Woodhaven 7640 User Manual

1

7640

Keller

Dovetail Kit

Please Read Carefully!

BEFORE BEGINNING

Read the instructions at least once, familiarizing yourself

with the parts and instructions before beginning.

Your stock should be flat, square and between 1/4 and 3/4"

thick. The boards do not all have to be the same thickness. Cut

the finished length of the boards between 1/32" and 1/16" longer

then the finished length. This gets removed after assembly. Use

scraps for the initial test cuts.

ASSEMBLY

Remove the existing template from your 7600-7603

Woodhaven Dovetail Jig and replace it with the Keller Dovetail

Template (7640T1).

first as this is the non-adjustable part of the joint.

Install the dovetail bit (7533) in your router and

set the depth of cut to 1/64" more than the thickness of

your stock (maximum 3/4" thick stock capacity), taking

into account the 1/2" thickness of the template.

Swap the locations of the existing stops and

position them even with the first opening at each

end of the template for now. See fig. 1.

CUT DOVETAILS

Loosen the two ratchet handles on the two template

nuts and raise or lower the template until a scrap board just

fits between the underside of the template and the top edge

of the Ultra Track, then retighten the handles. Position the

edge of the scrap flush with the face of the Ultra Track and

clamp it in place using the dovetail jigs clamps. The scrap

board should be at least 1/16" thicker and about 1" wider

than the work. The scrap board prevents tear out when the

bit exits the back of the work and provides an extra margin

of safety to help insure the bit won’t hit the Ultra Track.

