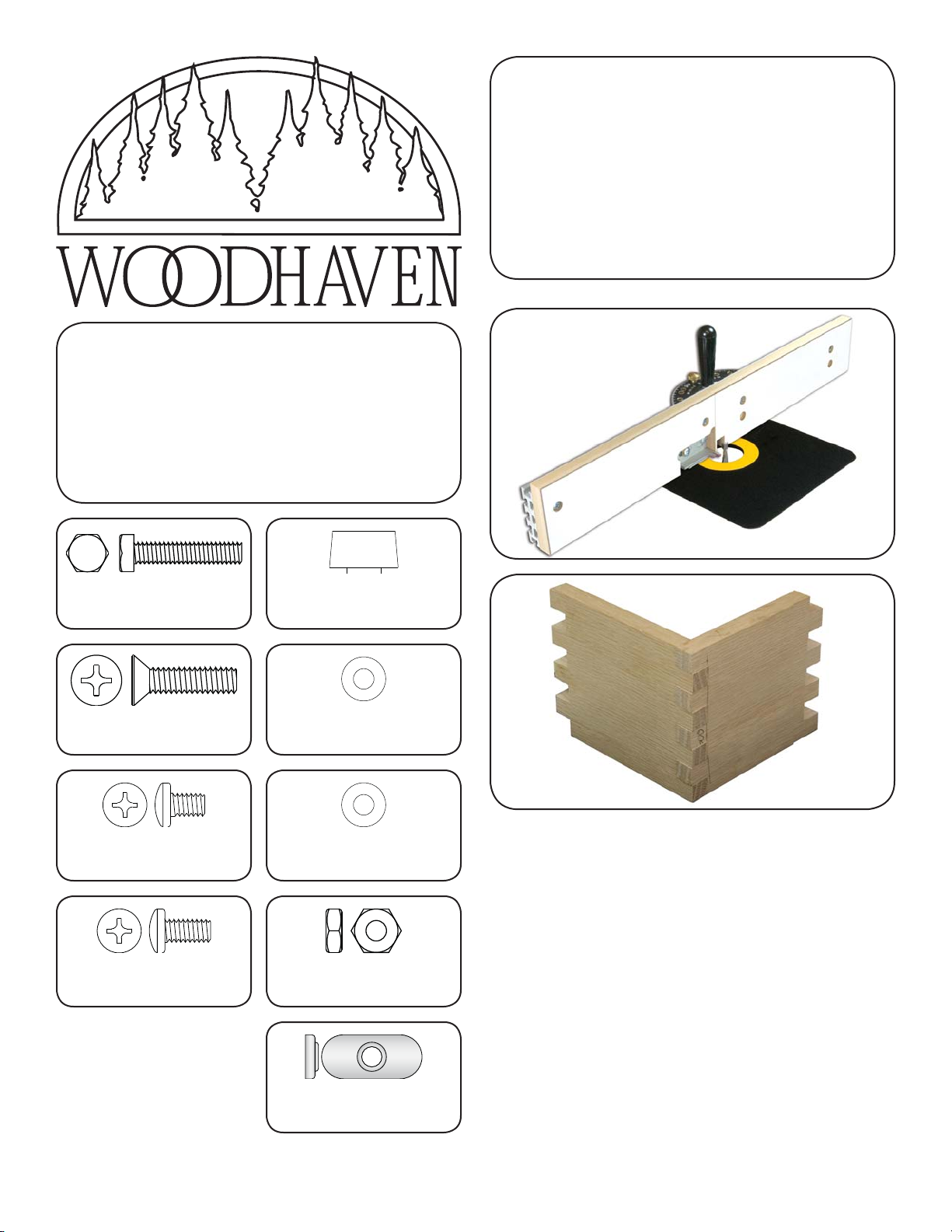

Woodhaven 4555 User Manual

Parts List

Please identify and verify that you have all of the hardware

prior to assembly. Parts listed in this box are not shown in

the hardware drawings. Refer to photos in the instructions:

Part Description Quantity

4555A 24” Ultra Track . . . . . . . . . . . . . . . . . . . . 1

4555F MDF Sub-Fence, 2 pc. set . . . . . . . . . . . 1

4555S Aluminum Stops, 2 pc. set . . . . . . . . . . 1

4555

Box Joint Jig

Owners Manual

Please Read Carefully!

Part# Description Qty.

HB040 1-1/4” Bolt 2

Part# Description Qty.

MF015 1” Screw 4

Part# Description Qty.

MP375 3/8” Screw 1

Part# Description Qty.

5770B 1/2” Screw 1

Part# Description Qty.

5540 K nob 2

Part# Description Qty.

WS001 1/2” Washer 2

Part# Description Qty.

WS002 5/8” Washer 2

Part# Description Qty.

NUT007 Nut 2

BEFORE BEGINNING

Identify and verify that you have all the parts

listed. Read the instructions at least once, familiarizing

yourself with the parts before beginning. You’ll

need a #3 Phillips screwdriver for assembly.

The most common router bits for box joints are

1/4”, 3/8” and 1/2” in diameter. 1/2” shank spiral

bits are excellent when cutting solid woods.

Dado blades work best for cuts over 1/2” wide

or cuts that are deeper than the width of the blade,

for example 1/4” wide x 3/4” deep box joints.

The maximum capacity of this jig is 13/16” wide

by 1-5/8”deep and the minimum depth is 1/4”.

Part# Description Qty.

