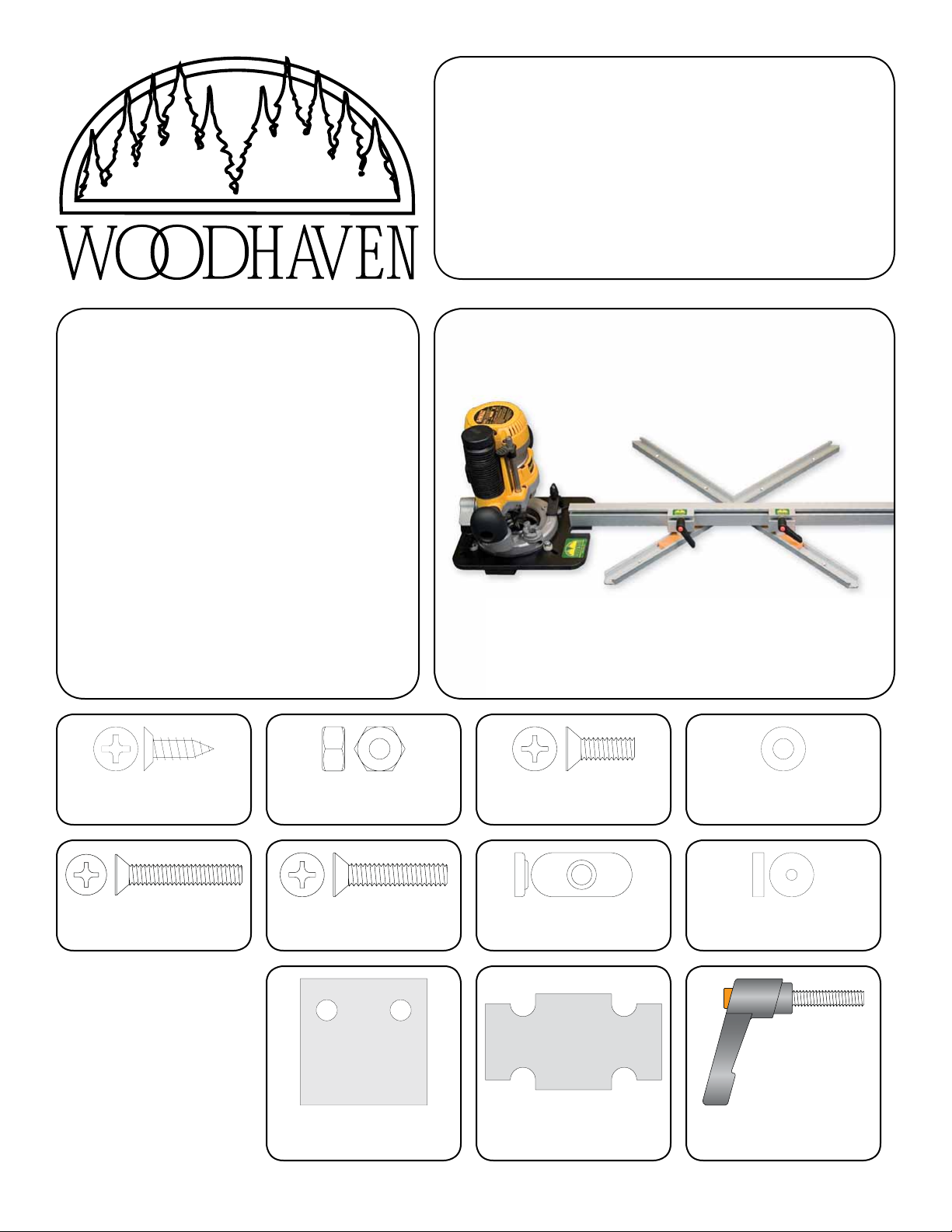

Woodhaven 3230, 3250 User Manual

Parts List:

Please identify and verify that you have all of the

hardware shown below prior to assembly.