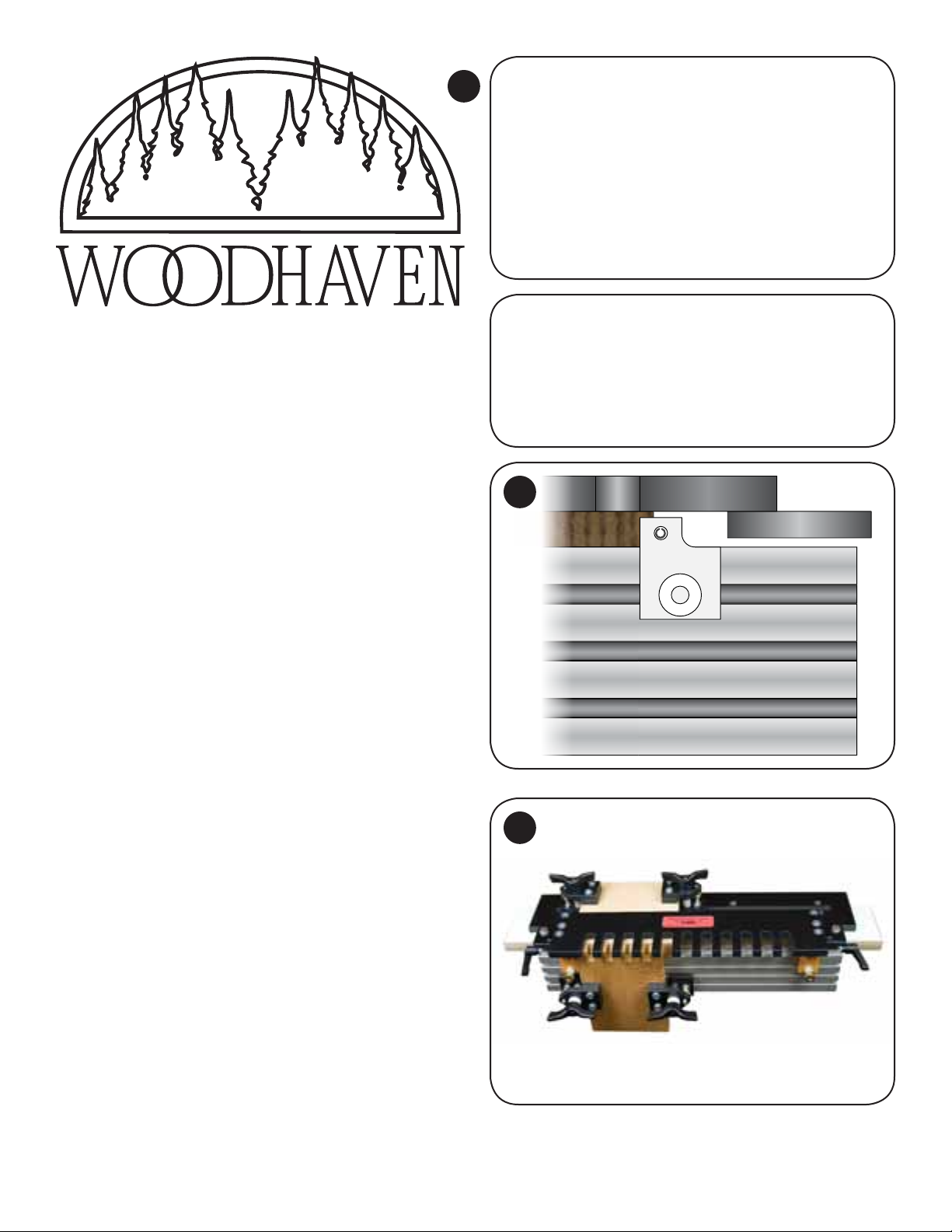

Install the work in the front of the jig with the OUTSIDE

FACE of the work against the Ultra Track. Place the end of

the work against the underside of the template and the edge of

the work against the edge of the stop. Adjust the stop position

to align the work where desired in relation to the fingers on

the template (center or offset pattern as desired). Tighten

the front clamps to hold the work in place. See fig. 2.

Make a test cut in some scrap. Cut from left to right,

following the fingers of the template. If you get chipping on

the exposed face of your work you may need to clamp a scrap

of 1/4" plywood or hardboard to the face of the work. When

satisfied, make all the dovetail cuts in all of your parts.

The dovetail half of the joints need to be cut

Parts List:

Part Description Quantity

7640T1 Keller Dovetail Template . . . . . . . . . . . . . . . . 1

7640T2 Keller Pin Template . . . . . . . . . . . . . . . . . . . . 1

7533 Dovetail Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7543 Straight Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1

2

CUTTING PINS

Install the Keller Pin Template (7640T2) in place of the

Keller Dovetail Template. Install the straight bit (7543) in your

router. Set the depth of cut to 1/64" to 1/32" more than the

thickness of your stock, taking into account the 1/2" thickness

of the Pin Template.

Install a new piece of scrap in place of the scarp

used for the dovetails, following the same process.

Install the work in the front of the jig with the INSIDE

FACE of the part against the Ultra Track. Place the end of

the work against the underside of the template and the edge

of the work against the edge of the stop. The stops must

not be moved from the location they were at when you cut

the dovetails or the parts will not line up when assembled!!

Tighten the front clamps to hold the work in place. See fig. 3.

Make a test cut in some scrap. Cut from left to right,

following the fingers of the template. If you get chipping on

the face of your work you may need to clamp a scrap

of 1/4" plywood or hardboard to the face of the work.

