Woodhaven 7600, 7603 User Manual

INSTALL DOVETAIL BIT

Depending on the Dovetail Jig purchased, you will have

either a dovetail bit (1/2" diameter x 14º) with a 1/4" shank &

5/8" bearing (780), or a 5/8" Guide Bushing (5030), Locknut

(5040) and a dovetail bit (1/2" diameter x 14º) with a 1/2"

shank (61404). Install the bit (and bushing if applicable) in

your router and set the bit depth at 25/32". The depth may

need to be adjusted later after making a test cut. See fig. 14.

STOCK

This jig is designed for 3/8" to 1-1/8" thick stock. 1/2"

stock is the most common thickness used for drawers. The stock

used for the fronts & backs can be a different thickness then the

stock used for the sides. All stock should be flat and straight.

Stock thinner than 3/8" may be used for the backs and

fronts, but the ends of the pins (dovetails) may show. Using

thinner stock for the sides will not effect the look of the joint

like it will on the fronts and backs.

We recommend a 1/64" overhang on each end of the fronts

and backs, so cut the fronts and backs are 1/32" longer than the

finished width of the drawer. Cut the sides approximately 9/16"

longer (this will depend on the final cutting depth of the router

bit and only applies to the standard dovetail template) than the

desired inside length of the drawer.

The width of the stock will depend on the height of the

drawer opening, desired drawer depth and the dovetail pattern

selected.

Cut two pieces of stock for a test cut at least 8" long, 4-6"

wide and 1/2" thick. Follow the directions below for a standard

drawer. After you have mastered making a standard drawer you

may want to attempt a rabbeted drawer. See the RABBETED

DRAWER section for instructions on that process.

14

Initial bit depth 25/32”

15

16

STANDARD DRAWER

Loosen the two ratchet handles on the two template

nuts and raise or lower the dovetail template at each

end until the drawer front (or back) just fits between the

underside of the dovetail template and the top edge of

the Ultra Track, then retighten the handles. Depending on

variations in the thickness of your stock, the dovetail template

height may have to be adjusted for each part. See 15.

Place a drawer side in the jig with the inside facing out, the

bottom edge against the stop and the end butted up against the

underside of the dovetail template. Slide the clamps as close as

possible to the edge of the part and tighten the clamps. See 16.

Slide the mating drawer front (or back) in between the

underside of the dovetail template and the top edge of the

Ultra Track, and slide it forward until it butts up against the

drawer side. The bottom edge of the part should be against

the pin in the stop and the inside face should be against

the template. Slide the clamps as close as possible to the

edge of the part and tighten them. The end of the drawer

side should be flush to top (inside face) of the drawer

front (or back). Check this with your finger between the

fingers of the dovetail template. See Cover & fig. 17.

17

Check that end of

drawer side is fl ush to

face of front (or back).

