Woodhead BF Series User Manual

BF Series

Service Manual

Aero-Motive Company

A Woodhead Industries, Inc. Subsidiary

IMPORTANT SAFETY INFORMATION

Please read this manual carefully and follow its instructions. Improper use or failure to follow these instructions could

result in serious injury, death or property damage. Operators should be instructed in the safe and proper use and

maintenance of this product. Keep this manual for future reference. All reference numbers are located on page 5.

The following safety precautions call attention to potentially dangerous conditions.

DANGER: Immediate hazards which WILL result in severe personal injury or death.

WARNING: Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION:

Hazards or unsafe practices which COULD result in minor personal injury or product or

property damage.

INSTALLATION

WARNING:

CAUTION:

MAIN SUPPORT

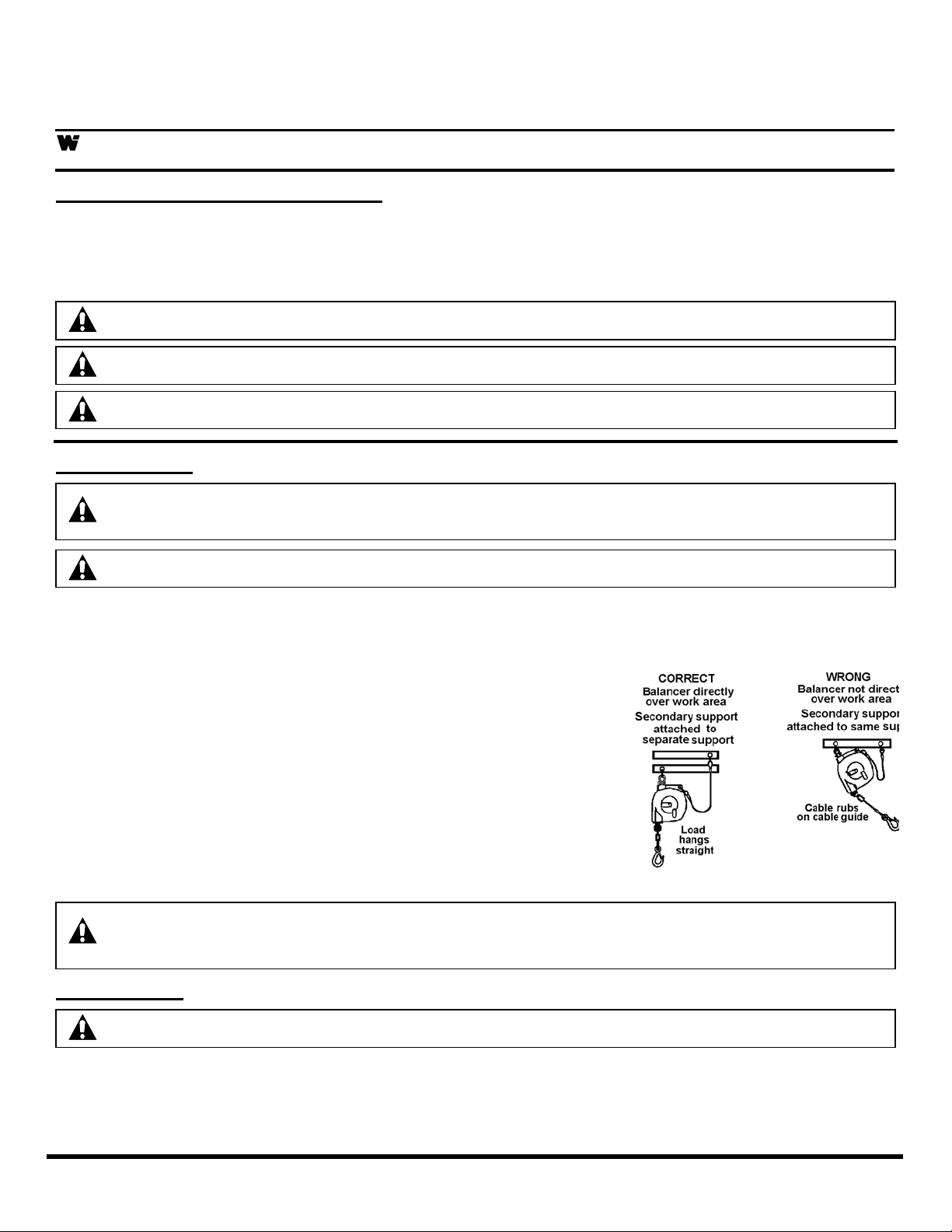

Install the main support device directly over work area. (See illustration). Attach balancer to main

support with swivel fork and clevis pin. Secure clevis pin with washer and cotter pin.

