Wolf CGU-2-18, CGU-2-24, CGG-2-18, CGG-2-24, CGU-2 K-18 Installation And Maintenance Instructions Manual

...Page 1

Part no. 30 62 347 Subject to modications

03/09 GB

Wolf GmbH · Postfach 1380 · D-84048 mainburg · Tel. +49-8751/74-0 · Fax +49-8751/741600 · Internet: www.wolf-heiztechnik.de

Installation and

maintenance instructions

Wall mounted gas red combi boilers

and wall mounted gas red boilers

with integral cylinder connection

CGU-2-18/24

CGG-2-18/24

CGU-2 K-18/24

CGG-2 K-18/24

Illustration:

Wall mounted gas red boiler with auxiliary equipment BM

Page 2

2

3062347_0309

General information

Safety instructions / Standards and regulations ............. 3-5

Installation and commissioning

Dimensions .......................................................................6

Layout / Equipment code ............................................... 7-9

Positioning information / Installation dimensions ........10-11

Installation on nished walls /

Installation on unnished walls ........................................12

General boiler installation ................................................13

Electrical connection ................................................. 14-17

Fill / Vent the system. .......................................................18

Guidelines for commissioning ..........................................19

Control / Function / Commissioning ........................... 20-21

Setting and adjusting the boiler

Displaying / Modifying control parameters ................ 22-30

DHW connection versions / Resetting control unit ...........31

Setting the eBUS address for cascade mode ..................32

Commissioning gas connection .......................................33

Conversion to other gas types / Nozzle change ..............34

Setting the control unit after converting the gas type .......35

Checking nozzle pressure .......................................... 36-37

Resetting gas valve / Setting nozzle pressure .................38

Adjusting the ue lengths CGG-2(K) ................................39

Flue gas test CGU-2(K) CGG-2(K) .................................40

Limiting the maximum output ...........................................41

Selecting the pump stage / Bypass ............................ 42-43

Checking the ue gas monitoring CGU-2(K) ....................44

Notes on planning ventilation /

Flue gas system CGU-2(K) ........................................ 45-49

Commissioning report ......................................................50

Maintenance and additional information

Inspection and maintenance steps ..................................51

Service report ...................................................................52

Maintenance .............................................................. 53-57

Wiring diagram CGU-2(K) ................................................58

Wiring diagram CGG-2(K) ................................................59

Specication ............................................................... 60-61

Fault / Cause / Remedy ...................................................62

Resistance table ..............................................................63

Notes ................................................................................64

Keyword index ........................................................... 65-67

EC declaration of conformity ............................................68

Contents

Page 3

3

3062347_0309

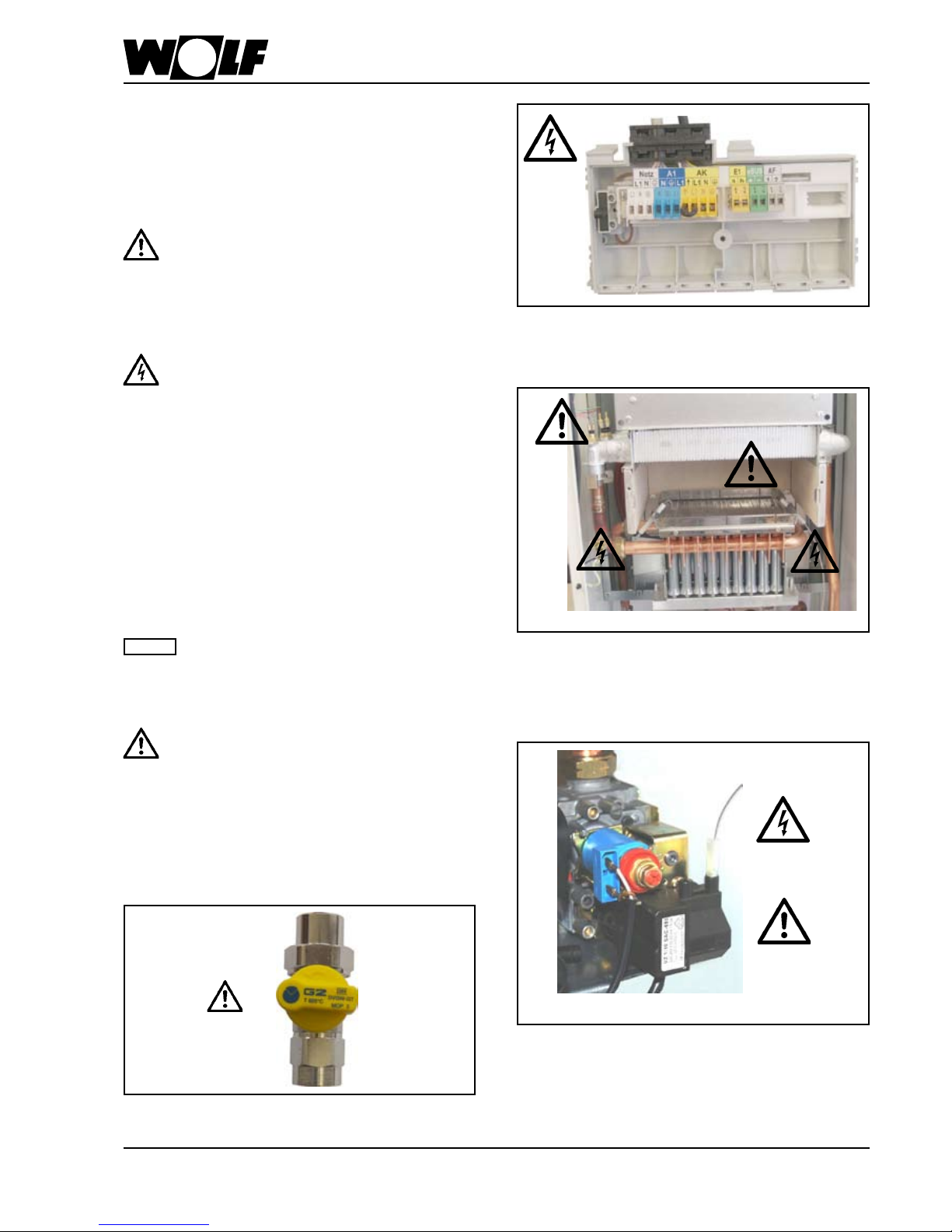

"Safety instructions" are instructions

with which you must comply exactly, to

prevent risks and injuries to individuals

and material losses.

The following symbols and reference symbols

are used in this description. These important

instructions concern personal safety, as well as

operational reliability.

"Note" indicates technical instructions

that you must observe to prevent material

losses and boiler malfunctions.

Note

D a n g e r t h r o u g h ' l i v e ' e l e c t r i c al

components.

Please note: Switch OFF the ON / OFF

switch before removing the casing.

Never touch electrical components or

contacts when the ON / OFF switch is in

the ON position. This results in a risk of

electrocution that poses a danger of injury

or death.

The main supply terminals are 'live' even

when the ON / OFF switch is in the OFF

position.

Fig.: Terminal box: Danger from electric current

Fig.: Gas connection: Escaping gas may cause poisoning

or the risk of explosion

Fig.: Ignition transformer, high voltage ignition electrode,

combustion chamber

Risk through 'live' electrical components, risk of burning

through hot components

Fig.: Gas combination valve:

Danger from electric current

Escaping gas may cause poisoning or the risk of

explosion

Balanced flue operated gas bo i l er s

must only be installed in a room that

complies with the appropriate ventilation

requirements. Otherwise there is a risk

of asphyxiation or poisoning. Read these

installation and maintenance instructions

before installing the boiler. Also take the

technical guide into consideration.

Safety instructions / Standards and regulations

Page 4

4

3062347_0309

Safety instructions / Standards and regulations

Please follow these safety instructions closely to prevent accidents and material

losses.

Commissioning - Commissioning must only be carried out by the system installer or a

commissioning engineer designated by him. All actual values must be

recorded in a commissioning/service report that should be kept with these

instructions.

Safety regulations - Observe all national safety regulations and installation requirements.

- Installation, commissioning, inspection, maintenance and repairs must

only be carried out by a competent person (heating engineer / installation

contractor).

- Before working on the equipment / heating system, switch OFF the power

supply (e.g. by removing a separate mains fuse or by means of a main

electrical isolator) and safeguard against unauthorised reconnection.

- Disconnect the system by means of an appliance that isolates all non-earthed

conductors simultaneously with at least 3 mm contact separation.

- It is not permitted to carry out repairs on parts that full a safety function.

- Use only original WOLF replacement parts or those that are equivalent and

that have been approved by the manufacturer.

Instructing the

system user

- The system installer must hand the operating instructions to the system user

and instruct them in the operation of the system.

Only use propane compliant with local regulations, otherwise

faults may arise with the starting characteristics and operation

of the wall mounted gas red boiler; this in turn, may lead to

boiler damage and risk of injury.

Poorly vented LPG tanks can lead to ignition problems. In such

cases, contact your local LPG supplier.

Note: Please read these instructions carefully before the installation

and keep them in a safe place. Please also note the technical

information in the appendix.

Any damage or loss resulting from technical modications to

the control unit or to the control components are excluded from

our liability.

Incorrect use can lead to a risk to life and limb or to a risk of

material losses.

Obtain the permission of your gas supply utility, the ue gas inspector

and the lower water authority [where appropriate] prior to the installation

of Wolf gas red boilers.

Page 5

5

3062347_0309

Safety instructions / Standards and regulations

Standards and regulations

Category: II2ELL3P<DE> and

II2H3P<AT>

NOx class: 5

Efciency: *** star rating according

to 92/42/CEE) for

balanced ue operation

Flue types: CGG-2:

C12x, C32x, C42x, C52, B32

CGU-2:

B11BS

Operating mode: open / balanced ue

To be connected to: chimney, ue chimney /

balanced ue system

- Obtain the permission of your mains gas supplier

and all relevant authorities prior to the installation of

Wolf gas red combi boilers.

- Open ue gas red boilers must only be installed

in a room that complies with the appropriate

ventilation requirements.

The gas red boiler meets with the following regulations

EC Directives

- 2006/95/EC Low Voltage Directive

- 2004/108/EC EMC Directive

- 90/396/EEC Gas user equipment

- 92/42/EEC Efciency directive

DIN / EN Standards

- EN 297; EN298; EN 483; EN 625;

EN 55014-2; EN 60335-1; EN 60335-2-102;

EN 60529; EN 61000-3-2; EN 61000-4-3

The following regulations, rules and guidelines must

be observed during installation:

- Boiler room guidelines or Building Regulations

relating to the construction and installation of

central boiler rooms and fuel storage facilities

- Technical regulations for gas and DHW installations

DVGW-TRGI 1996 and TRF 1996

(in the currently applicable form)

DIN / EN Standards

- EN 437 Test gases; test pressures;

appliance categories

- DIN EN 1283 Procedure for calculating the

standard heating load

- DIN EN 12828 Heating systems in buildings

- DIN EN 1717 Protection of DHW against

contaminations in DHW

installations

- DIN EN 50156-1 (VDE 0116 part 1)

Electrical equipment for

combustion systems

- On site regulatio ns from building and indust ry

regulatory agencies (mainly covered by the emission

test switch)

- On site regulations from the gas supply utility

Page 6

6

3062347_0309

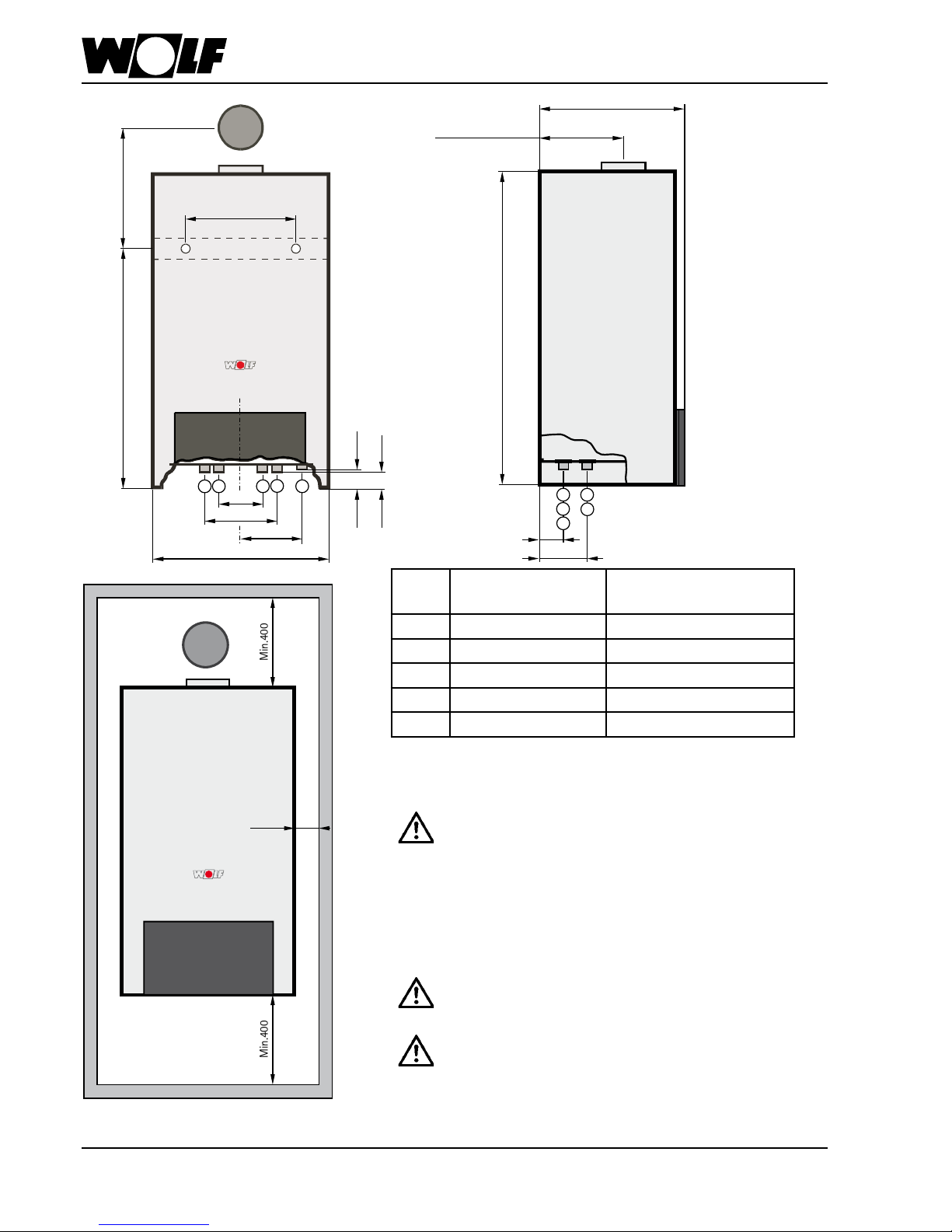

440

Dimensions

Gas red combi

boilers

Gas red boilers

1 Heating ow Heating ow

2 DHW DHW ow

3 Cold water DHW return

4 Heating return Heating return

5 Gas connection Gas connection

Installation inside a cupboard

For installation of the gas red boiler inside a cupboard

note the following:

Never install the gas red boiler on the back wall

of the cupboard, as it may not be substantial

enough to take the boiler's weight. This would

create the risk of water and gas leaks which in

turn would result in a risk of explosion

and ooding.