5

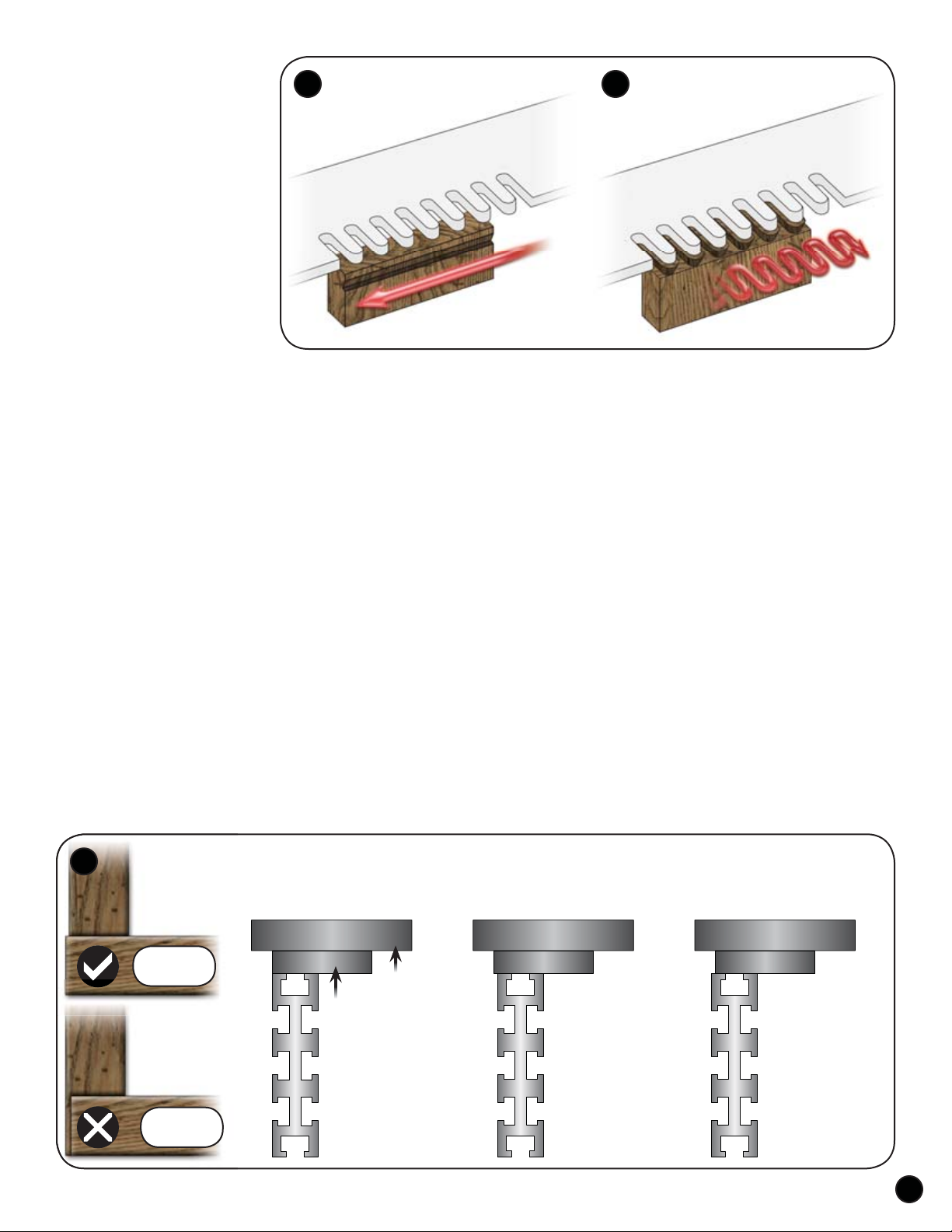

MAKE A TEST CUT

Set the router on the

template (or, if using portably,

the Dovetail Jig on the router

table), without the bit touching

the work, template or router

support. Turn the router on and

make a scoring cut from right

to left (left to right if using

portably) across the face of

the drawer front by skimming

across the ends of the fingers.

The scoring cut helps prevent

chipping and tear out during

the finish cut. See fig. 18A.

Next, moving from left to

right (right to left if using

portably), move the router in and out of each dovetail finger

to finish the cut. If you get tear out, go a little deeper into the

template openings as you make the scoring cut to insure that

you have scored the entire face of the part. See fig. 18B.

In portable use you may notice that the thickness

of the dovetail template (7600T) and the thickness of the

clamp base (7600B1) are slightly different, which may

cause the two parts to not sit perfectly flat on a router

table. As long as you maintain downward pressure at the

dovetail template (and not the clamp base) using the feed

handles supplied, this will not make a difference.

Sometimes it’s necessary to make a second pass

due to sawdust that may have lodged in the template.

Remove the parts and check the joint fit.

