.

1 The light source can not cause stroboscopic effect.

2-9 MHdoc012819 Operation

Operation

Resaw Setup

See Table 2-1. Depending on the number of saw heads, you should use different circuit

breakers and power cord cross sections. See the tables below for the required connection

specifications.

2

Number

of saw heads/

Main motors power

1

11kW (E15 )

2

11kW (E15 )

3

11kW (E15 )

4

11kW (E15 )

5

11kW (E15 )

6

11kW (E15 )

1

15kW (E20)

2

15kW (E20)

3

15kW (E20)

4

15kW (E20)

5

15kW (E20)

6

15kW (E20)

1

18.5kW (E25)

2

18.5kW (E25)

3

18.5kW (E25)

4

18.5kW (E25)

5

18.5kW (E25)

Total Power Circuit Breaker

12.5kW at

14.4kW at 460V 60Hz

23.5kW at

27.1kW at 460V 60Hz

34.5kW at

39.6kW at 460V 60Hz

45.5kW at

52.3kW at 460V 60Hz

56.5kW at

65kW at 460V 60Hz

67.5kW at

77.6kW at 460V 60Hz

17kW at

19.5kW at 460V 60Hz

32kW at

37kW at 460V 60Hz

47kW at

54kW at 460V 60Hz

62kW at

71kW at 460V 60Hz

77kW at

88.5kW at 460V 60Hz

93kW at

106kW at 460V 60Hz

20kW at

23kW at 460V 60Hz

38.5kW at

44kW at 460V 60Hz

54kW at

62kW at 460V 60Hz

72.5kW at

83.5kW at 460V 60Hz

91kW at

105kW at 460V 60Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

230/400V 50Hz

Power Cord

[A]

25 13 AWG/ 2.5

40 9 AWG/ 6

70 5 AWG/ 16

90 3 AWG/ 25

120 1 AWG/ 35

140 1 AWG/ 35

32 11 AWG/ 4

63 7 AWG/ 10

90 5 AWG/ 16

120 3 AWG/ 25

140 1 AWG/ 35

180 0 AWG/ 50

40 9 AWG/ 6

80 5 AWG/ 16

100 3 AWG/ 25

140 1 AWG/ 35

180 0 AWG/ 50

Cross Section

2

]

[mm

TABLE 2-1

Operation MHdoc012819 2-10

Operation

Pressure Adjusting Gauge

Air Supply Cut-OFF Valve

Air Supply

Connection

2

Electrical Requirements (US Version Only)

6

18.5kW (E25)

Locate the air assembly at the right side of the machine. Connect the incoming

air supply line to the fitting. Make sure the air gauge indicates 0,6MPa (6bar)

Adjust the pressure if needed. To adjust the pressure, lift the black cap located

behind the air gauge. Turn the cap clockwise to increase pressure, turn the cap

counterclockwise to decrease pressure. Push the cap down to secure when

adjustment is complete. Air supply cut-off valve should be used to disconnect air

supply and release compressed air from the pneumatic system. Set the cut-off

valve to “SUP.” position for normal operation or to “Exh.” to release compressed

air.

WARNING! Disconnect air supply and release compressed

air from the air system before servicing the saw! Failure to

do so may result in serious injury.

See Figure 2-8.

109.5kW at

126kW at 460V 60Hz

230/400V 50Hz

200 0 AWG/ 50

TABLE 2-1

Electrical Requirements (US Version Only)

2-11 MHdoc012819 Operation

FIG. 2-8

DANGER! Make sure all electrical installation, service

and/or maintenance work is performed by a qualified

electrician and is in accordance with applicable electrical

codes.

Operation

Electrical Requirements (US Version Only)

CAUTION! The resaw motors and the transformer are

prewired for 480 V, 60 Hz power supplies. If you plan to use

a 480 V, 60 Hz mill with another type of power supply, you

will need to rewire the motor to avoid damage to the

machine.

The electrical requirements for the resaw are listed below. IMPORTANT! The resaw is

wired for use with a 480 volt power supply. To operate the resaw with 240V or 380-415V

power supplies, a transformer is required. Refer to the table below:

See Table 2-2.

Conversion From/To 240 to 480 volts 380-415 to 480 volts

No. of Heads 2 4 624 6

Mfg. Part No. EE30T3118H EE45T3065H EE75T3065H EE30T2611H EE45T2611H EE75T2611H

AWMV Part No. 069712 069711 068057 069616 068054 068055

TABLE 2-2

2

See Table 2-3. The machine FLA required for the resaw is listed below.

Power Supply Machine FLA/# of Heads

Motor

HP

25

1

Transformer Required. FLAs include a transformer.

The operator’s positions and E-STOP locations are shown in the figures below.

VoltsPHHz246

1

240

380-415

480 3 60 50 95 140

3 50/60 125 188 313

1

3 50 75 113 188

TABLE 2-3

Operation MHdoc012819 2-12

Operation

E-STOP Locations

Operator’s Positions

!

