Page 1

DOWNDRAFT VENTILATION

INSTALLATION GUIDE

SPECIFICATIONS, INSTALLATION, AND MORE

Page 2

DOWNDRAFT VENTILATION

Contents

3 Downdraft Ventilation

4 Specications

9 Installation

14 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Wolf Customer Care 800.222.7820

Page 3

DOWNDRAFT VENTILATION

Product Information

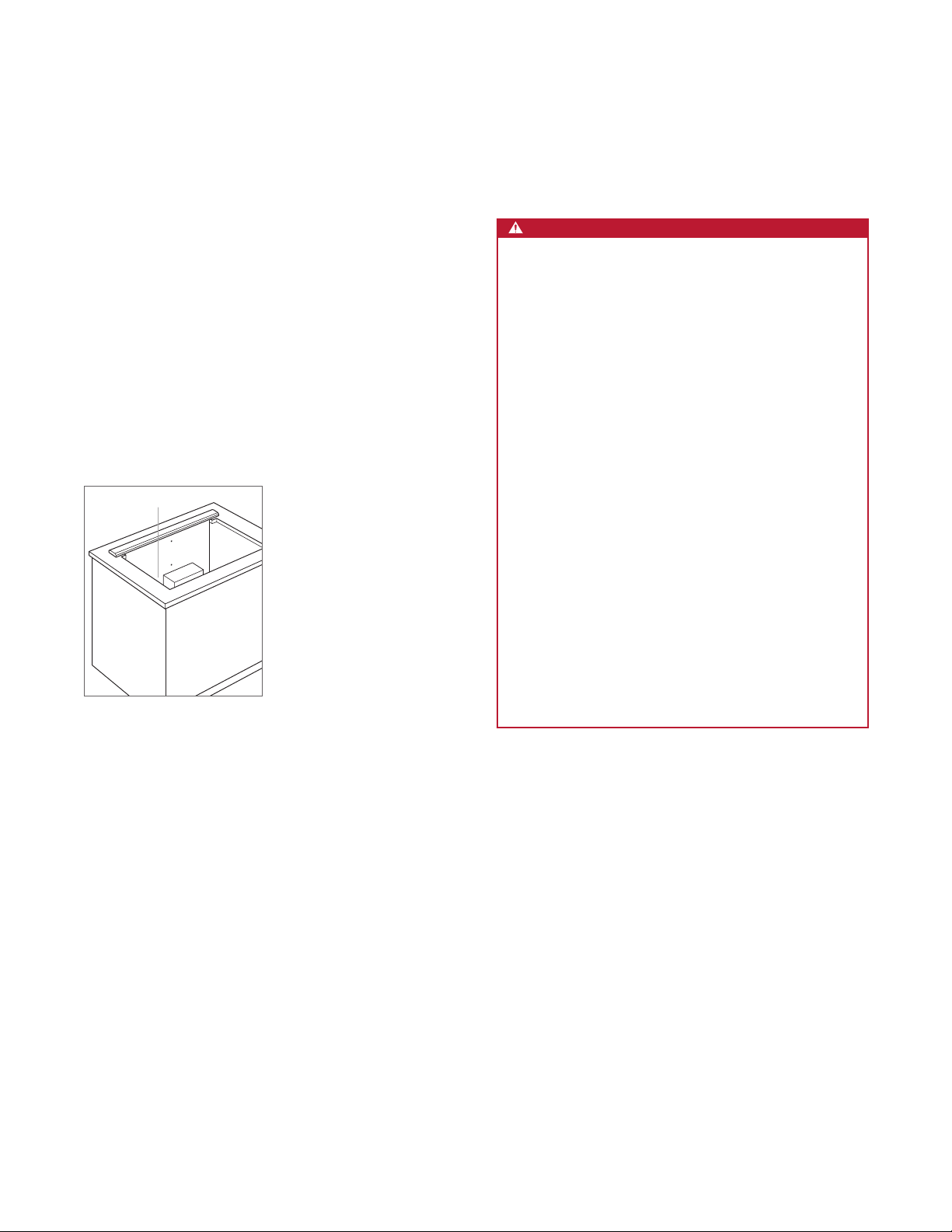

Important product information, including the model and

serial number, are listed on the product rating plate. The

rating plate is located next to the blower housing on the

front side of the downdraft, below the countertop. Refer to

the illustration below.

If service is necessary, contact Wolf Factory Certied

Service with the model and serial number. For the name of

the nearest Wolf Factory Certied Service or for questions

regarding the installation, visit the contact and support

section of our website, wolfappliance.com, or call Wolf

Customer Care at 800-222-7820.

RATING PLATE

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

Installation work and electrical wiring must be

a)

done by qualied person(s) in accordance with

all applicable codes and standards, including

re-rated construction.

b) Sufcient air is needed for proper combus-

tion and exhausting of gases through the ue

(chimney) of fuel burning equipment to prevent

back drafting. Follow the heating equipment

manufacturer's guideline and safety standards

such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the

local code authorities.

c) When cutting or drilling into the wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

Rating plate location

outdoors.

d) Ducted fans must always be vented to the

wolfappliance.com | 3

Page 4

SPECIFICATIONS

Installation Requirements

For installation with a Wolf cooktop, a minimum 251/8" (638)

deep at countertop is required.

For installation with a sealed burner rangetop or 30"

(914) contemporary cooktop, an accessory trim kit is

or 36"

(762)

required and available through an authorized Wolf dealer.

For local dealer information, visit the nd a showroom section of our website, wolfappliance.com.

The remote-mounted control module can be positioned

horizontally or vertically. It must be located within 9'

of the downdraft assembly and a minimum 3"

(2.7 m)

(76) from the

edge of the cooktop cutout.

Consult a qualied HVAC professional for specic installation and ducting applications.

BLOWERS

CAUTION

For use with Wolf 600 CFM internal blower and remote

blowers rated maximum 3 amps.

Internal, in-line, and remote blowers are available through an

authorized Wolf dealer.

DUCTWORK

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCTWORK.

Wolf downdrafts must be vented outside.

The downdraft operates most efciently with the fewest

number of elbows and transitions and when the ductwork

does not exceed 40'

(12 m).

Internal blowers have a 6"

(152) round discharge, can be

front or rear mounted, and can be discharged in any direction by rotating the blower box. In-line and remote blowers

have a 10"

(254) discharge and can be discharged from the

front or rear.

4 | Wolf Customer Care 800.222.7820

Page 5

SPECIFICATIONS

Electrical Requirements

Installation must comply with all applicable electrical codes.

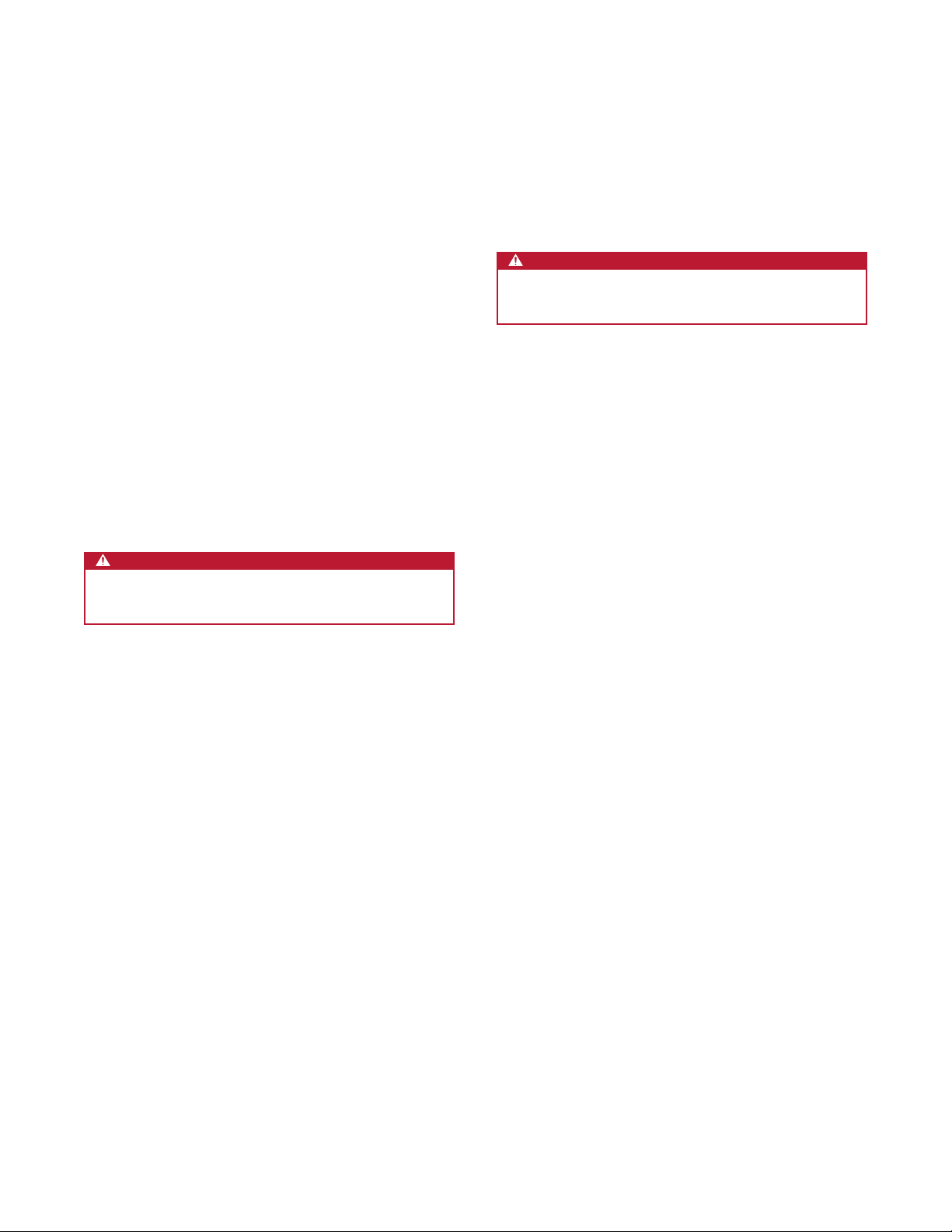

Locate the electrical supply as shown in the illustrations

on the following pages. A separate circuit servicing only

this appliance is required. A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation.

Certain installations may require the electrical supply be

placed in an adjacent cabinet.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type

1

Power Cord 2

RATING PLATE

/2' (.8 m)

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

This appliance is equipped with a cord having a grounding

wire with a grounding plug. The plug must be plugged into

an outlet that is properly installed and grounded.

WARNING

Improper grounding can result in risk of electric shock.

Consult a qualied electrician if the grounding instructions are not completely understood, or if doubt exists

as to whether the appliance is properly grounded.

Do not use an extension cord. Have a qualied electrician install an outlet near the appliance.

