Page 1

M SERIES OVEN

INSTALLATION GUIDE

SPECIFICATIONS, INSTALLATION, AND MORE

Page 2

M SERIES OVEN

Contents

3 M Series Oven

4 Specications

12 Installation

14 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Wolf Customer Care 800.222.7820

Page 3

M SERIES OVEN

Product Information

Important product information, including the model and

serial number, are listed on the product rating plate. The

rating plate is located near the bottom trim on the left. The

oven door must be open to view the rating plate. Refer to

the illustration below.

If service is necessary, contact Wolf Factory Certied

Service with the model and serial number. For the name of

the nearest Wolf Factory Certied Service or for questions

regarding the installation, visit the contact & support section

of our website, wolfappliance.com, or call Wolf customer

care at 800-222-7820.

RATING

PLATE

Rating plate location

wolfappliance.com | 3

Page 4

SPECIFICATIONS

Installation Requirements

The M series oven can be installed in a standard or ush

inset application. If a cooktop is being installed above an

1

oven, a minimum of

/4" (6) is required between units. Location of the electrical supply within the oven opening may

require additional cabinet depth.

Finish the edges of the opening. They may be visible when

the door is open.

For standard installations, the face trim overlaps stiles and

rails. Refer to the chart below.

1

For ush inset installations, a minimum

/8" (3) reveal is

required on all sides. To ensure consistent reveals, each

corner of the opening must be exactly 90°.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

Single Oven 250 lb (115 kg)

Double Oven 400 lb (181 kg)

TRIM OVERLAP

Top 1" (25)

Bottom 0" (0)

Sides

11

/16" (18)

DUAL INSTALLATION

Two 30" single M series ovens can be installed side by side

in a standard or ush inset application. A dual installation kit

is required. To maintain appropriate airow, the ovens must

be installed into one opening. Any cosmetic or structural

material placed between the ovens will impede airow and

is not recommended. Refer to illustrations on the following

pages.

The dual installation kit is available through an authorized

Wolf dealer. For local dealer information, visit the nd a

showroom section of our website, wolfappliance.com.

4 | Wolf Customer Care 800.222.7820

Page 5

SPECIFICATIONS

Electrical Requirements

Installation must comply with all applicable electrical codes.

Locate the electrical supply ush with the back wall and

within the shaded area shown in the illustrations on the

following pages. For ease of installation, the electrical

supply for the oven can be placed in an adjacent cabinet

within reach of the conduit.

Performance may be compromised if the electrical supply is

less than 240 volts.

The oven is supplied with a conduit consisting of two

insulated hot lead conductors and a bare ground conductor.

The wiring diagram covering the control circuit is provided

with the oven.

ELECTRICAL REQUIREMENTS—SINGLE OVEN

Electrical Supply grounded, 240/208 VAC, 60 Hz

Service 30 amp dedicated circuit

Conduit 4'

Total Amps 22

Max Connected Load 5.4 kW

ELECTRICAL REQUIREMENTS —DOUBLE OVEN

Electrical Supply grounded, 240/208 VAC, 60 Hz

Service 50 amp dedicated circuit

Conduit 5'

Total Amps 45

Max Connected Load 10.8 kW

(1.2 m)

(1.5 m)

