Wolo MCHWK-2 User Manual

MODEL MCHWK-2

Air Horn Wiring Kit

Kit Is Designed For An Easy Hook-Up T o The Vehicle’ s Factory

Horn System For any 12-Volt Motorcycle, Car or Truck

INSTALLATION INSTRUCTIONS

Your purchase of a Wolo air horn wiring kit is a perfect choice for an easy and professional installation of any direct drive

air horn (no air tank) to the vehicle’s factory horn system. Wolo’s products are manufactured with the finest materials.

Each wiring kit is tested to insure it meets all manufacturing specifications, before it is packaged.

If you need help installing this product, our technicians are available to answer your questions,

Monday through Friday from 9 AM to 4 PM ESTby calling 1-888-550-HORN (4676).

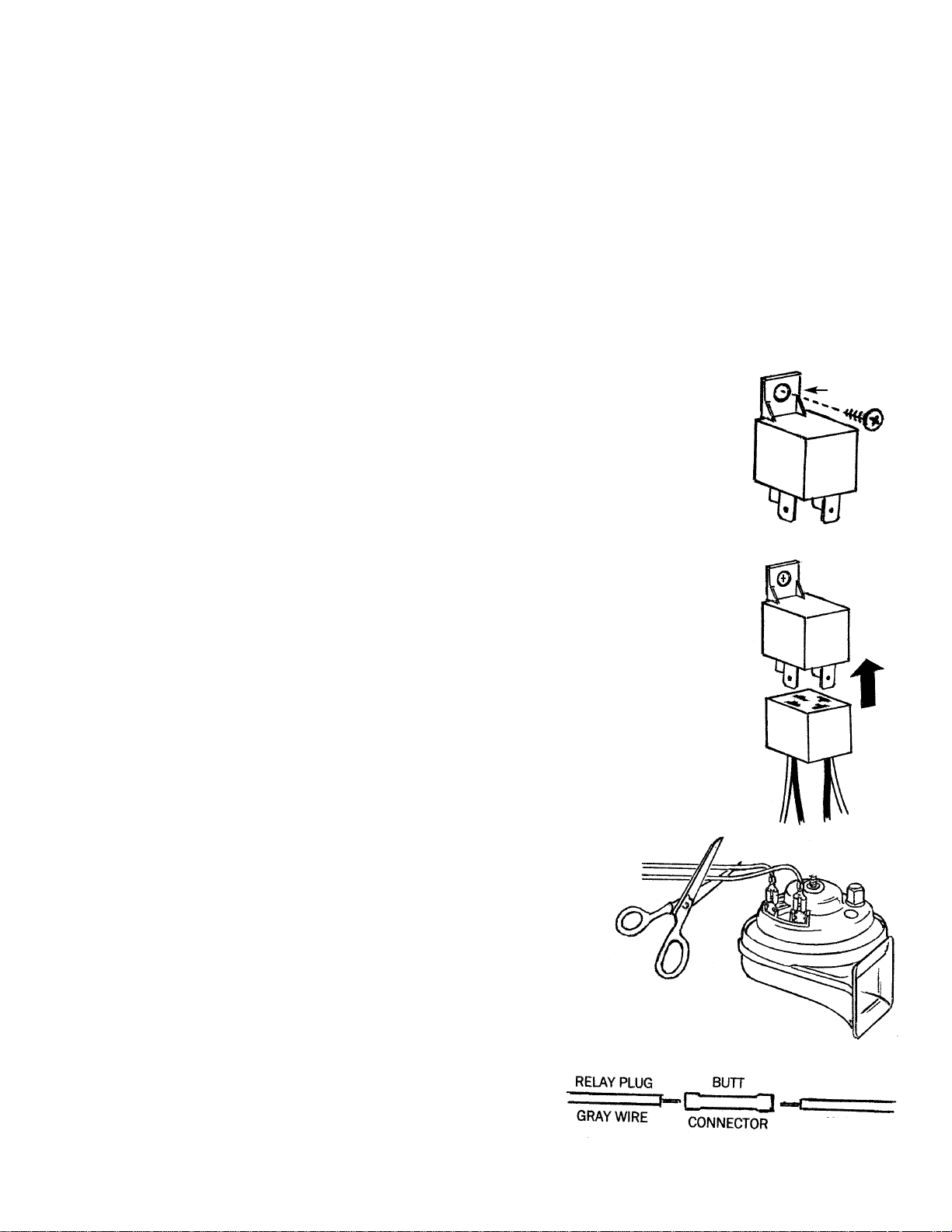

MOUNTING RELAY Fig. #1

(Relay is not included in kit)

1. The relay that was provided with your horn needs to be mounted in a dry location with the

terminals facing downward.