Rating plate location

wolfappliance.com | 5

Page 6

SPECIFICATIONS

Downdraft

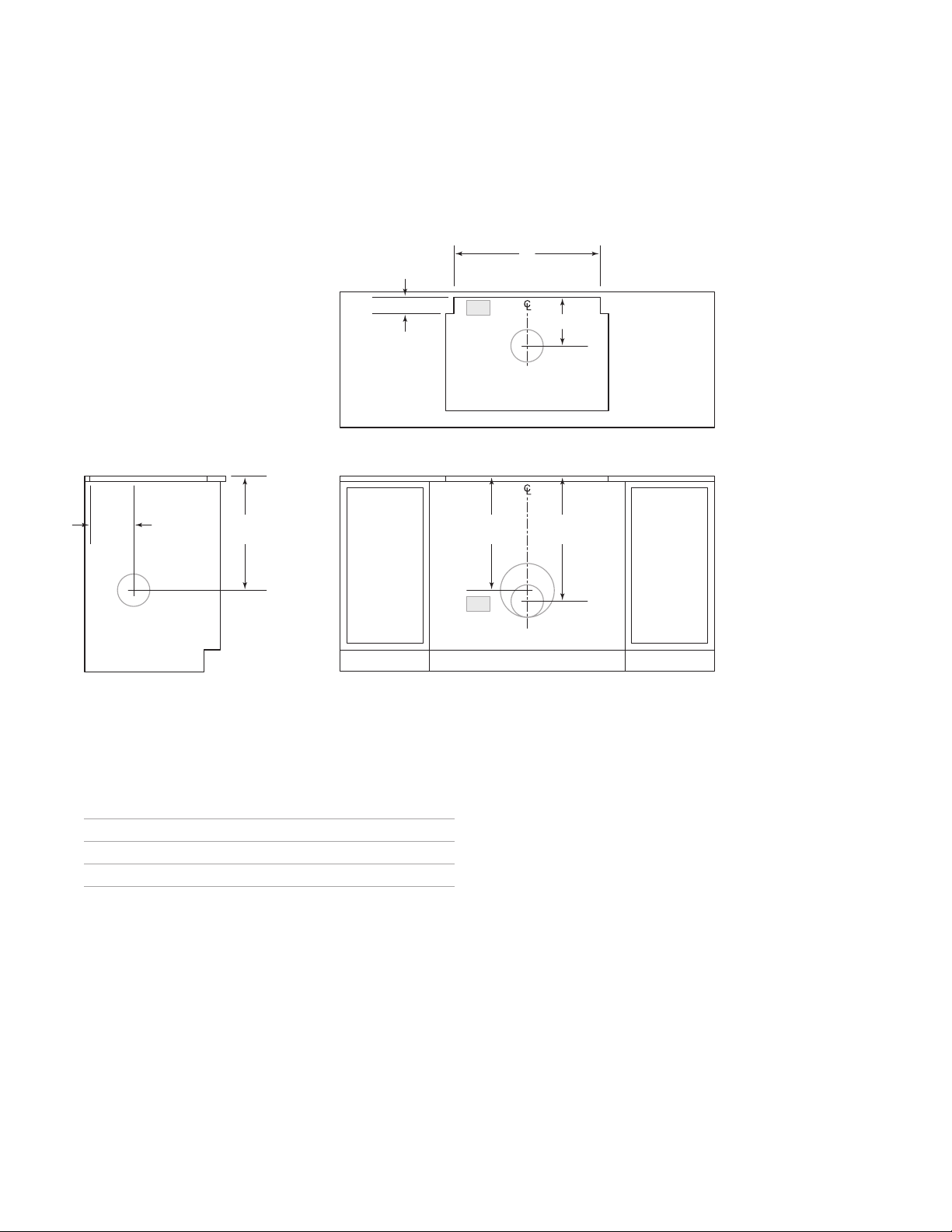

INSTALLATION WITH STANDARD INSTALLED COOKTOP

W

DOWNDRAFT

CUTOUT WIDTH

211/16" (68)

81/4"

(210)*

*6" (152) back from countertop cutout when internal blower is rear mounted.

NOTE: Internal blower 6"

Centerline indicates center of downdraft cutout.

211/4"

(540)

(152) round, side, rear or bottom discharge. In-line and remote blower 10" (254) round, rear discharge.

E

81/4" (210)*

COOKTOP CUTOUT

TOP VIEW

211/4"

(540)

233/8"

E

FRONT VIEWSIDE VIEW

(594)

CUTOUT WIDTH

DD30 271/2" (699)

DD36 331/2" (851)

DD45 391/2" (1003)

6 | Wolf Customer Care 800.222.7820

W

Page 7

SPECIFICATIONS

Downdraft

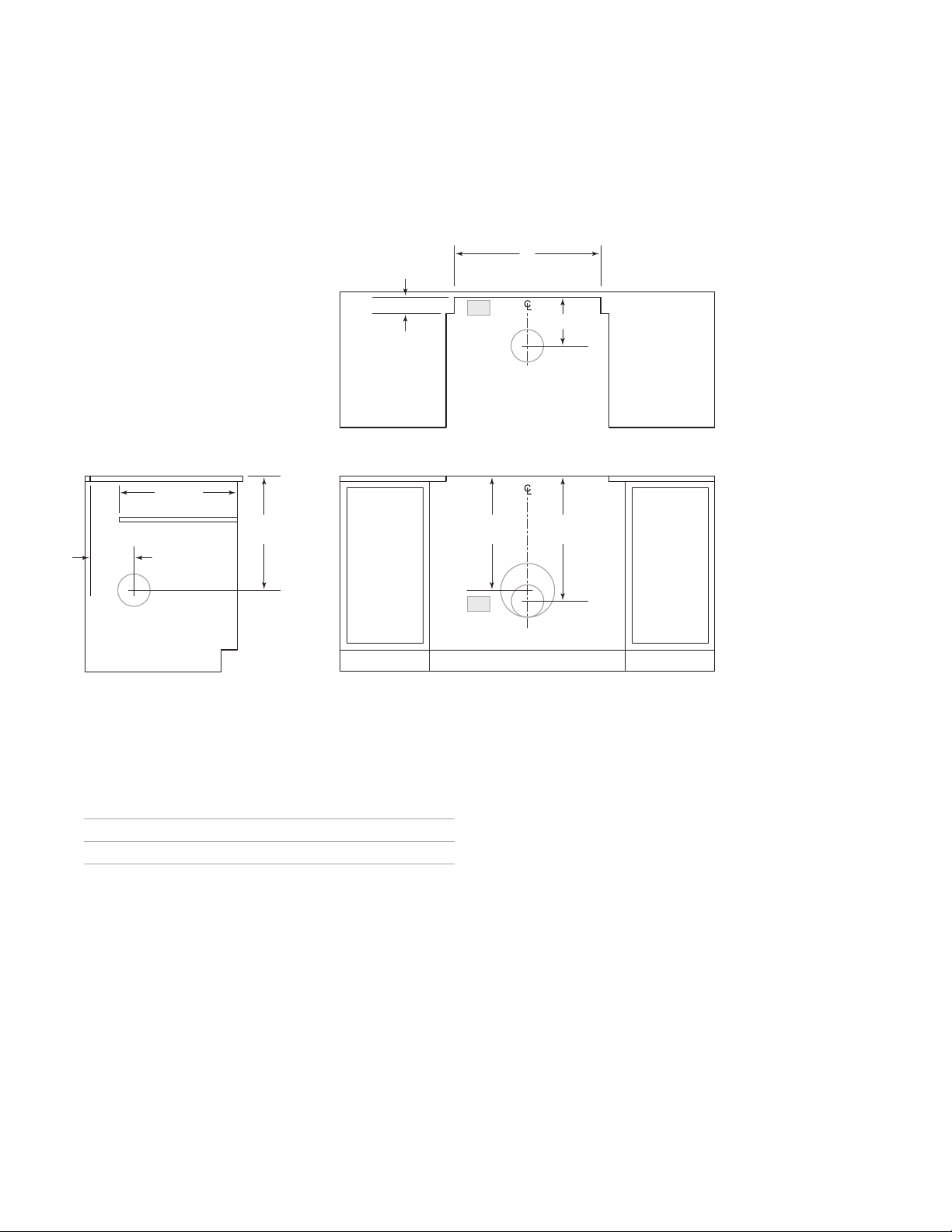

INSTALLATION WITH FLUSH INSTALLED COOKTOP

(59)

25/16"

W

DOWNDRAFT

CUTOUT WIDTH

E

81/4" (210)*

COOKTOP CUTOUT

TOP VIEW

81/4"

(210)*

*6" (152) back from countertop cutout when internal blower is rear mounted.

NOTE: Internal blower 6"

Centerline indicates center of downdraft cutout.

211/4"

(540)

(152) round, side, rear, or bottom discharge. In-line and remote blower 10" (254) round, rear discharge.

CUTOUT WIDTH

DD30 271/2" (699)

DD36 331/2" (851)

211/4"

(540)

233/8"

(594)

E

FRONT VIEWSIDE VIEW

W

wolfappliance.com | 7

Page 8

SPECIFICATIONS

Downdraft

INSTALLATION WITH SEALED BURNER RANGETOP

W

DOWNDRAFT

CUTOUT WIDTH

211/16" (68)

19" (483)

PLATFORM DEPTH

211/4"

(540)

81/4"

(210)*

*6" (152) back from countertop cutout when internal blower is rear mounted.

NOTE: Internal blower 6"

Centerline indicates center of downdraft cutout.

(152) round, side, rear, or bottom discharge. In-line and remote blower 10" (254) round, rear discharge.