RATING

PLATE

Rating plate location

wolfappliance.com | 5

Page 6

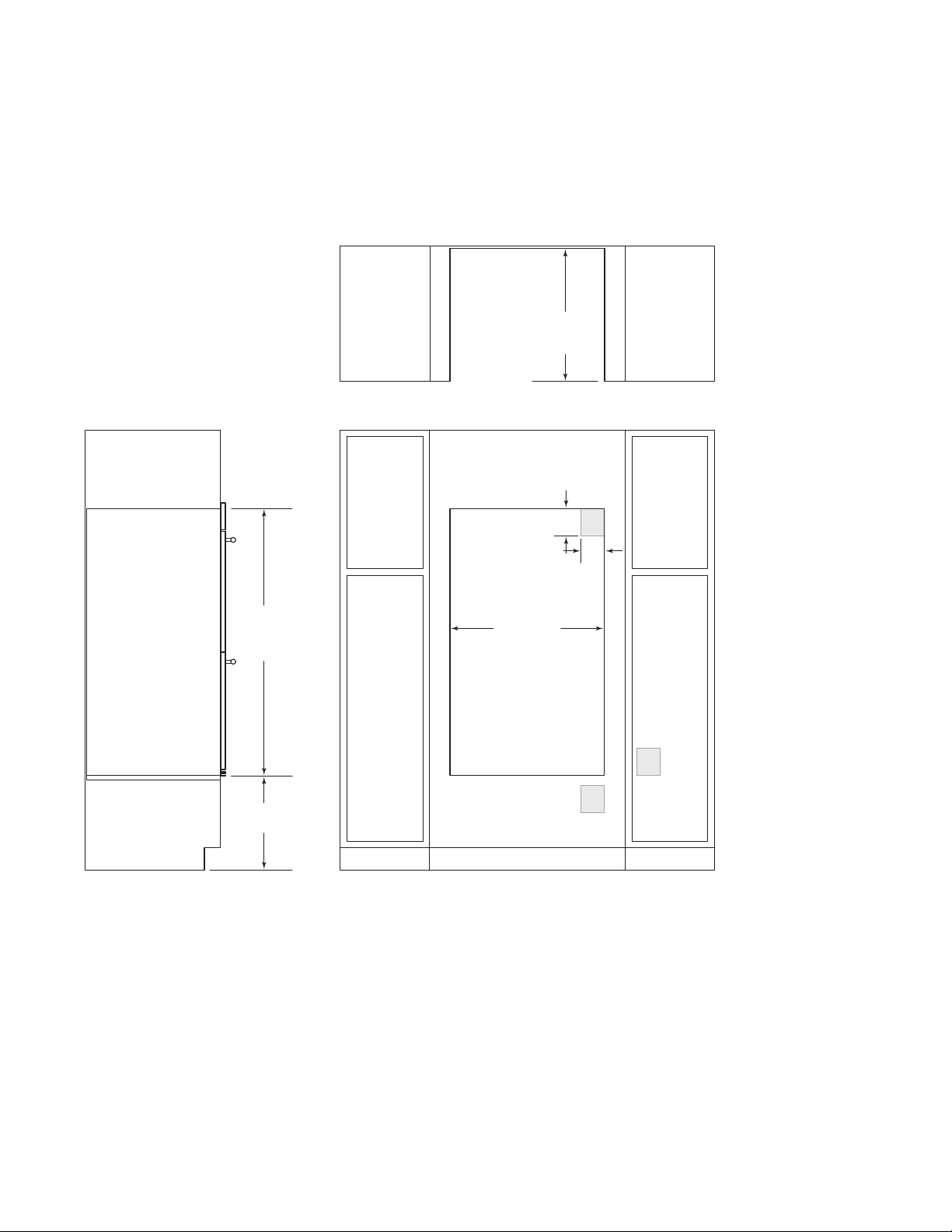

SPECIFICATIONS

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

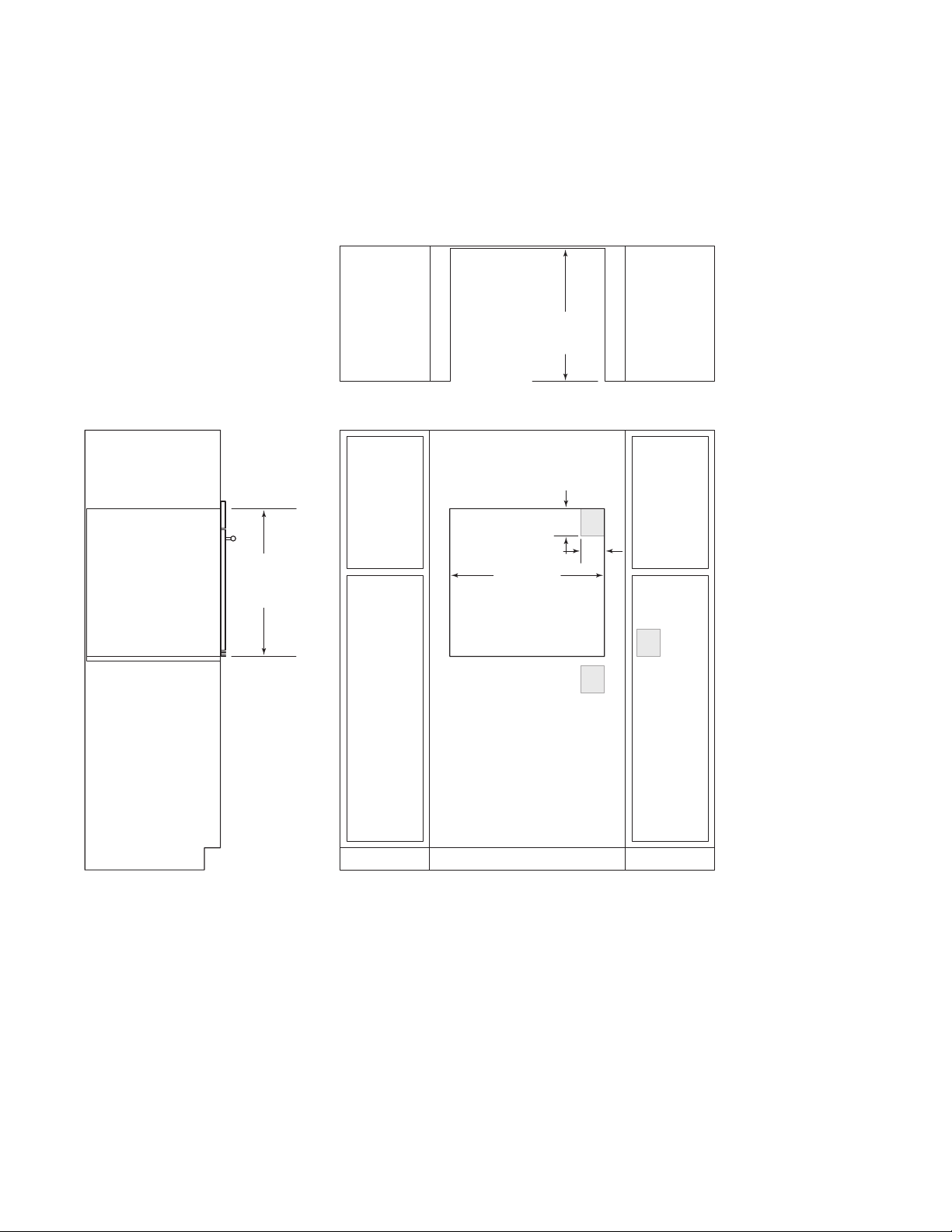

30" M Series Single Oven

STANDARD INSTALLATION

231/4" (591)

TOP VIEW

OPENING

DEPTH

VIEW

271/2"

(699)

OPENING

HEIGHT

281/2" (724)

OPENING WIDTH

FRONT VIEW

5"

(127)

E

4"

(102)

E

E

6 | Wolf Customer Care 800.222.7820

Page 7

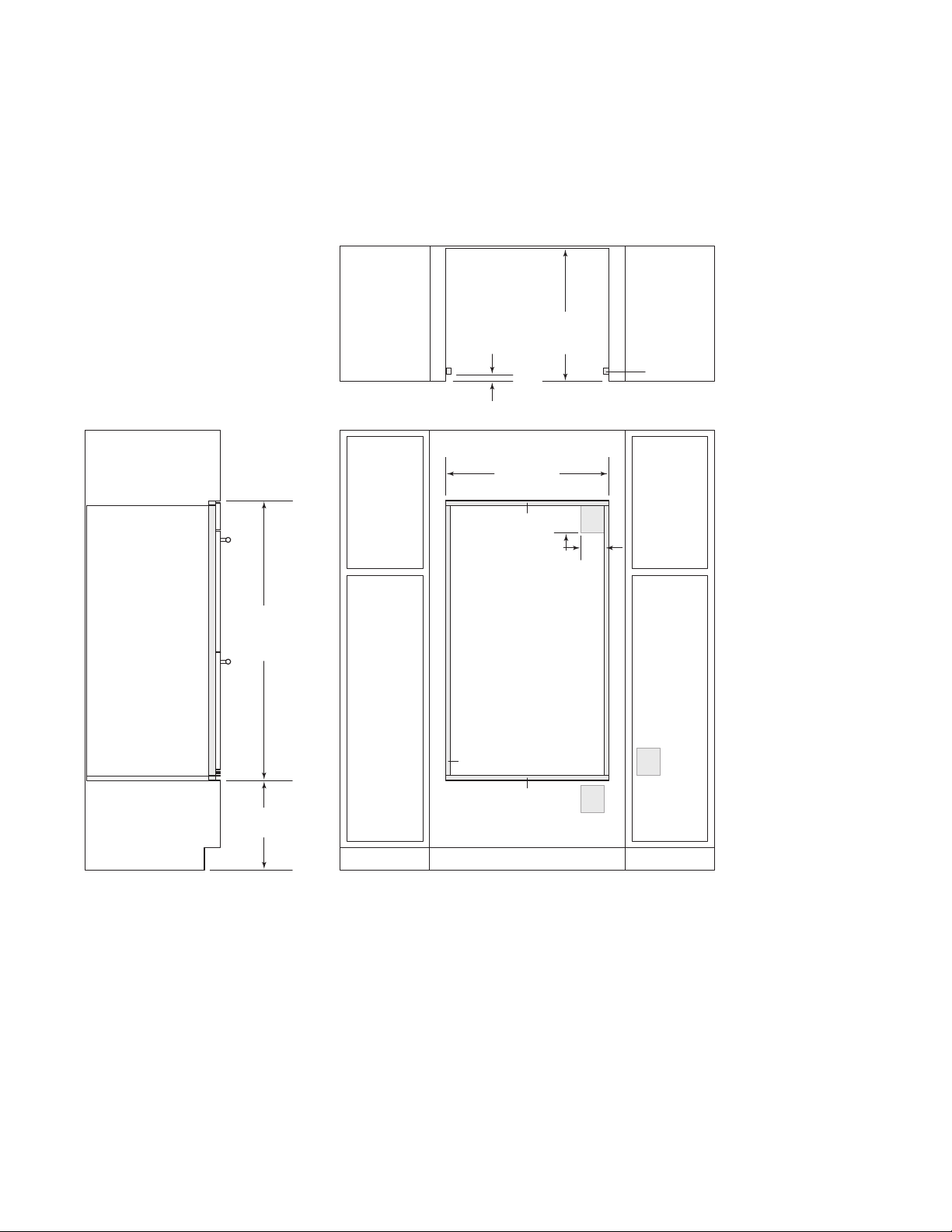

SPECIFICATIONS

*1

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth.

