Woodhaven 8661 User Manual

Parts List:

Please identify and verify that you have all of the parts

listed below prior to assembly.

Part Description . . . . . . . . . . . Quantity

8661 Hinge Jig for SOSS 101. . . . . . . . . . . . . . . . . . . 1

4008 8” Double Track. . . . . . . . . . . . . . . . . . . . . . . . . 1

MF010 1/4-20 x 3/4" flat head screw . . . . . . . . . . . . . 2

5760B 1/4-20 oval nut . . . . . . . . . . . . . . . . . . . . . . . . . 2

8660T 2-7/8" One Track . . . . . . . . . . . . . . . . . . . . . . . . 2

MF001 10-24 x 5/16” flat head screw. . . . . . . . . . . . . 2

5750B 10-24 oval nut . . . . . . . . . . . . . . . . . . . . . . . . . . 2

8661

SOSS 101 Hinge Jig

Owners Manual

Please Read Carefully!

BEFORE BEGINNING

Identify and verify that you have all the

parts listed. Read thru the instructions at least

once, familiarizing yourself with the parts and

their use before proceeding. You'll need a #2

& #3 Phillips screwdriver for assembly.

The 8661 SOSS Hinge Jig is designed to

work with a 5/8" bushing (our PN 5030K) and

a 3/8" upcut spiral bit (our PN 15406). If you

have your own 5/8" bushing, make sure the nose

isn't over 3/8" long. You'll need a plunge router

to cut the hinge mortises. The quality of the plunge mechanism

can effect the size of the mortise, resulting in a poor fit if the

plunge mechanism has excessive slop. Note: The pictures in the

instructions are of the 8663 SOSS 203 Hinge Jig, but all of the

SOSS Hinge Jigs assemble, and function, the same way.

