Page 1

D OWNDRAFT V ENTILATION

INSTALLATION INSTRUCTIONS

Page 2

CONTACT

INFORMATION

Wolf Customer

Service:

800-332-9513

Website:

wolfappliance.com

As you follow these instructions, you will

notice WARNING and CAUTION symbols.

This blocked information is important for the

safe and efficient installation of Wolf equipment. There are two types of potential

hazards that may occur during installation.

WOLF®is a registered trademark of Wolf Appliance Company, Inc.

signals a situation where minor injury or

product damage may occur if you do not

follow instr

states a hazard that may cause serious

injury or death if precautions are not

followed.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

uctions.

Page 3

WOLF DOWNDRAFT VENTILATION SYSTEMS

INSTALLATION REQUIREMENTS

IMPORTANT NOTE:

This installation must be

completed by a qualified installer or Wolf

uthorized service center technician.

a

nstaller:Please read the entire Installation

I

Instructions prior to installation. Save these

instructions for the local inspector’s refer-

nce, then leave them with the homeowner.

e

Homeowner:

Please read and keep these

instructions for future reference and be sure

to read the entire Use & Care Information

prior to use.

Any questions or problems about the

installation should be directed to your Wolf

dealer or Wolf Appliance Company, Inc. at

800-332-9513. You can also visit our website

at wolfappliance.com.

IMPORTANT NOTE:

This appliance must be

installed in accordance with National Electrical

Codes, as well as all state, municipal and local

codes. The correct voltage, frequency and

amperage must be supplied to the appliance

from a dedicated, grounded circuit which is

protected by a properly sized circuit breaker or

time delay fuse. The proper voltage, frequency,

and amperage ratings are listed on the product

rating plate.

BEFORE YOU START

Proper installation is the responsibility of

the installer. Product failure due to

mproper installation is not covered under

i

the Wolf Warranty. Refer to the Downdraft

Ventilation Use & Care Information for

arranty details, or visit our website,

w

wolfappliance.com.

Check with local utilities for electrical codes

that apply in your area. Local codes vary.

Installation, electrical connections and

grounding must comply with applicable

codes. In the absence of local codes, this

appliance should be installed in accordance

with National Electrical Code ANSI/NFPA

70-1990 or latest edition.

This appliance must be properly grounded.

Refer to Electrical Requirements on

page 8.

Make sure you have the tools and materials

necessary for proper installation.

Any required service must be performed by

a Wolf authorized service center. Wolf is not

responsible for service required to correct a

faulty installation.