SIDE

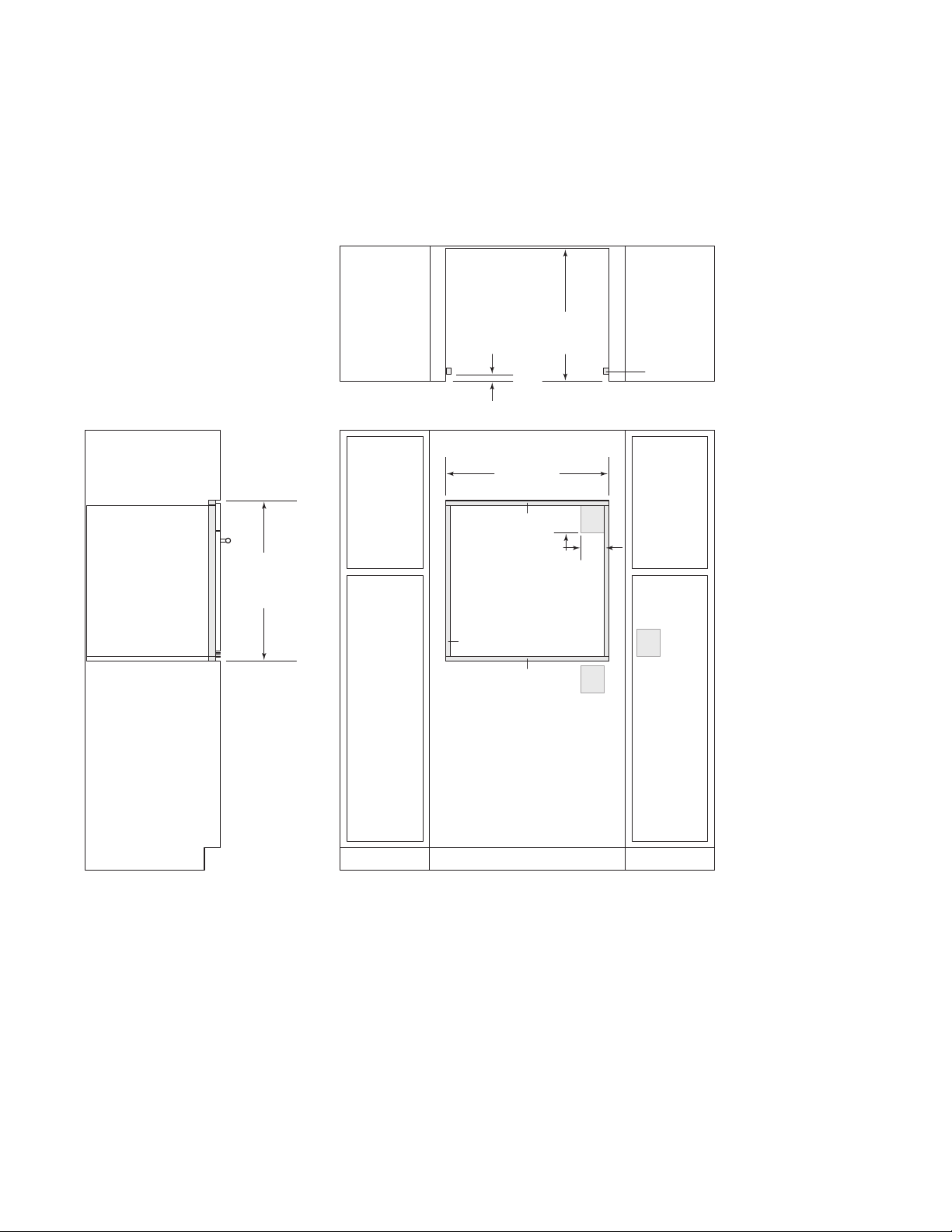

30" M Series Single Oven

FLUSH INSET INSTALLATION

283/4"

(730)

FLUSH INSET

HEIGHT***

7

(22)

/8"

OR

(25)**

1"

FLUSH INSET WIDTH***

24" (610)

FLUSH INSET

TOP VIEW

301/8" (765)

DEPTH

11/8" (29)

13

/16" (21)

1

/8" (3)

5"

(127)

E

4"

(102)

E

FINISHED

CLEATS*

E

VIEW

" (25) minimum depth. Shaded areas will be visible and should be finished to match cabinetry.

7

/8" (22) for transitional, professional and contemporary stainless steel models and 1" (25) for contemporary black glass model.

*Dimension provides minimum reveals.

FRONT VIEW

wolfappliance.com | 7

Page 8

SPECIFICATIONS

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

30" M Series Double Oven

STANDARD INSTALLATION

231/4" (591)

TOP VIEW

OPENING

DEPTH

VIEW

497/8"

(1267)

OPENING

HEIGHT

17" (432)

TYPICAL

281/2" (724)

OPENING WIDTH

FRONT VIEW

5"

(127)

E

4"

(102)

E

E

8 | Wolf Customer Care 800.222.7820

Page 9

SPECIFICATIONS

*1

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth.

SIDE

30" M Series Double Oven

FLUSH INSET INSTALLATION

511/8"

(1299)

FLUSH INSET

HEIGHT***

7

(22)

/8"

OR

(25)**

1"

FLUSH INSET WIDTH***

24" (610)

FLUSH INSET

TOP VIEW

301/8" (765)

DEPTH

11/8" (29)

13

/16" (21)

5"

(127)

E

4"

(102)

FINISHED

CLEATS*

E

(432)

17"

TYPICAL

VIEW

" (25) minimum depth. Shaded areas will be visible and should be finished to match cabinetry.

7

/8" (22) for transitional, professional and contemporary stainless steel models and 1" (25) for contemporary black glass model.

*Dimension provides minimum reveals.

1

/8" (3)