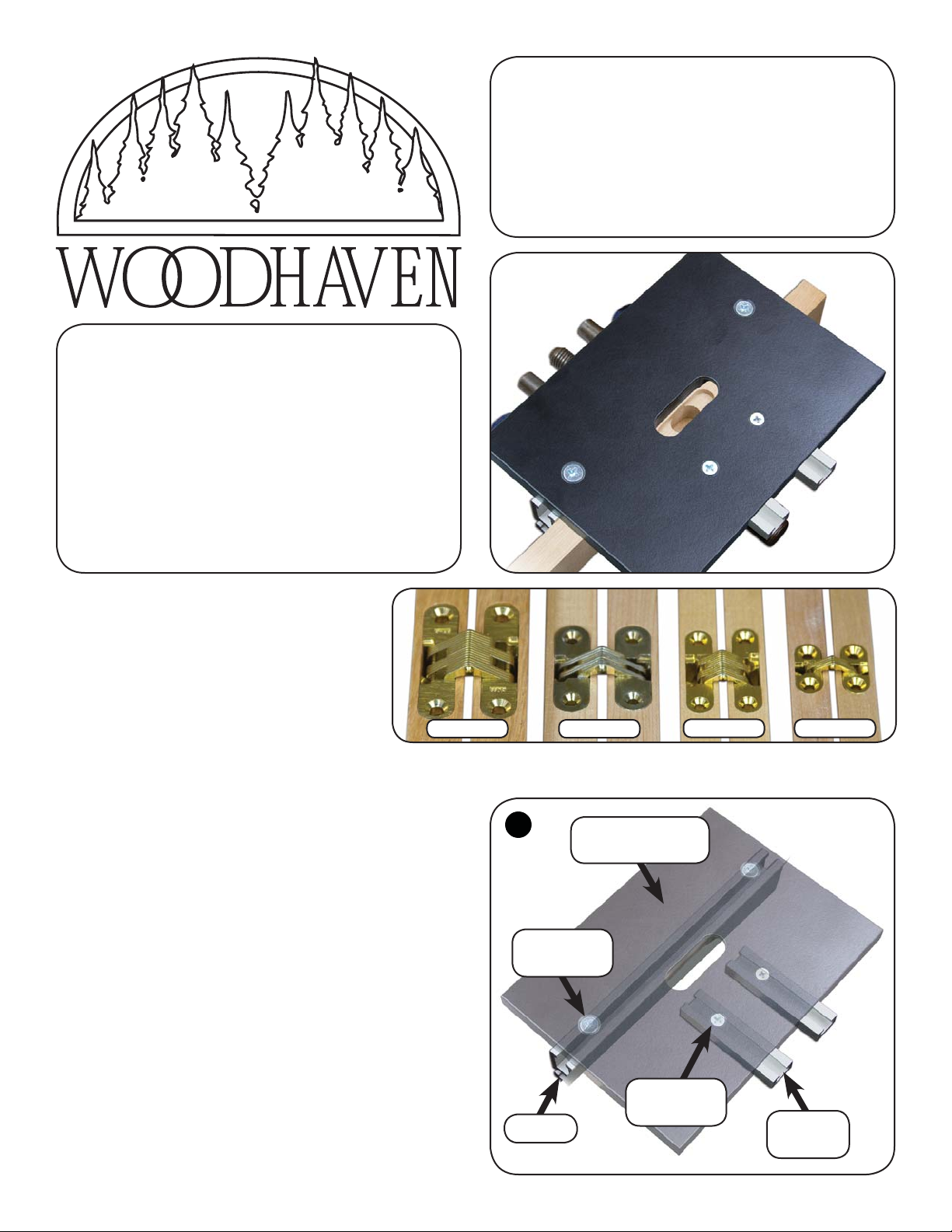

ASSEMBLY

Insert the two 1/4-20 x 3/4" flat head screws (MF010)

thru the larger countersunk holes in the SOSS Hinge Jig (8660-

8664). Start a 1/4-20 oval nut (5760B - flat side first) on the

end of each screw. Slide the 8" Double Track (4008) on to the

oval nuts and in the groove in the underside of the Hinge Jig

until centered end-to-end, then tighten the screws. See fig. 1.

Insert the two 10-24 x 5/16" flat head screws (MF001)