- Removing the rear wall of the cupboard

Minimum lateral clearance between the gas red boiler

and the cupboard sides 25 mm.

A cutout of 410 x 550 mm is required in the

cupboard top. Otherwise there is a risk of

suffocation and poisoning

With open ue gas red boilers the

ventilation grill in the cupboard door must

be installed with a free minimum diameter

of 600 cm

2

Otherwise there is a risk of suffocation

and poisoning

3

1

2

4

5

3

1

2

4

5

Min.400

Min.400

>25

694

366 CGU-2(K) 18

380 CGU-2(K) 24

258 CGG-2(K) 18/24

344

120

176

170

39

49

855

393

190

226

(CGG-2)

(CGU-2)

73

134

Page 7

7

3062347_0309

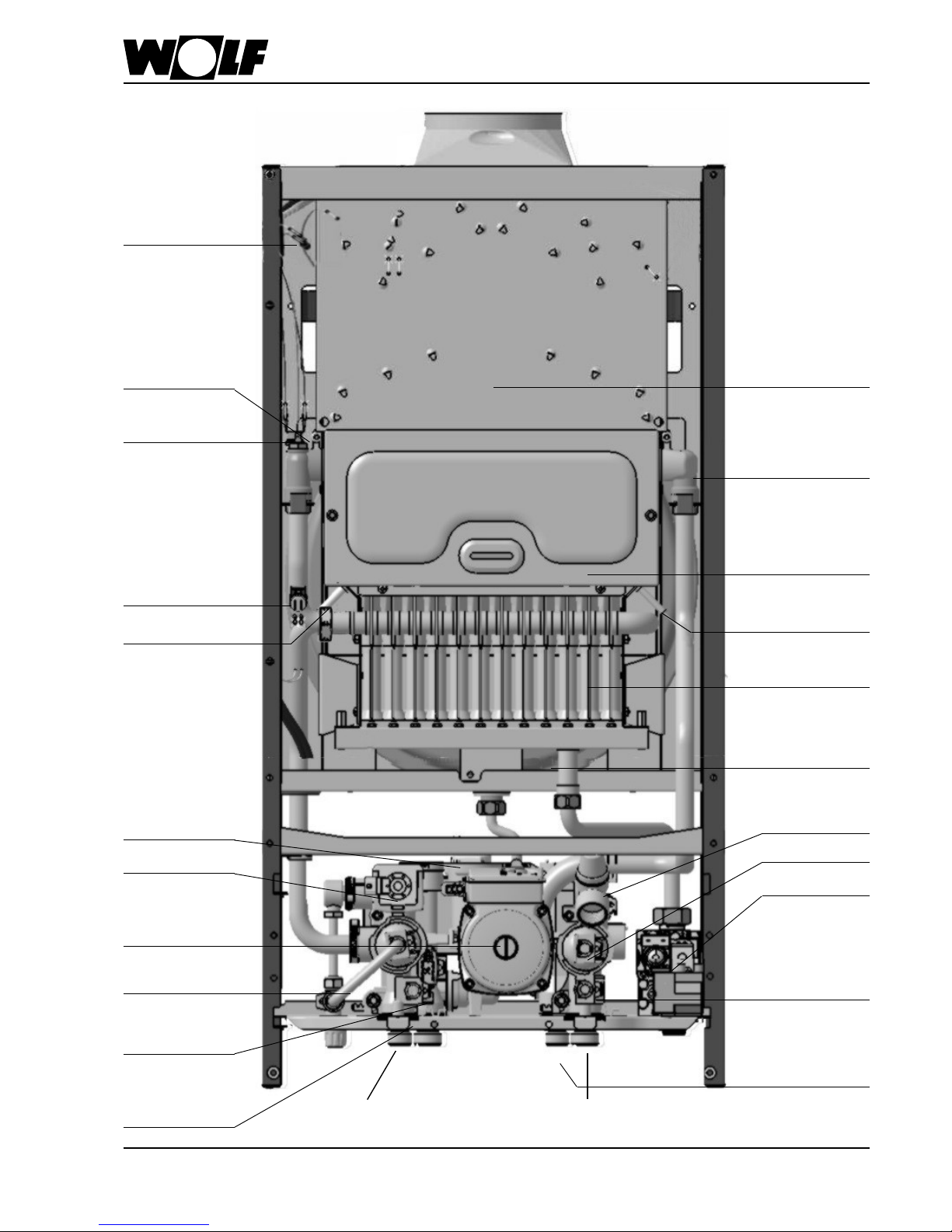

Layout CGU-2(K) 18/24

Combustion

chamber

Internal lling

equipment (optional)

not <DE><AT>

Gas combination

valve

Expansion vessel

Three-way

diverter valve

Flow sensor 2

Limit thermostat

Monitoring

electrode

Ignition electrode

Heating water heat

exchanger

Safety valve

Drain valve

DHW

Flow & temperature

sensor

Flow sensor 1

Draught hood

Gas burner

Heating circuit

strainer

Cold water strainer

with throughput

limiter

Heating circuit

pump

Air vent

Bypass

Flue gas

temperature limiter

HZ - VL

HZ - RL

Page 8

8

3062347_0309

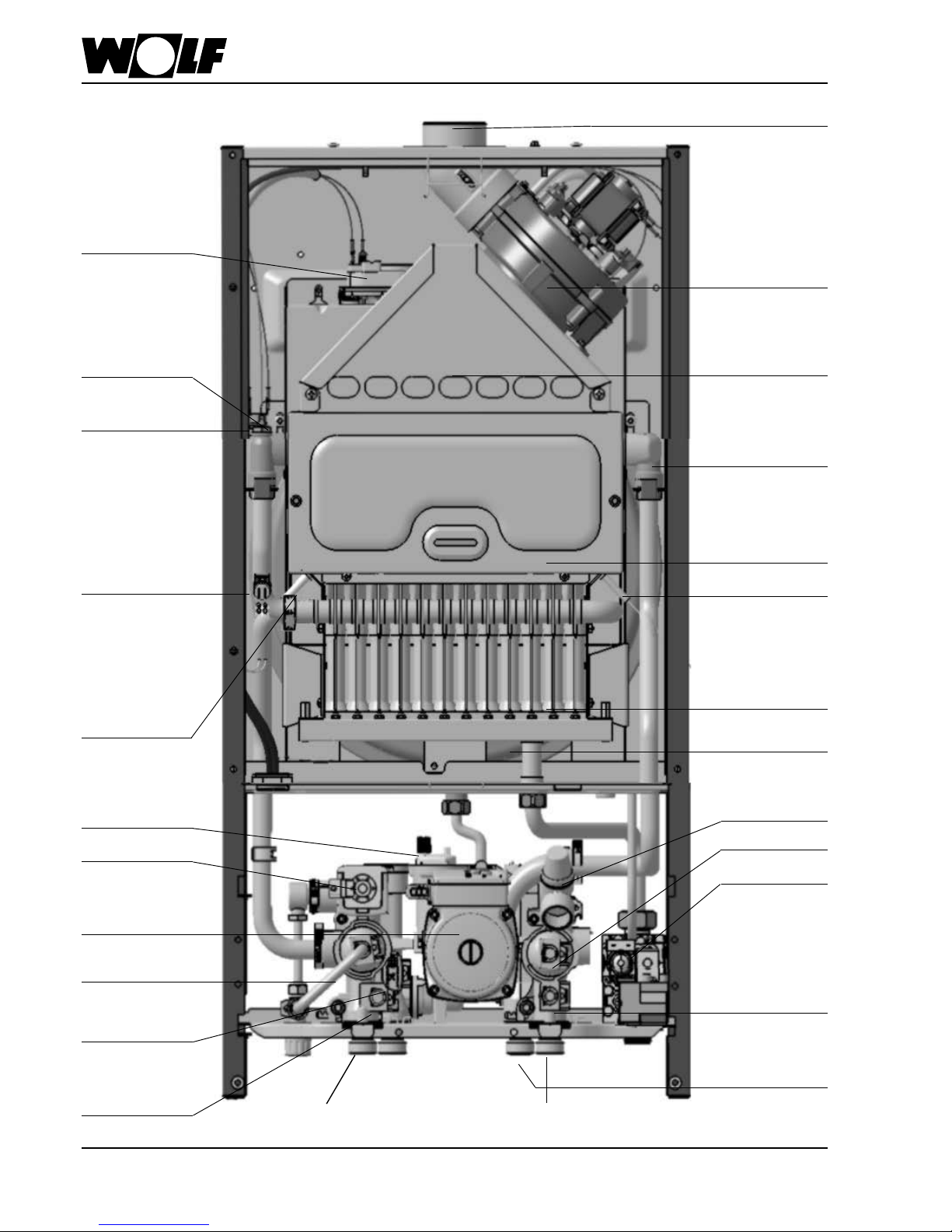

Layout CGG-2(K) 18/24

Flue gas fan

with speed

regulation

Combustion

chamber

Internal lling

equipment (optional)

not <DE><AT>

Gas combination

valve

Expansion vessel

Three-way

diverter valve

Flow sensor 2

Limit thermostat

LAF connection

Monitoring

electrode

Ignition

electrode

Heating water heat

exchanger

Differential

pressure switch

Safety valve

Drain valve

DHW

Flow & temperature

sensor

Flow sensor 1

Flue gas

collector

box

Gas burner

Heating circuit

strainer

Cold water strainer

with throughput

limiter

Heating circuit

pump

Air vent

Bypass

HZ - VL

HZ - RL

Page 9

9

3062347_0309

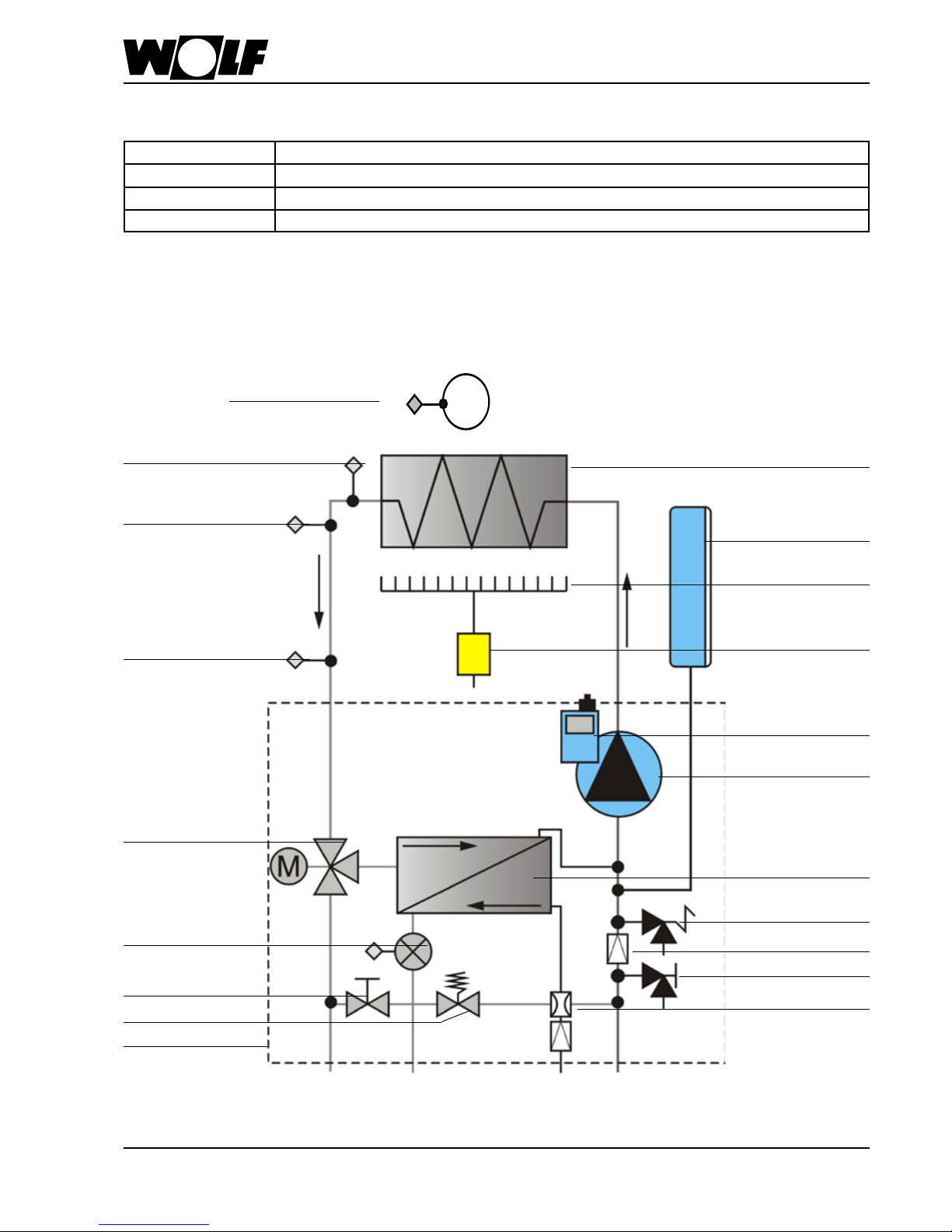

Layout / Equipment code

Heating water heat

exchanger

Gas burner

Gas

combination

valve

Expansion vessel

Air vent

Heating circuit

pump

DHW heat

exchanger

Safety valve

Drain valve

Heating circuit strainer

Cold water strainer with

throughput limiter

Limit thermostat

ow

Flow sensor 2

Flow sensor 1

Three-way

diverter valve

DHW ow

& temperature sensor

(only combi boilers)

Bypass valve

Hydro Tec system

(integrated

components)

Overow valve

Flue gas

temperature limiter

Wolf Low NOx unit with hydro tec system (plug-in technology for quick installation)

compactly designed for low emissions, high energy efciency.