FRONT VIEW

E

wolfappliance.com | 9

Page 10

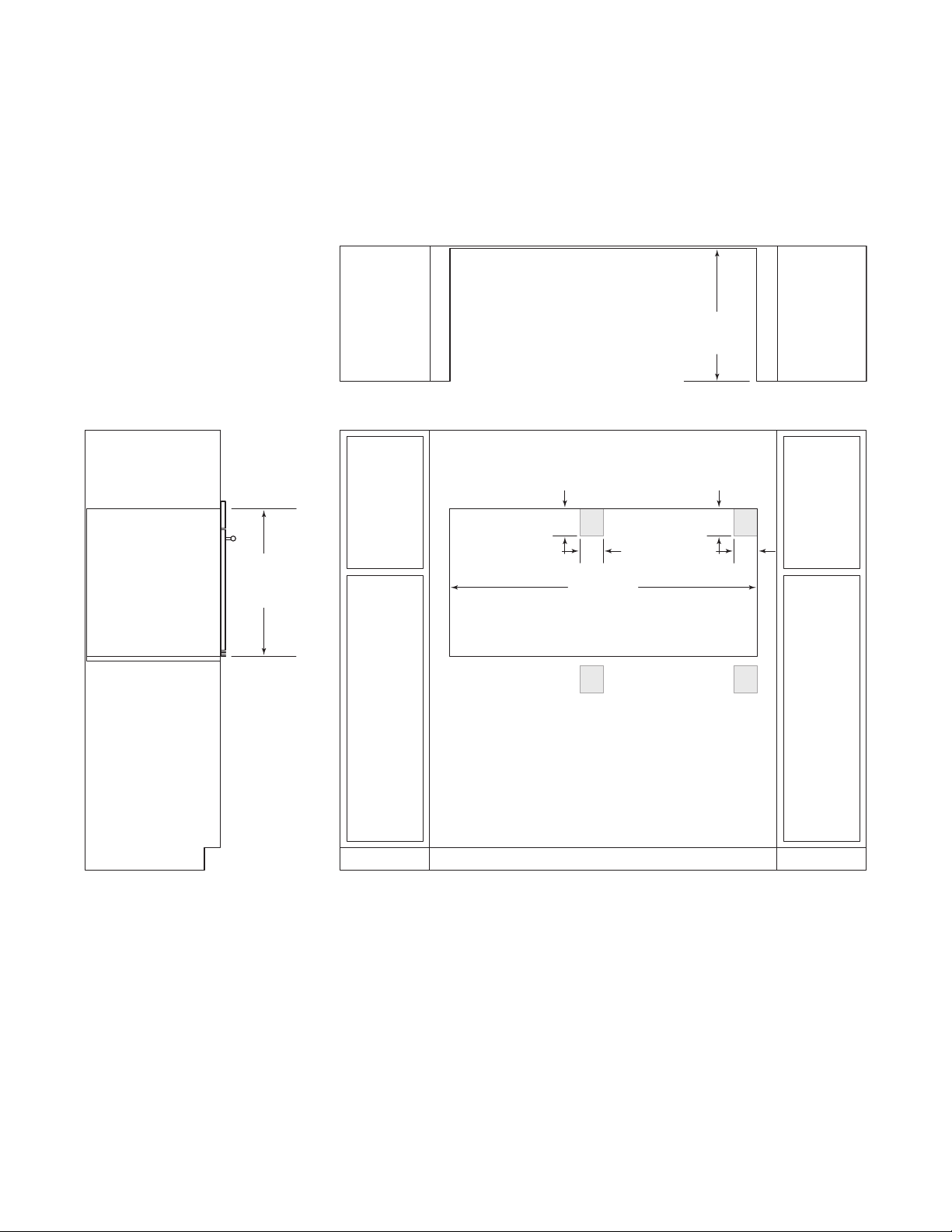

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth. A dual installation kit is required fo

SPECIFICATIONS

30" M Series Oven

DUAL STANDARD INSTALLATION

TOP VIEW

231/4" (591)

OPENING

DEPTH

VIEW

271/2"

(699)

OPENING

HEIGHT

5"

E

(127)

4"

(102)

581/2" (1486)

OPENING WIDTH

E E

FRONT VIEW

r this installation.

5"

(127)

E

4"

(102)

10 | Wolf Customer Care 800.222.7820

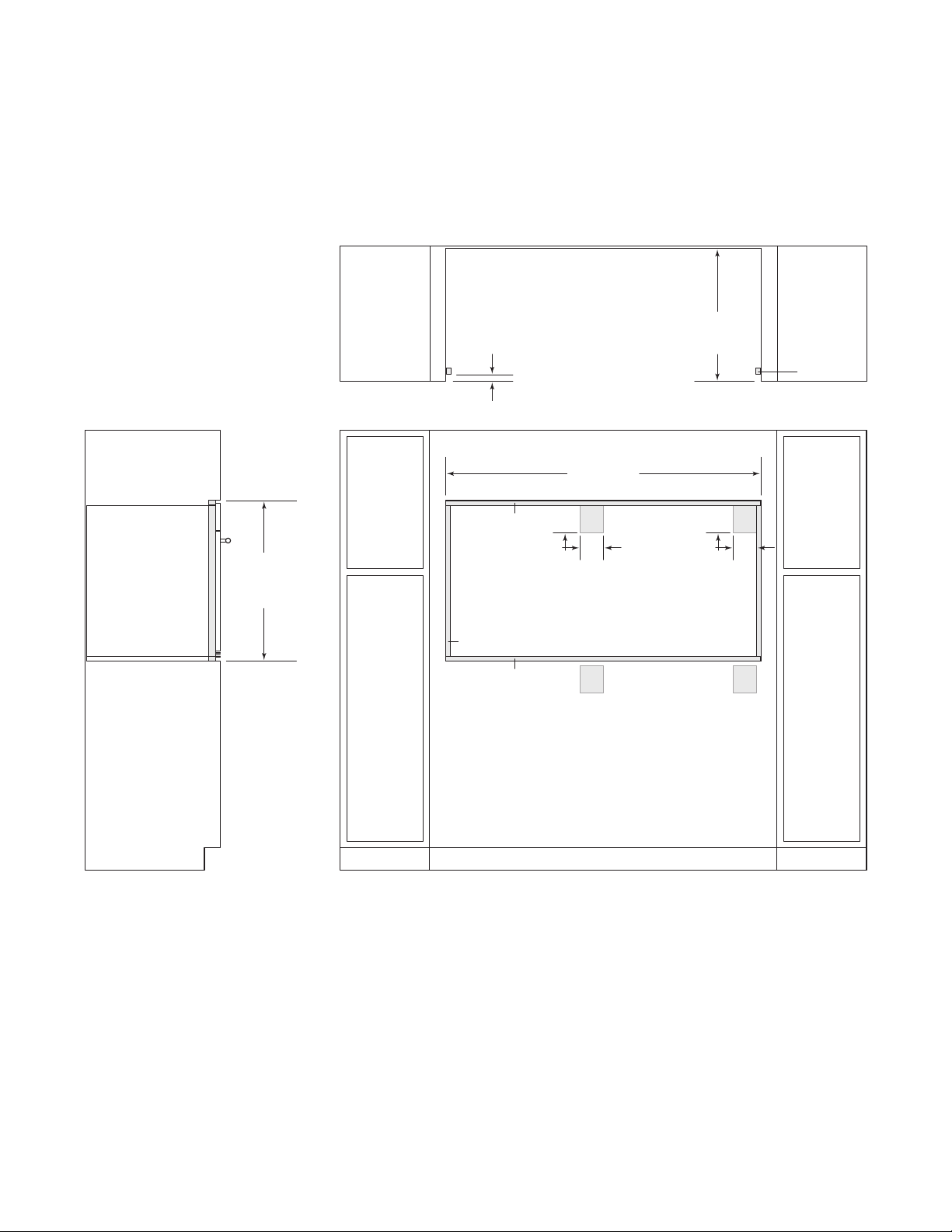

Page 11

SIDE

*1

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth. A dual installation kit is required fo

SPECIFICATIONS

30" M Series Oven

DUAL FLUSH INSET INSTALLATION

283/4"

(730)

FLUSH INSET

HEIGHT***

7

1"

13

/16" (21)

(22)

/8"

OR

(25)**

11/8" (29)

1

/8" (3)

TOP VIEW

601/8" (1527)

FLUSH INSET WIDTH***

5"

E

(127)

4"

(102)

24" (610)

FLUSH INSET

DEPTH

5"

(127)

(102)

FINISHED

CLEATS*

E

4"

EE

VIEW

" (25) minimum depth. Shaded areas will be visible and should be finished to match cabinetry.

7

/8" (22) for transitional, professional and contemporary stainless steel models and 1" (25) for contemporary black glass model.

*Dimension provides minimum reveals.

FRONT VIEW

r this installation.

wolfappliance.com | 11

Page 12

INSTALLATION

Preparation

Before moving the oven, protect any nished ooring and

secure the oven door(s) closed to prevent damage.

Use an appliance dolly to move the oven near the opening.

Place the appliance dolly on the side or back to prevent

damage. Remove and recycle packing materials. Do not lift

or carry the oven by the door handle.

OVEN DOOR REMOVAL

To lighten the load, the oven door(s) can be removed. Only

remove if necessary. Door removal should only be done by a

certied installer or service technician.

To remove, open the door completely. Rotate both hinge

latches forward to the open position, remove each screw

closest to the hinge, then lift the door up and out. Refer to

the illustration below.

To reinstall, insert door hinges into the frame openings, then

rotate hinge latches to the closed position.

CLOSED

SCREW

OPEN

Oven door removal

12 | Wolf Customer Care 800.222.7820

Page 13

INSTALLATION

Electrical Connection

WARNING

Verify power is disconnected from the electrical box

before proceeding.

