Page 1

subzero.com 800.222.7820

CT Gas Cooktop

Service Manual

General Information 2

Installation Information 6

Controls & Operation 13

Component Access & Removal 18

Troubleshooting Guide 26

Technical Data 29

Wiring Diagrams 31

Page 2

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

General Information

1-2

#802985 - Revision E - August, 2011

INTRODUCTION

This manual has been compiled to provide the most recent technical service information about this series. This

information will enable the service technician to troubleshoot and diagnose malfunctions, perform necessary repairs

and return a Wolf Gas Cooktop to proper operational condition.

The service technician should read the complete instructions contained in this Service/Training Manual before initiating any repairs on a Wolf Appliance.

* Some information in Section 2, Theory of Operation, has been provided by the American Gas Association

and reprinted with their approval.

IMPORTANT SAFETY INFORMATION

Below are the Product Safety Labels used in this manual. The "Signal Words" used are WARNING and

CAUTION.

Please note that these safety labels are placed in areas

where awareness of personal safety and product safety

should be taken and lists the precautions to be taken

when the signal word is observed.

INDICATES THAT HAZARDOUS OR UNSAFE

PRACTICES COULD RESULT IN SEVERE PERSONAL INJURY OR DEATH.

Indicates that hazardous or unsafe practices could

result in minor personal injury or product and/or

property damage.

In addition, please pay attention to the signal word

“NOTE”, which highlights especially important information within each section.

TECHNICAL ASSISTANCE

If you should have any questions regarding the appliance and/or this manual, please contact:

Wolf Appliance, Inc.

ATTN: Service Department

P.O. Box 44988

Madison, WI 53744 - 4988

Customer Assistance

Phone #: (800) 332 - 9513

Facsimile #: (608) 441 - 5887

Technical Assistance

(For Technicians in Customer’s Homes Only)

Phone #: (800) 919 - 8324

Warranty Claims

Phone #: (800) 404 - 7820

Facsimile #: (608) 441 - 5886

Service Department e-mail Address:

customerservice@wolfappliance.com

Main Office Hours:

8:00 AM to 5:00 PM Central Time

Monday through Friday

(24/7 Phone Coverage)

This manual is designed to be used by Authorized Service Personnel only. Wolf Appliance, Inc.. assumes

no responsibility for any repairs made to Wolf appliances by anyone other than Authorized Service

Technicians.

The information and images are the copyright property of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. Neither

this manual nor any information or images contained herein may be copied or used in whole or in part without the

express written permission of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. © Wolf Appliance, Inc. all rights

reserved.

Page 3

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

General Information

1-4

#802985 - Revision E - August, 2011

WARRANTY INFORMATION

This page contains a summary of the 2 & 5 Year

Warranty that is supplied with every Wolf product,

followed by details and notes about the warranties.

TWO & FIVE YEAR Warranty Summary

• Two year TOTAL PRODUCT warranty, parts and

labor.

• Limited Parts Only Warranty for the 3rd through

5th year on the following parts only:

• Gas Burners (excluding appearance).

Warranty Details:

The warranty applies only to products installed for

normal residential use. The warranty applies only to

products installed in the United States or Canada.

Warranty NOTES:

• All warranties begin at the time of the initial

installation.

• All Warranty and Service information collected by

Wolf Appliance, Inc.. is arranged and stored

under the unit serial number and/or the customer’s name. Please note that Wolf Appliance,

Inc. requests that you have the model serial

number available whenever contacting the factory or parts distributor.

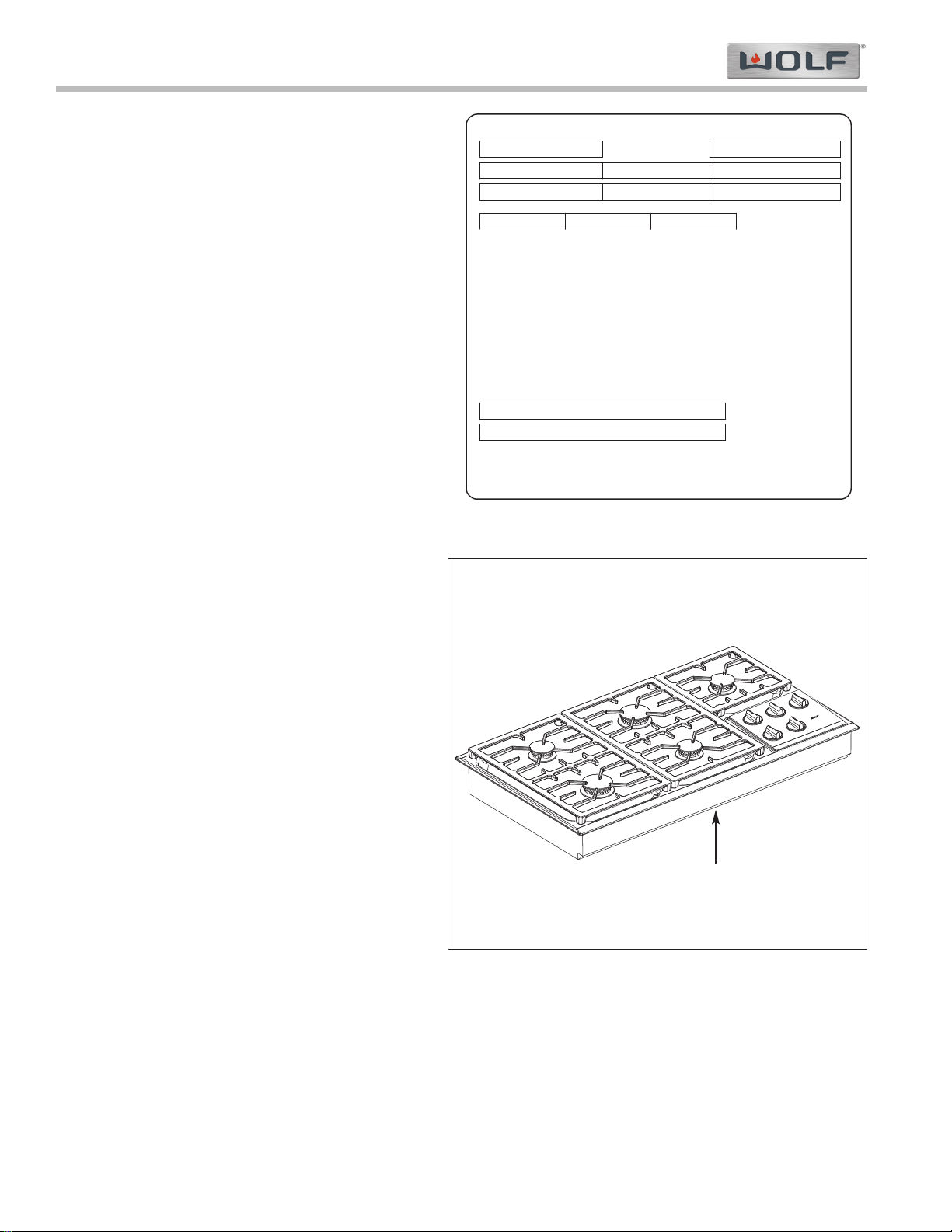

• See Figure 1-1 for serial tag layout.

• See Figure 1-2 for serial tag location.

Wolf Appliance Company, LLC

FITCHBURG, WI

GAS

LEFT

REAR

LEFT

FRONT

VOLTS

CENTER

REAR

CENTER

FRONT

AMP

PRESS.

MAIN

REAR

RIGHT

FRONT

RIGHT

HERTZ

ELECTRICAL RATING

000

000

60

INPUT RATING EACH

BURNER-BTU/HR.

MODEL

NO.

SERIAL

ANSI Z21.1 2000 "HOUSEHOLD GAS COOKING APPLIANCES"

"CAN1-1.1-M81"

BD

801503

Figure 1-1. Typical Serial Tag Layout

Figure 1-2. The serial tag is located on the bottom of

the cooktop.

Serial Tag Location

Page 4

General Information

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

1-5

#802985 - Revision E - August, 2011

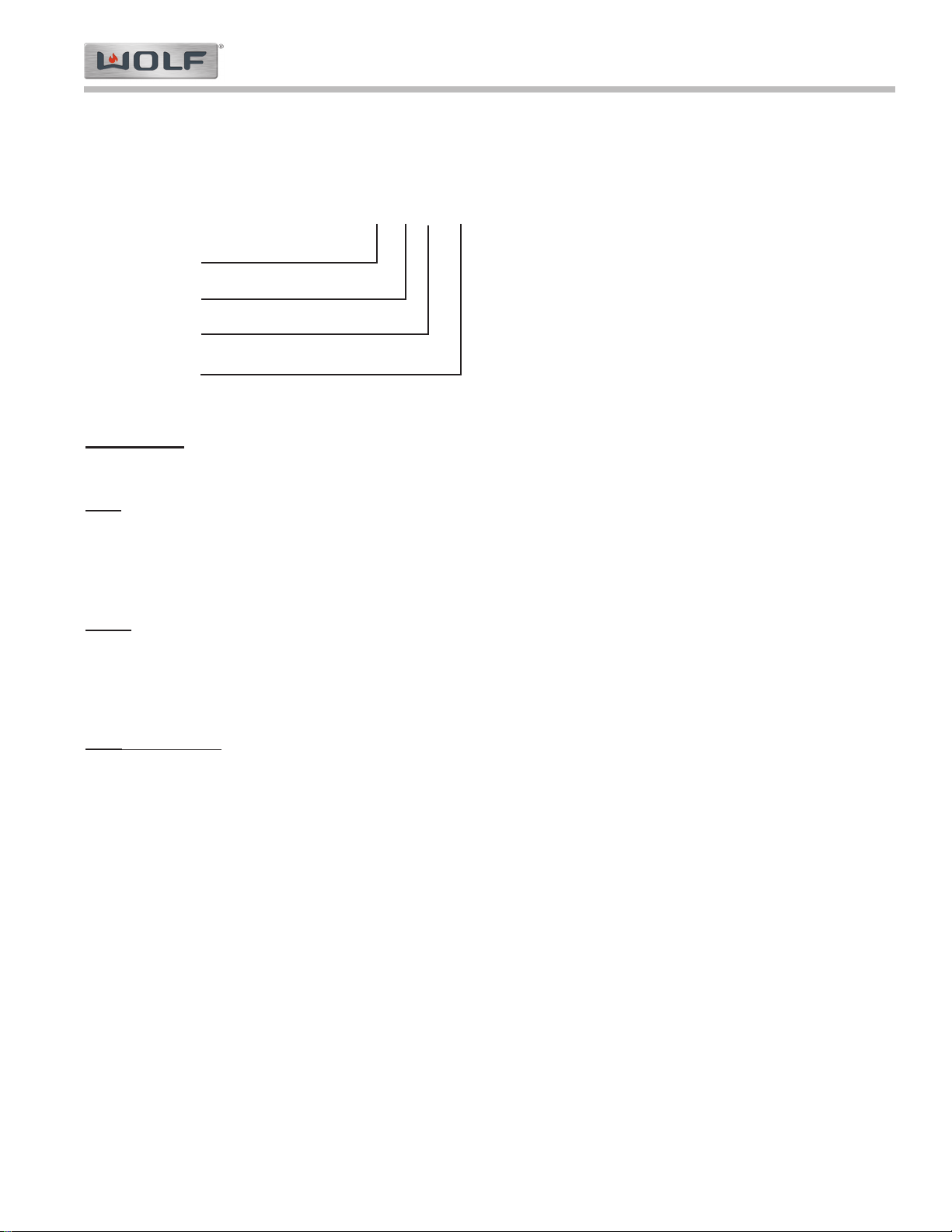

MODEL NUMBER KEY

Refer to this key for an example of the model numbers.