Parts listed below are not shown in the hardware

drawings and some parts listed below are model

specific. Refer to photos in the instructions:

Part Description Quantity

3230T 3230 - 12” T-Track . . . . . . . . . . . . . . . . . 4

4036 3230 - 36” Double Track . . . . . . . . . . . . 1

3240T 3240 - 24” T-Track . . . . . . . . . . . . . . . . . 4

4048 3240 - 48” Double Track . . . . . . . . . . . 1

3250T 3250 - 48” T-Track . . . . . . . . . . . . . . . . . 4

4072 3250 - 72” Double Track . . . . . . . . . . . . 1

3250P Pivot Assembly . . . . . . . . . . . . . . . . . . . . 2

3200D Pencil Holder . . . . . . . . . . . . . . . . . . . . . 1

3200P Router Plate . . . . . . . . . . . . . . . . . . . . . . . 1

3200S Plate Spacer . . . . . . . . . . . . . . . . . . . . . . . 1

4973 Router Plate Hardware . . . . . . . . . . . . . 1

3230S 4” Sandpaper Strip . . . . . . . . . . . . . . . . . 1

3230 - 3250

Oval Jig Owners

Manual

Please Read Carefully!

Part# Description Qty.

SFC001 5/8” Screw 24

Part# Description Qty.

MF025 1-1/2” Screw 2

Part# Description Qty.

NUT015 1/4-20 Nut 2

Part# Description Qty.

MF020 1-1/4” Screw 2

Part# Description Qty.

3200B Spacer 1

Part# Description Qty.

MF010 3/4” Screw 4

Part# Description Qty.

5760B Oval Nut 2

Part# Description Qty.

3250C Assembly Plate 1

Part# Description Qty.

WB002 Washer 2

Part# Description Qty.

BUSH1250 1/4” Spacer 4

Part# Description Qty.

5863 Ratchet Handle 2

BEFORE BEGINNING

Identify and verify that you have all the parts listed. Read

the instructions at least once, familiarizing yourself with the parts

before beginning. You'll need a #2 & #3 Phillips screwdriver

and a framing square or measuring tape for assembly.

