Page 1

Art.-Nr. 3043663_0203 Änderungen vorbehalten

Montageanleitung

Anschlußset für Verrohrungsset

Seite 3

D

Istruzioni di montaggio

Gruppo di collegamento per le tubazioni

Pagina 7

I

Instrucciones de montaje

Kit de conexiones para conjunto de distribución

Pagina 8

E

Montagehandleiding

Aansluitset voor buizenset

Pagina 6

B

Notice de montage

Set de connexions pour groupe de raccordement

Page 5

F

Installation instructions

Connection kit for pipework assembly

Page 4

GB

D

Wolf GmbH · Postfach 1380 · 84048 Mainburg · Tel. 08751/74-0 · Fax 08751/741600 · Internet: www.wolf-heiztechnik.de

Page 2

2

3043663_0203

CNK 17 / 20 / 25

CNK 32 / 40

CNK 50 / 63

CHK 22 - 60

CNG 10 - 35

FNG 10 - 41

CNG 48

FNG 57

Page 3

3

3043663_0203

Montage:

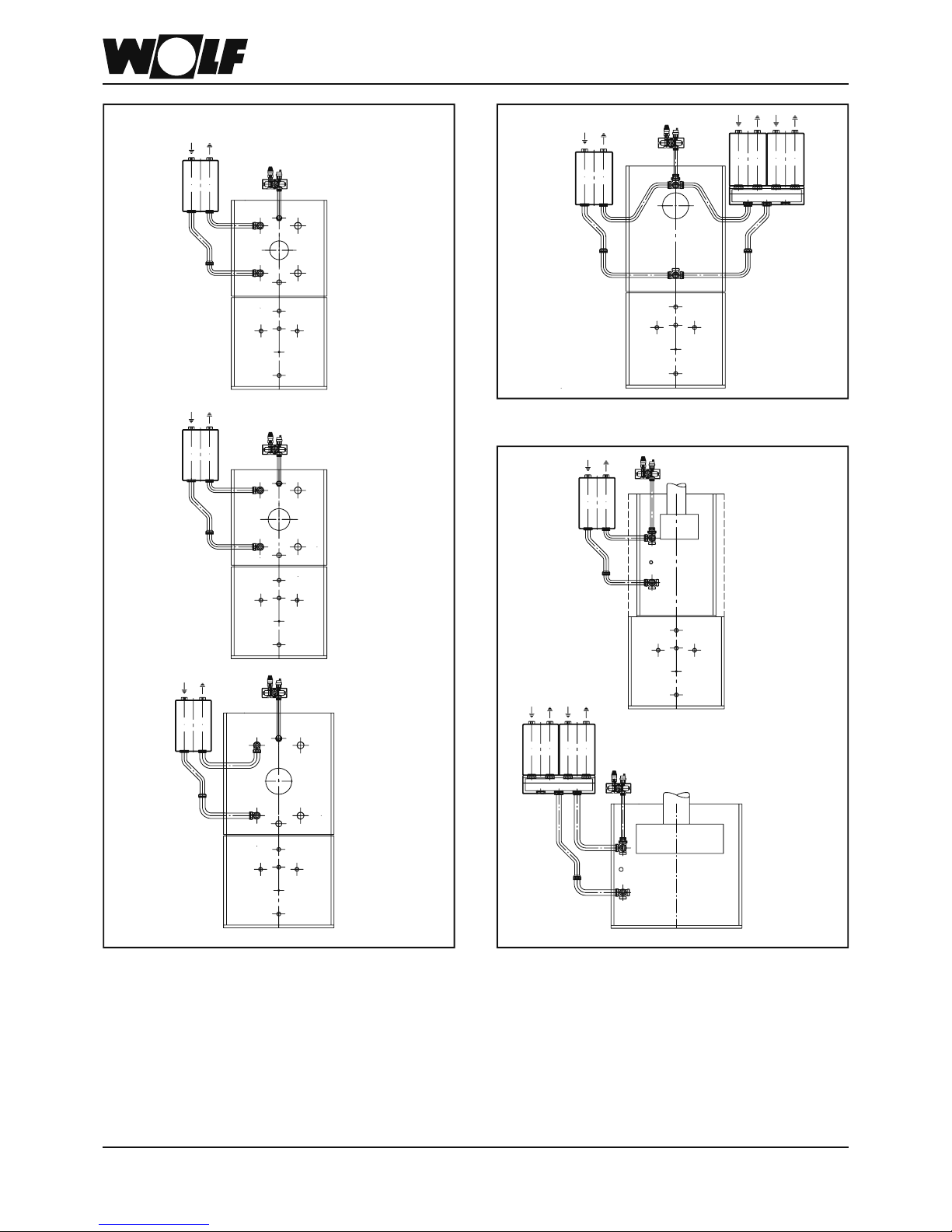

• Alle möglichen Montagepositionen für die Verrohrungssets

sind auf den Seiten 9 - 11 dargestellt.