Model: CT 36 G / S

Product Type

Size

Fuel

Finish

Product T

ype

CT Cooktop

Size

15 15'' - inch wide unit

30 30'' - inch wide unit

36 36'' - inch wide unit

Finish

S Classic Stainless Steel

P Platinum Stainless Steel (Not Available for IM, IG, IS and IF)

B Carbon Stainless Steel (Not available for Gas models. Not available for IM, IG, IS and IF)

Fuel

(If Applicable)

LP Liquid Propane Gas

Natural Gas (If there is no “LP” at End of Model Number)

Page 5

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

General Information

1-6

#802985 - Revision E - August, 2011

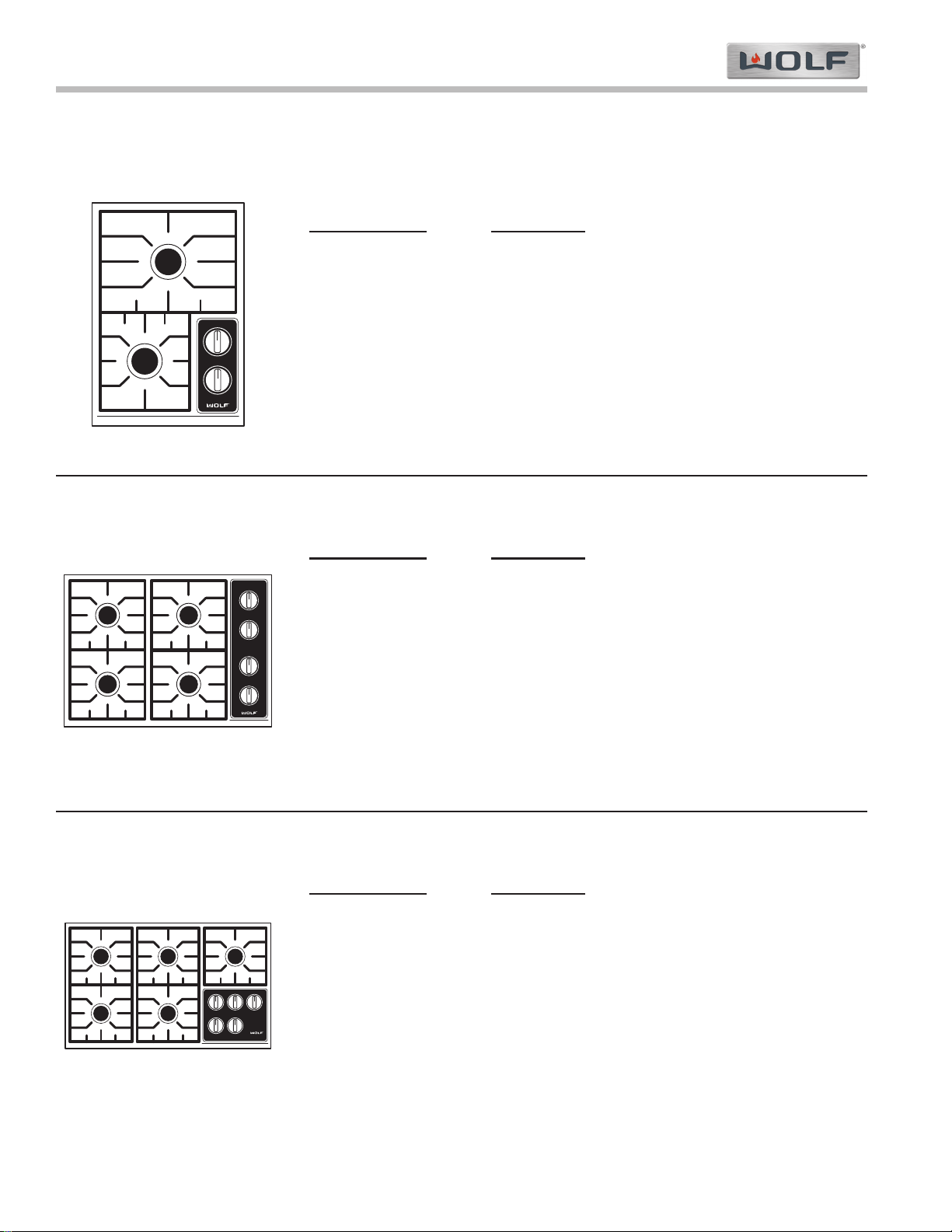

MODEL CONFIGURATIONS

Model Numbers

Descriptions

CT30G/S Cooktop 30” Gas Stainless Steel Natural Gas

CT30G/S- LP Cooktop 30” Gas Stainless Steel Propane

CT30G/P Cooktop 30” Gas Platinum Stainless Steel Nat Gas

CT30G/P- LP Cooktop 30” Gas Platinum Stainless Steel Propane

• Four burner

• Two burners at 12,000 BTU

700 BTU’S delivered at simmer

• Two burners at 9,200 BTU

300 BTU’s delivered at simmer

30” Gas

36” Gas

Model Numbers

Descriptions

CT36G/S Cooktop 36” Gas Stainless Steel Natural Gas

CT36G/S- LP Cooktop 36” Gas Stainless Steel Propane

CT36G/P Cooktop 36” Gas Platinum Stainless Steel Nat Gas

CT36G/P- LP Cooktop 36” Gas Platinum Stainless Steel Propane

• Five burner

• Two burners at 12,000 BTU

700 BTU’S delivered at simmer

• Three burners at 9,200 BTU

300 BTU’s delivered at simmer

Model Numbers Descriptions

CT15G/S Cooktop 15” Gas Stainless Steel Natural Gas

CT15G/S- LP Cooktop 15” Gas Stainless Steel Propane

• Two burner

• One burner at 12,000 BTU

700 BTU’S delivered at simmer

• One burner at 9,200 BTU

300 BTU’s delivered at simmer

15” Gas

Page 6

General Information

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

1-7

#802985 - Revision E - August, 2011

MODEL FEATURES for 15”, 30” & 36” GAS COOKTOPS

• Simmer on all burners

• Dual stacked sealed burners

• Single spark ignition with auto reignition for all burners

• 12,000 BTU/hr and 9,200 BTU/hr burners

• Low profile, continuous, porcelain-coated cast iron grates

• Smart porting of all burners

• Back lit illuminated control panel.

• Electric ratings: 110-120V/ 15 amp circuit

• Available in Natural or LP gas

• Two and Five year warranty

Page 7

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Installation Information

2-2

#802985 - Revision E - August, 2011

INSTALLATION INFORMATION

This section of the manual covers some of the installation issues that a service technician may need to know when

servicing a Wolf Gas Cooktop. If additional installation information is needed after reviewing this section of the manual, please refer to the Installation Guide or contact the Wolf Appliance Customer Service Department.

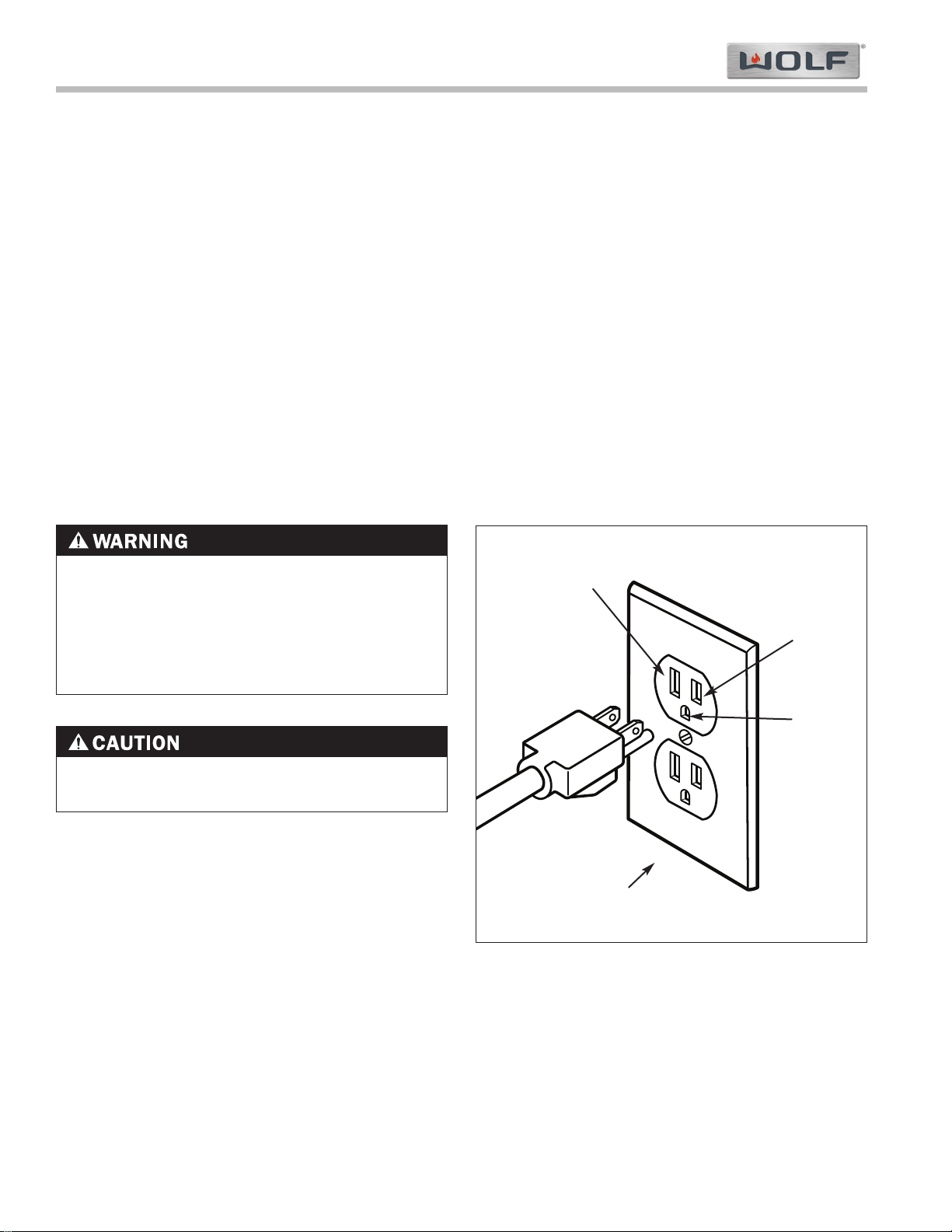

Electrical Requirements:

• 110-120 volts AC, 60 Hertz, 15 ampere fused electrical supply.

