Wolo 860 User Manual

Installation Instructions for

Model 860 AIR RAGE™ AIR TANK & COMPRESSOR

Your purchase of an AIR RAGE Air Tank & Compressor is a perfect choice to power your high-pressure air

horns, tools and accessories. The Wolo name, with more than thirty years of experience, is your guarantee of

a superior horn product. If you need help installing this product, our technicians are available to answer your

questions, Monday through Friday from 9 AM to 4 PM EST by calling 1-888-550-HORN (4676).

IMPORTANT: The compressor comes pre-mounted

to the air storage tank. The installer has the option to

separate the compressor from the tank and mount it

independently.

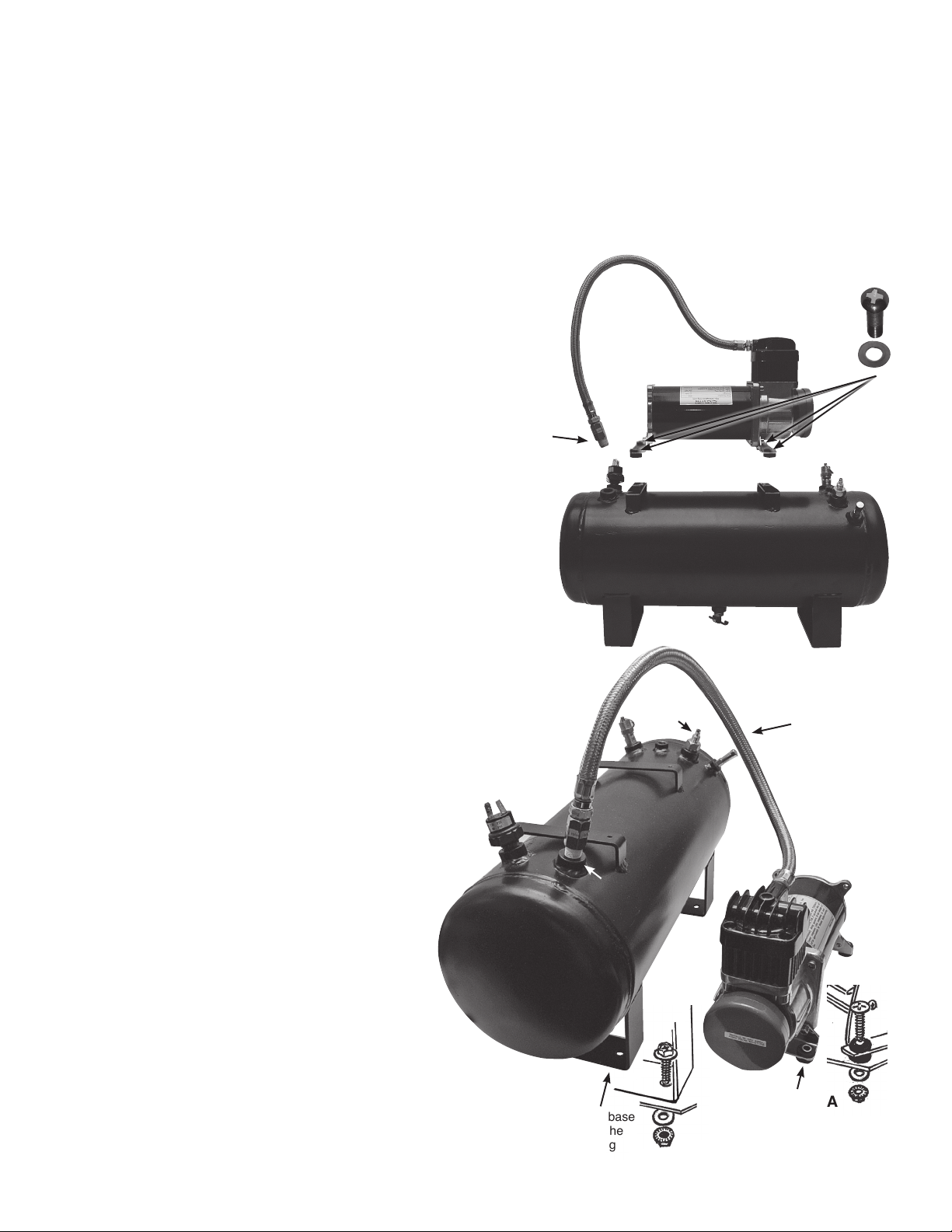

INDEPENDENT COMPRESSOR / TANK MOUNTING

(Fig. 1):

