Woodhaven 4965 User Manual

Part# Description Qty.

HB030 1" Bolt 3

4965 Super Sled

Owners Manual

Please Read Carefully!

Parts List

Part Desc . . . . . . . . . . . . . . . . . . . . . . . . . Qty

4924B 24" Jig Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4965A 32" Fence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4965B Sled Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4965C Fence Brackets, Pair . . . . . . . . . . . . . . . . . . . . . . . . 1

4965D Track Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6305A Outboard Clamp Bracket . . . . . . . . . . . . . . . . . . . 2

6305IC Inboard Clamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4519 Straight Flip Stop . . . . . . . . . . . . . . . . . . . . . . . . . . 1

BEFORE BEGINNING

Identify and verify that you have all the parts listed in

the parts list above, plus the parts shown on this page. Read

through the instructions at least once before beginning. You'll

need a #2 & #3 Phillips screwdriver for assembly.

The Super Sled is designed to be used on a table saw at

least a 27" deep with a 3/8" x 3/4" miter slot that's between

4-1/2" and 7-1/2" from the blade, measured from the blade

side edge of the slot. It can be used in the left or right miter

slot. Do not attempt to use on table saws with tables smaller

than 27". If necessary, add additional supports to your saw to

prevent the saw from tipping.

For the Super Sled to work properly, the miter slot of

your saw must be parallel to the saw blade. If this is not the

case, make those adjustments to your saw before proceeding.

Part# Description Qty.

MF006 5/8" Screw 4

Part# Description Qty.

5540 T-Knob 2

Part# Description Qty.

5590 Knob 1

Part# Description Qty.

5864 Ratchet Handle 2

Part# Description Qty.

MP150 1-1/2" Screw 2

Part# Description Qty.

BUSH001 1/8” Spacer 2

Part# Description Qty.

BUSH004 5/8" Spacer 1

Part# Description Qty.

BUSH002 1/4" Spacer 2

Part# Description Qty.

WS002 Washer 6

Part# Description Qty.

NUT025 Square Nut 4

Part# Description Qty.

4965PA Index Pin 2

Part# Description Qty.

5505 Thumb Screw 1

Part# Description Qty.

5760B Oval Nut 5

Crosscut Setup:

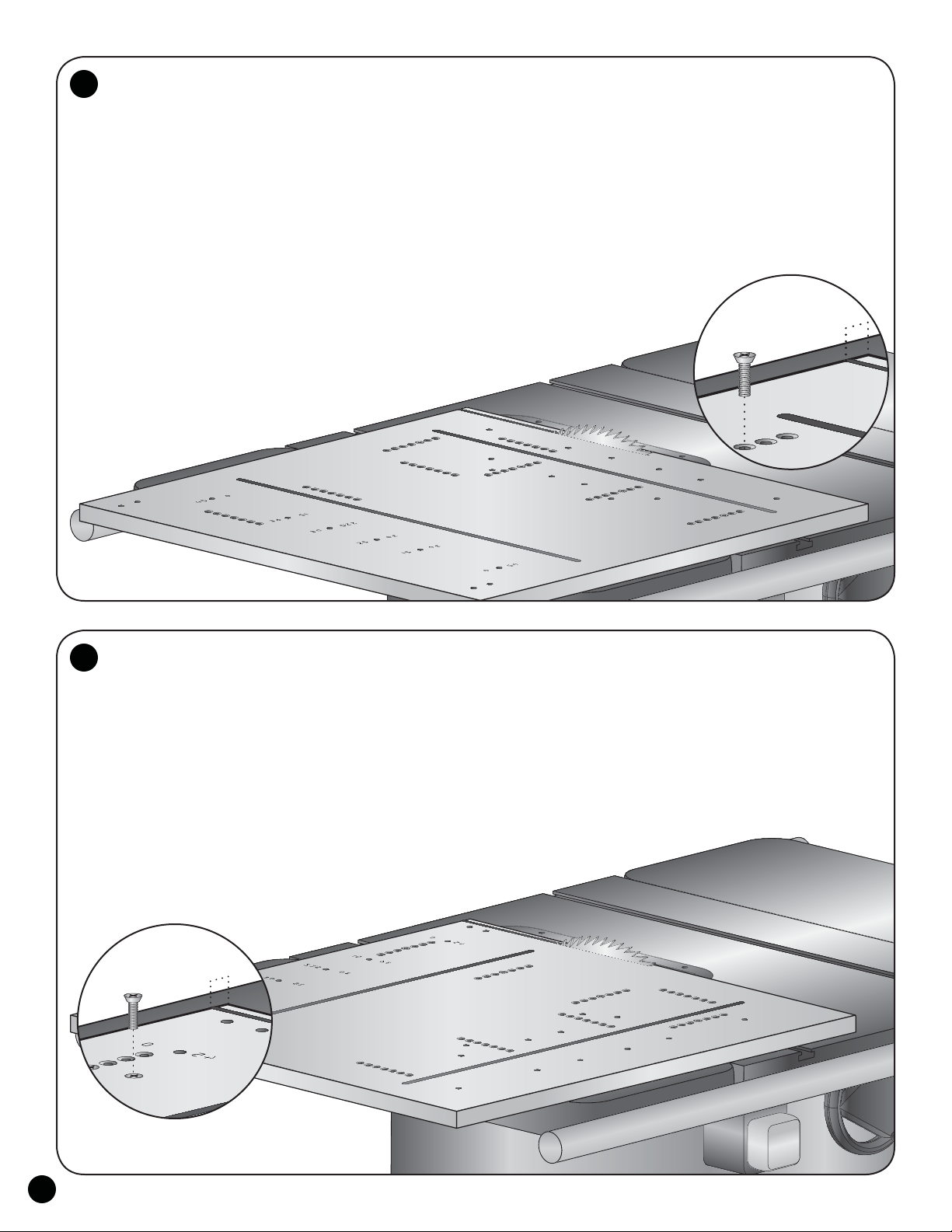

1

The Super Sled rides in the miter slot of the saw. Follow the instructions that come with