• A timed-delay fuse or circuit breaker is recommended.

• Separate circuit serving only this appliance.

• Installation site must be equipped with a properly grounded 3-prong receptacle.

This appliance when installed must be properly grounded. This appliance is equipped with a 3-prong (grounding)

plug. The power cord must be plugged into a mating 3-prong ground-type receptacle (See Figure 2-1).

If a mating receptacle is not available, it is the obligation of the customer to have a properly grounded, 3-prong

receptacle installed by a qualified electrician.

If the electric receptacle or the power cord are not properly grounded and polarized, a shock hazard could exist and

the appliance may experience ignition problems.

• A SHOCK HAZARD COULD EXIST IF THE ELECTRIC RECEPTACLE OR THE POWER CORD ARE

NOT PROPERLY GROUNDED AND POLARIZED.

• TO AVOID SHOCK HAZARD, NEVER REMOVE

THE GROUNDING PRONG FROM THE PLUG OF

THE POWER CORD.

Figure 2-1. Proper Polarity at Electric Receptacle

Grounding Type

Wall Receptacle

Neutral

Ground

Line

Voltage

(Power)

The appliance may experience ignition problems if

not properly grounded and polarized.

Page 8

Installation Information

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

2-3

#802985 - Revision E - August, 2011

GAS REQUIREMENTS:

NOTE: All Wolf gas appliances are manufactured to

work with natural gas or LP gas (Liquid Propane gas).

Natural Gas Manifold Pressure

Standard natural gas orifices on the appliance are set

for 5” WC (Water Column Pressure).

Liquid Propane Manifold Pressure

The standard propane gas orifices on the appliance are

set for 10” WC (Water Column Pressure).

Gas Supply Line Size

• 1/2 inch

Gas Supply Pressure

• Maximum line pressure for natural gas and LP is

14” WC; 1/2 psi (3.5 kPa).

• Minimum line pressure for natural gas is 7” WC.

• Minimum line pressure for LP gas is 11” WC.

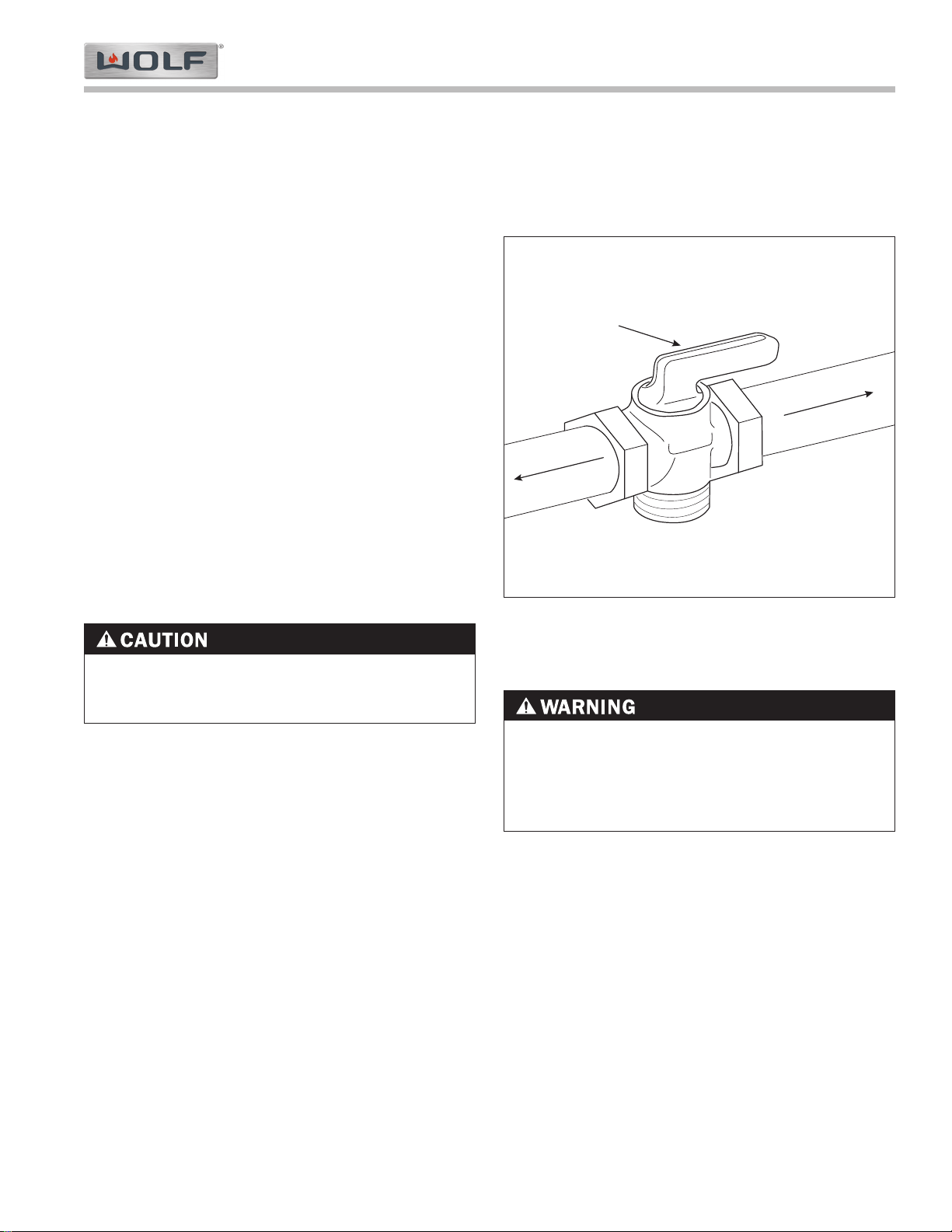

Gas Shut-off Valve

The supply line must be equipped with an approved

shut-off valve. This valve should be located in accordance to all national, local codes and ordinances (See

Figure 2-2).

NEVER USE OPEN FLAMES TO CHECK FOR GAS

LEAKS. ONLY USE A LEAK TESTING SOLUTION

OF SOAPY WATER OR AN ELECTRONIC LEAK

DETECTOR. DO NOT USE LIQUID NEAR VALVE

STEMS.

The maximum gas supply pressure to the regulator

should never exceed 14” WC (Water Column

Pressure); 1/2 psi (3.5kPa).

Shut-off Valve

(open position)

To Cooktop

Gas Supply Line

Figure 2-2. Shut-off Valve

Gas Pressure Regulator

To control and maintain a uniform gas pressure in thegas manifold, Wolf gas appliances must be connected

to the gas supply line through a pressure regulator.

The burner orifices are sized for the pressure delivered

by the regulator. Never attempt to operate a Wolf gas

appliance without the use of the proper pressure regulator.