If the electrical supply is located in the opening, electrical

connection must be made prior to placing the oven in the

opening. If the electrical supply is in an adjacent cabinet,

electrical connection can be made after placing the oven in

the opening. The conduit on the back of the unit allows for

a 3-wire or 4-wire installation.

1 Connect the black appliance wire to the black (L1)

power supply.

2 Connect the red appliance wire to the red (L2) power

supply.

3 Connect the bare appliance wire to the green/ground

wire.

4 For a four-wire system, seal the white/neutral wire with

a wire cap.

Installation

Place the oven in the opening and slide into position. To

ensure adequate depth for proper installation, the conduit

must t into the recessed area along the rear edge of the

oven.

1

Locate the mounting hole in each side trim. Drill

3

holes and install #6 x

/4" screws. Refer to the illustration

below.

Remove and recycle packing materials including the white

protective material behind each rack guide mounting

location.

MOUNTING

HOLE

/16" (2) pilot

Mounting hole

wolfappliance.com | 13

Page 14

TROUBLESHOOTING

Troubleshooting

IMPORTANT NOTE: If the oven does not operate properly,

follow these troubleshooting steps:

• Verify electrical power is supplied to the oven.

• Verify proper electrical connections.

• If the oven does not operate properly, contact Wolf Fac-

tory Certied Service. Do not attempt to repair the oven.

Wolf is not responsible for service required to correct a

faulty installation.

14 | Wolf Customer Care 800.222.7820

Page 15

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design are registered trademarks and service marks of Sub-Zero Group, Inc. and its subsidiaries.

All other trademarks are property of their respective owners in the United States and other countries.

Page 16

HORNO DE LA SERIE M

Contenido

3 Horno de la serie M

4 Especicaciones

12 Instalación

14 Resolución de problemas

Las características y especicaciones están sujetas a cambios sin previo aviso. Visite wolfappliance.com/specs para

obtener la información más actualizada.

Aviso importante

Para garantizar que este producto se instale y opere de

la forma más segura y eciente posible, tome nota de los

siguientes tipos de información resaltada en esta guía:

AVISO IMPORTANTE señala la información que es especial-

mente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

ADVERTENCIA indica peligro de que se produzcan heridas

graves o incluso la muerte si no se siguen las precauciones.

AVISO IMPORTANTE: en toda esta guía, las dimensiones

entre paréntesis son milímetros, a menos que se especique lo contrario.

AVISO IMPORTANTE: guarde estas instrucciones para el

inspector eléctrico local.

2 | Atención al cliente de Wolf 800.222.7820

Page 17

HORNO DE LA SERIE M

Información del producto

La información importante del producto, incluido el modelo

y número de serie de la unidad, se encuentra en la placa

de datos del producto. La placa de datos se encuentra

cerca de la moldura inferior. La puerta del horno debe estar

abierta para ver la placa de datos. Consulte la siguiente

ilustración.

Si necesita servicio, póngase en contacto con el centro de

servicio autorizado de Wolf y tenga a la mano el modelo y

número de serie de la unidad. Para obtener los datos del

centro de servicio autorizado de Wolf más cercano o si

tiene preguntas acerca de la instalación, visite la sección de

contacto y soporte técnico en nuestra página de Internet

wolfappliance.com o llame a la línea de atención al cliente

de Wolf al 800-222-7820.

PLACA DE

DATOS

Ubicación de la placa de datos

wolfappliance.com | 3

Page 18

ESPECIFICACIONES

Requisitos de instalación

El horno se puede instalar en una aplicación estándar o

empotrable. Si se instala una estufa sobre el horno, se

1

requiere un espacio mínimo de

/4" (6) entre las unidades.

Es posible que la ubicación del suministro eléctrico al interior de la abertura del horno requiera de un gabinete

de mayor profundidad. Consulte la tabla siguiente.

Dé el acabado a los bordes de la abertura. Pueden ser visibles cuando la puerta está abierta.

Para las instalaciones empotrables se requiere un margen

1

mínimo de

tener un margen uniforme de

/8" (3) en todos los lados. Para asegurarse de

1

/8" (3), cada esquina de la

abertura debe tener exactamente 90°.

REQUISITOS DE INSTALACIÓN

SOPORTE DE LA BASE MIN

Horno sencillo 250 lb (115 kg)

Horno doble 400 lb (181 kg)

SUPERPOSICIÓN DEL RIBETE

Parte superior 1" (25)

Parte inferior 0" (0)

Laterales

11

/16" (18)

INSTALACIÓN DOBLE

Se pueden instalar dos hornos 30" sencillo de la serie M,

uno junto al otro, en una aplicación estándar o empotrable.

Se requiere kit de instalación doble. Para mantener un ujo

de aire adecuado, los hornos se deben instalar en una sola

abertura. Cualquier elemento cosmético o estructural que

se coloque entre los hornos obstruirá el ujo de aire y, por

lo tanto, no se recomienda. Consulte las ilustraciones de las

páginas siguientes.

El kit de instalación doble está disponible a través de un

distribuidor autorizado de Wolf. Para obtener más información acerca de los distribuidores locales, visite la

sección de salas de exposiciones de nuestro sitio web,

wolfappliance.com.

4 | Atención al cliente de Wolf 800.222.7820

Page 19

ESPECIFICACIONES

Instalación eléctrica

La instalación debe tener una conexión a tierra de conformidad

con los códigos locales o, en ausencia de códigos locales,

con el Código Nacional de Electricidad, ANSI/NFPA 70.

Coloque el suministro eléctrico a ras con la pared posterior

y dentro del área sombreada que se muestra en la ilustración de las páginas siguientes para su instalación especíca. Para facilitar la instalación, el suministro eléctrico

para el horno se puede colocar en un gabinete adyacente

al alcance del conducto. Utilice únicamente el conducto

suministrado con este electrodoméstico.

El rendimiento puede verse comprometido si el suministro

eléctrico es menor a 240 voltios.

El horno se entrega con un conducto con cableado consistente en dos conductores aislados para energía y un

conductor desnudo para conexión a tierra. El diagrama

de cableado que abarca el circuito de control viene con el

horno.

REQUISITOS ELÉCTRICOS—HORNO SENCILLO

Suministro eléctrico Aterrizado, 240/208 VAC, 60 Hz

Servicio Circuito dedicado de 30 amperes

Conducto 4'

Total de amperes 22

Carga máxima conectada 5.4 kW

REQUISITOS ELÉCTRICOS—HORNO DOBLE

Suministro eléctrico Aterrizado, 240/208 VAC, 60 Hz

Servicio Circuito dedicado de 50 amperes

Conducto 5'

Total de amperes 45

Carga máxima conectada 10.8 kW

(1.2 m)

(1.5 m)

PLACA DE

DATOS

Ubicación de la placa de datos

wolfappliance.com | 5

Page 20

VIST

NOTA: es posible que la ubicación del suministro eléctrico al interior de la abertura requiera de un gabinete de mayor profundi

ESPECIFICACIONES

Horno sencillo de la serie M

INSTALACIÓN ESTÁNDAR

231/4" (591)

PROFUNDIDAD DE

LA ABERTURA

VISTA SUPERIOR

A LATERAL

271/2"

(699)

ALTURA DE

LA ABERTURA

5"

(127)

(102)

(724)

281/2"

ANCHURA DE LA ABERTURA

VISTA FRONTAL

E

4"

E

E

dad.

