Page 1

Technical Service Manual

© WOLF APPLIANCE COMPANY, LLC 2005 ALL RIGHTS RESERVED JOB AID #806372 • (Revision B - 2005)

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Wall Oven-2 & Wall Oven-3

Page 2

Page 3

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

1-1

SECTION 1

GENERAL INFORMATION

Page 4

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

1-2

INTRODUCTION

This Wolf Wall Oven Series Technical Service Manual, Part #806372, has been compiled to provide the most recent

technical service information about the Wolf Wall Ovens produced after serial number 11100847. This information

will enable the service technician to troubleshoot and diagnose malfunctions, perform necessary repairs and return a

Wolf Wall Oven Series to proper operational condition.

The service technician should read the complete instructions contained in this service manual before initiating any

repairs on a Wolf Appliance.

NOTE: Refer to the Wall Oven-2 Series Service Parts Manual #806373 for part numbers and exploded views for

units produced prior to serial number 16000000 and Wall Oven-3 Series Service Parts Manual #807041 for units

produced after serial number 16000000 .

IMPORTANT SAFETY INFORMATION

Below are the Product Safety Labels used in this manual. The "Signal Words" used are WARNING and

CAUTION.

Please note that these safety labels are placed in areas

where awareness of personal safety and product safety

should be taken and lists the precautions to be taken

when the signal word is observed.

TECHNICAL ASSISTANCE

If you should have any questions regarding a Wolf

appliance and/or this manual, please contact:

Wolf Appliance Company, LLC

ATTN: Service Department

P.O. Box 44988

Madison, WI 53744-4988

Customer Service

Phone #: (800) 332 - 9513

Technical Assistance

Phone #: (800) 919 - 8324

Parts / Warranty Claims

Phone #: (800) 332 - 9513

Customer Service E-Mail Address

customerservice@wolfappliance.com

Customer Service & Technical Assistance

Facsimile #: (608) 441 - 5887

Parts / Warranty Claims

Facsimile #: (608) 441 - 5886

Office Hours:

7:00 AM to 7:00 PM Central Standard Time

Monday through Friday

This manual is designed to be used by Authorized Service Personnel only. Wolf Appliance Company, LLC.

assumes no responsibility for any repairs made to Wolf appliances by anyone other than Authorized

Service Technicians.

INDICATES THAT HAZARDOUS OR UNSAFE PRACTICES COULD RESULT IN SEVERE PERSONAL

INJURY OR DEATH

Indicates that hazardous or unsafe practices could

result in minor personal injury or product and/or

property damage

In addition, please pay attention to the signal word

“NOTE”, which highlights especially important information within each section.

The information and images are the copyright property of Wolf Appliance Company, LLC, an affiliate of Sub-Zero

Freezer Company, Inc. Neither this manual nor any information or images contained herein may be copied or used

in whole or in part without the express written permission of Wolf Appliance Company, LLC, an affiliate of Sub-Zero

Freezer Company, Inc. © Wolf Appliance Company, LLC all rights reserved.

Page 5

1-3

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

TABLE OF CONTENTS

Page #

Section 1 - General Information

Introduction......................................................................... 1-2

Important Safety Information.............................................. 1-2

Technical Assistance.......................................................... 1-2

Table of Contents............................................................... 1-3

Table of Contents.............................................................. 1-4

Warranty Information......................................................... 1-5

Serial Tag Location............................................................ 1-5

Model Number Key.. ......................................................... 1-6

Model Configurations......................................................... 1-7

Model Configurations......................................................... 1-8

Oven Features................................................................... 1-9

Section 2 -Inst

allation Information

Electrical Requirements..................................................... 2-2

Minimum Wire Size............................................................ 2-2

Oven Installation................................................................ 2-3

Trim Installation.................................................................. 2-3

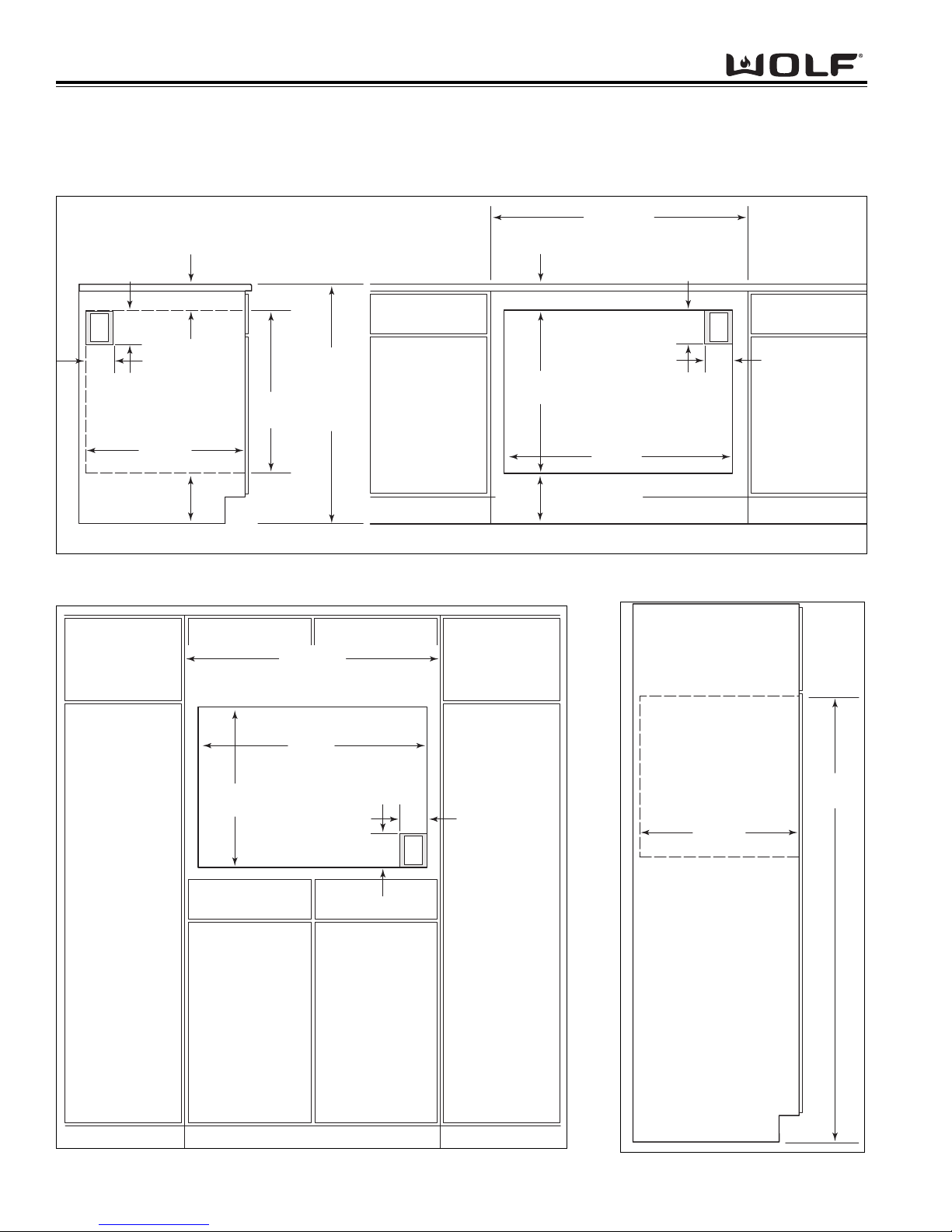

Wall Oven Dimensions....................................................... 2-4

Cabinet Cutout Dimensions............................................... 2-5

SO30........................................................................... 2-5

SO36........................................................................... 2-6

DO30........................................................................... 2-7

Side-by-Side................................................................ 2-8

Section 3 - Electronic Control System

Electronic Control Terminology and Component

Descriptions........................................................................ 3-2

Unique Electronic Control Input Operations....................... 3-3

Field Option Mode........................................................... 3-3

User Preference Offset................................................... 3-3

Temperature Display Preference.................................... 3-3

Clock Display Preference.................................................3-3

Sabbath Feature............................................................. 3-4

Time Cook Feature......................................................... 3-5

Delayed Start Feature..................................................... 3-6

Temperature Probe Mode............................................... 3-7

USDA Internal Temperature

Recommendations Chart................................................ 3-7

Self-Clean Mode............................................................. 3-8

Electronic Control Input Operations................................... 3-9

Bake Mode..................................................................... 3-9

Convection Mode...........................................................3-10

Convection Bake Mode................................................. 3-11

Broil Mode..................................................................... 3-12

Convection Broil Mode................................................. 3-13

Roast Mode.................................................................. 3-14

Convection Roast Mode................................................ 3-15

Bake Stone Mode.......................................................... 3-16

Dehydrate Feature.........................................................3-17

Proof Feature.......................................................... 3-18

Panel Lock..................................................................... 3-19

Time of Day Clock......................................................... 3-19

Diagnostics Mode............................................................. 3-19

Double Wall Oven Keyboard......................................... 3-19

Single Wall Oven Keyboard...........................................3-19

Page #

Section 3 - Electronic Control System (Continued)

Initiating Diagnostic Mode..............................................3-20

Possible Error Indicators............................................... 3-21

Testing The Oven Relay Board..................................... 3-24

Element Testing............................................................. 3-24

Fan and Motor Testing................................................. 3-25

RTD Testing................................................................... 3-25

Temperature Probe Testing............................................3-25

Section 4 - Component

Access and Removal

Important Warnings............................................................ 4-2

Control Panel Components................................................ 4-3

Control Panel Assembly ................................................ 4-3

Control Panel Drive Motor............................................... 4-3

C-Channel Top and Bottom............................................ 4-4

Switch Actuator and Plunger........................................... 4-4

Components Behind the Control Panel.............................. 4-5

Latch Cover..................................................................... 4-5

Motor Door Lock............................................................. 4-5

Limit Switch.................................................................... 4-5

Oven Control Board........................................................ 4-6

Stepper Motor Control Board......................................... 4-6

Relay Board.................................................................... 4-7

Light Transformer............................................................ 4-7

Light Fuse....................................................................... 4-7

Upper Cooling Fan......................................................... 4-8

Terminal Block................................................................ 4-8

Oven Cavity Components.................................................. 4-9

Left and Right Rack Guide.............................................. 4-9

Oven Lights..................................................................... 4-9

Convection Baffle Plate.................................................. 4-9

Probe Cover and Probe Switch......................................4-10

Temperature Sensor.......................................................4-10

Convection Fan..............................................................4-11

Broil Element and Broil Pan...........................................4-11

Smoke Catalyst.............................................................. 4-11

Bake Stone ....................................................................4-12

Oven Door Components....................................................4-13

Oven Door......................................................................4-13

Door Adjustments...........................................................4-13

Door Gasket...................................................................4-13

Outer Door Skin.............................................................4-13

Glass Pack.....................................................................4-14

Hinge..............................................................................4-14

Hydraulic Hinge............................................................. 4-14

Components Behind the Back Panel............................... 4-15

Back Panel.................................................................... 4-15

Divider Channels........................................................... 4-15

Lower Cooling Fan........................................................ 4-15

Bake Element................................................................ 4-15

Oven Side Components................................................... 4-16

Channel Venting............................................................ 4-16

Hinge Pocket................................................................. 4-16

Enclosure.......................................................................4-16

Insulation........................................................................4-16

Page 6

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

1-4

Section 5 -Troubleshooting Guide

General Troubleshooting Guide Layout................................5-2

Troubleshooting Guide Table of Contents............................5-2

Initiating Diagnostic Mode.....................................................5-3

Error Code Chart..................................................................5-4

Testing The Oven Relay Board............................................5-5

Element Testing....................................................................5-5

Ohm Testing Elements at the Relay Board.......................5-5

Fans and Motors...............................................................5-6

RTD Testing..........................................................................5-6

Probe Testing........................................................................5-6

Troubleshooting Guides........................................................5-7

Troubleshooting Flow Chart..................................................5-9

Head Assembly Doesn’t Rotate Flow Chart.......................5-10

Section 6 -T

echnical Data

Technical Data Chart............................................................6-2

Operation Time Chart...........................................................6-3

Section 7 -Wiring Diagrams

DO30 Wiring Diagram...........................................................7-2

DO30 Schematic...................................................................7-3

SO30 - SO36 Wiring Diagram..............................................7-4

SO30 - SO36 Schematic......................................................7-5

SO30 Schematic (SWS 16000000)......................................7-6

DO30 Schematic (SWS 16000000)......................................7-7

Page 7

1-5

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

WARRANTY INFORMATION

This page contains a summary of the 2 & 5 Year Warranty that is supplied with every Wolf product, followed by

details and notes about the warranties.

