Page 1

Document no.: 3063527_201308 Subject to technical modications. GB

Wolf GmbH · Postfach 1380 · D-84048 Mainburg · Tel. +49 (0)8751/74-0 · Fax +49 (0)8751/741600 · Internet: www.wolf-heiztechnik.de

Operating instructions

Control unit - CGL

20.0 °C

Friday

31/10/08

12 : 16

Zone 1

Page 2

3063527_2013082

Table of contents

Safety instructions, service / repair .............................................................................. 4

Standards and regulations ........................................................................................... 5

Unit description / disposaland recycling ..................................................................... 6

Zoning .............................................................................................................................. 7

Installation as an external remote control ................................................................... 8

Electrical connection ..................................................................................................... 8

BML overview ................................................................................................................. 9

Control level 1 .......................................................................................................... 10-13

L.h. rotary selector, program selection ....................................................................... 10

R.h. rotary selector ..................................................................................................... 10

Program selection ................................................................................................. 10-11

Automatic mode ................................................................................................... 10

Manual mode.........................................................................................................11

Ventilation mode ....................................................................................................11

Standby mode .......................................................................................................11

Info key ................................................................................................................. 11-12

Temperature selection key ......................................................................................... 12

Speed adjustment key ............................................................................................... 12

Display explained ......................................................................................................... 13

Control level 2 .......................................................................................................... 14-24

Main menu overview .................................................................................................. 14

Displays ..................................................................................................................... 15

Acknowledge faults .................................................................................................... 15

Basic settings ............................................................................................................. 16

Language ............................................................................................................. 17

Date ...................................................................................................................... 17

Time ..................................................................................................................... 17

Automatic summertime......................................................................................... 18

Key lock ................................................................................................................ 18

Zone Z1 ................................................................................................................ 19

Day temperature................................................................................................... 19

Economy temperature for heating ........................................................................ 19

Backup temperature for heating ........................................................................... 19

Speed adjustment ................................................................................................ 20

Setback mode program ........................................................................................ 20

Supply air minimum limit ...................................................................................... 20

Enable night ventilation ........................................................................................ 21

Time program ............................................................................................................. 21

Switching times, factory setting ............................................................................ 22

Holiday program ......................................................................................................... 23

Specialist .................................................................................................................... 24

Page 3

3063527_201308

3

Control level 3 .......................................................................................................... 24-32

Code scan .................................................................................................................. 24

New conguration / Sensor check ............................................................................. 24

Zone designat ............................................................................................................ 24

Ventilation unit parameters ........................................................................................ 25

Relay test ................................................................................................................... 25

Zone reset .................................................................................................................. 25

Setting parameters ....................................................................................................... 26

Specialist parameter list - overview ...................................................................... 26-27

Parameters / function description ......................................................................... 28-32

Master reset / standard functions .......................................................................... 33-34

Motor protection ......................................................................................................... 33

Room frost protection ................................................................................................. 33

Central heating backup mode .................................................................................... 34

Supply air minimum limit for heating .......................................................................... 34

Filter contamination fault trigger ................................................................................. 34

Active lter monitor .................................................................................................... 34

Fan run-on time .......................................................................................................... 34

External ON/OFF ....................................................................................................... 34

Additional functions ................................................................................................ 34-36

Room/supply air cascade control ............................................................................... 35

Night ventilation ......................................................................................................... 35

Preheater coil, HR ice guard ...................................................................................... 36

Condensate overow ................................................................................................. 36

Summer shutdown ..................................................................................................... 36

Heat recovery ............................................................................................................. 36

HR ice guard .............................................................................................................. 36

Fire alarm ................................................................................................................... 36

CO2 control ..................................................................................................... 31, 32, 37

Sensor resistances....................................................................................................... 37

Specication ................................................................................................................. 38

System conguration ................................................................................................... 39

Terminal assignments .................................................................................................. 40

Fault messages........................................................................................................ 41-43

Wiring diagram ........................................................................................................ 44-47

Menu structure ......................................................................................................... 48-51

Table of contents

Page 4

3063527_2013084

Safety instructions

The following symbols are used in this instruction manual. This

important information concerns personal as well as operational

safety.

"Safety instructions" must be complied with to the letter, to prevent

risks and injuries to individuals and material losses on the appliance.

Danger through 'live' electrical components!

Please note: Turn off the ON/OFF switch before removing the

casing.

Never touch electrical components or contacts when the ON/OFF

switch is in the ON position. This would lead to a risk of electrocution

that may lead to injury or death.

"Note" indicates technical instructions that must be observed to

prevent material losses and equipment malfunctions.

Even when the unit has been shut down, voltage will still be present

at terminals and connections of the EC fans. This means there is

a risk of electric shock that could result in injury or death.

Never touch the EC fans until ve minutes after disconnecting the

power across all poles have elapsed.

Please note

Safety instructions

Service / Repair

- Regularly check the perfect function of all electrical equipment.

- Only qualied personnel may remove faults or repair damage.

- Only replace faulty components or equipment with original Wolf

spare parts.

- Observe specied electrical fuse ratings (see specication).

Any damage or loss resulting from technical modications to Wolf

control units is excluded from our warranty.

Please note

Service / Repair

Page 5

3063527_201308

5

Standards / Regulations

- According to DIN EN 50110-1, only qualied electricians may

carry out the installation and commissioning of the ventilation

control unit and connected accessories.

- Observe all regulations stipulated by your local power supply

utility and all VDE or local regulations.

- DIN VDE 0100 regulations regarding the installation of high

voltage systems up to 1000 V

- DIN VDE 0105-100 Operation of electrical plants

- Use exclusively original Wolf accessories (electric heater coil,

condensate pump, servomotors, etc.), otherwise the Wolf

warranty will be void.

Only use cables that meet local wiring regulations with regard to

voltage, current, insulation material, load etc. Always t an earth

conductor.

Power supply:

An externally accessible, omnipolar isolator must be installed

with the appliance. Power cable, external: 3 x 2.5 mm².

Fuse/MCB protection: 230 V/16 A.

RCD

Only AC/DC-sensitive RCDs of type B with 300 mA rating are

permissible.

Connect the power cable and accessories in accordance with

the wiring diagram provided.

A high leakage current can be expected due to the EC

motors. Ensure that a secure earth connection is in place

before connecting the power supply and commencing

commissioning.

For Austria, the ÖVE regulations and local building regulations

apply.

Installation /

Commissioning

Warnings - Removing, bypassing or disabling of safety and monitoring

equipment is not permissible.

- The system must only be operated if it is in perfect technical

condition. Immediately have any faults and damage that may

impact on safety removed.

The appliance and control unit accessories comply with the

following regulations:

EC Directives

- 2006/95/EC Low Voltage Directive

- 2004/108/EC EMC Directive

EN Standards

- EN 60730-1 Automatic electrical controls for household and

similar use

- EN 60730-2-11 Particular requirements for temperature

sensing controls

- EN 61000-6-2 EMC Immunity for industrial environments

- EN 61000-6-3 EMC Emission standard for residential

environments

Standards / Directives

Page 6

3063527_2013086

The control panel is designed for regulating large area ventilation

units with variable speed EC motors.

Other functions

- HR control 0 - 10 V

- CO2-based fan speed matching

- Electric reheater coil: variable control 0 - 10 V

- Room / supply air cascade control or supply air control

- Night ventilation

- Electric preheater coil:

Switching ON/OFF by outside temperature

The control unit can be operated with the programming module

for ventilation units (BML programming module, material number

2744634). The BML programming module can also be used to

program switching times, to modify parameters and to display

fault messages.

The control unit has an eBUS interface and can therefore be fully

integrated into the Wolf control system.

There can only be one BML in any one system (eBUS).

Up to 7 CGL units can be operated with one programming unit.

Please note

Unit description

Unit description

Observe the following information regarding the disposal of faulty

system components or the system at the end of its service life:

Dispose of all components in accordance with applicable

regulations, i.e. separate material groups correctly. The aim should

be the maximum possible amount of basic materials recycled and

the lowest possible environmental impact.

Never dispose of electrical or electronic scrap through household

waste, but recycle it appropriately.

Generally, dispose of materials in the most environmentally

responsible manner according to environmental, recycling and

disposal standards.

Disposal and recycling

The ventilation unit is designed for air intake temperatures between

-20 °C and +40 °C. Only store the ventilation unit in dry conditions

at an ambient temperature between -25 °C and +55 °C.

Wolf CGL ventilation units are designed to heat and lter normal

air. The use of these units in wet rooms or rooms with explosive

atmospheres is not permissible. Handling very dusty or aggressive

media is not permissible.

Any on-site modication or unintended use of the unit is not

permissible and Wolf GmbH accepts no liability for any damage

caused as a result.

Intended use

Page 7

3063527_201308

7

Zoning

Zoning

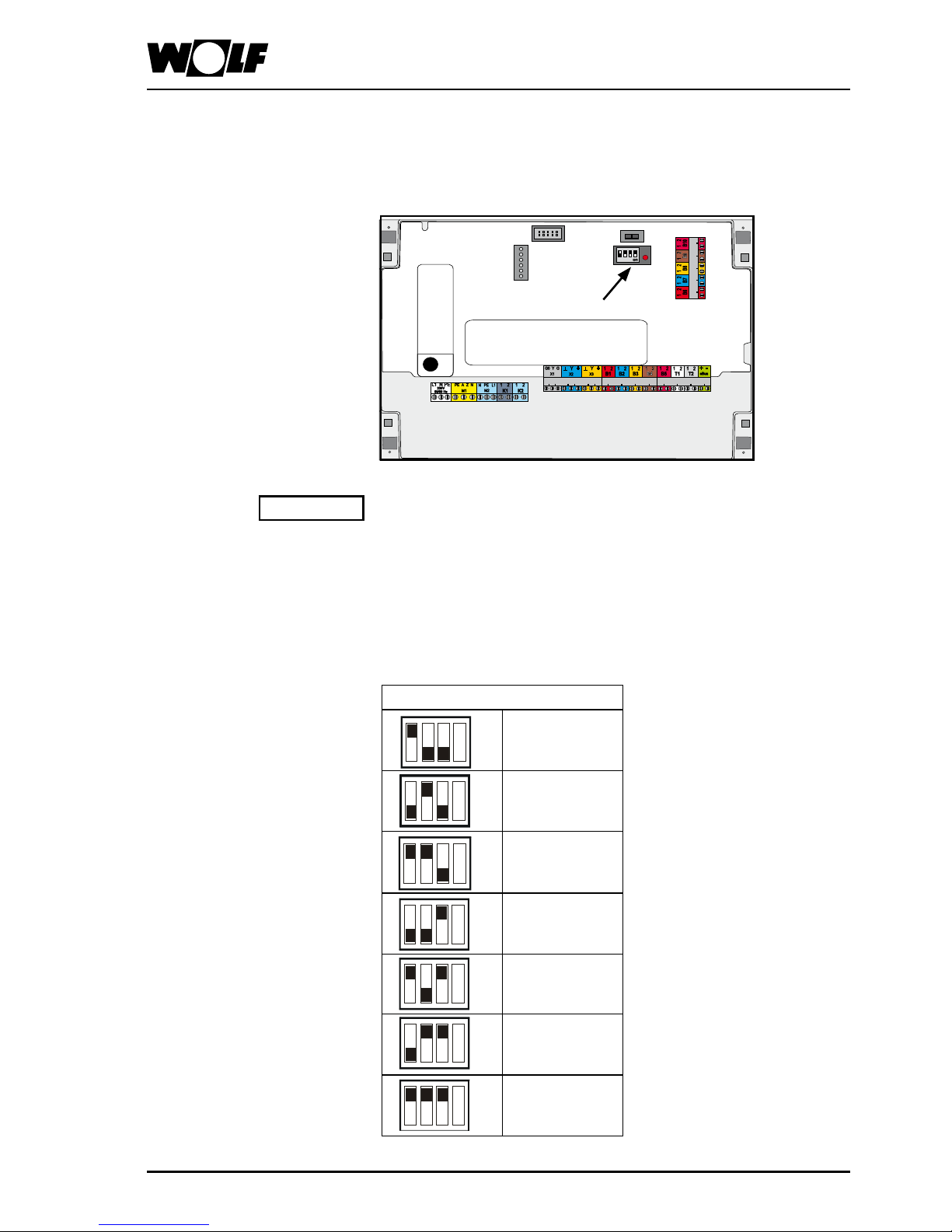

When more than one CGL is controlled with one programming unit,

the zone for each appliance must be set using the DIP switches

on the control PCB (in the control panel).