DHW heat exchanger and DHW ow temperature sensor

only with combi boilers

CGU-2 - 18/24 Open ue gas red boiler with integrated cylinder connection

CGU-2 K - 18/24 Open ue gas red combi boiler

CGG-2 - 18/24 Balanced ue gas red boiler with integrated cylinder connection

CGG-2 K - 18/24 Balanced ue gas red combi boiler

Equipment codes

Page 10

10

3062347_0309

Balanced ue gas red boilers must only

be installed in a room that complies with

the appropriate ventilation requirements.

Otherwise there is a risk of asphyxiation

or poisoning. Read these installation and

operating instructions before installing

the gas red boiler. Also take the technical

guide into consideration.

Sound insulation:

Under certain critical installation conditions

(e.g. installation on a drywall) additional

measures may be necessary to soundproof

the boiler. In this case use soundproof

plugs and, if necessary, rubber buffers or

insulation strips.

Positioning information /

Installation dimensions

l.h. turnbuckle

r.h. turnbuckle

Fig.: Opening the turnbuckle

- Determine the installation location for the gas red

boiler; maintain the specied minimum clearances

(see dimensions).

- Fit the supplied installation template (paper poster) to

the wall.

- Transfer the xing hole and connection positions

marked on the installation template to the wall (e.g.

with a power drill).

- Remove the installation template.

- Drill Ø 12 mm holes for the mounting bracket and

secure the bracket using the rawl plugs and screws

supplied. (Before securing the bracket, check that the

rawl plugs are suitable for the wall construction.)

- Remove the casing lid of the gas red boiler. For this,

pivot the control unit lid down, hook in the r.h. and

l.h. turnbuckle, undo the bottom of the casing lid and

unhook at the top.

- Hang the gas red boiler with the hook-in brace on the

back of the boiler onto the mounting bracket.

General

The gas red boiler may only be installed in rooms that

are protected from frost.

During the boiler installation ensure that all

xings are sufciently strong to carry its weight.

Also consider the wall consistency, otherwise

gas or water may escape which could lead to

explosions and ooding. It can also lead to

noise developing.

During the boiler installation, ensure that

no contaminants (e.g. drilling swarf) enter

the gas red boiler otherwise faults may

develop.

The combustion air supplied to the boiler must

be free from chemicals, e.g. uoride, chlorine

or sulphur. Such materials are contained in

sprays, solvents and cleaning agents. Under

the most unfavourable conditions, these

may lead to corrosion, even in the ue gas

system.

Note

500

25 25

(CGU-2-18) Ø110

(CGU-2-24) Ø130

(CGU-2) min.400

(CGG-2)

min.200

(CGG-2-18)

Ø100

1212

344

min.200

1478

Page 11

11

3062347_0309

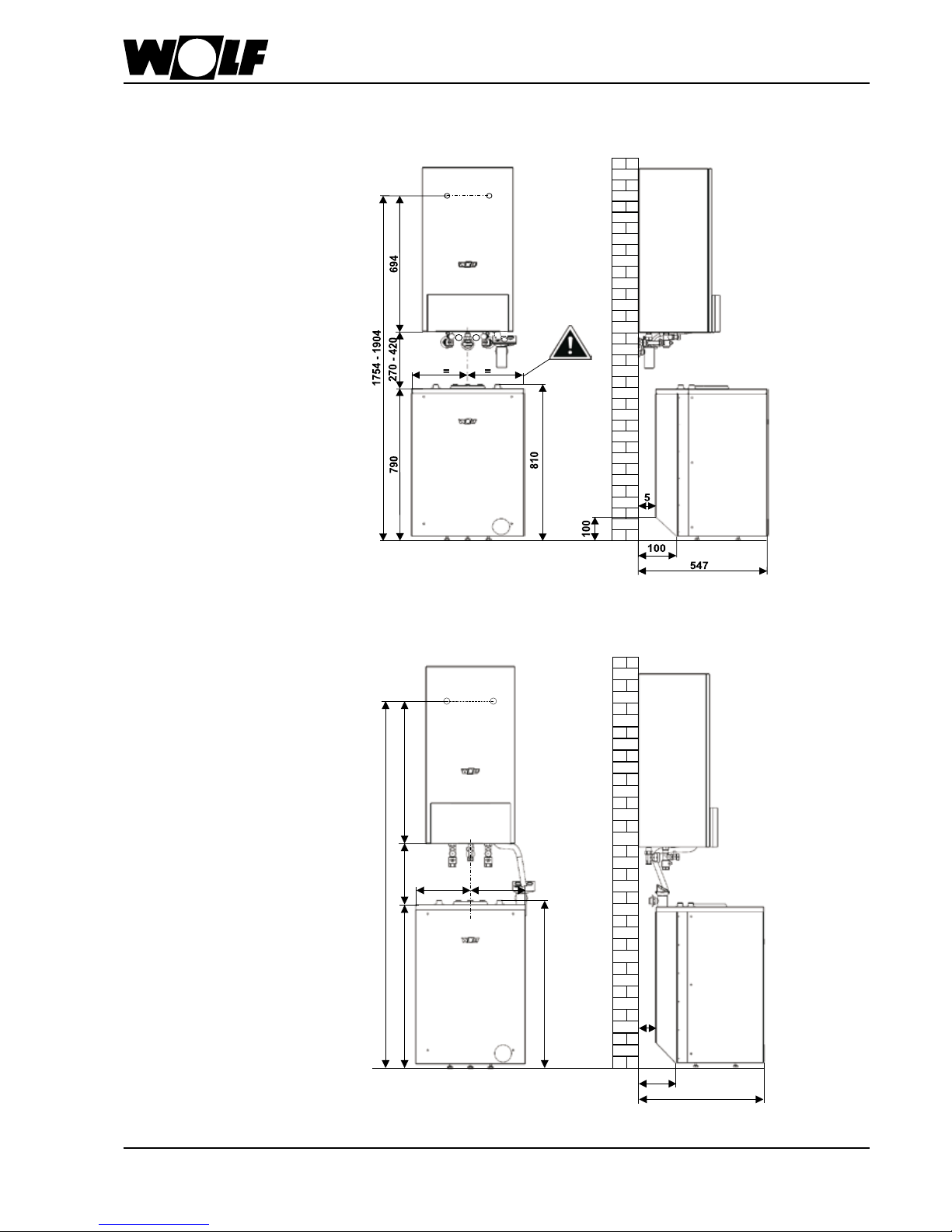

Positioning information /

Installation dimensions

270-420

790

694

1754-1904

810

5

=

=

100

547

Installation dimensions of the boiler with freestanding cylinder SW-120 / CSW-120

Installation on unnished walls

Installation dimensions of the boiler with freestanding cylinder SW-120 / CSW-120

Installation on nished walls

Page 12

12

3062347_0309

Installation on nished / unnished walls

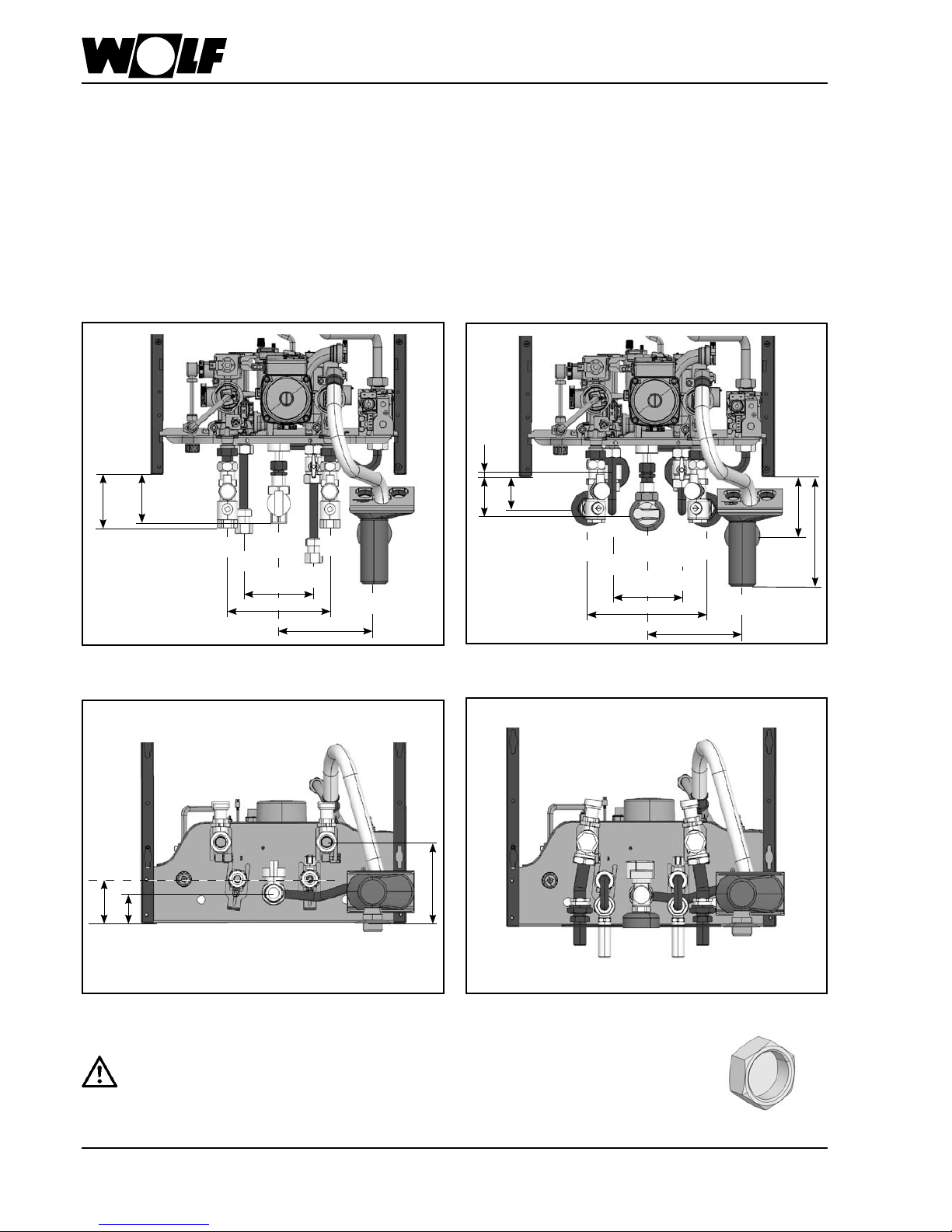

Fig.: View from below, connection set for installation on

nished walls

Installation on unnished walls (accessory)

Fig.: Front view, connection set for installation on unnished walls

Fig.: View from below, connection set for installation on

unnished walls

Installation on nished walls (accessory)

Fig.: Front view, connection set for installation on nished walls

Heating ow Rp ¾"

DHW Rp ¾" (gas combi boilers)

Cold water Rp ¾" (gas combi boilers)

Heating return Rp ¾"

Gas connection Rp ½"

Drain for safety valve R 1"

With boilers that are not used for DHW, seal the cold and DHW connections with locking

cap G ¾" (accessory).

If this is not done then the building and equipment may be damaged through uncontrolled

water leakages.

Heating ow R ¾"

DHW R ¾" (gas combi boilers)

Cold water R ¾" (gas combi boilers)

Heating return R ¾"

Gas connection R ¾"

Drain for safety valve R 1"

164

94

84

120

176

164

64

55

120

200

7

190

107

73

55

134

Page 13

13

3062347_0309

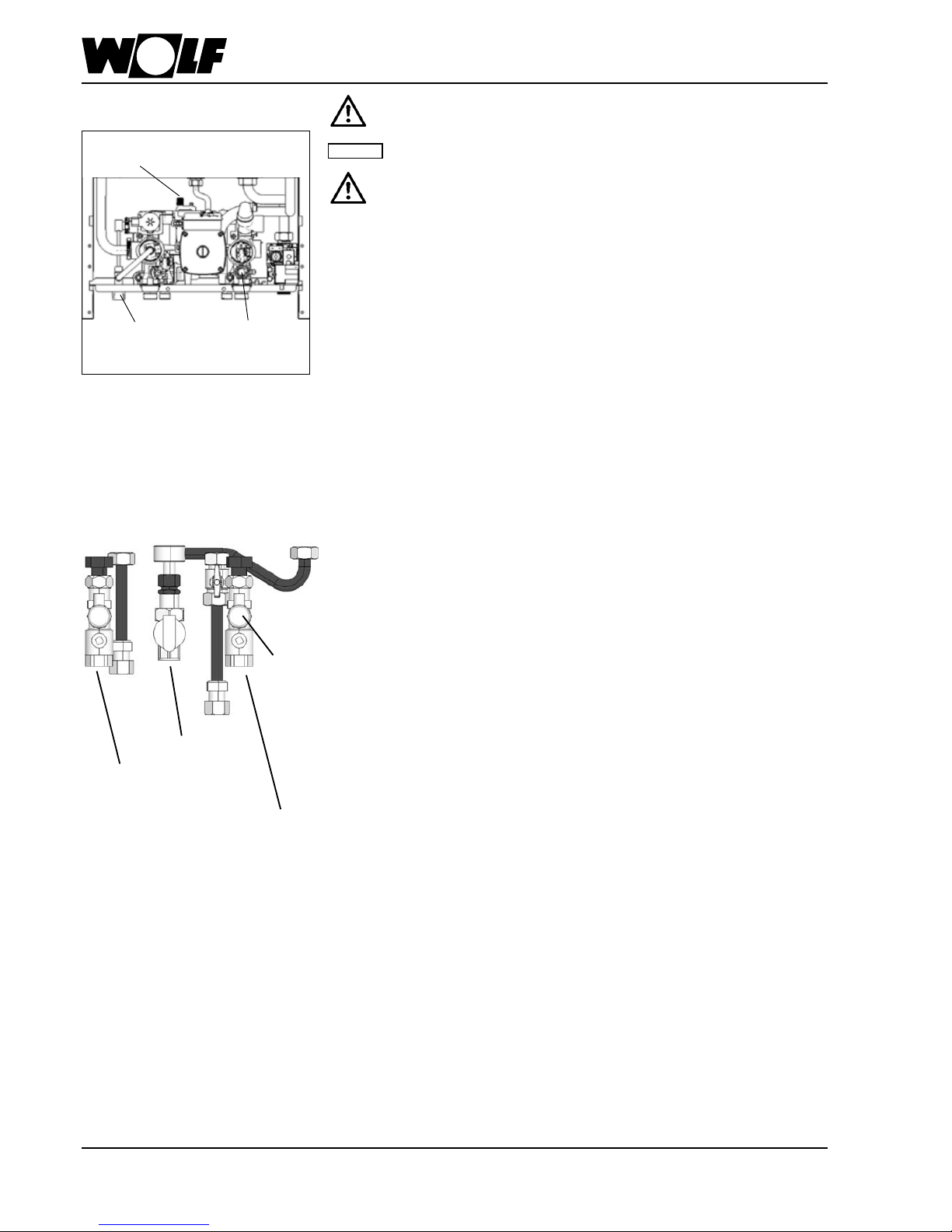

General boiler installation

Gas connection

Laying the gas pipe, as well as making the

gas connections, must only be carried out by

a licensed gas tter. Close the gas ball valve

on the gas red combi boiler to pressure test

the gas pipe.