TWO & FIVE YEAR Warranty Summary

• Two year TOTAL PRODUCT warranty, *parts and labor.

• Limited Parts Only Warranty for the 3rd through 5th year on the following parts only:

Electric heating elements

Electronic Control Boards

Warranty Details:

The warranty applies only to products installed for normal residential use. The warranty applies only to product

installed in the United States or Canada.

Warranty Notes:

• All warranties begin at the time of the unit’s initial installation.

• All Warranty and Service information collected by Wolf Appliance Company, LLC. is arranged and

stored under the unit serial number and/or the customer’s name. Please note that Wolf Appliance

Company LLC. requests that you have the model serial number available whenever contacting the

factory or parts distributor.

• See Figure 1-1 for serial tag layout.

• See Figure 1-2 for serial tag location.

Figure 1-1. Typical Serial Tag Layout

Figure 1-2. The serial tag is located underneath the control panel.

Wolf Appliance Company, LLC

FITCHBURG, WI

WALL OVEN

FOR HOUSEHOLD USE ONLY

X.X

VOLTS :

Hz :

60

MODEL# : XXXXXX-X

"DO NOT IMMERSE IN WATER" "NE PAS PLONGE DANS L'EAU"

KW :

120/208

120/240

Serial Tag Location

X.X

3 WIRE

SERIAL# : XXXXXXXX

-2

Page 8

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

1-6

MODEL NUMBER KEY

Refer to this key for an example of the model numbers.

Model: SO 30 F / S

Product Type

Size

Fuel

Feature (If Applicable)

Finish

Product T

ype

SO Single Oven

DO Double Oven

CT Cooktop

Size

30 30 - inch wide unit

36 36 - inch wide unit

Fuel

E Electric

Oven Door

F Framed

U Unframed

Finish

S Classic Stainless Steel

P Platinum Stainless Steel

B Carbon Stainless Steel

Page 9

1-7

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

MODEL CONFIGURATIONS

30” Single Oven Framed

Model Number Description

SO30F/S Single Oven 30” Framed Stainless

Model Number Description

SO30U/S Single Oven 30” Unframed Stainless

SO30U/P Single Oven 30” Unframed Platinum

SO30U/B Single Oven 30” Unframed Carbon

Single Ovens

36” Single Oven Unframed

Model Number Description

SO36U/S Single Oven 36” Unframed Stainless

SO36U/P Single Oven 36” Unframed Platinum

SO36U/B Single Oven 36” Unframed Carbon

Page 10

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

1-8

30” Double Oven Framed

Double Ovens

30” Double Oven Unframed

Model Number Description

DO30F/S Double Oven 30” Framed Stainless

Model Number Description

DO30U/S Double Oven 30” Unframed Stainless

DO30U/P Double Oven 30” Unframed Platinum

DO30U/B Double Oven 30” Unframed Carbon

Page 11

1-9

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

• Two door styles

Traditional Framed (30”)

Contemporary Unframed (30” & 36”)

• Framed door finish

Classic Stainless Steel

• Unframed door finishes

Classic Stainless Steel

Platinum Stainless Steel

Carbon Stainless Steel

• Dual Convection Logic Control System

• Rotating Control Panel

• Touch Control Panel

• Door Hinge with Hydraulic Damper System

• Large Viewing Window

• Triple Pane Window

• Dual Halogen Lighting

• Temperature Probe and Receptacle

• Six Level Rack Guide

• Full Extension Bottom Rack

• Hidden Bake Element

• Broil Element

• Bake Mode

• Convection Mode

• Convection Bake Mode

• Broil Mode

• Convection Broil Mode

• Roast Mode

• Convection Roast Mode

• Bake Stone Mode (Bake Stone Optional)

• Dehydrate Feature (Dehydrate Kit Optional)

• Proof Feature

• Self-Clean Mode

• Sabbath Mode

OVEN FEATURES

Page 12

General Information

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

1-10

Page 13

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

2-1

SECTION 2

INSTALLATION

INFORMATION

Page 14

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

2-2

INSTALLATION INFORMATON

This section of the manual covers some of the installation issues a service technician may need to know when servicing a Wolf Wall Oven. If additional information is needed after reviewing this section of the manual, please refer to

the Installation Guide or contact the Wolf Appliance Customer Service Department.

Electrical Requirements:

Single Oven

• 208/220-240 volts AC, 60 Hertz, 30 Ampere fused electrical supply.

Double Oven

• 208/220-240 volts AC, 60 Hertz, 50 Ampere fused electrical supply.

Minimum Wire Size:

• L1, L2 and Ground: 10 AWG

• Neutral: 12 AWG

This appliance must be properly grounded. This appliance is equipped with a 60” conduit consisting of two insulated

hot lead copper conductors, one insulated neutral copper conductor and one uninsulated ground copper conductor.

THIS APPLIANCE MUST BE PROPERLY GROUNDED AT ALL TIMES WHEN ELECTRICAL POWER IS

APPLIED.

DO NOT GROUND THE APPLIANCE WITH THE NEUTRAL (WHITE) HOUSE SUPPLY WIRE. A SEPERATE

GROUND WIRE MUST BE UTILIZED.

IF ALUMINUM HOUSE SUPPLY WIRING IS UTILIZED, SPLICE THE APPLIANCE COPPER WIRE TO THE ALUMINUM HOUSE WIRING USING SPECIAL CONNECTORS DESIGNED AND CERTIFIED FOR JOINING COPPER

AND ALUMINUM. FOLLOW THE CONNECTORS MANUFACTURERS RECOMMENDED PROCEDURE CAREFULLY. IMPROPER CONNECTION CAN RESULT IN A FIRE HAZARD.

Page 15

2-3

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

s

"

8-32

ew

Sc

"-18x

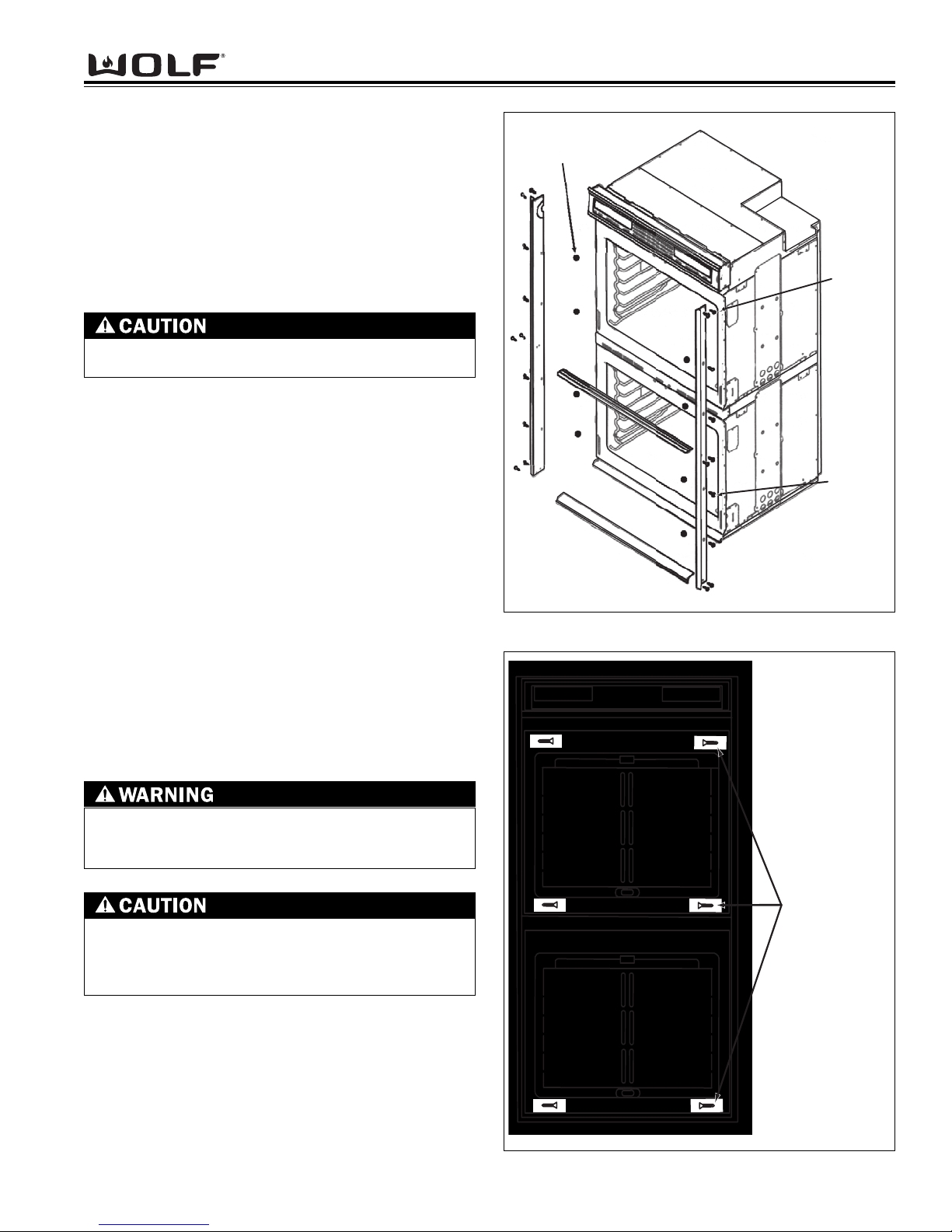

Figure 2-1. Trim Installation

Figure 2-2. Cabinet Mounting Screws

Oven Installation

Use the upper edge of the cavity opening and the bottom of the oven chassis side as gripping points to lift

the oven into the cabinet cutout. Slide the oven into the

recessed area until the unit is approximately six inches

from being fully installed. This will allow for installation

of the oven trim kit.

NOTE: The oven door(s) may be removed to reduce

the weight of the oven when lifting into cabinet opening.

Trim Installation

Attach the left and right side trim to the bottom and middle trim prior to installing on the oven.

(See Figure 2-1).

NOTE: The middle trim is for double ovens only.

Peel off the adhesive backing on the flat washers.

Attach the flat washers centered over the holes of the

raised sides of the oven cavity frame.

NOTE: Four washers for single oven and eight washers for double oven.

