Woodhead 20Ja, 100Ja, 9020Ja User Manual

20Ja through 100Ja

9020Ja through 9070Ja

Balancer Series

Service Manual

AERO-MOTIVE COMPANY

A Woodhead Industries, Inc. Subsidiary

IMPORTANT SAFETY INSTRUCTIONS

Please read this manual carefully and follow its instructions. Improper use or failure to follow these instructions could

result in serious injury, death or property damage. Operators should be instructed in the safe and proper use and

maintenance of this product. Keep this manual for future reference.

The following safety precautions call attention to potentially dangerous conditions.

DANGER:

WARNING:

CAUTION:

NOTE: Instruct operators in the safe, proper use and maintenance. Keep this manual for future reference.

Immediate hazards which WILL result in severe personal injury or death.

Hazards or unsafe practices which COULD result in severe personal injury or death.

Hazards or unsafe practices which MAY result in minor personal injury or product or

property damage.

INSTALLATION

WARNING:

CAUTION:

MOUNTING

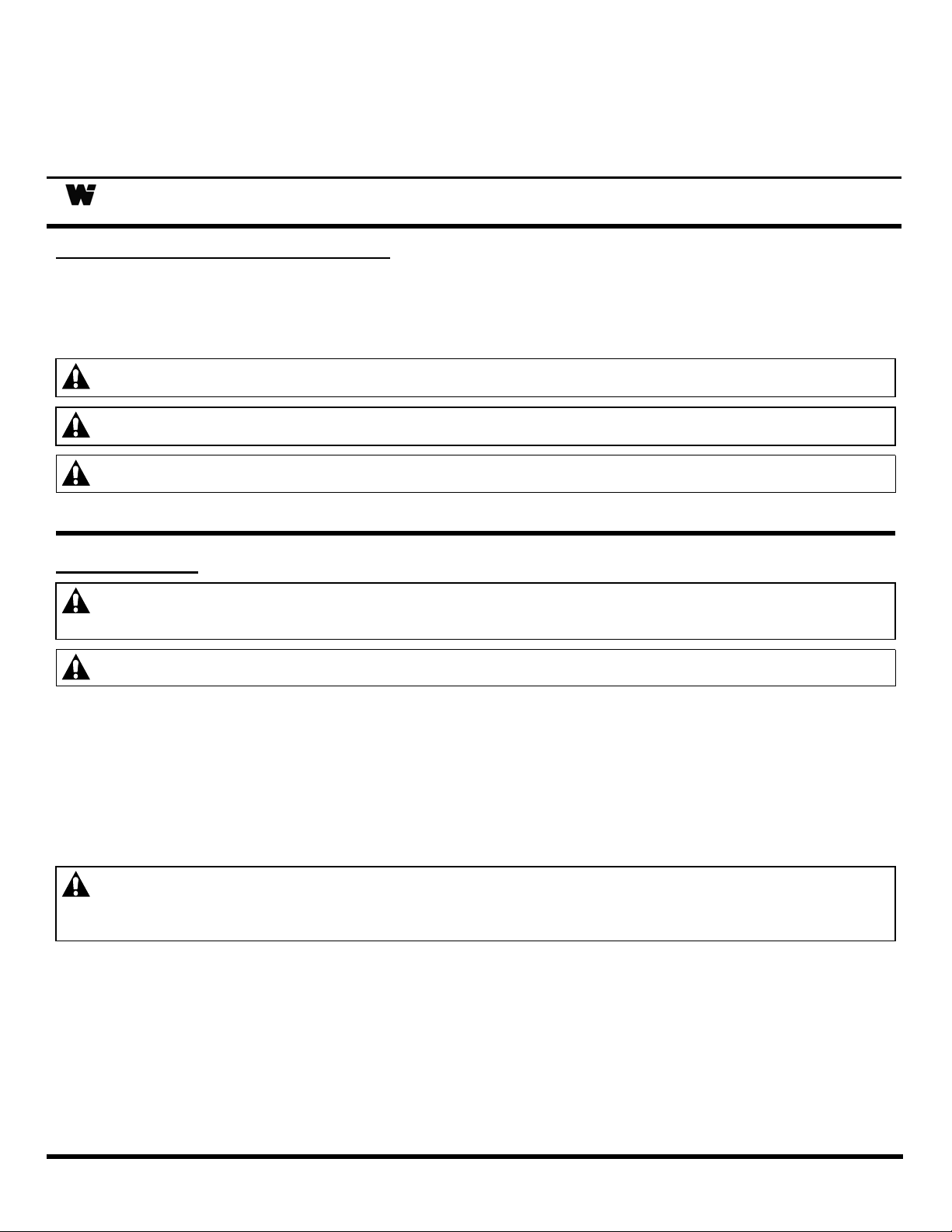

Hang balancer in the desired location by the clevis provided at the top. The balancer should be