Leak Testing

Page 9

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Installation Information

2-4

#802985 - Revision E - August, 2011

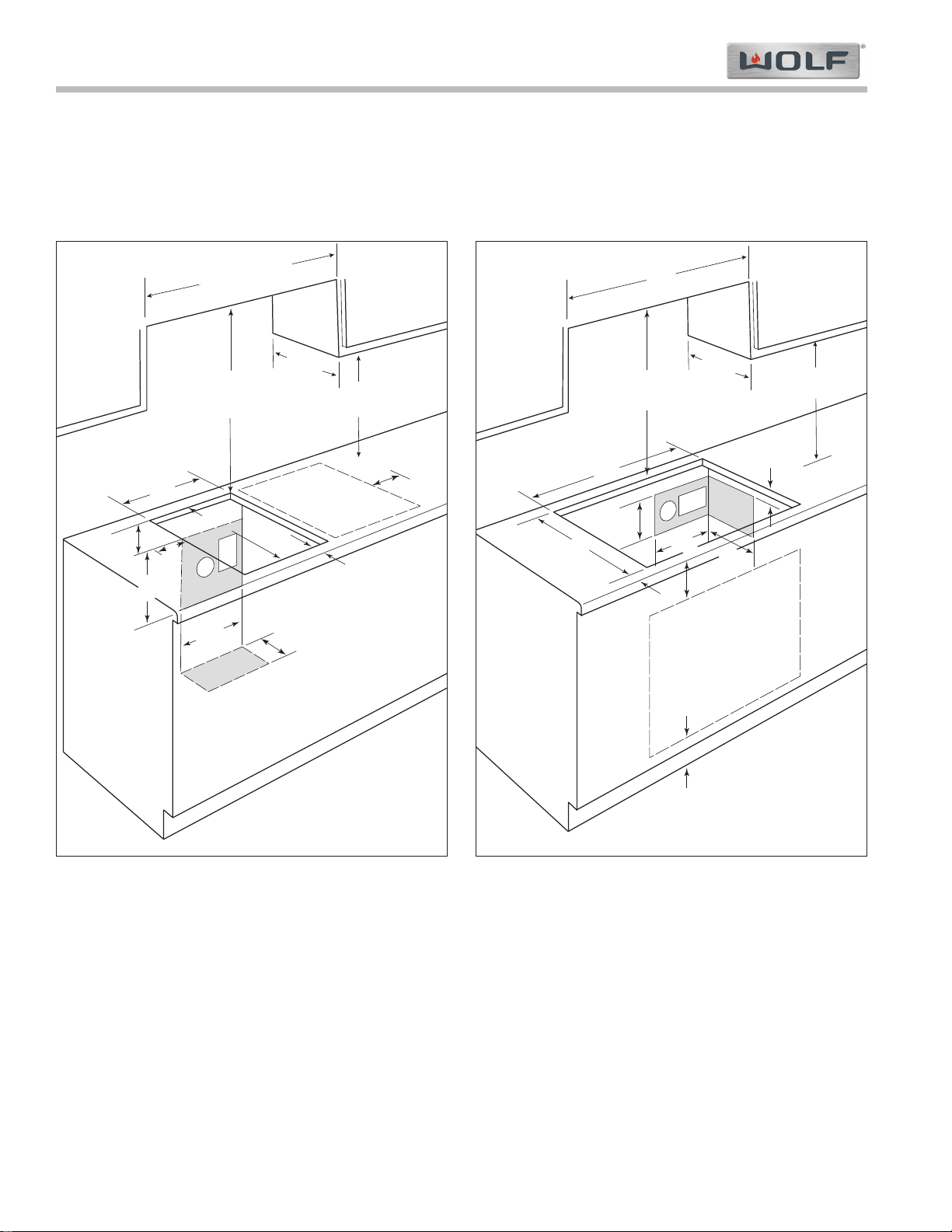

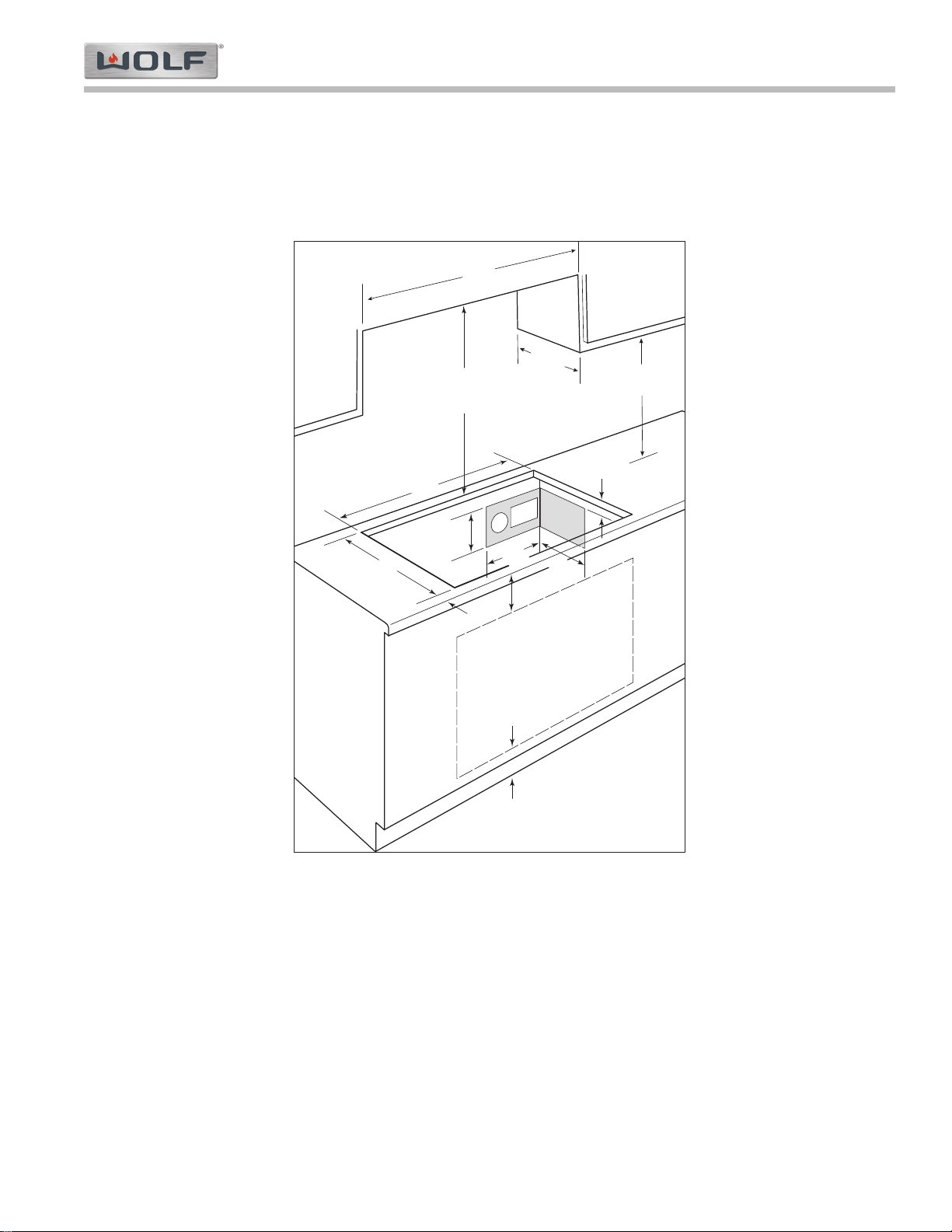

15” AND 30” GAS COOKTOP INSTALLATION DIMENSIONS

Area Requirements:

NOTE: Countertop opening dimensions that are shown must be used. Given dimensions provide required clear-

ances.

E

21/2"

min

(6.4)

15"

(38.1)

15"

(38.1)

14"*

(35.6)

4"

(10.2)

5"

(12.7)

G

* Dimensions may vary

by ± 1/8" (.3 cm)

13"

(33.0)

24" or 30"***

18"**

(45.7)

Combined width

of all cooktops

(61.0 or 76.2)

to cooking surface

7"

(17.8)

7"

(17.8)

"*

19

1

/

4

(49.0)

** 18” (45.7cm) minimum clearance upper cabinet to countertop within 7” (17.8cm) minimum side clearance to

combustible surface above countertop.

*** 24” (61cm) minimum clearance between top of cooking surface and bottom of wood or metal cabinet which is

protected by not less than 1/4” (.6cm) flame retardant millboard covered with not less than No. 28 MSG sheet

steel, .015” (.04cm) stainless steel, or .024” (.06cm) aluminum or .02” (.05cm) copper.

*** 30” (76.2) minimum clearance between top of cooking surface and bottom of an unprotected wood or metal

cabinet.

NOTE: Do not seal cooktop to countertop.

15” Installation Dimensions

E

31/2"

(8.9)

10"

(25.4)

4"

(10.2)

10"

(25.4)

29"*

(73.7)

191/4"*

(48.9)

21/2"

min

(6.4)

31/2"

min

(8.9)

30" oven cutout location

43/4"

min

(12.1)

E

G

* Dimensions may vary

by ± 1/8" (.3 cm)

30"

(76.2)

13"

(33.0)

24" or 30"***

(61.0 or 76.2)

18"**

(45.7)

to cooking surface

30” Installation Dimensions

Page 10

Installation Information

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

2-5

#802985 - Revision E - August, 2011

36” GAS COOKTOP INSTALLATION DIMENSIONS

Area Requirements:

NOTE: Countertop opening dimensions that are shown must be used. Given dimensions provide required clear-

ances.

** 18” (45.7cm) minimum clearance upper cabinet to countertop within 7” (17.8cm) minimum side

clearance to combustible surface above countertop.

*** 24” (61cm) minimum clearance between top of cooking surface and bottom of wood or metal cabinet which is

protected by not less than 1/4” (.6cm) flame retardant millboard covered with not less than No. 28 MSG sheet

steel, .015” (.04cm) stainless steel, or .024” (.06cm) aluminum or .02” (.05cm) copper.

*** 30” (76.2) minimum clearance between top of cooking surface and bottom of an unprotected wood or metal

cabinet.

NOTE: Do not seal cooktop to countertop.

36" oven cutout location

191/4"*

(48.9)

35"*

(88.9)

E

21/2"

min

(6.4)

31/2"

(8.9)

10"

(25.4)

4"

(10.2)

10"

(25.4)

31/2"

min

(8.9)

73/4"

min

(19.7)

E

G

* Dimensions may vary

by ± 1/8" (.3 cm)

36"

(76.2)

13"

(33.0)

24" or 30"***

(61.0 or 76.2)

18"**

(45.7)

to cooking surface

36” Installation Dimensions

Page 11

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Installation Information

2-6

#802985 - Revision E - August, 2011

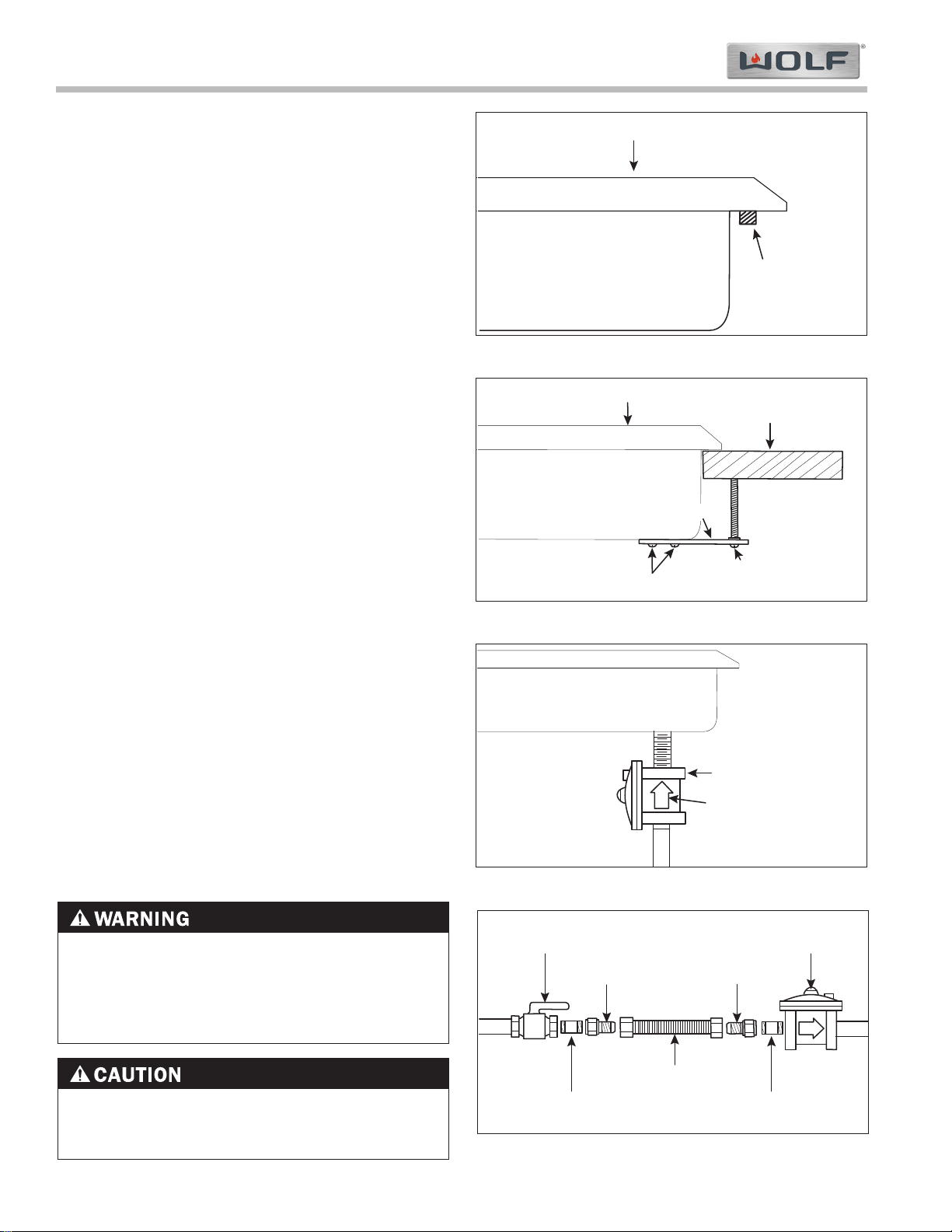

INSTALLATION PROCEDURE

• Insert cooktop into countertop opening and center

cooktop. Check that the front edge of the cooktop is

parallel to the front edge of the countertop. Check

that all required clearances are met.