Remove all residues from the heating pipework

and the gas pipe prior to connecting the gas

red boiler, particularly in older systems.

Prior to commissioning, test all pipe and gas

connections for leaks.

Inappropriate installation or using unsuitable

components or assemblies may lead to gas

escaping, which results in a risk of poisoning

and explosion.

The gas valve can be subj ecte d to a

maximum pressure of 150 mbar. Higher

pressure may dam age the gas valve,

resulting in a risk of explosion, asphyxiation

or poisoning. Close the gas ball valve on

the gas red boiler to pressure test the

gas pipe.

Install a tested and certified pressure

reducer, if the cold water supply pressure is

above the maximum permissible operating

pressure of 10 bar. Otherwise water could

escape resulting in a risk of ooding.

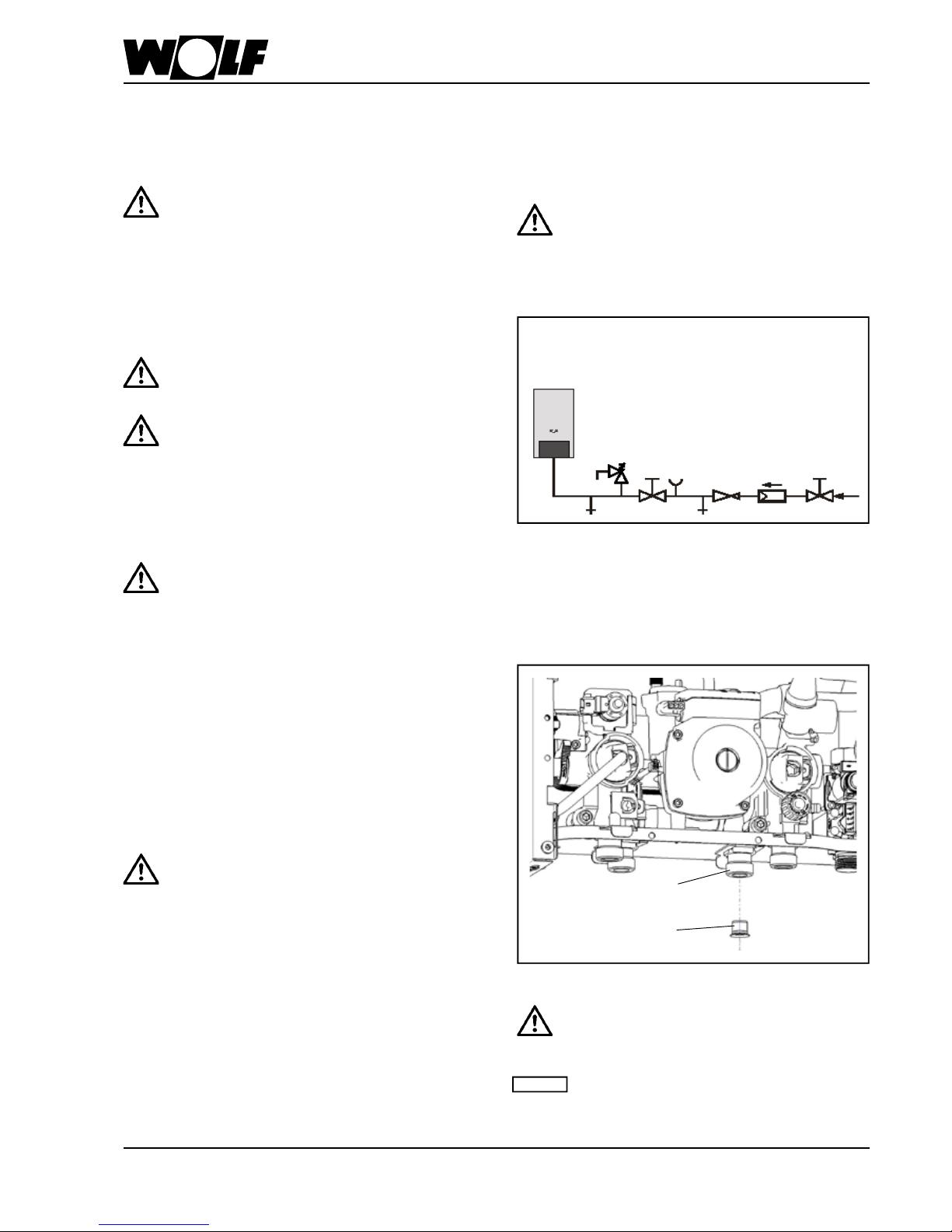

Fig.: Cold water connection

Cold water and DHW connection

For the cold water and DHW connection, we recommend

installation in accordance with the diagram below.

- Wolf connection sets (accessories) are available for

installation on nished and un nished walls. The

connection pipes are Cu 18x1.

Hydraulic connections

Note:

As standard, a combined cold water strainer

with throughput controller is tted at the cold

water connection of the boiler (see Fig.).

Fig.: Throughput controller with cold water strainer

Installation inside a cupboard

For installation of the gas red boiler inside a

cupboard note the following:

Never install the gas red boiler on the back wall

of the cupboard, as it may not be substantial

enough to take the boiler's weight. This would

create the risk of water and gas leaks which

in turn would result in a risk of explosion and

ooding.

Removing the rear wall of the cupboard

Minimum lateral clearance between the gas

red boiler and the cupboard sides 25 mm.

A cutout of 410 x 550 mm is required in the

cupboard top. Otherwise there is a risk of

suffocation and poisoning

With open ue gas red boilers the

ventilation grille in the cupboard door must

be installed with a free minimum diameter of

600 cm2.

Otherwise there is a risk of suffocation and

poisoning.

As the cold water strainer may need

to be cleaned, provide a facility for its

removal in site.

Otherwise there is a risk of faults.

Drain

Drain

Shut-off valve

Pressure

reducing valve

Shut-off valve

Cold water inlet

Pressure gauge port

DHW lter

Safety valve

Note

Page 14

14

3062347_0309

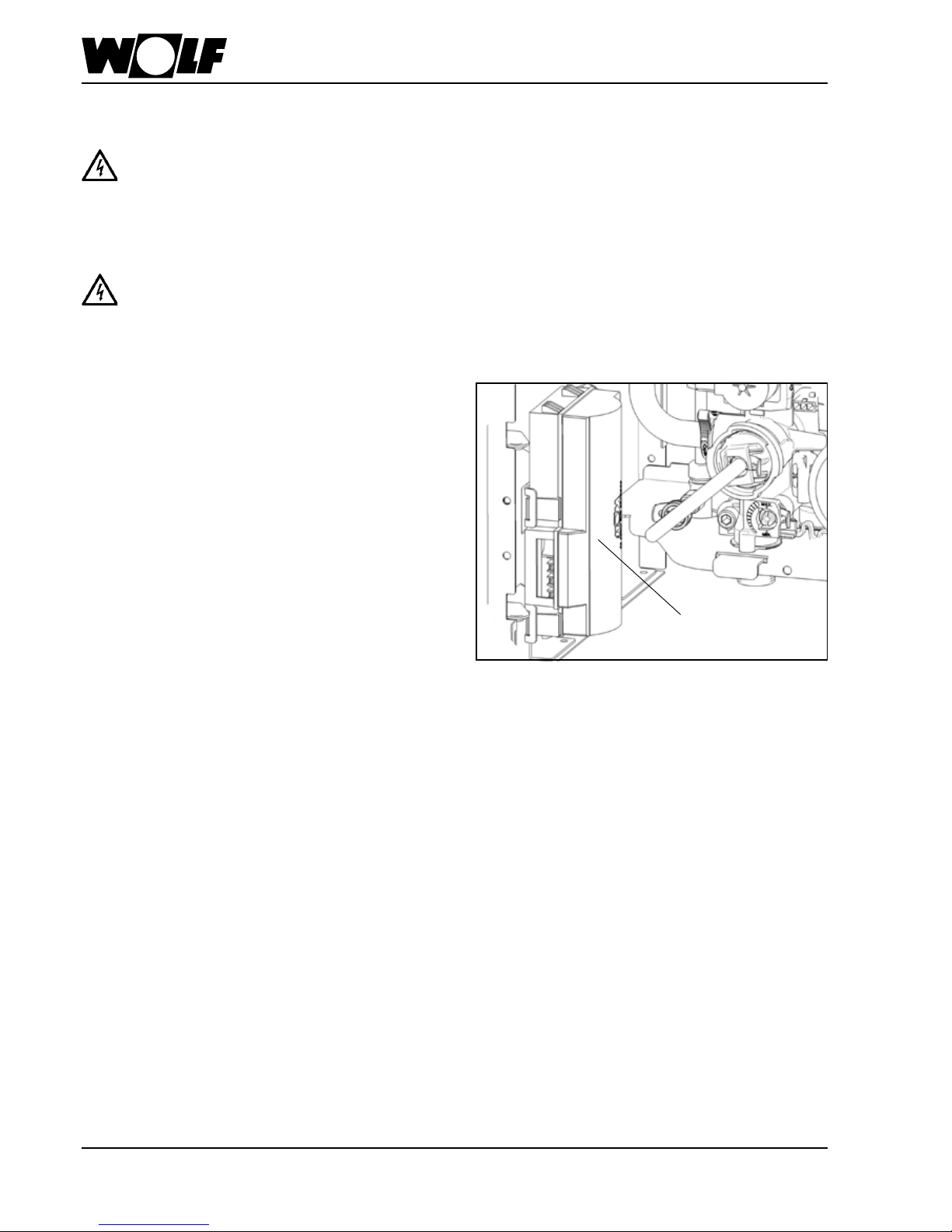

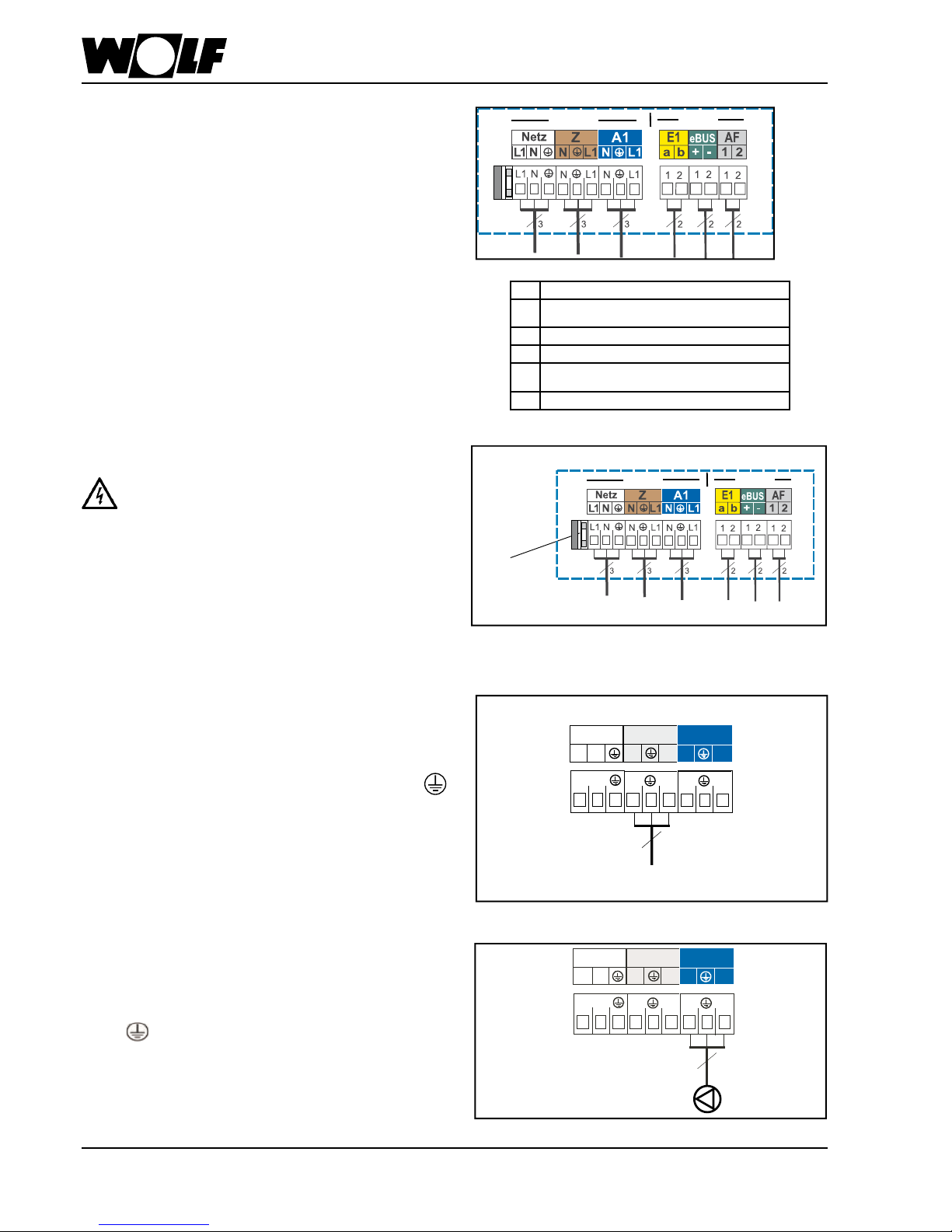

Electrical connection

CGU-2(K) / CGG-2(K)

General notes

The installation must be carried out by a

licensed electrical contractor. Observe

the regulations of the relevant authorities

and the local regulations of the power

supply company.

The power supply terminals are 'live'

even when the ON/OFF switch has been

switched OFF.

Terminal box

Terminal box

The control, regulating and safety equipment are fully

wired and tested.

You only need to connect the power supply and the

external accessories.

Power supply connection

Connect the power supply permanently or with a safety

plug (no plug connection in protective areas 1 and 2, i.e.

near a bath or shower).