suspended directly over work area using an eyebolt or similar device with a break strength exceeding 6

times the combined weight of the balancer and the load it is supporting. Balancer should be mounted in

such a manner as to minimize cable contact with the cable guide. For proper alignment, utilize the three

mounting holes at the top of balancer. If shackle is removed to make the connections, be sure that the

nut and cotter pin are properly replaced on the shackle pin.

Failure to read, understand or follow these instructions could lead to hazards or unsafe

practices COULD result in

Instruct operators in the safe, proper use and maintenance of this product. Hazards or

unsafe practices MAY result in minor personal injury or product or property damage.

severe

personal injury or death.

SECONDARY SUPPORT CHAIN

DANGER:

A hole has been provided at the side of the housing to permit installation of a secondary support chain.

All balancers mounted over head should have a secondary support chain to protect personnel in case of

structure or mounting component failure. Attach one end of secondary support chain or cable to

secondary support point (shackle) on balancer. Attach the other end of secondary support chain or

cable to a support component other than that which supports the balancer. The chain or cable should be

as short as possible allowing the balancer to drop no more than 6 to 12 inches if the primary connection

is released. (See Illustration) A secondary support is offered as an accessory item.

Sm1140-01C Page 1 of 7 ©Jun-01

A secondary safety cable or chain is to be attached to all balancers mounted overhead to

prevent balancer from falling. Immediate hazards WILL result in severe personal injury or

death.

OPERATION

TOOL ATTACHMENT

WARNING:

Never pull cable to device to be retracted. Always lift object to hook. If the hook is

accidentally released when it is extended, it will snap back. Hazards or unsafe practices

which COULD result in severe personal injury or death.

When attaching tool to lower hook, the tool should be lifted to hook rather than pulled to the empty hook

against the reel tension. The drum lock can be engaged to prevent cable from retracting (see illustration

in “Tool Replacement”). The retaining latch on lower hook MUST be snapped back in the closed position

after tool is attached.

SPRING TENSION ADJUSTMENT

CAUTION:

Only use adjusting nut to set tension. Hazards or unsafe practices MAY result in minor

personal injury or product or property damage.