SECONDARY SUPPORT CHAIN

A hole has been provided at side of housing to permit installation

of secondary support chain. All balancers mounted over head

must have a secondary support chain to protect personnel in

case of structure or mounting component failure. Attach one

end of secondary support chain or cable to secondary support

point (shackle) on balancer. Attach other end of secondary

support chain or cable to a support component other than that

which supports balancer. Chain or cable should be as short as

possible allowing balancer to drop no more than 6 to 12 inches if

primary connection is released. (See Illustration) A secondary

support is offered as an accessory item.

Main support device must have break strength exceeding five times weight of load.

Hazards or unsafe practices COULD result in severe personal injury or death.

Use new cotter pin when re-assembling clevis pin. Hazards or unsafe practices COULD

result in minor personal injury or product or property damage.

DANGER:

A secondary safety cable or chain is to be attached to all balancers mounted overhead to

prevent balancer from falling. Immediate hazards WILL result in severe personal injury or

death.

ADJUSTMENT

CAUTION:

TOOL ATTACHMENT

Lift the complete tool (including any hose, cable, fittings and attachments) up to the tool clip. After tool is

attached, make sure the retaining latch on tool clip has snapped back to the closed position.

SM1120-01E Page 1 of 4 ©Aero-Motive Company Sep-01

Do not pull cable down to tool clip. Raise tool to clip. Hazards or unsafe practices

COULD result in

personal injury or product or property damage.