Provide the power supply via a mains isolator (e.g. fuse,

heating system emergency stop), which ensures at least

3 mm contact separation for all poles.

Connection cable exible, 3 x 1.0 mm² or rigid,

max. 3 x 1.5 mm².

The plug must be accessible when using a power supply

cable with safety plug. Flexible power supply cable

3 x 1.0 mm².

Page 15

15

3062347_0309

Flue gas damper connection (230 V; max.200 VA)

Insert the cable glands into the terminal box. Insert

and secure the connecting cable through the cable

gland. Connect the connecting cable to terminals L1, N,

and .

Fig.: Flue gas damper connection

Changing a fuse

Isolate the boiler from the main supply prior

to changing a fuse. The ON/OFF switch on

the boiler does not provide separation from

the power supply.

Danger through 'live' electrical components.

Never touch electrical components or

contacts if the boiler has not been isolated

from the power supply. Danger of death.

Fig.: Pivot the control unit forward, terminal box

cover open

Fuse

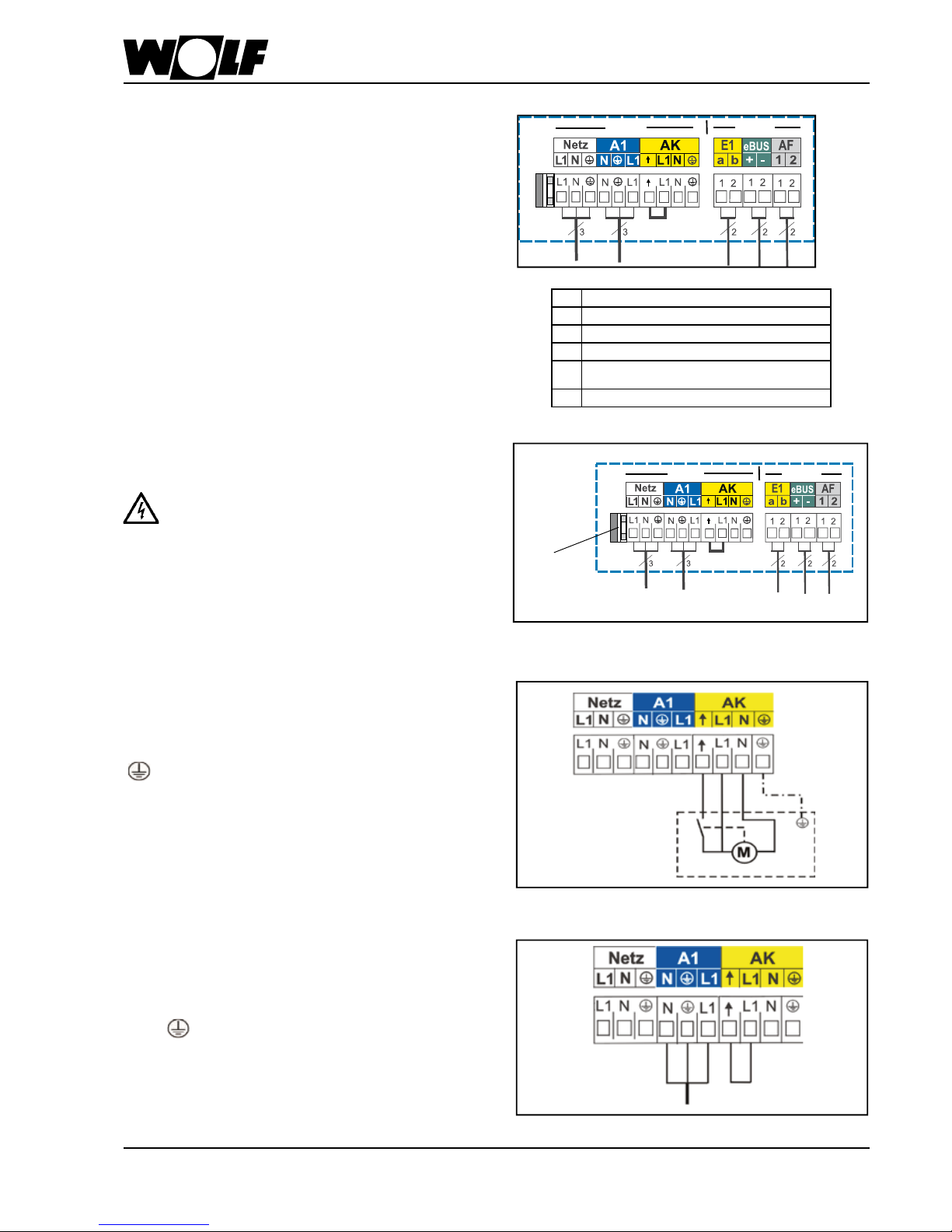

Electrical connection CGU-2(K)

Connection to Output A1 (230 VAC; max.200 VA)

Insert the cable glands into the terminal box. Insert

and secure the connecting cable through the cable

gland. Connect the connecting cable to terminals L1,

N and .

Fig.: Connection output A1

Installation information, electrical connection

- Isolate the system from the power supply before

opening the casing.

- Pivot the control unit to the side.

- Open the terminal box.

- Insert the strain relief into the holes provided.

- Strip approx. 70 mm off the power supply cable

insulation.

- Push the cable through the strain relief and

secure the strain relief.

- Pull the Rast-5 plug.

- Terminate the appropriate cores at the Rast-5 plug.

- Push the inserts back into the terminal box casing.

- Push the Rast-5 plugs back into the correct

positions.

A

Mains connection 230 VAC/50 Hz

C

Programmable output A1

G

Flue gas damper connection

D

Programmable input E1 zero volt

E

2-wire eBUS connection, digital Wolf control

accessories

F

Outside temperature sensor

A C G D E F

.

230 V < 24 V

230 V < 24 V

Page 16

16

3062347_0309

Electrical connection CGU-2(K)

Fig.: Connection DHW circulation pump / external

accessories

Changing a fuse

Isolate the boiler from the main supply prior

to changing a fuse. The ON/OFF switch on

the boiler does not provide separation from

the power supply.

Danger through 'live' electrical components.

Never touch electrical components or

contacts if the boiler has not been isolated

from the power supply. Danger of death.

Fig.: Pivot the control unit forward, terminal box

cover open

Fuse

Connection to Output A1 (230 VAC; max. 200 VA)

Insert the cable glands into the terminal box. Insert

and secure the connecting cable through the cable

gland. Connect the connecting cable to terminals L1,

N and .

Fig.: Connection output A1

Installation information, electrical connection

- Isolate the system from the power supply before

opening the casing.

- Pivot the control unit to the side.

- Open the terminal box.

- Insert the strain relief into the holes provided.

- Strip approx. 70 mm off the power supply cable

insulation.

- Push the cable through the strain relief and

secure the strain relief.

- Pull the Rast-5 plug.

- Terminate the appropriate cores at the Rast-5 plug.

- Push the inserts back into the terminal box casing.

- Push the Rast-5 plugs back into the correct

positions.

Power supply for external accessories

(230 VAC; max. 200 VA)

Insert the cable glands into the terminal box. Insert and

secure the connecting cable through the cable gland.

Connect the connecting cable to terminals L1, N and .

Netz

Z

A1

N

N

N

L1

L1

L1

L1

L1

L1

N

N

N

3

Z

A1

N

N

NL1

L1

L1

L1 L1

L1

NN

N

3

Netz

A

Mains connection 230 VAC/50 Hz

B

Power supply, ext. Accessories

230 VAC/50 Hz/max. 200 VA

C

Programmable output A1

D

programmable input E1 zero volt

E

2-wire eBUS

connection, digital Wolf control accessories

F

Outside temperature sensor

A B C D E F

230 V < 24 V

230 V < 24 V

Page 17

17

3062347_0309

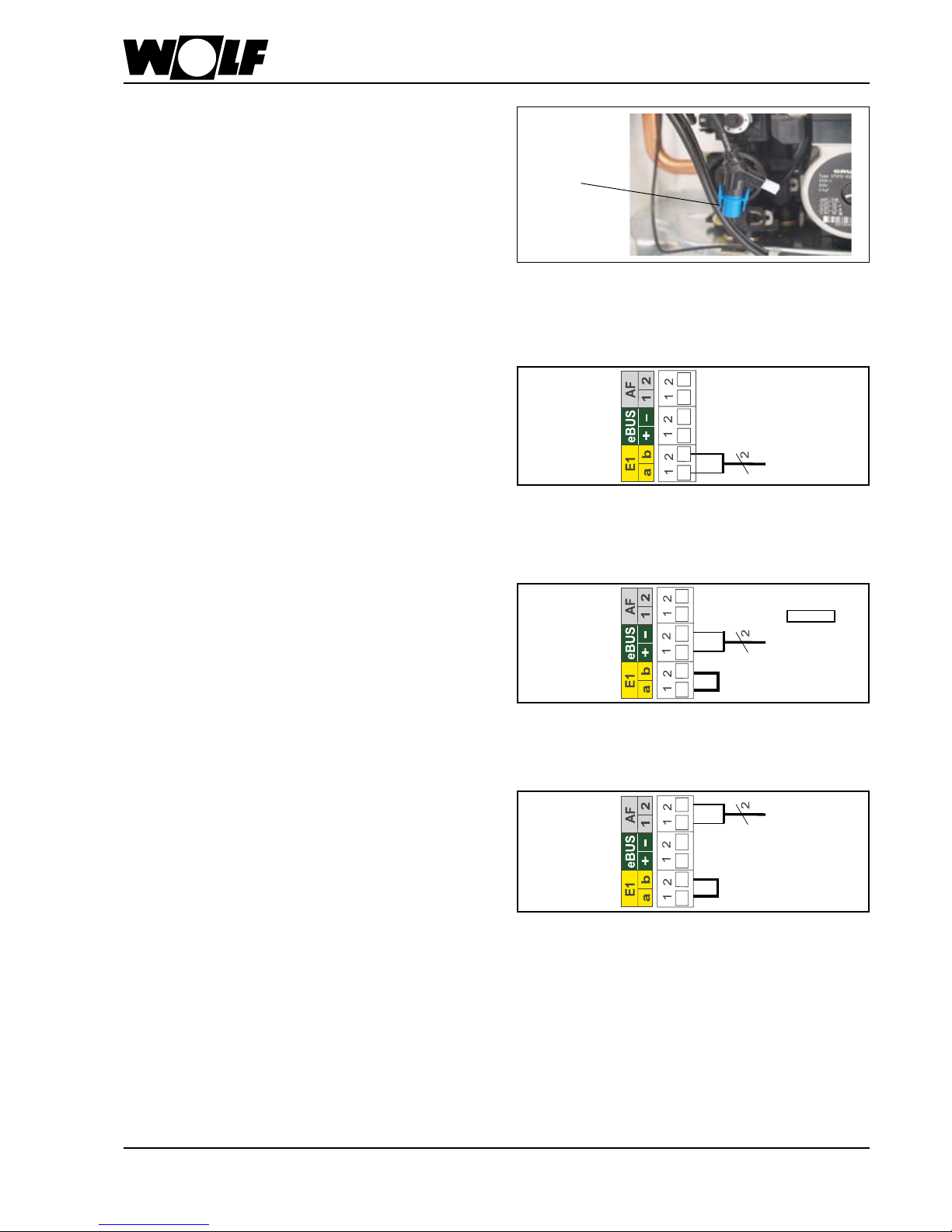

Connection, analogue outside temperature sensor

The analogue outside temperature sensor for digital

control accessory (e.g. BM) may be connected to the

terminal strip of the gas red boiler at the connection AF

or the terminal strip of the BM.

Fig.: Connection, analogue outside temperature sensor

Connection of digital Wolf control accessories

(e.g. BM, MM, SM1, SM2, KM)

Only connect control units from the Wolf accessory

range. Eac h accessory is supplied with its own

connection diagram.

Use a 2-core cable (cross-section > 0.5 mm²) as the

connecting cable between the control unit accessory

and the gas red boiler.

Fig.: Digital Wolf control accessories connection (eBUS

interface)

Electrical connection

CGU-2(K) CGG-2(K)

Fig.: Connection, programmable input

Connection, programmable input E1 (<24 V)

Connect the connecting cable for input 1 at terminals E1

in accordance with the wiring diagram; rst remove the

jumper between a and b from the respective terminals.

The functions of input E1 can only be scanned and

adjusted with Wolf control accessories with eBUS

capability.

DHW tank sensor connection

- When a cylinder is to be connected, the blue socket

of the cylinder sensor must be connected to the blue

plug of the control unit.

- Observe the cylinder installation instructions.

Fig.: Blue plug, cylinder sensor connection

Blue plug

Note

Pay attention

+ , to polarity

Page 18

18

3062347_0309

Fill / vent the system

Procedure for boilers with

internal lling facility

not for <DE> <AT>

- Fill the entire heating system and boiler via the lling facility or an on-site

ll & drain valve up to approx. 0.5 - 1 bar, whilst simultaneously venting the

heating system.

- Close the shut-off valves on the heating water side of the boiler (ow and

return).

- Push the drain hose onto the drain valve of the hydraulic assembly.

- Clean the heat exchanger by opening the internal lling facility and the

drain valve simultaneously on the hydraulic assembly (make sure there is

no air remaining in the heat exchanger).

Procedure for boilers without

internal lling facility

Filling the system

Fill the system and vent it thoroughly to safeguard the perfect

function of the gas red boiler.

Otherwise there is a risk of faults.

The heating water must not be mixed with inhibitors or antifreeze;

otherwise leaks and ooding could result.

- Close the gas ball valve.

- Before connecting the gas red boiler to the heating system, ush the entire

system to remove residues such as welding pearls, hemp, putty, etc. from

the pipework and to remove air that may have collected.

- Fill the DHW system of the boiler until water ows out of a DHW draw-off point.

- To ll the heating system use the ll & drain connections. Open the cap of the

automatic air vent valve on the heating circuit pump by approx. 2 revolutions, but

do not remove the cap.

- Open all radiator valves and the shut-off valves on the heating water side of the

boiler.

- Fill the entire heating system and boiler via the ll & drain valves (Wolf

accessory) up to approx. 0.5 bar, whilst simultaneously venting the heating

system.

- Close the return shut-off valve on the heating water side of the boiler.

- Attach drain hose to the drain valve on the hydraulic assembly (alternative, if only

a ll & drain connection is provided).

- Clean the heat exchanger by opening the ll & drain valve and/or the

drain valve simultaneously on the hydraulic assembly

(make sure there is no air remaining in the heat exchanger).

- Remove the drain hose and open the boiler shut-off valve(s) on the heating water

side again.