2. Use the relay’s mounting bracket as a template, mark the hole location and drill to size 1/8”.

3. Secure the relay to the mounting location using the sheet metal screw provided.

CONNECT PLUG TO RELAY Fig. #2

4. Connect the wiring kit’s square female plug to the relay. NOTE: The plug can only mate with

the relay in one position.

TWO WIRE FACTORYHORN SYSTEM Fig. #3-5

If your factory horn has two separate wires connected to it, follow instructions below starting at

number 5. If your factory horn has one wire connected to it proceed to step number 11.

5. GRAY WIRE: Remove the wires that are connected to your factory horn. Then using the

insulated butt connector provided, you will connect one of the gray wires from the wiring kit’s

plug to one of the factory horn wires. Note: It does not make a difference which factory horn

wire connects to the plug’s gray wire. The terminal on the factory horn wire will need to be

removed. Strip back the wires’plastic insulation so that 1/4” of wire is exposed and insert the

factory horn wire and one of the gray wires fully into the butt connector.

Crimp the connector and make sure that both wires are securely held in the

connector by lightly pulling on each wire while holding the butt connector. See

Fig. #3 & 4

6. GRAY WIRE: Using the insulated butt connector provided, connect the other

gray wire from the wiring kit plug, to the other factory horn wire. Follow the

same procedure as step #5.