1. If the method of mounting the compressor is to be

independent of the tank, remove the four screws that

secure the compressor to the tank, then disconnect

the braided hose from the tank. You will now be able

to separate the compressor from the tank.

COMPRESSOR and TANK INSTALLATION (Fig. 2):

IMPORTANT! When selecting a mounting location for

the compressor, make sure that the compressor’s

braided hose will be close enough to the tank’s inlet

connection.

COMPRESSOR INSTALLATION (Fig. 2A):

2. Locate a convenient location to mount the

compressor that will be dry. If the location

is the engine compartment make sure

the compressor is safe from the heat of

the exhaust manifold and try to mount

compressor as far to the front of vehicle as

possible to provide optimum airow around

compressor. IMPORTANT! Do not mount

on a plastic fender well, or on exible

material.

3. Using the compressor’s mounting base as

a template, mark the hole locations and

drill to size, use a 3/16” drill bit. Secure the

compressor to the mounting surface using

the hardware provided. (Fig. 2A)

Fig. 1

Disconnect

the braided

hose

Fig. 2

Tank’s

outlet

connection

Tank’s inlet

connection

Remove

the four

screws

Make sure

that the

locations

of the

compressor

and the tank

will be close

enough to

allow the

braided hose

to connect to

tank’s inlet

TANK INSTALLATION (Fig. 2B):

4. The mounting location for the tank should

be easily reachable so that the tank

can be periodically serviced, draining

condensation, water from the petcock

located on the bottom of the tank.

5. Use the tank’s mounting bracket as a

template, mark the hole locations and drill

to size 15/32”. Secure tank with hardware

provided.