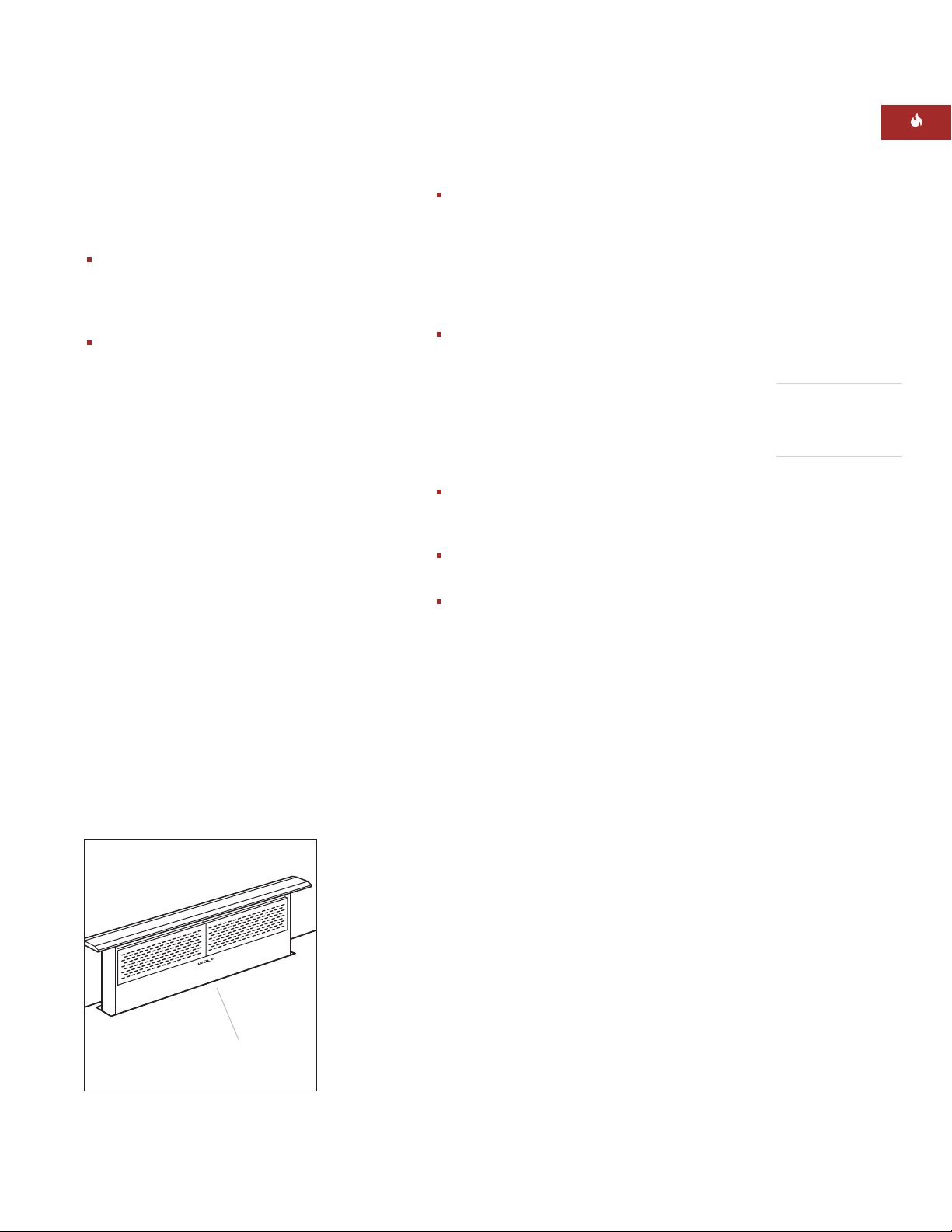

RATING PLATE

INFORMATION

Model Number

Serial Number

Record the model and serial numbers before

installing the downdraft ventilation system.

Both numbers are listed on the rating plate,

located

the unit.

Rating plate location

above the airbox on the front side of

Refer to the illustration below

Location of

rating plate

.

3

Page 4

WOLF DOWNDRAFT VENTILATION SYSTEMS

23/8"

(60)

30"

(762)

91/16"

(230)

261/4"

(667)

11/2" (38)

DEPTH OF

DOWNDRAFT CHIMNEY

36"

(914)

321/4"

(819)

23/8"

(60)

91/16"

(230)

11/2" (38)

DEPTH OF

DOWNDRAFT CHIMNEY

Model DD30

Model DD36

Model DD45

DOWNDRAFT VENTILATION

IMPORTANT NOTE:

Wolf downdraft ventila-

tion systems are recommended for use with

olf framed electric, gas, induction and

W

multi-function cooktops. They cannot be used

with unframed electric cooktops and are not

ecommended for use with the electric grill,

r

steamer and fryer modules. A Pro ventilation

hood is recommended for use with Wolf dual

fuel ranges, gas ranges, sealed burner rangetops and gas rangetops.

IMPORTANT NOTE:

A downdraft can be

used with sealed burner rangetop Models

SRT304 and SRT366. An accessory trim kit

(SRT/DDTRIM) is necessary for this installation.

Contact your Wolf dealer for details.

Wolf downdraft ventilation systems are

available in 30" (762), 36" (914) and 451/2"

(1156) widths. The downdraft should be at

least as wide as the cooktop.

