Wolo 842 User Manual

INSTALLATION INSTRUCTIONS ORIENT EXPRESS

Train Horn & On-Board Air System Model 842

Your purchase of a Wolo’s Orient Express Horn is your perfect choice to compliment your vehicle. Wolo‘s products are

manufactured with the finest materials. Each horn is tested to insure it meets all manufacturing specifications, before it is

packaged. If you need help installing your new Wolo horn, our technicians are available to answer your questions, Monday

thru Friday, 9 AM to 4 PM EST by calling 1-888-560-HORN (4676).

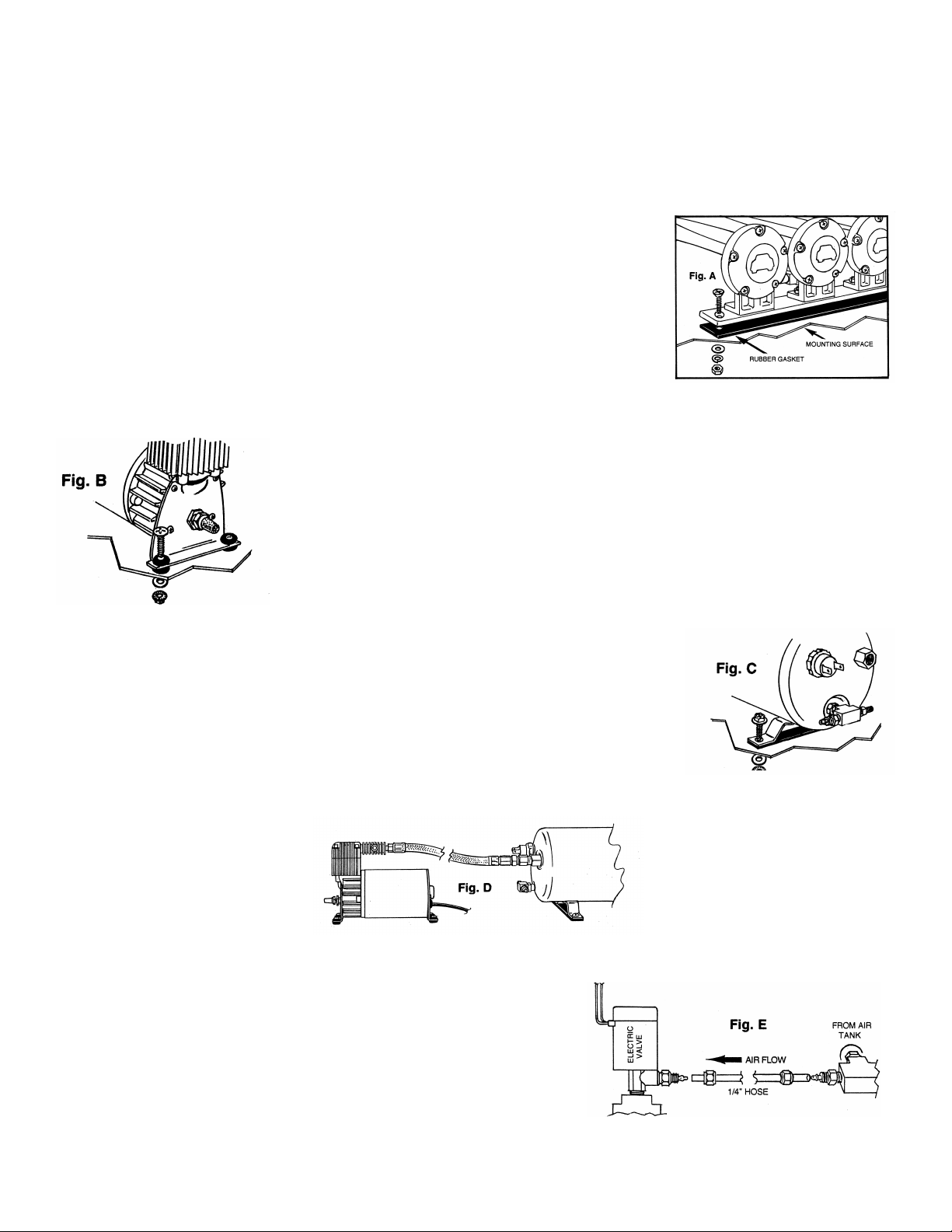

HORN INSTALLATION (Fig. A)

1. Locate a mounting location that is a solid metal surface such as the vehicle’s frame

or chassis to help prevent excessive vibration, which could damage the horn.

IMPORTANT: Do not mount horn on fender well or flexible material. For best results,

the front of the horn should be unobstructed so that the sound can project to it’s maximum.