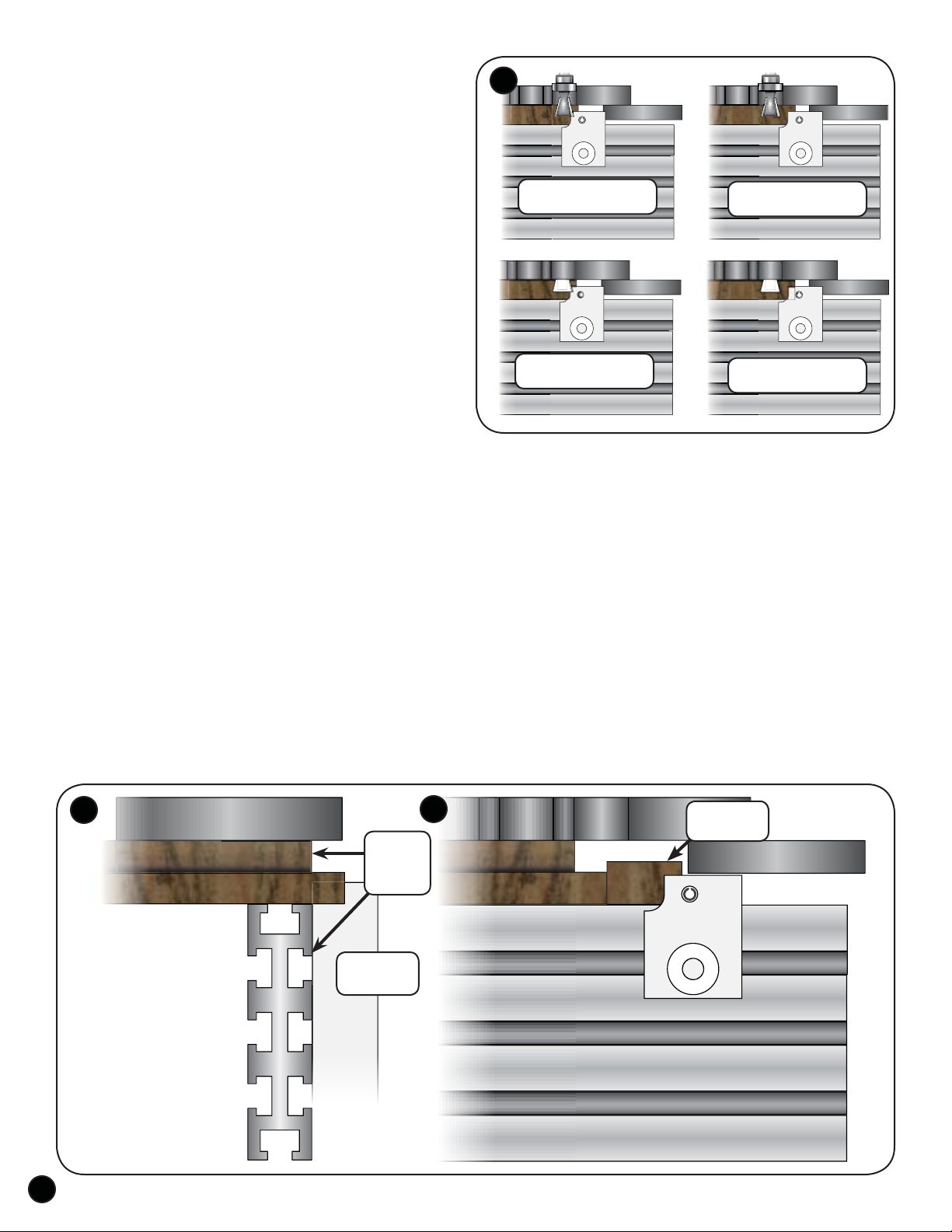

JOINT FIT - DRAWER SIDE TO DRAWER FRONT

We recommend that the end of the drawer front (or back)

stick out past the drawer side l/64". This way the end of the

drawer front (or back) can be sanded or routed flush to the

drawer side after assembly. This also compensates for any

variation in the thickness of the drawer sides. You can also adjust

the template to cut the parts flush if you prefer. See fig. 19.

18A 18B

If the drawer sides stick out past the ends of the drawer

front (or back), then the template brackets/template must be

moved back, away from the face of the Ultra Track. If the

ends of the drawer front (or back) protrude past the drawer

sides more than 1/64", then the template brackets/template

must be moved forward slightly. See fig. 19.

The template brackets/template is adjusted in or out by

loosening the two 3/4" bolts holding the template brackets to the

template nuts. Make equal adjustments to both template brackets.