If only one zone is to be connected, the following chapter can

be skipped.

Multiple zones in one

system

The three switches on the left hand side of the 4-position DIP switch

can be used to assign the ventilation unit to a zone.

Up to seven zones are possible in one system.

Zone setting

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7

Fig.:

DIP switches on the

control PCB

DIP switches

Control PCB

X1

Never pull out the coding card X1, otherwise malfunctions may

result.

Please note

Page 8

3063527_2013088

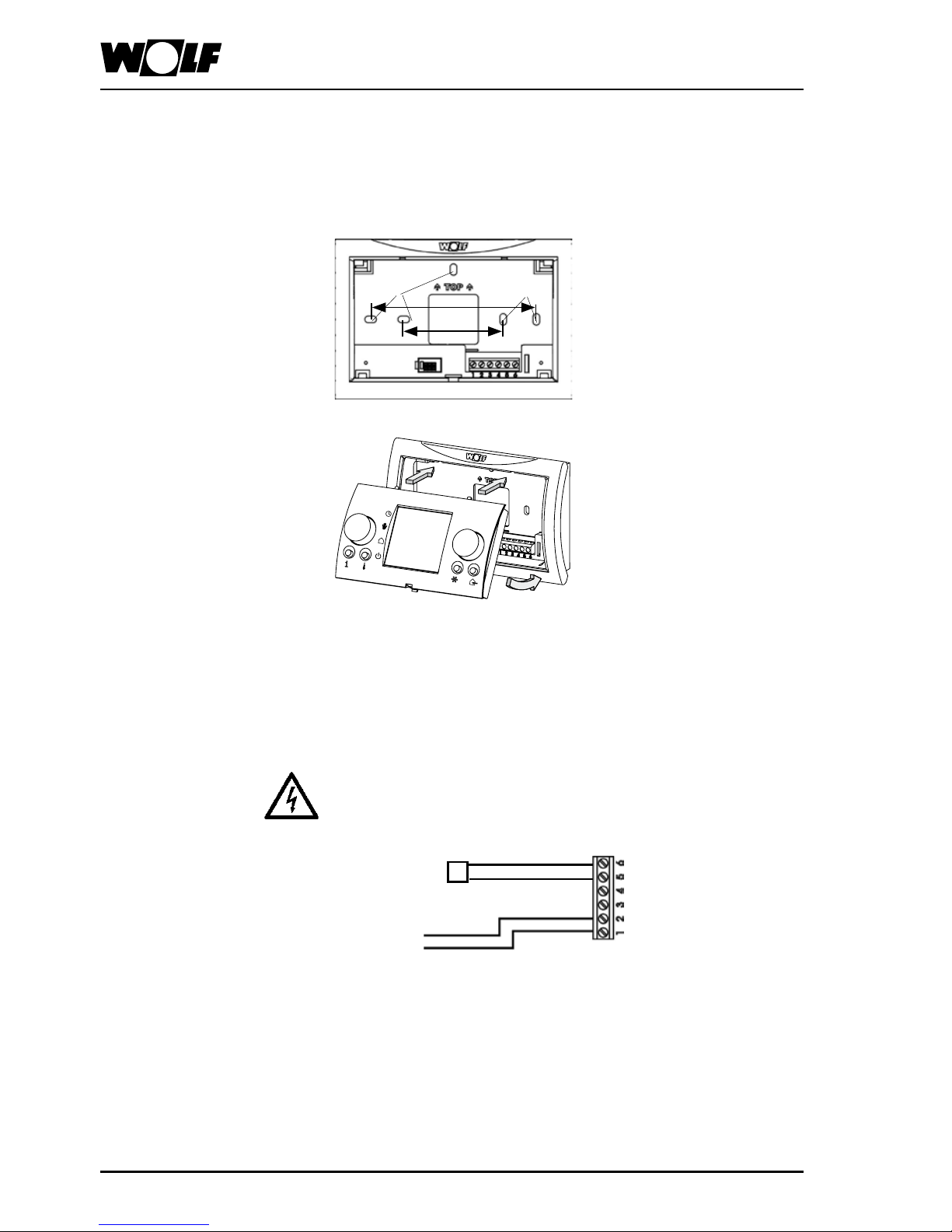

Installation as an external remote

control

Wall mounting base

installation

- Remove the wall mounting base from its packaging.

- Secure the wall mounting base on a ush-mounting box

(Ø 55 mm) or directly on the wall.

Wall mounting base

Fixing holes

Fixing holes

Installation of BML on wall mounting base

Wall mounting base

Mat. no. 2744275

60

100

Electrical connection of

remote control

- The electrical connection must be carried out only by a qualied

electrician.

- Never route sensor leads alongside mains power cables.

- Use the repair switch to switch off the power supply

- Wire the wall mounting base with a four-core cable (minimum

cross-section 0.5 mm²) in accordance with the diagram

eBUS

Terminal strip

Wall mounting base

+ -

+ -

Recommended cables

and

minimum cable

cross-sections:

H05VV-F 3 x 2.5 mm² power cable (230 V)

H05VV-F 4 x 1.0 mm² Open/Close servomotor 230 V

H05VV-F 2 x 0.5 mm² BUS cable (<400 m length)

Fuse/MCB protection: Power supply 230 V 1 x 16 A

ϑ

Outside temperature sensor

Page 9

3063527_201308

9

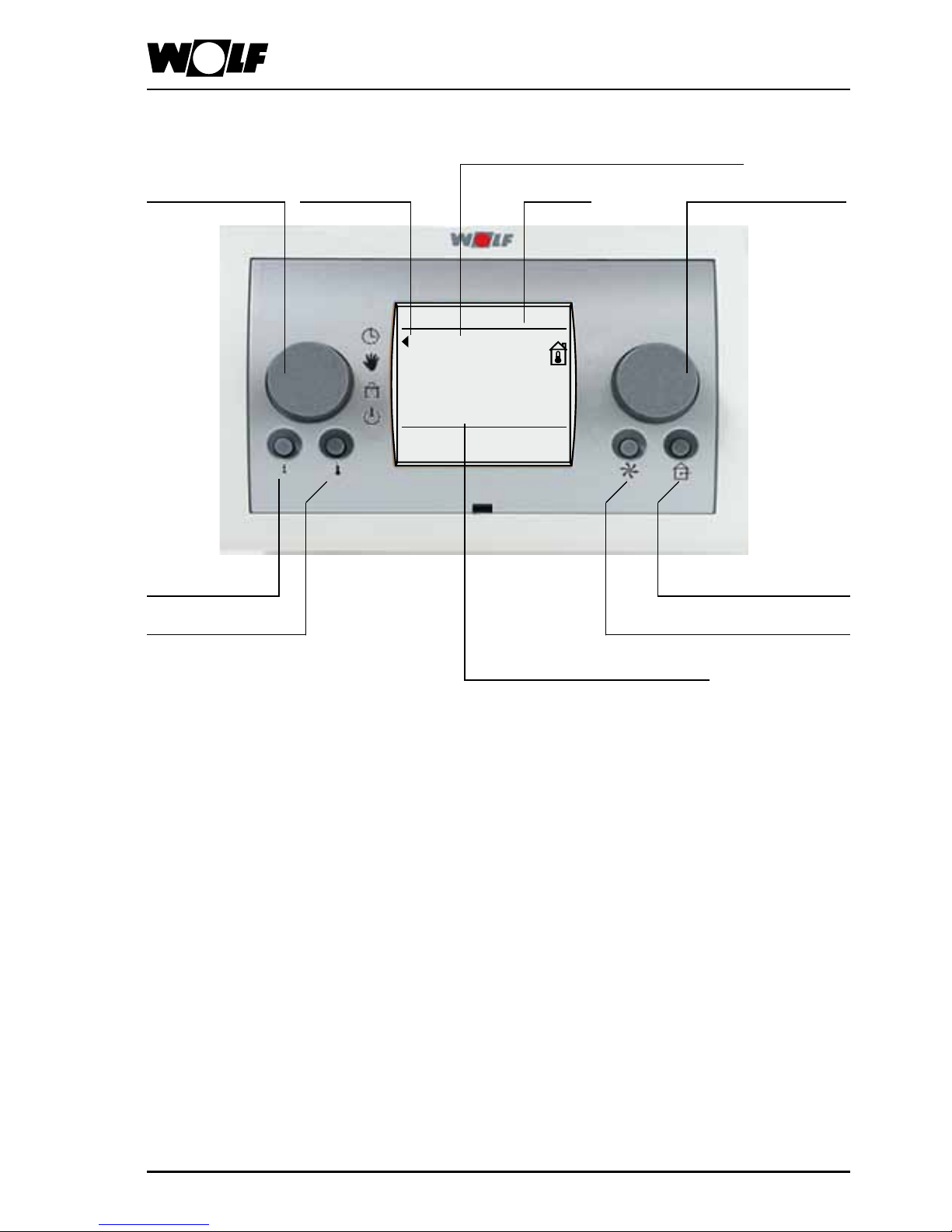

BML overview

L.h. rotary selector R.h. rotary selector

Info key

Temperature

adjustment

Speed adjustment

DisplayStatus indicator

Minimum fresh air proportion

(no function)

