Wolf ICBDF486C series, ICBDF366 series, ICBDF364C series, ICBDF364G series, ICBDF486G series Installation Instructions Manual

...Page 1

DUAL FUEL RANGES

INSTALLATION INSTR UCTION S

Natu ral ga s .

Le av e instructio ns w it h the owner.

This cookto p is a pprov ed for use with

Mo del Ser ies

ICBDF366

ICBDF304

ICBDF364C

ICBDF364G

ICBDF486C

ICBDF486G

ICBDF484CG

ICBDF484F

ICBDF606CG

ICBDF604CF

Page 2

As you read this use & care information,

take particular note of the CAUTION and

WARNING symbo ls when they appear.

This information is important for safe and

efficient use of the Wolf equipment.

In addition, this use & care information may

signal an IMPORTANT NO TE which highlights

information that is especially important.

signals a s ituation wher e minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

WOLF®is a registered trademar k of Wolf Appliance, Inc.

I NS T A LL A TI O N R E QUIREMENTS

IMPORTANT NOTE: This installation must

be completed byaqualified installer,

service agency or gas supplier.

IMPORTANT NOTE:

Save these installation

instructions for the local inspector’s use.

Installation to be carried out only by an

authorised person.

Do not modify this appliance.

Please read the entire installation instructions prior to installation.

Installer:

please retain these instructio ns

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep these

instructions for future reference and be sure

to read the entire use & care in

formation

prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with local codes. The

correct voltage, frequency and amperage must

be supplied to the appliance fromadedicated,

grounded circuit which is protected by a

properly sized circuit breaker or time delay

fuse. The proper voltage, frequenc y, and

amperage ratings are listed on the product

rating plate.

Record the model and serial nu mbers before

installing the dual fuel ran g e. Both numbers

are listed on the rating plate, loc ated rear of

removable lower panel.

W O L F DU A L F UEL RANGE S

IMPORTANT NOTE:

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Do not store or use gasoline or

other flammab le vapors and liquids

in the vicinity of this or any other

appliance.

A ventilation hood is recomme nded

for use with the Wolf dual fuel range.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electric al switch.

Do not use an y phone in your

building.

Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas

supplier, call the fire depar

tment.

If the information in this book is

not followed exactly,afire or

explosion may result, causing

property damage, personal injury

or death.

R A T I N G PL A T E

I N FORM A T I O N

Model Number

Serial Number

CONT A C T

INFOR M A T I O N

Imported and

distributed by:

Multyflex

Website:

www.multyflex.com.au

IMPORTANT NOTE:

Statutory requirements: This

appliance shall be installed in

accordance with the manu facturer’s installation instructions,

local gas fitting regulations,

municipal building codes, electrical wiring regulations, and

AS/NZ5601 the Australian Standard

for gas installations. Refer also to

AS/NZ5601 for gas pipe sizing

tables.

Unsuitability for use in marine

craft, c aravans or mobile homes,

unless each burner is fitted with a

flame safeguard.

Page 3

3

B EF O R E Y O U S T A R T

Proper installation i s your responsibility.

Installations must be performed by a

qualified or licensed contractor, plumber or

gas fitter, qualified or licensed by the state,

province or region w here th is appl iance is

being installed. You must also ensure that

electrical installatio n is a dequate and

conforms with all lo cal cod es and

ordinances.

Proper gas supply mu st be available; refer

to gas supply requir ements on page 9.

Electrical ground is requi

red; see electrical

requirements on page 10.

Check the location w here th e range will be

installed. The locati on shou ld be away from

strong draft areas, such as windows, doo r s

and strong heating v ents or fans. Do not

obstruct the flow of air. The area in which

you are installing t his app liance must have

an adequate supply o f fresh air to ensure

proper combustion and ventilation.

Make sure you have everything necessary

for proper installati o n. It is the responsibility of the i

nstaller to comply w ith the installation clearances spe cified on the product

rating plate. The ra ting pl ate is located rear

of removable lower p a nel.