E

81/4" (210)*

RANGETOP OPENING

TOP VIEW

211/4"

(540)

233/8"

(594)

E

FRONT VIEWSIDE VIEW

FRONT VIEWSIDE VIEW

CUTOUT WIDTH

DD30 271/2" (699)

DD36 331/2" (851)

8 | Wolf Customer Care 800.222.7820

W

Page 9

INSTALLATION

Installation

DOWNDRAFT

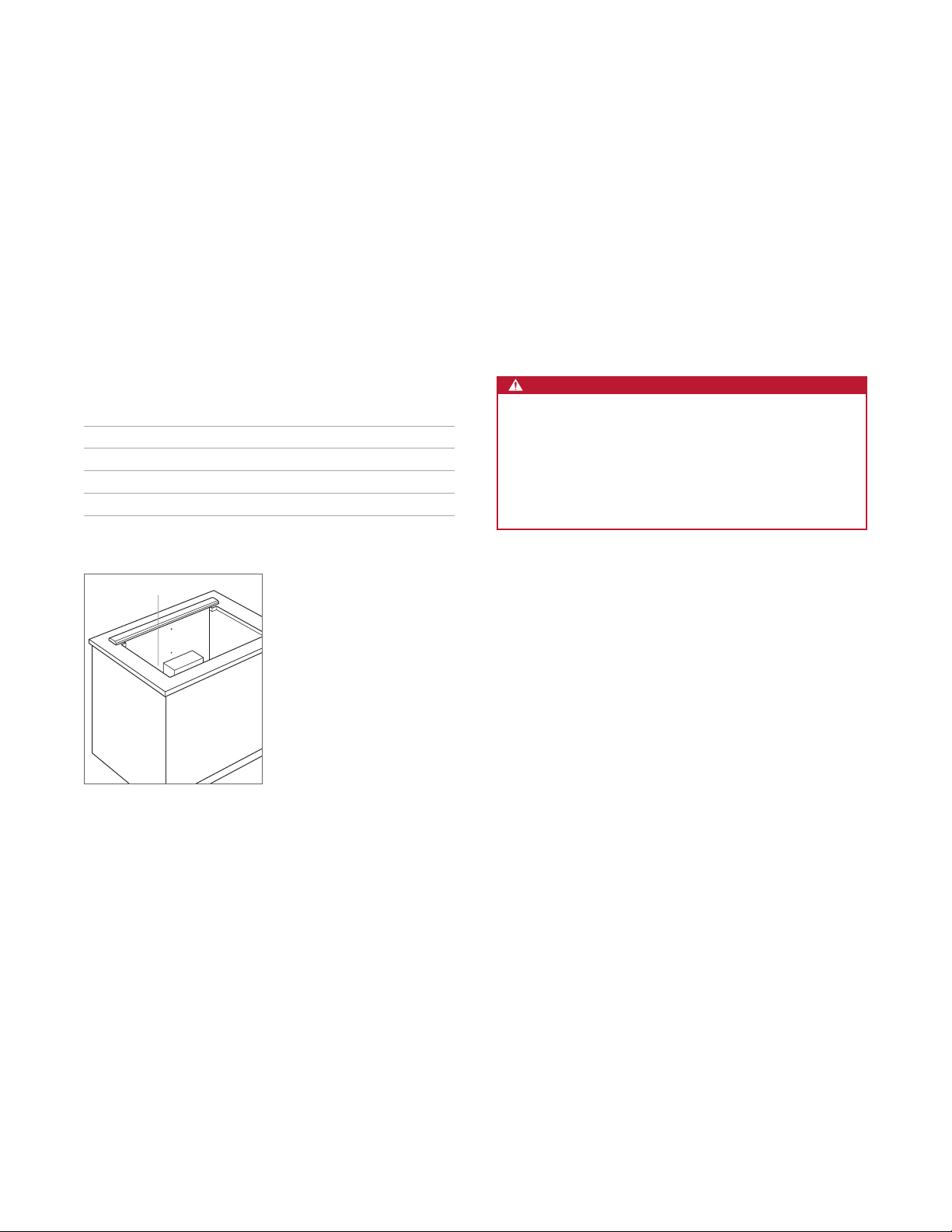

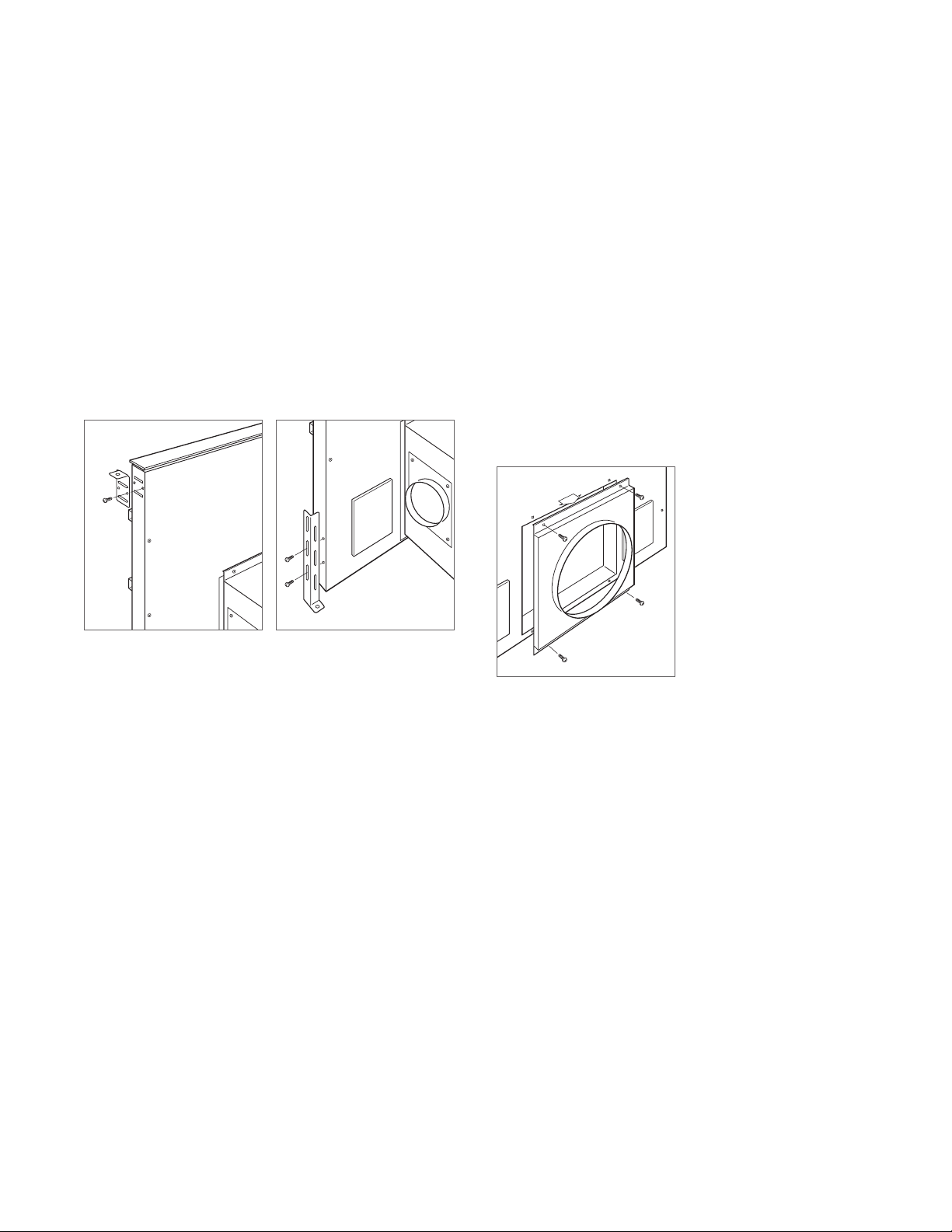

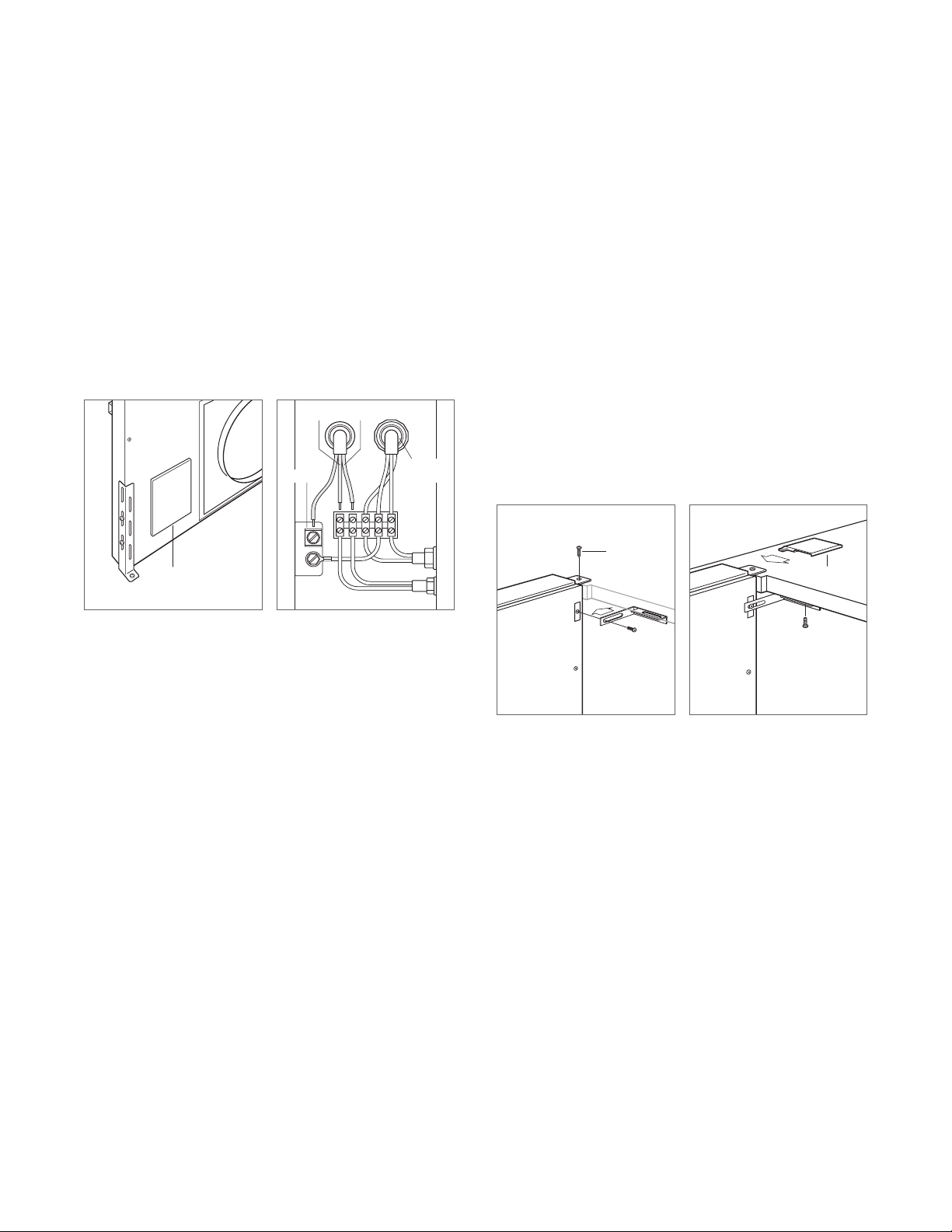

1 Install the top mounting brackets using the #4 sheet

metal screws provided. Refer to the illustration below.

2 Install the lower mounting brackets using the #8 x 32

sheet metal screws provided, but do not tighten. The

brackets need to be adjusted once the downdraft is

placed in the opening. Refer to the illustration below.

Top mounting bracket

Bottom leveling bracket

TRANSITION

For internal blowers, remove the existing 10" (254) round

transition. Refer to the illustration below.

For in-line and remote blowers with front discharge, leave

(254) round transition in place.

the 10"

For in-line and remote blowers with rear discharge, remove

(254) round transition from the front and the solid

the 10"

cover from the rear of the downdraft, then reinstall the transition on the rear and the solid cover on the front.