6 | Atención al cliente de Wolf 800.222.7820

Page 21

ESPECIFICACIONES

VIST

*1

**

***Las dimensiones especifican los márgenes mínimos.

NOTA: es posible que la ubicación del suministro eléctrico al interior de la abertura requiera de un gabinete de mayor profundi

Horno sencillo de la serie M

INSTALACIÓN EMPOTRABLE

283/4"

(730)

ALTURA DE LA

INSTALACIÓN

EMPOTRABLE***

7

(22)

/8"

O

(25)**

1"

ANCHO DE LA INSTALACIÓN

EMPOTRABLE***

13

/16" (21)

24" (610)

PROFUNDIDAD DE

LA INSTALACIÓN

EMPOTRABLE

VISTA SUPERIOR

301/8" (765)

/8" (3)

5"

(127)

11/8" (29)

1

(102)

CORNAMUSAS

TERMINADAS*

E

4"

E

E

A LATERAL

" (25) profundidad mínima. Las áreas sombreadas serán visibles y se les debe dar un acabado que combine con los gabinetes.

7

/8" (22) para los modelos de transición, profesionales y contemporáneas de acero inoxidable y 1" (25) para el modelo de cristal negro contemporáneo.

VISTA FRONTAL

dad.

wolfappliance.com | 7

Page 22

ESPECIFICACIONES

VIST

NOTA: es posible que la ubicación del suministro eléctrico al interior de la abertura requiera de un gabinete de mayor profundi

Horno doble de la serie M

INSTALACIÓN ESTÁNDAR

231/4" (591)

PROFUNDIDAD DE

LA ABERTURA

VISTA SUPERIOR

A LATERAL

497/8"

(1267)

ALTURA DE LA

ABERTURA

17" (432)

TÍPICA

5"

(127)

(102)

281/2" (724)

ANCHURA DE LA ABERTURA

VISTA FRONTAL

E

4"

E

E

dad.

8 | Atención al cliente de Wolf 800.222.7820

Page 23

ESPECIFICACIONES

*1

**

***Las dimensiones especifican los márgenes mínimos.

NOTA: es posible que la ubicación del suministro eléctrico al interior de la abertura requiera de un gabinete de mayor profundi

VIST

Horno doble de la serie M

INSTALACIÓN EMPOTRABLE

511/8"

(1299)

ALTURA DE LA

INSTALACIÓN

EMPOTRABLE***

7

(22)

/8"

O

(25)**

1"

ANCHO DE LA INSTALACIÓN

EMPOTRABLE***

13

/16" (21)

24" (610)

PROFUNDIDAD DE

LA INSTALACIÓN

EMPOTRABLE

VISTA SUPERIOR

301/8" (765)

11/8" (29)

5"

(127)

(102)

CORNAMUSAS

TERMINADAS*

E

4"

E

1

/8" (3)

(432)

17"

TÍPICA

A LATERAL

" (25) profundidad mínima. Las áreas sombreadas serán visibles y se les debe dar un acabado que combine con los gabinetes.

7

/8" (22) para los modelos de transición, profesionales y contemporáneas de acero inoxidable y 1" (25) para el modelo de cristal negro contemporáneo.

VISTA FRONTAL

E

dad.

wolfappliance.com | 9

Page 24

ESPECIFICACIONES

VIST

NOTA: es posible que la ubicación del suministro eléctrico al interior de la abertura requiera de un gabinete de mayor profundi

Dos hornos doble de la serie M

INSTALACIÓN ESTÁNDAR

VISTA SUPERIOR

231/4" (591)

PROFUNDIDAD

DE LA ABERTURA

A LATERAL

271/2"

(699)

ALTURA DE

LA ABERTURA

5"

E

(127)

4"

(102)

(1486)

581/2"

ANCHURA DE LA ABERTURA

E E

VISTA FRONTAL

dad.

5"

(127)

E

4"

(102)

10 | Atención al cliente de Wolf 800.222.7820

Page 25

ESPECIFICACIONES

*1

**

***

NOTA: es posible que la ubicación del suministro eléctrico al interior de la abertura requiera de un gabinete de mayor profundi

VIST

Dos hornos doble de la serie M

INSTALACIÓN EMPOTRABLE

283/4"

(730)

ALTURA DE LA

INSTALACIÓN

EMPOTRABLE***

7

(22)

/8"

O

(25)**

1"

VISTA SUPERIOR

(1527)

ANCHO DE LA INSTALACIÓN EMPOTRABLE***

11/8" (29)

13

/16" (21)

1

/8" (3)

601/8"

5"

E E

(127)

4"

(102)

24" (610)

PROFUNDIDAD DE

LA INSTALACIÓN

EMPOTRABLE

5"

(127)

4"

(102)

EE

CORNAMUSAS

TERMINADAS*

A LATERAL

" (25) profundidad mínima. Las áreas sombreadas serán visibles y se les debe dar un acabado que combine con los gabinetes.

7

/8" (22) para los modelos de transición, profesionales y contemporáneas de acero inoxidable y 1" (25) para el modelo de cristal negro contemporáneo.

Las dimensiones especifican los márgenes mínimos.

VISTA FRONTA L

dad.

wolfappliance.com | 11

Page 26

INSTALACIÓN

Preparación

Antes de mover el horno, proteja cualquier suelo acabado y

asegúrese de que la(s) puerta(s) del horno esté(n) cerrada(s)

para que no se dañe(n).

Utilice una plataforma rodante para mover la unidad

cerca de la abertura. Para evitar daños, coloque la carretilla del electrodoméstico en el costado o en la parte

posterior. Retire y recicle los materiales de embalaje. No

utilice la manija de la puerta del horno para levantarlo ni

transportarlo.

CÓMO QUITAR LA PUERTA DEL HORNO

Para aligerar la carga, puede quitarse la puerta del horno.

Quítela únicamente si es necesario. El proceso para quitar

la puerta del horno solamente debe ser realizado por un

instalador certicado o un técnico de servicio.

Para quitarla, abra la puerta completamente. Gire los pestillos de las dos bisagras hacia adelante a la posición abierta,

quite los tornillos más cercanos a las bisagras, y a continuación levante la puerta hacia arriba y hacia afuera. Consulte

la siguiente ilustración.

Para reinstalarla, inserte las bisagras de la puerta en las

aberturas del marco y gire los pestillos de las bisagras hacia

la posición de cerrado.

TORNILLO

CERRADO

CLOSED

ABIERTO

SCREW

OPEN

12 | Atención al cliente de Wolf 800.222.7820

Cómo quitar la puerta del

horno

Page 27

INSTALACIÓN

Conexión eléctrica

ADVERTENCIA

Verique que la alimentación esté desconectada de la

caja eléctrica antes de proceder.

Si el suministro eléctrico se ubica en la abertura, la conexión eléctrica debe hacerse antes de colocar la unidad en

la abertura. Si el suministro eléctrico está en un gabinete

anexo, la conexión eléctrica puede hacerse después de

colocar la unidad en la abertura. El conducto en la parte

posterior de la unidad permite una instalación de 3 cables o

4 cables.

1 Conecte el cable negro del electrodoméstico al cable

negro (L1) del suministro eléctrico.

2 Conecte el cable rojo del electrodoméstico al cable rojo

(L2) del suministro eléctrico.

3 Conecte el cable desnudo del electrodoméstico al cable

verde de tierra.

4 En un sistema de cuatro cables, selle el cable blanco

neutro con un tapón para cables.

Instalación

Coloque el horno en la abertura y deslícelo a su posición.

Para asegurarse de que tiene la profundidad adecuada para

la correcta instalación, el conducto debe ajustar en el área

deprimida a lo largo del borde trasero del horno.

Ubique el oricio de montaje en la moldura de cada lado.

Perfore oricios guía de

Consulte la siguiente ilustración.

Retire y recicle los materiales de empaque, incluyendo el

material blanco de protección detrás de la ubicación de

guía de montaje de cada rejilla.

ORIFICIO DE

MONTAJE

1

/16" (2) e instale tornillos #6 x 3/4".