20.0 °C

Friday

31/10/08

12 : 16

Zone 1

Room temperature / extract air temperature

Time alternating with

outside temperature

Page 10

3063527_20130810

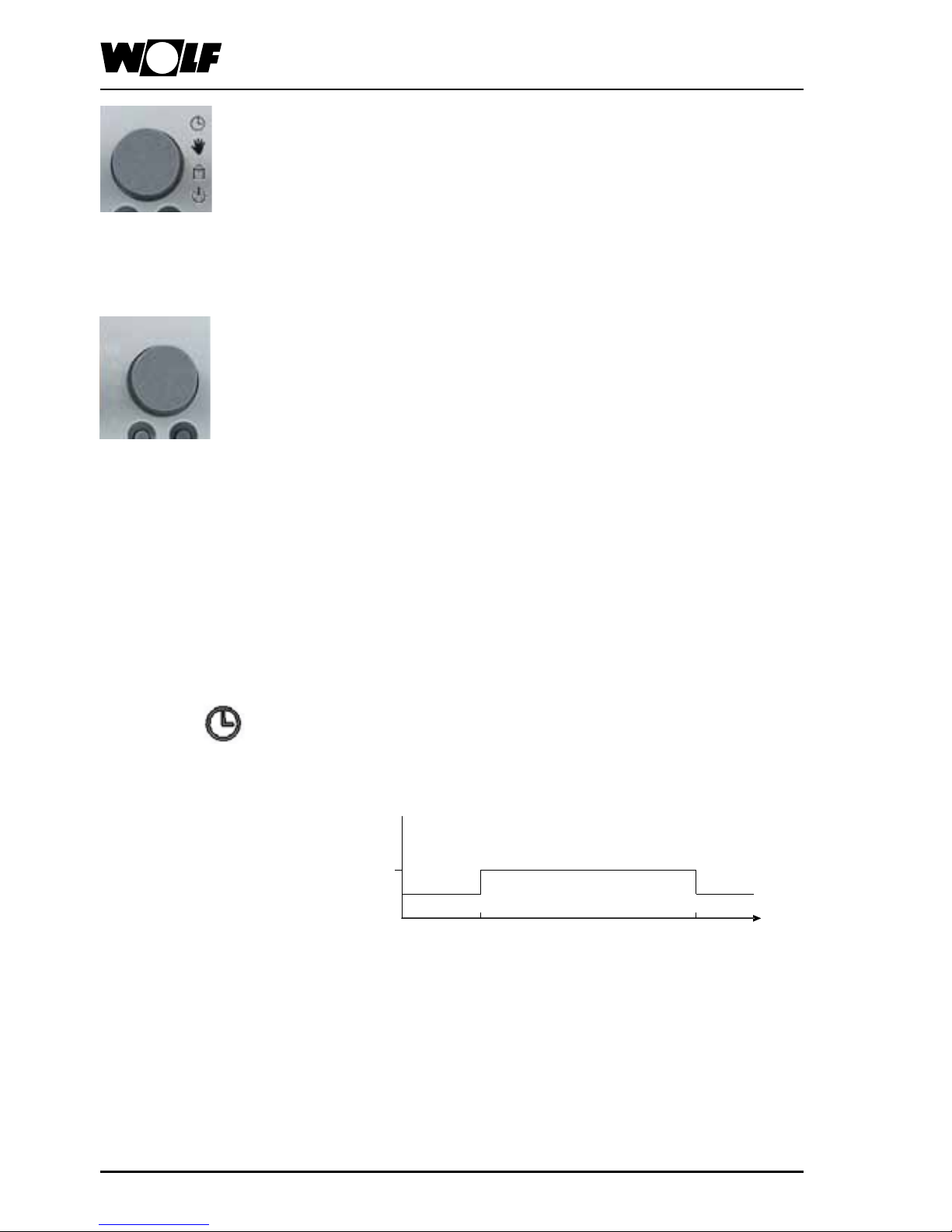

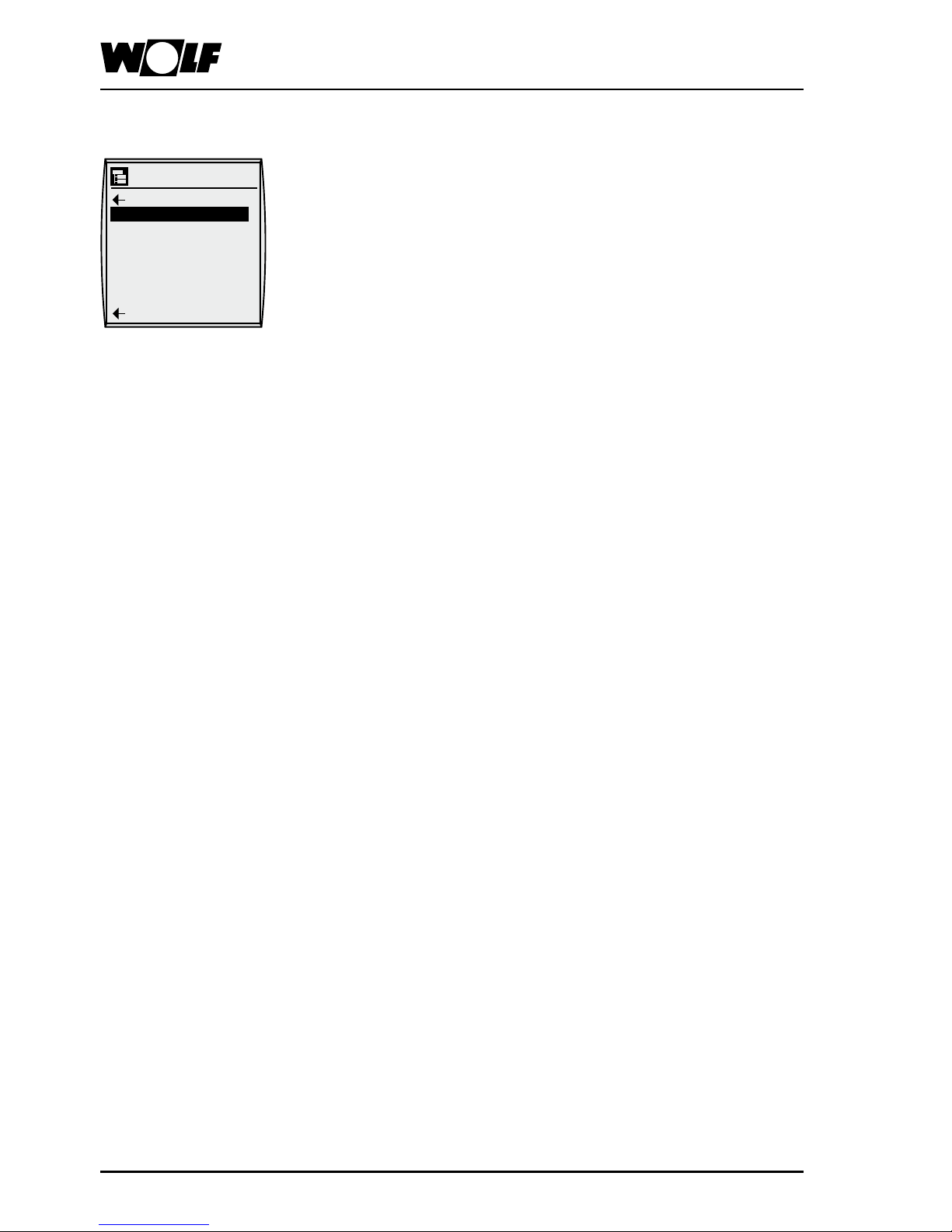

Program selection

You can select the programs listed below by turning the l.h. rotary

selector.

The arrow on the l.h. edge of the display points to the selected

program.

R.h. rotary selector

The right hand rotary selector is used for all programming steps.

Turning the rotary selector enables you to select the required

menu item.

Pressing the r.h. rotary selector conrms the programming step.

L.h. rotary selector, program selection

This rotary selector enables the program to be selected. The rotary

selector can be rotated indenitely, without an end stop. You will

feel it click into each position as it rotates. The selected function

is indicated by an arrow in the display.

Control level 1

Automatic mode

Ventilation according to a time switch program. Call-up of HR,

reheater and fan according to demand.

As shown in the diagram, you can preselect the operating mode

via the time program when the system has been switched off.

06:00

22:00

On

Off

„Day mode”

Time

Setback mode program

Selection:

- Economy operation

- Backup mode (factory setting)

- Standby

- Summer ventilation

Backup mode Backup mode

07:00

14:00

Page 11

3063527_201308

11

Control level 1

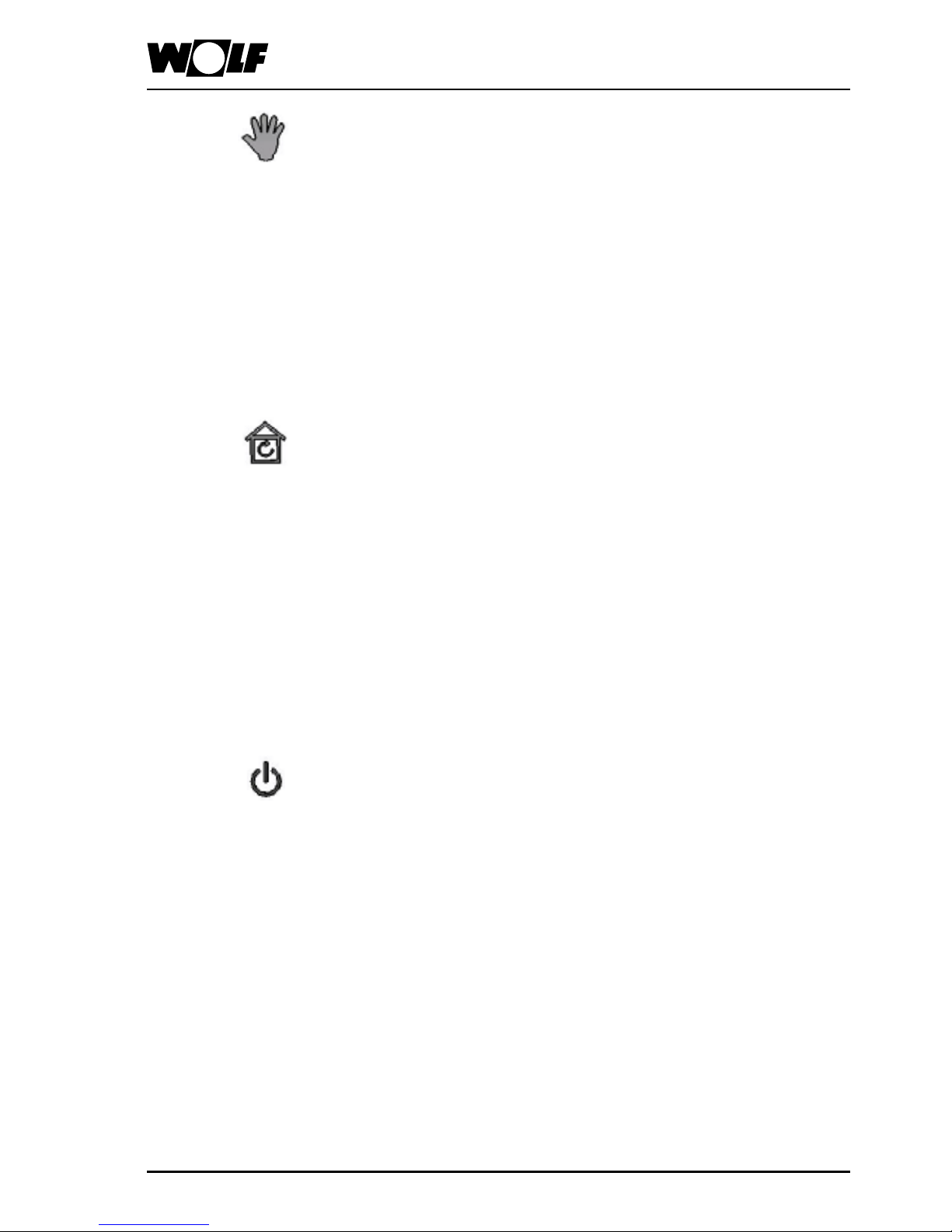

Manual mode

The ventilation time program is inactive. With this setting, ventilation

is enabled 24 hours a day. The set value from day mode is active.

The speed can be preselected manually or varied according to

CO

2

content. Activation of HR and reheater according to demand.

Ventilation mode

Ventilation according to the time switch program.

Fans start, and the speed of the ventilation units can be preselected

manually. This can be used to ensure an adequate air ow rate

through the room during the warmer months.

HR and the reheater are switched off.

The outside air dampers are opened.

Ventilation is disabled below an outside temperature of 7 °C.

Standby mode

Fan and actuating signal are switched off; room frost protection

remains active.

System start or stop is actuated via an air quality sensor (parameter

LM163 must be set to ON).

The CO2 sensor should be placed inside the room for this operating

mode.