- After venting, raise the system pressure to 2.5 bar.

- Start the boiler, set the heating water temperature selector to position "2"

(pump running, illuminated signal ring (status display) constantly green).

- Vent the pump; for this, briey open and then retighten the air vent

screw, optimum venting in pump stage 3.

Top up with water when the system pressure falls severely.

- Open the gas shut-off valve. Press the reset button.

- When in constant use the heating circuit vents automatically via the heating

circuit pump, venting optimum at pump stage 3. After venting set to pump

stage 1 or 2 for reduced noise, depending on customer preference.

- At system pressure below 1.0 bar the boiler may experience faults.

If necessary ll on heating side.

Internal lling

facility not for

<DE><AT>

Drain

valve

Fig.: Shut off valves (accessory)

Gas shut-off valve

Heating ow

(incl. ll & drain

connection)

Heating return

(incl. ll & drain

connection)

Automatic

air-vent valve

Fill & drain

Connection

Note

Page 19

19

3062347_0309

- Instruct the customer about energy-saving options.Saving energy

Commissioning guidelines

Only qualied personnel must carry out the commissioning and initial

start-up of the boiler as well as instruct the user.

Guidelines for commissioning

- Flush and vent boiler (use shut-off valve with ll & drain valve from Wolf

accessory range), ll boiler and system and test for tightness. Normal

operating pressure when system is cold 1.5 bar. Prevent water leaks.

- Check location and seating of the installation.

- Check the gas supply pressure.

- Check all connections and component links for leaks.

- If tightness cannot be ensured then there is a danger of water damage.

- Check that all ue gas accessories have been correctly installed.

- Open the water and shut-off valves on ow and return.

- Open gas connection.

- Switch ON emergency heating switch and switch ON the ON/OFF switch on

the control unit.

- Check the adjustment of the ue length, resetting if required.

See chapter "Adjusting the ue length".

- Check the ignition and ame structure of the burner.

- The illuminated ring shows a yellow colour, if the boiler starts correctly.

- Instruct the customer in the operation of the boiler, with the aid of the

installation instructions.

- Complete the commissioning report and hand over the instructions to the

customer.

- Implement the "Installation" and "Electrical connection" of the boiler

and all extension and programming modules in accordance with the

instructions in the associated manuals.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Step 10

Step 11

Step 12

Step 13

Step 14

Step 15

Note

Otherwise there is a risk of faults.

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

Page 20

20

3062347_0309

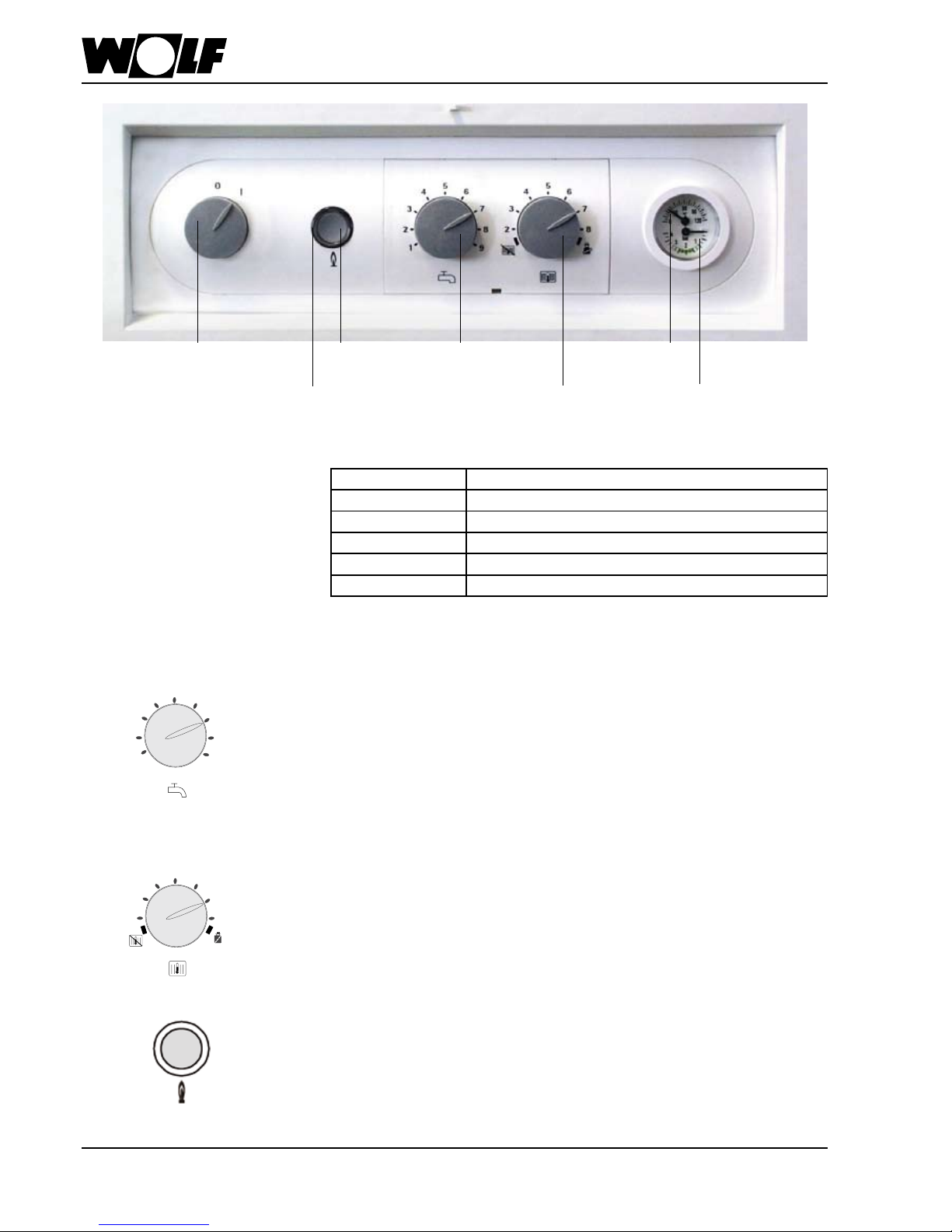

Control / Function / Commissioning

ON / OFF switch

DHW

temperature

selector

Pressure

gauge

Reset

button

Heating water

temperature

selector

Illuminated

signal ring

Thermometer

9

1

2

8

3

7

4

6

5

DHW temperature selector

Settings 1-9 correspond with a DHW temperature of 40-65 °C with gas combi

boilers, or 15-65 °C with gas boilers with a cylinder. Combined with a control

thermostat for wall mounted gas red boilers, the adjustment at the DHW

temperature selector is disabled; instead the temperature is selected at the

boiler control thermostat.

2

8

3

7

4

6

5

Heating water temperature selector

Settings 2-8 correspond to a heating water temperature of 40-80 °C. Combined

with a temperature controller for wall mounted gas red boilers, the adjustment

at the heating water thermostat is disabled; instead the temperature is selected

at the boiler temperature controller.

Signal ring as

status display

Display Explanation

Flashing green Standby (power supply ON, burner OFF)

Constant green light Heat demand: pump running, burner OFF

Flashing yellow Emissions test mode

Constant yellow light

Burner ON, ame steady

Flashing red

Fault

Reset

A fault is reset by pressing the reset button which will also restart the system.

Pressing the reset button reactivates the system, if there was no fault.

Page 21

21

3062347_0309

In conjunction with the accessory controllers BM / AWT / ART, the settings at

the boiler relating to DHW and heating water are disabled.

Note:

Setting

Winter mode (position 2 to 8)

In winter mode, the boiler heats to the temperature selected at the heating water

temperature controller. According to the pump operating mode, the circulation

pump operates constantly (factory setting) or only in parallel with the burner

activation / run-on period.

Summer mode

The winter mode is deactivated by rotating the heating water temperature

selector into position . In other words, the boiler will then operate in summer

mode. Summer mode (heating OFF) means, only DHW heating. Frost protection

for the heating system and pump anti-seizing protection, however, remain

enabled.

In summer mode, the circulation pump operates for approx. 30 seconds after

a maximum idle period of 24 hours.

Anti-seizing pump protection

Thermomanometer

The current heating water temperature is displayed in the upper area.

The water pressure in the heating system is displayed in the lower area. In

normal use, the water pressure should be between 2.0-2.5 bar.

Emissions test mode

The emissions test mode is activated by rotating the heating water temperature

selector into position . The signal ring ashes yellow. After the emissions

test mode has been activated, the boiler will heat with the selected maximum

heating output. Any previous cycle block will be cancelled. The emissions test

mode terminates after 15 minutes or when the maximum ow temperature has

been exceeded. For a renewed activation, turn the heating water temperature

selector anti-clockwise and then back into position .

Control / Function / Commissioning

Page 22

22

3062347_0309

Parameter overview / setting report

Column 1 settings apply to control accessories ART, AWT

Column 2 settings apply to Wolf control system with BM programming module

(Setting and function of the most important functions on the following pages, further description,

see BM installation instructions.)

Parameters Setting range

Factory setting

Individual settings

Column 1 Column 2

HG00 Adjusting ue lengths 1 to 5 4

GB05 A09 Frost protection limit -20 to +10 °C +2 °C

GB01 HG01 Burner switching differential 5 to 25 K 8 K

HG02 Lower burner output heating 1 to 100% 1%

HG03 Upper burner output DHW 1 to 100% 100%

GB04 HG04 Upper burner output heating 1 to 100% 100%

GB06 HG06 Pump operating mode 0 to 2 0

GB07 HG07 Boiler circuit pump run-on time 0 to 30 min 1 min

GB08 HG08 Maximum boiler temperature, heating 40 to 90 °C 80 °C

GB09 HG09 Burner cycle block 1 to 30 min 7 min

HG10 eBUS address (display only) 1 to 4 1

HG11 DHW quick start temperature 10 to 60 °C 10 °C

HG12 Gas type, 1=natural gas 0=LPG 0 to 1 1

HG13 Programmable input E1 1 to 11 1

HG14 Programmable output A1 0 to 15 6

HG15 Cylinder hysteresis 1 to 30 K 5 K

HG20 Max. cylinder heating time 0 to 5 h 2 h

HG21

Minimum boiler water temperature TK-min >40 °C*

20 to 60 °C 40 °C

HG23 Maximum DHW temperature 60 to 80 °C 65 °C

HG25

Boiler overtemperature during DHW cylinder heating

0 to 40 K 20 K

HG70

Manifold sensor (display only)

HG80-89 Fault history

The control parameters can only be modied or displayed via Wolf control accessories with eBUS

capability. For installation and procedures, check the operating instructions of the relevant accessories.

To prevent damage to the heating

system, cancel night setback when

outside temperatures fall below -12 °C. If

this rule is not observed, ice may form on

the ue outlet which may cause injury to

individuals or material losses.

Modications must only be carried out by

a recognised heating contractor or by the

Wolf customer service.

L.h. rotary selector

Program selection

Display R.h. rotary selector

Temperature selection

Info key Single cylinder

heating key

Setback keyHeating key

Note

BM programming module

Displaying / modifying control parameters

with Wolf control accessories

* To prevent damage to the boiler TK min must be set > 40 °C

Page 23

23

3062347_0309

Press the r.h. rotary selector to change to control level 2. Turn the r.h. rotary

selector clockwise to select the menu level Contractor and con rm the selection

by pressing the r.h. rotary selector again.

The display shows the code scan.

Contractor level

expert

The correct code is set by pressing (display indication ashes) and then

turning the r.h. rotary selector from 0 to 1. After changing the code from 0 to

1, pressing the r.h. rotary selector again con rms the setting; you are then at

the Contractor level.

Code scan

code-NO

- - - -

Factory setting: 1

The boiler circuit pump operates constantly if the outside temperature stays

below the selected value. The burner starts and heats the boiler to at least

TK-min., if the boiler water temperature falls below +5 °C.

Note:

Only change the factory setting if you can ensure that the heating system and

its components will not freeze up at low outside temperatures.

Frost protection limit

Parameter A09

A09

2.0

Factory setting: 2 °C

Setting range: -20 to +10 °C

Note

Incorrect operation can lead to system faults.

Please note when adjusting parameter A09 (frost protection / outside

temperature), that frost protection is no longer safeguarded if you set

temperatures lower than 0 °C. This can lead to heating system damage.

Displaying / modifying control parameters

with Wolf control accessories

The control parameter should be

set according to the table opposite,

subject to the calculated length of the

balanced ue routing. The calculated

length will be rounded up or down

accordingly.

(Also see chapter "Adjusting the ue

length".)

Matching the pipe length

Parameter HG00

HG00

4

Factory setting: 4

Setting range: 1 to 5

HG00

Adjusting

pipe lengths

Calculated length (m)

1 1.3 - 1.5

2 1.5 - 2.5

3 2.5 - 3.5

4

(factory setting)

3.5 - 4.0

5 4.0 - 5.0

The burner switching differential regulates the burner temperature within a set

range by switching the burner ON and OFF.

The higher the ON / OFF temperature differential, the higher the boiler

temperature uctuation around the set temperature.

Burner switching differential

Parameter HG01

HG01

8

Factory setting: 8 K

Setting range: 5 to 25 K

The lower burner output in heating mode can be adjusted within the modulation

range. The setting relates to the maximum heating output in kW (see table

"Limiting maximum heating output").

Lower burner output Hz

Parameter HG02

HG02

1

Factory setting: 1

Setting range: 1 to 100

Page 24

24

3062347_0309

J

J

J

Displaying / modifying control parameters

with Wolf control accessories

The higher burner output in DHW mode can be adjusted within the modulation

range. The setting relates to the maximum heating output in kW (see table

"Limiting maximum heating output").

Upper burner output DHW

Parameter HG03

HG03

100

Factory setting: 100

Setting range: 1 to 100

The higher burner output in heating mode can be adjusted within the modulation

range. The setting relates to the maximum heating output in kW (see table

"Limiting maximum heating output").

Upper burner output Hz

Parameter HG04

HG04

100

Factory setting: 100

Setting range: 1 to 100

Pump operating mode 0:

Heating circuit pump for heating systems without cascade control and

without low loss header

The boiler pump runs constantly when there is a heat demand. When the heat

has been switched off via the room thermostat or remote control, the boiler

pump runs for the set time (pump run-on Hz, parameter HG07).

Pump operating mode

Parameter HG06

HG06

0

Factory setting: 0

Setting range: 0 / 1 / 2

Pump operating mode 1:

Feed pump for heating systems with cascade control and/or low loss

header/buffer (manifold sensor essential)

Boiler pump becomes the feed pump.