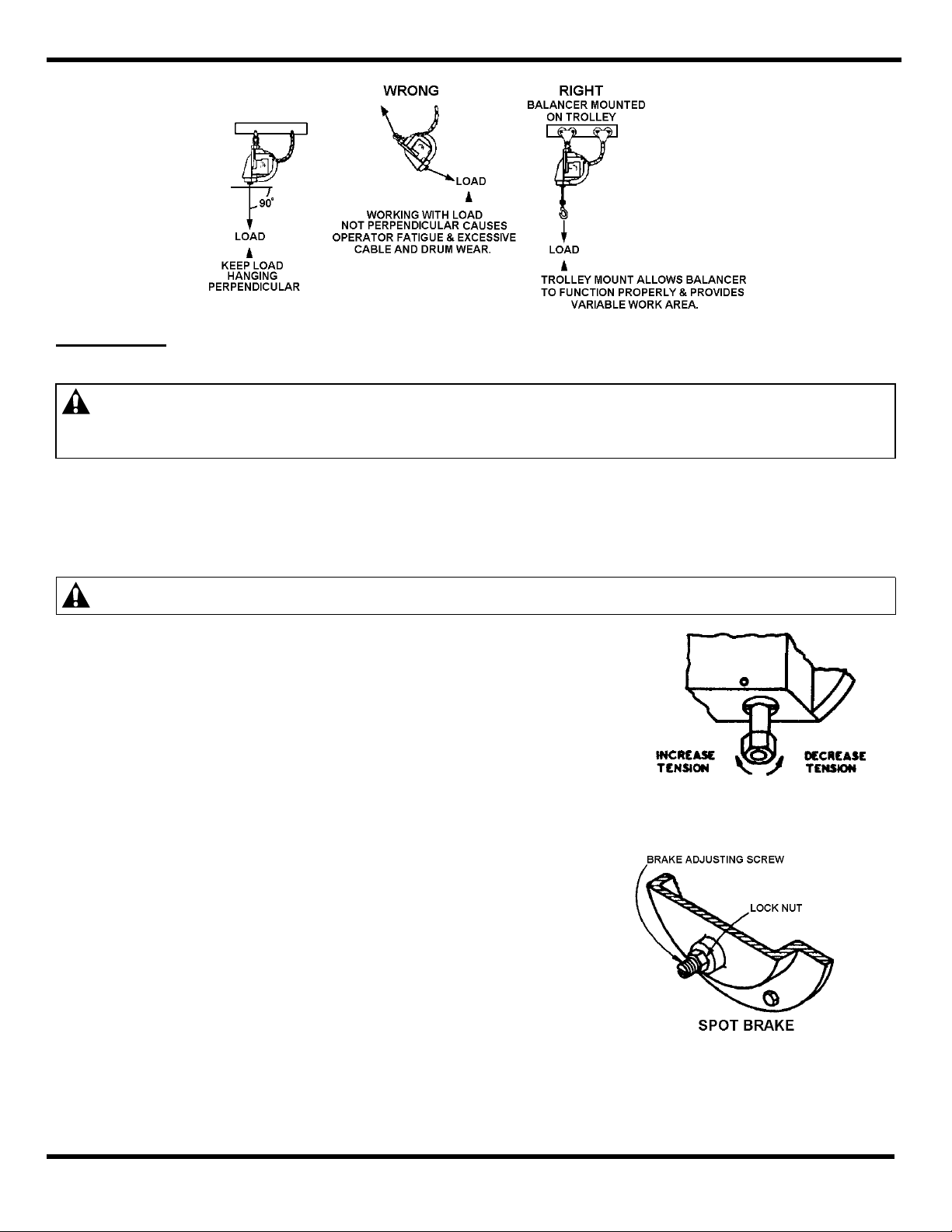

The complete tool including all attachments and connections

must be in place before adjusting spring tension. If load exceeds

spring tension, tool will move downward. If tension exceeds load,

tool will move upward. Spring tension can be adjusted by turning

the adjustment nut clockwise to increase tension or

counterclockwise to decrease tension.

SPOT BRAKE

NOTE: See “Automatic Lock” if balancer locks up.

A spot brake is provided for fine adjustment to eliminate any

“creeping” tendency. This adjustment is made only if desired

and after adjustment, as explained in “Spring Tension

Adjustment”. To adjust, loosen lock nut and back up brake

adjusting screw until the balancer works freely. Next, apply

pressure to spot brake by turning adjustment screw in until

desired setting is reached. Reset lock when adjustment is

completed.

SM1140-01C Page 2 of 7 ©Jun-01

AUTOMATIC LOCK

NOTE: If tension is removed well below rated range of the balancer during spring adjustment, lock will engage. It

CABLE STOP ADJUSTMENT

SERVICE

TOOL REPLACEMENT

will be necessary to apply more tension to release the lock.

If a spring should break or lose tension for any reason, an automatic lock will engage to prevent drum from

turning. Lock will disengage when tension is applied to a new spring.

Adjusting cable stop is not recommended due to reduction in active travel distance, and difficulty. If

additional cable extension is required, extension cable assemblies are offered as an accessory item. In

addition, special cables are available if needed.

WARNING:

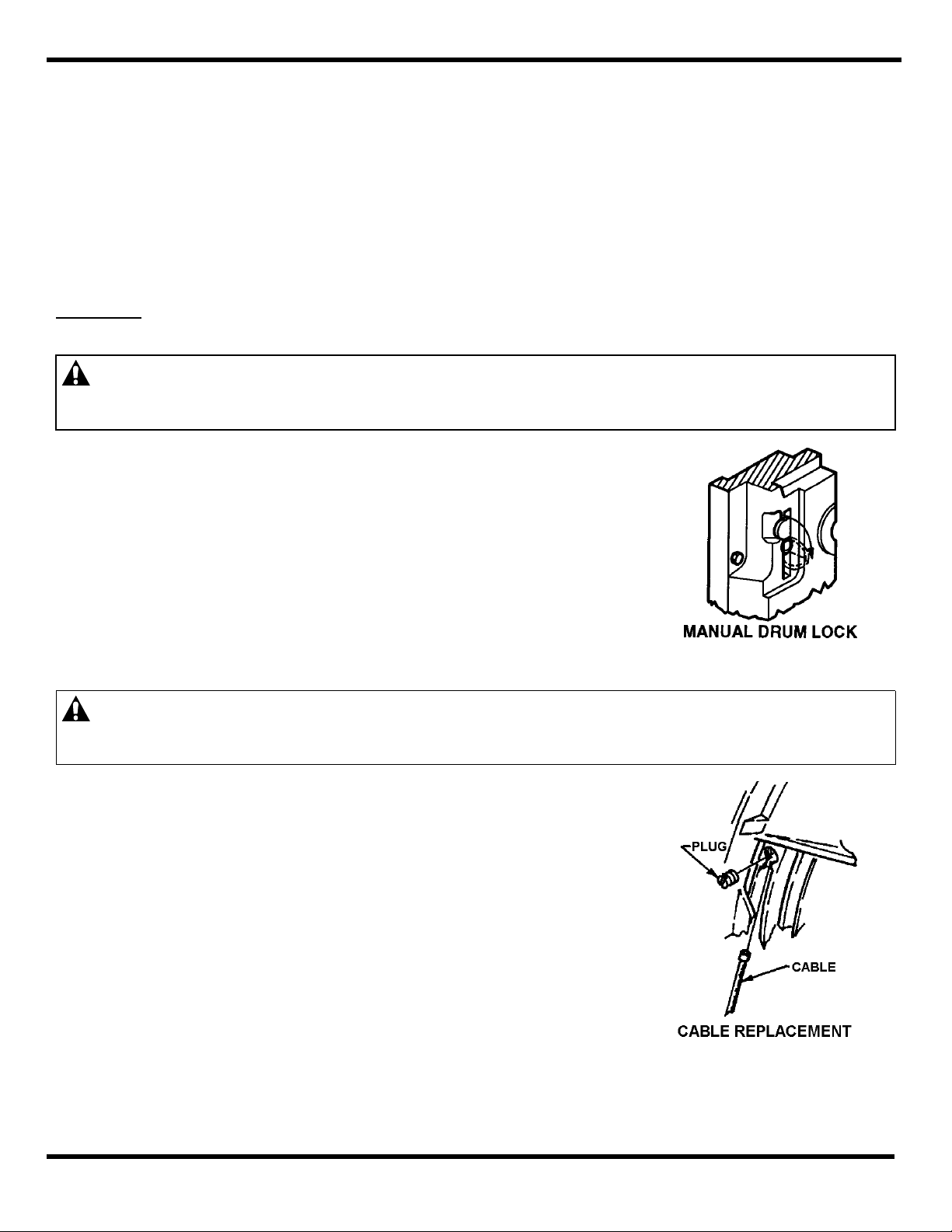

Pull tool down to the most convenient height and set manual drum lock

by lifting tab allowing pin to snap in (see illustration). This locks the

drum in place. Tool can now be removed and replaced. After replacing

tool, the drum lock can be released by pulling outward on tab and

folding it back into its original position.

CABLE REPLACEMENT

CAUTION:

Whenever cable shows signs of deterioration, it should be replaced

with a new cable. To replace cable, there is no need to

disassemble

balancer, remove tension, and/or remove it from its location. Simply

pull cable to its extreme lower limit, exposing threaded plug in the

drum as shown in the illustration. Engage manual drum lock (as

described in “Tool Replacement”) and remove tool. Remove plug

and old cable. Insert new cable and replace plug securely.

Reattach tool to lower hook and disengage drum lock.

Never release drum lock unless full load is hung on balancer. If released with no load,

hook will retract rapidly. Hazards or unsafe practices COULD result in severe personal

injury or death.

Never release drum lock unless full load is hung on the balancer. (If it is necessary to

disassemble balancer to change cable, always remove all spring tension prior to

disassembly (see Spring Tension Adjustment). Hazards or unsafe practices MAY result in

personal injury or product or property damage.

minor

SM1140-01C Page 3 of 7 ©Jun-01

Loading...

Loading...