Page 12

3063527_20130812

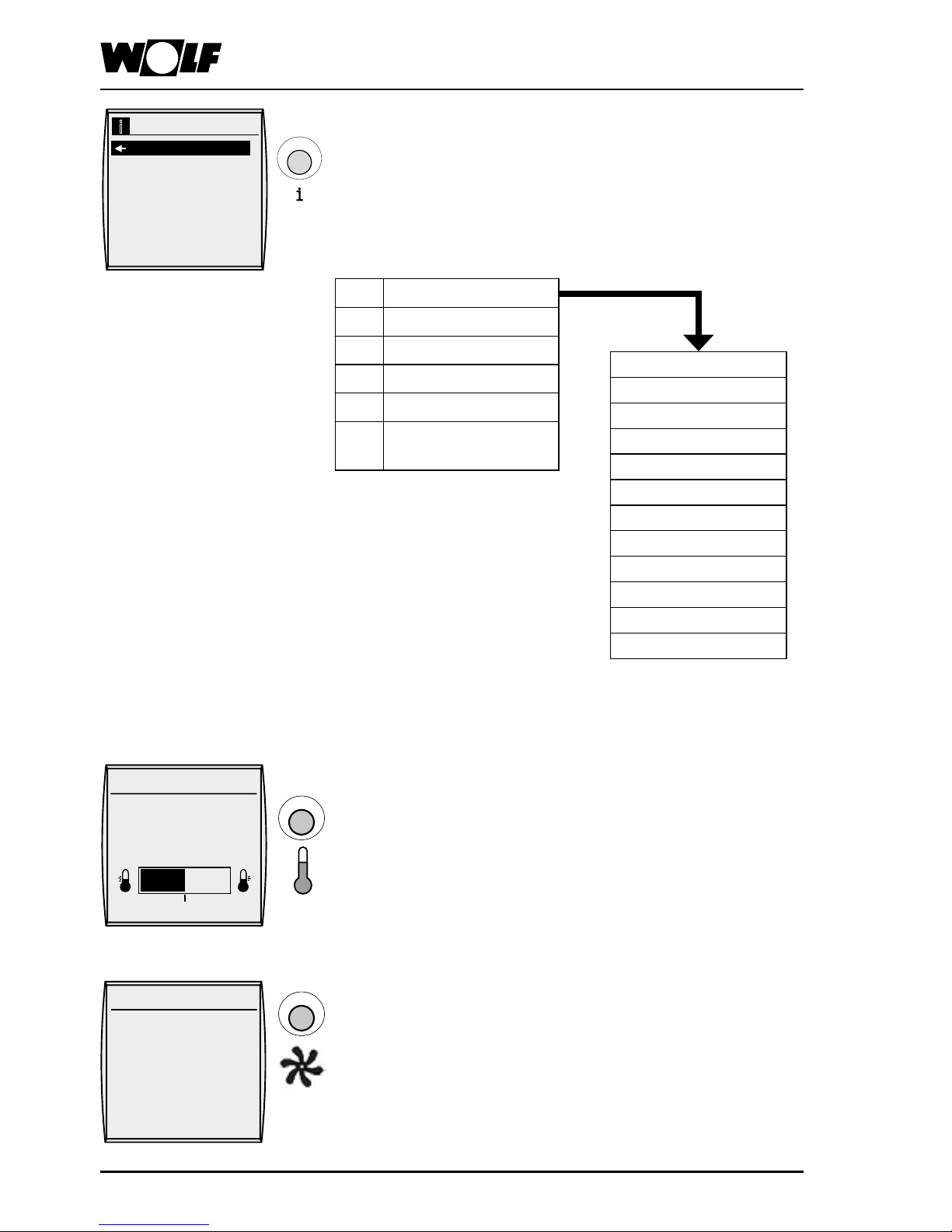

Control level 1

i

1 Operating mode

2 Current program

3 Extract air temp

4 Set room heating

5 Outside temperature

6 Actual vent air

temperature

Zone 1

Back

Operating mode

Ex. air temp.

Set room htg.

Outside temp

Act. vent air t

Curr program

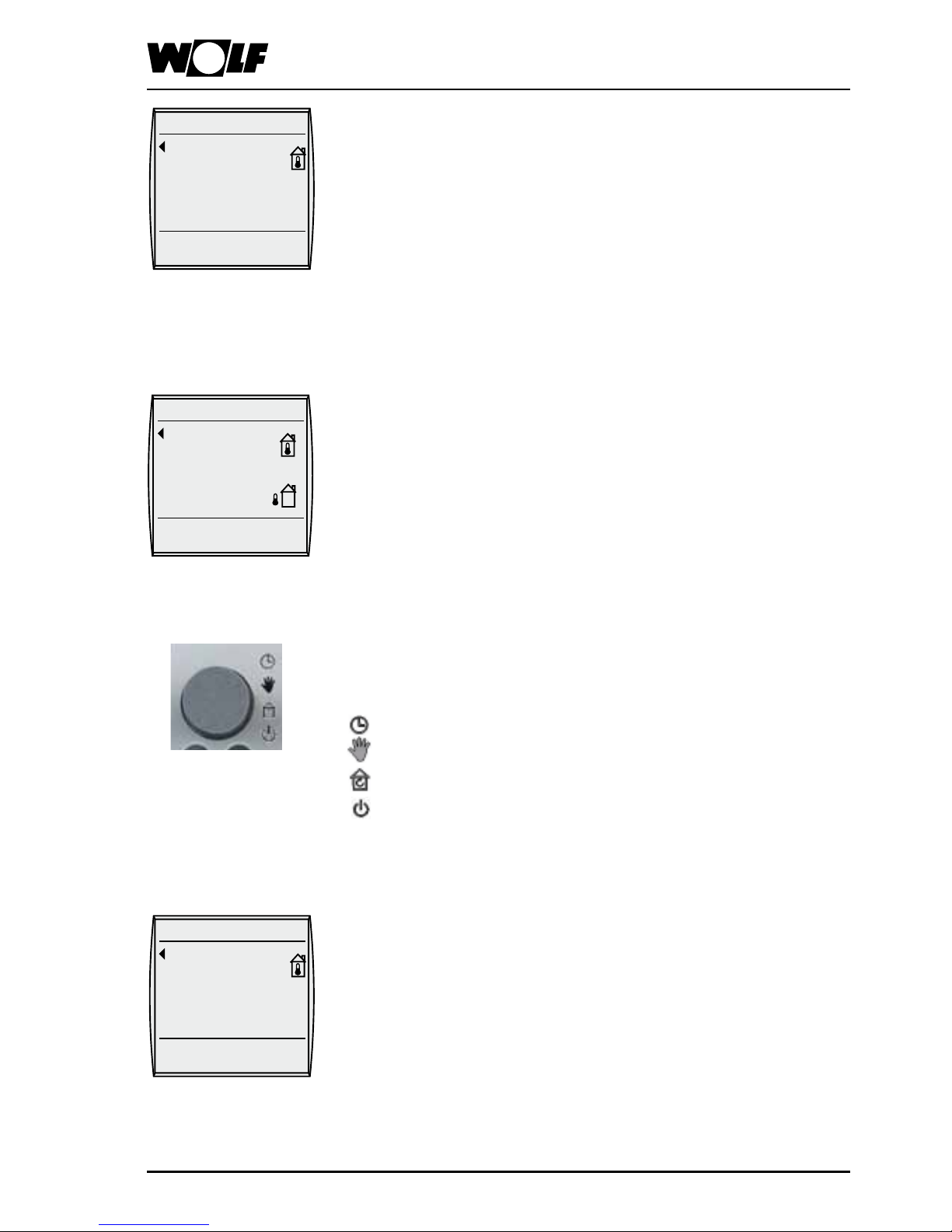

Temperature selection key

Please note:

Pressing the key enables quick correction of the set room

temperature (or the supply/extract air temperature). You can turn

the r.h. rotary selector to raise or lower the required temperature

by up to 4 K. The bar on the display moves to the left or the right

depending on the direction the selector is turned. Press the r.h.

rotary selector to conrm the modied value.

Zone 1

Temperature

selection

0.0 K

0

Speed adjustment key

Please note:

Pressing the key displays the current speed. You can then turn the

r.h. rotary selector to modify the speed to a value between 30 and

100 %. Press the r.h. rotary selector to conrm the modied value.

The speed preselected here (the base speed) cannot be reduced

by the CO2 sensor.

Zone 1

Speed adjust

30.0 %

Info key

Please note: In the case of more than one zone (up to 7), rst

select the zone for which the values are to be scanned.

You can use the Info key to display current temperatures and system

values. Turning the r.h. rotary selector displays the following values.

Fire alarm

Fault zone

Frost protection room

External ON/OFF

Filter check

Standby

Summer ventilation

VA min limit heating

Night ventilation

Room temperature reached

Outside temperature shutdn

Control operation

Page 13

3063527_201308

13

Display explained

Room temperature, supply air temperature, extract air

temperature

The temperature shown on the display depends on the temperature

sensors connected. The sensor value displayed is as follows:

Only supply air sensor connected: display of supply air temperature

Only room sensor connected: display of room temperature

Supply air sensor + room sensor connected:

display of room temperature

Supply air sensor + extract air sensor connected:

display of extract air temperature

Time and outside temperature

The time and the outside temperature are displayed alternately

(subject to an outside temperature sensor being installed).

Day / date

Display of the currently set day and date.

Status display

Symbols indicate the current operating state of your

ventilation system.

Clock = ventilation mode (heating) with time program

Manual = ventilation mode (heating) without time program

House = ventilation mode (summer mode)

with time program

Standby = system off or ventilation

(heating) ON/OFF via CO

2

sensor if

parameter LM163 set to ON

Indication of the current zone

If more than one zone is connected (up to 7)

you can select the zone you want by turning the r.h. rotary

selector.

20.0 °C

Friday

31/10/08

12 : 16

Zone 1

20.0 °C

Friday

31/10/08

10.0 °C

Zone 1

20.0 °C

Friday

31/10/08

12 : 16

Zone 1

Page 14

3063527_20130814

Control level 2 - Main menu

Back to the default display

Pressing the r.h. rotary selector calls up control level 2, where

you can select the menu levels shown in the overview by turning

the rotary selector clockwise. After selecting the parameter, you

enter the submenu by pressing the r.h. rotary selector again.

Pressing the Info key takes you back to the default display,

irrespective of which submenu is currently displayed.

The system also returns to the default display automatically when

no adjustment is made for more than one minute.

Overview

All available set and actual temperatures, the operating mode and

other system values can be displayed.

This is explained in the „Displays“ chapter.

Displays

Acknowledging (resetting) faults that have occurred.

This is explained in the „Acknowledge faults.“ chapter.

Acknowledge faults

Setting of the most important parameters in the ventilation system

such as time, date, room temperature, night temperature, supply

air minimum limit for heating, backup temperature, night setback,

and night ventilation.

Setting options and explanations of the individual parameters are

given in the "Basic settings" chapter.

Basic settings

Modication of the time switch programs for heating operation.

Setting options and how to modify the individual time programs

are explained in the "Time programs" chapter.

Time programs

Setting the specialist's parameters for the ventilation system.

Setting options and explanations of the individual parameters are

given in the "Specialist" chapter.

Specialist

Five different holiday programs can be set. The holiday program

takes precedence over the normal switching time.

When the holiday program ends, the system returns to the previously

set time program automatically.

Holiday program

Main menu

Back

Fault ackn.