• Vor- und Rücklaufrohr muß beim Gußkessel in den Kesselkörper fest und gleich tief eingeschraubt sein (-> mit Zollstock

zum Kesselanschlag hin messen)

• Bei allen Verschraubungen müssen die beiliegenden Flachdichtungen eingelegt werden

• Kreuz- bzw. T-Stücke handfest anschrauben.

Ausrichtung der Abgänge bei Vor- und Rücklauf:

-> Zeichnungen beachten!

• Vorlaufrohr und unteres Rücklaufrohr handfest anschrauben.

CNK 17 / 20 / 25: Das L-Rohr mit dem längeren

Schenkel wird am Vorlauf

montiert

CNK 32 / 40: Das L-Rohr mit dem längeren

Schenkel wird am Rücklauf

montiert

CNK 50 / 63: Das U-Rohr wird am Vorlauf

montiert

CNG 10 – 35 / FNG 10 – 41: beide L-Rohre sind identisch

• Rohre waagerecht ausrichten und Kreuzstücke am Kessel

festziehen.

• Oberes Rücklaufrohr mit unterem Rücklaufrohr handfest

veschrauben und in gewünschte Position drehen.

• Verrohrungsset bzw. Verteiler aufsetzen und handfest verschrauben.

• Vorlauf- und Rücklaufrohr an den Kreuzstücken festziehen.

• Verrohrungsset bzw. Verteiler vor- und rücklaufseitig festziehen.

• Verschraubung zwischen oberem und unteren Rücklaufrohr

festziehen.

• Verrohrungsset bzw. Verteiler nochmal ausrichten und alle

Verschraubungen nachziehen.

Lieferumfang:

• 1 Vorlaufrohr

• 2 Rücklaufrohre

• 2 Kreuz- bzw. T-Stücke (nicht im Erweiterungsset CHK

enthalten)

• Verschlußkappen 1 ½”

• Flachdichtungen 1 ½”

• Montageanleitung

Montageanleitung

Anschlußset für Verrohrungsset

Übersicht der Anschlußsets zur Montage eines Verrohrungssets bzw. Verteilers:

CNK 17 - 40 CNK 50 / 63 CHK 22 - 60 CNG 10 - 35 FNG 10 – 41 CNG 48 FNG 57

Art.-Nr. Grundset 24 10 092 24 10 095 24 10 093 24 10 094 24 10 094 24 10 097 24 10 097

Art.-Nr. Erweiterungsset 24 10 092 24 10 095 24 10 098 - - - -

Page 4

4

3043663_0203

Installation:

• Possible installation positions for pipework assemblies are

shown on pages 9 - 11.

• Flow and return pipe of cast iron boilers have to be fi tted tight

to the boiler body and project the rear surface at identical

dimensions (-> check dimensions to boiler rear by means

of folding meter).

• For any screwed fi tting use enclosed fl at seals.

• Cross or T-pieces to be hand-screwed.

Alignement of connections for fl ow and return:y

-> see drawings!

• Flow tube and inferior return tube have to be hand-screwed.

CNK 17 / 20 / 25: The L-shape tube with the longer

side has to be fi tted to the fl ow

CNK 32 / 40: The L-shape tube with the lon-

ger side has to be fi tted to the

return

CNK 50 / 63: The U-shape tube has to be

fi tted to the fl ow

CNG 10 – 35 / FNG 10 – 41: both L-shape tubes are identical

• Align tubes horizontally and screw cross pieces tight to

boiler.

• Superior return tube to be fi tted to inferior return tube (hand-

screwed) and to be turned to required position.

• Pipework assembly or header to be fi tted and hand screwed.

• Screw tight fl ow and return tubes on cross pieces.