The manifold sensor affects the heating operation as well as the cylinder heating

(please note: only cylinder mode possible). The boiler pump will not run for a

general heat demand, but rather only when there is a burner demand in the

heating operation, with pump run-on according to parameter HG07.

VL Sensor 1

Three-way valve

Header

Manifold sensor E1

VL Sensor 2

A1 as heating

circuit pump

A1 as primary

cylinder pump

DHW cylinder

Hydraulic scheme:

Gas red boiler

Boiler

pump

or

Page 25

25

3062347_0309

Subject to there being no heat demand from the heating circuits, the boiler

circuit pump will run-on in accordance with the set time, to prevent a boiler

safety shutdown at high temperatures.

Boiler circuit pump run-on time

Parameter HG07

HG07

1

Factory setting: 1 min

Setting range: 0 to 30 min

Displaying / modifying control parameters

with Wolf control accessories

J

J

J

J

Hydraulic scheme:

VL Sensor 2

VL Sensor 1

Three-way valve

Manifold

sensor E1

A1 as heating

circuit pump

Cylinder

sensor

Buffer

DHW cylinder

Gas red boiler

Boiler

pump

Pump operating mode 2:

Buffer cylinder primary pump

Boiler pump becomes the buffer primary pump.

The manifold sensor (buffer) only affects the heating operation. In case of DHW

heating, the reference temperature is provided by the internal boiler sensor.

The boiler pump will not run for a general heat demand, but rather only when

there is a burner demand in the heating operation, with pump run-on according

to pump run-on time.

With DHW demand (free standing cylinder, combi boiler, strati cation cylinder)

the heating circuit pump runs according to function.

Operation without manifold sensor:

Boiler pump only during burner operation; regulated by internal sensor.

This function limits the boiler water temperature upwards in heating mode, and

the burner shuts down. This parameter has no function during cylinder heating,

and the boiler water temperature may also be higher during this time. "Reheating

effects" can result in the temperature being exceeded a little.

Maximum limit

Boiler circuit TV-max.

Parameter HG08

HG08

80

Factory setting: 80 °C

Setting range: 40 to 90 °C

Page 26

26

3062347_0309

The eBUS address can only be displayed here. The setting is done as described

in "Conversion/eBUS address in cascade operation" and is only required in

cascade operation with several boilers.

eBUS address

Parameter HG10

HG10

1

Factory setting: 1

Setting range: 1 to 4

Gas type set according to the following table:

1 = Natural gas

0 = LPG

The modulating current for the gas combi valve is adjusted to t with the

relevant setting.

The conversion of the gas type can also be carried out through the selector or the

heating temperature selector (see control settings after gas type conversion).

Gas type

Parameter HG12

HG12

1

Factory setting: 1

Setting range: 0 to 1

Outside of the DHW switching times (in the control accessories) and in summer

mode, water can be heated to and kept at a certain temperature in the at-plate

heat exchanger.

10 °C = DHW quick start disabled

40-60 °C = DHW quick start enabled

DHW Quick Start

Parameter HG11

HG11

10

Factory setting: 10 K

Setting range: 40 to 60 K

Displaying / modifying control parameters

with Wolf control accessories

Each time the burner is shut down in heating mode, it will be blocked for the

duration of the burner cycle block.

The burner cycle block is reset by switching the ON / OFF switch OFF and ON

or by brie y pressing the reset button.

Burner cycle block

Parameter HG09

HG09

7

Factory setting: 7 min

Setting range: 1 to 30 min

Page 27

27

3062347_0309

Explanation

1

Room thermostat

Closed contact is a pre-requisite to enable the burner in heating mode.

No function (blocked) for DHW mode. No function (blocked) for emissions test mode and frost protection, no error message.

Open contact blocks the enabling of the heating and the boiler pump (pump run-on time)

2

Maximum thermostat / system pressure switch

Closed contact is a prerequisite for enabling burner in central heating, DHW and emissions test mode. When the

contact is opened the boiler switches off and the pump run-on begins.

A fault message is generated.

5

Ventilation damper

Function monitoring of the ventilation damper with zero volt contact

Closed contact is a prerequisite for enabling burner in central heating, DHW and emissions test mode

Output A1 must be programmed to 7, ventilation damper function

6

DHW circulation pushbutton

After the DHW circulation pushbutton is activated, output A1 is switched on for 5 minutes, if output A1 is programmed as

DHW circulation pump (A1 = 13)

7

Manifold sensor

A manifold sensor (5 K-NTC) is connected at E1. The ow temperature control in heating and DHW mode (pump

operating mode 1) or only in heating mode (pump operating mode 2) no longer relates to the ow sensor but rather the

manifold sensor. Safety functions and emissions test mode remain at the ow sensors. In case of break or short circuit

of the manifold sensor, the ow sensor takes on the temperature control. Observe parameter HG 06

8

Burner block (BOB)

Operation without burner

Closed contact, burner blocked

Heating circuit pump and cylinder primary pump run in normal operation

In emissions test mode and frost protection the burner is enabled

Open contact enables the burner again

10

External burner demand

Closed contact, set FT is set to TKmax ow hysteresis

Demand also functions in standby; cycle block active

(Control of output A1 when parameter output A1 = 14)

0, 3, 4, 9, 11 are without function

The functions of input E1 can only be scanned and adjusted with Wolf control

accessories with eBUS capability.

The following functions can be allocated to input E1:

Programmable

Input E1

Parameter HG13

HG13

1

Factory setting: 1

Setting range: 1 to 10

Displaying / modifying control parameters

with Wolf control accessories

The electrical control to input E1 must be made with a zero volt contact. Otherwise,

use an on-site relay for potential separation.

Page 28

28

3062347_0309

Explanation

0 No function

Output A1 is not enabled

1 DHW circulation pump 100%

Output A1 is switched by control accessories (BM), if DHW circulation has been enabled. Output A1 is constantly

enabled when no accessory controller is installed.

2 DHW circulation pump 50%

Output A1 is switched by control accessories (BM), if DHW circulation has been enabled. 5 minutes ON and 5

minutes OFF. Output A1 constantly cycled in 5 minute cycles when no accessory controller is installed.

3 DHW circulation pump 20%

Output A1 is switched by control accessories (BM), if DHW circulation has been enabled. 2 minutes ON and 8

minutes OFF. Output A1 cycles constantly when no accessory controller is installed.

4 Alarm output

Output A1 is controlled after a fault and expiry of 4 minutes.

5 Flame detector

Output A1 is controlled after a ame has been recognised.

6 Cylinder primary pump

Output A1 always closes along with the boiler pump in DHW operation. Both with 3-way valve idle period protection

and with pump kick.

7 Ventilation damper

Output A1 is activated before each burner start. The burner will, however, only be enabled after input E1 has been

closed.

Important: In any case, input E1 must also be programmed as "Ventilation damper"!

Otherwise there is a risk of faults.

The feedback to input E1 must be made with a zero volt contact. Otherwise, use an on-site relay for potential

separation.

8 External ventilation

Output A1 is controlled inverted to the burner. Switching OFF external ventilation (e.g. extractor fan) during burner

operation is only required, if the boiler is operated as open ue system.

9 External LPG valve

Output A1 switches with the gas combi valve

10 Direct heating circuit pump

Pump switches in accordance with the enabling of the direct heating circuit

11 External pump

Output A1 switches synchronously with the heating circuit pump (HKP). Use with, for example, system separation.

12 Diverter valve

If E1 is programmed for burner blocking (option 8) and closed, A1 switches ON. If E1 is not programmed as burner

blocking, A1 always stays OFF.

13 DHW circulation pump

DHW circulation pump ON for 5 mins, if input E1 is programmed as DHW circulation pushbutton and input E1 Key is

closed.

14 Pump with external burner demand

Synchronous control with input E1 (E1 = 10, ext. burner demand)

15 Constant voltage for accessories

A1 is always closed (constant voltage 230 VAC)

The functions of output A1 can only be scanned and adjusted with Wolf control

accessories with eBUS capability.

The following functions can be allocated to output A1:

Programmable

Output A1

Parameter HG14

HG14

6

Factory setting: 6

Setting range: 0 to 15

Displaying / modifying control parameters

with Wolf control accessories

Note

230 V AC

< 24 V

Page 29

29

3062347_0309

The cylinder hysteresis regulates the start point for cylinder heating. The greater

the hysteresis, the lower the start temperature.

Example: Set cylinder temperature 60 °C

Cylinder hysteresis 5 K

Cylinder heating commences at 55 °C and ends at 60 °C.

Cylinder hysteresis

Parameter HG15

HG15

5

Factory setting: 5 K

Setting range: 1 to 30 K

Cylinder heating commences as soon as the cylinder temperature sensor

demands heat. The heating circuit pump would be constantly switched OFF, if

the boiler was undersized, the cylinder was scaled-up or if DHW was constantly

drawn. The accommodation cools down signi cantly. One option enables a max.

cylinder heating time to be speci ed to limit this effect. The control unit reverts

to heating mode, when the set cylinder heating time has expired and cycles in

the selected rhythm between heating and cylinder heating mode, irrespective

of whether the cylinder has reached its set temperature or not.

Set this parameter to 0 in heating systems with a high DHW consumption, e.g.

hotels, sports facilities etc.

Max. cylinder heating time

Parameter HG20

Factory setting: 2 h

Setting range: 0 to 5 h

HG20

2

The control unit is equipped with an electronic boiler thermostat, with an

adjustable minimum switch-ON temperature. The burner is switched ON subject

to the cycle block if this temperature is not achieved when heat is demanded.

The minimum boiler water temperature TK-min. is also not necessarily achieved

when there is no heat demand.

Minimum boiler water temperature

TK-min.

Parameter HG21

HG21

40

Factory setting: 40 °C

Setting range: 20 to 60 °C

Displaying / modifying control parameters

with Wolf control accessories

This temperature can be enabled at 80 °C, if for commercial reasons a higher

DHW temperature is required.

If pasteurisation (BM) has been enabled, the DHW cylinder will be heated to

65 °C during the rst cylinder heating of the day, subject to parameter HG23

being set to this temperature or higher.

Take adequate measures to prevent scalding.

Maximum DHW temperature

Parameter HG23

HG23

65

Factory setting: 65 °C

Setting range: 60 to 80 °C

Note

Page 30

30

3062347_0309

The excess temperature differential between the cylinder temperature and the

boiler water temperature during cylinder heating is selected with parameter

HG25. This ensures that, even in spring and autumn, the boiler water

temperature is higher than the cylinder temperature, thereby ensuring short

heating times.

Boiler overtemperature during

DHW cylinder heating

Parameter HG25

HG25

20

Factory setting: 20 K

Setting range: 0 to 40 K

Displaying / modifying control parameters

with Wolf control accessories

Parameters

HG 80

Fault 1

HG 81

Fault 2

HG 82

Fault 3

HG 83

Fault 4

HG 84

Fault 5

HG 85

Fault 6

HG 86

Fault 7

HG 87

Fault 8

HG 88

Fault 9

HG 89

Fault 10

HG70

54

Display only:

With parameter HG70 analogue input E1 is displayed, if a manifold sensor is

connected (display only).

HG80

04

Display only:

Fault history

Parameter HG80

Page 31

31

3062347_0309

Reset

Observe the following steps to implement a reset:

- The operating mode switch must be set to O (OFF).

- Press the reset button on the control unit and hold it down.

- Switch on ON/OFF switch in I position.

- After 5 seconds the signal ring will illuminate and ash yellow/green and

red every 1 second.

- Then release the reset button again.

All parameters (individual settings) are returned to their factory

settings by a reset, except for gas type settings and adjustments

to pipe lengths.

ON / OFF switch

Press reset button

With boilers CGU-2 / CGG-2 there are 3 possible boiler versions.

The DHW circuit is bridged and is not used

When drawing DHW the ow rate sensor

recognises the DHW demand. The burner is

red-up and regulated to the set DHW outlet

temperature (adjusted via rotary selector or

control accessories)

When drawing DHW, the temperature

falls below the set DHW temperature. The

burner res up and regulates the boiler ow

temperature and boiler excess temperature

when preparing DHW

DHW connection versions /

Resetting control unit

Boiler

Combination

boiler

Boiler with cylinder

A VL sensor 2

B VL sensor 1

C Boiler pump

D Three-way valve

E Flow rate sensor

F Cylinder sensor

Legend

Note

A

B

C

D

A

B

C

D

E

F

A

B

C

D

Page 32

32

3062347_0309

Boiler in cascade

operation

eBUS address

Position

Rotary

selector, DHW

temperature

selection

Illuminated ring

display

1 (factory setting) 1 1 ashing red

2 2 2 ashing yellow

3 3 3 ashing yellow/red

4 4 4 ashing yellow/green

ON / OFF switch

DHW temperature

selector

Pressure

gauge

Reset

button

Heating water

temperature

selector

Illuminated

signal ring

Thermometer

- At the system ON / OFF switch, switch the boiler rst OFF and then ON again. There must not be any fault

present at the boiler.

- Press reset button for between 30 and 60 seconds after turning on the mains and keep pressed down during

the next step. Setting the address is only possible during this time window.

- After 10 seconds the illuminated signal ring indicates the currently selected gas type (see table: eBUS address).

- Turn the DHW temperature selector towards the required address and check the setting by means of the colour

of the illuminated signal ring.

- The adjustment will only be activated when the reset button is released.

- A successful setting of the eBus address is indicated by a triple ashing yellow/red (0.4 s ON / 1.0 s OFF) of the

signal ring.

Setting the eBUS address

for cascade mode

When operating several boilers (up to 4 control units) in conjunction with a cascade controller KM, adjust

the eBUS address of the boilers in accordance with the table, below.

Table: eBUS address

Page 33

33

3062347_0309

Start-up gas connection

Only qualied personnel must carry out the

commissioning and boiler operation as well

as the user instruction to prevent dangers

and injuries as well as material losses.

- The boiler and system must be fully vented and must

be absolutely tight.

- If the system water pressure falls below 1.5 bar, top

up with water until a pressure of 1.5 to max. 2.5 bar

has been achieved.

- Check that all ue gas accessories have been correctly

installed.

- The gas red boiler must be switched OFF. Open the

gas shut-off valve.

- Remove the casing cover.

- Release the plug at test nipple and vent the gas

supply pipe.

Check test nipple for gas-tightness,

otherwise gas may esc ape, resulting

in a risk of explosion, asphyxiation or

poisoning.

Prior to commissioning, ensure that the boiler corresponds

to the gas type available.