Models DD30I, DD36I and DD45I include a 500

CFM internal blower. Models DD30R, DD36R

and DD45R are shipped without a blower

assembly. Remote blowers are available as

sales accessories.

IMPORTANT NOTE:

The downdraft must be

used with a Wolf-approved control module and

top cover.

OVERALL DIMENSIONS

MODELS DD30I AND DD30R

verall Width 30" (762)

O

Width of Chimney 261/4" (667)

Overall Height

(above countertop)

91/16" (230)

Overall Depth 23/8" (60)

Depth of Chimney 11/2" (38)

MODELS DD36I AND DD36R

Overall Width 36" (914)

Width of Chimney 321/4" (819)

Overall Height

(above countertop)

91/16" (230)

Overall Depth 23/8" (60)

Depth of Chimney 11/2" (38)

MODELS DD45I AND DD45R

Overall Width 451/2" (1156)

Width of Chimney 411/4" (1048)

Overall Height

(above countertop)

91/16" (230)

Overall Depth 23/8" (60)

Depth of Chimney 11/2" (38)

4

The illustrations below provide the overall

dimensions for downdraft Models DD30, DD36

DD45.

and

Overall dimensions – Models DD30I and DD30R

1

Dimensions may vary to

Overall dimensions – Models DD36I and DD36R

+

–

/8" (3).

Page 5

INSTALLATION INSTRUCTIONS

451/2"

(1156)

411/4"

(1048)

23/8"

(60)

91/16"

(230)

11/2" (38)

DEPTH OF

DOWNDRAFT CHIMNEY

BLOWER OPTIONS

Wolf downdraft Models DD30I, DD36I and

DD45I include a 500 CFM internal blower.

odels DD30R, DD36R and DD45R are shipped

M

without a blower assembly and can be used

with the remote blowers listed below. Remote

lowers are available as sales accessories.

b

odels DD30R, DD36R and DD45R

M

900 CFM Remote Blower

1200 CFM Remote Blower

1500 CFM Remote Blower

IMPORTANT NOTE:

Blower options vary with

801641

801642

804701

the cooking surface. For recommendations,

refer to the Wolf Design Guide found on the

Wolf website, wolfappliance.com.

IMPORTANT NOTE:

Install this downdraft

ventilation system only with a Wolf blower.

CONTROL KITS

IMPORTANT NOTE:

The downdraft must be

used with a Wolf-approved control module and

op cover.

t

he remote-mounted control module and top

T

cover are available in the classic, platinum and

carbon stainless steel finish for Models DD30

nd DD36, and classic stainless steel only for

a

Model DD45.

The control kit, available as a sales accessory

for Models DD30 and DD36 and included with

Model DD45, includes the control module, top

cover, mounting brackets, RJ45 connector and

mounting hardware.

Models DD30I and DD30R

Classic Stainless

Platinum Stainless

Carbon Stainless

DD30CONTROL/S

DD30CONTROL/P

DD30CONTROL/B

Models DD36I and DD36R

Classic Stainless

Platinum Stainless

Carbon Stainless

DD36CONTROL/S

DD36CONTROL/P

DD36CONTROL/B

Optional downdraft accessories are available

through your Wolf dealer. To obtain local

dealer information, visit the Locator section of

our website, wolfappliance.com.

Overall dimensions – Models DD45I and DD45R

Dimensions in parentheses are in

millimeters unless otherwise specified.