JOINT FIT - LOOSEN OR TIGHTEN

The pins (also known as dovetails - cut in the

drawer side) should slide into the sockets (cut in the

drawer front or back) with light tapping, at most.

If the joint is too loose, then the cutting depth

of the router bit is not deep enough. Adjust the bit

lower (more than 25/32") so it cuts deeper.

If the joint is too tight, then the cutting depth

is too deep and the bit needs to be raised (less than

25/32"). Bit set deeper than 25/32" = tighter joint.

Bit set shallower than 25/32" = looser joint.

19

End of front

should stick

out past the

side 1/64”

or less

Drawer

Front

Side should

not stick out

past the end

of the front

Drawer

Front

On your initial setup

the edges of the template

brackets are fl ush to

the Ultra Track.

Template

Template

Bracket

Move template brackets/

template forward to increase

the amount the side will stick

out past the end of the front.

Move template brackets/

template back to increase the

amount the end of the front

will stick out past the side.

6

STOP POSITION

The position of the stop controls the location for the groove

for the drawer bottom, which is normally centered in the first

dovetail socket from the bottom so it is hidden after assembly. The

bottom of the groove is usually between 1/4" (for side mounted

drawer glides) to 1/2" (for bottom mounted drawer guides) from

the bottom edge of the drawer. If you set the stop for a 1/4" margin, you may cut into the stop slightly, which is OK. Once you’ve

established the stop position needed, cut the drawer stock to a

width that will give you a full pin & socket at the top of the drawer. See fig. 20.

RABBETED DRAWERS

Rabbeted drawers are drawers with a face that over laps the

cabinet face. The other three drawer parts (both sides and the back)

are of equal width. For a faster way to make Rabbeted drawers see

the QUICK RABBETED DRAWERS section.

The width of the rabbeted drawer front, measured between

rabbets, should equal the width of the drawer sides and back. The

length of the rabbeted drawer front, measured between rabbets,

should equal the length of the drawer back. See pg. 10.

A rabbeted drawer front and its adjoining sides must be cut

in separate operations, unlike the parts for a Standard drawer. The

remaining sides and back parts are cut like a Standard drawer, in

pairs. A Rabbeted drawer will require six setups, one setup (x 2)

for each rear drawer corner and two setups (x 2) for each front

drawer corner.

Rout the mating dovetails into the two front ends of the

adjoining drawer sides. Clamp a piece of scrap where the drawer

front usually goes, against the drawer side, to prevent tear out.

The rabbet in the drawer front should be at least 5/16" deep

to clear the dovetail bit. The end of the drawer should be indexed

so the shoulder of the rabbet is aligned with the front of the Ultra

Track. You’ll need to make an indexing block to position the

drawer front correctly. Cut a piece of scrap with the same width

rabbet as the drawer front and clamp it in the front of the dovetail

jig where the side would normally go. Slide the drawer front forward to index its front edge against the rabbeted lip in the indexing

block and tighten the top clamps. See fig. 21A. Rout both ends of

the rabbeted drawer front this way.

20

1/4” Stop Setting

1/4” Stop Setting

The bottom edge of rabbeted drawer front must be indexed

against the stop pin, with an additional spacer placed between the

rabbeted edge and the stop pin to offset it correctly. For example,

if you have a 3/8" wide rabbet and you’re using the standard 7/16"

dovetail template, you’ll need a 7/8" wide spacer. See fig. 21B.

QUICK RABBETED DRAWERS

Instead of making a Rabbeted drawer, make a Standard

drawer with the drawer front made of the same wood species as

the desired rabbeted drawer would be. After assembling the drawer

glue a larger drawer front to the standard drawer front. This provides the same appearance as a one-piece rabbeted drawer, but is

quicker and easier to make.

©Copyright WOODHAVEN INC. 11/8/10

(800) 344-6657 or WWW.WOODHAVEN.COM

1/2” Stop Setting

1/2” Stop Setting

On

21B

7/8”

spacer

21A

same

plane

Indexing

block

7

Loading...

Loading...