• Use a pencil to outline the rear of the cooktop on

the countertop. Then remove cooktop from countertop.

• Apply foam strip around bottom of burner box flush

with the edge (See Figure 3-8).

• Reinsert cooktop into the countertop opening.

Check that the cooktop is parallel to the front edge

of the countertop. Lift the entire cooktop to make

adjustments, aligning with the pencil line.

• Attach brackets to the burner box. Insert the

clamping screws into the brackets. Use a screwdriver to tighten clamping screws against the underside of the countertop (See Figure 3-8).

NOTE: Do not overtighten screws.

• Install the pressure regulator with the arrow on the

regulator pointing up towards the unit and in position where you can reach the access cap (See

Figure 3-9).

• Assemble the flexible metal connector from the gas

supply pipe to the pressure regulator (See Figure

3-10).

• Use a pipe-joint compound made for natural and

LP gas. If a flexible connector is used, be certain

the tubing is not kinked.

NOTE: All connections must be wrench tightened.

Do not make the connections to the regulator too

tight. Making the connections too tight could crack

the pressure regulator. Do not allow regulator to

turn on the pipe when tightening fittings.

• Open the shut-off valve in the supply line. Wait a

few minutes for the gas to move through the line.

• Leak testing of the appliance shall be conducted

accordingly using a soapy water solution or an

electronic leak detector.

The maximum gas supply pressure to the regulator

should never exceed 14” WC (Water Column

Pressure); 1/2 psi (3.5kPa).

NEVER USE OPEN FLAMES TO CHECK FOR GAS

LEAKS. ONLY USE A LEAK TESTING SOLUTION

OF SOAPY WATER OR AN ELECTRONIC LEAK

DETECTOR. DO NOT USE LIQUID NEAR VALVE

STEMS.

Regulator

Gas Flow

Arrow

Points Up

Rear of Burner Box

Figure 2-8. Foam Strip

Figure 2-10. Regulator Flow Arrow

Figure 2-11. Gas Connection

Manual

Shut-off Valve

1/2" Adapter 1/2" Adapter

Pressure

Regulator

1/2" Nipple

(use pipe-joint compound)

1/2" Nipple

(use pipe-joint compound)

Flexible Metal Connector

Burner Box

Cooktop Pan

Foam Strip

Cooktop Pan

Countertop

Burner Box

Bracket

Bracket Screws

3" (6.4cm)

Clamping Screw

Figure 2-9. Holding Clamp

Page 12

Installation Information

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

2-7

#802985 - Revision E - August, 2011

FILLER STRIP INSTALLATIONPROCEDURE (Refer to Figures 2-12 & 2-13 Below)

These instructions contain procedural information to install the Integrated Filler Strip Kit into countertop installations.

1. Locate the center of the Filler Strip Bracket (2) at the required distance from the cooktop cutout edge.

2. Position the Filler Strip Bracket (2) so that the top surface is flush with the counter top. You may need a straight

edge to assist in locating the bracket at the correct height.

3. Mark the center of the elongated slots of the Filler Strip Bracket (2) on the front and rear of the cooktop cutout.

4. Using a 3/32" drill bit, drill a ¾" deep pilot hole for the #6/32 (3) mounting screws.

5. Secure the Filler Strip Bracket (2) to the counter top.

14

5/8"

44

1/2"

15

1/4"

3

4

1

2

14

5/8"

Figure 2-13. Filler Strip with Two Integrated Cooktops and a 30" Gas or Electric Cooktop, Typical Installation

14 5/8"

59 1/2"

15 1/4"

29 5/8"

1

2

3

4

Figure 2-12. Filler Strip with Three Integrated Cooktops, Typical Installation.

PLEASE CONSULT WITH THE COUNTERTOP MANUFACTURER/INSTALLER FOR PROPER METHOD OF

INSTALLING SCREWS INTO INSIDE EDGE OF COUNTERTOP. DAMAGE MAY OCCUR IF PROPER METHODS

ARE NOT USED.

6. Install all cooktops into the corresponding openings.

7. Position the Filler Strip (1) into the Filler Strip Bracket (2) and install the three #10-24 nuts (4), but do not tighten.

8. Align and adjust cooktops and filler strips in the countertop opening and then tighten cooktop hold down clamps

and filler strip nuts.

Page 13

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Installation Information

2-8

#802985 - Revision E - August, 2011

SUPPORT KIT FOR DOWNDRAFT INSTALLATION PROCEDURE (Refer to 2-14 Below)

These instructions contain procedural information to install the Integrated Cooktop Support Kit for downdraft ventilation installations.

NOTE: This kit does not include the Filler Strip Kit Assembly. Please order Kit Model number: 803386.

1. Locate and center the Rear Bracket Support (1) in the downdraft cutout as shown.

2. Position the Rear Bracket Support (1) so that the top surface is flush with the counter top. You may need a

straight edge to assist in locating the bracket at the correct height.

3. Mark the center of the elongated slots of the Rear Bracket Support (1) at both ends on the countertop.

4. Mark the center of the elongated slots of the Filler Strip Bracket (not included) on the front of the cooktop cutout.

5. Using a 3/32" drill bit, drill a 3/4" deep pilot hole for the #6/32 mounting screws (3)

Figure 2-14. Support Kit for DownDraft Ventilation Installation.

3

1

2

2

Filler Strip Bracket

Not Included

CENTER OF

CUTOUT

Filler Strip

Not Included

Not Included

6. Install the Downdraft into the countertop opening, but do not secure in place at this time.

7. Secure the Rear Bracket Support (1) and Filler Strip Bracket (not included) to the countertop using items (2 & 3).

8. Install Integrated cooktops into the corresponding openings.

9. Position the Filler Strip (not included) into the Filler Strip Bracket (not included) and install the three #10-24

nuts, but do not tighten.

10. Align and adjust cooktops, downdraft and filler strip in the counter top opening and then tighten cooktop hold

down clamps, filler strip nuts and secure the downdraft per installation instructions.

PLEASE CONSULT WITH THE COUNTERTOP MANUFACTURER/INSTALLER FOR PROPER METHOD OF

INSTALLING SCREWS INTO INSIDE EDGE OF COUNTERTOP. DAMAGE MAY OCCUR IF PROPER METHODS

ARE NOT USED.

Page 14

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Theory of Operation

3-2

#802985 - Revision E - August, 2011

OPERATION INFORMATION

A service technician should understand how a gas appliance operates before attempting to service the appliance.

This section provides descriptions of the different types of fuel gases and explains gas heating values. A definition

of specific gravity of gas is given along with its characteristics and effects. Gas combustion principles are explained

and gas burner components are described and illustrated. The end of this section contains illustrations which

demonstrate basic cooking appliance theory of operation.

Types of Fuel Gas:

Gases used to supply heat energy are called fuel gases. Common fuel gases are not simply one kind of hydrocarbon, they are mixtures of hydrocarbon gases. They contain other gases as well, such as free hydrogen, carbon

dioxide and nitrogen. As an example, natural gas might contain 85% methane, 12% ethane and 3% of other gases.

The presence of each of these gases in the fuel gas has some effect on the nature of the gas.

Some common fuel gasses are methane [CH

4], ethane [C2H6], Propane [C3H8] and butane [C4H10]. Propane and

butane are nearly odorless. Natural gas that is processed to remove condensables and moisture, has little or no

odor and no color. Odorants are added to natural gas before distribution to aid in leak detection. A common odorant

used is a colorless liquid containing sulfur compounds.

Heating Value of Gas:

Heat energy produced when burning a fuel gas is commonly expressed in British Thermal Units (BTU). One BTU of

heat will raise the temperature of one pound of water one degree Fahrenheit.

The more carbon and hydrogen atoms in each molecule of a fuel gas, the higher its heating value. Natural gas

which is high in methane has a heating value of about 950 to 1150 BTU per cubic foot. The variance is due to the

various other substances found in natural gases. The more ethane, propane or butane in the gas raises the heating

value. Propane, or LP gas, has a heating value of about 2500-2800 BTU per cubic foot, and butane about 3200

BTU per cubic foot.

Specific Gravity of Gas:

The specific gravity of a gas is the weight of one cubic foot, or the gas compared to one cubic foot of dry air. When

stating the specific gravity of a gas, a pressure and temperature must be clearly stated. In the gas industry, the

standard conditions of pressure and temperature are 30.0 inches of mercury and 60° F. A pressure of 30.0 inches of

mercury will sustain a column of mercury 30 inches high in a tube with a vacuum on top of the column. Since air is

used as the reference, its specific gravity is always 1.0. This value of 1.0 has no direct physical meaning with

regard to air, such as its density. It is only a relative number or ratio used to express specific gravity of other gases.

The specific gravity of a gas will determine if the gas will rise or fall when released into the air. Natural gas will rise

since its specific gravity is less than 1.0 at 0.4 to 0.8. Propane has a specific gravity of 1.5 and butane 2.0. These

gases will fall when released into the air. They sometimes collect in low spots into pools which become a hazard if

open flames are present.

In addition, specific gravity has two other characteristics. It has an important effect on the flow of gases through orifices, and hence the rating of the burners. Gas flow through an orifice is dependent upon the orifice size and the

gas pressure upstream of the orifice. More of a lighter gas will flow through a given orifice size than a heavier gas

at the same gas pressure. This effect is taken into account in tables and calculators used to select orifice sizes for

burners.

Specific gravity also affects gas flow in pipes. A given driving pressure at a pipe inlet will move more lighter gas

than heavier gas through that pipe.

Page 15

Theory of Operation

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

3-3

#802985 - Revision E - August, 2011

PRINCIPLES OF GAS COMBUSTION:

Combustion - When oxygen acts with a substance to produce large amounts of heat rapidly.

Requirements for Combustion - There are three required elements for combustion to occur; Fuel (Gas), Oxygen

(Air) and Heat (Ignition Temperature, which for gas is between 1100°F/593°C and 1200°F/649°C). All must be present. Removing any one of the three and combustion will cease.

Chemistry of Combustion - Combustion of gas is a chemical reaction between fuel gas and oxygen. The basic

elements of common fuel gasses are hydrogen [H] and carbon [C]. When hydrogen burns, water vapor [H

2O] is pro-

duced. Complete burning of carbon in fuel gases form carbon dioxide [CO2] and water vapor [H2O].

Controlled Combustion - Controlled combustion takes place when gas and air are supplied at proper rates to

assure complete combustion of the gas in a steady flame. When a gas appliance is operating properly, burning

starts at the burner ports. Gas flow is controlled by gas orifice size and gas pressure upstream of the orifice. Air is

mixed with the gas before it passes through the burner ports. This added air is called “Primary Air”. The remaining

air required for complete combustion is supplied to the burner at the point of combustion and is called “Secondary

Air”.