Remove transition

wolfappliance.com | 9

Page 10

INSTALLATION

Installation

INTERNAL BLOWER

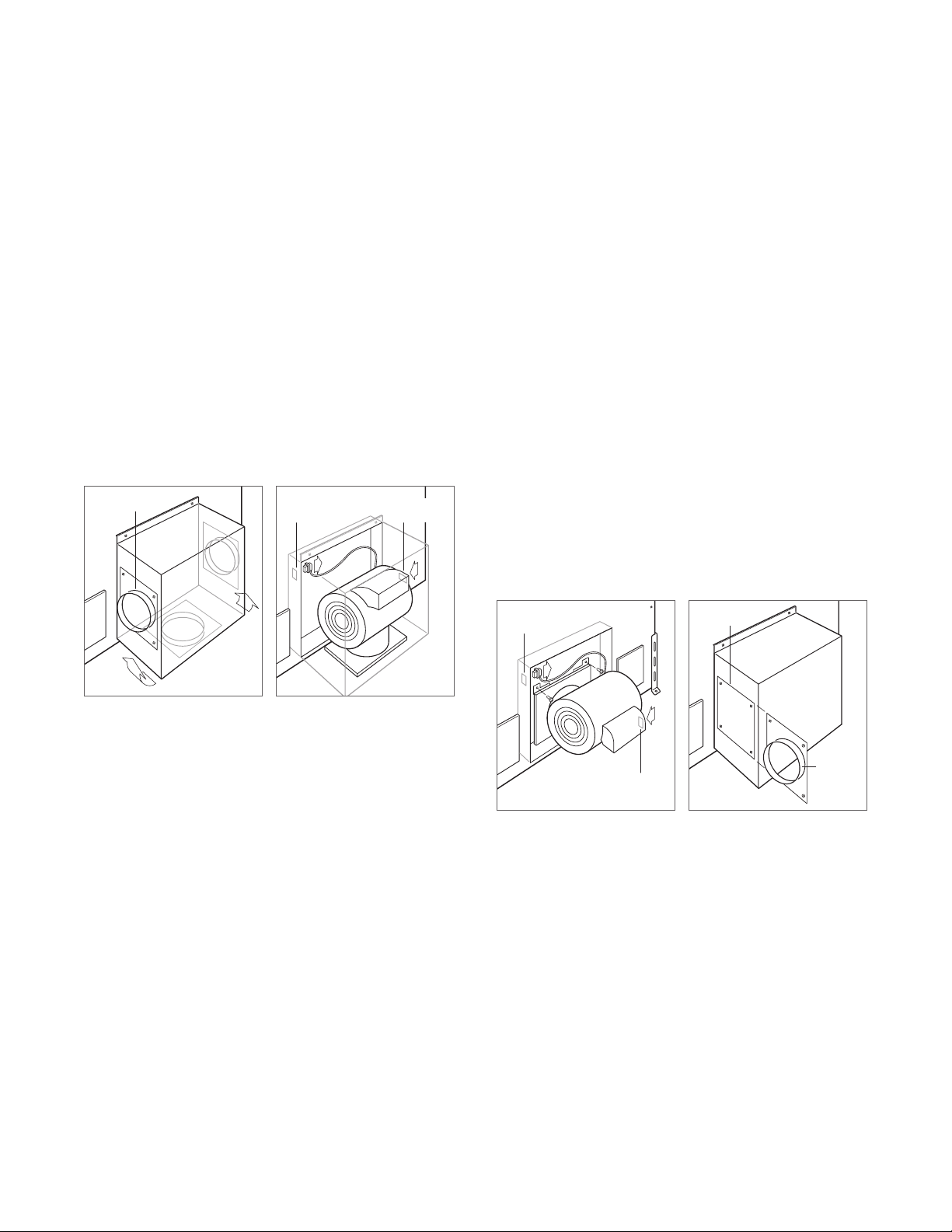

To mount the internal blower on the front or rear of the

downdraft:

1 Rotate the blower box so the 6" (152) round discharge

is properly located, then disconnect the cable from the

downdraft receptacle and connect it to the blower receptacle. Refer to the illustrations below.

2 Once the blower connection is made and the discharge

properly located, secure the blower to the downdraft

using the four screws provided.

DISCHARGE

DOWNDRAFT

RECEPTACLE

BLOWER

RECEPTACLE

To mount the internal blower on the front of the downdraft

but discharge from the rear:

1 Remove the blower from the blower box.

2 Mount the blower motor to the downdraft using the two

screws provided.

3 Remove the blower plug from the downdraft receptacle

and insert it into the blower receptacle. Refer to the illustration below.

4 Once the plug is installed and the blower secure, install

the blower box to the downdraft using the four screws

provided.

5 Remove the 6" (152) collar from the blower box and the

solid cover from the rear of the downdraft, then reinstall

(152) collar on the rear and the solid cover on the

the 6"

blower box. Refer to the illustration below.

DOWNDRAFT

RECEPTACLE

COVER

Left, right, or bottom discharge Blower connection

Blower mounting

BLOWER

RECEPTACLE

COLLAR

Install cover

10 | Wolf Customer Care 800.222.7820

Page 11

BLUE

BROWN

NEUTRAL

GROUND

HOT

POWER

SUPPLY

INSTALLATION

Installation

IN-LINE | REMOTE BLOWER

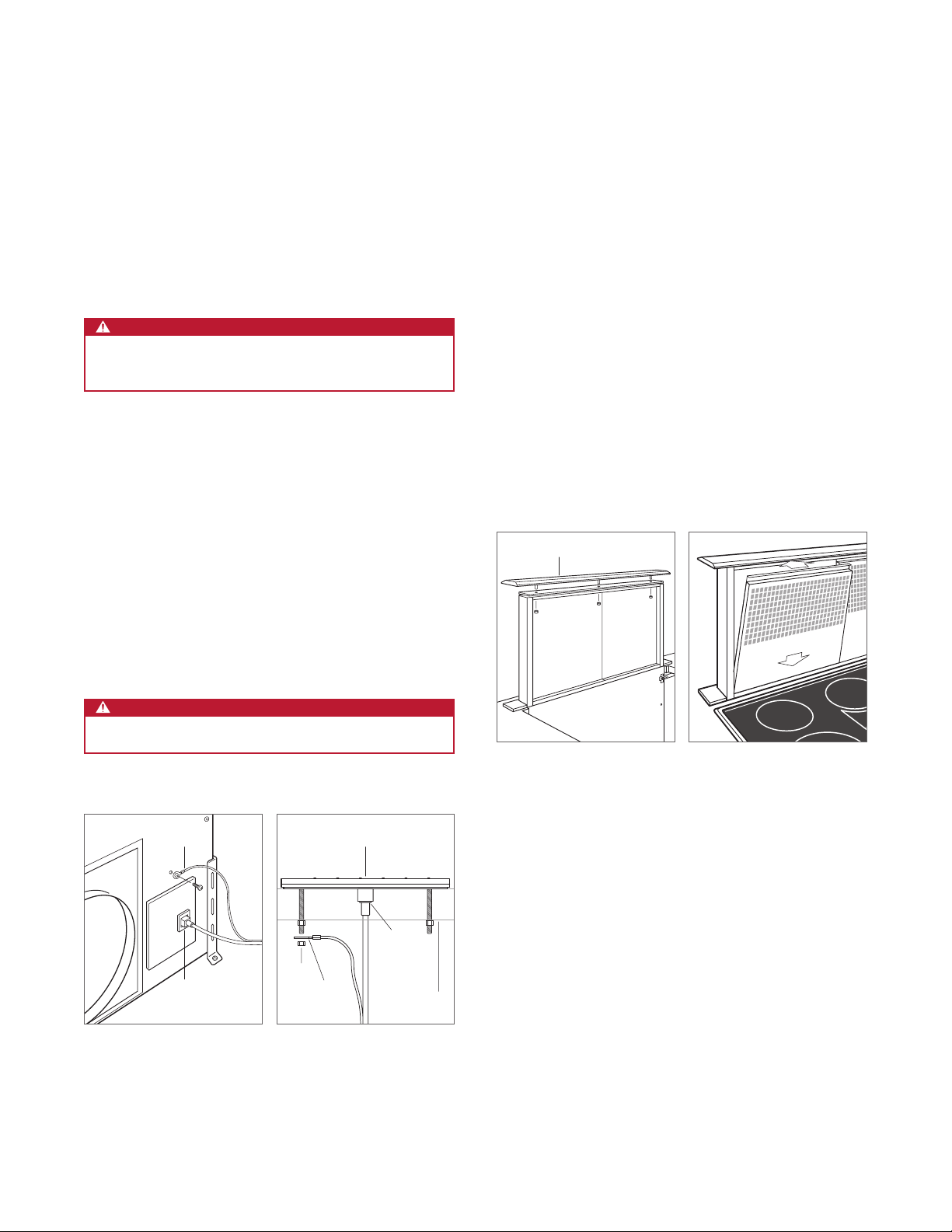

1 Insert the electrical supply (Romex) from the in-line or

remote blower through the opening on the downdraft

and secure using an approved cord strain relief.

2 Connect hot to brown, neutral to blue and ground to

green. Refer to the illustrations below.

WIRING

COVER

Wiring location

In-line | remote blower wiring

COUNTERTOP MOUNTING

Place the downdraft in the opening, then secure the bottom

brackets to the cabinet base using the wood screws provided. Once the brackets are secure, tighten the existing

lower bracket screws. Refer to the illustration below.

Secure the top mounting brackets to the countertop using

the wood screws provided. For solid surface countertops,

silicone may be used but is not provided.

Once the top is secure, install the undercounter brackets

using the screws provided, then install the side covers.

Refer to the illustration below.

