Woodhaven 8540 User Manual

8540

Hinge Jig

Please Read Carefully!

Parts List:

Part Description Quantity

8540 4" Hinge Jig . . . . . . . . . . . . . . . . . . . . . . . . . . 1

STP001 #8 x 3/4" Screws . . . . . . . . . . . . . . . . . . . . . 2

WS003 3/16" Washers . . . . . . . . . . . . . . . . . . . . . . . . 2

BUSH002 1/4" Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5503 1/2" Thumb Screws . . . . . . . . . . . . . . . . . . . 2

BEFORE BEGINNING

Identify and verify that you have all the parts listed.

Read the instructions at least once before beginning.

ASSEMBLY

Cut a wood fence to mount the Hinge Jig to.

The wood fence should be approximately 3/4" thick, 11/4" wide and 12" long. You can make the wood fence

longer if you want to mount more then one Hinge Jig to

a fence and cut two or more hinge mortises at a time.

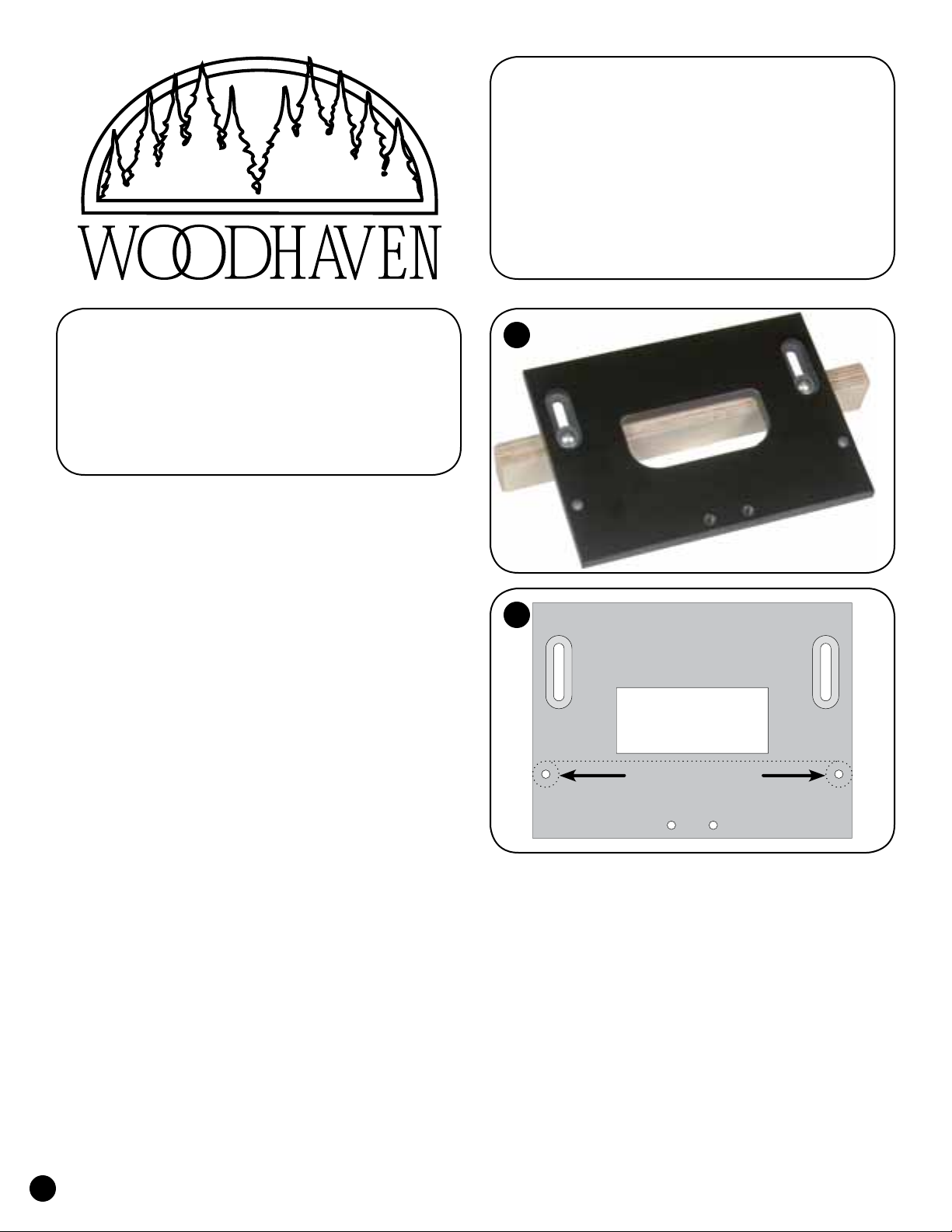

Drill two 1/8" pilot holes in the edge of the wood fence 63/8" on center. Mount the Hinge Jig to the wood fence using the

3/16" Washers (WS003) and 3/4" Screws (STP001). See fig. 1.

Place the 1/4" Spacers (BUSH002) on the 1/2" Thumb Screws

(5503) and screw them in to the two holes of the Hinge Jig shown.

