GENERAL INSTRUCTIONS

Some routers will require cocking one handle in and

partially under the table followed by the other handle, unless the

handles can be removed. ”D” handle or pistol grip routers will

not work on our plate in a table unless the handle is removed.

STORING THE ROUTER - READ ME!!!!!

Our plates are resistant to sagging and flexing during

use. However, long term storage of your router in the

table is not advisable. Prolonged hanging may cause

the plate to sag, proving again that gravity works.

After use, store the router (leave the plate attached) in

an upright position with the plate laying on a flat surface.

Router Plate

Instructions

Please Read Carefully!

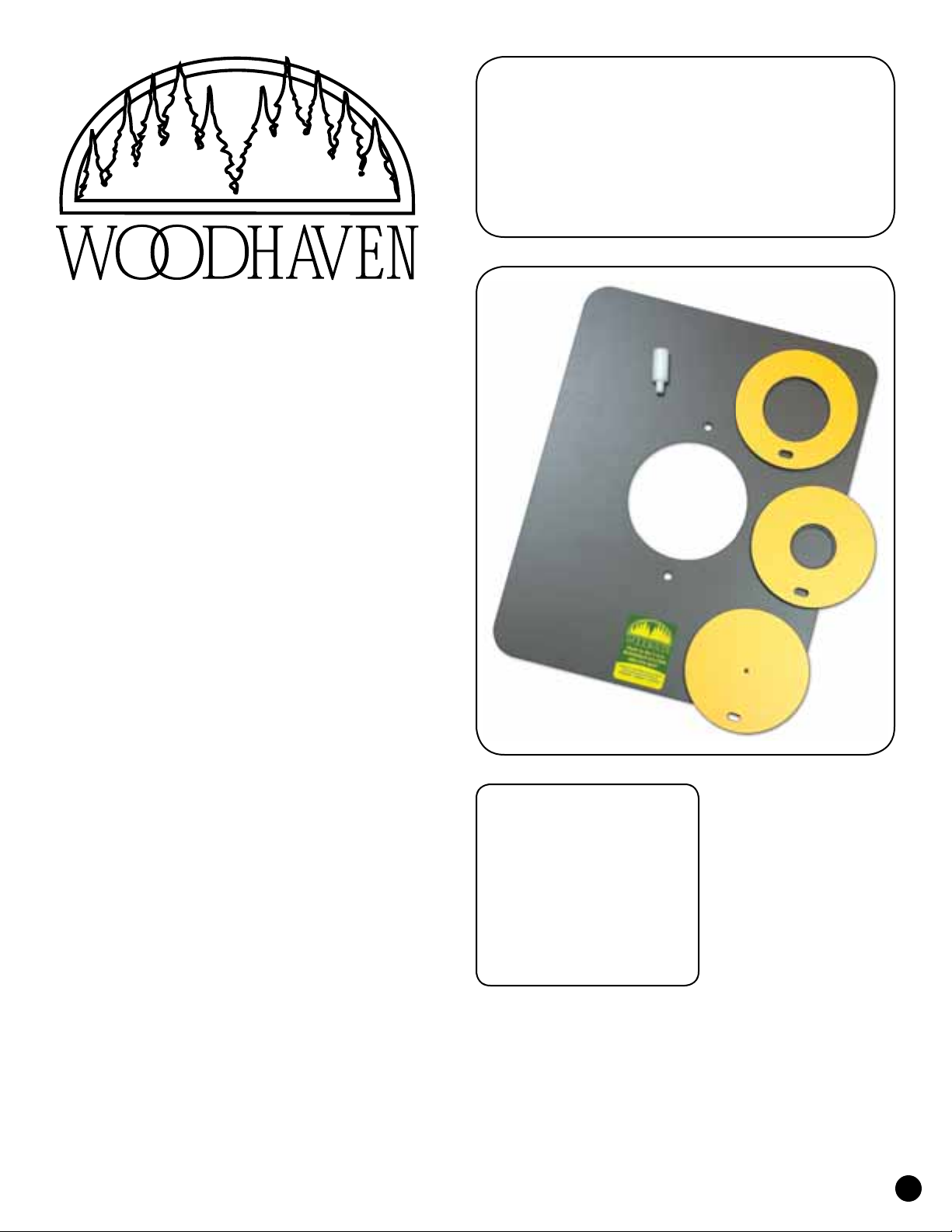

147 OR 147AP INSERT PLATE - PATENT #5,699,844

Be sure the O-ring is installed completely in the groove

of the router plate. We install the O-ring at our factory, but

sometimes they partially work their way out during shipping.

Before installing an insert, first determine which side

of the insert is the bottom. The bottom of the insert has a

machined face that is either black or dull yellow. The insert

snaps into the opening in the plate. Install the insert by

placing a bottom edge of the insert, at an angle, down into

the opening and then pressing the opposite edge into place.

Turn the insert 1/4 turn to be sure it is seated

on the O-ring. Test to be sure that it is held in place

and will not fall out. Extra inserts are available.

To remove the insert, reach underneath the plate and press

up, or insert a flat blade screwdriver in the slot in

the insert from above the plate and pry out.

If the insert falls out, lifts out or turns without

resistance, or the insert will not seat properly in the

opening, then replace the O-ring. The O-ring is a wear

item and will need to be replaced periodically. Always

check that the insert fits properly before using the

router. DO NOT use the plate if the insert is loose!

STARTING PIN

The starting pin is used with piloted type bits to aid in

starting the cut in an odd or irregular shaped piece where

it is impossible to use a router fence. It is a safety device

and should be used in lieu of trying to start the cut freehand.

If there is more than one starting pin hole in your router

plate, always use the one to the right of the router bit.