2

Electrical Requirements (US Version Only)

See Figure 2-9. Operator’s position layout

FIG. 2-9

IMPORTANT! When starting the machine for the first time,

check that the main motor rotation direction is as indicated

by the arrow located on the motor body (fan guard). If the

rotation direction is incorrect, invert the phases in the phase

inverter located in the power socket (electric box). Setting

the phases in the phase inverter correctly will ensure

correct rotation directions of all resaw motors.

The resaw can be lifted using a forklift only. The forklift must be rated for at least

2000kg (4410 lb). The HR modules must be separated before lifting. The resaw

is equipped with forklift pockets. Insert the forks into the pockets shown in the

2-13 MHdoc012819 Operation

figure below.

Operation

Electrical Requirements (US Version Only)

2

FIG. 2-9

Operation MHdoc012819 2-14

Operation

2

Replacing the Blade

2.3 Replacing the Blade

DANGER! Always shut off the resaw motor before

changing the blade. Failure to do so may result in serious

injury.

WARNING! Always wear gloves and eye protection

whenever handling bandsaw blades. Changing blades is

safest when done by one person! Keep all other persons

away from work area when changing blades. Failure to do

so may result in serious injury.

WARNING! In case of the blade brake, wait until all rotating

parts are completely stop. Failure to do so may result in

serious injury.

Raise the blade housing cover. Turn the blade tension valve handle to the “0” position to

release the blade tension until the wheel is pulled in and the blade is lying loose in the

2-15 MHdoc012819 Operation

blade housing. Lift the blade out of the blade housing.

HR700_Oper_006

509661_Manual

Operation

Replacing the Blade

2

Install a new blade around the two blade wheels so that the teeth located between the

blade guide assemblies point to the drive side of the machine. Make sure the teeth are

pointing the correct direction.

Position 1 1/4” wide blades on the wheels so the gullet is 3.0 mm (1/8”), (± 1.0 mm

(3/64”)) out from the front edge of the wheel.

Close the blade housing cover.

Next, tension the blade as described in the following instructions.

Operation MHdoc012819 2-16

Operation

HR700_Oper_0

TVS 505346

10

Blade Tension

Indicator

Cant

Control

Blade Tension

Handle

2

Using the Blade Tensioner Pump

2.4 Using the Blade Tensioner Pump

See Figure 2-10. Place the provided handle in the blade tensioner socket and secure

with a screw. Set the tensioner valve to the ”1” position. Move the tensioner handle up

and down to tension the blade. Depending on the installed blade type, tension the blade

to the value shown on the decal located below the blade tension valve. The values “F”

and “E” are: blade thickness and blade width. Check the blade tension occasionally when

adjusting the cant control or while cutting and adjust if necessary. As the blade and belts

heat up and stretch, the blade tension will change. Also, ambient temperature changes

can cause tension to change. To release the blade tension, set the tensioner valve to the

”0” position.

FIG. 2-10

CAUTION! Release the blade tension when the resaw is

not in use (for example at the end of a shift). Tension the

blade again before starting the motor.

2-17 MHdoc012819 Operation

2.5 Tensioning the Blade

See Figure 2-11. Place the provided handle (”D”) in the blade tensioner socket

and secure it with the bolt.

The decal ”E” in the figure below shows how the saw head valves should be set to

tension either blade.

1. To tension the blade on the first saw head of the module:

Open the main valve (”C”) by moving its lever all the way to the left;

Open the valve of the first saw head (”A”) by turning its lever all the way to the right;

Turn the lever of the second head valve (”B”) all the way to the left to close this

valve;

Operation

Tensioning the Blade

2

Move the lever ”D” up and down to tension the blade (See Section 2.4).

2. To tension the blade on the second saw head of the module:

Open the main valve (”C”) by moving its lever all the way to the left;

Close the valve of the first saw head (”A”) by turning its lever all the way to the left;

Turn the lever of the second head valve (”B”) all the way to the right to open this

valve;

Move the lever ”D” up and down to tension the blade.

3. To tension the blades on both saw heads of the module:

Open the main valve (”C”) by moving its lever all the way to the left;

Move the lever of the first head valve (”A”) all the way to the right to open this valve;

Open the valve of the second saw head (”B”) by turning its lever all the way to the

right;

Operation MHdoc012819 2-18

Operation

518900

A

A

A

B

B

B

I

I

I

II

II

II

2

Tensioning the Blade

Move the lever ”D” up and down to tension the blade.

FIG. 2-11

CAUTION! Release the blade tension after you have

finished sawing. Before restarting the motor, tension the

blade again.