5

Page 6

WOLF DOWNDRAFT VENTILATION SYSTEMS

2

1

/8

" (54)

19

1

/4

" (489)

COOKTOP CUT-OUT

DEPTH

36"

(914)

2

3

/8

" (60)

25

1

/8

"min (638)

OF FLAT COUNTERTOP

*

.344"

29

5

/16

"

(745)

COUNTERTOP

TO BOTTOM OF

AIR BOX

18"

(457)

3

5

/8

"

(92)

3

1

/4

"

(83)

5"

(127)

7

11

/16

"

(197)

5

/8

"

(16)

2

1

/2

"min

(64)

WITH NO

RAISED LIP

*

*

AREAS OF POTENTIAL INTERFERENCE

24"min (610)

CABINET DEPTH

1

3

/4

"min (44)

BACK EDGE

OF COOKTOP

TO INSIDE OF

CABINET BACK

*

7

1

/8

"

(181)

INSTALLATION SPECIFICATIONS

Wolf downdraft Model DD30 will fit most 30"

(762) wide cabinets, Model DD36 will fit most

6" (914) wide cabinets and Model DD45 will fit

3

most 45

1

/2" (1156) wide cabinets. It is recom-

mended that oversized cabinets be used for

asier installation. Cabinet backs may need to

e

be removed.

Wolf downdraft ventilation systems can be

mounted in an island, peninsula or standard

wall location.

The illustration below provides installation

dimensions for all Wolf downdraft models.

Pay careful attention to the areas of potential

interference as noted in the illustration.

IMPORTANT NOTE:

To install a downdraft

system and a Wolf cooktop, you must allow for

minimum 25

a

1

(638) flat counter space from

/8"

front to back. A countertop with a raised lip or

backsplash may not allow enough space for

roper installation. 2

p

is required behind the cooktop and 1

3

(60) of flat countertop

/8"

3

/4" (44) is

necessary between the back edge of the

cooktop and inside of cabinet back.

If downdraft Model DD30 is installed in

combination with with two cooktops or integrated modules, an integrated module support

(ISUPPORT) for downdraft ventilation is

required. ISUPPORT is not required for Model

DD45. If optional filler strips are used with the

cooktops or modules, be aware that they are

different for the Model DD30 and DD45. Be

sure to use the correct filler strip.

6

Downdraft installation dimensions

Page 7

INSTALLATION INSTRUCTIONS

27" (686)

FOR MODEL DD30

33" (838)

FOR MODEL DD36

42" (1067)

FOR MODEL DD45

2

1

/2

"min (64)

2

3

/4

" (70)

COOKTOP CUT-OUT

WIDTH

25

1

/8

"min

(638)

FLAT

COUNTERTOP

SPACE

19

1

/4

"

(489)

COUNTERTOP TOP VIEW

For installation of a downdraft system with a

cooktop, refer to the cooktop installation

nstructions for the dimensions of the cooktop,

i

countertop cut-out and cabinet requirements.

The depth of the cooktop may vary and will

ffect the location of the downdraft in the

a

countertop.

The illustration below provides countertop

cut-out dimensions for downdraft Models

DD30, DD36 and DD45 installed with a Wolf 30"

(762) or 36" (914) cooktop or combination of

cooktop and/or modules.

IMPORTANT NOTE:

For installation of a

downdraft with sealed burner rangetop Models

SRT304 and SRT366, an accessory trim kit

(SRT/DDTRIM) is necessary. Contact your

Wolf dealer for details. To obtain local dealer

information, visit the Locator section of our

website, wolfappliance.com.

CONTROL MODULE LOCATION

nstallation of the remote-mounted control

I

module can be located anywhere within 10'

(3 m) of the downdraft assembly and a

inimum of 4" (102) from the outer edge of

m

cooktop element or burner. You will be

required to drill three holes and connect the

control module to the downdraft assembly

using the cable provided.

The remote-mounted control module is

3

2

/8" (60) x 65/8" (168) and can be positioned

horizontally or vertically in the countertop. A

1" (25) diameter hole for the RJ45 connector

cable will be centered horizontally and vertically in the back side of the control module.

1

/4" (6) diameter holes for the mounting

Two

screws will be located 2" (51) from the center

of the RJ45 connector cable hole, one on each

side. Additional installation instructions are

provided with the control kit.

Mark the center of the control module on the

counter top. Measure 2" (51) up (or left) and 2"

(51) down (or right) to locate holes for the

mounting screws.