Adjustments of the gas-to-air ratio and the secondary air supply is the key to obtaining stable blue flames at a burner. Proper amounts of primary and secondary air are required for quiet and efficient burner operation and for complete combustion of the gas. Air Shutters or other devices provide control of primary air. Inlet opening and flue outlets control Secondary Air flow.

Total air - In an ideal situation, primary and secondary air is all that is needed (for the oxygen required) to burn the

gas, but some additional air is required to assure complete burning of the gas. The total air, “primary”, “secondary”

and “excess” are expressed as percentages of the amount needed. About ten cubic feet of air is required to completely burn one cubic foot of gas. For this reason an appliance should not be operated in an air tight home.

Limits of Flammability - Not all air-to-gas mixtures will burn. Mixtures with 0% - 4% natural gas in air are too lean

to burn. Mixtures of 4% - 14% natural gas in air can burn with a controlled flame. Flammability limits come into play

when primary air adjustments are made on burners. If too much primary air is used, the mixture may become too

lean and fall below flammability limits, thus preventing combustion.

Incomplete Combustion (Causes and Effects) - To obtain complete combustion, sufficient amounts of air must be

supplied to the process. This air must have a reasonably normal oxygen content. Complete burning of gas produces harmless carbon dioxide gas and water vapor. If the air supply is insufficient, incomplete combustion occurs

resulting in the formation of toxic by-products, such as carbon monoxide [CO] or aldehydes.

Carbon monoxide is colorless and odorless. Inhaling carbon monoxide in sufficient quantities could cause death by

reducing oxygen levels in the blood.

Aldehydes, which are equally dangerous, have a sharp and penetrating odor which is easily detected by smell at

very low concentrations. The odor caused by aldehydes should not be confused with odorants added to natural gas.

The absence of aldehydes does not assure that carbon monoxide is not present. However, if the odor of aldehydes

is present, then carbon monoxide is virtually always present.

Gas Burner Operation - A gas burner is a device to burn gas under control in order to produce useful heat.

Primary air is brought into the burner from outside of the appliance at atmospheric pressure. The gas jet streaming

from the orifice draws primary air with it into the burner.

The gas/air mixture, combined with a spark at the burner port(s) and the secondary air creates a controlled burn.

Page 16

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Theory of Operation

3-4

#802985 - Revision E - August, 2011

BURNER COMPONENTS for 15”, 30” and 36”

Burner Head - The component containing the burner ports where the gas/air mixture ignites. The burner ports are

distributed in a useful pattern to optimize heat transfer. The flames should be spread so they can be easily reached

by secondary air and provide a stable blue flame.

Venturi - Threaded brass pipe that threads into the jet holder through the distribution rings which narrows and then

flares out again. This pipe helps maintain proper and constant primary air injection.

Inner Distribution Ring - Routes the gas from the simmer orifice hood to the simmer port holes located on the

burner cap.

Outer distribution Ring - Routes the gas from the main burner orifice hood to the main burner port holes on the top

of the burner head.

Jet Holder - This component is mounted to the burner mounting bracket and to the burner box. The main burner

orifice is threaded into the jet holder as well as the venturi. It is the main support for the burner components.

Gas Orifice - An opening or hole which regulates or limits the amount of gas flowing to a burner. Gas flow rate (volume) depends on the size of the orifice (hole) and the gas pressure at the inlet of the orifice.

15”, 30” and 36” Burner Components

Burner Head

Venturi

Inner Distribution Ring

Outer Distribution Ring

With Connector and

Orifice

Jet holder with Orifice

Page 17

Theory of Operation

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

3-5

#802985 - Revision E - August, 2011

OPERATION OF THE 15”, 30” and 36” WOLF GAS COOKTOP

Surface Burners

A spark electrode ignites each surface burner. This control eliminates the need for continuous open flame pilots.

For added safety and convenience, each burner is designed with an electronic re-ignition system. This feature

enables any burner to automatically re-light in the event it is accidentally extinguished.

This cooktop has a unique dual stacked burner design that combines all the burner parts in one configuration. Large

burners provide a Btu/hr rating of 12,000 on HIGH. On small burners the Btu/hr rating is 9,200 on HIGH. All burners have simmer settings.

A distinguishing feature of Wolf’s low Btu/hr control is its constant, low heat output without continuous ignitions.

Flame diameter remains full size, only the heat output is lowered. This is the ultimate control for simmering food.

After removing burner parts for any reason, it is extremely important that the burners are re-assembled correctly.

The burner cap has a special orientation and should be seated flatly. Rotate burner cap until you feel it drop and

click into position.

This patent pending dual stacked burner configuration makes it possible to enjoy cooking at full flame as well as

maintaining control while simmering at the lowest flame setting.

Grate Placement

Low profile cast iron grates are designed for a close fit. This enables pans to move easily from one burner to another without having to lift the pan or have it tip over between the grates. Each grate sets securely on dimples on each

corner of the cooktop pan. Continuous grates are interchangeable with the exception of the single grate.

Control Knobs

Each knob is positioned to correspond to the burner regulated. For the 36-inch cooktop, the knob on the lower left

side regulates the lower left burner. Conversely, the knob on the upper right side regulates the upper right burner.

Each knob on the 30-inch cooktop control panel has a diagram above it. The diagram shows which knob to regulate.

It is normal for the knobs to be slightly elevated above the control panel surface. This space is an air inlet necessary for good combustion of gas. Each knob rests on a valve stem with a rubber grommet at the base. This design

prevents liquid spills from dripping into the controls below the burners.

Burner Lighting

Each burner has full flame and full simmer capabilities. Knobs are designed as a two- tiered, “push-to-turn” knob.

One tier is used for HIGH through LOW flame settings. The second tier controls SIMMER settings.

Push down and turn the corresponding control knob counter clockwise to the HIGH setting. You will hear “clicking”

and see the burner ignite. Once the burner is lit, continue turning the knob counter clockwise to any one of the settings, HIGH through LOW.

To select a simmer setting, turn the knob to the LOW setting. You will feel a stop-detente in the knob rotation. Push

down on the knob, continuing to turn it counter clockwise. This moves it to the second tier. Now, select any variation within the SIMMER flame settings, HIGH through LOW.

Illuminated Control Panel

This unique feature of the cooktop is an instant visual indicator that one or more burners are in use. It is also a

safety signal reminder that a flame is on and active.

Page 18

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Theory of Operation

3-6

#802985 - Revision E - August, 2011

Burner Spill Tray

Exterior Finish

Burner Cap

Burner Grates

Control Knobs

Control Panel

Spark Igniters

Part Identification

CLEANING and MAINTENANCE

15”, 30” and 36” Gas Cooktop

Material Care Recommendation

Stainless steel

Although resistant to most

stains, it is not totally impervious to damage. Salt and

some cooking liquids may pit

and stain surface. Always

remove these spills immediately.

Avoid using abrasive cleaners;

they will permanently scratch

the surface.

Porcelain enamel (matte finish)

Never wipe a warm or hot

porcelain surface with a damp

sponge; it may cause chipping

or crazing (tiny hair-like cracks)

Porcelain-coated cast iron

Chrome-plated

Tempered glass

Ceramic

General care: Use a clean cloth or sponge, wipe

with warm water and mild detergent. Rinse and

dry immediately. Apply protective polish, always in

the same direction.

Spray degreaser: Removes fingerprints and

greasy spatters. Spray on a cloth and wipe surface. Buff dry immediately to avoid streaking.

Protective polish: Apply to surface to maintain luster and protect from some food stains

Hard water stains: Use white vinegar and water.

Cool first. Wash in warm water with liquid detergent or mild abrasive cleaners.

Foods high in acid or sugar content, such as milk,

tomatoes, sauerkraut, fruit juices and pie filling,

may pit or craze the surface. Remove as soon as

possible. Do not cook the spill on again.

Remove from cooktop and place on a flat surface

near the sink.

Non-abrasive cleaners: Hot water and liquid detergent, paste of baking soda and water, plastic pad

or sponge.

Mild abrasive and abrasive cleaners: Use sparingly.

To remove the knobs, slip the edge of a dishtowel

under the knob; pull the edge together. Using the

towel for leverage, lift up; the knob pulls off of the

valve stem.

General care: Wipe each knob with a damp cloth

and mild soap and water; rinse and dry. Never

soak or use abrasive cleaners; they will scratch the

finish and remove the markings.

Spray cleaners: Removes fingerprints and greasy

food soils. Spray first on a cloth before wiping

panel.

Keep dry Never spray water or cleaner directly on

the igniter. When cleaning around the surface

burner, be careful that the cloth does not catch on

the igniter and damage it.

Page 19

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Component Access & Removal

4-2

#802985 - Revision E - August, 2011

COMPONENT ACCESS AND REMOVAL

This section explains how to access and remove components from a Wolf Gas Cooktop. Depending on which component you are going to access or remove in the following sections, you may have to remove other components first.

Refer to the appropriate section in this manual that explains how to access and remove those various components.

When reassembling, just reverse the steps that were used to access and remove the components.

NOTE: Before attempting to access or remove any components from a Wolf Appliance, take note of the following

warnings.

• TO AVOID SERIOUS BURNS AND/OR EXPLOSIONS, KEEP COMBUSTIBLES AWAY FROM THE APPLIANCE

WHENEVER A FLAME IS PRESENT. REMEMBER THAT SURFACES AND COMPONENTS GET HOT DURING

THE USE OF THE APPLIANCE.

• TO AVOID ELECTRICAL SHOCK, POWER TO THE UNIT MUST BE DISCONNECTED WHENEVER ACCESSING AND/OR REMOVING COMPONENTS POWERED BY ELECTRICITY OR COMPONENTS NEAR OTHER

ELECTRICAL COMPONENTS.

• TO AVOID HAZARDOUS EXPLOSION OR GAS LEAKS, GAS TO UNIT MUST

BE TURNED OFF AT THE GAS

SUPPLY SOURCE WHENEVER ACCESSING AND/OR REMOVING COMPONENTS.

• TO ENSURE PROPER BURNER OPERATION, THE O-RINGS MUST BE REPLACED ANY TIME THE UNIT IS

DISASSEMBLED FOR ANY REASON.

• WHEN REASSEMBLING GAS SUPPLY LINE TO REGULATOR, ONLY PIPE THREAD COMPOUND SHOULD

BE USED. DO NOT USE TEFLON TAPE TO SEAL GAS PIPE CONNECTIONS.

• WHEN REASSEMBLING REGULATOR TO MANIFOLD, ONLY PIPE THREAD COMPOUND SHOULD BE USED.

DO NOT USE TEFLON TAPE TO SEAL GAS PIPE CONNECTIONS.