2-19 MHdoc012819 Operation

Operation

H

3/16" (4.5 m

±1/ 6"(1.5m

1

3.0 mm (1/8”)

± 1.0 mm (3/64”)

Blade

11/4"

Blade

Tracking the Blade

2.6 Tracking the Blade

1. Open the blade housing cover.

2. Turn the key switch to the ”H” position.

3. Manually spin one of the blade wheels until the blade positions itself on the blade wheels.

4. Check that the blade is properly positioned on the blade wheels.

See Figure 2-12. 1 1/4” wide blades should be placed on the blade wheels so that the

gullet is 3.0 mm (1/8”) ± 1.0 mm (3/64”) out from the front edge of the wheel.

2

FIG. 2-12

5. Use the cant adjustment bolt, shown in Figure 2-10, to adjust where the blade travels on

the blade wheels.

To move the blade out on the blade wheel, turn the cant adjustment bolt clockwise.

To move the blade in on the blade wheel, turn the bolt counterclockwise.

6. Adjust the blade tension if necessary to compensate for any changes that may have

occurred while adjusting the cant control.

7. Close the blade housing cover.

Operation MHdoc012819 2-20

Operation

Saw #6

Saw #5

Saw #4

Saw #3

Saw #2

Saw #1

Feed Direction

MH0014

Saw #6

Saw #5

Saw #4

Saw #3

Saw #2

Saw #1

Feed Direction

2

Saw Head Height Adjustment

CAUTION! Make sure all guards and covers are in place

and secured before operating or towing the resaw. Failure

to do so may result in serious injury. Be sure the blade

housing cover is in place and secured.

NOTE: After aligning the blade on the wheels, always check the blade guide spacing and

location.

2.7 Saw Head Height Adjustment

You can raise or lower each individual saw head to determine the thickness of the

finished stock. The saw heads should be adjusted so that the last blade the material

passes through is closest to the feed track.

Example: You want to cut cants into 12.5 mm (1/2”) pallet material. Assuming your resaw

has six cutting heads, you will need to adjust each head in 14.0 mm (35/64”) increments

up from the feed track. This will allow 1.5 mm (1/16”) kerf for each blade.

See Figure 2-13. The sixth saw head (the last one the material will pass through) should

be adjusted to 12.5 mm (1/2”) above the feed track. The fifth head should be adjusted to

26.5 mm (1 3/64”) above the track, the fourth head to 40.5 mm (1 19/32”), etc....

FIG. 2-13

1. Install a blade if needed and check for correct blade tension. (See Section 2.4

2. Set the saw head at the desired height. (The blade height scale shows the height of the

blade above the feed track.)

)

2-21 MHdoc012819 Operation

Operation

Saw Head

Height Indicator

Saw Head Height Adjustment

See Figure 2-14. To raise or lower the saw head, use the acme screw as shown in the

figure. Turn the screw clockwise to raise the saw head; counterclockwise to lower the saw

head.

2

FIG. 2-14

NOTE: When adjusting the saw head height lower than

20mm (25/32”), adjust the blade guide arm so that it does

not touch the feed chain.

Operation MHdoc012819 2-22

Operation

<20mm

HR700_Oper_007

509661_Manual

HR700_Oper _006

509661_Manual

25/32”

2

Saw Head Height Adjustment

See Figure 2-15.

FIG. 2-15

2-23 MHdoc012819 Operation

2.8 Guide Fence Adjustment

HR700_Oper_008

509661_Manual

Knob

See Figure 2-16. Loosen the knobs. Move the guide fence to the desired cant width.

Operation

Guide Fence Adjustment

2

FIG. 2-16

Operation MHdoc012819 2-24

Operation

HR700_Oper_006

509661_Manual

hr_017a

Blade Guide Arm

Locking Pin

2

Blade Guide Arm Adjustment

2.9 Blade Guide Arm Adjustment

The outside blade guide arm can be adjusted in or out depending on the width of the

material to be cut. The arm should be adjusted about 25 mm (63/64”) wider than the

material to be cut.

Example: If the material to be cut is 150 mm (5 29/32”) wide, adjust the blade guide arm

so the area between the blade guides is 175 mm (6 7/8”) wide.

See Figure 2-17. To move the blade guide arm, unlock the locking pin and slide the arm

in or out. Lock the locking pin.

FIG. 2-17

2-25 MHdoc012819 Operation

2.10 Machine Start

DANGER! Before starting the resaw, perform these steps

to avoid injury and/or damage to the equipment:

Close the blade housing cover and replace any guards removed for service.

Check the feed track and remove all loose objects such as tools, wood, etc.

Check that the blade is properly tensioned.

Make sure all persons are at a safe distance from the machine.

Check that the emergency stops are released.

NOTE: The resaw will not start if either of the emergency

stops is on.

Operation

Machine Start

2

Before starting the saw heads, check that the main power switch servicing the resaw is

on.

See Figure 2-18. Start the blade motors. To do this, turn the key switch to the

position and then press the START button on the control panel (see the figure below).

The motors should start and the blades should start spinning.