Parts List

Quantity Item

1 . . . . . . . . . . . . . . . . 147/147AP

1 . . . . . . . . . .101A Starting Pin

1 . . . . . . .140R O-ring, in plate

Plate Inserts

1 . . . . . . . . . 140B Blank Insert

1 . . . . . . . . 140D 1-3/16" Insert

1 . . . . . . . . . . . . . 140E 2" Insert

1

Router

Mounting

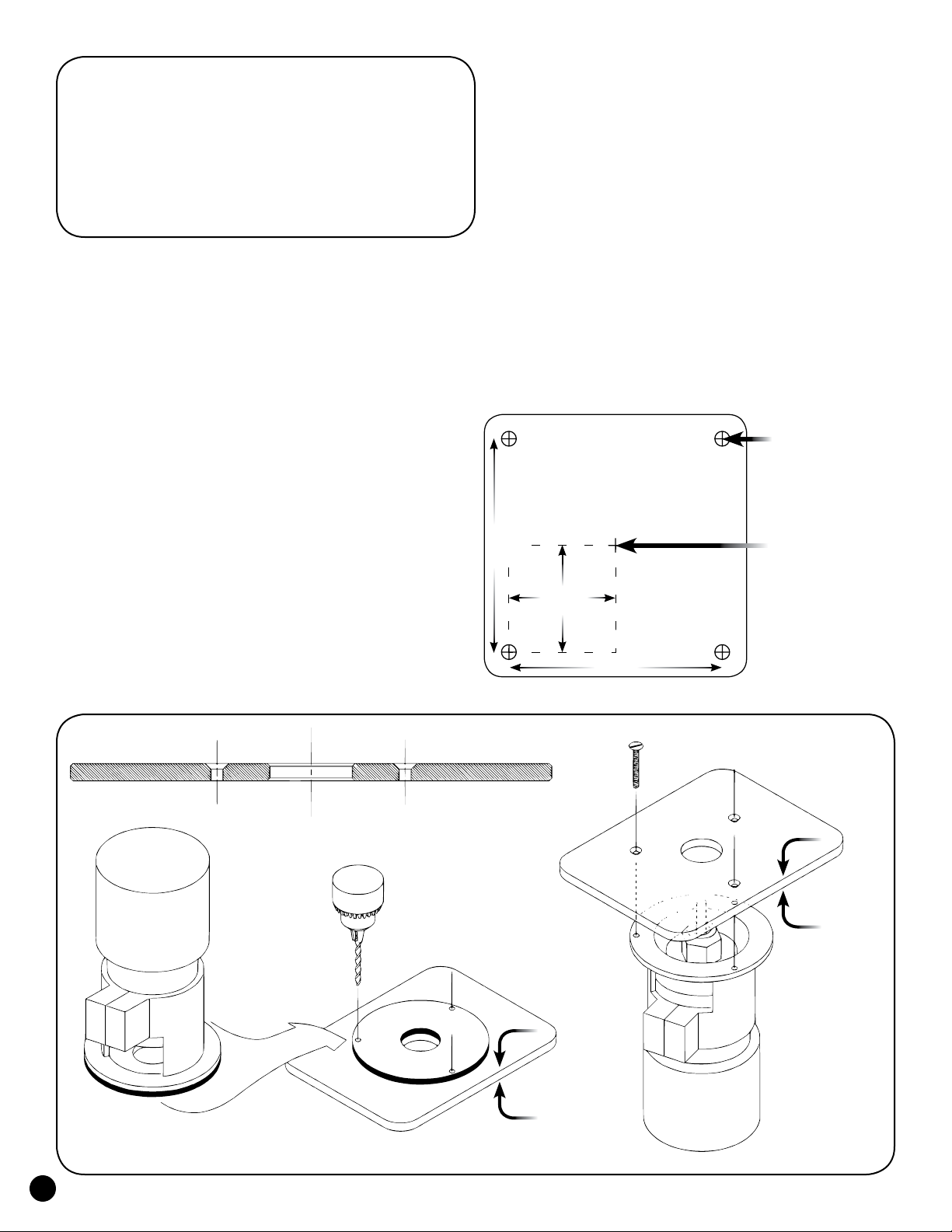

If your router base plate is not removable, lay out the

mounting hole locations by carefully measuring. We show some

bolt pattern charts with dimensions on the following page.

Verify all dimensions before marking and drilling the plate.

Some routers should have the handles mounted diagonally.

• Mark and drill from side ”B” (router side).

• Countersink holes from side ”A” (working side).

Please Read Carefully!

LAYOUT, MARK & DRILL PLATE

Side “B” is the side of the plate the router attaches

to. Side ”A” is the working side of the plate and

must be countersunk for the mounting screws.

If the router base plate from your router is

removable, it can serve as the template for marking the

mounting hole locations on the Woodhaven plate.

Put masking tape on the Woodhaven plate at the

approximate locations of the mounting holes. Remove

the base plate from your router and place the working

side of this plate against side ”B” of the Woodhaven plate

(label side of the 147 or similar table mounted plates,