Install the trim to the oven using the screws provided in

the trim kit. Now, locate the mounting holes found on

the sides of the oven trim. Then, use a drill with a 1/16”

drill bit and drill four pilot holes for the cabinet mounting

screws. Install the mounting screws through the oven

side trim and into the cabinet. (See figure 2-2).

NOTE: Do not overtighten the mounting screws.

FAILURE TO INSTALL THE MOUNTING SCREWS

MAY RESULT IN MOVEMENT OR TIPPING OF THE

OVEN DURING USE.

Do not block the oven air exhaust located at the

bottom of the oven. Blocking the exhaust may

result in cabinet damage and poor baking performance.

Do not lift or carry the oven door(s) by the door

handle.

Flat Washer

x3/4

r

1/2

Mounting Screw

6-18x1"

Page 16

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

2-4

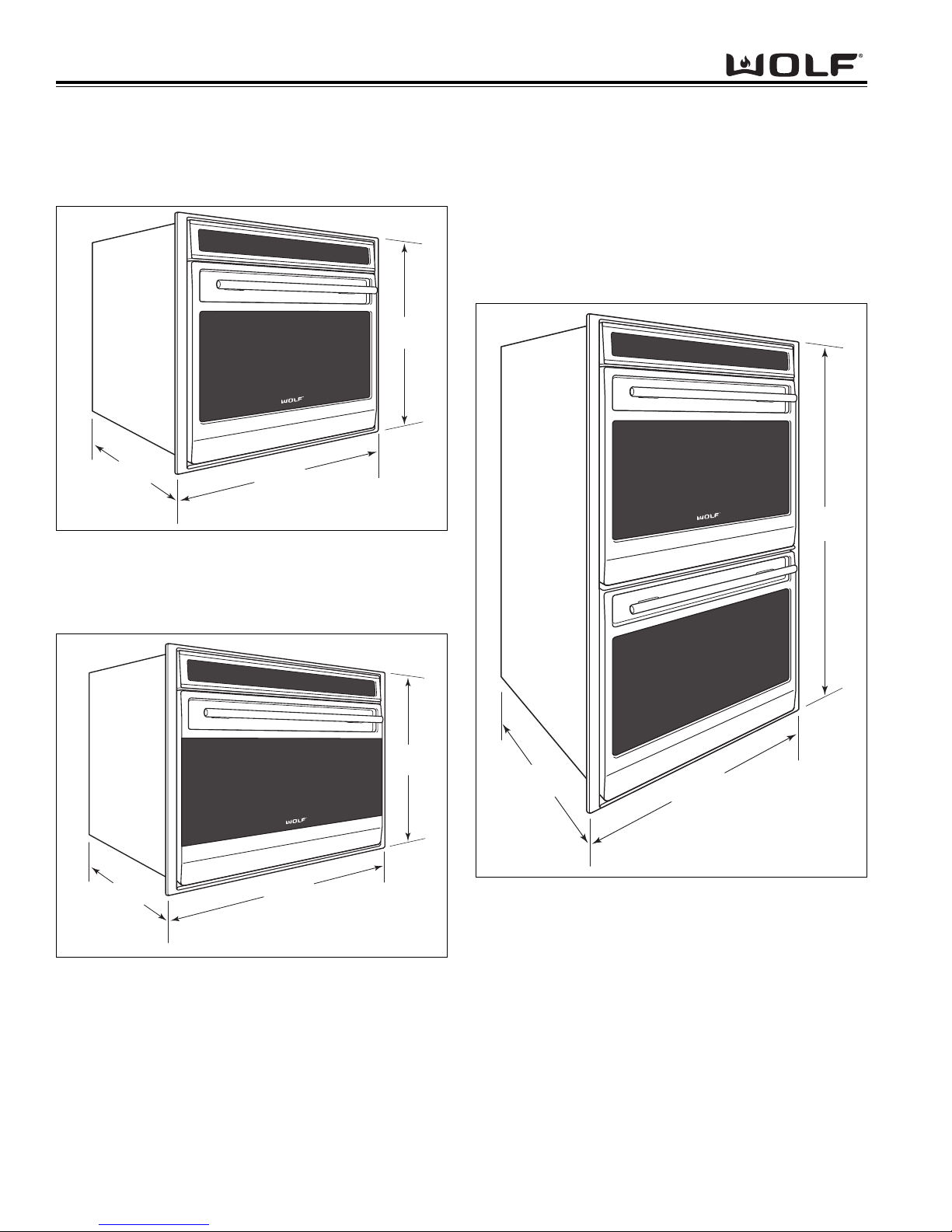

Figure 2-5. 30” Double Oven Overall Dimensions

Figure 2-3. 30” Single Oven Overall Dimensions

Figure 2-4. 36” Single Oven Overall Dimensions

WALL OVEN DIMENSIONS

271/2"

(699mm)

24"

(610

mm)

24"

mm)

(610

297/8"

mm)

(759

355/8"

(905mm)

243/8"

(619mm)

50"

(1269mm)

24"

(610

mm)

297/8"

mm)

(759

Page 17

2-5

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

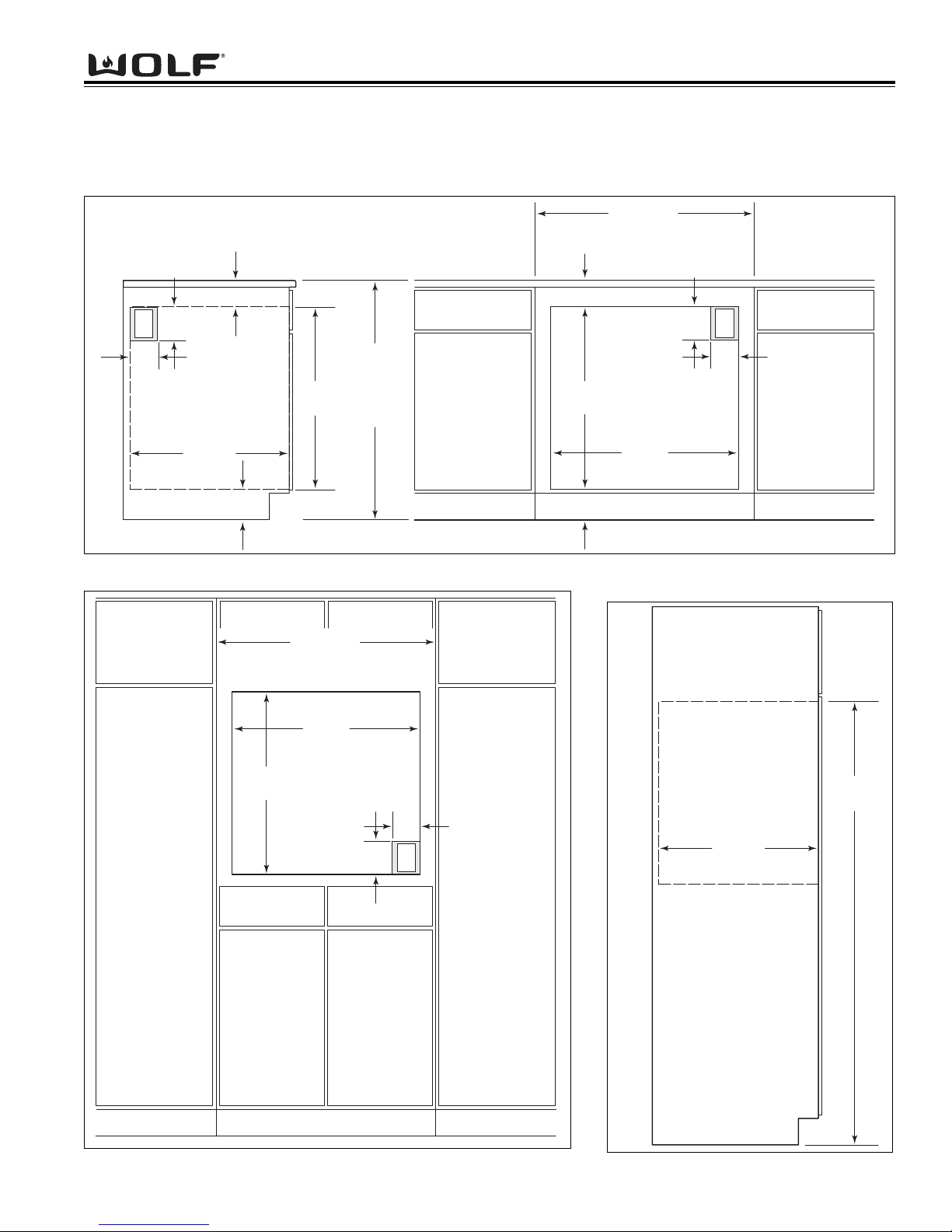

CABINET CUTOUT DIMENSIONS

Single 30 Inch Wall Oven

Figure 2-6. Undercounter Cutout Dimensions and Electrical Placement

Figure 2-7. Front Cutout Dimensions and Electrical Placement Figure 2-8. Side View

NOTE: Dimensions in parentheses are in millimeters.

33/4" min

(95)

5"

E

(127)

(691)

36" (914)

STANDARD

FLOOR T O

COUNTER

HEIGHT

4"

(102

)

ELECTRICAL

LOCATION IN

ADJACENT RIGHT

SIDE CABINET

24" min

(610)

43/4" min (121)

273/16"

RECOMMENDED CABINET WIDTH

33" (838)

30" min (762)

RECOMMENDED CABINET WIDTH

273/16"

43/4" min (121)

30" min (762)

33/4" min (95)

(691)

33" (838)

(102)

281/2"

(724)

5"

E

(127)

4"

NOTE: Dimensions in

parentheses are in

millimeters.

281/2"

(724)

273/16"

(691)

4"

(102)

5"

(127)

E

RIGHT SIDE

CABINET VIEW

24" min

(610)

67" max

(1702)