FIG. 2-18

Operation MHdoc012819 2-26

Operation

2

Machine Start

To stop the blade motors, press the STOP button shown in the figure above. The blade

motor also may be stopped by pushing either of the emergency stop buttons.

If either of the emergency stops has been used to stop the blade motor, rotate the switch

clockwise before restarting the saw head. The saw head cannot be restarted until the

emergency stop button is released.

See Figure 2-19. After the saw head has been successfully started, the feed track can be

started. To start the track feed, turn left the Track switch shown in Figure 2-5.

FIG. 2-19

The feed track can be stopped either by pressing the STOP button or one of the

emergency stop buttons. The emergency stop will also stop the blade motor.

NOTE: The feed track cannot be started if the blade motor

is not started.

2-27 MHdoc012819 Operation

Operation

Machine Start

See Figure 2-20. The speed at which the feed track moves is adjustable. The feed track

speed switch, located on the control panel, allows the operator to adjust the feed rate

from 0 to ca. 20 m (66 ft) per minute.

2

FIG. 2-20

Turn the switch clockwise to increase the feed rate, counterclockwise to slow the feed

rate down.

Factors that will determine what feed rate you can use include:

Number of saw heads.

Width of material to be cut. 200mm (7 7/8”) wide material will require a slower

feed rate than 100mm (3 15/16“) wide material.

Hardness of material to be cut. Some woods that are seasoned or naturally very

hard will require slower feed rates.

Sharpness of blades. Dull or improperly sharpened blades will require slower

feed rates than sharp and properly maintained blades.

Off-bearing capability. Your ability to feed end-to-end will also determine what

feed rate you can use.

Operation MHdoc012819 2-28

Operation

_Hr 700

Connect water hose to fitting

2

Water Lube Operation

2.11 Water Lube Operation

Standard Lube System (Supplied from a Water Supply Network)

The Water Lube System keeps the blade clean. It is supplied from a water-pipe network

(minimum pressure 0.35bar [0,05MPa], maximum 6bar [0.6MPa]). Water flows though a

hose, a solenoid and a manual valve to the blade guide where the blade enters the log.

The manual valve located on each saw head controls the amount of water flow.

See Figure 2-21. Connect the water hose to the lube system fitting shown below.

FIG. 2-21

2-29 MHdoc012819 Operation

Operation

_hr0097

Standard Lube System (Supplied from a Water Supply Network)

See Figure 2-22. Use the manual valve on each saw head to adjust the amount of water

flow.

2

FIG. 2-22

Operation MHdoc012819 2-30

Operation

Turn valve counterclockwise

to open; Clockwise to close

3H0129

Turn valve counterclockwise

to open; clockwise to close

2

Optional Lube System (Supplied from Water Tanks)

Optional Lube System (Supplied from Water Tanks)

See Figure 2-23. The Water Lube System keeps the blade clean. Water flows from a

5-gallon (18.9 liter) bottle through a hose to the blade guide where the blade enters the

log. A valve in the bottle cap controls the amount of water flow.

FIG. 2-23

Not all types of wood require the use of the Water Lube System. When it is needed, use

just enough water to keep the blade clean. This saves water, and lowers the risk of

staining the boards with water. Usual flow will be 1-2 gallons (3.8-7.6 liters) per hour

(on average, the bottle content is sufficient for 4-hour-long cutting). A squirt of liquid

dishwashing detergent in the water bottle will help clean the blade when cutting wood with

a high sap content. Before you start cutting, check the water level in the bottle.

WARNING! Use ONLY water with the water lube

accessory. Never use flammable fuels or liquids. If these

types of liquids are necessary to clean the blade, remove it

and clean with a rag. Failure to do so may result in serious

injury or death.

Before removing the blade, start the blade motor with the START button. Let the blade

spin with water running on it for about 15 seconds. This will clean the blade of sap

buildup. Wipe the blade dry with a rag before storing or sharpening.

If you are sawing in freezing temperatures, remove the water lube bottle from the resaw

when done sawing and store it in a warm place. Blow any remaining water from the water

lube hose.

2-31 MHdoc012819 Operation

2.12 Operation Procedure

1. Install a blade if necessary.

WARNING! Always wear gloves and eye protection when

handling bandsaw blades. Changing blades is safest when

done by one person! Keep all other persons away from

area when coiling, carrying or changing a blade. Failure to

do so may result in serious injury.

2. Close the blade housing cover.

Operation

Operation Procedure

2

3. Tension the blade - See Section 2.4

4. Spin the blade wheel by hand.

WARNING! Use extreme caution when spinning the blade

wheel by hand. Make sure your hands are clear of the

blade and the wheel spokes before spinning. Failure to do

so may result in serious injury.

5. Check alignment of the blade on the blade wheels and blade guides. Adjust as

necessary.

6. Raise or lower the saw heads to the desired setting.

DANGER! Make sure all guards and covers are in place

and secured before operating the resaw. Failure to do so

may result in serious injury.