Basic settings

Time program

Holiday prog

Specialist

Back

Displays

Page 15

3063527_201308

15

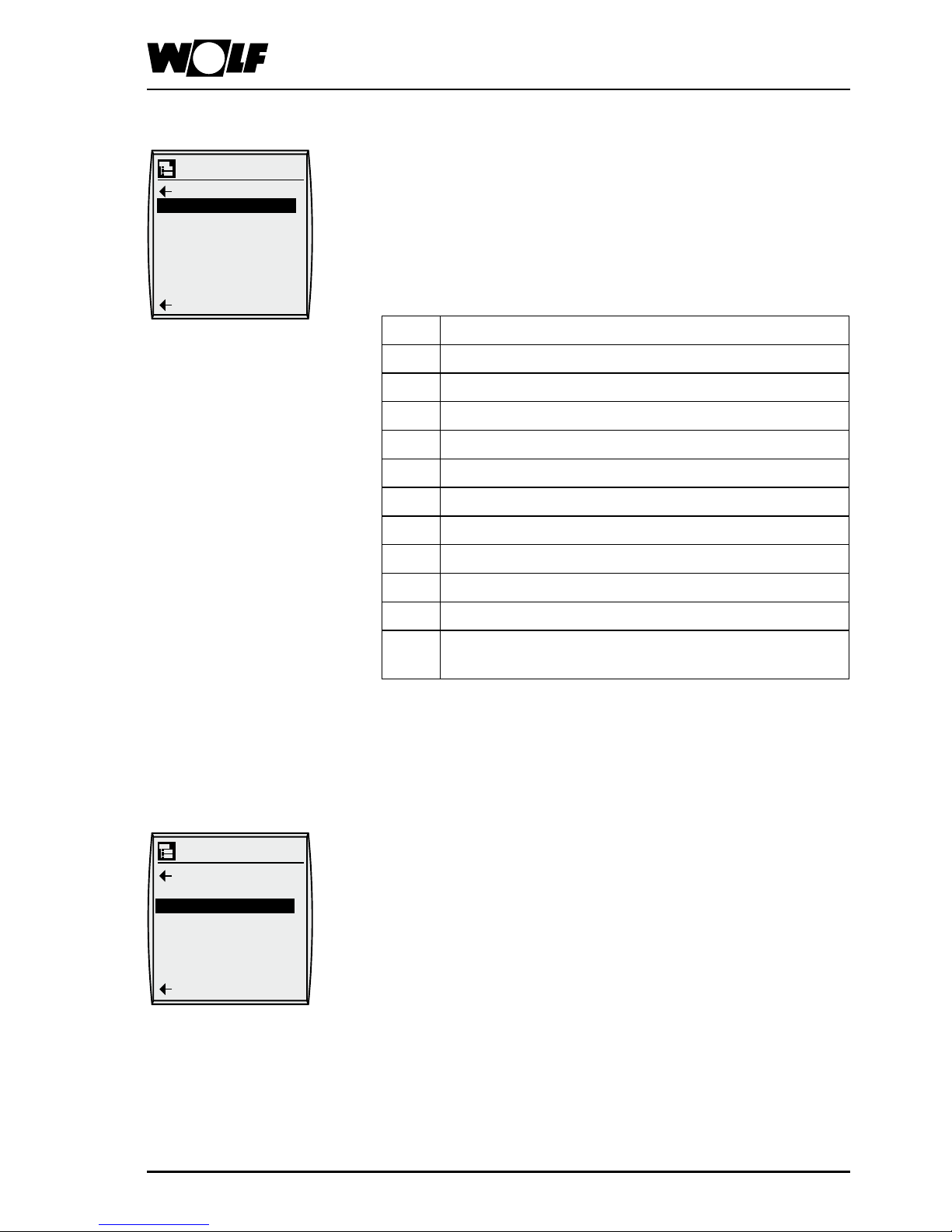

Displays Press the r.h. rotary selector to change to control level 2.

Turn the r.h. rotary selector clockwise to select the „Displays“

menu level and conrm the selection by pressing the r.h. rotary

selector again.

You can now display the following values in sequence by

turning the r.h. rotary selector.

Always select the zone rst in order to scan its values.

Control level 2 - Displays - Fault acknowledge

1 Operating mode

2 Current program

3 Extract air temperature

4 Set room heating

5 Outside temperature

6 Actual vent air temperature

7 Set vent air temperature

8 Motor speed

9 Heating mixer

10 Heat recovery

11 Conguration

12 Softwareversion LM x

Softwareversion LM y

Any sensors that are not connected are skipped, as only

available values can be displayed.

Acknowledge faults

Press the r.h. rotary selector to change to control level 2. Turn

the r.h. rotary selector clockwise to select the „Acknowledge

faults“ menu level and acknowledge faults by pressing the r.h.

rotary selector again.

After acknowledging faults, the display returns to the standard

mask immediately.

Main menu

Back

Fault ackn.

Basic settings

Time program

Holiday prog

Specialist

Back

Displays

Main menu

Back

Fault ackn.

Basic settings

Time program

Holiday prog

Specialist

Back

Displays

Page 16

3063527_20130816

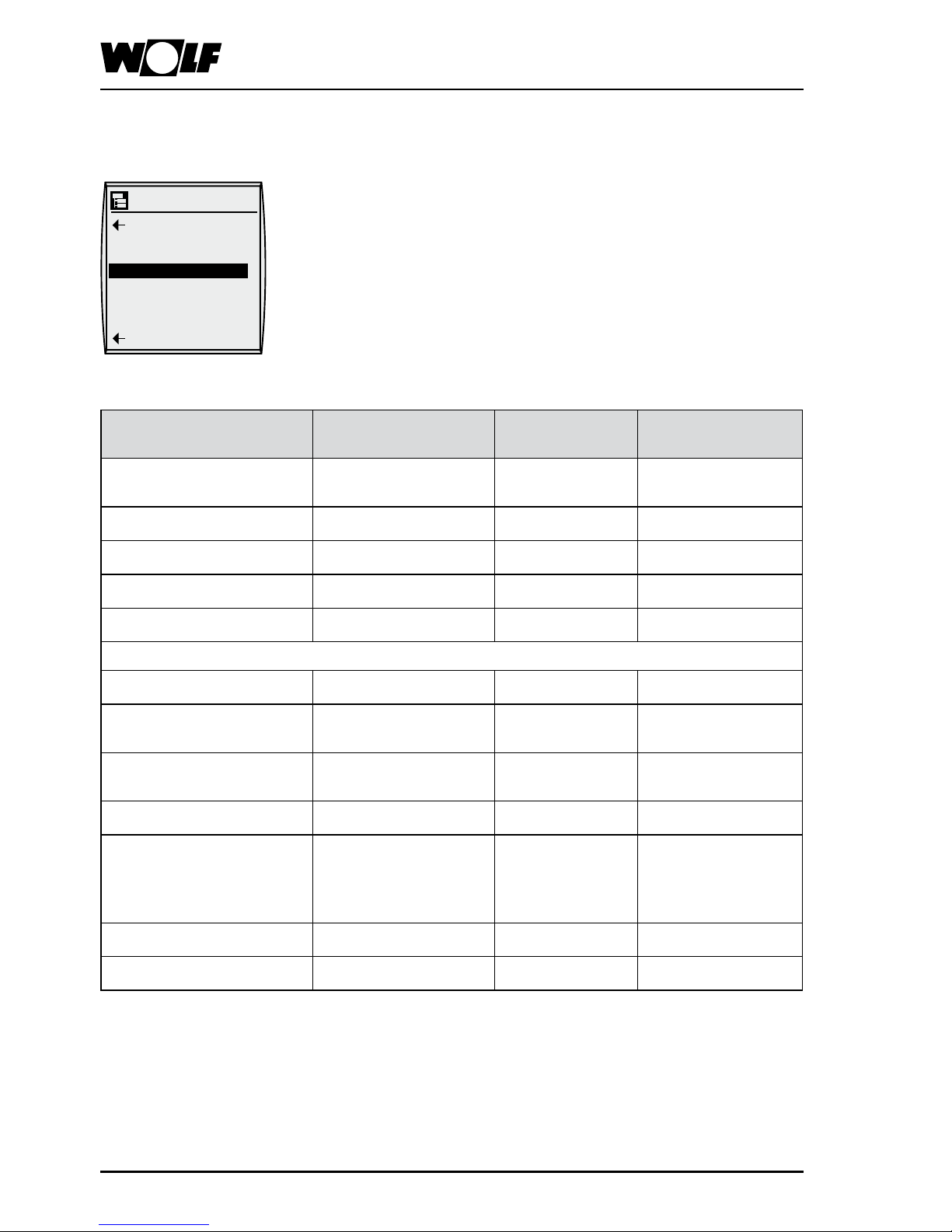

Parameter Setting range Factory setting Individual

settings

Language German / English

French / Dutch

German

Date --.--.--

Time 0 to 24 h

Auto summertime AUTO / OFF AUTO

Key lock ON/OFF OFF

Z1 Zone 1 . . Z7 Zone 7

Day temperature 5 °C – 50 °C 20 °C

Economy temperature for

heating

5 °C – 30 °C 16 °C

Backup temperature for

heating

5 °C – 30 °C 12 °C

Speed adjustment 30 - 70 % 40 %

Setback program Econ. operation

Backup mode

Standby

Hols summer vent

Backup mode

VA min limit 5 °C – 30 °C 16 °C

Night ventilation enable ON/OFF ON

Parameter overview, default settings

(settings and functions on the following pages)

Control level 2 - Default settings

Main menu

Back

Fault ackn.

Basic settings

Time program

Holiday prog

Specialist

Back

Displays

Page 17

3063527_201308

17

Control level 2 - Default settings

Language

Press the r.h. rotary selector to change to control level 2.

Turn the r.h. rotary selector clockwise to select the "Default

settings" menu level and conrm the selection by pressing the

r.h. rotary selector again.

Select the Language parameter by turning the rotary selector

further clockwise, and conrm your selection by pressing the

selector again.

The language is changed by turning the r.h. rotary selector and

pressing to conrm.

You can cancel your input by pressing the „Speed adjustment

key “.

Factory setting: German

Options: German / English

French / Dutch

Basic settings

Back

Language

Date

Time

Autom. summert.

Key lock

Z1 Hall1

Press the r.h. rotary selector to change to control level 2.

Turn the r.h. rotary selector clockwise to select the "Default settings"

menu level and conrm the selection by pressing the r.h. rotary

selector again. Select the Date parameter by turning the rotary

selector further clockwise, and press selector to conrm.

Turn the r.h. rotary selector to change the date.

Enter the day, month and year one after the other, pressing the

r.h. rotary selector each time to conrm.

You can cancel your input by pressing the „Speed adjustment key“.

The date will be displayed automatically if a radio clock module is

connected. However, the date cannot then be changed.

Date

Basic settings

Back

Language

Date

Time

Autom. summert.

Key lock

Z1 Hall1

Press the r.h. rotary selector to change to control level 2. Turn the

r.h. rotary selector clockwise to select the "Default settings" menu

and conrm the selection by pressing the r.h. rotary selector again.

Select the Time parameter by turning the rotary selector further

clockwise, and press selector to conrm.

Then turn the r.h. rotary selector to change the time.

Enter the hours, minutes and seconds one after the other, pressing

the r.h. rotary selector each time to conrm.

You can cancel your input by pressing the „Speed adjustment key”.

You must set the time again if the control unit has been disconnected

from the power supply longer than 48 hours.

The time will be displayed automatically if a radio clock module is

connected. However, the time cannot then be changed.

Time

Basic settings

Back

Language

Date

Time

Autom. summert.

Key lock

Z1 Hall1

Page 18

3063527_20130818

Control level 2 - Default settings

Automatic summer time

Turn the r.h. rotary selector further clockwise to select the „Autom.

summert.“ parameter and conrm the selection by pressing the

r.h. rotary selector again.

„Automatic summertime“ is disabled by turning the r.h. rotary

selector and by pressing to conrm.

Factory setting: auto.

Options: auto / off

Key lock Press the r.h. rotary selector to change to control level 2. Turn

the r.h. rotary selector clockwise to select the "Default settings"

menu level and conrm the selection by pressing the r.h. rotary

selector again. Select the "Key lock" parameter by turning the

rotary selector further clockwise, and press selector to conrm.

The key lock is activated by turning the r.h. rotary selector and by

pressing to conrm.

You can cancel your input by pressing the „Speed adjustment key“ .