Ubicación de los oricios

wolfappliance.com | 13

Page 28

RESOLUCIÓN DE PROBLEMAS

Resolución de problemas

AVISO IMPORTANTE: si el horno no funciona correctamente,

siga estos pasos para resolver los problemas:

• Compruebe que el horno tiene corriente eléctrica.

• Compruebe que las conexiones eléctricas estén

correctas.

• Si el horno no funciona correctamente, póngase en con-

tacto con el centro de servicio autorizado de Wolf. No

intente reparar el horno. Wolf no es responsable del servicio necesario para corregir una instalación defectuosa.

14 | Atención al cliente de Wolf 800.222.7820

Page 29

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design son marcas registradas y marcas de servicio de Sub-Zero Group, Inc. y sus asociados. Todas

las demás marcas registradas son propiedad de sus dueños respectivos en los Estados Unidos y otros países.

Page 30

FOUR DE LA SÉRIE M

Table des matières

3 Four de la série M

4 Spécications

12 Installation

14 Dépannage

Les caractéristiques et les spécications peuvent être modiées en tout temps sans préavis. Visitez wolfappliance.com/

specs pour obtenir les renseignements les plus récents.

Remarque importante

Pour s'assurer que ce produit est installé et utilisé en toute

sécurité et aussi efcacement que possible, prenez note des

types de renseignement mis en évidence tout au long de ce

guide :

REMARQUE IMPORTANTE met en évidence des renseigne-

ments qui sont particulièrement importants.

MISE EN GARDE indique une situation où une blessure

mineure ou des dommages au produit peuvent se produire

si les directives ne sont pas respectées.

AVERTISSEMENT décrit un danger qui peut causer une

blessure grave ou la mort si les précautions ne sont pas

respectées.

REMARQUE IMPORTANTE : tout au long de ce guide, les

dimensions entre parenthèses sont en millimètres à moins

d'indication contraire.

REMARQUE IMPORTANTE : conservez ces directives pour

l'inspecteur en électricité local.

2 | Service à la clientèle de Wolf 800.222.7820

Page 31

FOUR DE LA SÉRIE M

Renseignements sur le produit

Des renseignements importants sur le produit, y compris les

numéros de modèle et de série, se trouvent sur la plaque

signalétique du produit. La plaque signalétique est située

près du fond de la garniture. La porte du four doit être

ouverte pour voir la plaque signalétique. Reportez-vous à

l'illustration ci-dessous.

Si vous avez besoin de service, communiquez avec le

service Wolf certié par l'usine avec les numéros de

modèle et de série. Pour obtenir le nom du centre de

service Wolf certié par l'usine le près de chez vous ou

si vous avez des questions concernant l'installation,

consultez la section Contact et assistance de notre site

Web, wolfappliance.com ou appelez le service à la

clientèle de Wolf au 800-222-7820.

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

wolfappliance.com | 3

Page 32

SPÉCIFICATIONS

Exigences d'installation

Le four peut être installé dans une application standard

ou à afeurement. Si une surface de cuisson sera installée

au-dessus d'un four, un espace minimum de ¼po

(6) est

requis entre les unités. L'emplacement de l'alimentation

électrique dans l'ouverture du four peut exiger une profondeur d'armoire supplémentaire. Reportez-vous au tableau

ci-dessous.

Finissez les rebords de l'ouverture. Ils peuvent être visibles

lorsque la porte est ouverte.

Pour les applications à afeurement, un jeu minimum de

1

/8po (3) est requis de tous les côtés. Pour assurer l'obten-

tion de jeux uniformes de

1

/8 po (3), chaque coin de l'ouver-

ture doit mesurer exactement 90°.

EXIGENCES D'INSTALLATION

SUPPORT DE BASE MIN

Four simple 250 lb (115 kg)

Four double 400 lb (181 kg)

CHEVAUCHEMENT DE LA GARNITURE

Dessus 1po (25)

Fond 0 po (0)

Côtés

11

/16po (18)

INSTALLATION DOUBLE

Deux fours 30 po simple de la série M peuvent être installés

un à côté de l'autre dans une application standard ou à

afeurement. Une trousse d'installation double est requise.

Pour préserver un débit d'air approprié, les fours doivent

être installés dans une seule ouverture. Tout matériau

cosmétique ou structurel placé entre les fours empêchera

le débit d'air et n'est pas recommandé. Reportez-vous aux

illustrations sur les pages suivantes.

La trousse d'installation double est offerte par les dépositaires Wolf autorisés. Pour obtenir des renseignements sur

le dépositaire local, visitez la section salle d'exposition de

notre site Web, wolfappliance.com.

4 | Service à la clientèle de Wolf 800.222.7820

Page 33

SPÉCIFICATIONS

Électricité

L'installation doit être mise à la terre électriquement

conformément aux codes locaux ou, en l'absence de codes

locaux, au code national de l'électricité, ANSI/NFPA 70.

Placez l'alimentation électrique à égalité avec le mur arrière

et à l'intérieur de la zone ombragée indiquée dans l'illustration pour votre installation précise se trouvant sur les pages

suivantes. Pour faciliter l'installation, l'alimentation électrique du four peut être placée dans une armoire adjacente

à portée de la canalisation. Utilisez seulement la canalisation fournie avec cet appareil.

La performance peut être compromise si l'alimentation électrique est inférieure à 240volts.

Le four est fourni avec une canalisation composée de deux

ls conducteurs chargés isolés et d'un conducteur nu mis

à la terre. Le diagramme de câblage couvrant le circuit de

contrôle est fourni avec le four.

EXIGENCES ÉLECTRIQUES—FOUR SIMPLE

Alimentation électrique mise à la terre, 240/208 volts CA, 60 Hz

Service circuit dédié de 30 ampères

Canalisation 4 pi

Intensité électrique 22

Charge max de connexion

EXIGENCES ÉLECTRIQUES—FOUR DOUBLE

Alimentation électrique mise à la terre, 240/208 volts CA, 60 Hz

Service circuit dédié de 50 ampères

Canalisation 5 pi

Intensité électrique 45

Charge max de connexion

(1,2m)

5,4 kW

(1,5m)

10,8 kW

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

wolfappliance.com | 5

Page 34

VUE DE PR

REMARQUE : l'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'armoire supplémentaire

SPÉCIFICATIONS

Four simple de la série M

INSTALLATION STANDARD

PROFONDEUR

D'OUVERTURE

231/4 PO (591)

DE

VUE DE DESSUS

OFIL

HAUTEUR

D'OUVERTURE

271/2 PO

DE

(699)

5 PO

(127)

4 PO

(102)

2 PO (724)

281/

LARGEUR DE L'OUVERTURE

VUE DE FACE

E

E

E

.

6 | Service à la clientèle de Wolf 800.222.7820

Page 35

SPÉCIFICATIONS

*

**

***

REMARQUE : l'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'armoire supplémentaire

VUE DE PR

Four simple de la série M

INSTALLATION À AFFLEUREMENT

PROFONDEUR

D'AFFLEUREMENT

PO (610)

24

7

8 PO (22)

/

PO (25)**

1

LARGEUR DE L'AFFLEUREMENT***

DE

OU

VUE DE DESSUS

301/8 PO (765)

TAQUETS

FINIS*

PO

1

/8 PO (3)

5

(127)

E

4 PO

(102)

E

E

.

1

/8 PO (29)

1

HAUTEUR

D'AFFLEUREMENT

283/4 PO

DE

(730)***

13

/16 PO (21)

OFIL

Profondeur minimale de 1 po (25). Les zones ombragées seront visibles et doivent être finies pour s'agencer avec les armoires.