5760B Oval Nut 4

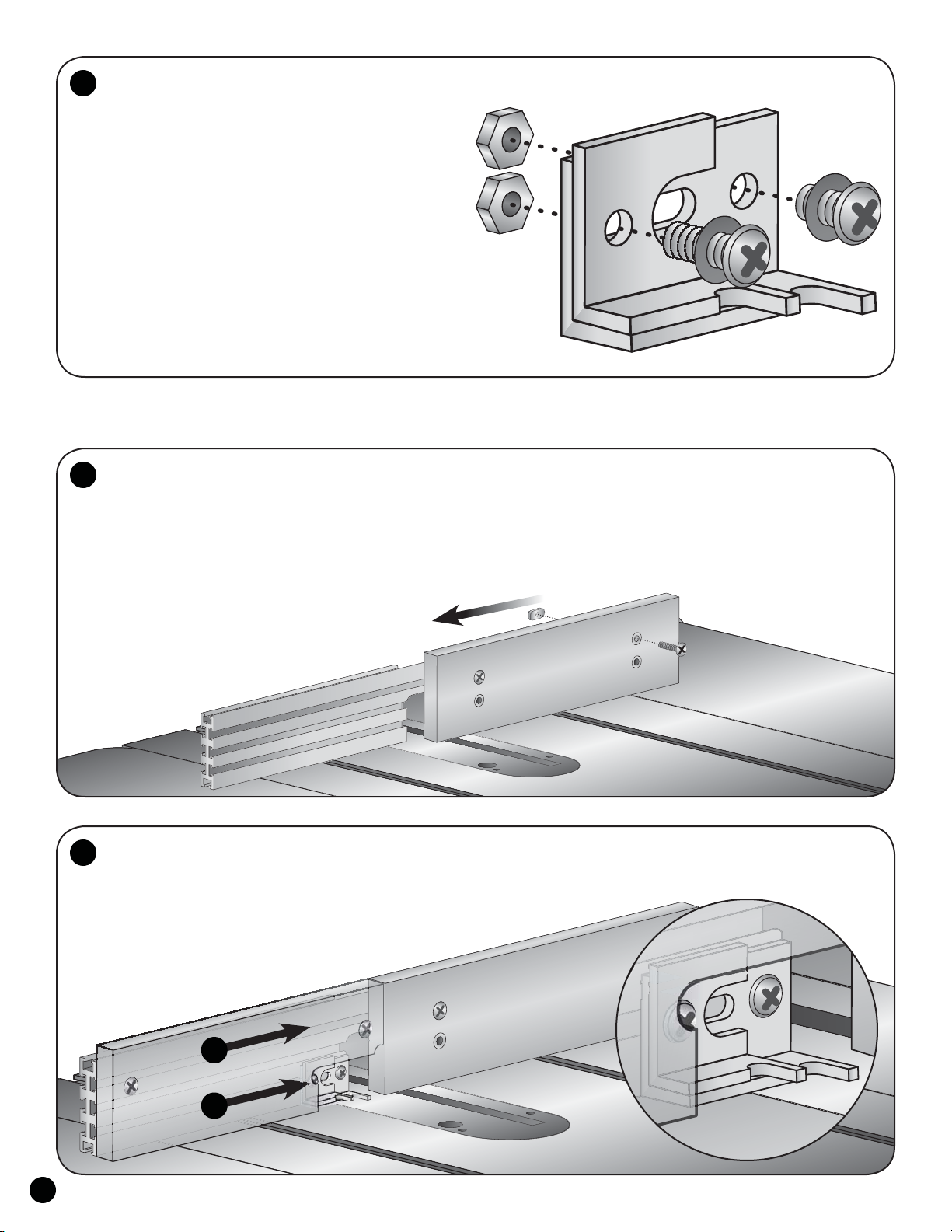

1

STOP ASSEMBLY:

The 4555S Stop is assembled with two aluminum

angle components and hardware: Stationary Stop - angle

with a slot and a hole, and an Adjustable Stop - angle with a

notch and a hole.

Place the Adjustable Stop on top of the Stationary

Stop. Install a washer (WS001) on the 3/8” screw (MP375)

placing it thru the right hand hole in the Stationary Stop,

starting a nut (NUT007) on the other side. Install a washer

(WS001) on the 1/2” screw (5770B) and insert it thru both

the hole of the Adjustable Stop and slot of the Stationary

Stop, starting a nut (NUT007) on the other side.

NUT007 - Nuts

Adjustable Stop -

Front

MP375

WS001

5770B

WS001

Stationary Stop - Rear

2

SUB-FENCE ASSEMBLY:

The 4555F Sub-Fence is a two piece set. Both pieces

are rectangular in shape with one of the pieces having a

rectangular cutout. Install the 1” flathead screws (MF015) into

the countersunk holes in both MDF Sub-Fences (4555F) and

start oval nuts (5760B, raised side first) on the ends of the

screws.

4555A

3

a flat surface, slide the Stops to the right, against the end

of the rectangular Sub-Fence, and tighten both screws.

Install the Stop assembly (A - 4555S) on the

Track by inserting the nuts in the lower T-slot of the

Track. With the bottom edge of the Track resting on

With the bottom edge of the 24” Ultra Track (4555A)

resting on a flat surface, install the rectangular Sub-Fence

(without the cutout) on the Track. The oval nuts will

slide in the upper T-slot of the track. Position the end of

the Sub-Fence even with the end of the track and tighten

the screws. This Sub-Fence has an extra set of holes so it

can be rotated 180º and the opposite end can be used.

4555F

Install the remaining MDF Sub-Fence (B - 4555F

with the cut out) on the track, butted up against

the first Sub-Fence and tighten the screws.

MF015

5760B

B

4555F

A

4555S

1

Loading...

Loading...