7. Start the blade motor.

8. Perform pre-start check (rotation direction of the blade motors).

.

9. Using the feed track speed switch, set the feed rate as desired.

DANGER! Always be sure all persons are out of the path of

the blade before starting the motor. Failure to do so will

result in serious injury.

WARNING! Always wear eye, ear, respiration and foot

protection when operating or servicing your resaw.

10. Place the test material on the feed track and start the feed track.

Operation MHdoc012819 2-32

Operation

2

Operation Procedure

DANGER! Always be aware of and take proper protective

measures against rotating shafts, pulleys, fans, etc. Always

stay a safe distance from rotating members and make sure

that loose clothing or long hair does not engage rotating

members resulting in possible injury.

11. Shut off the blade and feed track. Measure the finished material and adjust the saw heads

up or down as necessary. Repeat with the test material until the desired finished

dimension is obtained.

12. Restart the blade and feed track.

13. Place material on the infeed table. Return unfinished material to be re-fed into the resaw,

i.e. place it on the return table.

14. Monitor the blade tension as the operation continues. Adjust the blade tension if required.

15. If material jam occurs, stop the blade motors and feed track.

WARNING! Allow the blade to come to a complete stop

before servicing. Failure to do so will result in serious injury.

16. After the operation is complete, shut off the blade motors and feed track.

17. Release the blade tension if done sawing for the day.

CAUTION! Remove tension from the blade when the resaw

is not in use.

2-33 MHdoc012819 Operation

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

General Information

SECTION 3 MULTISETWORKS OPERATION (OPTIONAL

EQUIPMENT)

3.1 General Information

A new Multisetwork has been designed to automatically set the saw heads at any required height.

It can be mounted on HR500 and HR700 resaw.

Saw head height is measured continuously and its accuracy depends on condition of the up/down

system and feed track.

Multisetwork includes programmable PLC controller, incremental encoder, programmable control

panel, motor breakers, frequency converters and limit switches.

3

3.2 Functions

Multisetwork can work in two modes:

MANUAL – each saw head can be set by the operator separately, kerf is not included.

X-BOARD – the saw heads are set automatically according to pre-selected board thickness

values - first saw head is set on the highest calculated height, the last saw head is set on the

lowest calculated height. Blade kerf loss is included.

The values can be displayed in metric or imperial (decimal or fractional) units of measure.

There are two languages of the menu: Polish and English,

Diagnostic mode.

Tuning mode.

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-1

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Start-up

3.3 Start-up

After starting the controller, the initial welcome screen will appear:

See Figure 3-1.

3.3.1 Calibration

After few seconds the CALIBRATION screen is displayed:

FIG. 3-1

3-2 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-2.

Start-up

3

Depending on the number of saw heads, the appropriate number of fields to enter values will appear.

Measure the height of each saw head and enter these values in the fields. Then press ACCEPT

button. After accepting the entered values, the Choose mode screen will appear:

See Figure 3-3.

FIG. 3-2

FIG. 3-3

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-3

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Manual Mode

3.4 Manual Mode

After choosing the MANUAL mode in the main window, the screen shown below will be displayed:

See Figure 3-4.

On this screen the current blade height value for each saw head and the target height values are

displayed.

Press BACK button to move to the main window.

After pressing SET button, all saw heads will be moved to their preset target heights.

To change any target values, press on this value the TARGET window. Next, enter the required

height value and confirm by pressing ENTER button.

Additionally saw head heights can be changed manually by operator. To do this, press the REAL

window and use arrows to change saw head height with minimal speed:

FIG. 3-4

3-4 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-5.

Manual Mode

3

FIG. 3-5

Press OK button to back to MANUAL MODE screen.

Screen with imperial fractional unit of measure is shown below:

See Figure 3-6.

FIG. 3-6

Press OK to confirm entered value.

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-5

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Manual Mode

When positioning is started, the blinking POSITIONING button will appear instead of SET button.

See Figure 3-7.

FIG. 3-7

3-6 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

Feed direction

Saw Head # 6

Saw Head # 5

Saw Head # 4

Saw Head # 3

Saw Head # 2

Saw Head # 1

3.5 X-Board Mode

It is necessary to set the correct kerf value to allow the X-Board mode to work properly. Kerf value

X-Board Mode

3

can be set in Diagnostic menu (See Section 3.6.3

See Figure 3-8.

).

After choosing the X-Board menu, depending on chosen units of measure, the following screen will

be displayed:

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-7

FIG. 3-8

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

X-Board Mode

See Figure 3-9.

The X-Board screen includes a list of all saw head heights and board thickness values preset for

each saw head.

To move to the main window (Choose Mode screen), press the BACK button.

After pressing SET button, each saw head will automatically be set at the calculated height.

To change any board thickness value, press on this value, enter the desired value and press ENTER.

The entered board thickness value will automatically be copied to all dimensions above this value.