7

/8 po (22) pour les modèles de transition, professionnels et contemporaine en acier inoxydable et 1 po (25) pour le modèle contemporain de verre noir.

Les dimensions fournissent des jeux minimums.

VUE DE FACE

wolfappliance.com | 7

Page 36

SPÉCIFICATIONS

VUE DE PR

REMARQUE : l'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'armoire supplémentaire

Four double de la série M

INSTALLATION STANDARD

PROFONDEUR

D'OUVERTURE DE

231/4 PO (591)

VUE DE DESSUS

OFIL

HAUTEUR

D'OUVERTURE

497/8 PO

DE

(1267)

17 PO (432)

TYPIQUE

5 PO

(127)

4 PO

(102)

281/2 PO (724)

LARGEUR DE L'OUVERTURE

VUE DE FACE

E

E

E

.

8 | Service à la clientèle de Wolf 800.222.7820

Page 37

SPÉCIFICATIONS

VUE DE PR

*

**

***

REMARQUE : l'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'armoire supplémentaire

Four double de la série M

INSTALLATION À AFFLEUREMENT

PROFONDEUR

OU

VUE DE DESSUS

1

30

D'AFFLEUREMENT

24 PO (610)

DE

/8 PO (765)

7

8 PO (22)

/

PO (25)**

1

LARGEUR DE L'AFFLEUREMENT***

TAQUETS

FINIS*

PO

5

11/8 PO (29)

HAUTEUR

D'AFFLEUREMENT

511/8 PO

DE

(1299)***

13

/16 PO (21)

1

/8 PO (3)

PO (432)

17

TYPIQUE

OFIL

Profondeur minimale de 1 po (25). Les zones ombragées seront visibles et doivent être finies pour s'agencer avec les armoires.

7

/8 po (22) pour les modèles de transition, professionnels et contemporaine en acier inoxydable et 1 po (25) pour le modèle contemporain de verre noir.

Les dimensions fournissent des jeux minimums.

VUE DE FACE

(127)

E

4 PO

(102)

E

E

.

wolfappliance.com | 9

Page 38

SPÉCIFICATIONS

VUE DE PR

REMARQUE : l'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'armoire supplémentaire

Deux fours de la série M

INSTALLATION STANDARD

VUE DE DESSUS

PROFONDEUR

D'OUVERTURE DE

231/4 PO (591)

OFIL

HAUTEUR

D'OUVERTURE

271/2 PO

DE

(699)

5 PO

E

(127)

4 PO

(102)

581/2 PO (1486)

LARGEUR DE L'OUVERTURE

E E

VUE DE FACE

5 PO

E

(127)

4 PO

(102)

.

10 | Service à la clientèle de Wolf 800.222.7820

Page 39

SPÉCIFICATIONS

*P

**

***

REMARQUE : l'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'armoire supplémentaire

VUE DE PR

Deux fours de la série M

INSTALLATION À AFFLEUREMENT

HAUTEUR

D'AFFLEUREMENT

283/4 PO

DE

(730)***

7

/8 PO (22)

OU

1 PO (25)**

11/

13

/16 PO (21)

1

/8 PO (3)

VUE DE DESSUS

601/8 PO (1527)

LARGEUR DE L'AFFLEUREMENT***

5 PO

8 PO (29)

E E

(127)

4 PO

(102)

PROFONDEUR

D'AFFLEUREMENT

24 PO (610)

DE

5 PO

(127)

4 PO

(102)

EE

TAQUETS

FINIS*

OFIL

rofondeur minimale de 1 po (25). Les zones ombragées seront visibles et doivent être finies pour s'agencer avec les armoires.

7

/8 po (22) pour les modèles de transition, professionnels et contemporaine en acier inoxydable et 1 po (25) pour le modèle contemporain de verre noir.

Les dimensions fournissent des jeux minimums.

VUE DE FACE

.

wolfappliance.com | 11

Page 40

INSTALLATION

Préparation

Avant de déplacer le four, protégez tout plancher ni et xez

la (les) porte(s) du four en position fermée pour éviter tout

dommage.

Utilisez un chariot à appareil pour déplacer l'unité près de

l'ouverture. Placez le chariot à appareil sur le côté et l'arrière

pour éviter tout dommage. Retirez et recyclez les matériaux

d'emballage. Ne soulevez pas et ne transportez pas le four

par la poignée de porte.

RETRAIT DE LA PORTE DU FOUR

Pour alléger la charge, la (les) porte(s) du four peut (peuvent)

être retirée(s). Procédez au retrait seulement si cela est

nécessaire. Le retrait de la porte doit être effectué par un

technicien de service ou un installateur qualiés.

Pour la retirer, ouvrez la porte complètement. Pivotez les

deux loquets de charnière vers l'avant en position ouverte,

retirez chaque vis située la plus près de la charnière, puis

soulevez la porte vers le haut et l'extérieur. Reportez-vous à

l'illustration ci-dessous.

Pour réinstaller, insérez les charnières de porte dans les

ouvertures du cadre, puis pivotez les loquets de charnière

en position fermée.

SCREW

FERMÉ

CLOSED

OUVERT

OPEN

VIS

12 | Service à la clientèle de Wolf 800.222.7820

Retrait de la porte du four

Page 41

INSTALLATION

Connexion électrique

AVERTISSEMENT

Assurez-vous que le courant est coupé à partir du

coffret électrique avant de procéder.

Si l'alimentation électrique est située dans l'ouverture, la

connexion électrique doit être effectuée avant de placer

l'unité dans l'ouverture. Si l'alimentation électrique est située

dans une armoire adjacente, la connexion électrique doit être

effectuée avant de placer l'unité dans l'ouverture. La canalisation située à l'arrière de l'unité permet une installation à trois

ou quatre ls.

1 Reliez le l d'appareil noir au l d'alimentation noir (L1).

2 Reliez le l d'appareil rouge au l d'alimentation rouge (L2).

3 Reliez le l d'appareil nu au l de mise à la terre/vert.

4 Pour les systèmes à quatre ls, scellez le l blanc/neutre

avec un muselet.

Installation

Placez le four dans l'ouverture et glissez-le en position.

Pour obtenir une profondeur adéquate pour l'installation, la

canalisation doit pouvoir être insérée dans la zone encastrée

le long du rebord arrière du four.

Repérez le trou de montage dans chaque garniture latérale.

Percez des avant-trous de

x ¾po. Reportez-vous à l'illustration ci-dessous.

Retirez et recyclez les matériaux d'emballage, y compris le

matériau protecteur blanc derrière chaque emplacement de

montage du guide de grille.

TROU DE

MONTAGE

1

/16po (2) et installez des vis n°6

Emplacement du trou

wolfappliance.com | 13

Page 42

DÉPANNAGE

Dépannage

REMARQUE IMPORTANTE : si le four ne fonctionne pas cor-

rectement, suivez les étapes de dépannage suivantes :

• Vériez l'alimentation électrique du four.

• Vériez les connexions électriques.

• Si le four ne fonctionne pas correctement, communiquez

avec le centre service Wolf certié par l'usine. Ne tentez

pas de réparer le four. Wolf n'est pas responsable du

service requis pour corriger une installation défectueuse.

14 | Service à la clientèle de Wolf 800.222.7820

Page 43

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, les boutons de couleur rouge, Cove et Cove & Design sont des marques déposées et de service de Sub-Zero Group, Inc. et ses liales.

Toutes les autres marques de commerce appartiennent à leurs propriétaires respectifs aux États-Unis et dans d'autres pays.

Page 44

WOLF APPLIANCE, INC. P.O. BOX 44848 MADISON, WI 53744 WOLFAPPLIANCE.COM 800.222.7820

0000000 REV-A 2/2018

Loading...

Loading...