Countertop cut-out dimensions

Dimensions in parentheses are in

millimeters unless otherwise specified.

IMPORTANT NOTE:

The length of the control

module cable is 10' (3 m). You must plan the

installation of the control module to be within

10' (3 m) of the downdraft assembly.

7

Page 8

WOLF DOWNDRAFT VENTILATION SYSTEMS

36" min (914)

FOR MODEL DD36

451/2" min (1156)

FOR MODEL DD45

30" min (762)

FOR MODEL DD30

OPTIONAL

ELECTRICAL

LOCATION IN

ADJACENT RIGHT

SIDE CABINET

E E

31/2" (89)

4" min (102)

10" (254)

24" min (610)

CABINET DEPTH

ELECTRICAL REQUIREMENTS

IMPORTANT

NOTE

You must follow

all National

Electrical Code

regulations. In

addition, be aware

of local codes and

ordinances when

installing your

service.

Wolf downdraft ventilation systems require a

separate, grounded 120 V, 60 Hz power supply.

he service should have its own 15 amp circuit

T

breaker, and a grounded 3-prong receptacle

should be located within the reach of the 2

.8 m) power cord. The specific location of the

(

1

/2'

outlet is not critical, as long as it is within

reach of the power cord that is located midway, top and bottom, on the right side of the

downdraft.

IMPORTANT NOTE:

If Model DD30 is to be

installed in a 30" (762) wide cabinet, Model

DD36 in a 36" (914) wide cabinet or Model

DD45 in a 451/2" (1156) wide cabinet, the

electrical outlet cannot be located on the back

wall of the cabinet. The outlet can be placed in

an adjacent cabinet within reach of the power

cord. An access hole for the power cord must

be drilled in the cabinet wall.

Choose the electrical location shown in

the illustration below that best suits your

installation.

IMPORTANT NOTE:

A ground fault circuit

interrupter (GFCI) is not recommended and

ay cause interruption of operation.

m

ou must follow all National Electrical Code

Y

regulations. In addition, be aware of local

codes and ordinances when installing your

ervice.

s

The electrical outlet must be checked by

a qualified electrician to be sure that it is

wired with the correct polarity. Verify

that the outlet provides 120 V AC and is

operly grounded.

pr

Do not use an extension cord or twoprong adapter. Electrical ground is

required on this appliance. Do not remove

the power supply cord ground prong.

8

Location of electrical

Page 9

INSTALLATION INSTRUCTIONS

DISCHARGE CUT-OUT

DIMENSIONS:

10

1

/4

" (260) x 3

1

/2

" (89)

INTERNAL BLOWER

14

1

/4

" (362) x 3

1

/2

" (89)

IN-LINE OR

CENTERLINE OF COUNTERTOP CUT-OUT

16

3

/8

" (416)

INTERNAL BLOWER

21

1

/2

" (546)

IN-LINE OR

REMOTE BLOWER

5

1

/2

" (140)

INTERNAL BLOWER

4

1

/4

" (108)

IN-LINE OR

REMOTE BLOWER

C

L

22

1

/8

" (562)

INTERNAL BLOWER

19" (483)

IN-LINE OR

REMOTE BLOWER

RIGHT

DISCHARGE

LOCATION

LEFT

DISCHARGE

LOCATION

CENTERLINE OF COUNTERTOP CUT-OUT

14

1

/4

" (362) x 3

1

/2

" (89)

IN-LINE OR

REMOTE BLOWER

CENTERLINE OF COUNTERTOP CUT-OUT

5

1

/2

" (140)

INTERNAL BLOWER

4

1

/4

" (108)

IN-LINE OR

REMOTE BLOWER

C

L

NOTE: Measurements are to centerline of duct cut-outs

ADJUSTMENT:

5" MAX (127)

IN-LINE OR

REMOTE BLOWER

ADJUSTMENT:

1" (25) – 7" (178)

INTERNAL BLOWER

2

1

/2

" MAX (165)

IN-LINE OR

REMOTE BLOWER

BOTTOM

DISCHARGE

LOCATION

BLOWER CONSIDERATIONS

The blower will vary in size and is dictated by

the cooking surface, the volume of air that

eeds to be moved and the length of the duct

n

run. A straight, short duct run with a limited

number of elbows and transitions will allow

he downdraft to perform most efficiently.

t

remote-mounted blower will minimize the

A

amount of blower noise, but will not eliminate

the noise completely.