• Screw tight fl ow and return of pipework assembly or header.

• Fasten screwed fi tting between superior and inferior return tube.

• Pipework assembly or header to be aligned once more and

all screwed fi ttings to be fastened.

Scope of supply:

• 1 Flow tube

• 2 return tubes

• 2 Cross or T-pieces (not enclosed in extension kit for CHK)

• Sealing caps 1 ½”

• Flat seals 1 ½”

• Installation instructions

Installation instructions

Connection kit for pipework assembly

Survey of connection kits for the installation of a pipework assembly or header:

CNK 17 - 40 CNK 50 / 63 CHK 22 - 60 CNG 10 - 35 FNG 10 – 41 CNG 48 FNG 57

Art.-No. basic kit 24 10 092 24 10 095 24 10 093 24 10 094 24 10 094 24 10 097 24 10 097

Art.-No. extension kit 24 10 092 24 10 095 24 10 098 - - - -

Page 5

5

3043663_0203

Montage:

• Tous les montages possibles des groupes de raccordement

sont présentés en pages 9 à 11.

• Sur les chaudières en fonte, les tuyauteries départ et retour

doivent être solidement vissées au corps de chauffe .

• Mettre les joints plats fournis sur chaque raccord union.

• Visser solidement les raccords en X ou les Tés.

Alignement des sorties sur les tuyauteries départ et retour:

-> se conformer aux schémas !

• Visser solidement la tuyauterie départ et la tuyauterie retour

inférieure.

CNK 17 / 20 / 25: Le tuyau en L avec la partie

coudée la plus longue est monté

sur le départ.

CNK 32 / 40: Le tuyau en L avec la partie

coudée la plus longue est monté

sur le retour.

CNK 50 / 63: Le tuyau en U est monté sur le

départ.

CNG 10 – 35 / FNG 10 – 41: Les 2 tuyaux sont identiques.

• Aligner horizontalement les tuyaux et fi xer les raccords en

X sur la chaudière.

• Visser le tuyau retour supérieur avec le tuyau retour inférieur

et les faire pivoter dans la position souhaitée.

• Mettre en place le groupe de raccordement et le visser

solidement.

• Fixer les tuyauteries départ et retour aux raccords en X.

• Fixer le groupe de raccordement aux sorties latérales départ

et retour.

• Serrer les écrous entre la tuyauterie retour supérieure et la

tuyauterie retour inférieure.

• Réaligner le groupe de raccordement et resserer solidement

tous les écrous.

Comprenant:

• 1 Tuyau Départ

• 2 Tuyaux Retour

• 2 Raccords en X ou Tés (non inclus avec le kit

d’entension pour CHK)

• Robinets boisseaux 1 ½”

• Joints plats 1 ½”

• Notice de Montage

Notice de Montage

Set de connexions groupe de raccordement

vue d’ensemble du set de connexions pour montage d’un groupe de raccordement chauffage

CNK 17 - 40 CNK 50 / 63 CHK 22 - 60 CNG 10 - 35 FNG 10 – 41 CNG 48 FNG 57

N°Art.kit de base 24 10 092 24 10 095 24 10 093 24 10 094 24 10 094 24 10 097 24 10 097

N°Art.kit d’extension 24 10 092 24 10 095 24 10 098 - - - -

Page 6

6

3043663_0203

Montage:

• Alle mogelijke montageposities voor de buizensets worden

op bladzijde 14 - 16 voorgesteld.

• Bij de gietijzeren ketel moeten de voor- en terugloopleiding

stevig en even diep in het ketellichaam geschroefd worden

(-> met een duimstok tot aan de ketelaanslag meten).

• Bij alle schroefverbindingen moeten de bijgevoegde vlakdichtingen ingevoegd worden.

• Schroef de kruis- resp. T-stukken stevig vast.

Uitrichting van de uitgangen bij voor- en terugloop:

-> Houd u aan de tekeningen!

• Schroef de voorloopleiding en de onderste terugloopleiding

stevig vast.

CNK 17 / 20 / 25: De L-buis met het langere

been wordt op de voorloop

gemonteerd

CNK 32 / 40: De L-buis met het langere

been wordt op de terugloop

gemonteerd

CNK 50 / 63: De U-buis wordt op de voorloop

gemonteerd

CNG 10 – 35 / FNG 10 – 41: beide L-buizen zijn identiek

• Richt de buizen horizontaal uit en draai de kruisstukken aan

de ketel vast.