the Jig Bar (4924B), install the hardware in the bar and adjust the bar to fit the left or right miter

slot you've elected to use. These directions show the left miter slot being used.

Lower the saw blade below the saw table. Place the Jig Bar, with the countersunk holes facing down, in the miter slot.

There are two sets of bar mounting holes in the Sled Base (4965B). One set is for crosscut work (Slots in Sled Base are

parallel to miter slot.) and the other set is for taper work (Slots in Sled Base are square to miter slot.). See fig. 1 & 2

Setup for crosscut work: Align the crosscut bar mounting holes in the Sled Base with the threaded holes in the Jig Bar,

positioning the Sled Base over the bar so that it doesn't overhang the cutting path of the saw blade by more than 1/2". Attach the

Jig Bar to the Sled Base with the 1" flat head screws (MF010) included in the 4924B hardware. After mounting the Jig Bar to

the Sled Base, recheck the fit of the Jig Bar in the miter slot, making sure it slides smoothly but without slop.

Raise the blade, turn the saw on and cut off the crosscut edge of the base overhanging the

saw blade (This should be no more than 1/2"!), guiding the bar/base assembly in the miter slot.

Turn the saw off, disconnect the power and lower the blade below the saw table.

4965B Sled Base - Crosscut Setup

Slots in Base parallel to blade

MF010 x4

Taper Setup:

2

Lower the saw blade below the saw table. Place the Jig Bar, with the countersunk holes facing down, in the miter slot.

There are two sets of bar mounting holes in the Sled Base (4965B). One set is for crosscut work (Slots in Sled Base are

parallel to miter slot.) and the other set is for taper work (Slots in Sled Base are square to miter slot.). See fig. 1 & 2

Align the taper bar mounting holes in the Sled Base with the threaded holes in the Jig Bar, positioning the Sled

Base over the bar so that it doesn't overhang the cutting path of the saw blade by more than 1/2". Attach the Jig

Bar to the Sled Base with the 1" flat head screws (MF010, in the 4924B hardware). After mounting the Jig Bar to

the Sled Base, recheck the fit of the Jig Bar in the miter slot, making sure it slides smoothly but without slop.

Raise the blade, turn the saw on and cut off the crosscut edge of the base overhanging the

saw blade (This should be no more than 1/2"!), guiding the bar/base assembly in the miter slot.

Turn the saw off, disconnect the power and lower the blade below the saw table.

When switching between crosscut and taper setups, leave the bar in the

miter slot to insure it's always remounted in its original position.

4965B Sled Base - Taper Setup

MF010 x4

Slots in Base at 90º to blade

1

FENCE BRACKET ASSEMBLY

The vertical fence configuration is normally used for

crosscuts. Insert two 5/8" screws (MF006) thru the countersink

holes in the Fence Brackets (4965C) and start an oval nut

(5760B - flat side first) on the end of each screw. Slide the

Fence Brackets on to the T-slot in the edge of each Track Bracket

(4965D), position the narrow end of the Fence Bracket even with

the end of the Track Bracket and tighten the screws. See fig. 3

Install a washer (WS002) and a 1/8" spacer (BUSH001) on

the ratchet handles (5864). Insert the stud of the ratchet handle

thru the hole of the Track Bracket. Set each Track Bracket on

the Sled base so the wide end of the Fence Brackets are towards

each other. Insert the stud of the ratchet handle thru the slot in

the Sled Base. Place a square nut (NUT025) in the recess in the

underside of the Sled Base and screw the ratchet handle into the

nut. See fig. 3-4

5864

3

WS002

BUSH001

MF006 x2

4965C

5760B x2

Crosscut Fence Setup:

5

The vertical fence configuration is normally used for crosscuts. Insert a 1" bolt (HB030) thru

the hole in each of the Fence Brackets, install a washer (WS002) and a knob (5540) on the end of each

bolt. Slide the the 32" Fence (4965A) on to the bold heads and tighten the knobs. Assemble the Flip Stop

(4519) according to the directions that come with it and attach it to the top T-slot of the Fence.

See fig. 3-4

INSTALL INBOARD CLAMPS

Assemble the two Inboard Clamps (6305IC) according to the directions that come with them and attach each to an

Outboard Clamp Bracket (6305A). Insert a washer (WS002) on the 1-1/2" screws (MP150), insert the screw thru the hole in the

Outboard Clamp Bracket, place a square nut (NUT025) in the recess in each slot in the underside of the Sled Base and tighten

the screw into the nut.

4965D

HB030

WS002

5540

4

4965A

Fence

NUT025

Fence Bracket

Assembly

4965B

Sled Base

4965A

Fence

Clamp

Assembly

4519

Flip Stop

Fence Brackets

2

Loading...

Loading...