Woodhead T-TORQUE REEL User Manual

T-TORQUE REEL

Service Manual

Aero-Motive Company

A Woodhead Industries, Inc. Subsidiary

IMPORTANT SAFETY INSTRUCTIONS

Please read this manual carefully and follow its instructions. Improper use or failure to follow these instructions

could result in serious injury, death or property damage. Operators should be instructed in the safety, proper use

and maintenance of this product. Keep this manual for future reference.

The following safety precautions call attention to potentially dangerous conditions.

DANGER: Immediate hazards which WILL result in severe personal injury or death.

WARNING: Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION:

Hazards or unsafe practices which MAY result in minor personal injury or product or

property damage.

INSTALLATION

RIGID MOUNT

Locate in line with the direction of pull to minimize cable contact with roller guides. This provides longer

cable and reel life. Mount torque reel in desired location by using mounting brackets. When mounting

reel, use brackets as template for pre-drilling bolt holes.

SWIVEL MOUNT

Adjust reel in line with the direction of pull and swing movement of reel when in use. Hang torque reel in

desired location by using the shackle. If it is necessary to remove shackle to hang the reel, be sure the nut

and cotter pin are properly replaced on the shackle bolt. Adjust yoke collar for even balance. Adjust yoke

rod, utilizing three mounting holes on yoke plate for minimum cable contact.

WARNING: To prevent personal injury, death or property damage, a secondary support chain is

recommended for all reels mounted overhead to protect personnel in case of failure in

the mounting components or the structure to which they are attached.

SECONDARY SUPPORT CHAIN

Attach one end of the support chain to reel on the end plate. Connect other end of support chain to a

support other than that which the reel is supported on. Safety support chain assemblies are available from

Aero-Motive as an option item.

ADJUSTMENT

CAUTION:

TOOL ATTACHMENT

If after installation it is determined that the overhang of the reel for active travel required is not sufficient,

an overhang extension cable can be used to extend overhang without reducing the active travel. This is

available as an optional item from Aero-Motive. To adjust length of overhang, first all tension must be removed,

then pull cable down and position hook at desired height. Loosen cable stop by securing bottom portion, and

turning top nut of cable stop counter-clockwise. Then slide cable upward to roller guide and tighten. Moving

cable stop upward and lengthening overhang of cable will reduce active travel distance. Every foot more of

overhang will reduce active cable travel by a foot.

Sm142001A Page 1 of 6 ©Aero-Motive Sep-99

NEVER pull cable to device to be retracted. Always lift object to hook. If the hook is

accidentally released when extended, it will snap back. Hazards or unsafe practices

MAY result in minor personal injury or product or property damage.

SPRING TENSION

NOTE: Before adjusting tension, attach full load including all attachments.