thru the remaining two countersunk holes in the Hinge Jig and

start a 10-24 oval nut (5750B - raised side first) on the end of

each screw. Slide a 2-7/8" One Track (8660T) on to each oval

nut and in to the grooves in the underside of the Hinge Jig until

covering the oval nut, then tighten each screw. See fig. 1

Turn Page Over

SOSS 204

1

MF010 &

5760B x 2

4008

SOSS 203

8660-8664

SOSS Hinge Jig

MF001 &

5750B x 2

SOSS 101

SOSS 100

8660T

x 2

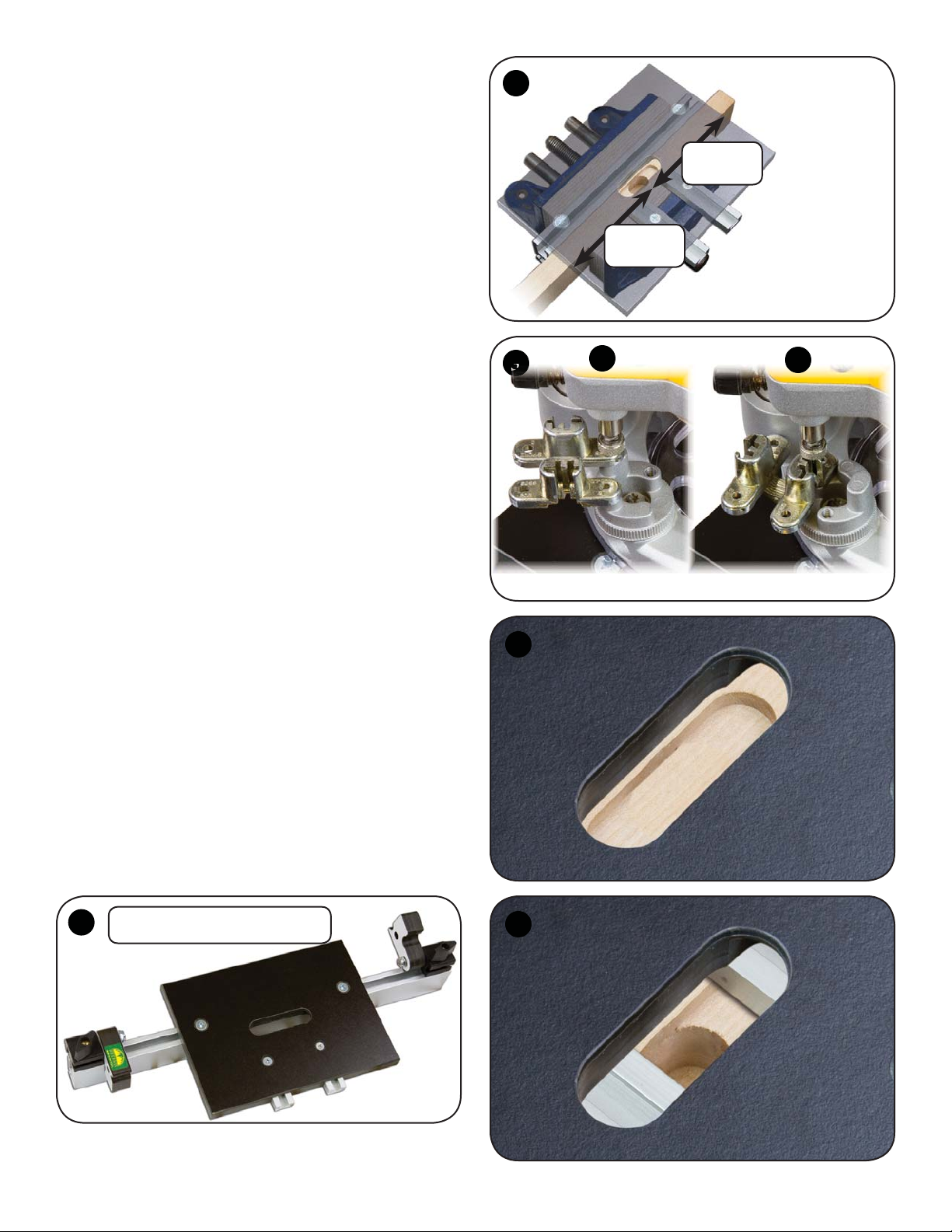

USAGE

The SOSS Hinge Jig has the correct setback for your SOSS hinge

built-in. Always index the face of the work against the Double Track

and an edge against the underside of the Hinge Jig. The center of the

Hinge Jig is 3-7/8" from each end. Use this measurement to index your

work along the Double Track and locate where the hinge mortise will

be cut. Clamp the work/Double Track together in a vise. See fig. 2

After installing the bushing and bit in your plunge router, set

the bushing in the opening in the Hinge Jig, plunge the bit down until

it touches the work edge and lock it in place. If your router has a

multiple depth turret, turn it to the highest stop. Place the mounting

portion of the hinge body between the top of the stop and the bottom

of the stop rod. Adjust the stop rod so it's resting on the hinge body

to set the plunge depth for the shallow/long mortise. See fig. 3A.

For the deep/short mortise, measure the thickness of the main

hinge body and add approximately 1/16". If you have a low adjustable

stop on the turret, turn the turret to it and, without moving the stop

rod, adjust the distance between the adjustable stop and stop rod

for the deep/short mortise depth. If you don't have an adjustable

stop, turn the turret to a fixed lower stop that will provide the

minimum depth required for the deep/short mortise. See fig. 3B.

The debris generated during mortising can interfere with the

bushing travel in the Hinge Jig. Make as many passes as needed,

cleaning out the debris between passes, until the mortise is complete.

Cut the long/shallow mortise first. Adjust the turret

to the shallow setting. Slide the One Tracks out until they

are no longer visible in the Hinge Jig opening, tighten the

screws and cut the long/shallow mortise. See fig. 4.

Cut the short/deep mortise last. Adjust the turret to

the deep setting. Loosen the two One Tracks and push them

under the Hinge Jig until they bottom out and are visible in

the Hinge Jig opening, tighten the screws and cut the short/

deep mortise in incremental passes. For best results, you should

not cut deeper than the bit diameter in each pass. See fig. 5.

2

3-7/8" ed g e

to center

3-7/8" ed g e

to center

3

A

B

4

ACCESSORIES

ptional 4512 Fl ip St o p mounts on a 4016 16" Do uble Tr ac k

O

(minimu m le ngth rec ommended) for qu icker p a rt index i ng and allows

setti ng t h e sto p up t o 6" f rom t he h i nge mortise, w it h a sp ac e r re qu i r ed for

dista nc e s les s t h a n 4-1/4". We recommen de d t wo Fl ip St op s, one for e ach

side of the jig. Optional longer Double Tracks available to mount mult iple

jigs & s t o p s . Optional Self-Ce nt ering d r i l l (6507 o r 65 0 9 ) centers itself in the

hinge sc rew mounting hole for a pe r fe ct ly ce nt e re d pilot hole.

©Copyright WOODHAVEN INC. 11/15/10

(800) 344-6657 or www.woodhaven.com

6

8663 SOSS Hinge Jig on 4016 16”

Double Track with two 4512 Flip Stops.

See fig. 6.

5

Loading...

Loading...