IMPORTANT NOTE:

Blower options vary with

the cooking surface. For recommendations,

refer to the Wolf Design Guide found on the

Wolf website, wolfappliance.com.

ADJUSTABLE DISCHARGE

Wolf downdraft systems have an adjustable

discharge that will allow you to negotiate

ucting around floor joists and other obstacles.

d

Three different discharge locations are available with side-to-side adjustment for accurate

lignment of ductwork. Refer to the illustration

a

below for the discharge location and adjustment that best suits your installation.

Downdraft adjustable discharge

Dimensions in parentheses are in

millimeters unless otherwise specified.

9

Page 10

WOLF DOWNDRAFT VENTILATION SYSTEMS

12" MIN

TO

GROUND

WALL CAP

INTERNAL BLOWER

INSTALLATION THROUGH WALL

R

12" MIN

TO

GROUND

INTERNAL BLOWER

INSTALLATION THROUGH WALL

1

12" MIN

TO

GROUND

10"

ROUND

REMOTE BLOWER

INSTALLATION THROUGH WALL

REMOTE

BLOWER

REMOTE BLOWER

ROOF MOUNT INSTALLATION

REMOTE

BLOWER

10"

ROUND

DUCTING CONSIDERATIONS

IMPORTANT NOTE:

Always consult a

qualified HVAC Engineer for specific ducting

pplications.

a

MPORTANT NOTE:Wolf ventilation down-

I

draft systems must be vented to the outside.

Use only metal ductwork.

Wolf downdraft ventilation systems are

designed for use with 3

1

/4" (83) x 10" (254)

ductwork for Models DD30I, DD36I and DD45I,

1

/4" (83) x 14" (356) ductwork for Models

and 3

DD30R, DD36R and DD45R. Each can be

transitioned to 8" (203) or 10" (254) round

ductwork.

For best performance, 10" (254) round

ductwork is recommended. The downdraft will

operate most efficiently when the ductwork

does not exceed 40' (12 m) in length.

Choose the ducting option that allows the

shortest length of ductwork and a minimum

umber of elbows and transitions. Check the

n

location of floor joists, wall studs, electrical

wiring or plumbing for possible interference

ith the ductwork. Refer to the illustrations

w

below for ducting options.

IMPORTANT NOTE:

Use duct tape to seal the

connection between the blower outlet and

ductwork. Support the weight of the ductwork

as necessary to ensure sealed joints.

Downdraft ducting options

10

Page 11

INSTALLATION INSTRUCTIONS

bottom

flange

clamp

channel

nuts

sheet metal

screw

blower

cover plate

clamp

channel

nut

sheet metal

screw

blower

motor plug

ADJUSTING BLOWER DISCHARGE

Wolf downdraft systems have an adjustable

discharge that will allow you to negotiate

ucting around floor joists and other obstacles.

d

The blower is shipped with the discharge

facing down.

DOWN DISCHARGE LEFT TO RIGHT

Adjusting the down discharge left to right will

keep the blower discharge in the down

position but allows some side-to-side adjustment.

Follow these steps if the position of the blower

discharge needs to be moved left to right so

that ductwork does not interfere with floor

joists, plumbing or wiring below the unit. Refer

to the illustration below.

Place the downdraft assembly on its back

on a flat work surface.

Loosen the 4 nuts and 2 clamp channels.

Slide the blower to the desired position.

Use the supplied cover plate to close any

open space.