MOUNTING

SCREW

COVER

Countertop mounting

Cover installation

wolfappliance.com | 11wolfappliance.com | 11

Page 12

MELT

HIGH

OFF ON

OFF ON

SIM

HIGH

OFF ON

SIM

HIGH

BRIDGE

OFF ON

SIM

HIGH

ZONE 2

CLEAR

OFF

O

ZONE 2

ZONE 3

HIGH

SIM

OFF ON

INSTALLATION

Installation

CONTROL MODULE

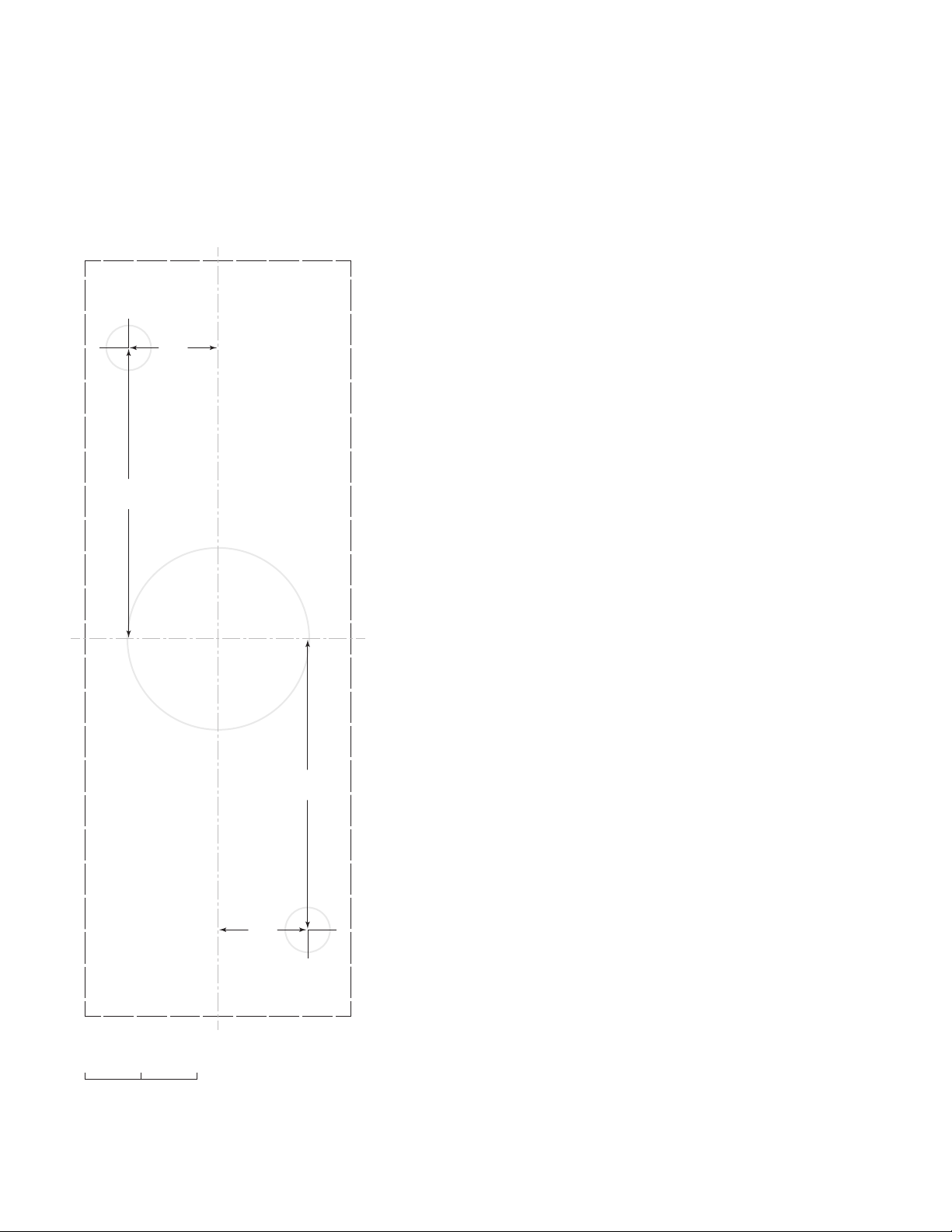

1 Use the template provided on the following page to mark

holes for the mounting screws. Drill one 1

3

center and two

/8" (10) holes for the mounting screws.

9

/16" (40) in the

CAUTION

Verify the scale of the template if not using the installation guide shipped with the downdraft.

2 Check the countertop thickness to make sure the

threaded studs are long enough to allow the thumbnuts

to fully engage. Thicker countertops may require the

countertop be countersunk from below.

3 Place the control module on the countertop then secure

using the two nuts provided. Once secure, install the

ground wire and nut.

4 Use the provided cable or a cable designated by the

National Electric Code, NFPA/ANSI 70 or local codes.

Connect one end of the control cable to the back side of

the control module and other to the electrical connection

on the front of downdraft assembly. Ensure all connections are tight.

TOP COVER

Plug the downdraft power cord into a grounded 3-prong

receptacle, then route beneath the appliance and away from

heat generated by the cooktop. Check downdraft operation.

Once operation is veried, raise the downdraft chimney and

install the top trim using the three nuts provided. Verify the

top trim is properly aligned with the side covers. Refer to the

illustration below.

FILTERS

Remove the stickers and shipping brackets and install the

lters. Refer to the illustration below.

TOP COVER

WARNING

Do not connect to a telecommunication network.

GROUND

RJ45

CONNECTOR

Downdraft connection

CONTROL MODULE

NUT

GROUND

Control module connection

RJ45

CONNECTOR

COUNTERTOP

Top cover installation

Filter installation

12 | Wolf Customer Care 800.222.7820

Page 13

INSTALLATION

Installation

CONTROL MODULE TEMPLATE

13

/16

"

(21)

9

/16

2

"

(65)

C

L

9

/16

2

"

(65)

13

/16

"

(21)

C

L

1" (25)0"

SCALE

wolfappliance.com | 13

Page 14

TROUBLESHOOTING

Troubleshooting

IMPORTANT NOTE: If the downdraft ventilation system does

not operate properly, follow these troubleshooting steps:

• Verify electrical power is supplied to the downdraft.

• Verify proper electrical connections.

• If the downdraft does not operate properly, contact Wolf

Factory Certied Service. Do not attempt to repair the

downdraft. Wolf is not responsible for service required to

correct a faulty installation.

14 | Wolf Customer Care 800.222.7820

Page 15

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design are registered trademarks and service marks of Sub-Zero Group, Inc. and its subsidiaries.

All other trademarks are property of their respective owners in the United States and other countries.

wolfappliance.com | 15

Page 16

VENTILACIÓN DE TIRO DESCENDENTE

Contenido

3 Ventilación de tiro descendente

4 Especicaciones

9 Instalación

14 Resolución de problemas

Las características y especicaciones están sujetas a cambios sin previo aviso. Visite wolfappliance.com/specs para

obtener la información más actualizada.

Aviso importante

Para garantizar que este producto se instale y opere de

la forma más segura y eciente posible, tome nota de los

siguientes tipos de información resaltada en esta guía:

AVISO IMPORTANTE señala la información que es especial-

mente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

ADVERTENCIA indica peligro de que se produzcan heridas

graves o incluso la muerte si no se siguen las precauciones.

AVISO IMPORTANTE: en toda esta guía, las dimensiones

entre paréntesis son milímetros, a menos que se especique lo contrario.

AVISO IMPORTANTE: guarde estas instrucciones para el

inspector eléctrico local.

2 | Atención al cliente de Wolf 800.222.7820

Page 17

VENTILACIÓN DE TIRO DESCENDENTE

Información del producto

La información importante del producto, incluido el modelo

y número de serie de la unidad, se encuentra en la placa

de datos del producto. La placa de datos se encuentra al

lado de la cubierta del extractor en la parte frontal del tiro

descendente, debajo del mostrador. Consulte la siguiente

ilustración.

Si necesita servicio, póngase en contacto con el centro de

servicio autorizado de Wolf y tenga a la mano el modelo y

número de serie de la unidad. Para obtener los datos del

centro de servicio autorizado de Wolf más cercano o si

tiene preguntas acerca de la instalación, visite la sección de

contacto y soporte técnico en nuestra página de Internet

wolfappliance.com o llame a la línea de atención al cliente

de Wolf al 800-222-7820.

PLACA DE DATOS

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO,

DESCARGA ELÉCTRICA O LESIONES A LAS

PERSONAS, OBEDEZCA LAS PRECAUCIONES

SIGUIENTES:

a)

Una persona calicada debe realizar el trabajo

de instalación y cableado eléctrico de conformidad con todos los códigos y normas aplicables, incluyendo la de construcción a prueba

de fuego.

b) Se necesita suciente aire para permitir una

combustión y escape de gases adecuados por

el humero (chimenea) del equipo quemador

de combustible para evitar que se produzcan

llamaradas. Siga las directrices del fabricante

del equipo de calefacción y las normas de

seguridad como las publicadas por la Asociación Nacional de Protección contra Incendios

(NFPA, por sus siglas en inglés) y la Sociedad

Estadounidense de Ingenieros en Calefacción,

Refrigeración y Aire Acondicionado (ASHRAE,

por sus siglas en inglés) y los códigos de las

autoridades locales.

Ubicación de la placa de datos

c) Al cortar o perforar la pared o el techo, no dañe

el cableado eléctrico ni otros servicios ocultos.

d) Los ventiladores con conductos siempre deben

descargarse hacia el exterior.

wolfappliance.com | 3

Page 18

ESPECIFICACIONES

Requisitos de instalación

Para instalarlo con una estufa Wolf, se necesita un mos-

1

trador plano de 25

/8" (638) de profundidad.

Para la instalación con un quemador sellado o una estufa

contemporánea de 30"

(762) o 36" (914), se necesita un kit

de accesorios de ribetes. Póngase en contacto con su distribuidor autorizado de Wolf para obtener más información.

Para obtener más información acerca de los distribuidores

locales, visite la sección para encontrar una sala de exposición de nuestro sitio web, wolfappliance.com.

El módulo de control montado en forma remota se puede

colocar horizontalmente o verticalmente. Debe colocarse

a menos de 9'

descendente y a un mínimo de 3"

(2.7 m) del montaje del ventilador de tiro

(76) del borde del recorte

de la estufa.

EXTRACTORES

PRECAUCIÓN

Para usarse con extractor interno Wolf 600 CFM y

extractores remotos con capacidad para 3 amperes

como máximo.

INSTALACIÓN DE CONDUCTOS

WARNING

PARA REDUCIR EL RIESGO DE INCENDIO, USE SOLAMENTE TUBERÍAS DE METAL.

Los ventiladores de tiro descendente Wolf deben ventilarse

hacia afuera. Consulte a un profesional de climatización

calicado para la instalación especíca y las aplicaciones

de conductos. La ventilación de tiro descendente tendrá

un funcionamiento más eciente con el menor número de

codos y transiciones y cuando los conductos no excedan

(12 m).

40'

Los extractores internos, en línea y remotos están disponibles a través de un distribuidor autorizado de Wolf.

Los extractores internos incluyen un escape circular de 6"

(152)

, que puede montarse al frente o en la parte posterior

y descargarse en cualquier dirección mediante la rotación

de la caja del extractor. Los extractores en línea y remotos

tienen un escape circular de 10"

(254) y puede descargarse

desde el frente o desde la parte posterior.

4 | Atención al cliente de Wolf 800.222.7820

Page 19

ESPECIFICACIONES

Instalación eléctrica

La instalación debe tener una conexión a tierra de conformidad

con los códigos locales o, en ausencia de códigos locales,

con el Código Nacional de Electricidad, ANSI/NFPA 70.

Coloque el suministro eléctrico tal y como se muestra en las

ilustraciones de las páginas 5 y 6. Es necesario un circuito

independiente que dé servicio únicamente a este aparato.