If the imperial fractional unit of measure was selected, the screen shown below will appear:

FIG. 3-9

3-8 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-10.

X-Board Mode

3

FIG. 3-10

In this case, press OK button to confirm the entered value.

When positioning is started, the blinking POSITIONING button will appear instead of SET button.

First saw head is set at the highest calculated height, last active saw head is set on the lowest

calculated height.

As it is in Manual Mode, saw head heights can be changed manually by the operator. To do this,

press the REAL window and use arrows to change saw head height with minimal speed:

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-9

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Diagnostic

See Figure 3-11.

FIG. 3-11

When saw heads are set, press OK button to move to X-Board mode screen.

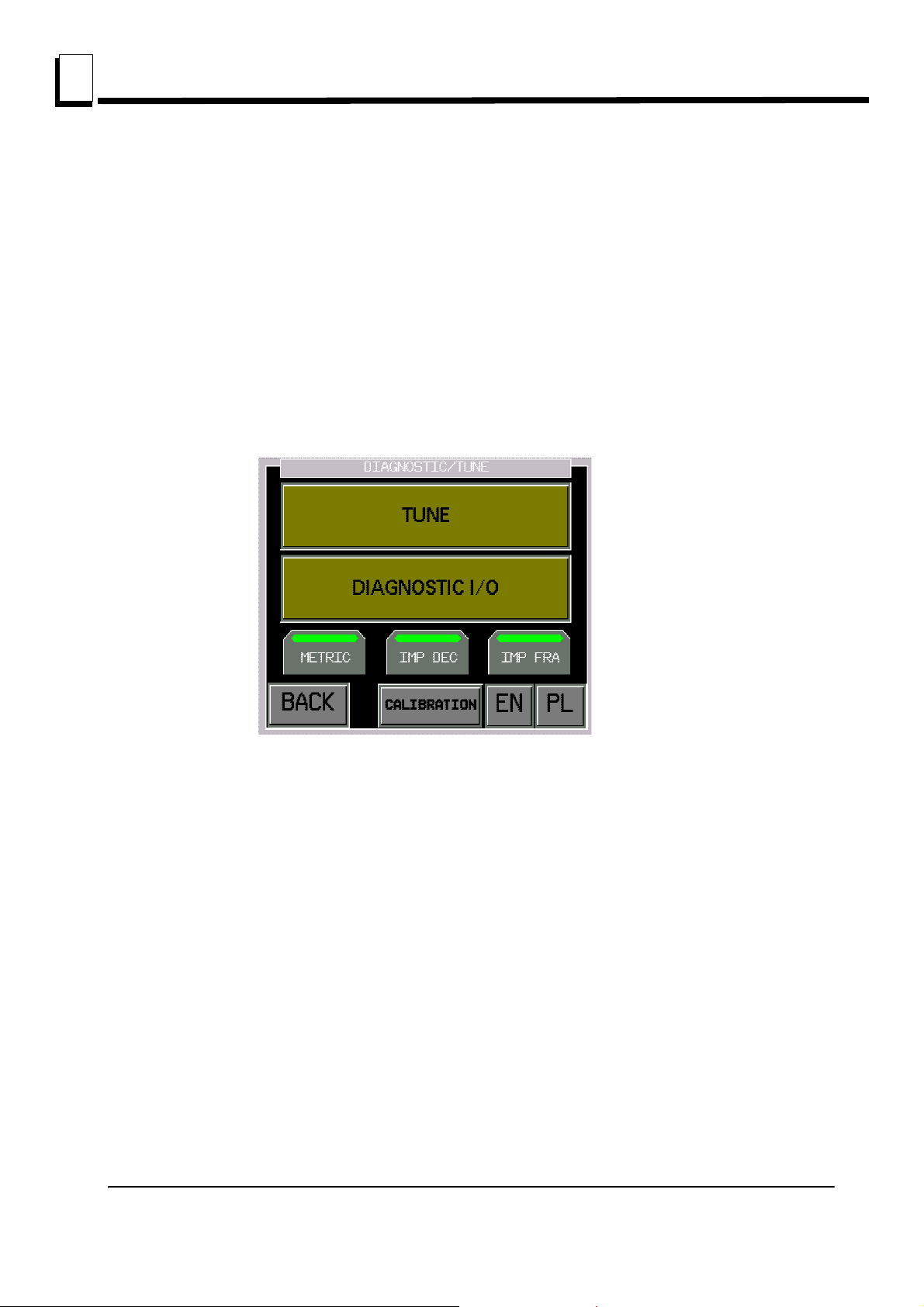

3.6 Diagnostic

Press DIAGNOSTIC button on the Choose mode screen:

See Figure 3-12.

FIG. 3-12

The following screen will be displayed:

3-10 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-13.

Diagnostic

FIG. 3-13

3

Units of measure and language can be set on the DIAGNOSTIC screen. Also controller calibration

can be made by pressing calibration button.

