Woodhead XX15TR User Manual

Torque Reel Series

XX15T & XX15TR

Service Manual

AERO-MOTIVE COMPANY

A Woodhead Industries, Inc. Subsidiary

IMPORTANT SAFETY INSTRUCTIONS

Please read this manual carefully and follow its instructions. Improper use or failure to follow these instructions could

result in serious injury, death or property damage. Operators should be instructed in the safe and proper use and

maintenance of this product. Keep this manual for future reference.

The following safety precautions call attention to potentially dangerous conditions.

DANGER:

WARNING:

CAUTION:

NOTE: Instruct operators in the safe, proper use and maintenance. Keep this manual for future reference.

Immediate hazards which WILL result in severe personal injury or death.

Hazards or unsafe practices which COULD result in

Hazards or unsafe practices which MAY result in minor personal injury or product or

property damage.

severe

personal injury or death.

INSTALLATION

WARNING:

CAUTION:

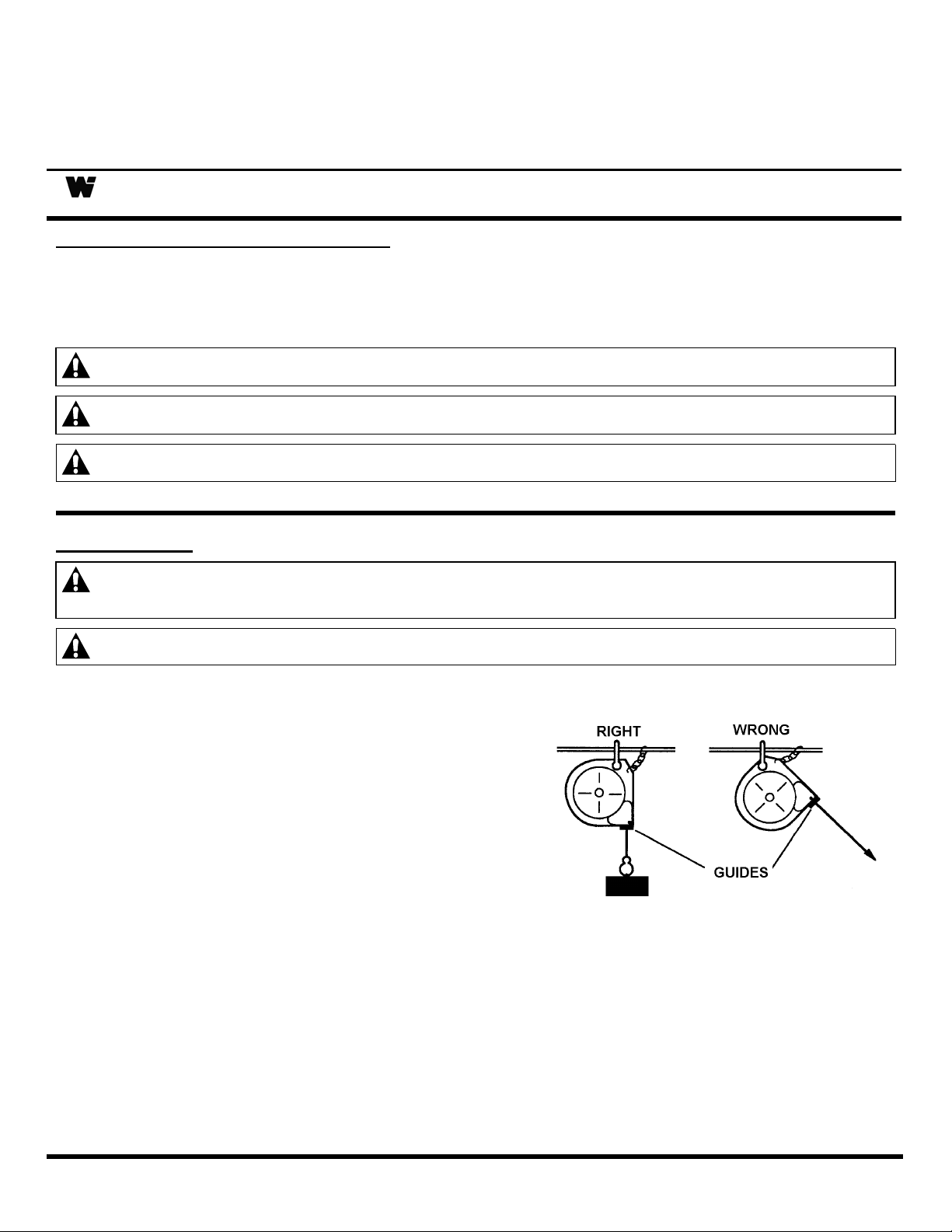

SWIVEL MOUNT

Hang the torque reel in the desired location by

clevis provided at top. The torque reel should be

suspended directly over the work area (see

illustration), using an eyebolt or similar device with

a break strength exceeding 6 times the combined

weight of torque reel and load it is supporting.