• Schroef de bovenste terugloopleiding stevig met de onderste

terugloopleiding vast en draai ze in de gewenste positie.

• Zet er de buizenset resp. verdeler op en schroef stevig vast.

• Draai de voor- en terugloopleiding aan de kruisstukken vast.

• Draai de buizenset resp. verdeler aan de kant van de vooren terugloop vast.

• Draai de schroefverbinding tussen de bovenste en onderste

terugloopleiding vast.

• Richt de buizenset resp. verdeler nogmaals uit en draai alle

schroefverbindingen vaster aan.

Leveringsomvang:

• 1 voorloopleiding

• 2 terugloopleidingen

• 2 kruis- resp. T-stukken (niet in de uitbreidingsset CHK

inbegrepen)

• Afsluitkappen 1 ½”

• Vlakdichtingen 1 ½”

• Montagehandleiding

Montagehandleiding

Aansluitset voor buizenset

Overzicht van de aansluitsets voor de montage van een buizenset resp. verdeler:

CNK 17 - 40 CNK 50 / 63 CHK 22 - 60 CNG 10 - 35 FNG 10 – 41 CNG 48 FNG 57

Art.nr. basisset 24 10 092 24 10 095 24 10 093 24 10 094 24 10 094 24 10 097 24 10 097

Art.nr. uitbr.set 24 10 092 24 10 095 24 10 098 - - - -

Page 7

7

3043663_0203

Montaggio:

• Le posizioni di montaggio possibili per i gruppi di collegamento sono mostrate a pag. 9-11.

• La tubazione di mandata e ritorno per le caldaie in ghisa deve

essere avvitata a tenuta nel corpo caldaia (-> mit Zollstock

zum kesselanschlag hin messen)

• In tutti i raccordi a vite devono essere inserite le apposite

guarnizioni piatte.

• I raccordi a croce ed a T devono devono essere avvitati

saldamente.

Per l‘allineamento degli scarichi di mandata e ritorno pre-

stare attenzione alle fi gure!

• Avvitare saldamente il tubo di mandata ed il tubo di ritorno

sottostante.

CNK 17 / 20 / 25: Il tubo a L con il lato più lungo

viene montato sulla mandata.

CNK 32 / 40: Il tubo a L con il lato più lungo

viene montato sulla mandata.

CNK 50 / 63: Il tubo a U viene montato sulla

mandata.

CNG 10 – 35 / FNG 10 – 41: i due tubi a L sono identici.

• Posizionare i tubi orizzontalmente e fi ssare i raccordi a croce

alla caldaia.

• Avvitare saldamente il tubo di ritorno superiore a quello

inferiore e girare nella posizione desiderata.

• Posizionare il gruppo di collegamento ed il collettore ed

avvitare saldamente.

• Fissare il tubo di mandata e ritorno ai raccordi a croce.

• Fissare il gruppo di collegamento ed il collettore sul lato

mandata e ritorno.

• Fissare il raccordo tra il tubo di ritorno superiore e quello

inferiore.

• Allineare nuovamente il gruppo di collegamento ed il collettore

e stringere tutti i raccordi a vite.

Composto da:

• 1 tubo di mandata

• 2 tubi di ritorno

• 2 raccordi a croce o a T (non compresi nel gruppo di espansione CHK)

• Cappucci 1 ½”

• Guarnizioni piatte 1 ½”

• Istruzioni di montaggio

Istruzioni di montaggio

Gruppo di collegamento per le tubazioni

CNK 17 - 40 CNK 50 / 63 CHK 22 - 60 CNG 10 - 35 FNG 10 – 41 CNG 48 FNG 57

Art. Gruppo di collegam. 24 10 092 24 10 095 24 10 093 24 10 094 24 10 094 24 10 097 24 10 097

Art. Gruppo di espansione 24 10 092 24 10 095 24 10 098 - - - -

Prospetto dei gruppi di collegamento per il montaggio delle tubazioni e del collettore:

Page 8

8

3043663_0203

Montaje:

• Todas las posibilidades de montaje estan refl ejadas en las

paginas 9 - 11 .

• La tuberia de impulsión y retorno tienen que enroscarse de

igualmanera ( fuerte y misma longitud ) en el cuerpo de fundición de la caldera (-> medir desde el tope del cuerpo)

• En todas las uniones se ha de montar la junta suministrada.