Note:

The key lock parameter is intended to prevent unintentional

adjustment of the ventilation system.

If the key lock parameter is set to "ON", the key lock will be activated

automatically one minute after the last adjustment.

No adjustments or scans can be implemented when the key lock

is enabled. If, nevertheless, a key or rotary selector is activated,

then the display shows KEY LOCK.

The key lock can be lifted for a single adjustment or to display

the set/actual values by holding down the r.h. rotary selector for

approx. three seconds.

To disable the key lock permanently, the "Key lock" parameter

must be set to "Off" again.

Function keys remain active

Speed adjust , fresh air proportion adjustment and temperature

correction).

Please note

Factory setting: off

Options: on / off

Basic settings

Back

Language

Date

Time

Autom. summert.

Key lock

Z1 Hall1

Basic settings

Back

Language

Date

Time

Autom. summert.

Key lock

Z1 Hall1

Page 19

3063527_201308

19

Control level 2 - Default settings

Select "Z1 Zone 1". If there is more than one zone in the

system, select the zone for which you want to change values

(max. 1-7) and conrm your selection by pressing the r.h. rotary

selector again. You can now modify the following values for

the selected zone one after the other by turning the r.h. rotary

selector.

Select and conrm Day temperature using the r.h. rotary

selector. Turn the r.h. rotary selector to set the required

temperature and then press to conrm.

Tagtemperatur

[Day temperature]

Factory setting: 20 °C

Range: 5 - 50 °C

Economy temperature

Heating

Select and conrm Economy temperature heating using the r.h.

rotary selector. Turn the r.h. rotary selector to set the required

economy temperature and press selector to conrm.

Factory setting: 16 °C

Range: 5 - 30 °C

Backup temperature

Heating

Select and conrm Backup temperature heating using the r.h.

rotary selector. Turn the r.h. rotary selector to set the required

backup temperature for heating and press selector to conrm

(see "Standard functions" - "Central heating backup mode").

Factory setting: 12 °C

Range: 5 - 30 °C

Basic settings

Back

Language

Date

Time

Autom. summert.

Key lock

Z1 Zone 1

Basic settings

Back

Day temperature

Econ temp htg

Backup temp htg

Speed adjust

Setback prog

Back

Basic settings

Back

Day temperature

Econ temp htg

Backup temp htg

Speed adjust

Setback prog

Back

Basic settings

Back

Day temperature

Econ temp htg

Backup temp htg

Speed adjust

Setback prog

Back

Z1 Zone 1

Page 20

3063527_20130820

Control level 2 - Default settings

Speed adjustment Select and conrm Speed adjustment using the r.h. rotary

selector. Turn the r.h. rotary selector to set the required speed

(30-70 %) and press selector to conrm.

Function:

The speed preselected here applies during day temperature,

backup mode, Summer ventilation and night ventilation and

cannot be reduced by the CO

2

sensor.

Factory setting: 40 %

Range: 30 - 70 %

Basic settings

Back

Day temperature

Econ temp htg

Backup temp htg

Speed adjust

Setback prog

Back

Setback

program

Select and conrm Setback prog. using the r.h. rotary selector.

Turn the r.h. rotary selector to set the required operating mode,

and press selector to conrm:

- Backup mode

- Economy operation (setback mode)

- Standby

- Summer ventilation

.

You can preselect the above operating modes when the time

program has switched off the system.

Backup mode function:

Backup mode can become active when the time program

switches the system off (this is the factory setting). If the

temperature in the room falls below the set backup temperature,

the fan, HR and reheater are activated until the backup

temperature is reached (+/- 1 K).

Backup mode = Economy mode: In the periods when the

system is not switched on by the time program, the fan is only

activated if the temperature falls below the backup temperature.

Factory setting: Backup mode

Range: Backup mode

Econ.operation

Standby

Summer ventil.

Basic settings

Back

Day temperature

Econ temp htg

Backup temp htg

Speed adjust

Setback prog

Back

Supply air minimum limit Select and conrm VA min limit using the r.h. rotary selector.

Turn the r.h. rotary selector to set the required supply air

minimum temperature and press selector to conrm.

Function:

The air blown into the room must be at or above this

temperature at all times. If the temperature falls below the set

value by the set hysteresis (2 K), HR and the reheater are

activated.

Please note:

The set temperature (for day, economy temperature) cannot be

set below the value of the minimum limit.

Factory setting: 16 K

Range: 5 - 30 K

Basic settings

Back

Econ temp htg

Backup temp htg

Speed adjust

Setback prog

VA min limit

Nght vent enable

Page 21

3063527_201308

21

Night ventilation enable

Select and conrm Night ventilation enable using the r.h. rotary

selector. Turn the r.h. rotary selector to set the required control

type (ON / OFF) and press selector to conrm.

Function:

This function is used in summer to supply the room with cool

outdoor air during periods when the system is not switched on by

the time program.

If the room temperature exceeds a certain value, the system is

switched on until the room temperature returns to the set value.

For a more detailed description, see "Additional functions".

This only works in backup mode

This function requires an outside temperature sensor and a

room sensor/extract air sensor.

Factory setting: off

Options: off / on

Control level 2 Default settings / time programs

Time program

Press the r.h. rotary selector to change to control level 2.

Turn the r.h. rotary selector clockwise to select the

"Time program" menu and conrm the selection by pressing

the r.h. rotary selector again.

Select the zone for which you want to program the switching times

and conrm by pressing.

Select the day for which you want to program the switching times

and conrm your selection by pressing the r.h. rotary selector again.

Turn the r.h. rotary selector to select the start time and press

selector to conrm.

Turn to set the required switching time and press selector to conrm.

Follow the same procedure for the end time.

You can then turn the r.h. rotary selector further to program switching

times 2-8 in the same way as described above.

When you have programmed all switching times for the selected

day, you can exit the menu with "Back".

Turn the r.h. rotary selector further to select „Copy day“ and conrm

the selection by pressing the selector again. You are automatically

taken to the copy area.

The source day of the week is displayed.

Turn the r.h. rotary selector to select the day you programmed

previously and press selector to conrm.

The target day of the week is displayed.

Select the day or block of days to which you want to copy the

switching times and press selector to conrm.

Copy selection: Mo, Tu, We, Th, Fr, Sa, Su

Mo - Th

Mo - Fr

Sa - Su

Basic settings

Back

Econ temp htg

Backup temp htg

Speed adjust

Setback prog

VA min limit

Nght vent enable

Time program

Zonenübersicht

Back

Z1 Zone 1

Z2 Zone 2

Time program

Zone 1

Thursday

Friday

Saturday

Sunday

Copy day

Zone 1

Monday

Start time 07 : 00

End time 14 : 00

Start time 07 : 00

End time 14 : 00

Start time 07 : 00

End time 14 : 00

Back

Back

Back

Page 22

3063527_20130822

Control level 2 - Time programs

If no switching time is entered, that means the system is shut down.

Each day of the week begins at 0:00 h and ends at 23:59 h.

Time program for zone 1 - factory setting

Zone 1

Time

program

1

Time

program

2

Time

program

3

Time

program

4

Time

program

5

Time

program

6

Time

program

7

Time

program

8

Monday

On 07:00

Off 14:00

Tuesday

On 07:00

Off 14:00

Wednesday

On 07:00

Off 14:00

Thursday

On 07:00

Off 14:00

Friday

On 07:00

Off 14:00

Saturday

On --:--

Off --:--

Sunday

On --:--

Off --:--

Page 23

3063527_201308

23

Press the r.h. rotary selector to change to control level 2.

Turn the r.h. rotary selector clockwise to select the „Holiday program“

[Holiday program] menu and conrm the selection by pressing the

r.h. rotary selector again.

Select the zone for which you want to program the holiday times

and conrm by pressing the selector.

Select the holiday program (from 1 to 5) for which you want to

program the holiday times and conrm your selection by pressing

the r.h. rotary selector again.

Turn the r.h. rotary selector to select the date for holiday start and

press selector to conrm.

Turn to set the required date and press selector to conrm.

Follow the same procedure to set the time.

Then set the date and time for holiday end.

Next, under Prog. selection, select "Standby" and

conrm by pressing the selector.

You can select from the following:

- Standby (factory setting)

- Backup mode

- Econ.operation

- Hols day mode

- Summer ventil.

Follow the same procedure for holiday programs 2 to 5.

Holiday prog

Control level 2 - Holiday prog

Holiday prog

Zone overview

Back

Z1 Zone 1

Z2 Zone 2

Back

Holiday prog Zone

1

Back

Holiday prog 1

Holiday prog 2

Holiday prog 3

Holiday prog 4

Holiday prog 5

Back

Holiday prog

Zone 1

Back

Holiday start

Date 01/01/09

Time 00:00

Holiday start

Date 01/01/09

Time 00:00

Prog. selection

Standby

Back

Page 24

3063527_20130824

Control level 2 - Specialist

You can use the BML programming module to set the parameters

of the ventilation units.

Setting options and explanations of the individual parameters are

given in chapter

Control level 3 - Specialist - System parameters.

After selecting the zone and conrming the selection, the data is

retrieved from the ventilation appliance control unit and displayed

approx. 5 seconds later.

If the parameter is present in the ventilation appliance control

unit, the

value currently set for it will be shown in the display and can be

modied.

Press the r.h. rotary selector to change to control level 2. Turn the

r.h. rotary selector clockwise to select the "Specialist" menu level

and conrm the selection by pressing the r.h. rotary selector again.

Turn the r.h. rotary selector to enter the digit 1 and conrm it.

Repeat this three times (to enter password 1111).

After entering this code, you will be in specialist level 3.

Password requirement

If modules are removed from the system or existing systems are

extended or modied with modules, a re-conguration must be

carried out.

The re-conguration process is completed when „New congurat“

is selected and conrmed.

If a temperature sensor is removed from the system or one is

retrotted after commissioning, sensor detection must be carried

out.

The sensor detection process is completed when „Sensor check“

is selected and conrmed.

New congurat /

Sensor check

Zone designat Any text can be entered as the Zone designat for the zone, e.g.

Restaurant.

With the r.h. rotary selector, select the required zone (from

zones 1 to 7) in the "Specialist" menu level (after entering the

code) and press selector to conrm.

Select the Zone designat parameter and press selector to

conrm.

Use the r.h. rotary selector to enter your selection (letters,

numbers, symbols, etc.).

Conrm the selected character with the r.h. rotary selector.

You can then enter the next character.

You can enter up to 16 characters.

=

User password

authorisation

required.

Cancel

Specialist

System

Z1 Zone 1

Z2 Zone 2

Back

Back

Back

System

New congurat

Sensor check

Back

=

Zone 1

Cancel

Zone designat

Restaurant

Page 25

3063527_201308

25

Control level 3 - Specialist - System parameters

Ventilation unit

parameters

The settings can be modied for LM001 to LM204.

See "Specialist parameter list - Overview"

Specialist

Zone designat

LM001 K20

LM015 25 %

LM016 70 %

LM017 10 K

LM018 93

LM023 ON

Back

Relay test

Relay test can be used to activate the outputs for particular

modules.

With the r.h. rotary selector, select the required zone (from

zones 1 to 7) in the "Specialist" menu level (after entering the

code) and press selector to conrm.

Select the "Relay test" parameter and press selector to conrm.

Use the r.h. rotary selector to make your selection (see below)

and press selector to conrm (for relay assignment, see

terminal assignments).

- Rel o.air open

- Rel o.air cl.

- Inverter relay

- Analogue Y1

- Analogue Y2

- Analogue Y3

- Analogue T1

This function can be used to activate the individual outputs

in sequence. When you exit the menu, relay test is disabled

automatically and the system returns to the previously selected

operating mode.