All openings in the wall or floor where the

range is to be inst a lled m u st be sealed.

The cooking range to be installed only on

the floor.

When installing the range under existing

cabinets where the i nstallation does not

meet the minimum cab inet cl earances,

install a ventilation hood or other noncombustible surface a bove th

e range to

avoid burn hazards. Refer to minimum

clearances on page 3 .

V EN T I L AT IO N O P T I O N S

IMPORTANT NOTE:

A suitable ventilatio n

hood must be install ed. We recomm end a Wolf

Pro Ventilation Hood be installed with the Wolf

dual Fuel Range. Con tact yo ur Wolf deal e r for

details.

IMPORTANT NOTE:

When installing a ve n tilation hood, refer to the specific requirem ents

of the hood for the minimum dimension to

countertop.

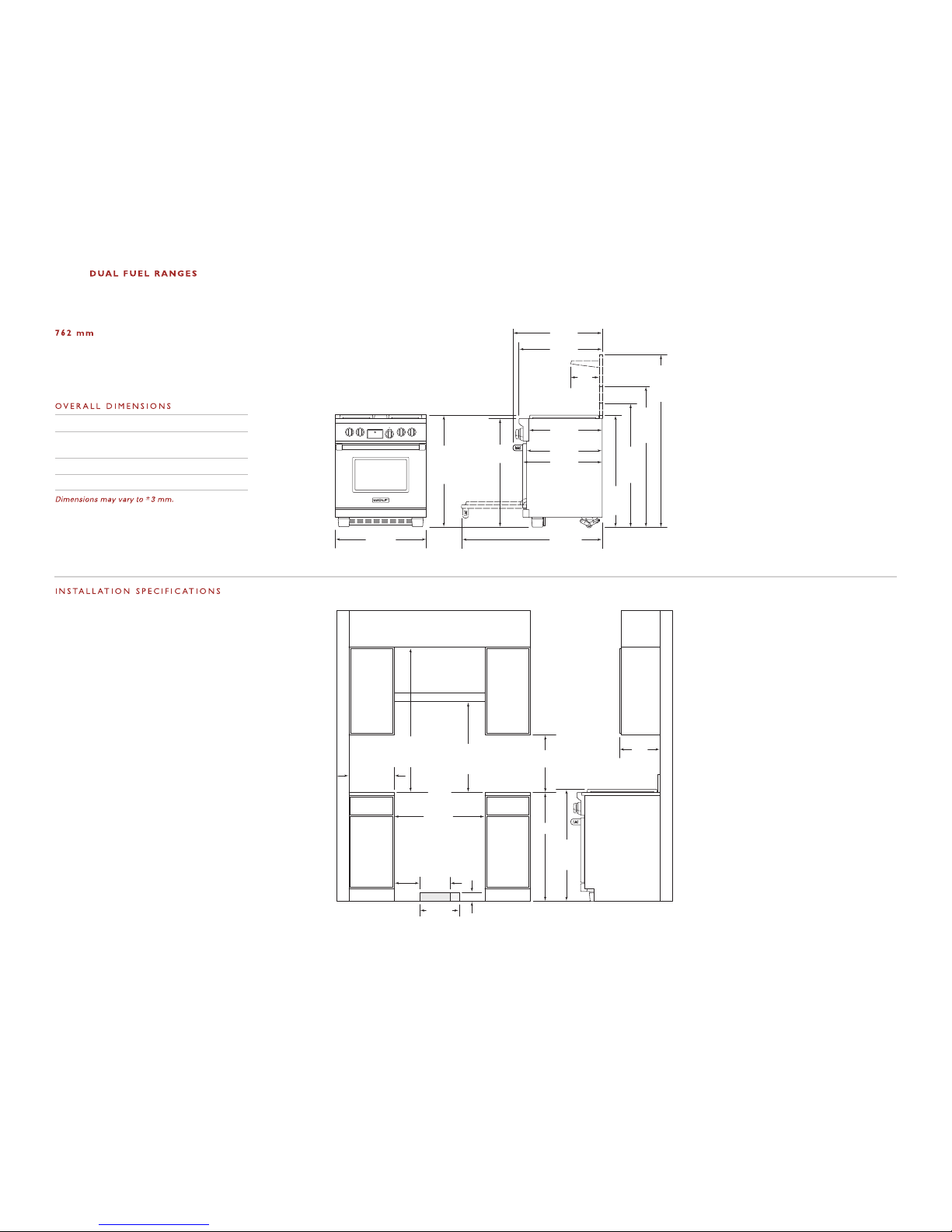

I NS TA L L AT I ON S P E C I F I C A T I O N S

Wolf dual fuel ranges come in 762 mm,

914 mm, 1219 mm and 1524 mm widths.

Illustrations on page s 4–

7 provide the overal l

dimensions and instal l ation specifications for

each width of dual fuel range.

Each range is design ed to fit between cabinets

set at the distance specified by the un it. For

example, a 914 mm r ange wi ll fit a 914 mm

opening. The exceptio n is t he 1524 mm unit

which will require a 1530 mm opening.

IMPORTANT NOTE:

Cabinet opening dimen sions shown in the installation specifica t ions

illustrations must be used. These dimensi ons

provide for required clearanc

es.

Each unit is designe d with a terminal block on

the rear of the ran g e. Hav e a qu alified electrician or installer wi re your unit from the elec t rical supply, through the knock out in the unit

base and to the ter minal b lock on the range.

IMPORTANT NOTE:

Locate the electrical

supply within dimensi ons sho wn in the

installation specifica tions i llustrations and

flush with back wall .

Refer to the install ation s pecifications illustration for your model on pages 4– 7 for the ex

act

