Wolo 135 User Manual

INSTALLATION INSTRUCTIONS

™

Model 135-24 SEA SAFE

24-Volt

Your purchase of a Wolo SEA SAFE™ Air Horn will complement your boat, while offering an extra level of

protection. Wolo’s products are manufactured with the finest materials. Before being packaged, each horn

is tested to ensure it meets all of our manufacturing specifications. If you need help installing your new Wolo

horn, our technicians are available to answer your questions, Monday thru Friday, 9 AM to 4 PM EST at

1-888-550-HORN (4676).

Before installation of the horn is attempted, it is important to read these instructions completely. The lives of

people can be dependent on a proper installation of the horn. The person doing the installation must have

knowledge of the proper method for mounting and securing the horn to the exterior of the boat as well as

knowledge of the boat’s electrical system. Again, read the instructions completely and note any messages

marked “IMPORTANT” or “WARNING’’. A safe installation will prevent injury or damage to the boat.

WARNING: Installation of the SEA SAFE requires drilling. The installer must carefully inspect both sides of

the selected mounting locations to ensure that there are no wires, fuel lines and or any other components that

could be damaged by drilling.

WARNING: If any wires are routed through drilled holes; always de-burr, ensuring that there are no sharp

edges. Install a rubber grommet into all metal holes that wires are being routed through.