Torque reel should be mounted in such a manner

as to minimize cable contact with cable guide. For

proper alignment, utilize the three (3) mounting

holes at top of torque reel. If shackle is removed to

make connections, be sure that nut and cotter pin

are properly replaced on the shackle pin.

Failure to read, understand or follow these instructions could lead to hazards or unsafe

practices COULD result in severe personal injury or death.

Instruct operators in the safe, proper use and maintenance of this product. Hazards or

unsafe practices MAY result in

personal injury or product or property damage.

minor

RIDGID MOUNT

Install torque reel in desired location using rigid mount housing. Use housing as a template to drill

mounting holes. Mount reel in line with cable pay out to minimize rubbing of cable against cable guide.

See illustration.

SM141001C Page 1 of 5 ©Aero-Motive Company Aug-01

SECONDARY SUPPORT CHAIN

DANGER:

OPERATION

TOOL ATTACHMENT

WARNING:

A secondary safety cable or chain is to be attached to all reels mounted overhead to

prevent reel from falling. Immediate hazards WILL result in severe personal injury or

death.

A hole has been provided at the side of the housing to permit installation of a secondary support chain.

All reels mounted over head should have a secondary support chain to protect personnel in case of

structure or mounting component failure. Attach one end of secondary support chain or cable to

secondary support point on reel. Attach the other end of secondary support chain or cable to a support

component other than that which supports the balancer. The chain or cable should be as short as

possible allowing the reel to drop no more than 6 to 12 inches if the primary connection is released. (See

Illustration On Page 2) A secondary support is offered as an accessory item.

Never pull cable to device to be retracted. Always lift object to hook. If the hook is

accidentally released when it is extended, it will snap back. Hazards or unsafe practices

COULD result in severe personal injury or death.

If, after installation, it is determined that the overhang of the torque reel for the active travel required is not

sufficient, an overhang extension cable can be used to extend the overhang without reducing the active

travel. This is available as an optional item. Torque reel is furnished with a tool clip. Attach tool

complete with hose or cable and fittings. To adjust length of overhang, remove all tension, then pull down

and position hook at desired height. Loosen cable stop, then slide cable stop upward to roller guide and

tighten. Move cable stop upward and lengthen overhang of cable to reduce active travel distance. For

every foot more of overhang, the active travel will be reduced by a foot.

SPRING TENSION ADJUSTMENT

WARNING:

Attach full load including all attachments before adjusting tension. Hazards or unsafe

practices COULD result in severe personal injury or death.

The complete tool including all attachments and connections must be in place before adjusting the spring

tension. If the load exceeds the spring tension, the tool will move downward. Increase tension of

mainspring by applying a wrench on flats of mainspring shaft and rotate counterclockwise until proper

tension is reached and load begins to retract. If the tension exceeds the load, the tool will move upward.

Spring tension can be decreased by applying a wrench to the flats on mainspring shaft and hold. Release

tension of main shaft by squeezing together spring lever slowly on opposite side of torque reel, then rotate

wrench clockwise until proper tension is reached and load descends properly. After adjusting tension, pull

cable to fullest extension to ensure proper travel is achieved. If cable does not reach full extension, some

tension must be released. If proper tension and extension cannot be achieved, consult the factory.

RATCHET LOCK

The ratchet lock works in two positions in one complete rotation. Pull cable to desired location and let

cable retract slightly until lock engages. To release lock, pull cable out slightly. For constant tension,

ratchet lock may be disengaged. Turn lock release knob counterclockwise while pulling cable in and out

slightly to engage lock release lever.

CABLE STOP ADJUSTMENT

NOTE: Moving the cable stop will reduce the active travel distance. If additional cable extension is

required, extension cable assemblies (Kit E) are offered as an accessory.

The cable stop can be moved up along the cable to attain the most desirable working height. NOTE:

Moving the cable stop will reduce the active travel distance. If additional cable extension is required,

extension cable assemblies (Kit E) are offered as an accessory.

SM141001C Page 2 of 5 ©Aero-Motive CompanyAug-01

Loading...

Loading...