rough opening dimensi ons and location of the

gas supply and elect rical.

Wolf dual fuel ranges usin g natur al gas will

operate up to an al t itude of 2438 m without

any adjustment. Natur a l gas and LP gas installations from 2438 m to 3353 m need the high

altitude conversion k it.

I NS TA L L AT I ON I N S T R U C T I O N S

I NS TA L L AT I ON S P E C I F I C A T I O N S

M I N I M U M C L E A R A N C E S

IMPORTANT NOTE:

Caution must be used in

planning the proper installation of the Wolf

dual fuel range to a void fi re or damag

e to

adjacent cabinetry or kitchen equipment.

Be sure to follow t he mini mum cle arances

established in the f inished rough opening

dimensions.

For installation against a rear combustible

surface a 254 mm classic stainless steel riser

must be used. Refer part number 8 04387.

Refer to the install ation s pecifications illustration for your model on pages 4– 7 for the exact

rough opening dimensio ns.

Maintain th e fol lowing clearances to

combustible materials:

Minimum 457 mm clear ance fr om bott om

of upper cabinet to countertop, within

152 mm minimum side clearance.

Minimum 762 mm clear ance b e tween c ountertop and bottom of wood or metal

cabinet, which is pr otected by not less than

6 mm flame retardant millboard covered

with not less than No. 28 MSG sheet st e el,

.4 mm stainless stee l, or .6 mm aluminum

or .5 mm copper.

Minimum 914 mm clear ance b e tween c ountertop and bottom of an unprotected wood

or metal cabinet.

Bottom of ventilation hood must be

600 mm minimum to 9 14 mm maximum

from countertop.

I S L A N D | P E N I N S U L A I N S T A L L A T I O N S

For island i n stallations,

the range should

not be installed wit hin an enclosure having an

adjacent rear wall l ess tha n 305 mm from the

rear of the unit th at rise s above the countertop.

For peninsula installati ons,

the range must

have a 152 mm minim u m clea rance t o the side

wall, left or right side, and 305 mm mi nimum

clearance to the rea r wall.