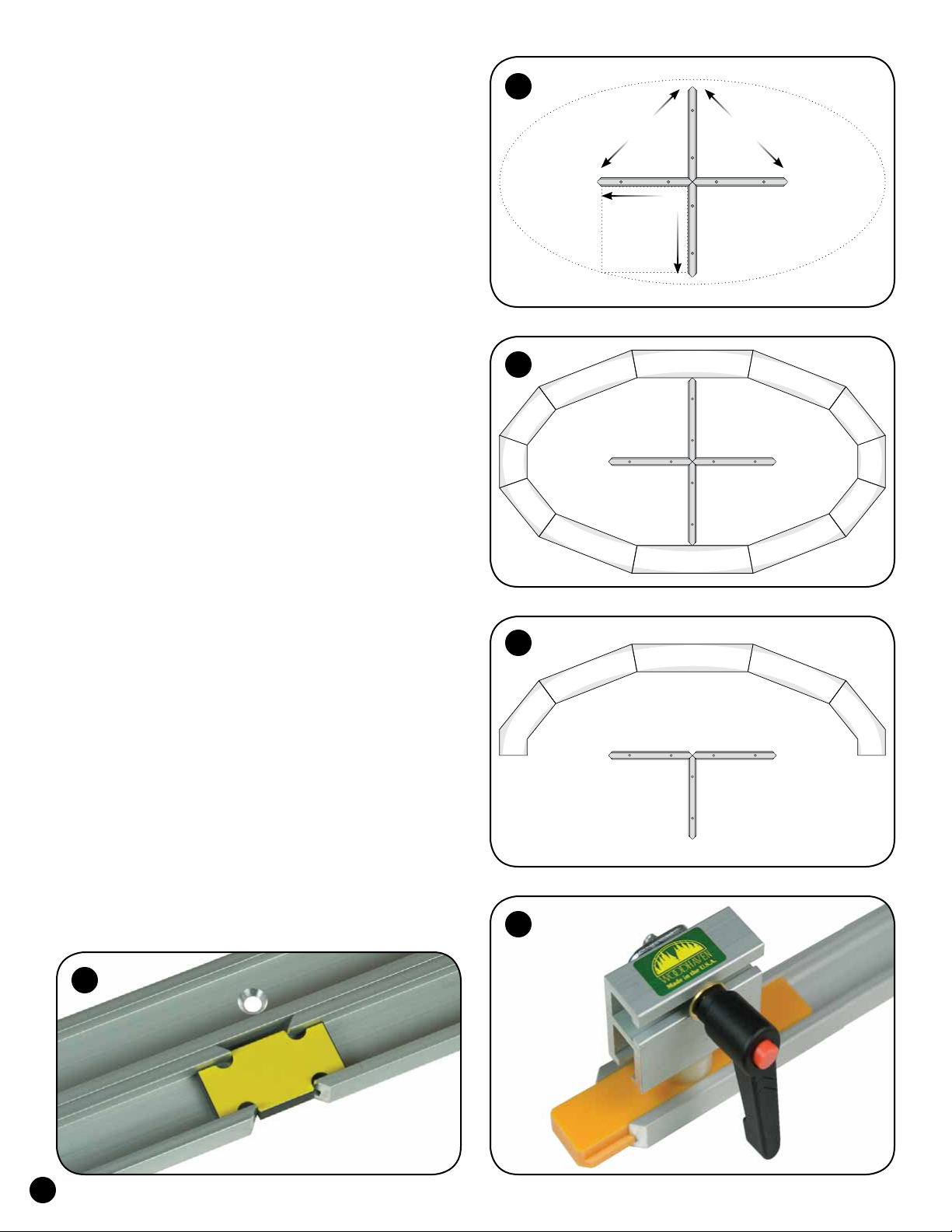

DETERMINE USE

There are several ways to mount the T-Tracks, depending on

the desired work setup. The top of the T-Tracks must also be mounted

at one of three different heights in relation to the top of the work: 1.

At the same height as the top of the work. 2. 1/2" above the work.

3. 1" above the work. Keep in mind that the higher above the work

you mount the tracks, the longer bit you’ll need to make the cut.

Option A: T-Tracks are mounted directly on (1/2" above) the work,

for example a solid table top. Or mount the T-Tracks to a 1/2"

plywood base (1" above), then mount the plywood to the work.

Option B: T-Tracks (and/or plywood base) and work are mounted on a

bench and the work surrounds the tracks, for example a segmented open

frame. Tracks must be even with top of work, 1/2" above or 1" above.

Option C: Mount three T-Tracks if only half an oval (or less) is needed.

Tracks must be even with top of work, 1/2" above or 1" above.

ASSEMBLY

Mark the center of your work, or center the tracks on a square

piece of 1/2" plywood to serve as a base. Depending on the Oval

Jig model purchased, you’ll need the following size square piece of

plywood to mount the T-Tracks to: 3230: 17-1/8" square, 3240: 341/8" square, 3250: 68" square (requires two pieces of plywood joined

together), 60" or 48" square (won’t allow use of all mounting holes).

Align the pointed ends of two T-Tracks (3230T, 3240T or 3250T,

depending on model) together at the center to form one continuous

track. Take the assembly plate (3250C) and insert it between both tracks

and snug the tracks against the assembly plate. Use a third track as a

straightedge to align the two tracks in a straight line. See fig. 1.

Drill pilot holes with a self-centering bit and fasten the T-Tracks

to the work, or plywood base, using the 5/8" screws (SFC001). Remove

the assembly plate and place the two remaining tracks so the points

intersect with the two tracks just installed. Using a framing square,

or measuring from corner to corner, position the tracks so they're

square to each other and fasten with the 1/2" screws. See fig. A.

A

Equal

Measurements

Square

B

C

2

1

1

Loading...

Loading...