Gas type Wobbe index Ws

kWh/m³ MJ/m³

Natural gas H 11.4 - 15.2 40.9 - 54.7

LPG P 20.3 - 21.3 72.9 - 76.8

Commissioning gas train:

- Pull the hose off and tighten the test nipple again.

- Retighten the plug.

- Start the boiler.

- Check the ignition and the regular ame structure of

the burner.

Never take the boiler into use if the actual value falls

outside the specied limits.

→ Notify gas supply utility.

Gas type Nominal supply pressure,

Permissible range

Natural gas H 20 mbar 18 - 25 mbar

LPG P 50 mbar 43 - 57 mbar

LPG P 37 mbar 25 - 45 mbar

LPG P 29 mbar 25 - 35 mbar

- Connect the hose to the pressure test appliance at

test nipple and check against atmosphere.

- Read off value and enter in the commissioning

report.

Page 34

34

3062347_0309

- Continue with adjusting of the control unit subject to gas type

- Adjusting the nozzle pressure

- Identication

1. Nozzle change:

- Switch OFF the boiler at the ON/OFF switch and

isolate it from the power supply

- Remove the casing lid of the gas red boiler. For this,

pivot the control unit lid down, hook in the r.h. and l.h.

turnbuckle, undo the lower casing lid and unhook at

the top

- Close the gas valve, observe all safety instructions

and crack open the gas ttings at the gas manifold

- Remove xing screw

- Pull out the gas manifold

- Undo all burner nozzles (spanner size 7) at the gas

manifold

- Insert new burner nozzles with new gaskets

- Reassemble the boiler in reverse order

Table: Number of nozzles, nozzle size

Boiler No. of nozzles Natural gas H LPG/propane

Nozzle ID Nozzle

Ø mm

Nozzle ID Nozzle

Ø mm

CGU-2(K) 18 090 0.90 060 0.60

CGU-2(K) 24 090 0.90 060 0.60

CGG-2(K) 18 087 0.87 057 0.57

CGG-2(K) 24 087 0.87 057 0.57

Conversion to other gas types

CGU-2(K) / CGG-2(K)

Fixing screws

Gas tting

Gas manifold

The conversion to other gas types is made in four steps:

1. Nozzle replacement

2. Adjusting the control unit after converting the gas type

3. Checking and adjusting the nozzle pressure

4.

Identication

Note

Carry out all steps, otherwise there is a risk of

incorrect functions or system damage.

Page 35

35

3062347_0309

Control unit settings after

gas type conversion

ON / OFF switch

DHW temperature

selector

Pressure

gauge

Reset

button

Heating water

temperature

selector

Illuminated

signal ring

Thermometer

- At the system ON / OFF switch, switch the boiler rst OFF and then ON again. There must not be any fault

present at the boiler.

- Press the reset button within the following 30 seconds and hold it down during the next steps.

- On (CGU) after 5 seconds the currently set gas type is displayed at the signal ring,

see table: Setting gas type.

On (CGG) after 5 seconds the currently set pipe length is displayed at the signal ring.

- Turn the heating water temperature selector towards the required gas type and check the setting by means of

the colour of the illuminated signal ring (see table adjusting the gas type).

- The adjustment will only be activated when the reset button is released.

- A successful conversion of the gas type is indicated by a triple ashing yellow/red (0.4 s ON / 1.0 s OFF) of the

signal ring.

Table: Adjusting the gas type

2. Adjusting the control unit:

Check the nozzle pressure after converting the gas type, otherwise material losses and

incorrect functions can occur.

Gas type Natural gas LPG

Illuminated ring display quickly ashing yellow quickly ashing red

Heating water temperature adjustment

l.h. closing r.h. end stop

Note: The adjustment of the gas type can also be done with the BM accessory controller

(Contractor parameter HG12, description see chapter

"Displaying / modifying control parameters with Wolf control accessories").

Note

Page 36

36

3062347_0309

Check nozzle pressure

3. Checking and adjusting the nozzle pressure:

- The gas red boiler must be switched OFF.

- Open the gas shut-off valve.

- Remove boiler casing cover and move the control unit

to the front.

- Undo the plug at the test nipple [2].

- (+) Connect the differential pressure tester with a hose

at test nipple [2].

- (-) Connect the differential pressure tester with a hose

at test port [3] of the combustion chamber casing (only

CGG-2(K)).

- Start the boiler by turning the heating water temperature

selector to position 8.

- Read off the nozzle pressure P

min

(at minimum boiler

output) within 180 seconds of ignition (soft start phase

= minimum output).

- Turn the heating water temperature selector further to

the emissions test position [chimney symbol].

- Read off the nozzle pressure P

max

(at maximum boiler

output) within the 15 minute test phase.

- Compare the actual values with those in the table.

- Close the plug again.

[2]

[3]

Gas pressures for gas throughput adjustment according to the nozzle pressure method

Table: Nozzle pressure table

Nozzle pressure in mbar (1013 ±0.5 mbar; 15 °C)

Gas red boilers

(gas fired combi

boilers)

Rated output P

in kW

Rated thermal

load

Q in kW

Natural gas H

W

1

= 45.7 MJ/m³

= 12.7 kWh/m³

LPG P

W1= 70.7 MJ/m³

= 19.6 kWh/m³

CGU-2(K) -18 18.0 20.2 12.7 26.7

15.3 17.3 9.5 20.0

13.0 14.8 7.1 14.8

10.9 12.5 5.2 10.7

8.0 8.8 3.2 5.8

CGU-2(K) -24 24.0 26.5 12.9 25.4

20.4 22.5 9.4 18.7

16.0 18.1 6.3 12.3

13.0 14.9 4.4 8.5

10.9 12.0 3.1 6.0

CGG-2(K) -18 18.0 19.7 15.9 36.0

15.3 16.7 11.4 25.9

13.0 14.2 8.8 19.3

10.9 12.0 6.3 14.1

8.0 8.5 3.3 7.5

CGG-2(K) -24 24.0 26.5 16.8 35.8

20.4 22.5 12.2 26.1

16.0 17.7 7.5 15.9

13.0 14.0 4.8 10.0

10.9 11.7 3.4 7.3

Page 37

37

3062347_0309

The gas red boiler corresponds to protection level IP X4D and can be installed in bathrooms in safety zone 1 and

more widely in accordance with VDE 0100 Part 701.

Boiler certication

1)

Balanced ue B32 required

Gas throughput table for gas volume adjustment according to the volume ow method

If the actual values fall outside these limits, readjust the gas valve (see the respective chapter),

otherwise material losses at the boiler and incorrect functions can result.

Otherwise continue under the point "Removing the test equipment again".

Note

Gas volume adjustment check

If the actual net caloric value is known, the gas volume can be checked with a stop watch and a gas meter

according to the following formula:

Gas throughput [l/min] =

Rated thermal load [kW] x 1 000

Net caloric value Hi [kWh/m³] x 60

Check nozzle pressure

Boiler Type Category Operating mode

To be connected to

Open

ue

Open

balanced

ue

Chimney

Air /

ue gas

chimney

Balanced

ue system

CGU-2(K)

B

11BS

II

2H3P

X X

CGG-2(K)

B32, C

12x

,

C

32x

, C

42x

II

2H3P

X

1)

X X

1)

X X

Gas red

boilers

(gas red

combi

boilers)

Thermal

output

kW

Rated

thermal

load

kW

Gas throughput in l/min (1013 mbar; 15 °C)

Natural gas H

with an operational net caloric value of H

i

in MJ/m³ (kWh/m³)

25.9(7. 2) 27.4(7. 6) 28. 8(8.0) 30. 2(8.4) 31. 7(8.8) 33. 1(9.2)

34.6(9. 6)

36.0(10. 0) 37. 4(10.4) 38. 9(10.8)

40.3(11. 2)

equivalent of a gross caloric value of HS in MJ/m³ (kWh/m³)

28.8(8.0) 30.2(8.4) 31.7(8.8) 33.8(9.4) 35.3(9.8) 36.7(10.2) 38.1(10.6) 40.0(11.1) 41.8(11.6) 43.2(12.0) 4.6(12.4)

18.0 20.2 47.0 44.5 42.3 40.3 38.4 36.8 35.2 33.8 32.5 31.3 30.2

15.3 17.2 40.0 37.9 36.0 34.3 32.8 31.3 30.0 28.8 27.7 26.7 25.7

CGU-2(K) -18 13.0 14.8 34.3 32.5 30.8 29.4 28.0 26.8 25.8 24.7 23.7 22.8 22.1

10.9 12.5 28.9 27.4 26.0 24.8 23.7 22.6 21.6 20.9 20.0 19.3 18.6

8.0 8.8 21.3 20.2 19.2 18.3 17.4 16.7 16.0 15.4 14.7 14.2 13.7

24.0 26.5 61.3 58.1 55.2 52.6 50.2 48.0 46.1 44.3 42.4 40.8 39.5

20.4 22.5 52.8 40.0 47.5 45.2 43.2 41.3 39.7 38.0 36.5 35.1 34.0

CGU-2(K) -24 16.0 18.1 41.9 39.7 37.7 35.9 34.3 32.8 31.5 30.2 29.0 27.9 27.0

13.0 14.9 34.5 32.7 31.0 29.6 28.2 27.0 25.9 24.8 23.9 23.0 22.2

10.9 12.0 28.9 27.4 26.0 24.8 23.7 22.6 21.8 20.9 20.0 19.3 18.6

18.0 19.7 45.6 43.5 41.0 39.9 37.3 35.7 34.1 32.8 31.5 30.4 29.3

15.3 16.7 38.6 36.6 34.8 33.1 31.7 30.2 29.0 27.8 26.7 25.8 24.8

CGG-2(K) -18 13.0 14.2 32.8 31.1 29.6 28.2 26.9 25.8 24.8 23.7 22.8 21.9 21.2

10.9 12.0 27.8 26.3 25.0 23.8 22.7 21.8 20.6 20.0 19.3 18.5 17.9

8.0 8.5 19.6 18.6 17.7 16.8 16.1 15.4 14.8 14.2 13.6 13.1 12.7

24.0 26.5 61.3 58.2 55.2 52.6 50.2 48.0 49.0 44.2 42.5 40.9 39.4

20.4 22.5 52.1 49.3 46.9 44.6 42.6 40.8 39.1 37.5 36.6 34.8 33.5

CGG-2(K) -24 16.0 17.7 41.0 38.8 36.9 35.1 33.5 32.1 30.8 29.5 28.4 27.4 26.3

13.0 14.0 32.4 30.7 29.2 27.7 26.5 25.4 24.3 23.3 22.4 21.6 20.9

10.9 11.7 27.0 25.6 24.4 23.2 22.1 21.2 20.3 19.5 18.8 18.1 17.4

Page 38

38

3062347_0309

Readjusting the gas valve:

Carry out the nozzle pressure adjustment in the following

order:

- Remove transparent plastic cap [4] from the gas

combination valve.

- Operate the boiler in emissions test mode (P

max

).

-

Adjust the maximum pressure at nut [5] (spanner size 10).

- Tightening increases the pressure.

- Releasing reduces the pressure.

- Pull the cable from the gas valve. The boiler goes to

minimum output (P

min

).

- Adjust the minimum pressure at screw [6] in accordance

with nozzle pressure table (Philips screwdriver 6x1);

during this adjustment, hold nut [5] tightly.

- Turning right increases the pressure.

- Turning left reduces the pressure.

- Replace the plastic cap [4].

- Reconnect the cable.

[4]

[6]

[5]

4. Identication:

Carry out the re-designation of the gas type in

accordance with the instructions supplied with the

conversion kit.

Remove the test equipment:

Readjust the gas valve

Checking / adjusting the nozzle pressure

- Shut down the boiler. Close the gas shut-off valve.

- Pull the hoses off and retighten the test nipple [2] and

the test port [3]. Open the gas shut-off valve.

Check gas tightness of the test nipple,

otherwise there is a danger of gas escaping

and consequent damage to health.

[2]

Page 39

39

3062347_0309

Flue gas

pipe length

CGG-2(K)

Position

Rotary selector

Temperature

selection

DHW

Illuminated ring

display

(green)

Calculated length

(m)

1

1

1x0.4 s ON/OFF

1x1.5 s pause

1.3 - 1.5

2 2

2x0.4 s ON/OFF

1x1.5 s pause

1.5 - 2.5

3 3

3x0.4 s ON/OFF

1x1.5 s pause

2.5 - 3.5

4*

(factory setting)

4

4x0.4 s ON/OFF

1x1.5 s pause

3.5 - 4.0

5* 5

5x0.4 s ON/OFF

1x1.5 s pause

4.0 - 5.0

ON / OFF switch

DHW temperature

selector

Pressure

gauge

Reset

button

Heating water

temperature

selector

Illuminated

signal ring

Thermometer

- At the system ON / OFF switch, switch the boiler rst OFF and then ON again. There must not be any fault

present at the boiler.

- Press the reset button within the following 30 seconds and hold it down during the next steps.

- After 5 seconds, the illuminated signal ring indicates the currently selected gas type

(see table: Pipe length adjustment).

- Turn the DHW temperature selector towards the required pipe length and check the setting by means of the

ash sequence of the illuminated signal ring.

- The adjustment will only be activated when the reset button is released.

- A successful conversion of the gas type is indicated by a triple ashing green (0.4 s ON / 1.0 s OFF)

of the signal ring.

Adjusting the ue lengths CGG-2(K)

Note: The adjustment of the ue pipe length can also be done with the BM accessory controller

(Contractor parameter HG12, description see chapter

"Displaying / modifying control parameters with Wolf control accessories").

* Operation only with condensate drain pipe in the balanced ue routing (see accessories)

Table: Pipe length adjustment

Page 40

40

3062347_0309

Flue gas test CGU-2(K) / CGG-2(K)

The ue gas emissions must be tested with the boiler

closed.

- Remove the screw from the test port "inlet air".

- Insert the test probe until it bottoms out.

- Start the boiler and turn the heating water temperature

selector to emissions test [chimney sweep symbol].

(The illuminated status display ring ashes yellow).

- Test the temperature and CO

2

or O2 value.

The balanced ue is not gas-tight if the CO2 content

≥ 0.3%; rectify the leak.

- After the test has been completed, switch the boiler

OFF, remove the test probe and close the test port.

Ensure the screws are seated rmly.

Testing the combustion air CGG-2

Vertical boiler ue connection

- Remove the screw from the test port "ue gas".

- Insert the test probe into the centre of the pipe.

- Start the boiler and turn the heating water temperature

selector to emissions test [chimney sweep symbol].

(The illuminated status display ring ashes yellow).