Page 18

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

2-6

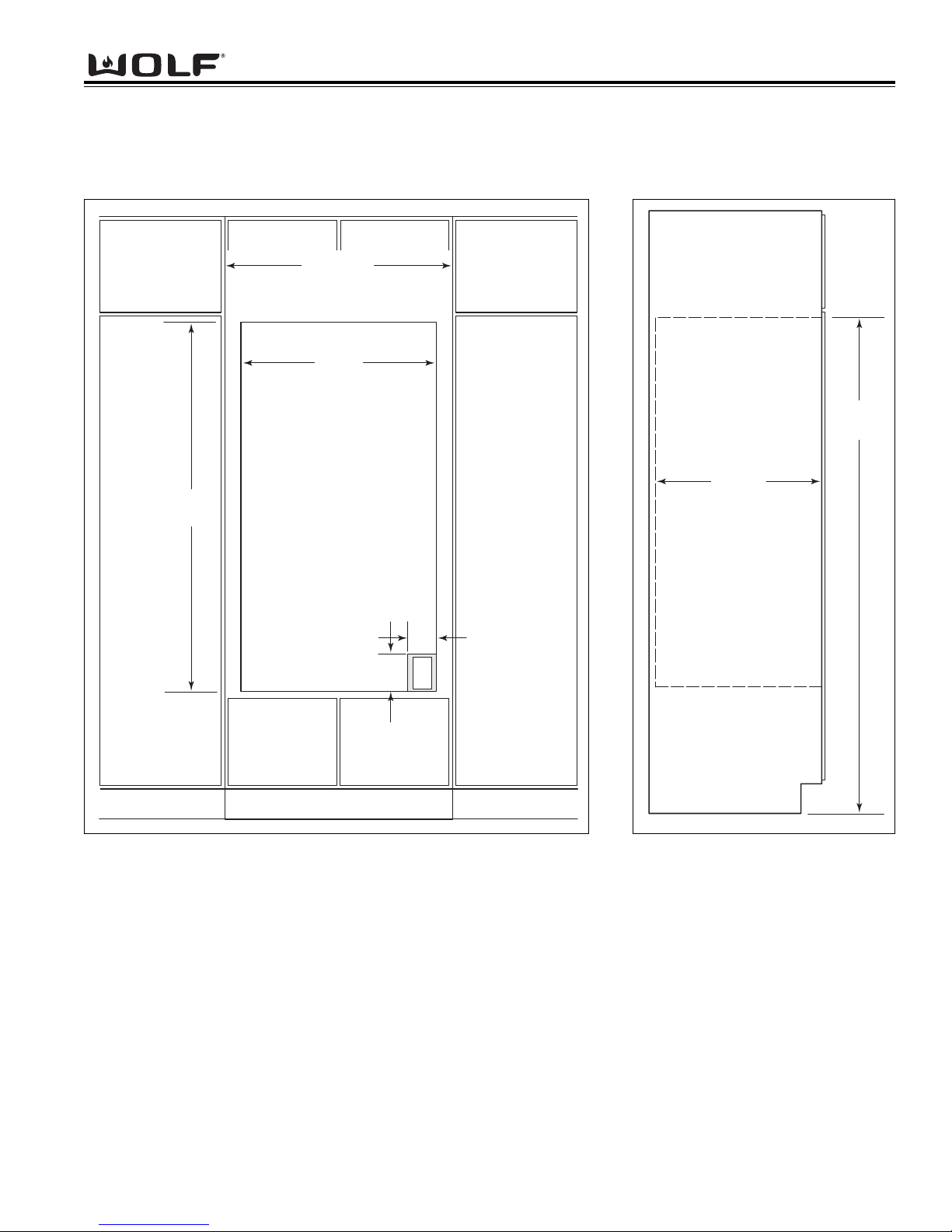

CABINET CUTOUT DIMENSIONS

Single 36 Inch Wall Oven

Figure 2-9. Undercounter Cutout Dimensions and Electrical Placement

Figure 2-10. Front Cutout Dimensions and Electrical Placement Figure 2-11. Side View

NOTE: Dimensions in parentheses are in millimeters.

33/4" min

(95)

5"

E

(127)

(611)

36" (914)

STANDARD

FLOOR T O

COUNTER

HEIGHT

4"

(102

)

ADJACENT RIGHT

73/4" (197) rec

(121) min

43/4"

ELECTRICAL

LOCATION IN

SIDE CABINET

24" min

(610)

241/16"

RECOMMENDED CABINET WIDTH

39" (991)

36" min (914)

RECOMMENDED CABINET WIDTH

241/16"

(611)

39" (991)

36" min (914)

33/4"

min (95)

341/2"

(876 )

73/4" (197) rec

43/4" (121) min

5"

(127)

4"

(102)

Dimensions in

NOTE:

parentheses are in

millimeters.

E

341/2"

(876 )

241/16"

(611)

4"

(102)

5"

(127)

24" min

E

RIGHT SIDE

CABINET VIEW

(610)

67" max

(1702)

Page 19

2-7

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

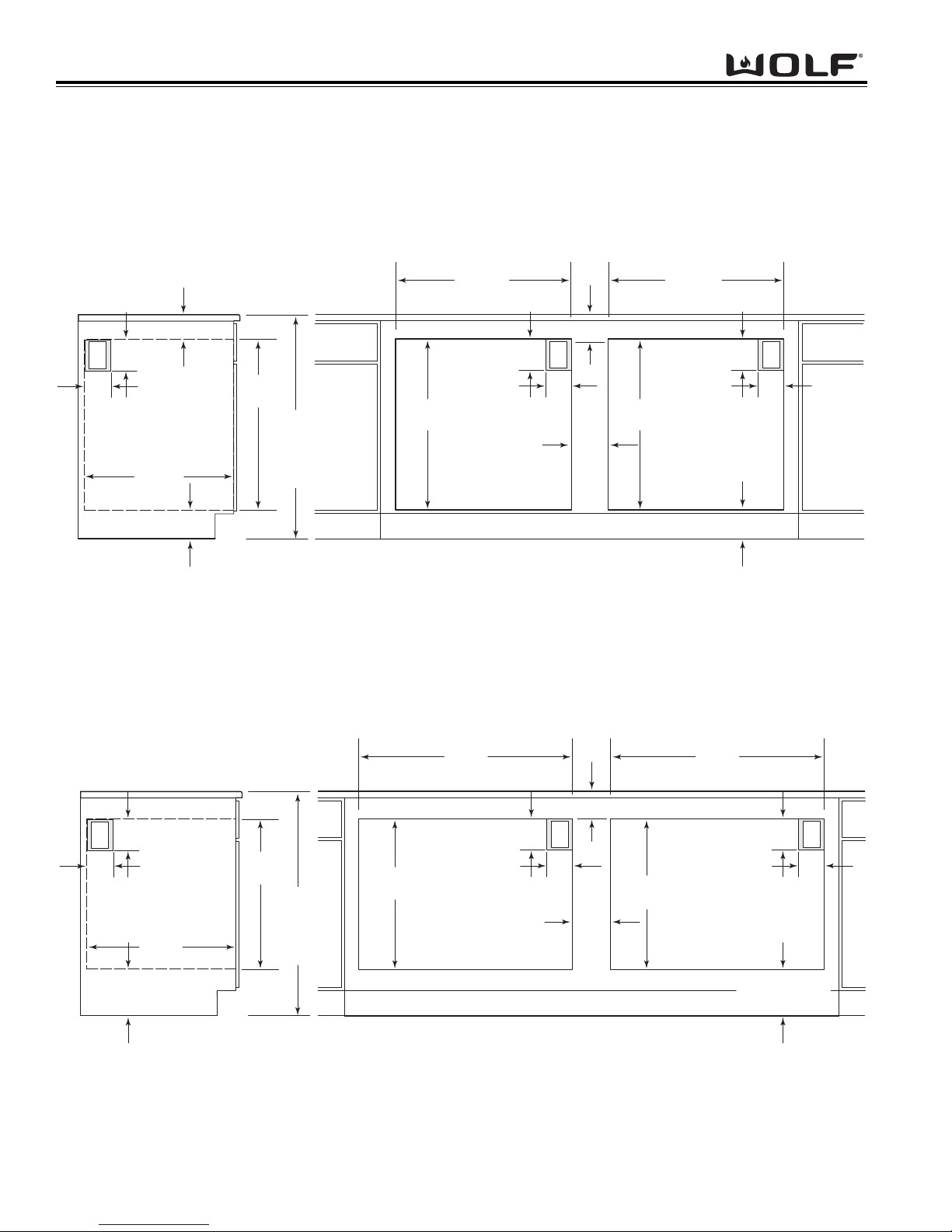

CABINET CUTOUT DIMENSIONS

Double 30 Inch Wall Oven

Figure 2-12. Front Cutout Dimensions and Electrical Placement

Figure 2-13. Side View

33" (838)

RECOMMENDED CABINET WIDTH

30" min (762)

281/2"

(724)

495/8"

(1260)

NOTE: Dimensions in

parentheses are in

millimeters.

67" max

(1702)

24" min

(610)

4"

(102)

5"

E

(127)

RIGHT SIDE

CABINET VIEW

Page 20

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Installation Information

2-8

CABINET CUTOUT DIMENSIONS

Side-by-Side Wall Oven

Figure 2-14. Undercounter Cutout Dimensions and Electrical Placement for SO30

Figure 2-15. Undercounter Cutout Dimensions and Electrical Placement for SO36

NOTE: Dimensions in parentheses are in millimeters.

33/4" min

(95)

5"

E

(127)

4"

(102

)

ELECTRICAL

LOCATION IN

ADJACENT RIGHT

SIDE CABINET

24" min

(610)

43/4" min (121)

273/16"

(691)

STANDARD

FLOOR TO

COUNTER

36" (914)

HEIGHT

281/2"

(724)

30" OVEN CUT-OUT

273/16"

(691)

4"

(102)

5"

(127)

33/4"

E

min (95)

71/2"

(191)

281/2"

(724)

30" OVEN CUT-OUT

273/16"

(691)

4"

(102)

43/4"

5"

(127)

min (121)

E

NOTE: Dimensions in parentheses are in millimeters.

min (95)

5"

E

(127)

4"

(102

73/4" (197) rec

43/4" (121) min

ELECTRICAL

LOCATION IN

)

ADJACENT RIGHT

SIDE CABINET

24" min

(610)

241/16"

(611)

STANDARD

FLOOR TO

COUNTER

36" (914)

HEIGHT

241/16"

(611)

341/2"

(876)

36" OVEN CUT

-OUT

4"

(102)

5"

(127)

341/2"

(876)

36" OVEN CUT-OUT

33/4" min (95)33/4"

5"

E

4"

(102)

73/4" (197) rec

43/4"

71/2"

(191)

241/16"

(611)

(127)

(121) min

E

Page 21

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-1

SECTION 3

ELECTRONIC CONTROL

SYSTEM

Page 22

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-2

ELECTRONIC CONTROL TERMINOLOGY & COMPONENT DESCRIPTIONS

All Wolf wall ovens utilize an electronic control system. The electronic control system monitors, regulates and controls a variety of functions. The control system also displays error codes to identify possible problems with the unit.

The table below defines some of the basic electronic control system terminology and describes some of the electronic system components. An understanding of the following information is needed in order to comprehend the

input operations and functions of the electronic control system.

T

erm / Component Definition / Description

Oven Controller.......................................The printed circuit board containing the microprocessor and logic inputs

which communicates with the oven display, keyboard, stepper motor control

board.

Relay Board............................................The printed circuit board containing the microprocessor, relays and electrical

connections which control and monitor functions and operations of the unit.

Oven Display...........................................A vacuum fluorescent display which shows oven temperature, cooking

modes, error codes, cook times and stop time.

Stepper Motor Control Board..................The printed circuit board containing a transformer and logic control to drive

the stepper motor.

Control Panel Assembly..........................The head assembly containing the oven display(s) and keyboard.

Relays.....................................................The electrical components on the relay board that switch other components

in the unit ON and OFF when instructed to do so by the microprocessor.

Microprocessor........................................An electrical component on the control board which receives electrical sig-

nals from other components, processes that information, then sends an

electrical signal to the relays on the board to open or close, and other components in the unit to switch on or off.

Keyboard.................................................An assembly of glass and mylar which connects into the upper oven display.

Error Codes.............................................Number or word description which appears on the oven display if the unit

experiences specific problems related to electrical signals supplied by the

electrical components.

MDL.........................................................Motor door latch assembly which incorporates the latch motor drive, unlatch

switch, latch switch and door switch.

RTD.........................................................The oven(s) temperature sensing device.

DLB...........................................................A component on the relay board which is a relay that connects and discon-

nects the L2 line to the elements when energized by logic from the oven

controller.

Page 23

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-3

UNIQUE ELECTRONIC CONTROL INPUT OPERATIONS

The following few pages illustrate electronic control input operations that you would not expect a customer to perform everyday.

The input operations described are: Field Option Mode, Sabbath Mode, Delayed Start Mode, Probe Mode and Self-Clean Mode.