• Apretar las piezas en t y/o en cruz con la mano

Tener en cuenta las posiciones de conexión de imp./ ret.

-> Ver dibujo!

• Apretar con la mano tubo de impulsión y retorno.

CNK 17 / 20 / 25: El tubo en L se conecta con la

parte mas larga a l la impulsión

CNK 32 / 40: El tubo en L se conecta con la

parte mas mas larga al retorno

CNK 50 / 63: El tubo en U se monta en la

impulsión

CNG 10 – 35 / FNG 10 – 41: los dos tubos en L son identicos

• Posicionar a nivel los tubos y apretar las piezas en T y en

cruz.

• Apretar a mano la tuberias de retorno superior e inferior y

girar en la posición adecuada.

• Posicionar el colector o conjunto de distribución y apretar

a mano .

• Apretar el tubo de impulsión y retorno a las piezas en

cruz.

• Apretar conjunto de distribución o colector a impulsión y

retorno.

• Apretar las conexiones entre retorno superior e inferior.

• Volver a nivelar colector o conjunto de distribución y apretar

de nuevo todas las uniones.

Suministro:

• 1 Tubo de impulsión

• 2 Tubo de retorno

• 2 Pieza en cruz y/o T (no incluidas con juego de ampliación de la CHK )

• Cierre 1 ½”

• Junta plana 1 ½”

• Instrucciones de montaje

Instrucciones de montaje

Kit de conexiones para conjunto de distribución

Tabla de kits de conexiones para conjuntos de distribuciónpara el montajed de un conjunto o colector:

CNK 17 - 40 CNK 50 / 63 CHK 22 - 60 CNG 10 - 35 FNG 10 – 41 CNG 48 FNG 57

Nº kit básico 24 10 092 24 10 095 24 10 093 24 10 094 24 10 094 24 10 097 24 10 097

Nº.art. juego ampliación 24 10 092 24 10 095 24 10 098 - - - -

Page 9

9

3043663_0203

TNU / TNK ; CNU / CNK

* Höhe der Füße/Fußschrauben 20mm ±10mm beachten! * Hoogte van de voetstukken/stelschroeven 20 mm ± 10 mm in acht nemen!

* Height of feet/levelling screws 20mm ±10mm to be taken into account! * Fare attenzione all‘altezza dei piedini/viti di appoggio 20mm ±10mm!

* Prendre en considération une hauteur de pieds chaudière de 20mm ±10mm! * Tener en cuenta la altura de los pies de nivelación 20mm ±10mm !

M*

L*

355125

355

K*

J*

355

125

I*

355

H*

Höhenmaße / with triple header / Hauteurs / Dimensioni verticali /

Afmetingen in de hoogte

125

750

D

G

2

G

1

178

58

mit 3-fach Verteilerbalken / with triple header / avec collecteur 3 circuits / con collettori tripli / met drievoudige verdeelbalken

D

F

2

F

1

178

58

125

500

A

E

178

58

125

500

mit 2-fach Verteilerbalken / with double header / avec collecteur 2 circuits / con collettori doppi / met tweevoudige verdeelbalken

C

1

D

125

178

58

250

C

2

A

178

58

125

250

B

ohne Verteilerbalken / without header / sans collecteur / senza collettori circuito riscaldamento / zonder verdeelbalken

TopOne TNU/TNK ComfortLine CNU/CNK

17 20 25 17 20 25 32 40 50 63

A mm 184 184 184 169 169 169 169 169 170 170

B mm 318 318 318 338 338 338 338 338 333 333

C1/C2 mm 188/313 188/313 188/313 173/298 173/298 173/298 173/298 173/298 174/299 174/299

D mm 250 250 250 270 270 270 270 270 265 265

E mm 505 505 505 525 525 525 525 525 520 520

F1/F2 mm 251/501 251/501 251/501 236/486 236/486 236/486 236/486 236/486 237/487 237/487

G1/G2 mm 376/626 376/626 376/626 361/611 361/611 361/611 361/611 361/611 362/612 362/612