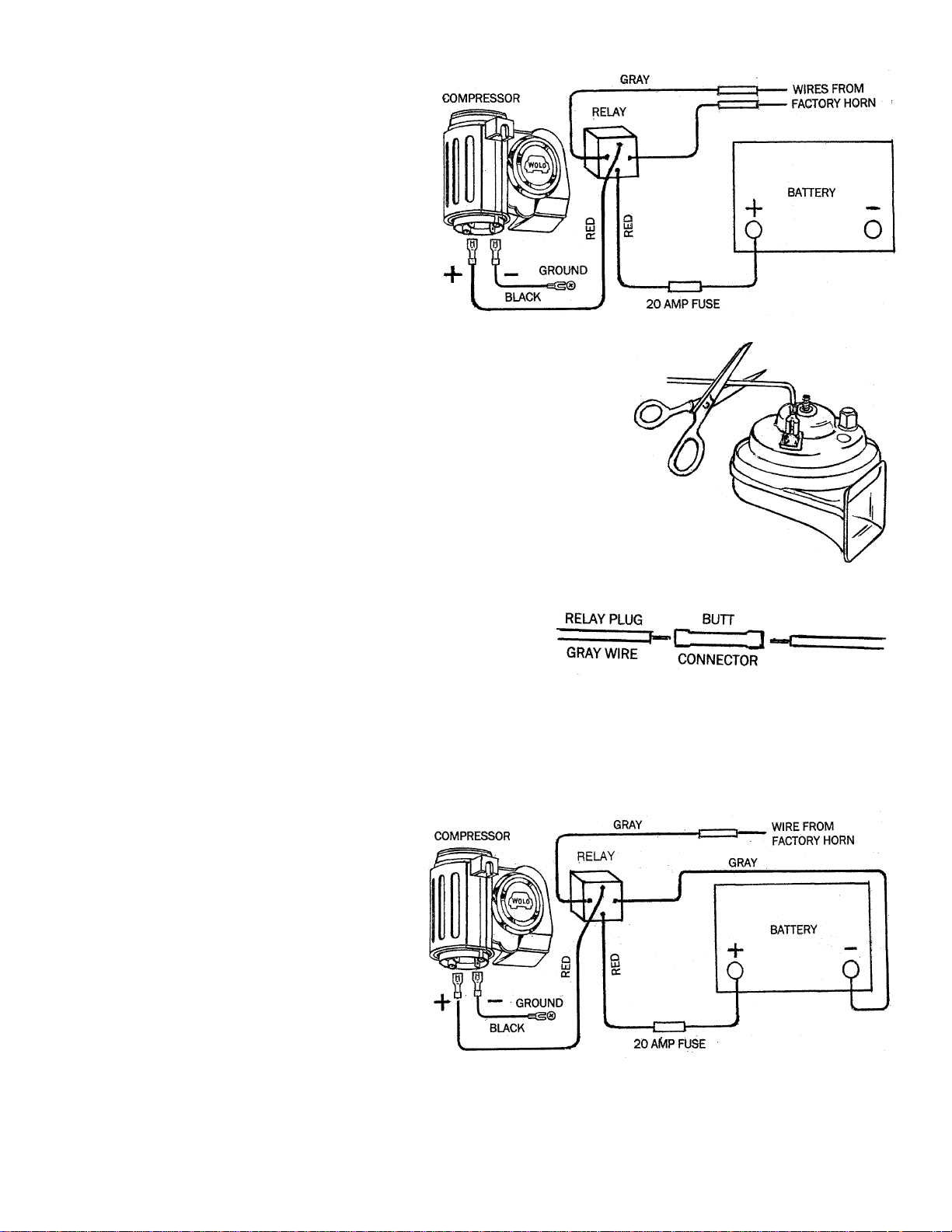

7. RED WIRE with inline fuse: Is connected to POSITIVE (+) 12-volts such as the

battery, alternator and etc. See Fig. #5

8. RED WIRE without inline fuse: Is connected to the compressor terminal marked positive or (+). Cut

the red wire to length and strip back the plastic insulation so that 1/4” of wire is exposed. Insert the wire

into the 1/4” female push-on terminal and crimp terminal. Make sure

that the wire is securely held in the terminal by lightly pulling on the

wire while holding the terminal. Connect the terminal to compressor’s

(+) male terminal. See Fig. #5

9. BLACK WIRE: Is connected to the compressors (-) terminal and the

other end of the wire will be connected to ground such as the negative (-) battery post or any clean body bolt.. Cut the

Fig. 1

Fig. 2

Fig. 3

Fig. 4

VEHICLE’S FACTORY

HORN WIRE

1/8” hole

Relay not included

black wire to length and strip back the plastic

insulation so that 1/4” of wire is exposed. Insert the

wire into the spade terminal and crimp terminal.

Make sure that the wire is securely held in the

terminal by lightly pulling on the wire while holding

the terminal. Secure the spade terminal to (-) ground.

NOTE: IMPORTANT: Make sure that any paint or

rust is cleaned from bolt and metal surface that will

be in contact with the terminal. (Sheet metal screw

provided if needed.) See Fig. #5

10. Secure all wires using the plastic wire ties provided

to ensure that no wire touches the engine, exhaust

manifold or any moving engine parts. Installation is

complete.

ONE WIRE FACTORYHORN SYSTEM Fig. #6-8

If your factory horn has one wire connected to it proceed to step number 11.

11. GRAYWIRE: Remove the wire that is connected to your factory horn The

terminal on the factory horn wire needs to be removed. Strip back the plastic

insulation of the horn’s wire so that 1/4” of wire is exposed. Insert the factory

horn wire and one of the gray wires from the wiring kit plug, fully into the butt

connector. Crimp the butt connector and make sure that both wires are securely held in

the connector by lightly pulling on each wire while holding the butt connector. See Fig. #6

& 7

12. GRAY WIRE: The other gray wire is connected to (-) ground, such as the negative (-) battery post or

any clean metal body bolt. Cut the gray wire to length and strip back

the plastic insulation so that 1/4” of wire is exposed. Insert the wire

into the spade terminal and crimp terminal. Make sure that the wire

is securely held in the terminal by lightly pulling on the wire while

holding the terminal. Secure the spade terminal to (-) ground

NOTE: IMPORTANT: Make sure that any paint or rust is cleaned from bolt and metal surface that will be in contact

with the terminal. (Sheet metal screw provided if needed.) See Fig. #8

13. RED WIRE with inline fuse: Is connected to POSITIVE (+) 12-volts such the battery, alternator and etc. (Sheet

metal screw provided if needed.) See Fig. #8

14. RED WIRE without inline fuse: Is connected to the compressor terminal marked positive or (+). Cut the red wire to

length and strip back the plastic insulation so that

1/4” of wire is exposed. Insert the wire into the

1/4” female push-on terminal and crimp terminal.

Make sure that the wire is securely held in the

terminal by lightly pulling on the wire while

holding the terminal. Connect the terminal to

compressor’s (+) male terminal. See Fig. #8

15. BLACK WIRE: Is connected to the compressors

(-) terminal and the other end of the wire will be

connected to ground,such as the negative (-)

battery post or any clean metal body bolt. Cut the

black wire to length and strip back the plastic

insulation so that 1/4”of wire is exposed. Insert

the wire into the spade terminal and crimp

terminal. Make sure that the wire is securely held in the terminal by lightly pulling on the wire while holding the

terminal. Secure the spade terminal to (-) ground,. NOTE: IMPORTANT: Make sure any paint or rust is cleaned from

bolt and metal surface that will be in contact with the terminal. (Sheet metal screw provided if needed.) See Fig. #8

16. Secure all wires using the plastic wire ties provided so to ensure that no wire touches the engine, exhaust manifold or

any moving engine parts. Installation is complete.

Fig. 5

Fig. 6

Fig. 7

Fig. 8

VEHICLE’S FACTORY

GRAY

HORN WIRE

Loading...

Loading...