Field Option Mode

Field option mode allows for the user to adjust specific options of the oven controller, such as User Preference Offset (adjusting

temperature ± 35°), Temperature Display Preference (choosing between °F, Fahrenheit or °C, Celsius) and Clock Display

Preference (12 Hour Clock or 24 Hour Clock).

NOTE: Field Option Mode must be entered with the oven(s) turned OFF.

To initiate Field Option Mode, Press and hold the TEMPERATURE key for five seconds.

NOTE: Pressing the CLEAR key will cancel the Field Option Mode.

User Preference Offset

This option allows the user to offset a specific oven temperature ±35° in 1°F (Fahrenheit) increments. Once in Field Option

Mode, press the number keys to input the numeric value of the offset and press the TEMPERATURE key to toggle between ±.

The new offset is accepted ten seconds after the last key stroke or by pressing the ENTER key. (See Figure 3-1). Pressing the

CLEAR key will cancel the Field Option Mode.

NOTE: Entering a positive number will increase oven temperature.

NOTE: User Preference Offset will only work for °F (Fahrenheit).

f

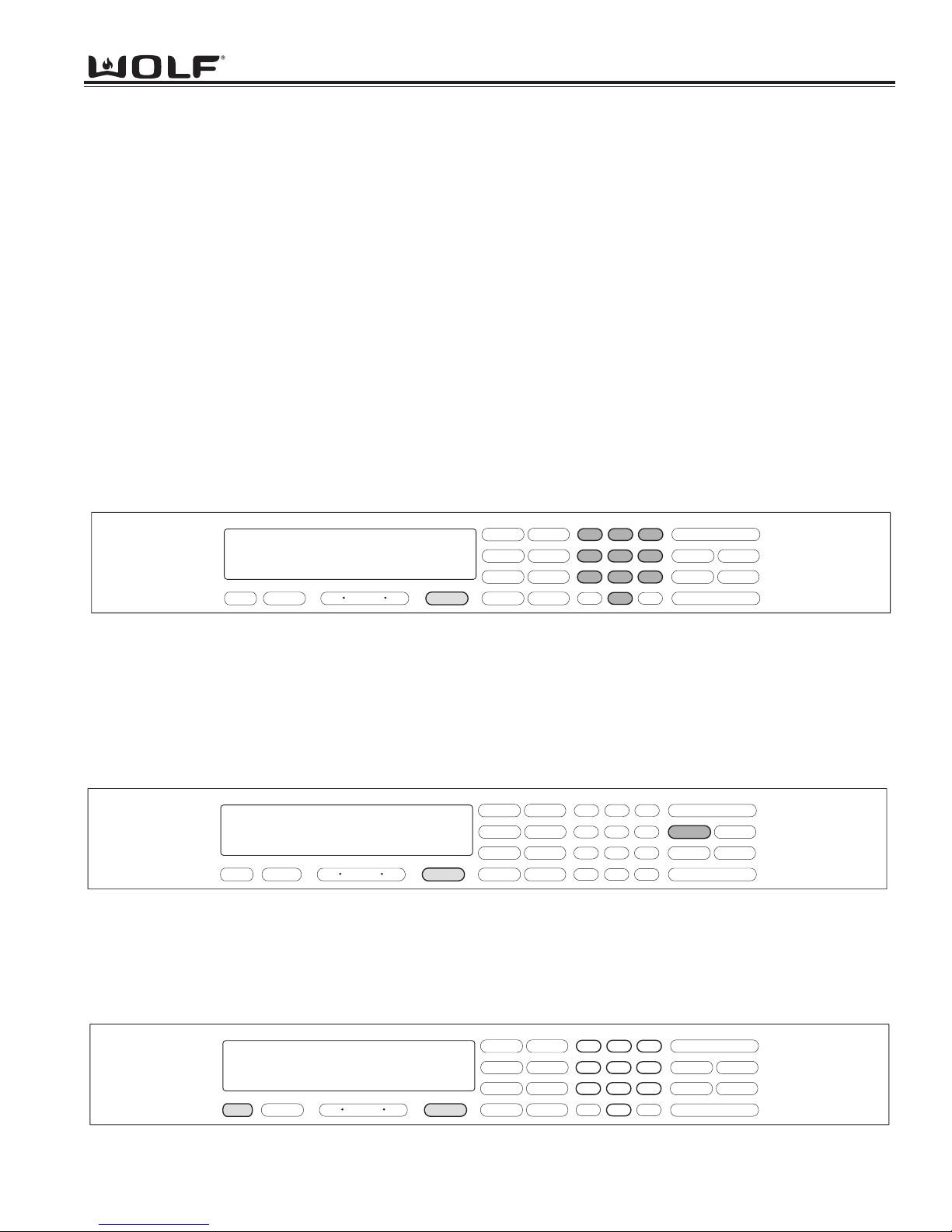

Figure 3-1. User Preference Offset. Press and HOLD the TEMPERATURE key for five seconds. Then, press the number

keys to enter a new numeric value up to 35. Now, press the TEMPERATURE key to toggle between ±.

Figure 3-2. Temperature Display Preference. Must be in Field Option Mode. Now, press the COOK TIME key to toggle

between °C and °F.

Temperature Display Preference

This option allows the user to choose how the temperature is displayed, °F (Fahrenheit) or °C (Celsius), and/or back again.

Once in Field Option Mode, press the COOK TIME key to toggle between °C and °F. The new display, °C or °F is accepted ten

seconds after the last key stroke or by pressing the ENTER key. See Figure 3-2. Pressing the CLEAR key will cancel the Field

Option Mode.

c

Figure 3-2.1. Clock Display Preference. Must be in Field Option Mode. Now, press the CLOCK key to toggle between 12

hour and 24 hour clock.

Clock Display Preference

This option allows the user to choose how the clock is displayed, 12 hour or 24 hour, and/or back again. Once in Field Option

Mode, press the CLOCK key to toggle between 12 hour or 24 hour clock. The new display is accepted ten seconds after the last

key stroke or by pressing the ENTER key. See Figure 3-2.1. Pressing the CLEAR key will cancel the Field Option Mode.

f

ON/OFF

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

3 00

CLOCK

CONV. BAKE

BAKE

.

.

12 hr clock

OFF ON

TIMER

OVEN

0

set upo

TEMPERATURE

°

ROAST

CONV. ROAST

BROIL

CONV. BROIL

BAKE STONE

CONVECTION

1

4

7

ENTER

2

56

89

0

ON/OFF

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

3 00

CLOCK

CONV. BAKE

BAKE

.

.

TIMER

12 hr clock

OFF

OVEN

ON

TEMPERATURE

°

ROAST

CONV. ROAST

BROIL

CONV. BROIL

BAKE STONE

CONVECTION

1

4

7

ENTER

2

56

89

0

.

.

3 00

CLOCK

TIMER

24 hr clock

OFF ON

OVEN

CONV. BAKE

BAKE

°

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

0

set upo

TEMPERATURE

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 24

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-4

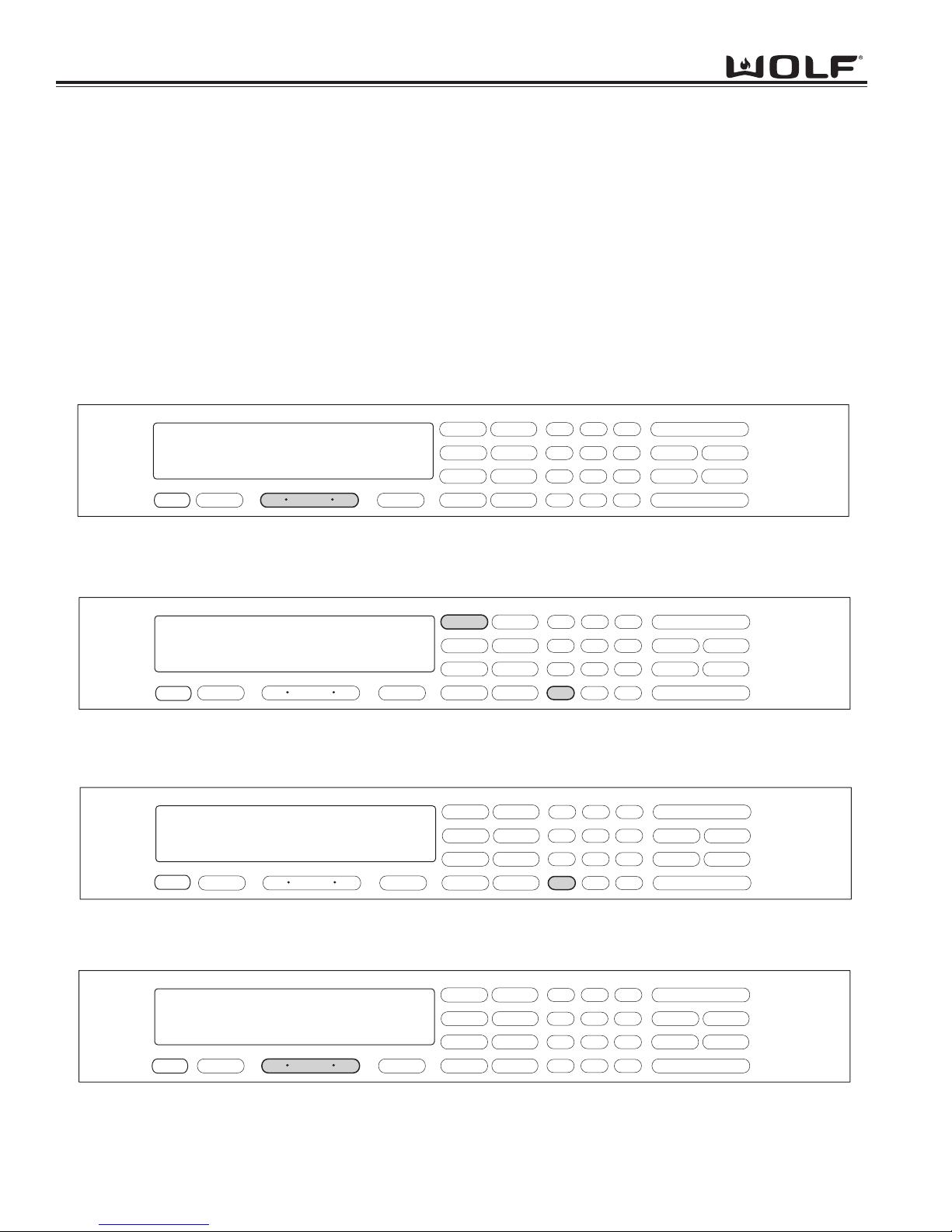

Sabbath Feature

Sabbath Feature was incorporated into the electronic control system for the observance of certain religious holidays.

Once Sabbath Mode has been entered, all of the oven functions have been disabled except the OFF key.

To initiate Sabbath feature, the oven must be OFF. Press UPPER or LOWER OVEN ON key for a double oven or

OVEN ON key for a single oven. (See Figure 3-3). Turn on the interior oven lights by pressing the OVEN LIGHT

ON key (Optional). Press the BAKE or ROAST key. A preset temperature of 350° will be shown in the display. To

change temperature, immediately enter another temperature using the number keys, then press ENTER. (See

Figure 3-4). Now, press and hold the ENTER key for five seconds. The oven will chime twice and the word SABBATH appears in the display window. (See Figure 3-5). Repeat these steps above for each oven(s).

To exit the Sabbath Mode, press the UPPER or LOWER OVEN OFF key or the OVEN OFF key, depending on the

model. (See Figure 3-6).

NOTE: The oven(s) will remain on until the Sabbath Mode is cancelled.