DOWN TO LEFT OR RIGHT DISCHARGE

ubstituting down discharge with left or right

S

discharge will switch the blower discharge

from the down position to the left or right of

owndraft assembly.

d

Follow these steps if it is necessary to rotate

the blower to the left or right discharge

location. Refer to the illustration below.

Place the downdraft assembly on its back

on a flat work surface.

Remove the 4 nuts and 2 clamp channels.

Carefully lift the blower and disconnect the

motor plug if necessary. Reposition the

blower and reconnect the motor plug.

Use the supplied cover plate to close any

open space.

Replace the clamp channels and use the

nuts to secure the blower in its new

position.

Use sheet metal screws through the bottom

flange to secure the bottom of the blower.

Tighten nuts to secure the top of blower

and use sheet metal screws through the

bottom flange to secure the bottom of the

blower.

Down blower discharge adjustment Left or right blower discharge

Dimensions in parentheses are in

millimeters unless otherwise specified.

11

Page 12

WOLF DOWNDRAFT VENTILATION SYSTEMS

leveling bracket – flange facing in

leveling bracket –

flange facing out

mounting screws

DOWNDRAFT INSTALLATION

CUT THE COUNTERTOP

ay out and cut the cooktop cut-out far

L

enough forward so the downdraft will fit

behind it.

Set the cooktop in place and slide it as far

forward as possible. Center and square the

cooktop with edges of countertop.

Place the plastic template included with the

downdraft against the back flange of the

cooktop and centered. Trace around the

template to mark the downdraft opening.

Remove the cooktop from countertop.

Cut the downdraft opening. Be careful not

to chip the edges of the countertop.

MOUNT THE UNIT

et the downdraft into the opening. Extend

S

the leveling brackets to the floor of the

cabinet so the downdraft sits straight.

OTE: The leveling brackets can be

N

removed and reattached in other positions.

The flange of the leveling bracket may have

to face inward in tight cabinet installations.

Refer to the illustration below.

Secure the downdraft to the countertop by

holding the downdraft against the back of

the countertop cut-out and tightening the

two mounting screws (one on each end of

unit) on the underside of the countertop.

Screw the leveling brackets to the bottom

of the cabinet. Tighten the screws holding

the leveling brackets to unit on each side.

CONNECT THE CONTROL MODULE

Connect the RJ45 connector cable to the back

side of the remote-mounted control module.

Connect the other end of the cable to the

electrical connection located on the right

side of downdraft assembly. Make sure that

all connections are tight.

12

Refer to the illustration on the front of the

downdraft for the correct orientation of the

RJ45 connector

during installation into the

downdraft assembly.

Downdraft mounting brackets

Page 13

INSTALLATION INSTRUCTIONS

DOWNDRAFT INSTALLATION

INSTALL DUCTWORK

To reduce the risk of fire, use only metal

ductwork.

IMPORTANT NOTE:

Before cutting the hole in

the cabinet for ductwork, check for interference

with floor joists, wall studs, electrical wiring or

plumbing.

Cut the hole in the cabinet as well as holes

in wall or floor as necessary for the

ductwork.

Mount the roof or wall cap and work back

towards the cabinet, attaching all ductwork,

elbows and transitions as previously

planned. Tape all ductwork connections to

make them secure and air tight.

Connect the ductwork and transition (if

required) to the downdraft. If necessary,

loosen the nuts and screws that hold the

blower in place, and slide the blower left or

right to align with the ductwork. Retighten

the screws and nuts.

INTERNAL BLOWER WIRING

odels DD30I, DD36I and DD45I

M

Mount a standard 120 V AC electrical box,

with 3-pronged grounded receptacle, inside

the cabinet or adjacent cabinet. Make sure

it is located within the reach of the downdraft’s 2

1

/2' (.8 m) power cord.

Run the appropriate power cable into the

cabinet and connect it to electrical box and

outlet.

Plug the power cord of the downdraft into

the outlet.