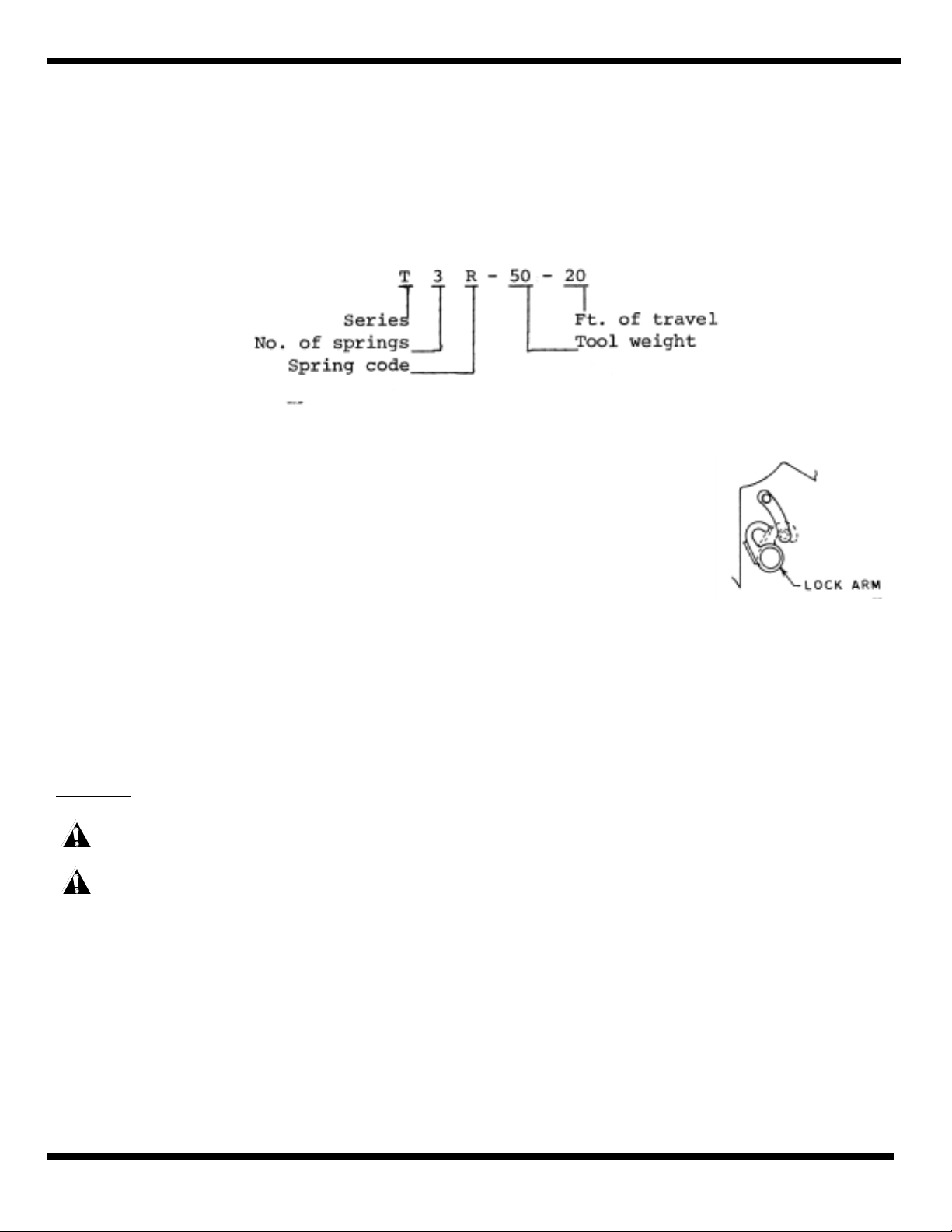

All torque reels are preset at the factory according to their specified weight. (See Illustration Below) If

increased tension is desired, turn adjustment nut clockwise. An impact tool is recommended to adjust

tension. If less tension is required, or to remove tension, turn adjustment nut counter-clockwise.

NOTE: A power tool is recommended for many turns may be required because the adjustment is

accomplished through a 20:1 worm gear.

NOTE: If tension is removed well below the rated range of the reel during spring adjustment, the safety lock

will engage. It will be necessary to apply more tension to release the lock.

RATCHET LOCK

The ratchet/holding lock (separate from safety lock) will function in three positions per

revolution, providing approximately five to six inch increments. To hold, pull cable

down to desired height, halt, and let lock engage. (In much the same way a window

shade works). To disengage, simply pull cable down slightly, permitting lock to release.

Cable will retract until end of travel, or until lock is re-engaged. If ratchet lock is not

required, it can be disengaged by moving the pin, entering through the slot in the

housing, downward and engaging the hook shaped lock arm over it.

AUTOMATIC SAFETY LOCK

If a spring should break or loose tension for any reason, an automatic lock will engage and prevent drum

from turning. Lock will disengage when tension is applied to a new spring. (For spring replacement, see

SERVICE—SPRING REPLACEMENT).

NOTE: If tension is removed well below the rate range of the reel during spring adjustment, the safety lock

engage. It will be necessary to apply more tension to release the lock.

SERVICE

CAUTION:

CAUTION:

CABLE REPLACEMENT

Remove tool from hook, ONLY with cable FULLY retracted. Release tension from the springs by turning

tension adjustment nut counter-clockwise. Remove two bolts from yoke plate. (On rigid mounted reels this

step is not necessary). Remove six nuts on the outer edge of endplate and remove endplate. Lift cable drum

out of band assembly until plug and cable are visible. DO NOT REMOVE COMPLETELY. Remove plug and

cable. Be sure to feed the replacement cable through guide rollers on end plate when replacing.

Reassemble by reversing the above procedure, making sure that all parts seat properly. To replace desired

tension, see spring tension adjustment.

Always remove all spring tension before attempting to service the reel. Hazards or

unsafe practices MAY result in minor personal injury or product or property damage.

Never remove the tool when cable is extended. Remove tool when cable is fully

retracted. Hazards or unsafe practices MAY result in minor personal injury or product or

property damage.

SM142001A Page 2 of 6 ©Aero-Motive Sep-99

Loading...

Loading...