Figure 3-4. Press the BAKE key. A preset temperature of 350°F will be shown in the display.

To change temperature, immediately enter another temperature using the number keys. Then, press ENTER.

Figure 3-6. To exit Sabbath Mode. Press the Oven OFF key.

For Double Ovens select either Upper Oven OFF key or Lower Oven OFF key.

Figure 3-3. To initiate Sabbath Mode, the oven must be OFF. Press Oven ON key.

For Double Ovens select either Upper Oven ON key or Lower Oven ON key.

f

f

f

f

f

Figure 3-5. Now, press and HOLD THE ENTER key for 5 seconds.

The oven will chime twice and the word Sabbath appears in the display.

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

3 00

CLOCK

CONV. BAKE

BAKE

.

.

select mode

TIMER

OFF ON

OVEN

TEMPERATURE

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

3 00

OVEN ON

CLOCK

CONV. BAKE

.

.

bake

OFF ON

TIMER

OVEN

TEMPERATURE

350

setpoint

TEMPERATURE

°

BAKE

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

3 00

CLOCK

.

.

OVEN ON

TIMER

sabbath setpoint

OFF ON

OVEN

350

TEMPERATURE

TEMPERATURE

CONV. BAKE

BAKE

°

ROAST

CONV. ROAST

BROIL

CONV. BROIL

BAKE STONE

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

.

.

3 00

OFF ON

CLOCK

TIMER

OVEN

TEMPERATURE

BAKE STONE

BAKE

ROAST

BROIL

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 25

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-5

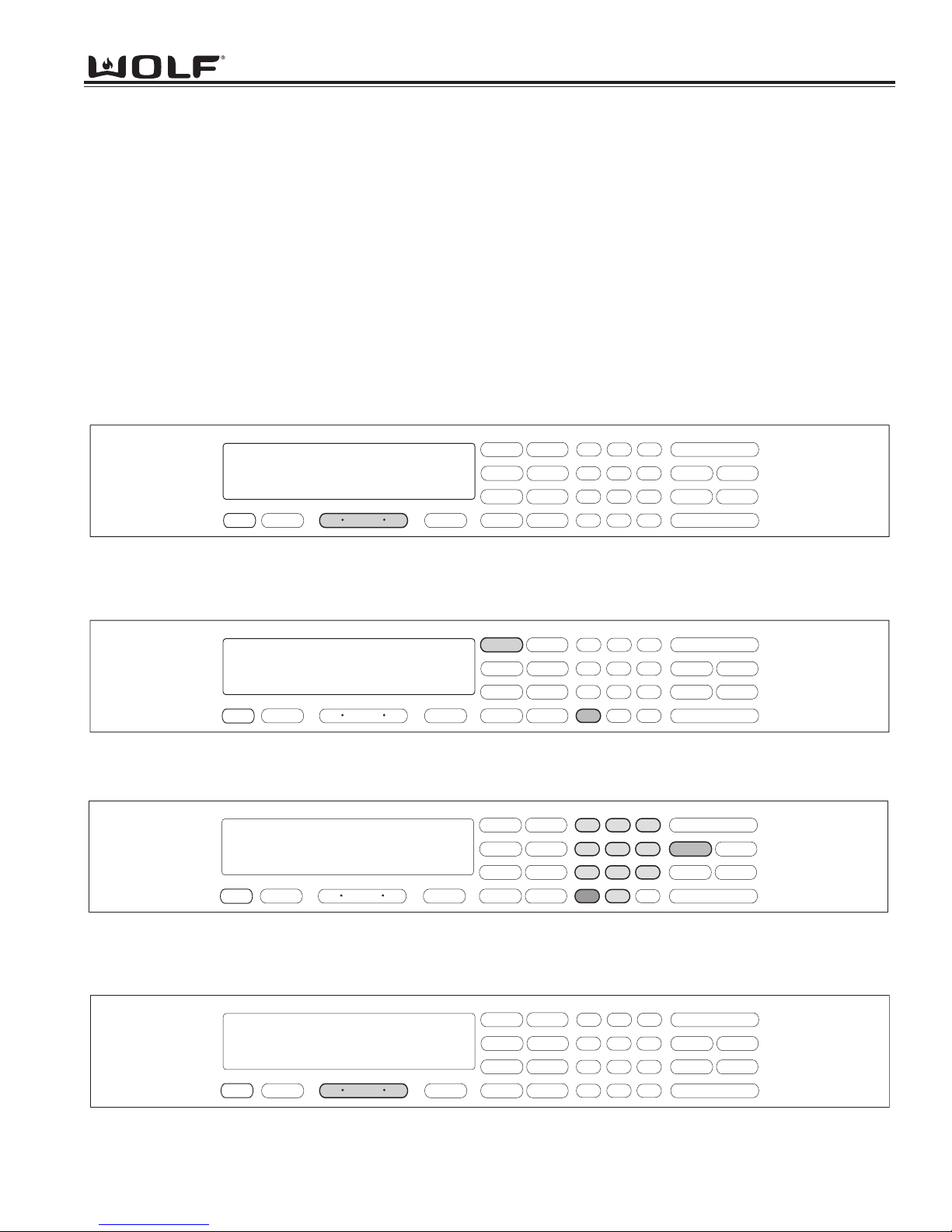

Time Cook Feature

Time Cook Feature controls the automatic timing of the oven(s) ON and OFF function by setting the cooking time to

start immediately and turn off when the desired cooking is complete. To accomplish time cook, the time of day clock

is used and therefore the correct time must be displayed prior to programming.

To initiate Time Cook, the oven must be OFF. First press the Oven ON key. (See Figure 3-7). For Double Ovens

press the Upper Oven ON key or the Lower Oven ON key. Now, press a desired cooking mode (example Bake

Mode). A preset temperature of 350°F is shown in the display. To change the temperature from 350°F, immediately

enter another temperature using the number keys. (See Figure 3-8). Then, press the COOK TIME key. Then, enter

the hours/minutes desired for cooking. The oven(s) will start heating after a five second delay or by pressing the

ENTER key. (See Figure 3-9). To exit TIME COOK feature, press the Oven OFF key. (See Figure 3-10). For the

Double Oven, press the Upper Oven OFF key or the Lower Oven Off key.

NOTE: The oven should always be preheated in this mode. The oven will chime after the oven reaches preheat

temperature.

Figure 3-8. Press a desired Cooking Mode. (Example: Bake Mode). A preset temperature of 350°F will be shown in the

display

. To change temperature, immediately enter another temperature using the number keys.

Figure 3-10. To exit the Cook Time Feature. Press the Oven OFF key.

For Double Ovens select either Upper Oven OFF key or Lower Oven OFF key.

Figure 3-7. To initiate Time Cook Feature, the oven must be OFF. Press Oven ON key.

For Double Ovens select either Upper Oven ON key or Lower Oven ON key.

f

f

f

f

f

Figure 3-9. Now, press the Cook Time key. Now, enter the hours/minutes desired for cooking. The Stop Time will auto-

matically be entered in the display. Then, press the ENTER key. The oven(s) will now start heating and then turn off

when the cooking times has completed.

ON/OFF

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

.

.

3 00

CLOCK

TIMER

select mode

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

0

ON/OFF

CLOCK

3:00

OVEN ON

TIMER

Bake

OFF ON

OVEN

TEMPERATURE

350

SETPOINT

TEMPERATURE

°

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

0

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

ON/OFF

CLOCK

3:00

OVEN ON

TIMER

COOK TIME

MINUTES

HOURS

2:30

bake

OFF ON

OVEN

STOP TIME

HOURS

5:30

MINUTES

TEMPERATURE

350

SETPOINT

TEMPERATURE

°

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

0

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

3:00

CLOCK

TIMER

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

COOK TIME

SELF CLEAN

LIGHT

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 26

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-6

Delayed Start Feature

This feature controls the automatic timing of the oven(s) ON and OFF function by setting the cooking mode to start later

in the day and turn off when the cooking is complete. It can also be set to turn off at a preset time. To accomplish

delayed start and/or stop, the time of day clock is used and therefore the correct time must be displayed prior to programming.

NOTE: This mode will work for all cooking modes except Broil, Convection Broil and Bake Stone Mode.

To initiate Delayed Start Mode, the oven must be OFF. Press the Upper or Lower Oven ON key or the Oven ON key,

depending on the model. (See Figure 3-11). Press the desired cooking mode key. (See Figure 3-12). To change preset temperature, immediately enter another temperature using the number keys. Next, press Stop Time. Then, using

the number keys, enter the time for which the oven needs to turns off. Example: Set 6:00 for the time of day the oven

turns off. (See Figure 3-13). Then, enter the Cook Time using the number keys to set the hours/minutes the oven will

stay on. Example: Set 3:30 for the oven to remain on for 3-1/2 hours. Now, press the ENTER key. (See Figure 3-14).

The display appears as if the oven is on. To exit Delayed Start Mode, press Upper or Lower Oven OFF or Oven OFF

key. (See Figure 3-15).

NOTE: With the example used above, heating will not start for 3-1/2 hours prior to 6 o’clock which will be 2:30 on the time

of day clock.

Figure 3-11. To initiate Delayed Start Mode, Press Oven ON key.

For Double Ovens select either Upper Oven ON key or Lower Oven ON key.

f

Figure 3-12. Press desired Cooking Mode. Bake, Roast, Convection Bake, Convection Roast or Convection.

NOTE: Broil, Convection Broil and Bake Stone will not work in this mode.

f

f

Figure 3-13. Press Stop Time. Then, using number keys, enter time of day to turn oven off. Example 6:00

f

f

f

Figure 3-14. Press Cook Time. Then, using number keys, enter hours/minutes the oven will stay on.

Example 3:30. Now, press ENTER.

f

f

f

f

Figure 3-15. Display appears as if oven is on.

ON/OFF

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

8 00

CLOCK

CONV. BAKE

BAKE

.

.

select mode

TIMER

OFF ON

OVEN

TEMPERATURE

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

0

ON/OFF

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

8 00

CLOCK

CONV. BAKE

BAKE

°

ROAST

CONV. ROAST

BROIL

CONV. BROIL

BAKE STONE

CONVECTION

TEMPERATURE

350

setpoint

TEMPERATURE

.

.

bake

OFF ON

TIMER

OVEN

1

4

7

ENTER

2

56

89

0

ON/OFF

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

8 00

CLOCK

CONV. BAKE

STOP TIME

.

.

TIMER

HOURS

:

6 00

set stop time

OFF ON

OVEN

MINUTES

TEMPERATURE

350

setpoint

TEMPERATURE

BAKE

°

ROAST

CONV. ROAST

BROIL

CONV. BROIL

BAKE STONE

CONVECTION

1

4

7

ENTER

2

5 6

89

0

ON/OFF

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

CONV. BAKE

COOK TIME

.

.

8 00

CLOCK

TIMER

3 30

:

6 00

set cook time

OFF ON

:

OVEN

STOP TIME

MINUTES

HOURS

HOURS

MINUTES

TEMPERATURE

350

setpoint

°

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

0

COOK TIME

STOP TIME

MINUTES

HOURS

HOURS

.

.

8 00

CLOCK

TIMER

:

3 30

6 00

bake

OFF ON

:

OVEN

MINUTES

TEMPERATURE

350

setpoint

°

TEMPERATURE

BAKE STONE

BAKE

ROAST

BROIL

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 27

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-7

Temperature Probe Feature

The Temperature Probe Feature is used to measure internal temperatures of the food being cooked. It is an accurate way to achieve the perfect doneness regardless of the type, cut or weight of food. When using the Temperature

Probe Mode, program the recommended internal carving temperature, as found in the Use and Care Information

Guide. (See Figure 3-16). The temperature should be reduced by five degrees when setting the Temperature

Probe Mode.

