Wolo 815 User Manual

Your purchase of a Wolo’s Challenger Horn System is a perfect choice to

compliment your vehicle. Wolo’s products are manufactured with the finest

materials. Each horn is tested to insure it meets all manufacturing specification,

before it is packaged. If you need help installing your new Wolo horn, our

technicians are available to answer your questions, Monday through Friday from

9 AM to 4 PM EST by calling 1-888-550-HORN (4676).

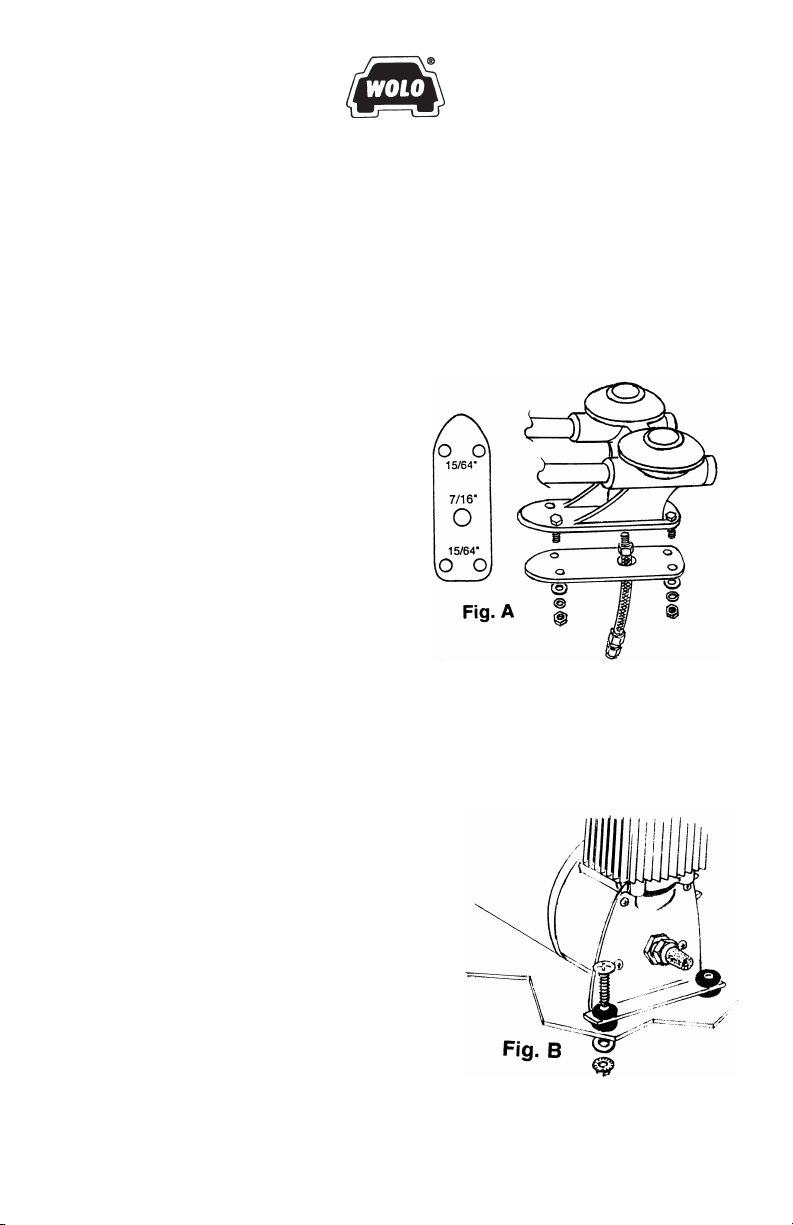

HORN INSTALLATION (Fig. A)

1. Locate the desired area you wish to

mount the dual trumpet air horn. For best

results, the front of the horn should be

unobstructed so that the sound can carry

straight ahead.

2. Use the horn’s rubber gasket as a

template, mark hole locations and drill to

sizes as shown in Fig. A.

3. Secure the horn with the hardware

provided. Tighten screws evenly to

provide a good watertight seal..

4. Secure the flexible inlet hose into the

base of the horn base. Do not remove

the Teflon tape on the threaded end of the hose. The tape is used to help

prevent air leaks.

CAUTION: Avoid making any kinks or sharp bends in

flexible hose that will reduce airflow and alter the horn’s sound.

COMPRESSOR INSTALLATION (Fig. B)

5. Locate an area in the engine compartment

that is dry and safe from the heat of the

exhaust manifold heat. Try to mount

compressor as far to the front of vehicle as

possible to provide a good airflow around

compressor.

IMPORTANT! Do not mount on fender well

or other flexible material.

6. Using the compressors mounting brackets

as a template, mark the hole locations and

drill to size. 15/64’’. Secure the compressor

to the mounting surface with the hardware

provided.