H mm 1661 1661 1661 1573 1573 1573 1573 1573 1561 1561

I mm 1786 1786 1786 1698 1698 1698 1698 1698 1686 1686

J mm 1290 1290 1290 1227 1227 1227 1227 1227 1215 1215

K mm 1025 1025 1025 937 937 937 937 937 925 925

L mm 1415 1415 1415 1352 1352 1352 1352 1352 1340 1340

M mm 1150 1150 1150 1062 1062 1062 1062 1062 1050 1050

Page 10

10

3043663_0203

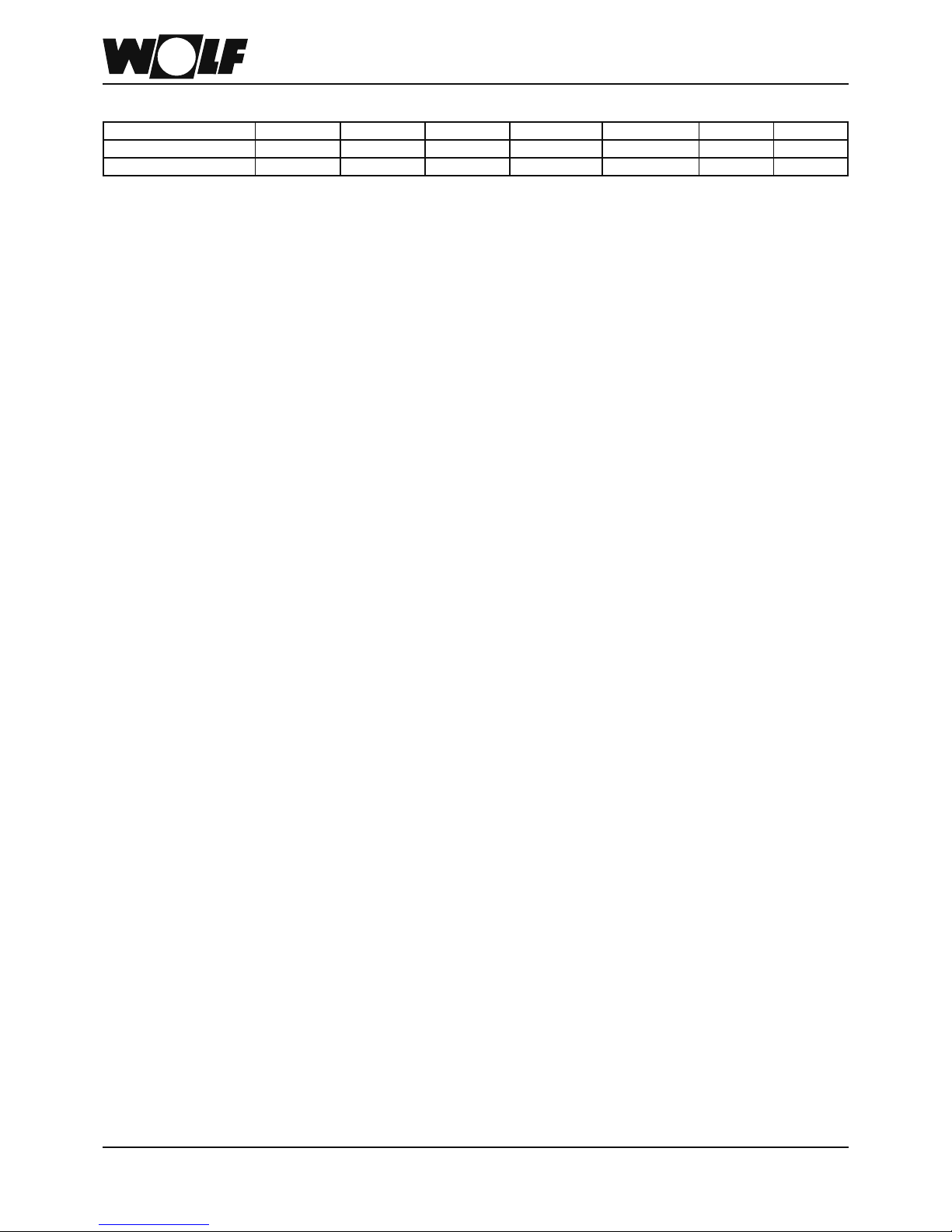

TOK / THU / THK ; CHU / CHK

* Höhe der Füße/Fußschrauben 20mm ±10mm beachten! * Hoogte van de voetstukken/stelschroeven 20 mm ± 10 mm in acht nemen!