No es recomendable utilizar un circuito de fallos de conexión a tierra (GFCI, por sus siglas en inglés) ya que puede

interrumpir el funcionamiento de la unidad.

Ciertas instalaciones pueden requerir que el suministro eléctrico se encuentre en un gabinete adyacente.

REQUISITOS ELÉCTRICOS

Suministro eléctrico Con conexión a tierra, 120 V CA, 60 Hz

Servicio Circuito dedicado de 15 amperes

Receptáculo Conexión a tierra de 3 clavijas

1

Cable de alimentación eléctrica 2

PLACA DE DATOS

/2' (.8 m)

INSTRUCCIONES PARA REALIZAR LA CONEXIÓN A

TIERRA

Este electrodoméstico debe ser conectado a tierra. En caso

de que se produzca un cortocircuito eléctrico, la conexión a

tierra reduce el riesgo de descarga eléctrica al proporcionar

un cable de escape para la corriente eléctrica. Este electrodoméstico está equipado con un cable de alimentación

eléctrica con un enchufe de conexión a tierra. El enchufe

debe conectarse a un tomacorriente que esté correctamente instalado y conectado a tierra.

ADVERTENCIA

Una conexión a tierra incorrecta puede resultar en un

riesgo de descarga eléctrica. Consulte a un electricista

calicado si no entiende completamente las instrucciones de conexión a tierra o si tiene duda de que el

aparato esté conectado correctamente a tierra.

No utilice un cable de extensión. Si el cable de alimentación eléctrica es demasiado corto, pida a un electricista calicado que instale un tomacorriente cerca del

electrodoméstico.

Ubicación de la placa de datos

wolfappliance.com | 5

Page 20

ESPECIFICACIONES

Ventilador de tiro descendente

INSTALACIÓN CON COCINERO INSTALADO ESTÁNDAR

81/4"

(210)*

211/4"

(540)

211/16" (68)

ANCHURA DEL RECORTE

PARA EL VENTILADOR

DE TIRO DESCENDENTE

W

E

81/4" (210)*

RECORTE PARA ESTUFA

VISTA SUPERIOR

211/4"

(540)

233/8"

(594)

E

VISTA FRONTALVISTA LATERAL

*6" (152) detrás del recorte del mostrador cuando el extractor interno está montado en la parte posterior.

NOTA: extractor interno 6" (152) para descarga alrededor, a los lados, en la parte posterior o en la parte inferior. Extractor en línea y remoto

10" (254) para descarga alrededor o en la parte posterior. La línea central indica el centro del recorte del ventilador de tiro descendente.

ANCHURA DEL RECORTE

W

DD30 271/2" (699)

DD36 331/2" (851)

DD45 391/2" (1003)

6 | Atención al cliente de Wolf 800.222.7820

Page 21

ESPECIFICACIONES

Ventilador de tiro descendente

INSTALACIÓN CON COCINA INSTALADA EN LAVADO

81/4"

(210)*

211/4"

(540)

25/16"

(59)

ANCHURA DEL RECORTE

PARA EL VENTILADOR

DE TIRO DESCENDENTE

W

E

81/4" (210)*

RECORTE PARA ESTUFA

VISTA SUPERIOR

211/4"

(540)

233/8"

(594)

E

VISTA FRONTA LVISTA LATERAL

*6" (152) detrás del recorte del mostrador cuando el extractor interno está montado en la parte posterior.

NOTA: extractor interno 6" (152) para descarga alrededor, a los lados, en la parte posterior o en la parte inferior. Extractor en línea y remoto

10" (254) para descarga alrededor o en la parte posterior. La línea central indica el centro del recorte del ventilador de tiro descendente.

ANCHURA DEL RECORTE

W

DD30 271/2" (699)

DD36 331/2" (851)

wolfappliance.com | 7

Page 22

ESPECIFICACIONES

Ventilador de tiro descendente

INSTALACIÓN CON ESTUFA CON QUEMADORES SELLADOS

PROFUNDIDAD DE

LA PLATAFORMA

81/4"

(210)*

VISTA LATERAL

19" (483)

211/4"

(540)

211/16" (68)

ANCHURA DEL RECORTE

PARA EL VENTILADOR

DE TIRO DESCENDENTE

W

E

(210)*

81/4"

ABERTURA PARA ESTUFA

VISTA SUPERIOR

211/4"

(540)

233/8"

(594)

E

VISTA FRONTAL

*6" (152) detrás del recorte del mostrador cuando el extractor interno está montado en la parte posterior.

NOTA: extractor interno 6" (152) para descarga alrededor, a los lados, en la parte posterior o en la parte inferior. Extractor en línea y remoto

10" (254) para descarga alrededor o en la parte posterior. La línea central indica el centro del recorte del ventilador de tiro descendente.

ANCHURA DEL RECORTE

W

DD30 271/2" (699)

DD36 331/2" (851)

8 | Atención al cliente de Wolf 800.222.7820

Page 23

INSTALACIÓN

Instalación

VENTILADOR DE TIRO DESCENDENTE

1 Instale los soportes de montaje superior con los torni-

llos de metal #4 proporcionados. Consulte la siguiente

ilustración.

2 Instale los soportes de montaje inferior con los tornillos

de metal #8 x 32 proporcionados, pero no los apriete.

Los soportes deberán ajustarse una vez que el tiro

descendente se encuentre en la abertura. Consulte la

siguiente ilustración.

Soporte de montaje superior Soporte nivelador inferior

TRANSICIÓN

Para los extractores internos, retire la transición circular de

(254) existente. Consulte la siguiente ilustración.

10"

Para los extractores en línea y remotos que se ventilan

desde el frente, deje la transición circular de 10"

(254) en su

lugar.

Para los extractores en línea y remotos que se ventilan

desde la parte de atrás, retire la transición circular de 10"

(254)

de la parte frontal y la cubierta sólida de la parte posterior del tiro descendente, a continuación vuelva a instalar

la transición de 10"

(254) en la parte de atrás y la cubierta

sólida al frente.

Retire la transición

wolfappliance.com | 9

Page 24

INSTALACIÓN

RECEPTÁCULO

Instalación

EXTRACTOR INTERNO

Para montar el extractor interno al frente o en la parte de

atrás del tiro descendente:

1 Gire la caja del extractor de tal manera que el escape

circular de 6"

(152) se encuentre en el lugar apropiado, a

continuación desconecte el cable del receptáculo del tiro

descendente y conéctelo al receptáculo del extractor.

Consulte las siguientes ilustraciones.

2 Una vez que haya realizado la conexión del extractor y

el escape se encuentre correctamente ubicado, asegure

el extractor al tiro descendente con los cuatro tornillos

proporcionados.

DESCARGA

DEL VENTILADOR DE

TIRO DESCENDENTE

RECEPTÁCULO

DEL EXTRACTOR

Para montar el extractor interno en la parte frontal del tiro

descendente, pero el escape en la parte trasera:

1 Retire el extractor de la caja del extractor.

2 Monte el motor del extractor en el tiro descendente con

los dos tornillos proporcionados.

3 Retire el enchufe del extractor del receptáculo del tiro

descendente e insértelo en el receptáculo del extractor.

Consulte la siguiente ilustración.

4 Una vez que haya instalado el enchufe y el extractor esté

asegurado, instale la caja del extractor en el tiro descendente con los cuatro tornillos proporcionados.

5 Retire el collar de 6" (152) de la caja del extractor y la

cubierta sólida de la parte posterior del tiro descendente, a continuación vuelva a instalar el collar de 6"

(152)

en la parte posterior y la cubierta sólida en la caja

del extractor. Consulte la siguiente ilustración.

RECEPTÁCULO DEL

VENTILADOR DE

TIRO DESCENDENTE

CUBIERTA

Descarga a la izquierda,

Conexión del extractor

derecha o abajo

10 | Atención al cliente de Wolf 800.222.7820

RECEPTÁCULO

DEL EXTRACTOR

Montaje del extractor

COLLAR

Instale la cubierta

Page 25

INSTALACIÓN

AZUL

MARRÓN

NEUTRO

TIERRA

CALIENTE

Instalación

EXTRACTOR EN LÍNEA | REMOTO

1 Inserte el suministro eléctrico (Romex) del extractor en

línea o remoto por la abertura en el tiro descendente y

asegúrelo con un liberador de tensión aprobado.

2 Conecte el cable de la corriente al cable marrón, el

neutro al azul y la tierra al verde. Consulte la siguiente

ilustración.

SUMINISTRO

EL´ECTRICO

CUBIERTA DEL

CABLEADO

Ubicación del cableado

Cableado del extractor en

línea | remoto

MONTAJE DEL MOSTRADOR

Coloque el tiro descendente en la abertura, a continuación

asegure los soportes inferiores al gabinete con los tornillos

para madera proporcionados. Una vez que los soportes

estén asegurados, apriete los tornillos existentes del

soporte inferior. Consulte la siguiente ilustración.

Asegure los soportes de montaje superior al mostrador con

los tornillos para madera proporcionados. Para los mostradores de supercie sólida, puede utilizar silicón pero no se

proporciona como parte del paquete.

Una vez que la parte de arriba está asegurada, instale los

soportes bajo el mostrador con los tornillos proporcionados

y a continuación instale las cubiertas laterales. Consulte la

siguiente ilustración.

TORNILLO

DE MONTAJE

CUBIERTA

Montaje del mostrador

Instalación de la cubierta

wolfappliance.com | 11

Page 26

MELT

HIGH

OFF ON

OFF ON

SIM

HIGH

OFF ON

SIM

HIGH

BRIDGE

OFF ON

SIM

HIGH

ZONE 2

CLEAR

OFF

O

ZONE 2

ZONE 3

HIGH

SIM

OFF ON

INSTALACIÓN

Instalación

MÓDULO DE CONTROL

1 Utilice la plantilla proporcionada en la página 13 para

marcar los oricios para los tornillos de montaje. Taladre

9

un oricio de 1

/16" (40) en el centro y dos de 3/8" (10)

para los tornillos de montaje.

PRECAUCIÓN

Verique la escala de la plantilla si no va utilizar la guía

de instalación enviada con el tiro descendente.

2 Compruebe el grosor del mostrador para asegurarse de

que los pernos roscados son lo sucientemente largos

para permitir que las tuercas de mariposa engranen

completamente. Con mostradores más gruesos puede

ser necesario avellanar el mostrador desde abajo.

3 Coloque el módulo de control sobre el mostrador y a

continuación asegúrelo con las dos tuercas proporcionadas. Una vez asegurado, instale el cable a tierra y la

tuerca.

4 Utilice el cable proporcionado o un cable designado

por el Código Nacional de Electricidad, NFPA/ANSI 70

o los códigos locales. Conecte un extremo del cable de

control en la parte de atrás del módulo de control y el

otro a la conexión eléctrica al frente del montaje del tiro

descendente. Asegúrese de que todas las conexiones

estén bien ajustadas.