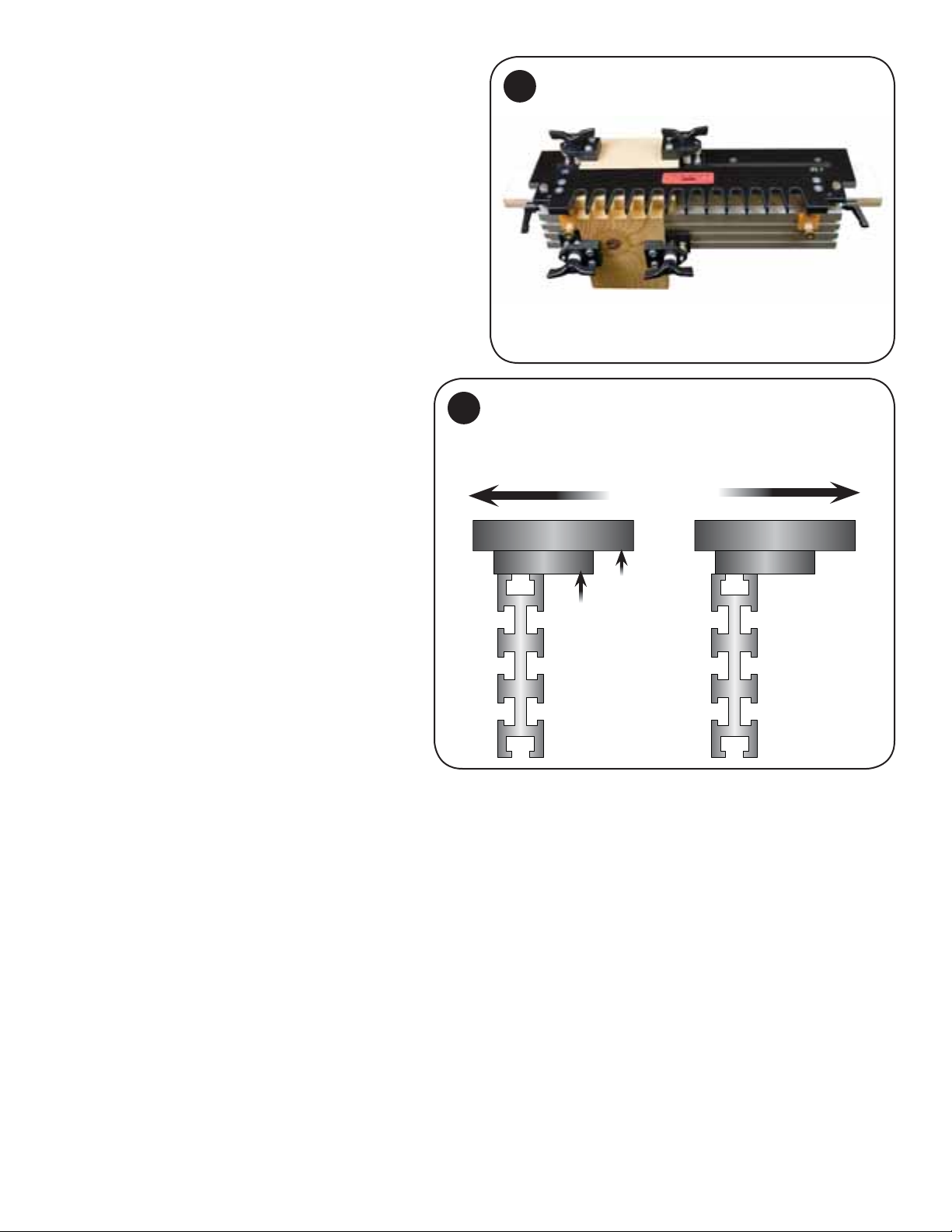

Test the fit of the pins in the dovetailed part. The

parts should go together with light tapping at most. If the

pins are too loose, move the Pin Template forward. If the

pins are too tight, move the Pin Template back. A 1/16"

(.0625) adjustment (forward or back) of the Pin Template

makes a 1/64" (.015) difference in pin width. The template

brackets/pin template are adjusted in or out by loosening

the two 3/4" bolts holding the template brackets to the template nuts. Make equal adjustments to both template brackets. When satisfied, make all the pin cuts on all of your

parts. See fig. 4.

Any excess overhang of pins and dovetails can be

removed by sanding or routing after assembly.

3

4

Move template

brackets/pin template

forward to make

the pins larger and

tighten the joint..

Move template brackets/

pin template back to

make the pins smaller

and loosen the joint.

Template

Template

Bracket

©Copyright WOODHAVEN INC. 9/10/07

(800) 344-6657 or WWW.WOODHAVEN.COM

Loading...

Loading...