Page 20

Component Access & Removal

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

4-3

15”, 30” AND 36” GAS COOKTOP

Surface Burner Components:

Surface Burner Grate, Burner Head with Cap,

Venturi, Inner Distribution Ring, Spark Electrode,

Outer Distribution Ring, Jet Holder and Burner

Mounting Bracket

Preliminary Steps:

• Disconnect the power cord from the electrical supply source.

• Turn off the gas supply source to the cooktop.

• Lift the surface burner grate from the cooktop pan.

Burner Head with Cap Removal

The burner head consists of a top and bottom layer of

holes. When main burner heat is required, the gas

travels through the main burner orifice hood (mounted

to the jet holder), then through the venturi to the burner

head and then out the top layer of holes. When simmer

heat is required, the gas travels through the simmer orifice hood (located on the side of the outer distribution

ring), up through the outer portion of the inner distribution ring, then to the bottom layer of holes on the burner

head. To remove the burner head, remove the burner

grates and lift the burner head off of the inner distribution ring (See Figure 4-1).

Venturi Removal

The brass venturi mounts through the inner distribution

ring and is threaded to the jet holder. There are two

sizes of venturi. One size is for the large 12,000 BTU

burners. The other size is for the smaller 9,200 BTU

burners. The threads on the venturi are different for the

large and for the small. They will only thread back into

the appropriate sized jet holder. To remove the venturi,

first remove the burner head with cap and then extract

the venturi using a 7/8 inch socket wrench from the jet

holder (See Figure 4-2).

Figure 4-1. Burner Head w/Cap Removal

Figure 4-2. Venturi Removal

WHEN REINSTALLING VENTURI USE TORQUE

WRENCH TO TIGHTEN TO 100 INCH/LBS. OVER

TIGHTENING WILL DAMAGE UNIT AND GAS

LEAKS MAY OCCUR.

Page 21

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Component Access & Removal

4-4

#802985 - Revision E - August, 2011

Spark Electrode Removal

The surface burner electrode is inserted down through

the inner distribution ring. It is held in place by a retainer clip, which is inserted into the mounting hole in the

cooktop pan. When the spark electrode is inserted fully

through the inner distribution ring and the cooktop pan,

the retainer clip holds the electrode down tight. In order

to remove the spark electrode, the burner head will

need to be removed. Now, pull the spark electrode up

through the hole in the inner distribution ring and unplug

the lead wire from the electrode (See Figure 4-3).

NOTE: If just removing the top portions of one or two

of the surface burner components without removing the

cooktop pan, use a small piece of electrical tape and

secure the electrode wire to the top of the cooktop pan.

This will make re-connecting the electrode wire to the

electrode easier when reinstalling.

Inner Distribution Ring Removal

The inner distribution ring routes the gas from the simmer orifice hood to the simmer holes located in the

burner head. To remove the inner distribution ring, the

preliminary steps must be followed first. Now, remove

the electrode and the venturi. Then, lift the inner distribution ring from the cooktop pan, being careful not to

lose the O-ring which is mounted in a groove in the

underside of the inner distribution ring. This O-ring provides the seal between the cooktop pan and the inner

distribution ring (See Figure 4-4).

Cooktop Pan Removal

In order to remove the cooktop pan you will need to

remove the burner valve control knobs. Then, remove

the surface burner grates, burner heads w/caps, venturi, electrodes and inner distribution rings. Now the

cooktop pan can be lifted straight up and off of the

burner box (See Figure 4-5).

NOTE: It may be necessary to remove the entire cook-

top from its installation before removing any of the surface burner components. This will make the alignment

of the distribution rings and O-rings easier when reinstalling the surface burner components and the cooktop

pan.

Figure 4-4. Inner Distribution Ring Removal

Figure 4-3. Spark Electrode Removal

Figure 4-5. Cooktop Pan Removal

Page 22

Component Access & Removal

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

4-5

#802985 - Revision E - August, 2011

Outer Distribution Ring Removal

The outer distribution ring routes the gas from the main

burner orifice hood to the main burner holes at the top

of the burner head. To remove the outer distribution

ring, follow the preliminary steps listed at the beginning

of this section. Then, using wrenches, disconnect the

flexible gas tube that is mounted to the outer distribution ring connector. Next, lift the outer distribution ring

from the jet holder. There are two different sized Orings, which sit in grooves in the outer distribution ring

(See Figure 4-6).

Jet Holder Removal

The jet holder is mounted to burner mounting bracket

on the bottom of the burner box. The main burner orifice is threaded into the jet holder as well as the venturi.

In order to remove the jet holder, the preliminary steps

listed at the beginning of this section will need to be

removed first. Then, disconnect the flexible gas tube

that is mounted to the jet holder. Now, extract the nuts

from the pem studs that secure the jet holder to the

burner mounting bracket and lift the jet holder off (See

Figure 4-7).

Burner Mounting Bracket Removal

The burner mounting bracket is mounted to the bottom

of the burner box and acts as a spacer to keep the surface burner components at the proper height. Two

studs that protrude upward from the bottom of the burner box are used to secure both the burner mounting

bracket and the jet holder. To remove the burner

mounting bracket, follow the preliminary steps listed at

the beginning of this section first. Then, slide the burner mounting bracket up and off of the protruding studs

(See Figure 4-7).

Surface Burner Orifice Removal

Simmer - The simmer orifice is hex shaped and

attached to the inside of the outer distribution ring. Use

a wrench to remove it.

Main - The main orifice is hex shaped and is attached

to the bottom of the jet holder. Use a nut driver or

socket to remove it (See Figure 4-7).

Simmer

Orifice

Main

Orifice

Figure 4-6. Outer Distribution Ring Removal

Figure 4-7. Jet Holder, Bracket & Orifice Removal

Page 23

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Component Access & Removal

4-6

#802985 - Revision E - August, 2011

Preliminary Steps

• Unplug the power cord from the electrical supply

source

• Remove grates

• Remove control knobs

• Remove burner heads with caps

• Remove venturi

• Remove electrodes and inner distribution rings

• Remove cooktop pan

Ring Light Removal

There is a ring light under the control panel glass which

is mounted to each burner valve switch. When the control knob is turned on, the entire ring light will illuminate

the wording highlighted in the red portion of the control

panel glass. To remove the ring light you will need to

follow the preliminary steps listed at the beginning of

this section first. Next, extract the Phillips head screw

that secures the ring light to the valve switch. Lift the

ring light off of the valve switch. Now, disconnect the

electrical wires attached to the ring light and remove

(See Figure 4-8).

Figure 4-8. Ring Light Removal

Valve Switch

The valve switch is located below the ring light. When the control knob is turned, the shaft of the burner valve

makes contact with the valve switch and closes the electrical circuit to the spark module (which provides the high

voltage spark needed to ignite the burner). To remove the valve switch you must first follow the preliminary steps

listed at the beginning of this section. Then, extract the screw which secures the switch cover and remove. Now, lift

the ring light off from the valve switch and disconnect the wiring and remove.

Light Harness Removal

The light harness is attached to one terminal of the ring light and one terminal of the valve switches. To remove the

light harness, follow the preliminary steps listed at the beginning of this section. Now, unplug the terminal connection at the ring lights and the valve switches and remove the light harness.

Harness Removal

The harness is connected to the ring lights, valve switches, spark modules and power cord. To remove the harness,

follow the preliminary steps listed at the beginning of this section. Next, unplug the harness from the power cord at

the Molex connector. Now, unplug the harness from the terminal connections at the ring lights, valve switches and

the spark modules and remove the harness.

ELECTRICAL SYSTEM COMPONENTS:

Ring Light, Valve Switch and Cover, Light Harness, Harness, Spark Module, Spark Module Support Plate,

Lead Wire and Power Cord with Grip

Page 24

Component Access & Removal

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

4-7

#802985 - Revision E - August, 2011

Spark Module Removal

NOTE: It is recommended to note and label the elec-

trode wire locations before removing a spark module.

To remove the spark module, you first need to follow

the preliminary steps listed at the beginning of this section. Disconnect the wires from the spark module.

Then, extract the module mounting screws and pull the

module from the support plate (See Figure 4-9).

Spark Module Support Plate

The spark module support plate is mounted to the burner box with screws. To remove the spark module support plate, follow the preliminary steps listed at the

beginning of this section first. Now, extract the screws

that secure the support plate and lift off (See Figure 4-

9).

Lead Wire Removal

The lead wire is connected to the spark module and the

spark electrode. To remove the lead wire, follow the

preliminary steps listed at the beginning of this section

first. Now, unplug the lead wire from the terminal connection at the spark module and lift the lead wire out.

Power Cord with Grip Removal

To remove the power cord, follow the preliminary steps

listed at the beginning of this section first. Next, unplug

the power cord plug connector at the harness. Now,

extract the screw that secures the ground terminal of

the power cord to the burner box. Squeeze the tabs of

the grip connector (grip connector secures the power

cord to the burner box) and pull the power cord down

through the opening and out of the burner box (See

Figure 4-10).

Figure 4-9. Spark Module & Support Plate Removal

Figure 4-10. Power Cord Removal

Page 25

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Component Access & Removal

4-8

#802985 - Revision E - August, 2011

MANIFOLD SYSTEM COMPONENTS:

Gas Valve, Gas Valve Orifice, Gas Tubing, Manifold,

and Regulator Removal

NOTE: The following components will need to be

removed in order to gain access to the components of

the manifold. Refer to the appropriate component

access removal section for proper removal instructions

of these components.

Preliminary Steps

• Unplug the power cord from the electrical supply

source.

• Remove grates

• Remove control knobs

• Remove burner heads with caps

• Remove venturi

• Remove electrodes and inner distribution rings

• Remove cooktop pan

Gas Valve Removal

The gas valves are mounted to the manifold pipe with

bolts that pass through a bracket on the side of the

pipe, and are threaded into the body of the valve. To

remove the gas valves, follow the preliminary steps listed at the beginning of this section first. Next, remove

the ring light and valve switch. Disconnect the flexible

gas tubes from the valve and extract the bolts from the

valve body and mounting bracket. Now, pull or twist the

valve off of the manifold pipe (See Figure 4-11).

Gas Valve Orifice

Each gas valve has two by-pass screw orifices installed

into it. To remove these orifices, turn off the gas supply

source. Next, follow the preliminary steps listed at the

beginning of this section. Then, using a small flat bladed screwdriver, insert the screwdriver down along the

opening through the control panel glass and cooktop

pan. (The by-pass screws are located on the left side

of the valve.) Now, turn the by-pass screw orifice counterclockwise to remove and lift the orifice out of the

valve (See Figure 4-12).

Manifold Pipe

Valve

Bolts

Bracket

Burner Valve

Microswitch

Orifice

Figure 4-12. Gas Burner Valve

Figure 4-11. Gas Valve Removal

Page 26

Component Access & Removal

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

4-9

#802985 - Revision E - August, 2011

Gas Tubing Removal

First you will need to follow the preliminary steps listed

at the beginning of this section.