* Height of feet/levelling screws 20mm ±10mm to be taken into account! * Fare attenzione all‘altezza dei piedini/viti di appoggio 20mm ±10mm!

* Prendre en considération une hauteur de pieds chaudière de 20mm ±10mm! * Tener en cuenta la altura de los pies de nivelación 20mm ±10mm !

M*

L*

355125

355

K*

J*

355

125

I*

355

H*

Höhenmaße / with triple header / Hauteurs / Dimensioni verticali /

Afmetingen in de hoogte

125

750

D

G

2

G

1

178

58

mit 3-fach Verteilerbalken / with triple header / avec collecteur 3 circuits / con collettori tripli / met drievoudige verdeelbalken

F

2

F

1

178

58

125

500

D

A

178

58

125

500

E

mit 2-fach Verteilerbalken / with double header / avec collecteur 2 circuits / con collettori doppi / met tweevoudige verdeelbalken

C

1

C

2

125

178

58

250

D

A

178

58

125

250

B

ohne Verteilerbalken / without header / sans collecteur / senza collettori circuito riscaldamento / zonder verdeelbalken

TOK TopOne THU/THK ComfortLine CHU/CHK

22 22 29 22 29 37 45 60

A mm 177 297 297 177 177 177 177 177

B mm 318 318 318 338 338 338 338 338

C1/C2 mm 181/306 301/313 301/313 181/306 181/306 181/306 181/306 181/306

D mm 250 250 250 270 270 270 270 270

E mm 505 505 505 525 525 525 525 525

F1/F2 mm 244/494 364/614 364/614 244/494 244/494 244/494 244/494 244/494

G1/G2 mm 369/619 489/739 489/739 369/619 369/619 369/619 369/619 369/619

H mm - 1565 1565 1566 1566 1566 1566 1566

I mm - 1690 1690 1691 1691 1691 1691 1691

J mm 1344 1194 1194 1220 1220 1220 1220 1220

K mm 929 929 929 930 930 930 930 930

L mm 1469 1319 1319 1345 1345 1345 1345 1345

M mm 1054 1054 1054 1055 1055 1055 1055 1055

Page 11

11

3043663_0203

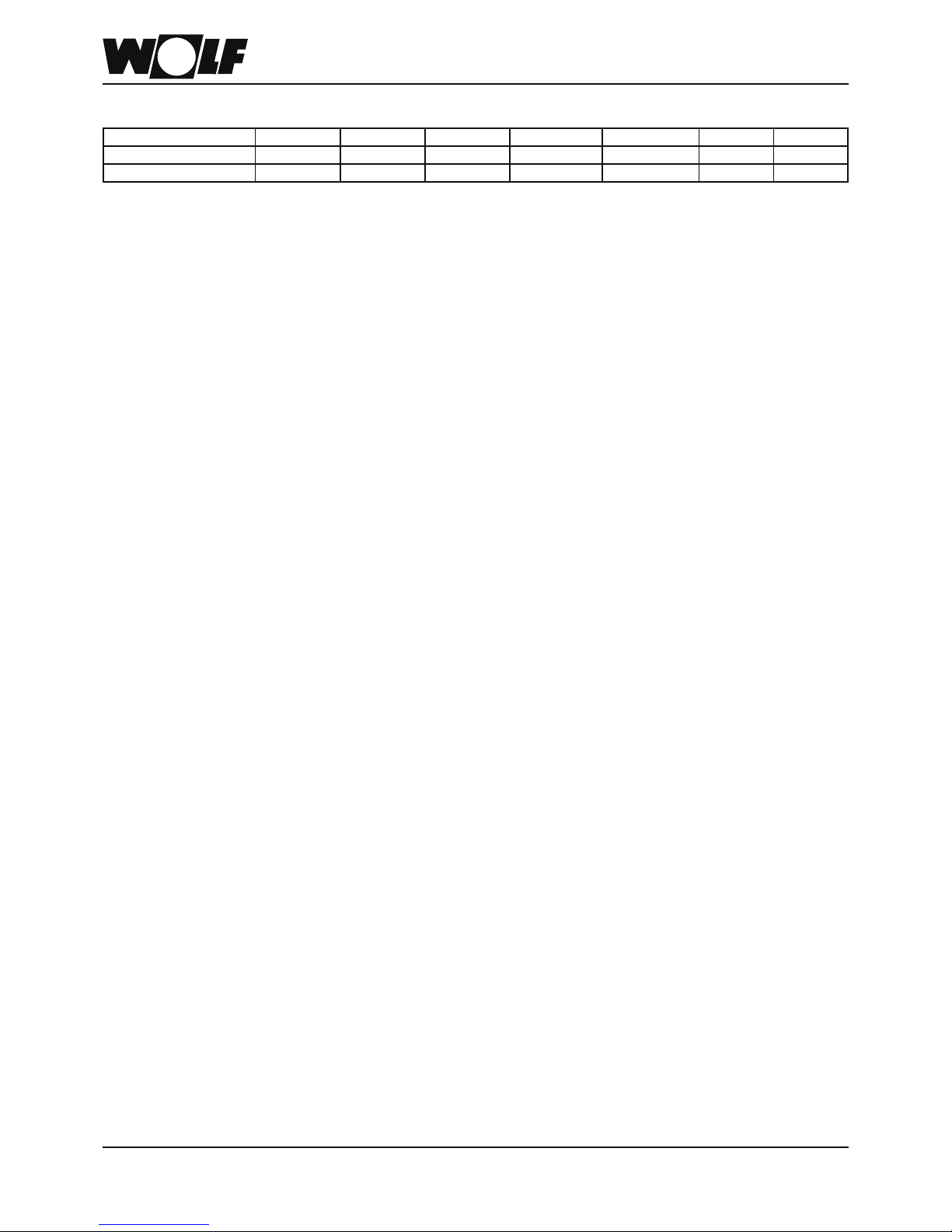

TNG; CNG; FNG

* Höhe der Füße/Fußschrauben 20mm ±10mm beachten! * Hoogte van de voetstukken/stelschroeven 20 mm ± 10 mm in acht nemen!