Use the tank’s mounting base

Fig. 2B

as a template to mark the

15/32” holes for drilling

Use the compressor’s mounting

Fig. 2A

base as a template to mark the

3/16” holes for drilling

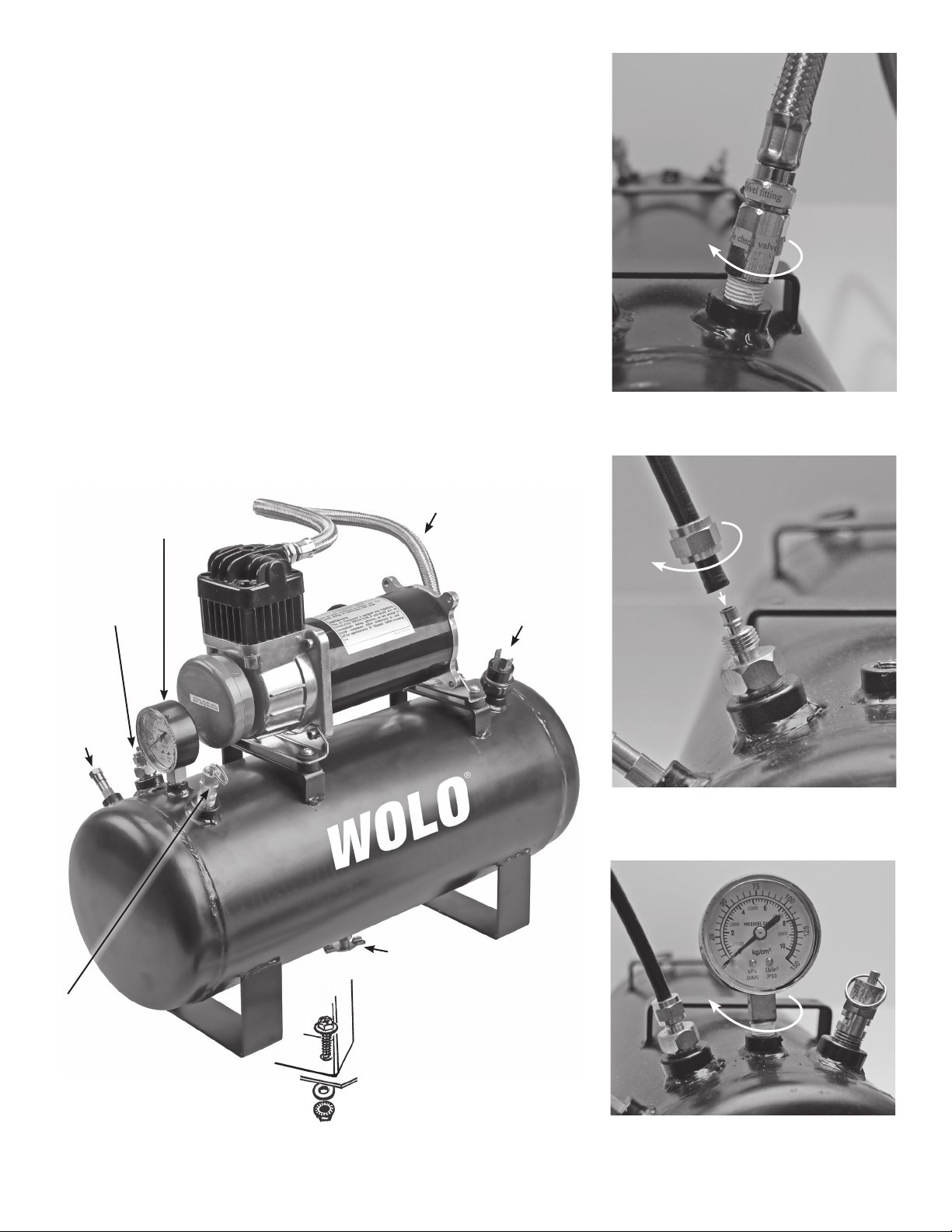

HOSE INSTALLATION (Fig. 3 and Fig. 4):

6. If the compressor was separated from the tank, connect the

stainless steel braided hose from the compressor to tanks inlet

port. (Fig. 3.) IMPORTANT: Make sure the threaded tting

on the end of the braided hose has either been wrapped with

®

Teon

tape or coated with pipe sealant to prevent air leaks.

7. Using the high-pressure plastic hose provided, cut to size to

be able to connect the tank to inlet tting of the accessory or

valve requiring high-pressure air. Place the brass nut from the

tank’s outlet tting onto the high-pressure plastic hose. Push

the plastic hose fully onto the outlet tting, tighten the brass nut

onto the outlet tting. (Fig. 4.).

CAUTION: Do not over tighten the brass nut.

8. The other end of the plastic hose is connected to the accessory

or valve requiring high-pressure air.

PRESSURE GAUGE INSTALLATION (FIG. 5)

9. Install the pressure gauge to tank. IMPORTANT: The threads of

®

the gauge have been wrapped with Teon

tape to prevent air

leaks, do not remove the tape. CAUTION: Do not over tighten

the gauge when installing.

Turn

clockwise

Fig. 3 Connecting the metal braided hose

High-pressure

tank outlet

Schrader

Valve-

to connect

to 20’

coiled

hose

Pressure

Gauge

Braided

hose

Turn brass nut

clockwise

Pressure

Switch

Fig. 4 Connecting the high-pressure

plastic hose

Turn

clockwise

Pressure

relief

valve

Use the tank’s mounting base

as a template to mark the

15/32” holes for drilling

Petcock

should be easily

reachable so that

the tank can be

periodically serviced

Shown above: Compressor mounted on the tank

Fig. 5 Connecting the pressure gauge

Loading...

Loading...