Refer to the install a tion s pecifications illustration for your model on pages 4– 7 for the exact

rou

gh opening dimensions .

Failure to locate the range wit h out t he

proper clearances will result in a fire

hazard.

Page 4

4

W

ICBDF304

OLF

330 mm

LOCATION OF

ELECTRICAL

914 mm

937 mm

TO

COOKING

SURFACE

600 mm min

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

VENTILATION HOOD

457 mm min

TO COUNTERTOP

LOCATION OF GAS AND

ELECTRICAL EXTENDS 57 mm

ON FLOOR FROM BACK WALL

762 mm

FINISHED ROUGH

OPENING WIDTH

83 mm

216

mm

254 mm

LOCATION

OF GAS

SUPPLY

600 mm min TO

914 mm max

TO BOTTOM OF

VENTILATION HOOD

ISLAND INSTALLATIONS: 305 mm MINIMUM

CLEARANCE FROM BACK OF RANGE TO

COMBUSTIBLE REAR WALL ABOVE COUNTERTOP–

0 mm TO NON-COMBUSTIBLE MATERIALS

330 mm

max

152 mm

min TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

759 mm

OVERALL WIDTH

937

mm

ISLAND

TRIM

1165

mm

WITH

254 mm

RISER

1419

mm

WITH

508 mm

RISER

1038

mm

WITH

127 mm

RISER

1194 mm

664 mm

635 mm

613 mm

699 mm

235

mm

749 mm

OVERALL DEPTH

*937 mm MIN TO 991 mm MAX.

911

mm

937 mm

OVERALL

HEIGHT TO

COOKING

SURFACE*

Overall Width 759 mm

Overall Height

(to cooking surface) 937 mm

Overall Depth 749 mm

Opening Width 762 mm

DUAL FUEL RANGE

IMPORTANT NOTE: In non-island applications,

a minimum 127 mm riser is required for model

ICBDF304.

Note A:

Side clearances. If the distance

measured from the periphery of the

nearest burner to any vertical surface

is less than 200 mm, the surface shall

be protected in accordance with

AS/NZ5601.

Note B:

The rangehood fitted above the

cooktop must be installed according

to the installation instructions for

the rangehood. A minimum

distance of 750 mm is required for a

range hood and 750 mm for an

exhaust fan

.