IMPORTANT NOTE:

the ductwork is riveted to the unit, a 3

For installations where

1

/4" (83)

x 10" (254) collar is provided for Models DD30I,

DD36I and DD45I, and a 3

collar is pr

ovided for Models DD30R, DD36R

1

/4" (83) x 14" (356)

and DD45R. This will allow the blower to be

removed and replaced easily for service

without disturbing the ductwork.

Dimensions in parentheses are in

millimeters unless otherwise specified.

13

Page 14

WOLF DOWNDRAFT VENTILATION SYSTEMS

black to black

white to white

green to green

120 VAC line in

DOWNDRAFT INSTALLATION

REMOTE BLOWER WIRING

odels DD30R, DD36R and DD45R

M

Mount a standard 120 V AC electrical box,

with 3-pronged grounded receptacle, inside

the cabinet or adjacent cabinet. Make sure

it is located within the reach of the downdraft’s 2

1

/2' (.8 m) power cord.

Run the appropriate power cable into the

cabinet and connect it to electrical box and

outlet.

The remote blower may not exceed a 6.0

amp rating.

Run 2-wire plus ground power cable from

the remote blower to the electrical box on

the remote blower adapter plate.

Connect the downdraft wiring to the power

cable from the remote blower. Wire black to

black, white to white and green to green or

bare wire. Refer to the illustration below.

Replace the electrical box cover.

Plug the power cord of the downdraft into

the outlet.

INSTALL THE TOP COVER

odels DD30 and DD36 only

M

IMPORTANT NOTE:

Model DD45 comes with

the top cover already installed.

Press the UP/DOWN button on the control

odule.

m

Remove shipping brackets from the down-

draft chimney.

Align the mounting brackets on the back

surface of the top cover with the corner

mounting positions on top of downdraft

chimney.

Screw the top cover mounting brackets into

the mounting holes on downdraft chimney

with the four screws provided. Make sure

that the top cover is secure and runs flush

with the front edge of the downdraft.

IMPORTANT NOTE:

For mounting and

installation of the remote blower, refer to the

installation instructions for your specific

blower.

Wiring connections

14

Page 15

INSTALLATION INSTRUCTIONS

TROUBLESHOOTING

IMPORTANT NOTE:

If the downdraft ventila-

tion system does not operate properly, follow

hese troubleshooting steps:

t

erify that power is being supplied to the

V

downdraft.

Check electrical connections to ensure that

the installation has been completed

correctly.

Refer to the Troubleshooting Guide in the

Wolf Downdraft Ventilation Use & Care

Information.

If the downdraft still does not work, contact

a Wolf authorized service center. Do not

attempt to repair the downdraft yourself.

Wolf is not responsible for service required

to correct a faulty installation.

IF YOU NEED SERVICE

Maintain the quality built into your downdraft ventilation system by calling a Wolf

uthorized service center.

a

or the name and number of the Wolf

F

authorized service center nearest you,

check the Locator section of our website,

olfappliance.com,or call Wolf Customer

w

Service at

800-332-9513

.

When calling for service, you will need the

model and serial number of your downdraft. This information is found on the

product rating plate, located above the

airbox on the front side of the unit.

CONTACT

NFORMATION

I

Wolf Customer

Service:

800-332-9513

Website:

wolfappliance.com

The information and images are the copyright

ty of W

oper

pr

affiliate of Sub-Zero Freezer Company, Inc.

Neither this book nor any information or images

contained her

or in part without the express written permission

of Wolf Appliance Company, Inc., an affiliate of

Sub-Zer

olf Appliance Company

©W

olf Appliance Company

ein may be copied or used in whole

eezer Company

o Fr

, Inc.

, Inc. all rights r

, Inc., an

eserved.

15

Page 16

WOLF APPLIANCE COMPANY, INC. P.O. BOX 44848 MADISON, WI 53744 800-332-9513 WOLFAPPLIANCE.COM

808256 REV

-B 11/2006

Loading...

Loading...