Specialist

LM203 1000

Relay test

Off

Zone designat

Back

Zone reset You can use Zone reset to reset all the parameters saved on a

module to their factory settings.

With the r.h. rotary selector, select the required zone (from

zones 1 to 7) in the "Specialist" menu level (after entering the

code) and press selector to conrm.

Select the Zone reset parameter and press selector to conrm.

The following values are reset to their factory settings:

- Zone parameters

- Time program

- Default settings

- Holiday prog

Specialist

LM203 1000

Relay test

Off

Zone reset

Back

Page 26

3063527_20130826

Specialist parameter list - Overview

Parameter Setting

range

Factory

setting

Individual

settings

LM001 Conguration

-

K20

LM013 Hysteresis OFF 0-3 K 1 K

LM015 Minimum fan speed 5 % - 60 % 30 %

LM016 Maximum fan speed 25 % - 100 % 70 %

LM017 P component for speed control 1 - 20 10

LM018 Ratio of extract air to supply air

fan speed

50 - 150 93

LM020 Weather-compensated

winter/summer changeover

ON/OFF OFF

LM021 Differential for heating 1 K – 20 K 1 K

LM023 Room frost protection ON/OFF ON

LM024 Room frost protection

temperature

0 °C – 30 °C 5 °C

LM060 Fan speed for Economy

operation, speed control preselection for backup mode, night

ventilation, summer mode, room

frost protection

40 % - 100 % 70 %

LM080 P component for heating circuit

mixer

5 - 20 12

LM081 Integral action time for heating

circuit mixer

0 - 25 min 2 min

Control level 3 - Specialist - System parameters

Setting parameters With the r.h. rotary selector, select the required zone (from

zone 1 to 7) in the "Specialist" menu level (after entering a

password) and press selector to conrm.

Select the ventilation unit parameter (LM...) you want to

modify, conrm by pressing the selector and then modify

it by turning the r.h. rotary selector. Once you have set the

ventilation unit parameter (LM...) you wanted to modify, press

the r.h. rotary selector again to conrm the setting.

Specialist

Zone designat

LM001 K20

LM015 25 %

LM016 70 %

LM017 10 K

LM018 93

LM023 ON

Back

Page 27

3063527_201308

27

LM100 Cascade effect 0 - 20 2

LM101 Integral action time for cascade 0 - 25 min 2 min

LM102 Supply air maximum limit 20 - 60 °C 50 °C

LM103 Control type Supply air control,

cascade control

Supply air

control

LM114 Damper lead time 0 - 150 s 120 s

LM130 Night ventilation limit 10 - 30 °C 22 °C

LM131 Night ventilation start condition

differential TR > TA

2 K - 20 K 5 K

LM132 Night ventilation, minimum

outside temperature

5 - 20 °C 12 °C

LM150 P component for HR 5 - 20 12

LM151 Integral action time for HR 0 - 25 min 2 min

LM160 Air quality control OFF/ON ON

LM161 Air quality, start 0 - 10 V 4 V

LM162 Air quality, maximum 0 - 10 V 8 V

LM163 System OFF/ON via air quality OFF/ON OFF

LM180 Alarm function, re dampers (OFF) System

Off

(ON) Message

only

System OFF

LM190 Delay for

air ow fault

5 - 600 s 60 s

LM200 Active lter monitor ON/OFF OFF

LM201 Filter check interval 1 -10 weeks 1 week

LM202 Service message

via hours run

ON/OFF OFF

LM203 Fan hours run 100 - 8000 1000

LM204 Filter check ON/OFF OFF

Parameter Setting

range

Factory

setting

Individual

settings

Control level 3 - Specialist - System parameters

Page 28

3063527_20130828

Parameters / Function description

Parameter description The specialist parameters listed in the table in the last section

are described in detail below.

The column on the left shows the designation of each

parameter and its number.

Not all parameters listed in the table will be present in every

system conguration.

Hysteresis OFF

LM013

Factory setting: 1 K

Range: 0 - 3 K

The heating control by temperature stops if the currently

actual room temperature or extract air temperature exceeds

the set temperature by the Hysteresis OFF value.

Minimum fan speed

LM015

Factory setting: 30 %

Range: 5 - 60 %

Min. speed "n-min" (minimum output voltage)

Setting (if required) of a minimum output voltage, i.e. a base

speed (minimum air change) for the connected fans which

must be maintained during temperature control and CO2

control.

Never set below 30 %!

Maximum fan speed

LM016

Factory setting: 70 %

Range: 25 - 100 %

Max. speed "n-max" (maximum output voltage)

Setting (if required) of a maximum output voltage, i.e. a speed

limit (to prevent excessive air noise) for the connected fans

which must not be exceeded during temperature control and

CO

2

control.

P component

for speed control

LM017

Factory setting: 10

Range: 1 - 20

The P component for speed control determines how sharply

the output signal of the Analogue output is modied in

proportion to a control deviation. (0-100 %)

If the P component is set low, the control unit responds more

quickly.

If the P component is set high, the control unit responds more

slowly.

Ratio of extract air/

supply air fan speed

LM018

Factory setting: 93

Range: 50 - 150

In order to run air handling systems so that positive or

negative pressure is created in the room, the speeds of the

supply air and extract air fans must be set differently.

Setting LM018 at 100 → parallel operation

LM018 at > 100 → negative pressure

LM018 at < 100 → positive pressure

Weather-compensated

summer shutdown

LM020

Factory setting: OFF

Range: ON/OFF

By enabling this parameter, the system can be switched on

and off according to the outside temperature.

The system must be connected to an outside temperature

sensor for this function to be available (see "Additional

functions"). In the control panel, disconnect the internal wires

across terminals X2 21/22 and connect the external outside

temperature sensor.

Enable this parameter only if you are replacing an

internal temperature sensor with an outside temperature

sensor one.

Page 29

3063527_201308

29

Differential for heating

LM021

Factory setting: 1

Range: 1 - 10 K

This parameter denes the outside temperature, relative to

the set room temperature, at which the ventilation unit stops.

Example:

Set room temperature 20 °C, parameter LM021 set to 5.

If the outside temperature is > 25 °C the ventilation unit

will be switched off. At 1 kelvin below that, the unit will be

enabled again.

Room frost protection

LM023

Factory setting: ON

Range: ON/OFF

Activating this parameter allows the system to be switched

on when the room temperature falls below the room frost

protection limit.

Room frost protection

temperature

LM024

Factory setting: 5

Range: 0 - 30 °C

If the room temperature falls below the set value, the reheater

and the fan are activated. Once the temperature rises 2 K

above the set temperature, the system stops again.

The fan speed can be preselected manually.

Fan speed for

Econ.operation

LM060

Factory setting: 70 %

Range: 40 - 100 %

When Economy operation is active, the fan is operated at the

speed preselected here. The set speed applies to backup

mode, night ventilation, summer mode and peak ventilation.

P component for

heating circuit mixer

LM080

Factory setting: 12

Range: 5 - 20

The P component for the heating circuit mixer (HR)

determines how sharply the output signal of the heating

circuit mixer is modied in proportion to a control deviation.

If the P component is set low, the control unit responds more

quickly.

If the P component is set high, the control unit responds more

slowly.

Integral action time for

heating circuit mixer

LM081

Factory setting: 2 min.

Range: 0 - 25 min.

The integral action time for the heating circuit mixer (HR)

determines how great the time effect is on the output signal of

the heating circuit mixer due to a control deviation.

If the integral action time is set low (high time effect), short

correction times result. However, so do greater uctuations

around the set value. If the integral action time is set high,

longer correction times result. This also means lesser

uctuations around the set value.

Cascade effect

LM100

Factory setting: 2

Range: 0 - 20

The cascade effect determines how sharply the set

temperature for supply air is modied in proportion to a

control deviation in the room temperature.

If the P component is set low (low gain), longer correction

times result, whilst uctuations around the set value will be

minor. If the P component is set high, shorter correction times

result. However, so do greater uctuations around the set

value.

Parameters / Function description

Page 30

3063527_20130830

Integral action time for

cascade

LM101

Factory setting: 2 min.

Range: 0 - 25 min.

The cascade integral action time determines how great the

time effect is on the set temperature for supply air due to a

control deviation in the room temperature.

If the integral action time is set low (high time effect), shorter

correction times result. However, this also means greater

uctuations around the set value. If the integral action time

is set high, longer correction times result. This also means

lesser uctuations around the set value.

Supply air maximum limit

LM102

Factory setting: 50 °C

Range: 20 - 60 °C

The supply air maximum limit determines the maximum

temperature at which supply air can be blown into the room.

If the differential in temperature between the set temperature

and the actual temperature is high, control based on room

temperature could lead to very warm air being conveyed into

the room. This high supply air temperature would cause the

air quality in the room to worsen. To prevent that, the supply

air temperature is limited to a maximum value in the case of

heating.

Temperature - control

type

LM103

Factory setting:

Supply air temperature control

This parameter sets the type of temperature control.

- Auto

- Supply air temperature control

- Extract air:supply air cascade

For a detailed description of the control functions, see BML.

Damper lead time

LM114

Factory setting: 0 s

Range: 0 - 150 s

To prevent whistling noises occurring on the dampers when

the fan is switched on, the outside air dampers are opened

rst, with the fans being switched on after this time (60 s) has

elapsed.

Night ventilation limit

LM130

Factory setting: 22 °C

Range: 10 - 30 °C

If night ventilation is activated (DEFAULT SETTING), this

parameter is used to determine the room temperature or

extract air temperature at which night ventilation starts or

stops (±1 K).

Night ventilation starts if the room or extract air temperature is

higher than the set value ± 1 K.

Night ventilation stops if the room or extract air temperature is

lower than the set value.

Night ventilation

start condition

LM131

Factory setting: 5 K

Range: 2 - 20 K

If night ventilation is activated (DEFAULT SETTING), this

parameter sets the outside temperature, relative to room

temperature, at which night ventilation starts.

Night ventilation starts when the outside temperature is lower

than the room temperature minus the "Night ventilation start

condition" parameter.

Parameters / Function description

Page 31

3063527_201308

31

Night ventilation,

minimum outside

temperature

LM132

Factory setting: 12 °C

Range: 5 - 20 °C

The "Night ventilation minimum outside temperature"

parameter sets the minimum outside temperature below

which night ventilation is disabled.

P component for HR

LM150

Factory setting: 12

Range: 5 - 20

The P component for HR determines how sharply the output

signal of the HR damper is modied in proportion to a control

deviation.

If the P component is set low, the control unit responds more

quickly.

If the P component is set high, the control unit responds more

slowly.

Integral action time for

HR

LM151

Factory setting: 2 min

Range: 0 - 25 min

The integral action time for HR determines how great the

time effect is on the output signal of the HR damper due to a

control deviation.

If the integral action time is set low (high time effect), shorter

correction times result. However, this also means greater

uctuations around the set value. If the integral action time

is set high, longer correction times result This also means

lesser uctuations around the set value.

Air quality control / CO2

LM160

Factory setting: ON

Options: OFF - ON

If the system is equipped with an air quality sensor / CO2

sensor, this parameter must be set to ON in order to make

this function available.

Air quality / CO2

start

LM161

Factory setting: 4 V

Range: 0 - 10 V

If air quality control is enabled, this parameter denes the

default value from which the speed is increased.

Air quality / CO2

maximum

LM162

Factory setting: 8 V

Range: 0 - 10 V

If air quality control is enabled, this parameter denes the

default value at which the maximum speed is reached.

Observe compliance with the limits set by parameters LM015,

LM016.

Parameters / Function description

Page 32

3063527_20130832

System OFF/ON

via air quality / CO

2

LM163

Factory setting: OFF

Options: OFF - ON

If you want the system to be switched on an off according to

the air quality (CO2 content), this parameter must be set to

ON.