* Height of feet/levelling screws 20mm ±10mm to be taken into account! * Fare attenzione all‘altezza dei piedini/viti di appoggio 20mm ±10mm!

* Prendre en considération une hauteur de pieds chaudière de 20mm ±10mm! * Tener en cuenta la altura de los pies de nivelación 20mm ±10mm !

M*

L*

355125

355

K*

J*

355

125

I*

355

H*

Höhenmaße / with triple header / Hauteurs / Dimensioni verticali /

Afmetingen in de hoogte

178

58

G

2

G

1

125

750

D

mit 3-fach Verteilerbalken / with triple header / avec collecteur 3 circuits / con collettori tripli / met drievoudige verdeelbalken

178

58

F

2

F

1

125

500

D

A

178

58

125

500

E

mit 2-fach Verteilerbalken / with double header / avec collecteur 2 circuits / con collettori doppi / met tweevoudige verdeelbalken

C

2

C

1

125

178

58

250

D

B

178

A

58

125

250

ohne Verteilerbalken / without header / sans collecteur / senza collettori circuito riscaldamento / zonder verdeelbalken

Top One Comfort Line / Function Line

TNG-17 TNG-23 TNG-29 CNG-10

FNG-10

CNG-17

FNG-17-FNG-21

CNG-23

FNG-26

CNG-29

FNG-34

CNG-35

FNG-41

CNG-48

FNG-57

A mm 260 260 260 255 255 255 255 255 255 257

B mm 360 402 444 399 399 399 399 427 427 421

C1/C2 mm 264/353 264/353 264/353 259/348 259/348 259/348 259/348 259/348 259/348 261/350

D mm 292 334 376 331 331 331 331 359 359 353

E mm 547 589 631 586 586 586 586 614 614 608

F1/F2 mm 327/577 327/577 327/577 322/572 322/572 322/572 322/572 322/572 322/572 324/574

G1/G2 mm 452/702 452/702 452/702 477/697 477/697 477/697 477/697 477/697 477/697 449/699

H mm 1675 1675 1675 - 1585 1585 1585 1585 1585 -

I mm 1800 1800 1800 - 1710 1710 1710 1710 1710 -

J mm 1304 1304 1304 1239 1239 1239 1239 1239 1239 1549

K mm 1039 1039 1039 949 949 949 949 949 949 1259

L mm 1429 1429 1429 1364 1364 1364 1364 1364 1364 1674

M mm 1164 1164 1164 1074 1074 1074 1074 1074 1074 1384

Loading...

Loading...