145°F Medium Rare 170°F Breast

160°F Medium 180°F Thigh

170°F Well Done 165°F Stuffing

USDA Internal Temperature Recommendations

Beef, Lamb, Pork and Veal Poultry

Figure 3-16. USDA Internal Temperature Recommendations

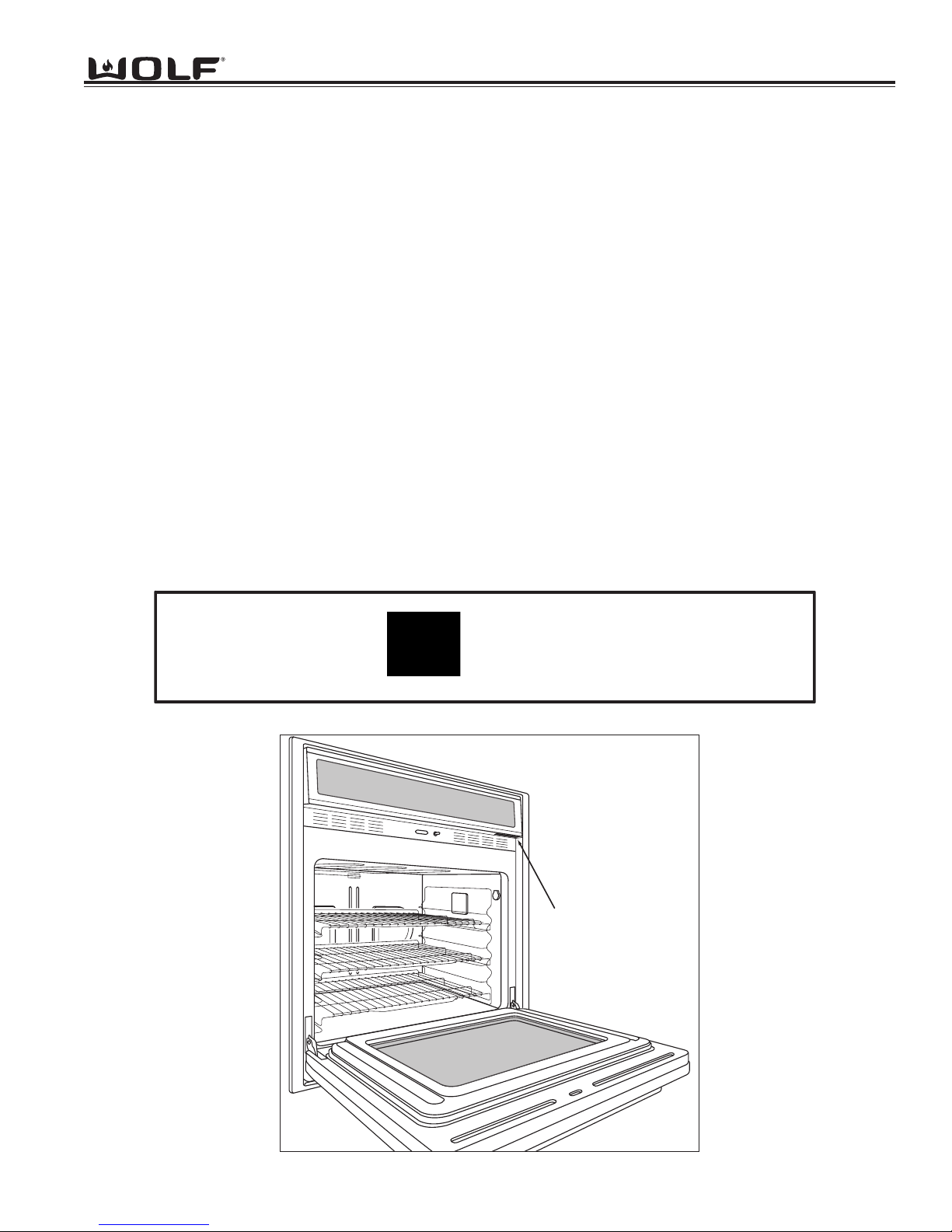

To initiate Temperature Probe Mode, first preheat the oven. Now, the probe should be inserted into the thickest part

of the product being cooked. Plug the probe connector into the oven receptacle (located on the top right side of the

oven cavity), all the way until it snaps into place. Next, press the PROBE key. (See Figure 3-17). Now, using the

number keys enter the recommended internal cooking temperature minus five degrees. (See Figure 3-18). Then,

press ENTER. The word “Lo” appears in the display as the probe temperature, until the probe registers 100°F.

(See Figure 3-19). Once the probe has registered 100°F, the display will start showing the degrees rising up to the

programmed setting for the probe temperature. Once the probe temperature has been reached the oven will chime

three times signaling the item being cooked is done. Now, unplug the probe connector from the oven receptacle. To

exit the Temperature Probe Mode, press the Oven OFF key. For the double oven, press the Upper Oven OFF key

or Lower Oven OFF key.

NOTE: The oven will continue to chime every thirty seconds until the probe has been removed from the oven

receptacle.

NOTE: Oven temperature remains on even when temperature probe is unplugged.

f

f

f

f

f

f

Figure 3-17. To initiate Temperature Probe Mode, press PROBE key.

Figure 3-18. Using number keys, enter internal cooking temperature minus five degrees.

Figure 3-19. Press ENTER, the word Lo appears in the oven display.

3

CLEAR

LIGHT

COOK TIME

SELF CLEAN

PROBE

STOP TIME

PANEL LOCK

ON/OFF

3 00

OVEN ON

CLOCK

CONV. BAKE

.

.

BAKE

OFF ON

TIMER

OVEN

TEMPERATURE

350

probe

TEMPERATURE

BAKE

°

ROAST

CONV. ROAST

BROIL

CONV. BROIL

BAKE STONE

CONVECTION

1

4

7

ENTER

2

56

89

0

ON/OFF

ON/OFF

3

CLEAR

LIGHT

COOK TIME

SELF CLEAN

PROBE

STOP TIME

PANEL LOCK

ON/OFF

3 00

OVEN ON

CLOCK

CONV. BAKE

.

.

BAKE

OFF ON

TIMER

OVEN

TEMPERATURE

888

probe

TEMPERATURE

BAKE

°

ROAST

CONV. ROAST

BROIL

CONV. BROIL

BAKE STONE

CONVECTION

1

4

7

ENTER

2

56

89

0

3 00

OVEN ON

CLOCK

.

.

BAKE

OFF ON

TIMER

OVEN

TEMPERATURE

lo

probe

TEMPERATURE

°

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

COOK TIME

SELF CLEAN

LIGHT

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 28

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-8

Self-Clean Mode

In Self-Clean Mode, the oven is heated in graduated stages to a preset high temperature. The cycling of the bake

and broil elements in Stage One last for the first twelve minutes. In Stage Two, the bake element cycles for 0 - 12

seconds and the broil element cycles for 12 - 60 seconds. The cycling of the elements in Stage Two continues until

the high preset temperature of 850°F is obtained. During this process, food soil is burned off leaving some white

ash residue.

Once the Self-Clean Mode has been initiated the oven door locks, unless the Self-Clean Mode is used with the

Delayed Start Mode. The oven door will remain locked until the oven temperature drops below 300°F.

NOTE: If the Self-Clean Mode is stopped once it has been started, the door will remain locked until the temperature

inside has cooled below 300°F.

NOTE: The average time for the Self-Clean Mode is three hours plus one hour to cool down.

NOTE: For model DO30 only one cavity can be self-clean at a time.

NOTE: For Model DO30, when self-cleaning one cavity the other cavity is non-functional until self-clean is finished.

To initiate Self-Clean Mode, first the oven must be OFF. Press the Oven ON key. (See Figure 3-20). For Double

Ovens, press the Upper Oven ON key or Lower Oven ON key. Next, press the SELF-CLEAN key. Follow instructions in display, if applicable, then press the ENTER key. (See Figure 3-21). Press ENTER key again to activate

SELF-CLEAN. To exit the Self-Clean Mode, press the Oven OFF key. (See Figure 3-22). For Double Oven press

the Upper Oven OFF key or the Lower Oven OFF key.

NOTE: To use Self-Clean Mode with Delayed Start Mode, follow the instruction for Delayed Start Mode.

To change the Self-Clean time for 3 to 4 hours. Press the Oven ON key. Next, press the SELF-CLEAN key. Then,

press the COOKTIME key. Now, using the number keys enter the desired self-cleaning time. (Example: 3 hours 15

minutes). As long as the self-clean time is between 3 to 4 hours, the time can be entered. Then, press ENTER.

Figure 3-21. Press the SELF-CLEAN key. Scrolling display will instruct to remove racks, press the “ENTER” key to

initiate SELF-CLEAN. Starting with serial #16000000 rack guides must also be removed.

Figure 3-20. To initiate Self-Clean Mode, Press the Oven ON key.

For Double Oven, press the Upper Oven ON key or the Lower Oven ON key.

Figure 3-22. Press ENTER again to activate SELF-CLEAN.

To exit the Self-Clean Mode, press the Oven OFF key.

For Double oven, press the Upper Oven OFF key or the Lower Oven OFF key.

ON/OFF

CLOCK

CONV. BAKE

.

.

3

00

TIMER

select mode

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

0

CLEAR

LIGHT

3

COOK TIME

STOP TIME

PANEL LOCK

SELF CLEAN

ON/OFF

PROBE

3

CLEAR

LIGHT

COOK TIME

SELF CLEAN

PROBE

STOP TIME

PANEL LOCK

ON/OFF

CLOCK

CONV. BAKE

.

.

3

00

Please remove all.....

TIMER

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

0

ON/OFF

MINUTES

HOURS

.

.

00

TIMER

4:00

SElf clean

OFF ON

3

CLOCK

OVEN

TEMPERATURE

BAKE STONE

BAKE

ROAST

BROIL

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 29

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-9

ELECTRONIC CONTROL INPUT OPERATIONS

The following few pages illustrate electronic control input operations that you might expect a customer to perform

everyday. The input operations described are: Bake, Convection, Convection Bake, Broil, Convection Broil, Roast,

Convection Roast and Bake Stone Mode.

Bake Mode

In Bake Mode both the hidden bake element and the broil element are used to heat the air and cycle to maintain

temperature. The hidden bake element operates approximently 80 percent of the time and the broil element operates approximently 10 percent of the time. The oven(s) should always be preheated when using Bake Mode.

To initiate Bake Mode, the oven must be OFF. First press the Oven ON key. (See Figure 3-23). For Double Ovens

press the Upper Oven ON key or the Lower Oven ON key. Now, press the BAKE key. A preset temperature of

350°F is shown in the display. The oven begins to heat after 5 seconds or by pressing the ENTER key.

(See Figure 3-24). To change the temperature from 350°F, immediately enter another temperature using the number

keys. Then, press the ENTER key. (See Figure 3-25). To exit the Bake Mode, press the Oven OFF key.

(See Figure 3-26). For the Double Oven, press the Upper Oven OFF key or the Lower Oven Off key.

NOTE: The oven should always be preheated in this mode. The oven will chime after the oven reaches preheat

temperature.

Figure 3-23. To initiate Bake Mode, Press the Oven ON key.