In order to use this function, the operating mode selector

must be set to standby or setback mode with standby must

be preselected.

This function is only possible in the standby mode.

The CO2 sensor should be located inside the room.

Alarm function,

re dampers

LM180

Factory setting: OFF

Options: ON/OFF

There are different possible responses when a re alarm

damper responds.

Setting OFF: The fans are switched off and all outputs are set

to 0. A fault message is displayed on the BML programming

module.

Setting ON: The system continues running in control mode;

only a fault message is displayed on the BML programming

module.

Delay for

air ow monitor

LM190

Factory setting: 60 s

Range: 5 - 600 s

If the differential pressure cell for air ow monitoring

responds, the system stops after the delay time set here

(fans off, all outputs set to 0).

A fault message appears on the BML programming module.

Active lter monitor

LM200

Factory setting: OFF

Options: ON/OFF

If there is a lter monitor (differential pressure cell) installed in

the ventilation unit, this parameter must be set to ON. If set to

OFF, lters will not be monitored.

Filter check interval

LM201

Factory setting: 1 week

Range:1 -10 weeks

Subject to setting, the process is as follows:

After the motor starts, lters are checked after the test interval

has elapsed. Fan runs at 100 % speed, and after a delay of 60 s

a fault message is issued on the BML programming module if

lters are dirty. The system resumes its control mode and the

fan speed is reset again. If the system continues running day

and night, a lter check will be carried out after the test interval

has elapsed plus 24 hours.

Filter service message

LM202

Factory setting: OFF

Options: ON/OFF

If there is no active lter monitoring input, this parameter can

be used to enable the lters to be reported as dirty according

to the number of hours that the fans have been running.

Fan hours run

LM203

Factory setting: 1000 h

Range: 100 - 8000 h

Here you can set the number of hours of fan operation after

which the lters should be reported as dirty.

Filter check

LM204

Factory setting: OFF

Options: ON/OFF

If set to "ON" a lter check can be carried out immediately

(checking of cable/differential pressure cell), otherwise test

procedure as described under LM201

Please note: Parameter LM200 must be set to "ON" to be

able to activate a lter check.

Parameters / Function description

Page 33

3063527_201308

33

Master reset / Standard functions

Master reset

Take the programming module (BML) in the ventilation unit out

of its wall mounting base and clip it back in again while holding

down the r.h. selector.

Hold the selector down until Parameter reset appears on the

display.

The following values are reset to their factory settings:

- Zone designat

- Language

- Key lock

- Auto summertime

- System parameters

Please note

Also carry out a master reset if an eBUS error occurs when the

system is rst switched on.

Standard functions The standard functions of the controller are described below.

Motor protection The motor winding temperature is monitored with the aid of

thermistors set into the motor windings or PTC thermistor

pellets.

If the winding temperature rises above the dened value, the

motor and all outputs are switched off. A fault message is

displayed on the programming module. The motor will only

restart once the fault is removed (motor cooled down) and the

fault message is reset.

The fault is reset by acknowledging the fault on the BML

programming module.

Relevant parameters: none

Room frost protection

(room sensor)

The room frost protection function prevents the room from

cooling down too much, thereby preventing damage to the

building that might otherwise result

(moisture damage, mould growth, etc.).

Relevant parameters:

Room frost protection on (LM023),

Room frost protection temperature (LM024)

Pre-requisites:

Room sensor / extract air sensor

If the room temperature falls below the set value, HR,

the reheater and the fan are activated and the outside air

dampers are opened. Once the temperature rises 1 K above

the set temperature, the system stops again.

This works in all operating modes

Page 34

3063527_20130834

Standard functions

Backup mode, heating If backup mode is enabled, and the current room temperature

falls below the backup temperature (DEFAULT SETTING),

the fan is run at the preselected speed and HR and the

reheater are activated. Once the current room temperature

rises 1 K above the backup temperature, everything stops

again.

Relevant parameters:

Program selector, time program, in OFF mode, backup

temperature, night mode

Supply air minimum limit

for heating

If the supply air temperature (temperature of air blown in)

falls below the set minimum limit value, the heating mixer is

activated (100 %) (HR and reheater coil).

The heating modules are not switched off again until the

temperature has risen above the set value.

In addition, if the supply air temperature falls below the

minimum limit, the current fan speed is set to the minimum

speed (parameter LM 015) after 900 s have elapsed. If the

supply air minimum limit then ceases to be active, the fan

speed is returned to its nominal speed.

If the supply air minimum limit is still active after 5 minutes

despite the speed reduction, a fault message is issued (and

the system shuts down).

This will be reset automatically once 5 hours have elapsed or

when the fault is acknowledged on the BML.

Filter contamination

fault trigger

Parameters LM202 and LM203 can be used to activate a lter

fault by means of the number of hours of fan operation.

Active lter monitor A differential pressure cell can be used to trigger a fault

message when the lter is dirty; see parameter LM200.

Fan run-on time To prevent re-heating by the electric heater coil, the fan stops

only after a run-on time of 45 seconds after system shutdown.

External ON/OFF An on-site contact can be used to switch the system on and

off within the time program.

Contact closed:

System runs according to the time program

Contact open:

System switched off by time program

If the system is always going to be operated via the external

switch, the time program must be enabled 24 hours a day

The additional functions of the controller are described below.

Additional functions

Page 35

3063527_201308

35

Additional functions

Room/supply air

cascade control

With room/supply air cascade control, the set supply air

temperature is corrected according to the control deviation of the

room temperature.

Relevant parameters:

Cascade effect LM100, integral action time for cascade LM101,

supply air minimum limit (default setting), supply air minimum limit

LM102

Pre-requisites:

Room sensor (extract air sensor) and supply air sensor

The set supply air temperature is dependent on the load

conditions in the room. The actuating variable from the room

temperature control is transferred as set value to the supply air

temperature control. This results in the set supply air temperature

being varied according to the deviation in room temperature.

Night ventilation In summer, night ventilation pre-cools the room for the

following day with cool outdoor air.

Relevant parameters:

Night ventilation limit LM130; start condition Tr > Ta LM131;

permissible outside temperature LM132

Pre-requisites:

- Room sensor (extract air sensor) and outside temperature

sensor are installed

- Time program set to "OFF"

- Outside temperature > minimum outside temperature

(LM132)

- Outside temperature < room temperature + delta (LM131)

- Room temperature > set room temperature (LM130)

- Works only when backup mode is selected

- Enabled from 1 March to 31 October

- Enabled from 20:00 to 07:00 h

Effects:

- Fans are switched on

- Speed according to parameter LM060

- HR heater coil is switched off

- Outside air dampers are opened

- Set temperatures for switching night ventilation on and off

are dened by parameter LM130.

When night ventilation is activated, sensor values are

checked for the rst 7 minutes.

(Fan speed according to parameter LM 060; checking

outdoor air, extract air/room air temperatures.)

If the conditions dened by parameters LM 130 - LM 132 are

met, night ventilation continues. If the conditions are not met,

night ventilation stops again.

If, during the time in which night ventilation is enabled, a

shutdown occurs (temperature below threshold in parameter

LM 130), another sensor check is activated after 125 minutes

and runs for 7 minutes.

In order to use night ventilation efciently, the outside

temperature sensor in the appliance should be disabled and

shifted outside.

Page 36

3063527_20130836

Additional functions

Preheater coil for HR

Ice guard,

Filter drying

When the outside temperature is below 0 °C, the preheater

coil is activated.

Once the temperature rises to the set temperature +

hysteresis, the preheater coil is switched off again.

Condensate overow When a condensate pump is connected, the amount of

condensate is monitored. If the limit is exceeded, the

ventilation unit stops and a fault message is issued on the

BML (active only with cooling congurations).

Summer shutdown With parameters LM020 / LM021, ventilation can be

switched off automatically in the event of very high outside

temperatures to prevent the interior getting too hot.

When summer shutdown is activated, the outside

temperature sensor in the appliance must be disabled and an

external outside temperature sensor used.

Heat recovery In many industrial plants, waste heat from cooling circuits/

lighting is available. Heat recovery allows the utilisation of

this free heat source for heating purposes. With a crossow

heat exchanger, energy costs can be drastically reduced in

this way.

Heat recovery is actuated by an Analogue control signal

(0-10 V). Heat recovery is applied for heating and cooling

purposes by capturing and comparing the room (extract air)

temperature, the outside temperature and the supply air

temperature.

HR actuation takes priority over the actuating signal for

heating. The reheater coil is not activated unless and until

the HR control signal is at 10 V and the set temperature has

still not been reached.

Relevant parameters:

P band for HR LM150, integral action time for HR LM151

The parameters are switched to active only in accordance

with the conguration

Function is only supported in conjunction with an outside

temperature sensor/room sensor or extract air sensor.

HR ice guard To prevent frost forming on the extract air side of the HR

system, the extract air temperature is captured by an ice

guard sensor and if the temperature falls below +6 °C, the HR

system is steadily closed. At 1 °C the HR system is closed

completely. The heating valve continues to be controlled

towards its set value independently. If the temperature stays

below the icing-up temperature for more than 2 minutes, a

fault message is issued. The fault message automatically

extinguishes when the temperature rises above the limit

temperature. Ice guard function does not become active until

the fan has been running for at least 5 minutes.

Page 37

3063527_201308

37

Peak ventilation:

CO2 sensor diagram

NTC

sensor resistances

Outside temperature sensor, room sensor, supply air sensor,

extract air sensor

Sensor resistances

Temp. °C Resist. Ω Temp. °C Resist. Ω Temp. °C Resist. Ω Temp. °C Resist. Ω

-21 51393 14 8233 49 1870 84 552

-20 48487 15 7857 50 1800 85 535

-19 45762 16 7501 51 1733 86 519

-18 43207 17 7162 52 1669 87 503

-17 40810 18 6841 53 1608 88 487

-16 38560 19 6536 54 1549 89 472

-15 36447 20 6247 55 1493 90 458

-14 34463 21 5972 56 1438 91 444

-13 32599 22 5710 57 1387 92 431

-12 30846 23 5461 58 1337 93 418

-11 29198 24 5225 59 1289 94 406

-10 27648 25 5000 60 1244 95 393

-9 26189 26 4786 61 1200 96 382

-8 24816 27 4582 62 1158 97 371

-7 23523 28 4388 63 1117 98 360

-6 22305 29 4204 64 1078 99 349

-5 21157 30 4028 65 1041 100 339

-4 20075 31 3860 66 1005 101 330

-3 19054 32 3701 67 971 102 320

-2 18091 33 3549 68 938 103 311

-1 17183 34 3403 69 906 104 302

0 16325 35 3265 70 876 105 294

1 15515 36 3133 71 846 106 285

2 14750 37 3007 72 818 107 277

3 14027 38 2887 73 791 108 270

4 13344 39 2772 74 765 109 262

5 12697 40 2662 75 740 110 255

6 12086 41 2558 76 716 111 248

7 11508 42 2458 77 693 11 2 241

8 10961 43 2362 78 670 113 235

9 10442 44 2271 79 670 114 228

10 9952 45 2183 80 628 115 222

11 9487 46 2100 81 608 11 6 216

12 9046 47 2020 82 589 117 211

13 8629 48 1944 83 570 118 205

Connect external oating contact to input B5. The speed

is ramped up as set in parameter LM060. The speed is not

ramped down again (control operation) until the contact

switches off. This works in all operating modes (On/Off switch

function).

CO

2

control An external contact can be used to switch the system off or

simply issue a fault; see parameter LM180.

The fan speed is adjusted according to the CO

2

content of the

room air.

Relevant parameters: LM015, LM016, LM160, LM161, LM162

This function is only supported in conjunction with a CO2

sensor.