CUBIERTA SUPERIOR

Conecte el cable de alimentación del ventilador de tiro

descendente en un receptáculo de 3 clavijas, luego direccione por debajo del aparato y lejos del calor generado por

la estufa. Verique el funcionamiento del ventilador de tiro

descendente.

Una vez vericado el funcionamiento, levante la chimenea

e instale el ribete superior con las tres tuercas proporcionadas. Verique que el ribete superior esté correctamente

alineado con las cubiertas laterales. Consulte la siguiente

ilustración.

FILTROS

Retire las etiquetas y los soportes de transporte e instale los

ltros. Consulte la siguiente ilustración.

CUBIERTA SUPERIOR

ADVERTENCIA

No lo conecte a una red de telecomunicación.

TIERRA

CONECTOR

RJ45

Conexión del tiro descendente Conexión del módulo de control

12 | Atención al cliente de Wolf 800.222.7820

MÓDULO DE CONTROL

TUERCA

TIERRA

CONECTOR

RJ45

MOSTRADOR

Instalación de la cubierta

superior

Instalación del ltro

Page 27

INSTALACIÓN

L

Instalación

PLANTILLA DEL MÓDULO DE CONTROL

13

/16

"

(21)

9

/16

2

"

(65)

C

9

/16

2

"

(65)

13

/16

"

(21)

C

L

1" (25)0"

ESCALA

wolfappliance.com | 13

Page 28

RESOLUCIÓN DE PROBLEMAS

Resolución de problemas

AVISO IMPORTANTE: si el sistema de ventilación de tiro des-

cendente no tiene un funcionamiento apropiado, siga estos

pasos para resolver los problemas:

• Compruebe que el tiro descendente tenga corriente

eléctrica.

• Compruebe que las conexiones eléctricas son las

adecuadas.

• Si el tiro descendente no funciona correctamente, pón-

gase en contacto con el centro de servicio autorizado

de Wolf. No intente reparar el tiro descendente. Wolf no

es responsable del servicio necesario para corregir una

instalación defectuosa.

14 | Atención al cliente de Wolf 800.222.7820

Page 29

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design son marcas registradas y marcas de servicio de Sub-Zero Group, Inc. y sus asociados. Todas

las demás marcas registradas son propiedad de sus dueños respectivos en los Estados Unidos y otros países.

wolfappliance.com | 15

Page 30

VENTILATION À ASPIRATION DESCENDANTE

Table des matières

3 Ventilation à aspiration descendante

4 Spécications

9 Installation

14 Dépannage

Les caractéristiques et les spécications peuvent être modiées en tout temps sans préavis. Visitez wolfappliance.com/

specs pour obtenir les renseignements les plus récents.

Remarque importante

Pour s´assurer que ce produit est installé et utilisé en toute

sécurité et aussi efcacement que possible, prenez note des

types de renseignement mis en évidence tout au long de ce

guide :

REMARQUE IMPORTANTE met en évidence des renseigne-

ments qui sont particulièrement importants.

MISE EN GARDE indique une situation où une blessure

mineure ou des dommages au produit peuvent se produire

si les directives ne sont pas respectées.

AVERTISSEMENT décrit un danger qui peut causer une

blessure grave ou la mort si les précautions ne sont pas

respectées.

REMARQUE IMPORTANTE : tout au long de ce guide, les

dimensions entre parenthèses sont en millimètres à moins

d´indication contraire.

REMARQUE IMPORTANTE : conservez ces directives pour

l´inspecteur en électricité local.

2 | Service à la clientèle de Wolf 800.222.7820

Page 31

VENTILATION À ASPIRATION DESCENDANTE

Renseignements sur le produit

Des renseignements importants sur le produit, y compris les

numéros de modèle et de série, se trouvent sur la plaque

signalétique du produit. La plaque signalétique est située à

côté du boîtier de la souferie sur le devant de l´aspiration

descendante, sous le comptoir. Reportez-vous à l´illustration

ci-dessous.

Si vous avez besoin de service, communiquez avec le

service Wolf certié par l´usine avec les numéros de modèle

et de série. Pour obtenir le nom du centre de service Wolf

certié par l´usine le plus près de chez vous ou si vous avez

des questions concernant l´installation, consultez la section

Contact et assistance de notre site Web, wolfappliance.com

ou appelez le service à la clientèle de Wolf au 800-222-7820.

PLAQUE SIGNALÉTIQUE

AVERTISSEMENT

EN VUE DE RÉDUIRE LE RISQUE D´INCENDIE,

DE CHOC ÉLECTRIQUE OU DE BLESSURES,

RESPECTEZ LES ÉLÉMENTS SUIVANTS :

a)

Le travail d´installation et le câblage électrique

doivent être effectués par une (des) personne(s) qualiée(s) conformément à tous les

codes et normes applicables, y compris ceux

concernant la construction résistante au feu.

b) Il faut sufsamment d´air pour la combustion

appropriée et l´évacuation des gaz dans la

sortie (cheminée) de l´équipement de chauffage

au mazout pour éviter le refoulement de l´air.

Suivez les directives du fabricant de l´équipement de chauffage et les normes de sécurité

comme celles publiées par la National Fire

Protection Association (NFPA ou association

nationale de protection contre les incendies),

l´American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE ou

société américaine des ingénieurs de chauffage, réfrigération et climatisation) et les autorités locales concernant les codes.

Emplacement de la plaque

signalétique

c) Lorsque vous coupez ou percez dans un mur

ou un plafond, n´endommagez pas les ls électriques ou d´autres services publics cachés.

d) Les ventilateurs à enveloppe doivent toujours

être ventilés vers l´extérieur.

wolfappliance.com | 3

Page 32

SPÉCIFICATIONS

Exigences d´installation

Pour l´installation avec une surface de cuisson Wolf, un

1

comptoir plat d´au moins 25

/8 po (638) de profondeur est

requis.

Pour installation avec un plan de cuisson scellé ou une table

de cuisson contemporaine de 30 po

(762) ou 36 po (914), une

trousse de garniture accessoire est requise. Communiquez

avec votre dépositaire Wolf autorisé pour de plus amples

renseignements. Pour obtenir des renseignements sur le

dépositaire local, visitez la section salle d´exposition de

notre site Web, wolfappliance.com.

Le module de commande monté à distance peut être placé

horizontalement ou verticalement. Il doit se trouver à une

distance de 9 pi

cendante et à une distance d´au moins 3 po

(2.7 m) de l´assemblage de l´aspiration des-

(76) du rebord

de la surface de cuisson ou de la découpe du dessus de

cuisinière.

SOUFFLERIES

MISE EN GARDE

Pour utilisation avec la souferie interne Wolf 600 CFM

et les souferies à distance d´une capacité maximale

de 3 ampères.

RÉSEAU DE GAINES

WARNING

POUR RÉDUIRE LE RISQUE D'INCENDIE, UTILISEZ

SEULEMENT DES GAINES MÉTALLIQUES.

Les aspirations descendantes de Wolf doivent être ventilées vers l´extérieur. Consultez un professionnel en CVC

qualié pour des installations et des applications de gaines

précises. L´aspiration descendante fonctionnera de façon

plus efcace lorsqu´elle a le plus petit nombre de coudes et

lorsque l´ensemble de gaines ne dépasse pas 40 pi

(12 m).

Des assemblages de souferie interne, en ligne ou à distance sont offerts par votre dépositaire Wolf autorisé.

Les souferie internes comprennent une évacuation ronde

de 6 po

(152), peuvent être montées à l´avant ou à l´arrière

et peuvent être évacuées dans toute direction en pivotant la

boîte de la souferie. Les souferies en ligne et à distance

possèdent une évacuation ronde de 10 po

(254) et peuvent

être évacuées vers l´avant ou l´arrière.

4 | Service à la clientèle de Wolf 800.222.7820

Page 33

SPÉCIFICATIONS

Électricité

L´installation doit être mise à la terre électriquement

conformément aux codes locaux ou, en l´absence de codes

locaux, conformément au code national de l´électricité,

ANSI/NFPA 70.

Repérez l´alimentation électrique, comme il est montré dans

les illustrations aux pages 5 et 6. Un circuit séparé servant

uniquement cet appareil est requis. Un disjoncteur de fuite

de terre (GFCI) n´est pas recommandé et peut interrompre le

fonctionnement.

Certaines installations peuvent nécessiter que l´alimentation

électrique soit placée dans une armoire adjacente.

EXIGENCES ÉLECTRIQUES

Alimentation électrique mise à la terre, 120 volts CA, 60 Hz

Service circuit dédié de 15 ampères

Prise mise à la terre à trois broches

1

Cordon d´alimentation 2

PLAQUE SIGNALÉTIQUE

/2 pi (0,8 m)

DIRECTIVES DE MISE À LA TERRE

Cet appareil doit être mis à la terre. Dans le cas d´un

court-circuit, la mise à la terre réduit le risque de choc

électrique en fournissant un l de décharge au courant

électrique. Cet appareil est muni d´un cordon avec un l de

masse et une che de masse. La che doit être branchée

dans une prise qui est adéquatement installée et mise à la

terre.

AVERTISSEMENT

Une mauvaise mise à la terre peut entraîner un risque

de choc électrique. Consultez un électricien qualié si

vous ne comprenez pas complètement les directives

de mise à la terre ou si vous avez des doutes quant à la

mise à la terre appropriée de l´appareil.

N´utilisez pas de rallonge électrique. Si le cordon d´alimentation est trop court, demandez à un électricien

qualié d´installer une prise plus près de l´appareil.

Emplacement de la plaque

signalétique

wolfappliance.com | 5

Page 34

SPÉCIFICATIONS

Aspiration descendante

INSTALLATION AVEC LA TABLE DE CUISSON INSTALLEE STANDARD

81/4 po

(210)*

211/4 po

(540)

211/16 po (68)

LARGEUR DE LA DÉCOUPE DE

L’ASPIRATION DESCENDANTE

L

E

81/4 po (210)*

DÉCOUPE DE LA SURFACE

DE CUISSON

VUE DE DESSUS

211/4 po

(540)

233/8 po

(594)

E

VUE DE FACEVUE DE PROFIL

*6 po (152) de l’arrière de la découpe du comptoir lorsque la soufflerie interne est installée à l’arrière.

REMARQUE : soufflerie interne ronde de 6 po (152), évacuation latérale, arrière ou inférieure. Soufflerie en ligne et à distance ronde de

10 po (254), évacuation arrière. La ligne centrale indique le centre de la découpe de l’aspiration descendante.