2. Use the base of the horn as a template, mark the hole locations and drill to size9/64”.

3. Place the gasket between the mounting surface and the base of the horn.

4. Secure the horns with the hardware provided and tighten screws evenly.

COMPRESSOR INSTALLATION (Fig B)

5. Locate an area in the engine compartment that is dry and safe from the heat of the

exhaust manifold heat. Try to mount compressor as far to the front of vehicle

as possible to provide a good airflow around compressor. IMPORTANT! Do not mount

on fender well or other flexible material.

6. Using the compressors mounting brackets as a template, mark the hole locations and

drill to size 13/64”. Secure the compressor to the mounting surface with the hardware

provided.

TANK INSTALLATION (Fig C)

7. Locate a convenient area in the vehicle to mount the air storage tank. IMPORTANT!

When selecting a mounting location for the tank, make sure that the compressor metal

braided hose is close enough to connect to the tanks brass female fitting.

8. Use the tanks mounting bracket as a template, mark the hole locations and drill to size

15/64”. Secure tank with hardware provided using the rubber gasket to prevent vibration noise

HOSE INSTALLATION

19. Connect the metal braided hose from the compressor to the tanks female brass inlet fitting. (Fig D).

10. Using the plastic hose provided, cut to size to connect the tank to

the horn’s electric solenoid valve. Place the brass nut onto the

hose. Push the hose onto the tank’s male fitting. Tighten the brass

nut onto outlet fitting. CAUTION: Do not over tighten brass nut.

(Fig E).

11. Place the brass nut onto the hose. Push the hose onto the electric

solenoid valve‘s male fitting. Tighten the brass nut onto outlet fitting.

CAUTION: Do not over tighten brass nut. (Fig E).