For Double Oven, press the Upper Oven ON key or the Lower Oven ON key.

f

Figure 3-24. Press the BAKE key. A preset temperature of 350°F will be shown in the display.

The oven begins to heat after 5 seconds or by pressing the ENTER key.

f

f

Figure 3-25. To change the preset temperature, immediately press the number keys to enter a new temperature.

Then, press the ENTER key.

f

f

Figure 3-26. To exit the Bake Mode, press the Oven OFF key.

For Double oven, press the Upper Oven OFF key or the Lower Oven OFF key.

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

CLOCK

TIMER

select mode

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

CLOCK

3:00

OVEN ON

TIMER

bake

OFF ON

OVEN

TEMPERATURE

350

SETPOINT

TEMPERATURE

°

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

CLOCK

3:00

OVEN ON

TIMER

bake

OFF ON

OVEN

TEMPERATURE

375

SETPOINT

TEMPERATURE

°

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

3:00

CLOCK

TIMER

OFF ON

OVEN

CONV. BAKE

BAKE

ROAST

CONV. ROAST

BROIL

CONV. BROIL

TEMPERATURE

BAKE STONE

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 30

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-10

Convection Mode

The Convection Mode uses dual convection fans, each with heating elements mounted on the back wall of the oven

cavity. The convection fans move air sequential, throughout the entire oven cavity creating uniform air movement.

This air movement makes it possible to cook on all six levels of the cooking racks simultaneously. The heating elements and convection fans are cycled sequentially (on and off), resulting in even browning.

NOTE: In Convection Mode, standard recipe temperature should be reduced by 25°F.

NOTE: The oven should always be preheated in this mode. The oven will chime after the oven reaches preheat

temperature.

To initiate Convection Mode, the oven must be OFF. First, press the Oven ON key. (See Figure 3-27). For the

Double Ovens, press the Upper Oven ON key or the Lower Oven ON key. Now, press the CONVECTION key. A

preset temperature of 325°F will appear in the display. The oven begins to heat after 5 seconds or by pressing the

ENTER key. (See Figure 3-28). To change the temperature from the preset 325°F, immediately enter another temperature using the number keys. Then, press the ENTER key. (See Figure 3-29). To exit the Convection Mode,

press the Oven OFF key. (See Figure 3-30). For Double Ovens press the Upper Oven OFF key or the Lower Oven

OFF key.

Figure 3-27. To initiate Convection Mode, Press the Oven ON key.

For Double Oven, press the Upper Oven ON key or the Lower Oven ON key.

f

Figure 3-28. Press the CONVECTION key. A preset temperature of 325°F will be shown in the display.

The oven begins to heat after 5 seconds or by pressing the ENTER key.

f

f

Figure 3-29. To change the preset temperature, immediately press the number keys to enter a new temperature.

Then, press the ENTER key.

f

f

Figure 3-30. To exit the Convection Mode, press the Oven OFF key.

For Double oven, press the Upper Oven OFF key or the Lower Oven OFF key.

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

CLOCK

TIMER

select mode

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

OVEN ON

CLOCK

TIMER

TEMPERATURE

convection setpoint

OFF ON

OVEN

325

TEMPERATURE

CONV. BAKE

BAKE

°

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

.

.

3 00

OVEN ON

CLOCK

TIMER

TEMPERATURE

ON

400

TEMPERATURE

convection setpoint

OFF

OVEN

CONV. BAKE

BAKE

°

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

OFF ON

CLOCK

TIMER

OVEN

ROAST

BROIL

TEMPERATURE

BAKE STONE

BAKE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 31

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-11

Convection Bake Mode

Convection Bake Mode combines heat from two convection heating elements with some heat from the hidden bake

element. The two convection fans and convection elements operate sequentially (on and off), to circulate the heat

within the oven cavity. The added heat from the hidden bake element make this an ideal cooking mode for pie baking. In this mode the convection elements are on 45 percent of the time and the hidden bake element is on 90 percent of the time.

NOTE: In Convection Bake Mode, standard recipe temperature should be reduced by 25°F.

NOTE: The oven should always be preheated in this mode. The oven will chime after the oven reaches preheat

temperature.

To initiate Convection Bake Mode, the oven must be OFF. First, press the Oven ON key. (See Figure 3-31). For

the Double Ovens, press the Upper Oven ON key or the Lower Oven ON key. Now, press the CONVECTION BAKE

key. A preset temperature of 375°F will appear in the display. The oven begins to heat after 5 seconds or by pressing the ENTER key. (See Figure 3-32). To change the temperature from the preset 375°F, immediately enter another temperature using the number keys. Then, press the ENTER key. (See Figure 3-33). To exit the Convection

Mode, press the Oven OFF key. (See Figure 3-34). For Double Ovens press the Upper Oven OFF key or the

Lower Oven OFF key.

Figure 3-31. To initiate Convection Bake Mode, Press the Oven ON key.

For Double Oven, press the Upper Oven ON key or the Lower Oven ON key.

f

Figure 3-32. Press the CONVECTION BAKE key. A preset temperature of 375°F will be shown in the display.

The oven begins to heat after 5 seconds or by pressing the ENTER key.

f

f

Figure 3-33. To change the preset temperature, immediately press the number keys to enter a new temperature.

Then, press the ENTER key.

f

f

Figure 3-34. To exit the Convection Bake Mode, press the Oven OFF key.

For Double oven, press the Upper Oven OFF key or the Lower Oven OFF key.

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

CLOCK

TIMER

select mode

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

OVEN ON

CLOCK

TIMER

TEMPERATURE

convection bake setpoint

OFF ON

OVEN

375

TEMPERATURE

CONV. BAKE

BAKE

°

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

.

.

3 00

OVEN ON

CLOCK

TIMER

TEMPERATURE

ON

400

TEMPERATURE

convection bake setpoint

OFF

OVEN

CONV. BAKE

BAKE

°

ROAST

BROIL

BAKE STONE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

COOK TIME

SELF CLEAN

PROBE

LIGHT

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

CLOCK

TIMER

OFF ON

CONV. BAKE

BAKE

ROAST

CONV. ROAST

BROIL

CONV. BROIL

OVEN

TEMPERATURE

BAKE STONE

CONVECTION

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 32

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-12

Broil Mode

In Broil Mode the top broil element is used to conduct an intense radiant heat which browns one side of the food

being cooked. Food cooked in any of the Broil Modes must be turned to finish cooking and browning the other side.

There are three Broil Level temperatures that can be used in this mode, Hi Broil, Medium Broil and Lo Broil.

NOTE: Preheat is never used in Broil Mode.

NOTE: The oven door MUST be closed during this mode.

To initiate Broil Mode, the oven must be OFF. First, press the Oven ON key. (See Figure 3-35). For the Double

Ovens, press the Upper Oven ON key or the Lower Oven ON key. Now, press the BROIL key. A preset temperature of 550° and the number “1” and the word HI will appear in the display. The broiler begins to heat after 5 seconds or by pressing the ENTER key. (See Figure 3-36). To change the preset temperature, immediately press the

“2” key for Medium Broil at 450° or press the “3” key for Lo Broil at 350°F. Then, press the ENTER key.

(See Figure 3-37). To exit the Broil Mode, press the Oven OFF key. (See Figure 3-38). For Double Ovens press

the Upper Oven OFF key or the Lower Oven OFF key.

Figure 3-35. To initiate Broil Mode, Press the Oven ON key.

For Double Oven, press the Upper Oven ON key or the Lower Oven ON key.

Figure 3-36. Press the BROIL key. A preset temperature of 550°F is selected and the number “1” and HI will be shown

in the display. The oven begins to heat after 5 seconds or by pressing the ENTER key.

Figure 3-37. To change the preset temperature, immediately press the “2” key for Medium Broil at 450°F.

Press the “3” key for Low Broil at 350°F Then, press the ENTER key.

Figure 3-38. To exit the Broil Mode, press the Oven OFF key.

For Double oven, press the Upper Oven OFF key or the Lower Oven OFF key.

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

CLOCK

TIMER

select mode

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

OVEN ON

CLOCK

TIMER

broil hi

OFF ON

OVEN

TEMPERATURE

TEMPERATURE

CONV. BAKE

BAKE

ROAST

BROIL

CONV. ROAST

CONV. BROIL

CONVECTION

1

BAKE STONE

1

4

7

ENTER

2

56

89

CLEAR

0

LIGHT

3

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

OVEN ON

CLOCK

TIMER

broil

OFF ON

OVEN

TEMPERATURE

3

lo

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

.

.

3 00

OFF ON

CLOCK

TIMER

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 33

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-13

Convection Broil Mode

Convection Broil Mode uses intense radiant heat from the top broil element. The convection fans also operate continuously to maintain air movement. Convection Broil Mode shortens broiling times for thicker cuts of meat. The

intense radiant heat browns and sears the surface of the meat, while the convection fans keep the interior of the

meat moist.

NOTE: Preheat is never used in Convection Broil Mode.

NOTE: The oven door MUST be closed during this mode.

To initiate Convection Broil Mode, the oven must be OFF. First, press the Oven ON key. (See Figure 3-39). For the

Double Ovens, press the Upper Oven ON key or the Lower Oven ON key. Now, press the CONVECTION BROIL

key. A preset temperature of 550° and the number “1” and the word HI will appear in the display. The broiler

begins to heat after 5 seconds or by pressing the ENTER key. (See Figure 3-40). To change the preset temperature, immediately press the “2” key for Medium Broil at 450° or press the “3” key for Lo Broil at 350°F. Then, press

the ENTER key. (See Figure 3-41). To exit the Convection Broil Mode, press the Oven OFF key.

(See Figure 3-42). For Double Ovens press the Upper Oven OFF key or the Lower Oven OFF key.

Figure 3-39. To initiate Convection Broil Mode, Press the Oven ON key.

For Double Oven, press the Upper Oven ON key or the Lower Oven ON key.

Figure 3-42. To exit the Convection Bake Mode, press the Oven OFF key.

For Double oven, press the Upper Oven OFF key or the Lower Oven OFF key.

Figure 3-40. Press the CONVECTION BROIL key. A preset temperature of 550°F is selected and the number “1” and HI

will be shown in the display. The oven begins to heat after 5 seconds or by pressing the ENTER key.

Figure 3-41. To change the preset temperature, immediately press the “2” key for Medium Broil at 450°F.

Press the “3” key for Low Broil at 350°F Then, press the ENTER key.

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

CLOCK

TIMER

select mode

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

OVEN ON

CLOCK

TIMER

TEMPERATURE

broil hi

OFF ON

OVEN

1

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

.

.

3 00

OVEN ON

CLOCK

TIMER

broil

OFF ON

OVEN

TEMPERATURE

3

lo

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

.

.

3 00

CLOCK

TIMER

OFF ON

OVEN

TEMPERATURE

BAKE

ROAST

BROIL

BAKE STONE

CONV. BAKE

CONV. ROAST

CONV. BROIL

CONVECTION

1

4

7

ENTER

2

3

56

89

CLEAR

0

LIGHT

COOK TIME

SELF CLEAN

PROBE

ON/OFF

STOP TIME

PANEL LOCK

ON/OFF

Page 34

WWaallll OOvveenn SSeerriieess

WWaallll OOvveenn SSeerriieess

Electronic Control System

3-14

Roast Mode

In Roast Mode both the hidden bake element and the broil element are cycled to maintain the desired temperature.

The hidden bake element operates 75 percent of the time and the broil element operates 25 percent of the time.