INSTALLATION INSTRUCTIONS

For Model 815

CHALLENGER LV

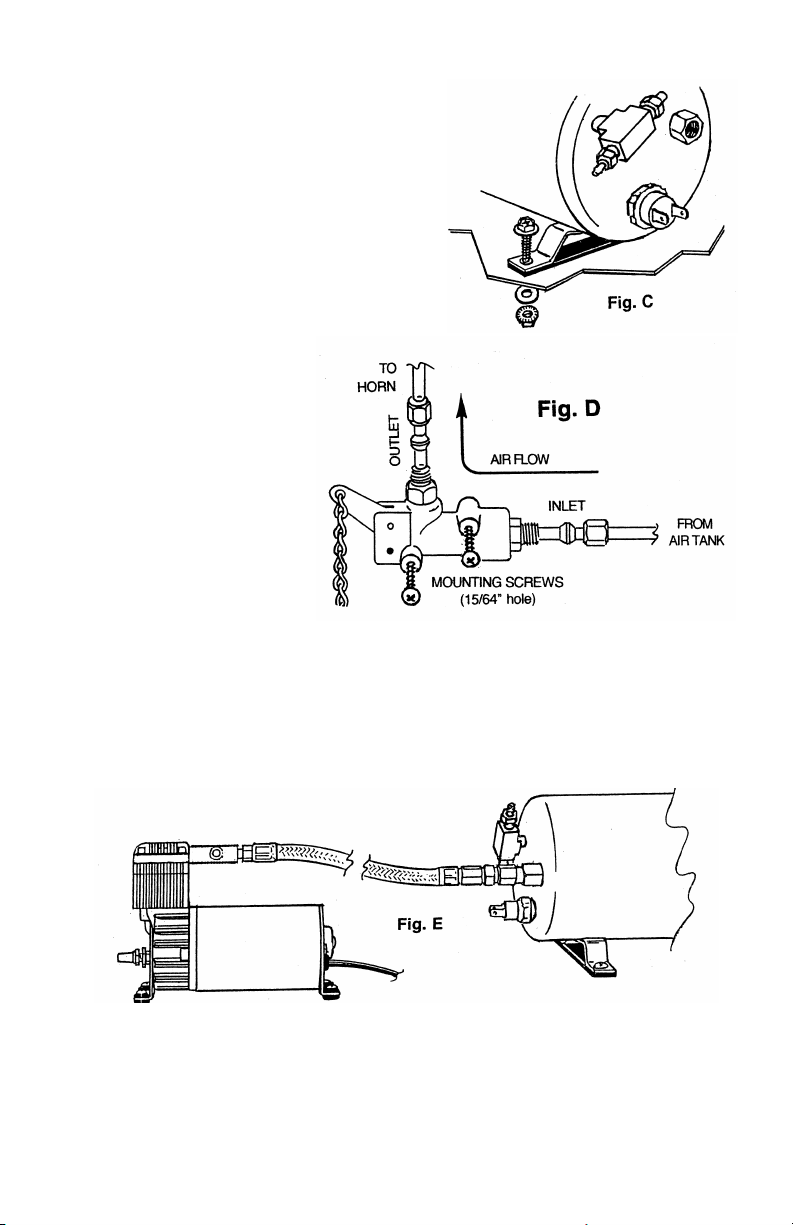

TANK INSTALLATION (Fig. C)

7. Locate a convenient area in the vehicle to

mount the air storage tank.

IMPORTANT!

When selecting a mounting location for the

tank, make sure that the compressor metal

braided hose is close enough to connect to

the tanks brass female fitting.

8. Use the tanks mounting bracket as a

template, mark the hole locations and drill

to size 15/64”. Secure tank with hardware

provided using the rubber gasket to

prevent vibration noise.

LANYARD VALVE

INSTALLATION (Fig. D)

9. Mount the lanyard valve

with the screws provided

in a convenient location

so that the chain can be

easily reached. Using the

lanyard valve as a

template, mark hole

locations and drill to size

5/16”.

IMPORTANT:

When connecting the air

hose to the lanyard valve,

they must be connected

only as shown in Fig. D.

HOSE INSTALLATION (Fig. E)

10. Connect the metal braided hose from the compressor to the tanks female

brass fitting.

11. Using the 1/4” plastic high pressure hose provided, cut to size to connect

the horn’s flexible inlet hose to the lanyard’s outlet fitting.

12. Unscrew the brass-fitting nut from the flexible inlet hose. Place the brassfitting nut onto the hose. Push the hose onto the male fitting of the flexible

hose and tighten the brass nut.

CAUTION: Do not over tighten nut.

13. Connect the other end of the hose to the outlet fitting of the lanyard’s valve.

Follow the same procedure as above number 12.

14. Using the 1/4” plastic high pressure hose provided, cut to size so to connect

the lanyard valves inlet fitting to the tank. Follow the same procedure as

above number 12 to connect hose to the lanyard and tank.

Loading...

Loading...