The remaining two holes in the Hinge Jig are for storing the thumb

screws & spacers when not needed. Place the Hinge Jig on the

edge of the door so it's sandwiched between the two spacers and

the wood fence, snug the wood fence against the door and tighten

the screws. This positions the hinge 1/4" from the back of the

door and insures that the wood fence is square and parallel on the

Hinge Jig. You can leave the thumb screws/spacers in place when

routing doors, but you'll need to remove them for jambs. See fig. 2.

The 1/4" backset margin is an industry standard, but you

can change it by adjusting the wood fence forward or back

in relation to the spacers. If a different backset is needed,

cut a 1/4" thick x 8" long spacer to the width required to

position the hinge in the desired location. Place it between

the spacers and the wood fence to set the backset

USING THE JIG ON A JAMB WITHOUT A STOP

Mark the strike plate location on the jamb. The Strike

Plate Jig is 1/8" wider (1/16" on each side) then the actual strike

plate opening it cuts. Position the Strike Plate Jig so its edges

are 1/16" from the strike plate location marks, or make the

strike plate marks 1/8" further apart to correspond to the actual

opening in the Strike Plate Jig. Clamp the Strike Plate Jig to

the jamb using the wood fence and two clamps. See fig. 1.

1

1

2

Attach spacers here

Install our 8500 Hinge Bit (1/2" diameter with a 5/8" bearing

and a 1/4" cut length), or a 1/2" bit (13416) and 5/8" bushing

(5030K), in your router. If using the 8500 Hinge Bit, make sure

the bearing rides firmly on the edge of the jig before attempting

any cuts. Since the cutting depth for locks is shallow (usually

1/8" or less), either a standard or plunge router will work. Set the

cutting depth of the bit, taking into account the thickness of the jig.

Plunge or tilt the router bit into the approximate center

of the jig opening, moving in a small clockwise circle as you

do so to cut a relief opening. With the router base riding

firmly on the jig, move towards an edge of the jig opening.

Moving clockwise, follow the jig until the outline has been

cut. Make clean up passes to remove any remaining material.

After making the first cut, the wood fence will have a

cut out area that corresponds to the strike plate size. You can

use this cut out area to position the jig on the next parts.

USING THE JIG ON A JAMB WITH A STOP

If you are cutting a strike plate in a jamb with a door stop

and casing in place, you'll need a longer bit (PN 8505 Hinge

Bit, 3/4" cut length). You'll also need a wood fence that will

position the Hinge Jig at least 1/2" above the jamb and straddle

the casing. If your door stops are 1/2" thick, part of the Strike

Plate Jig will be supported on top of the door stop. If the door

stop is thinner than 1/2" you'll need to shim between the Strike

Plate Jig and jamb so it's at least 1/2" above the jamb. This can

be accomplished by using double stick tape to attach 1/2" thick

shims to the underside of the Strike Plate Jig. The 8505 Hinge

Bit will work on doors with stops up to 3/4" thick. See fig. 3.

Mark the strike plate location on the jamb. The Strike

Plate Jig is 1/8" wider (1/16" on each side) then the actual strike

plate opening it cuts. Position the Strike Plate Jig so its edges

are 1/16" from the strike plate location marks, or make the

strike plate marks 1/8" further apart to correspond to the actual

opening in the Strike Plate Jig. Clamp the Strike Plate Jig to

the jamb using the wood fence and two clamps. See fig. 1.

Install our the 8505 Hinge Bit (1/2" diameter with a

5/8" bearing and a 3/4" cut length), or a 1/2" bit (13416)

and 5/8" bushing (5030K), in your router. If using the 8505

Hinge Bit, make sure the bearing rides firmly on the edge of

the jig before attempting any cuts. Since the cutting depth

for hinges is shallow (usually 1/8" or less), either a standard

or plunge router will work. Set the cutting depth of the bit,

taking into account the thickness of the jig. Plunge or tilt the

router bit into the approximate center of the jig, moving in a

small clockwise circle as you do so to cut a relief opening.

With the router base riding firmly on the jig, move towards

an edge of the jig. When you get to an edge, move clockwise,

following the edge of the jig until the outline has been cut.

Make clean up passes to remove any remaining material.

After making the first cut, the wood fence will have a

cut out area that corresponds to the strike plate size. You can

use this cut out area to position the jig on the next parts.

3

OPTIONAL ACCESSORIES

Self-centering drill bits (PN 6509 - 9/64", 6511 - 11/64" and

6513 - 13/64") are available to insure perfectly centered pilot holes.

A Corner Chisel (PN 8508) is available to square

the radiused corners left by the 1/2" router bit.

The Hardware Kit (PN 8510) and Double Track (72" - PN

4072 or 96" - PN 4096) allow you to attach up to three hinge jigs

to an aluminum extrusion for consistent and even hinge spacing.

©Copyright WOODHAVEN INC. 9/18/06

(800) 344-6657 or WWW.WOODHAVEN.COM

2

Loading...

Loading...