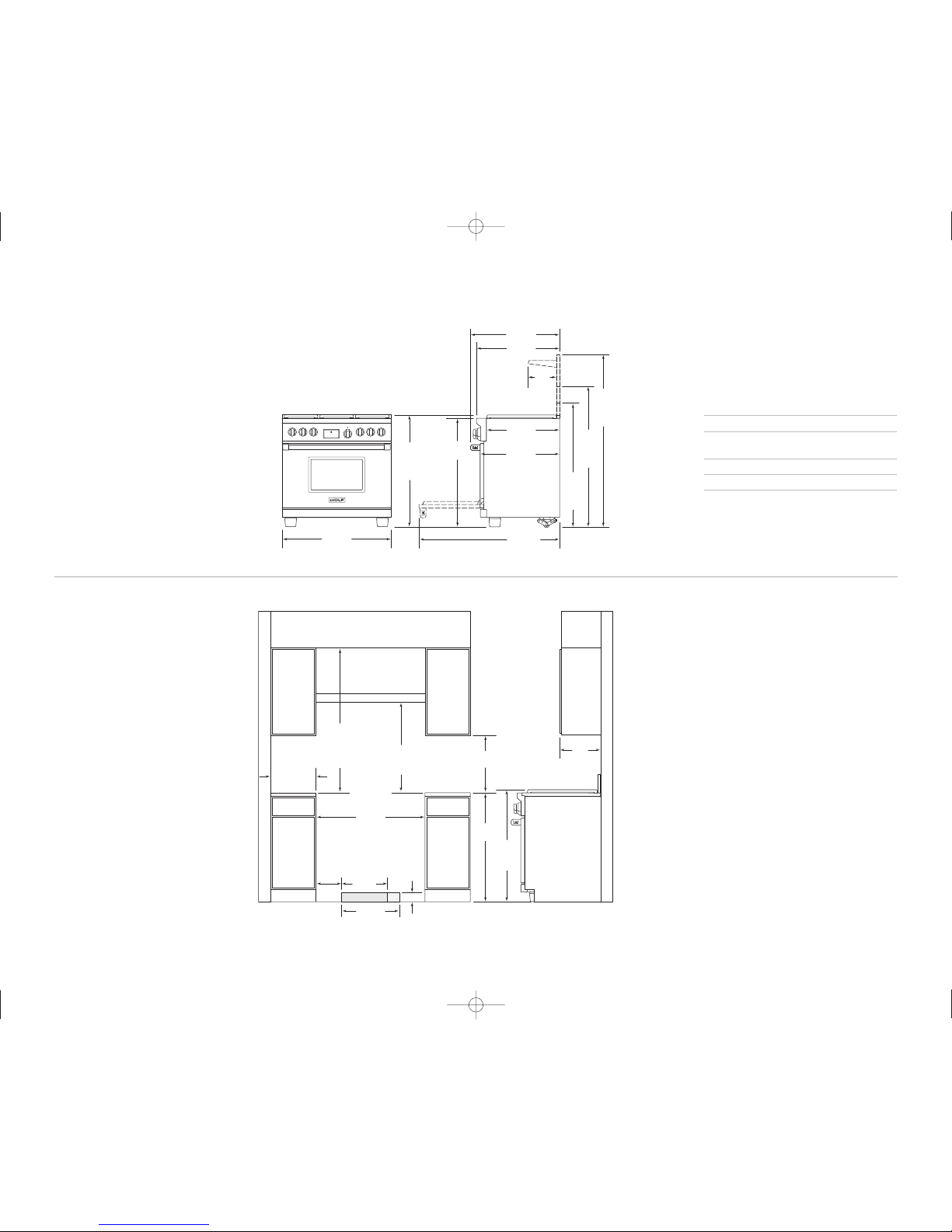

Page 5

5

I NS T A LL A TI O N I N S T R U C T I O N S

483 mm

LOCATIONOF

ELECTRICAL

914

mm

937 mm

TO

COOKING

SURFACE

VENTILATIONHOOD

457 mm min

TO COUNTERTOP

LOCATIONOF GAS AND

ELECTRICAL EXTENDS 76 mm

ON FLOOR FROM BACK WALL

914 mm

FINISHED ROUGH OPENING WIDTH

83 mm

216

mm

381 mm

LOCATION

OF GAS

SUPPLY

mm min TO

914 mm max

TO BOTTOMOF

VENTILATIONHOOD

600 mm min

COUNTERTOP

TO COMBUSTIBLE

MATERIALS

762 mm min

FOR CHARBROILER

ISLAND INSTALLATIONS: 305 mm MINIMUM

CLEARANCE FROM BACK OF RANGE TO

COMBUSTIBLE REAR WALL ABOVECOUNTERTOP–

330 mm

max

911 mm

OVERALLWIDTH

1194 mm

699 mm

235

mm

749 mm

OVERALL DEPTH

LEGS AND CASTERS ALLOW

54 mm HEIGHT ADJUSTMENT

911

mm

937 mm

OVERALL

HEIGHT TO

COOKING

SURFACE

616 mm

641 mm

1064

mm

WITH

127 mm

RISER

1191

mm

WITH

254 mm

RISER

1445

mm

WITH

254 mm

RISER

I N S T A L L A T I O N SPE C I F I C A T I O N S

O VERA L L D I M E N S I O N S

Overall Width 911 mm

Overall Height

(to cooking surface) 937 mm

Overall Depth 749 mm

Opening Width 914 mm

Dimensions may vary to±3 mm.