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-11

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Diagnostic

3.6.2 Calibration

After pressing CALIBRATION button, following screen will be displayed.

See Figure 3-14.

FIG. 3-14

Check, if values of each saw head height are the same with real saw heads height read on the scale

located on each saw head mast. If any of these values is incorrect, press this value, enter the correct value

and confirm.

3.6.3 Diagnostic I/O

After pressing DIAGNOSTIC I/O button, the following screen will be displayed:

3-12 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-15.

Diagnostic

3

The values in each HEAD window represent the current numbers of encoder revolutions. Use arrows

to manually control the up/down system.

Kerf. Press KERF window to enter the kerf value. Next confirm by pressing ENTER button.

The correct kerf value for Wood-Mizer blades is 2.

Control Power LED, shows the condition of the machine main control circuit.

CANOpen button is used to move to CAN diagnostic screen:

FIG. 3-15

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-13

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Diagnostic

See Figure 3-16.

FIG. 3-16

In the DRIVES section, LEDs show the communication status with each drive.

Green - communication is ok, Red - there is no communication.

OTB Modules show the communication status with OTB modules. These modules are active only

when machine is equipped with 3, 4, 5 or 6 saw heads. When there is only one or two saw heads, control

lights will be red - there will be no communication with OTB modules.

Press the window with saw head number/mode to move to the extended drive status. The following

window will appear:

3-14 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-17. Drives values may vary.

Diagnostic

3

Point Bit0-Bit7 – drive register status

Drive velocity – Input – Entered speed (Hz).

Drive velocity – Output – Motor speed (Hz).

Motor current – nominal value for 400/460V should be ~ 1,5A.

Up and down limit switches – conditions of up and down limit switches.

Green – limit switch is released, Red – limit switch is active.

Use arrows to move the saw head up and down with minimal speed.

FIG. 3-17

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-15

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Diagnostic

3.6.4 Tuning

Caution! – All changes have to be agreed with Wood-Mizer

Customer Service! These parameters influence up/down

operation.

If there are problems with saw head positioning, change parameters. These changes influence saw

head movement.

Choose Tuning on the DIAGNOSTIC/TUNE menu:

See Figure 3-18.

FIG. 3-18

The screen below will appear:

3-16 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-19. Values displayed by the controller may vary.

Diagnostic

FIG. 3-19

3

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-17

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Errors

3.7 Errors

After choosing the X-BOARD mode, the following message may occur:

See Figure 3-20.

Enter the DIAGNOSTIC I/O mode. Check if number of saw heads displayed on the screen and

mounted on the machine are the same:

See Figure 3-21.

FIG. 3-20

FIG. 3-21

When one saw head (e.g. saw head no 3) is missing, the diagnostic screen looks like shown below:

3-18 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-22.

Errors

3

Make sure if COF error is displayed on the drive controller after opening electric box.

CAN_R LED should be steady on, I/O and CAN_E LED should blinks red:

See Figure 3-23.

FIG. 3-22

FIG. 3-23

If so, check connection between drive and cantap (patchcord with RJ45 terminals). When two or

more saw heads are missing, check connection between cantaps and PLC controller. Next turn off and turn

on the power to restart the connection. Connection condition can be also check on the Diagnostic screen by

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-19

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Errors

pushing CanOpen button:

See Figure 3-24.

FIG. 3-24

In the DRIVES section, LEDs show the communication status with each drive.

Green - communication is ok, Red - no communication.

OTB Modules show the communication status with OTB modules. These modules are active only

when machine is equipped with 3, 4, 5 or 6 saw heads. When there is only one or two saw heads, control

lights will be red - there will be no communication with OTB modules. If there is no connection between

controller and OTB module(s), on the OTB module ERR LED will turn on:

3-20 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

See Figure 3-25.

Errors

FIG. 3-25

3

3.7.5 Impulses are not counted.

See Figure 3-26.

FIG. 3-26

This error may be caused by damage of: encoder, clutch between encoder and motoreducer, wire

connecting encoder and connectors or wires connecting PLC controller inputs and power supply with

connectors.

First remove encoder cover and check if encoder clutch is tightened and is not damaged.

Next, check the encoder connection to PLC controller or OTB module (encoders of the saw head

number 1 and 2 are connecting with PLC 1.0 controller; encoders of the saw head number 3 and 4 are

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-21

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Errors

connecting with PLC 2.0 controller; encoders of the saw head number 5 and 6 are connecting with PLC 3.0

controller).

Controller/Module Encoder/Saw Head Inputs

PLC 1.0 Encoder 1/Saw Head 1 I0 and I1

PLC 1.0 Encoder 2/Saw Head 2 I4 and I5

PLC 2.0 Encoder 3/Saw Head 3 I0 and I1

PLC 2.0 Encoder 4/Saw Head 4 I6 and I7

PLC 3.0 Encoder 5/Saw Head 5 I0 and I1

PLC 3.0 Encoder 6/Saw Head 6 I6 and I7

TABLE 3-1

3-22 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

Next choose the Diagnostic Mode:

See Figure 3-27.