grooved and unlabed side of the 577P or 578P).

Center the opening in your router base plate

with the opening in the Woodhaven plate. If they

are within 1/32" of being centered to each other that

is usually adequate, except for bushing work.

Verify the handle, switch and other control locations

before marking and drilling the plate. Some routers

should have the handles mounted diagonally.

Tape the router base plate to the Woodhaven plate and

mark the mounting hole locations on the masking tape. Use a

center punch to mark the hole locations on the plate for drilling.

ATTACH ROUTER TO PLATE

Remove your router’s existing base plate, unless

it’s glued on, or your router’s sub-base has protruding

ribs which prevent the Woodhaven plate from laying flat.

In either of these cases, leave the existing router base

plate on and attach the Woodhaven plate over it.

Use longer flat head mounting screws to compensate

for the additional thickness of the Woodhaven plate. You

should use at least three screws to mount your router (except

trim routers - two screws are adequate) to the plate.

Drilling Pattern

85mm

42.5mm

85mm

Drill Hole

Plate Center

Side A

Side B

Side A

Side B

Side B

Side A

2

PC 690-93

PC 892 & 7529

DeWalt 616/618

Makita RF1101

Hitachi M12VC

Makita 5615

PC 7518/19

PC 7538/39

Milwaukee 5625

Triton

2.3125" radius

4.005" approx.