9 14 m m DU A L F U E L R A N G E S

M O D E L I C B D F 3 6 6

M O D E L I C B D F 3 6 4 C

M O D E L I C B D F 3 6 4 G

IMPORTANT NOTE: In non-island applications,

a mini mum 127 mm riser is required for model

ICBDF366 and minimum 254 mm ri ser required for

models ICBDF364C and ICBDF364G installed against

a combu stible surface. The island trim and 127 mm

riser may on ly be used against a non-combustible

surface for m odels ICBDF364C and ICBDF364 G .

NOTE

A

NOTE

B

Note A:

Side clearances. If the distance

measured from the periphery of the

nearest burner to any vertical surface

is less than 200 mm, the surface shall

be protected in accordance with

AS/NZ5601.

Note B:

The rangehood fitted above the

cooktop must be installed according

to the installation instructions for

the rangehood. A minimum

distance of 750 mm is required for a

range hood and 750 mm for an

exhaust fan

.

600

50 mm TO NON-COMBUSTIBLE MATERIALS

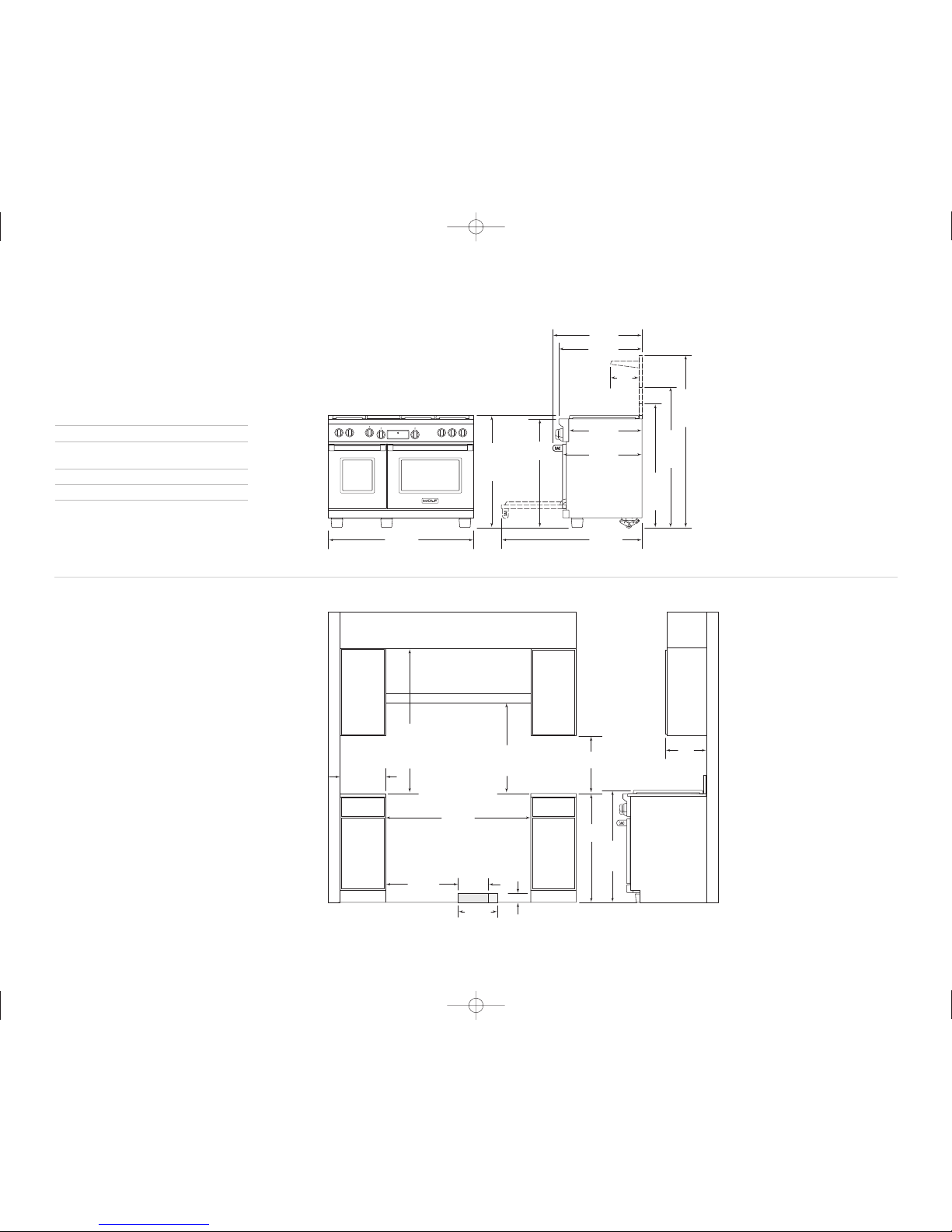

Page 6

6

W O L F DU A L F UE L R A N GE S

330 mm

LOCATIONOF

ELECTRICAL

914

mm

937 mm

TO

COOKING

SURFACE

VENTILATIONHOOD

LOCATIONOF GAS AND

ELECTRICAL EXTENDS 76 mm

ON FLOOR FROM BACK WALL

ISLAND INSTALLATIONS: 305 mm MINIMUM

CLEARANCE FROM BACK OF RANGE TO

COMBUSTIBLE REAR WALL ABOVECOUNTERTOP–

1219 mm

FINISHED ROUGH OPENING WIDTH

610 mm

83 mm

254 mm

LOCATION

OF GAS

SUPPLY

457 mm min

TO COUNTERTOP

mm min TO

914 mm max

TO BOTTOMOF

VENTILATIONHOOD

600 mm min

COUNTERTOP

TO COMBUSTIBLE

MATERIALS

762 mm min

FOR CHARBROILER

330 mm

max

1216 mm

OVERALLWIDTH