Using wrenches, disconnect the flexible gas tubing from

the gas valve and then using wrenches disconnect the

flexible gas tubing from either the jet holder or outer

distributing ring (depending on what flexible gas tube

you are removing).

Manifold

The manifold a black pipe that is mounted to the burner

box. To remove, you will need to follow the preliminary

steps listed at the beginning of this section first. To

gain better access to the mounting bolts of the gas

valves, you may have to remove the ring lights. Now,

remove the gas valves and extract the nuts that secure

the manifold pipe to the manifold mounting studs.

Then, lift out manifold pipe (See Figure 4-13).

Regulator

The regulator is attached to the threaded end of the

manifold pipe that protrudes out of the bottom of the

burner box.

NOTE: To gain better access to the regulator you may

have to pull the entire cooktop from its installation.

To remove the regulator, turn off the gas supply source.

Unplug the power cord from its electrical supply source.

Then, remove gas connections coming into the regulator from the supply source. Now, unthread the regulator

from the end of the manifold pipe. (See Figure 4-14).

Figure 4-13. Manifold Removal

Right Side View

M

a

n

u

a

l

S

h

u

t-

o

f

f

V

a

lv

e

1/2" Adapter

1/2" Adapter

Pressure

Regulator

1/2" Nipple

1/2" Nipple

Flexible Metal

Connector

Front

Rear

Figure 4-14. Regulator Removal

Page 27

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Troubleshooting Guide

5-2

#802985 - Revision E - August, 2011

TROUBLESHOOTING GUIDE

This section of the manual contains the General Troubleshooting Guide which will help the Service Technician troubleshoot a Wolf Gas Cooktop.

How to Use the Troubleshooting Guide

The troubleshooting guide table of contents shows how the troubleshooting guide is laid out. The troubleshooting

guide is organized into component areas with the most common problems listed first.

On the table of contents below, identify the description of the problem that the unit is experiencing. To the left of the

problem description is a letter. Locate that letter in the left column of the Troubleshooting Guide. The center column of the troubleshooting guide will identify the possible causes for the problem. The information to the right of the

possible causes will explain what tests to perform in order to determine if what you are checking is the cause, and/or

what action to take to correct the problem.

Troubleshooting Guide Table of Contents

page #

Problems Associated with the Surface Burners

A. Constant Sparking .................................................... 5-3

B. Intermittent Spark .................................................... 5-3

C. Poor ignition .............................................................. 5-3

D. No ignition .................................................................. 5-4

E. Popping noise ............................................................ 5-4

F. Flame appearance .................................................... 5-4

1. Tall flame

2. Yellow flame

3. Pulsing flames

Page 28

May have to call an electrician. Check internal

connections, may have to wire correctly

May have to call an electrician. Check internal

connections, may have to wire correctly

Rewire spark module(s) or replace

Reposition electrode. Electrode should be seated down to cooktop pan. (Refer to Tech Data)

Rotate to correct position and advise owner

Replace micro switch

Replace electrode wire

Clean with wire brush

Replace electrode

Replace electrode wire

Repair wire connection

Replace spark module(s)

Rotate to correct position and advise owner

Reposition electrode. Electrode should be seated down to cooktop pan. (Refer to Tech Data)

Clear/clean as necessary

Install properly or replace if defective

Clean/remove debris

Replace inner distribution ring

Check orifice stamp number

Check gas pressure with a manometer

Check for gas type and advise owner if improper. May have to convert unit to LP/Natural gas

Reverse Polarity at outlet or unit

Ground wire disconnected at outlet or

inside unit

Spark module(s) wired incorrectly or defective

Electrode not positioned properly

Burner head not properly positioned on

inner distribution ring

Defective micro switch at burner valve

Cut or splice in electrode wire

Dirty electrode

Cracked or damaged electrode

Cut or splice in electrode wire

Bad wire connection at spark module(s)

Defective spark module(s)

Burner head not properly seated on inner

distribution ring

Electrode not positioned properly

Partially plugged ports in burner head

O-rings not properly installed

Debris on inner distribution ring

Inner distribution ring has burr or crack

Improper Gas orifice

Gas pressure

Improper gas type

A. CONSTANT SPARKING AT

SURFACE BURNERS

B. INTERMITTENT SPARKING

AT SURFACE BURNERS

C. POOR IGNITION AT SUR-

FACE BURNERS

Troubleshooting Guide

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

5-3

#802985 - Revision E - August, 2011

PROBLEM POSSIBLE CAUSE TEST / ACTION

Page 29

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Troubleshooting Guide

5-4

#802985 - Revision E - August, 2011

PROBLEM POSSIBLE CAUSE TEST / ACTION

D. NO IGNITION AT SURFACE

BURNERS

E. POPPING NOISE AT SUR-

FACE BURNER DURING

SIMMER MODE

F. FLAME APPEARANCE ON

SURFACE BURNER

1. Tall flame

2. Yellow flame

3. Pulsing flames

Defective micro-switch at burner valve

Defective/dirty electrode

Defective or loose wiring

Defective spark module(s)

No Power

No gas to unit

Burner head not seated properly

O-rings damaged or not seated properly

Burr on bottom of burner head

Burner head damaged or dirty with food

debris

Inner distribution ring cracked or warped

Burner head not positioned properly

Burners not getting enough primary or secondary air

Port holes in burner head not to specification or damaged/dirty

Incorrect gas orifices

Gas pressure

Replace micro switch

Replace/clean electrode

Replace/repair wiring

Replace spark module(s)

Check outlet and circuit breaker

Check gas pressure with a manometer

Reposition burner head and advise owner

Replace/reposition o-ring

Replace burner head

Replace/clean burner head

Replace inner distribution ring

Make sure burner head is locked in properly

Make sure air vents at front of burner box are

not blocked

Replace/clean burner head

Check stamp number on orifices

Check gas pressure using a manometer

Page 30

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Technical Data

6-2

#802985 - Revision E - August, 2011

GAS PRESSURE

Natural Gas Minimum

Liquid Propane Minimum

Natural Gas and Liquid Propane Maximum

Gas Supply Line Pressure

Liquid Propane Manifold Pressure, with Standard Orifice

14” WC

Natural Gas Manifold Pressure, with Standard Orifice

7” WC

11” WC

10” WC

5” WC

ORIFICE CHART

Natural Gas 5” WC

Liquid Propane Gas 10” WC

NOTE: For Natural Gas Units Installed Over 10,250 Feet, Contact the Factory for High Altitude Conversion Kit.

ORIFICE CHART

Description Stamp No. Elevation In Feet

Valve, Burner, Large

Orifice, Main, Bypass 61 0 - 10,250

Orifice, Simmer, Bypass 57 0 - 10,250

Valve, Burner, Small

Orifice, Main, Bypass 57 0 - 10,250

Orifice, Simmer, Bypass 54 0 - 10,250

Distribution Ring, Large

Orifice, Simmer M 0 - 10,250

Distribution Ring, Small

Orifice, Simmer J 0 - 10,250

Jet Holder, Large

Orifice 161 0 - 10,250

Orifice *140 0 - 10,250

Jet Holder, Small

Orifice *140 0 - 10,250

Orifice *119 0 - 10,250

Description Stamp No. Elevation In Feet

Valve, Burner, Large

Orifice, Main, Bypass 46 0 - 8,600

Orifice, Simmer, Bypass 36 0 - 8,600

Valve, Burner, Small

Orifice, Main, Bypass 33 0 - 8,600

Orifice, Simmer, Bypass 33 0 - 8,600

Distribution Ring, Large

Orifice, Simmer Burner X 0 - 8,600

Distribution Ring, Small

Orifice, Simmer Burner D 0 - 8,600

Jet Holder, Large

Orifice, Main Burner 104 0 - 8,600

Jet Holder, Small

Orifice, Main Burner 89 0 - 8,600

NOTE: For LP Gas Units Installed Over 8,600 Feet, Contact the Factory for High Altitude Conversion Kit.

Page 31

Technical Data

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

6-3

#802985 - Revision E - August, 2011

Electrode Alignment

Electrode lines up with

second row of ports on

burner head.

Electrode Gap

.11'' (2.7mm) +/- .02 '' (.5 mm)

Cooktop Pan

Page 32

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Wiring Diagrams

7-2

#802985 - Revision E - August, 2011

11

22

A

N

N

A

F SPARK

MODULE

REAR

FRONT

3 CONDUCTOR

POWER CORD

BLK

WHITE

WHITE

GREEN

RED

RED

BLACK

WHITE

WHITE

WHITE

BLACK

WHITE

R SPARK

MODULE

WIRING DIAGRAM

Model: 15" GAS COOKTOP

- This wiring information is provided for use by qualified service personnel only.

- Disconnect appliance from electrical supply before beginning service.

- Be sure all grounding devices are connected when service is complete.

- Failure to observe the above warnings may result in severe electrical shock.

Page 33

Wiring Diagrams

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

7-3

#802985 - Revision E - August, 2011

LR SPARK

MODULE

RR SPARK

MODULE

LF SPARK

MODULE

RF SPARK

MODULE

3 CONDUCTOR

POWER CORD

LEFT

REAR

RIGHT

REAR

LEFT

FRONT

RIGHT

FRONT

N

A

N

A

N

A

N

A

WHITE

RED

IGN

IGN

IGN

IGN

RED

RED

RED

RED

WHITE WHITE

WHITE

BLACK

WHITE

BLACK

WHITE

WHITE

GREEN

BLK

11

22

WHITE WHITE

RED

RED

BLK

BLK

BLK

WIRING DIAGRAM

Model: 30" GAS COOKTOP

- This wiring information is provided for use by qualified service personnel only.

- Disconnect appliance from electrical supply before beginning service.

- Be sure all grounding devices are connected when service is complete.

- Failure to observe the above warnings may result in severe electrical shock.

Page 34

Gas Cooktop (CTG) Series

Gas Cooktop (CTG) Series

Wiring Diagrams

7-4

#802985 - Revision E - August, 2011

LR SPARK

MODULE

CR SPARK

MODULE

RR SPARK

MODULE

LF SPARK

MODULE

CR SPARK

MODULE

RED

RED

RED

RED

RED

RED

IGN

IGN

IGN

IGN

IGN

WHITE

N

A

N

A

N

A

N

A

N

A

WHITE

RED

WHITE WHITE WHITE

WHITE

BLACK

WHITE

GREEN

BLK

BLACK

BLKBLK

RIGHT

REAR

CENTER

REAR

LEFT

REAR

CENTER

FRONT

LEFT

FRONT

BLK

BLK

RED

RED

WHITE WHITE

1

1

22

3 CONDUCTOR

POWER CORD

WIRING DIAGRAM

Model: 36" GAS COOKTOP

- This wiring information is provided for use by qualified service personnel only.

- Disconnect appliance from electrical supply before beginning service.

- Be sure all grounding devices are connected when service is complete.

- Failure to observe the above warnings may result in severe electrical shock.

Loading...

Loading...