Errors

3

Use arrow buttons to move the saw head up or down and watch LED of the encoder input.

See Figure 3-28.

FIG. 3-27

FIG. 3-28

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-23

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Errors

See Figure 3-29.

LED should blink during the saw head movement. If LEDs of the encoder don’t blink or only one of

them blinks, check encoder power supply and damage of the connecting wires.

FIG. 3-29

Voltage on the connectors between brown and blue wire should be ~24VDC.

3.7.6 Incorrect up/down movement direction

See Figure 3-30.

This error may be caused by improper connection of the encoder or up/down motor. Enter the

FIG. 3-30

Diagnostic mode. Check if saw head is moving up when you press the UP arrow button and down when you

press the DOWN arrow button.

If not, invert the phases on the motor or on the up/down motor contactors.

3-24 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

If the saw head movement is still incorrect, change places of the wires on the PLC controller (or PLC

module) input - black and white wires.

3.7.7 Limit Switches

See Figure 3-31.

Errors

3

Possible error cause:

Saw head run on the up/down limit switch

limit switch or wire between limit switch and connector is damaged

wire between connector and inputs LI4 or LI5 of the drive are damaged.

When saw head run on the limit switch, it can move in the opposite direction.

Status of the limit switch can be checked on the Diagnostic screen for CanOpen devices.

FIG. 3-31

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-25

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Errors

See Figure 3-32.

Press the window with saw head number/mode to move to the extended drive status. The following

FIG. 3-7

window will appear:

See Figure 3-33.

FIG. 3-8

Upper and lower limit switches – conditions of the upper and lower limit switches.

Green – limit switch is released, Red – limit switch on (is active)

If the saw head is not on the limit switch and limit switch LED is on, check the limit switch and next

check connections between limit switch and drive.

3-26 Multisetworkdoc012819 MULTISETWORKS OPERATION

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3.7.8 Positioning error

See Figure 3-34.

Saw head run too slow or too far.

Errors

3

FIG. 3-9

It is connected with saw head movement parameters on the TUNING screen:

See Figure 3-35.

FIG. 3-10

First push BACK TO DEFAULT VALUES button, to set the factory set, default positioning

parameters.

If error occurs once more, please contact with Wood-Mizer Customer Service.

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)Multisetworkdoc012819 3-27

MULTISETWORKS OPERATION (OPTIONAL EQUIPMENT)

3

Errors

Caution! – All changes have to be agreed with Wood-Mizer

Customer Service! These parameters influence up/down

operation.

3-28 Multisetworkdoc012819 MULTISETWORKS OPERATION

SECTION 4 MAINTENANCE

0

This section lists the maintenance procedures that need to be performed.

WARNING! Disconnect and lock out power supply before

servicing, cleaning and doing maintenance to the saw!

Failure to do so may result in serious injury.

This symbol identifies the interval (hours of operation) at which each maintenance

procedure should be performed.

Be sure to refer to the motor manual for maintenance procedures concerning the blade

motor.

4.1 Wear Life

See Table 4-1. This chart lists estimated life expectancy of common replacement parts if

proper maintenance and operation procedures are followed. Due to the many variables

which exist during resaw operation, actual part life may vary significantly. This information

is provided so that you may plan ahead in ordering replacement parts.

MAINTENANCE

Wear Life

4

Part Description Estimated

Life

B57 Blade Wheel Belts 500 hours

Blade Guide Rollers 1000 hours

Drive Belt 1250 hours

TABLE 4-1

MHdoc012819 4-1

MAINTENANCE

50

4

Blade Guides

4.2 Blade Guides

1. Check the rollers for performance and wear every blade change. Make sure the rollers

are clean and spinning freely. If not, rebuild them. Replace any rollers which have worn

smooth or have become cone shaped. See the Parts manual for blade guide rebuild kits

and complete roller assemblies.

4.3 Sawdust Removal

1. Remove the excess sawdust from the blade wheel housing and sawdust chute every

blade change.

4.4 Vertical Mast

Clean the vertical mast angles, wipe them dry and lubricate with a WD40 oil every 50

hours of operation.

CAUTION! Never use grease on the mast angles as it will

collect sawdust.

4-2 MHdoc012819

MAINTENANCE

505050

200

Miscellaneous Lubrication

4.5 Miscellaneous Lubrication

1. Apply a thin film of a lithium grease to the blade guide arm to help prevent it from rusting.

2. Lubricate the feed track chain with an easily penetrating oil such as WD-40.

CAUTION! Never apply grease to the feed track chain.

It causes sawdust buildup in chain links.

3. Make sure all safety warning decals are readable. Remove sawdust and dirt. Replace any

damaged or unreadable decals immediately. Order decals from your Customer Service

Representative.