LARGEUR DE LA DÉCOUPE

L

DD30 271/2 po (699)

DD36 331/2 po (851)

DD45 391/2 po (1003)

6 | Service à la clientèle de Wolf 800.222.7820

Page 35

SPÉCIFICATIONS

Aspiration descendante

INSTALLATION AVEC LA TABLE DE CUISSON INSTALLEE DE FLUSH

81/4 po

(210)*

211/4 po

(540)

25/16 po

LARGEUR DE LA DÉCOUPE DE

L’ASPIRATION DESCENDANTE

(59)

E

DÉCOUPE DE LA SURFACE

DE CUISSON

VUE DE DESSUS

211/4 po

(540)

E

VUE DE FACEVUE DE PROFIL

L

81/4 po (210)*

233/8 po

(594)

*6 po (152) de l’arrière de la découpe du comptoir lorsque la soufflerie interne est installée à l’arrière.

REMARQUE : soufflerie interne ronde de 6 po (152), évacuation latérale, arrière ou inférieure. Soufflerie en ligne et à distance ronde de

10 po (254), évacuation arrière. La ligne centrale indique le centre de la découpe de l’aspiration descendante.

LARGEUR DE LA DÉCOUPE

L

DD30 271/2 po (699)

DD36 331/2 po (851)

wolfappliance.com | 7

Page 36

SPÉCIFICATIONS

Aspiration descendante

INSTALLATION AVEC DESSUS DE CUISINIÈRE À BRÛLEUR SCELLÉ

PROFONDEUR DE

LA PLATE-FORME

81/4 po

(210)*

VUE DE PROFIL

19 po (483)

211/4 po

(540)

211/16 po (68)

LARGEUR DE LA DÉCOUPE DE

L’ASPIRATION DESCENDANTE

L

E

81/4 po (210)*

OUVERTURE DU DESSUS

DE CUISINIÈRE

VUE DE DESSUS

211/4 po

(540)

233/8 po

(594)

E

VUE DE FACE

*6 po (152) de l’arrière de la découpe du comptoir lorsque la soufflerie interne est installée à l’arrière.

REMARQUE : soufflerie interne ronde de 6 po (152), évacuation latérale, arrière ou inférieure. Soufflerie en ligne et à distance ronde de

10 po (254), évacuation arrière. La ligne centrale indique le centre de la découpe de l’aspiration descendante.

LARGEUR DE LA DÉCOUPE

L

DD30 271/2 po (699)

DD36 331/2 po (851)

8 | Service à la clientèle de Wolf 800.222.7820

Page 37

INSTALLATION

Installation

ASPIRATION DESCENDANTE

1 Installez les supports de montage supérieurs au moyen

des vis autotaraudeuses n° 4 fournies. Reportez-vous à

l´illustration ci-dessous.

2 Installez les supports de montage inférieurs en utilisant

les vis autotaraudeuses n° 8 x 32 fournies, mais ne

serrez pas. Les supports devront être ajustés lorsque

l´aspiration descendante sera placée dans l´ouverture.

Reportez-vous à l´illustration ci-dessous.

Support de montage supérieur Support de nivellement

inférieur

TRANSITION

Pour les souferies internes, retirez la transition ronde

existante de 10 po

(254). Reportez-vous à l´illustration

ci-dessous.

Pour les souferies en ligne et à distance évacuées vers

l´avant, laissez la transition ronde de 10 po

(254) en place.

Pour les souferies en ligne et à distance évacuées vers

l´arrière, retirez la transition ronde de 10 po

(254) de l´avant

et le couvercle plein de l´arrière de l´aspiration descendante,

puis réinstallez la transition de 10 po

(254) à l´arrière et le

couvercle plein à l´avant.

Retirez la transition

wolfappliance.com | 9

Page 38

INSTALLATION

PRISE DE

Installation

SOUFFLERIE INTERNE

Pour installer la souferie interne sur l´avant ou l´arrière de

l´aspiration descendante :

1 Pivotez la boîte de la souferie an que l´évacuation

ronde de 6 po

(152) soit correctement placée, puis

débranchez le câble de la prise de l´aspiration descendante et branchez-le sur la prise de la souferie.

Reportez-vous aux illustrations ci-dessous.

2 Une fois la connexion de la souferie effectuée et

l´évacuation correctement placée, xez la souferie

à l´aspiration descendante au moyen des quatre vis

fournies.

ÉVACUATION

PRISE DE L’ASPIRATION

DESCENDANTE

PRISE DE LA

SOUFFLERIE

Pour installer la souferie interne sur le devant de l´aspiration descendante, mais évacuer par l´arrière :

1 Retirez la souferie de la boîte de souferie.

2 Installez le moteur de la souferie sur l´aspiration des-

cendante au moyen des deux vis fournies.

3 Retirez la che de la souferie de la prise de l´aspiration

descendante et insérez-la dans la prise de la souferie.

Reportez-vous à l´illustration ci-dessous.

4 Une fois la che installée et la souferie xée, installez la

boîte de souferie sur l´aspiration descendante au moyen

des quatre vis fournies.

5 Retirez le collier de 6 po (152) de la boîte de souferie

et le couvercle plein de l´arrière de l´aspiration descendante, puis réinstallez le collier de 6 po

(152) à l´arrière

et le couvercle plein sur la boîte de souferie. Reportez-vous à l´illustration ci-dessous.

L’ASPIRATION

DESCENDANTE

COUVERCLE

Évacuation gauche, droite ou

Connexion de la souferie

inférieure

10 | Service à la clientèle de Wolf 800.222.7820

PRISE DE LA

SOUFFLERIE

Montage de la souferie

COLLIER

Installez le couvercle

Page 39

BLEU

BRUN

NEUTRE

MISE À

LA TERRE

CHAUD

INSTALLATION

Installation

SOUFFLERIE EN LIGNE | À DISTANCE

1 Insérez l´alimentation électrique (Romex) de la souferie

en ligne ou à distance dans l´ouverture de l´aspiration

descendante et xez au moyen d´un cordon approuvé

comme réducteur de tension.

2 Reliez le l chaud au brun, le l neutre au bleu et la

mise à la terre au vert. Reportez-vous à l´illustration

ci-dessous.

ALIMENTATION

´

ELECTRIQUE

COUVERCLE

DU CÂBLAGE

Emplacement du câblage

Câblage de la souferie en

ligne | à distance

MONTAGE SUR UN COMPTOIR

Placez l´aspiration descendante dans l´ouverture, puis xez

les supports inférieurs à la base de l´armoire au moyen des

vis à bois fournies. Une fois les supports xés, serrez les vis

du support inférieur existant. Reportez-vous à l´illustration

ci-dessous.

Fixez les supports de montage supérieurs au comptoir au

moyen des vis à bois fournies. Pour les comptoirs à surface

solide, de la silicone peut être utilisée, mais elle n´est pas

fournie.

Une fois le dessus xé, installez les supports de dessous du

comptoir au moyen des vis fournies, puis installez les couvercles latéraux. Reportez-vous à l´illustration ci-dessous.

VIS DE

MONTAGE

COUVERCLE

Montage sur le comptoir

Installation du couvercle

wolfappliance.com | 11

Page 40

MELT

HIGH

OFF ON

OFF ON

SIM

HIGH

OFF ON

SIM

HIGH

BRIDGE

OFF ON

SIM

HIGH

ZONE 2

CLEAR

OFF

O

ZONE 2

ZONE 3

HIGH

SIM

OFF ON

INSTALLATION

Installation

MODULE DE COMMANDE

1 Utilisez le gabarit fourni à la page 13 pour marquer les

trous pour les vis de montage. Percez un trou de 1

(40)

au centre et deux trous de 3/8 po (10) pour les vis de

9

/16 po

montage.

MISE EN GARDE

Vériez l´échelle sur le gabarit si vous n´utilisez pas le

guide d´installation expédié avec l´aspiration descendante.

2 Vériez l´épaisseur du comptoir pour vous assurer que

les tiges letées soient assez longues pour permettre

aux écrous à ailettes de s´enclencher complètement.

Des comptoirs plus épais pourront nécessiter le fraisage

du comptoir à partir du dessous.

3 Placez le module de commande sur le comptoir, puis

xez-le au moyen des deux écrous fournis. Un fois xé,

installez le l et l´écrou de mise à la terre.

4 Utilisez le câble fourni ou un câble désigné par le code

national de l´électricité, la norme NFPA/ANSI 70 ou les

codes locaux. Reliez une extrémité du câble de commande à l´arrière du module de commande et l´autre à

la connexion électrique située sur le devant de l´assemblage de l´aspiration descendante. Assurez-vous que

toutes les connexions soient bien serrées.

COUVERCLE SUPÉRIEUR

Branchez le cordon d'alimentation de l'aspiration descendante dans une prise à trois broches, puis acheminez-le

sous l'appareil et loin de la chaleur générée par la surface de cuisson. Vériez le fonctionnement de l'aspiration

descendante.

Une fois le fonctionnement vérié, relevez la cheminée et

installez la garniture supérieure au moyen des trois écrous

fournis. Vériez que la garniture supérieure est bien alignée

avec les couvercles latéraux. Reportez-vous à l´illustration

ci-dessous.

FILTRES

Retirez les autocollants et les supports d´expédition et installez les ltres. Reportez-vous à l´illustration ci-dessous.

COUVERCLE SUPÉRIEUR

AVERTISSEMENT

Ne reliez pas à un réseau de télécommunication.

MISE À LA

TERRE

CONNECTEUR

RJ45

Connexion de l´aspiration

descendante

12 | Service à la clientèle de Wolf 800.222.7820

MODULE DE COMMANDE

ÉCROU

MISE À LA

TERRE

Connexion du module de

commande

CONNECTEUR

RJ45

COMPTOIR

Installation du couvercle

supérieur

Installation du ltre

Page 41

INSTALLATION

L

Installation

GABARIT DU MODULE DE COMMANDE

13

/16

po

(21)

9

/16

2

po

(65)

C

9

/16

2

po

(65)

13

/16

po

(21)

C

L

1 po (25)0 po

ÉCHELLE

wolfappliance.com | 13

Page 42

DÉPANNAGE

Dépannage

REMARQUE IMPORTANTE : si le système de ventilation à

aspiration descendante ne fonctionne pas correctement,

suivez ces étapes de dépannage :

• Assurez-vous que l´aspiration descendante est

alimentée.

• Vériez les connexions électriques.

• Si l´aspiration descendante ne fonctionne pas correc-

tement, communiquez avec le service Wolf certié par

l´usine. Ne tentez pas de réparer l´aspiration descendante. Wolf n´est pas responsable du service requis pour

corriger une installation défectueuse.

14 | Service à la clientèle de Wolf 800.222.7820

Page 43

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, les boutons de couleur rouge, Cove et Cove & Design sont des marques déposées et de service de Sub-Zero Group, Inc. et ses liales.

Toutes les autres marques de commerce appartiennent à leurs propriétaires respectifs aux États-Unis et dans d'autres pays.

wolfappliance.com | 15

Page 44

WOLF APPLIANCE, INC. P.O. BOX 44848 MADISON, WI 53744 WOLFAPPLIANCE.COM 800.222.7820

808256 REV-F 5/2018

Loading...

Loading...