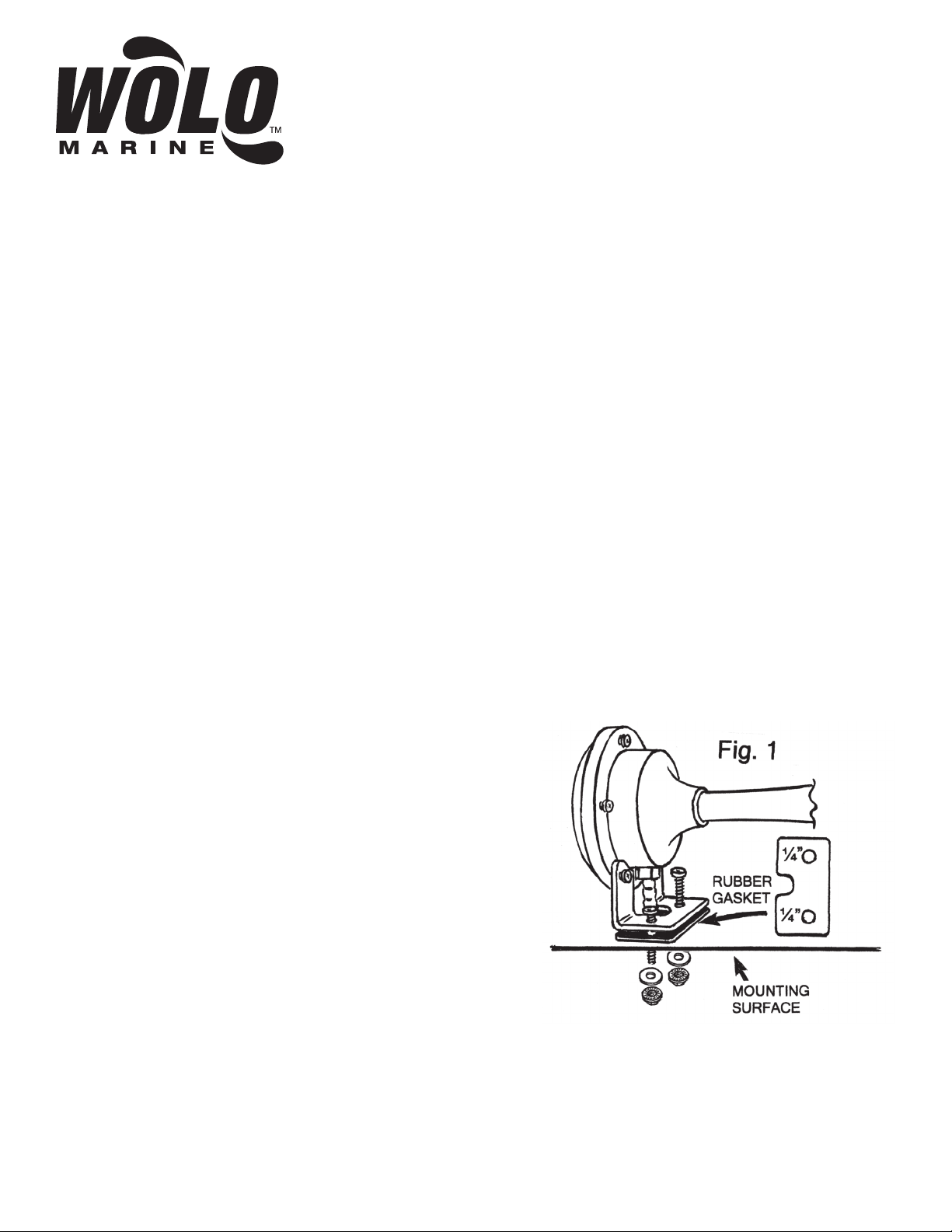

MOUNTING TRUMPET: Fig. 1

IMPORTANT: The horn should be mounted facing forward

whenever possible. The NMMA Certification Program requires

this for boats 39’ or longer.

1. Locate the desired mounting location of the trumpet. For

best results, the front of the horn should be unobstructed so

that the sound can carry straight ahead.

IMPORTANT: FOR BEST PERFORMANCE AND SOUND,

ALWAYS MOUNT THE COMPRESSOR CLOSE TO

TRUMPET, KEEPING THE HOSE LENGTH AS SHORT AS

POSSIBLE. THE COMPRESSOR MUST BE MOUNTED IN A

DRY INTERIOR LOCATION).

2. Use the horn’s gasket as a template, mark hole locations

and drill to size.

3. Mount and secure the horn as shown in Fig. 1. IMPORTANT: Be sure to use the rubber gasket provided to

protect against water leaks. Tighten the screws evenly to ensure a watertight seal.