minor

SPRING TENSION ADJUSTMENT

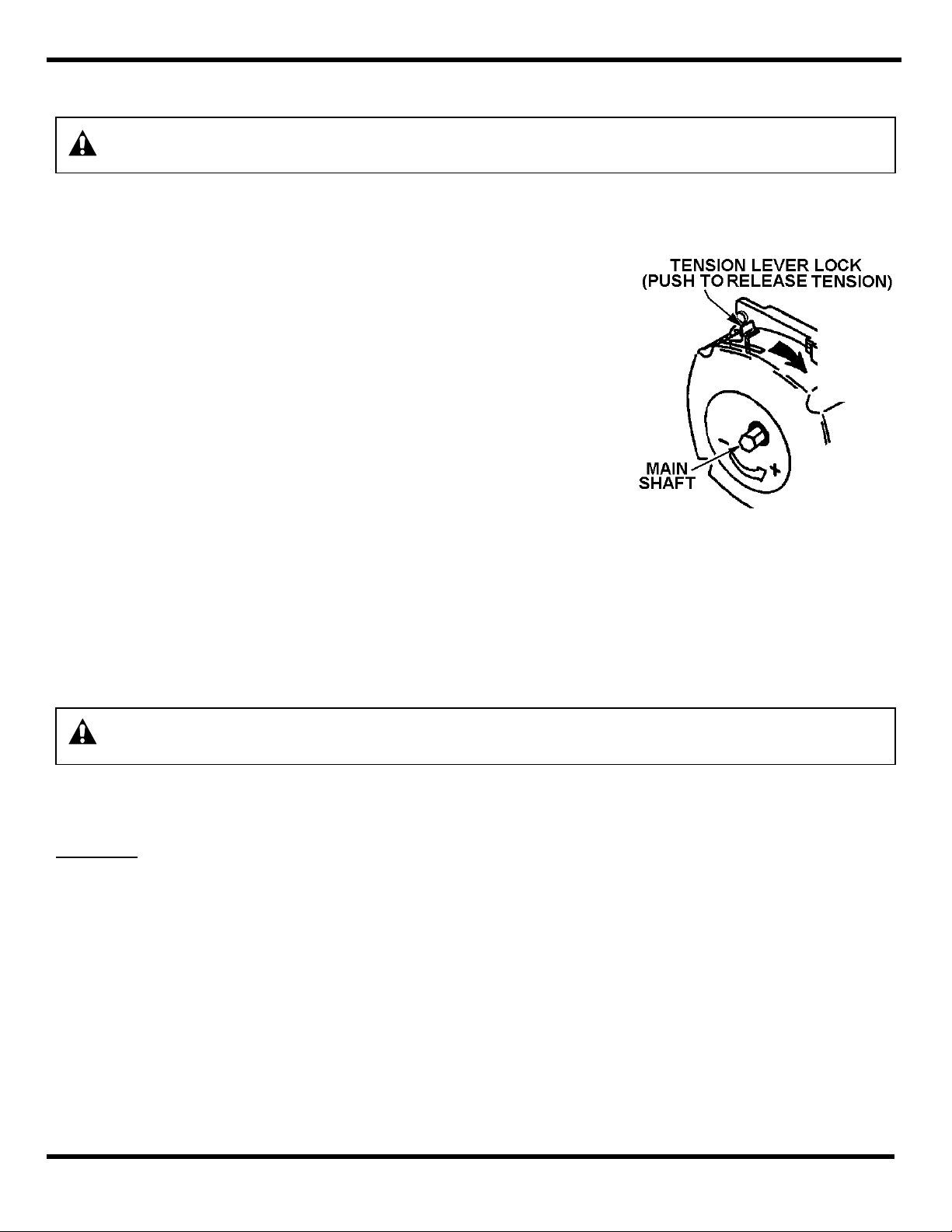

Do not push tension lock lever without placing wrench onto mainshaft first. Extreme

CAUTION:

amounts of stored spring torque will turn mainshaft rapidly clockwise. Hazards or unsafe

practices COULD result in minor personal injury or product or property damage.

NOTE: Do NOT over-tension balancer main spring. This will reduce cable travel and spring life.

NOTE: If drum locks up (cable will not pull out) when reducing spring tension, increase tension until

automatic lock disengages. (See Automatic Lock)

Observe following before making spring tension adjustments:

• Tool and all accessories are attached to tool clip.

• All balancers are factory pre-set.

• Tool will lower if the weight of tool exceeds tension

adjustment of balancer mainspring.

• If cable stop is up against cable guide prior to adjustment,

there is too much tension on balancer mainspring.

To increase spring tension, turn mainshaft with wrench ¼ turn

(one click at a time) in a counter-clockwise direction ( “+” symbol

on case). Repeat process until desired tension is achieved.

To reduce spring tension, turn mainshaft with wrench in counterclockwise direction until tension lock lever disengages. Hold

tension lock lever in disengaged position and allow mainshaft to

turn clockwise. Repeat process until desired tension is achieved.

CABLE STOP ADJUSTMENT

NOTE: Make all cable stop adjustments after tool and accessories have been attached to tool clip and

NOTE: Moving cable stop and bumper closer to the cable guide will shorten active travel of cable.

AUTOMATIC LOCK

WARNING:

SERVICE

TOOL REPLACEMENT

DRUM & SPRING ASSEMBLY REPLACEMENT

after adjusting spring tension. (See Spring Tension Adjustment)

Loosen two hex nuts and machine screws. Slide cable stop and bumper up or down on cable so that tool

is positioned at desired working height. Tighten loosened hardware to hold cable stop at set position.

Never remove spring from drum and spring assembly. Replacement springs are sealed

for safety. Hazards or unsafe practices COULD result in severe personal injury or death.

If tension is reduced to below rated range, automatic lock will engage and prevent cable drum from

turning. Increase tension until automatic lock disengages. If a spring should break, automatic lock will

engage to prevent drum from turning. Lock will disengage after new spring assembly is installed.

When replacing tool and attachments, make sure cable is fully retracted. (See Tool Attachment).

Remove balancer from service and remove all spring tension from balancer. (See Spring Tension

Adjustment). Remove two screws and cable guide. Remove four screws and nuts. Remove rear case

assembly & retaining ring from mainshaft. Remove mainshaft, hub and tension lock and cable assembly

with all attached parts from drum and spring assembly. Remove cable assembly from old drum and

spring assembly. Attach cable assembly to new drum and spring assembly (See Cable Replacement).

Reassemble unit in reverse order. Place balancer back in service and attach tool. (See Tool

Attachment). Set spring tension with tool and attachments in place. (See Spring Tension Adjustment.).

SM1120-01 E Page 2 of 4 ©Aero-Motive Company Sep-01

Loading...

Loading...