Makita 3612BR/C

85mm

42.5mm

Freud FT2000

69.5mm

85mm

2.33" radius

4.035" approx.

Bosch 1617 & 1618

98mm

49mm

98mm

Bosch 1450 & 1613

75mm

92mm

2.875" radius

4.062" approx.

Hitachi MV12

46mm

131mm

DeWalt 625

75mm

65.5mm

99mm

66mm

29.5mm

105mm

DeWalt 621

93mm

33mm

50mm 46mm

96mm

52.5mm

43mm

107mm

71mm

32mm

110 mm

Ryobi RE-600

42mm

40mm

52.5mm

94.5mm

105mm

55mm

52.5mm

31mm

62mm

90mm

15mm

57.5mm

115mm

3

Router Table

Instructions

Please Read Carefully!

The Woodhaven router table you have purchased is one

of the best investments you can make in your shop. We hope

you enjoy this product and are able to put it to good use. To

aid you in getting the most out of this router table we have

prepared this brief instruction sheet. Please read it carefully.

1. INSPECT THE ROUTER TABLE

We take every precaution to insure that your router table

arrives in the same condition it was sent. After unpacking

your table, inspect it for any damage caused in shipping.

Dented edges or marks in the surface are some signs of shipper

damage. If you purchased the table directly from Woodhaven,

call us and we will let you know what to do next. If you

purchased the table from one of our dealers, call them.

5. TABLE FLATNESS SPECS

Our tops are guaranteed flat to within .001 (one

thousandths of an inch) per 1" of table length. For example,

a 24" x 32" table can be up to .024" out of flat across the 24"

width and up to .032" out of flat across the 32" length and

still be within our specs. It is rare for a table to be that far

out of spec and if it does warp it will usually only be in one

direction. An exception to our flatness specs is a table with a

miter slot. These can warp along the length of the slot. We do

not guarantee table flatness on these tables because cutting

a miter slot relieves stress on one side of the table and can

cause it to warp. The good news is that it is easily re-flattened.

If your table is warped slightly but within our specs,

or warped along the miter groove, it can be re-flattened by

pulling the "high" part of the table down and/or applying

shims between the leg rail and the underside of the table

to force the "low" part of the table up. See fig. 5.

5

Warps up: pull down at ends, shim in center

Warps down: pull down center, shim ends

2. INSTALL MITER TRACK

If your table includes an aluminum T-Slot Miter Track,

attach it to the table using the screws provided. The screws are

self-drilling and don't require a pilot hole. A power screwdriver

may be used too, but be careful not to strip the holes.

3. MOUNT THE TABLE

3

Angle brackets at

four corners

recommend you place the angle brackets at, or near, the

four corners of the router table. See fig. 3. You can

screw into the bottom of our MDF tables, but not into the

edge. Our Phenolic tables have T-slots machined in the

bottom for attaching it to a leg set with angle brackets.

4. TABLE SAW ROUTER TABLES

These router tables can be mounted on the right or left

side of the table saw and may be trimmed shorter to suit

your needs. Sometimes a support frame can be attached

to the fence rails of the table saw. See fig. 4A. If not,

you will need an inboard bracket that attaches to the table

saw. See fig.4B & 4C. It will also need legs or braces to

support the outboard end of the frame/table. See fig.4D.

The router table needs to

be properly supported to

insure that it stays flat. This

requires a well designed

support frame, which

Woodhaven leg sets and

cabinets provide. Attach

the table to your homemade

leg set using four (or more)

1" angle brackets. We

If your table is out of spec we will replace it, provided

that it is not warped along the miter slot and it has

been mounted to one of our leg sets or cabinets, or a

leg set that meets our design criteria for support.

4A

Fence Rails

4B 4C

4D

Router Table

Support Frame

4

Loading...

Loading...