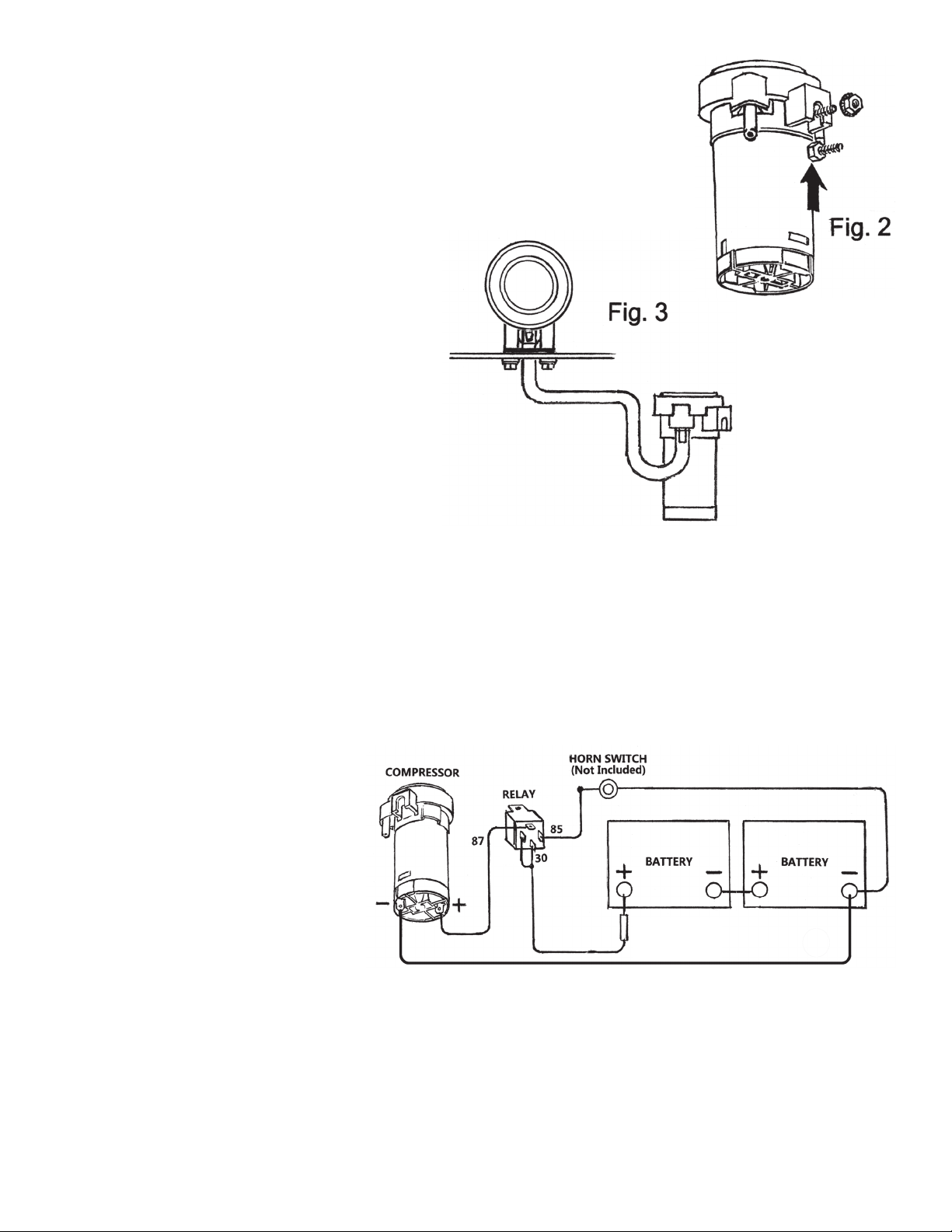

COMPRESSOR INSTALLATION: Fig. 2 & 3

4. Install the compressor in a dry interior location. IMPORTANT: The

compressor should not be mounted further than 30 inches from the

trumpet to ensure best sound.

5. To secure the compressor, drill one 3/16” hole. When possible,

mount the compressor vertically (air outlet on top). Install the head of

the bolt into the mounting bracket’s slot on the side of the compressor.

Secure the compressor using the lock washer/nut provided as shown in

Fig. 2.

6. Using the plastic tubing provided, cut to size

and connect the compressor to the horn’s inlet as

shown in Fig. 3.

WARNING: Avoid making any kinks or sharp

bends in plastic tubing that can reduce air flow

and alter the horn’s sound. For best performance,

always keep the plastic tubing as short as

possible.

WIRING:

ELECTRICAL CONNECTIONS FOR USING A NEW HORN BUTTON SWITCH Fig. 4

7. Install the horn relay provided, located close to the compressor, in a dry interior location with the terminals

facing downward.

8. Connect relay terminal 87 to the compressor’s positive (+) terminal. Use 16-gauge wire or heavier.

9. Connect relay terminal 85 to the horn button switch terminal. (Horn switch not provided).

10. The horn switch’s, other terminal, is connected to negative (-) such as the (-) battery post or any clean

metal negative surface. Use 18 gauge wire or heavier.

11. Connect relay terminal 30 & 86 to

positive (+) 24-volts such as battery,

Fig. 4

alternator, fuse block or etc. Use

16-gauge wire or heavier. IMPORTANT:

Protect the electrical circuit with the

fifteen (15)-amp inline fuse provided.

WARNING: The inline fuse must be

connected directly to the power source.

86

12. Connect the compressor’s negative

(-) terminal to boat’s negative (-) battery

post or any clean metal negative surface.

Use not less than 16-gauge wire.

15 AMP

FUSE

RECAP OF RELAY TERMINAL

CONNECTIONS

Relay terminals 30 & 86: the two terminals are connected to 24-Volts (+) positive, using the 15-amp inline fuse.

Relay terminal 85: is connected to horn switch.

The horn switch’s other terminal: is connected to negative (-) battery post.

Relay terminal 87: is connected to the compressor’s (+) motor terminal.

The compressor’s negative (-) terminal is connected the boat’s negative (-) battery post.

Loading...

Loading...