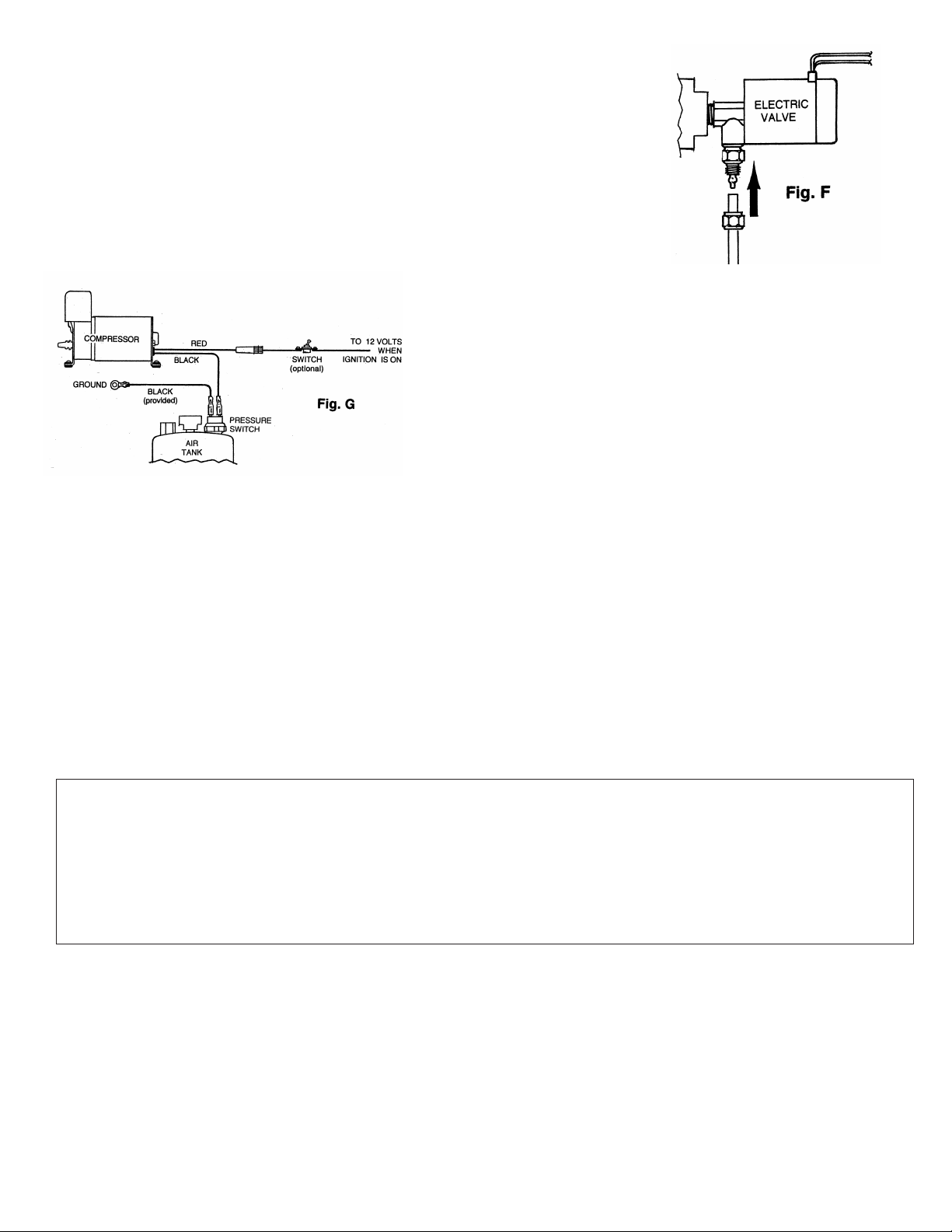

ELECTRIC VALVE WIRING (Fig. F)

12. Connect one (1) wire from the electric solenoid valve to the positive (+) battery termi-

nal, alternator and etc. Always protect this electrical circuit with a three (3)-amp fuse

(not included).

13. Connect the other wire of the electric solenoid valve to the horn switch

14. Connect the horn switch’s other terminal to ground, any metal body bolt that is clean

of paint and rust.

WIRING COMPRESSOR (Fig. G)

15. The compressor’s red wire is connected to (+) 12-volt power

source using the fuse provided. IMPORTANT! The red wire must

be connected to a (+) 12-volt power source only when the vehicle

ignition is turned on. This will protect your compressor from running

continuously and being damaged if an air leak develops when the

vehicle is not in operation. Suggested connection points are: blower

motor, windshield wiper motor or accessory terminal on the fuse

panel. Make sure the connection point has a wire that is as heavy

as the compressor wire.

OPTIONAL: A switch can be installed into the compressor’s red

wire. This will permit the driver to turn-off the system if it is not

required.

16. The compressor’s black wire is connected to one of the terminals of the pressure switch on air tank. (Fig 5).

17. Connect the short black length of wire provided to the other terminal of the pressure switch.

18. The other end of the black wire is connected to ground; secure the wire’s terminal to either the (-) side of vehicles

battery or under any metal body bolt. Make sure that ground connection is free of rust and paint.

NOTE: The compressor is now ready to be used and will automatically start when the pressure drops in the tank. The

built-in regulator will automatically turn off the compressor when the tank pressure is approximately 110 p.s.i. If the compressor does not shut off after 4 minutes of running time, check all air hose connections for leaks. Use soapy water or

bubble solution on each fitting while the compressor is pumping. Use a thread sealant if leak persists after tightening.

CAUTION: Do not touch compressor or fittings with bare hands during or immediately after usage, they will be hot.

IMPORTANT! Compressor is equipped with THERMAL OVERLOAD PROTECTOR. If unit should shut off automatically

during operation, do not attempt to restart compressor. Allow compressor to cool off for approximately 40 minutes before

resuming use.

WARRANTY

Wolo Manufacturing Corporation (“Wolo”) warranties to the original purchaser, for three months from the date of purchase, that this product is free from defects in workmanship and materials. If there is such a proven defect, Wolo, at

its option, will either repair or replace the item free of charge, if it is returned to Wolo within three months from the date

of purchase together with proof of purchase as described below. Wolo reserves the right to inspect any defect prior to

settling any warranty claim by repair or replacement. This warranty is limited as above provided and Wolo will not be

responsible for fire or other casualty or accident, due to neglect, abuse, abnormal use, modifications, faulty installation

of this product, or natural causes.

ANY EXPRESSED WARRANTY NOT PROVIDED HEREIN IS EXCLUDED AND DISCLAIMED. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY LIMITED TO

A TERM OF THREE (3) MONTHS. UNDER NO CIRCUMSTANCES SHALL WOLO BE LIABLE TO PURCHASER OR ANY

OTHER PERSON FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES, WHETHER ARISING OUT OF BREACH OF

WARRANTY OR OTHERWISE.

To obtain warranty service, return the product prepaid, and include the original bill of sale showing the date of purchase.

Provide with the return a brief description of the problem. Also, include with the return a check or money order in the

amount of $10.00 to cover return shipping. Mail to:

Wolo Manufacturing Corp.

One Saxwood Street, Deer Park, NY 11729

Attn: Warranty Service

E-mail: tech@wolo-mfg.com

©0 2006 Wolo Mfg. Corp All Rights Reserved.

Loading...

Loading...