1194 mm

699 mm

235

mm

749 mm

OVERALL DEPTH

LEGS AND CASTERS ALLOW

54 mm HEIGHT ADJUSTMENT

911

mm

937 mm

OVERALL

HEIGHT TO

COOKING

SURFACE

616 mm

641 mm

1064

mm

WITH

127 mm

RISER

1191

mm

WITH

254 mm

RISER

1445

mm

WITH

254 mm

RISER

I N S T A L L A T I O N S P E C I F I C A T I O N S

O V E R A L L D I M E N S I O N S

Overall Width 1216 mm

Overall Height

(to cooking surface) 937 m m

Overall Depth 749 mm

Opening Width 1219 mm

Dimensions may vary to±3 mm.

1 21 9 m m D U A L F U E L R A N G E S

GC8 44FDBCI

I C B D F 4 8 4 F

C8 64FDBCI

I C B D F 4 8 6 G

IMPORTANT NOTE: In non-island applications, a

minimum 254 mm ris er is required for all 1219 mm

models installed against a combustible surface.

The is land trim and 127 mm riser may only be used

against a no n -combustible surf ace.

NOTE

B

Note A:

Side clearances. If the distance

measured from the periphery of the

nearest burner to any vertical surface

is less than 200 mm, the surface shall

be protected in accordance with

AS/NZ5601.

Note B:

The rangehood fitted above the

cooktop must be installed according

to the installation instructions for

the rangehood. A minimum

distance of 750 mm is required for a

range hood and

750 mm for an

exhaust fan

.

NOTE

A

600

50 mm TO NON-COMBUSTIBLE MATERIALS

Page 7

7

I NS T A LL A TI O N I N S T R U C T I O N S

330 mm

LOCATIONOF

ELECTRICAL

914

mm

937 mm

TO

COOKING

SURFACE

VENTILATIONHOOD

LOCATIONOF GAS AND

ELECTRICAL EXTENDS 76 mm

ON FLOOR FROM BACK WALL

83 mm

787 mm

254 mm

LOCATION

OF GAS

SUPPLY

1530 mm

FINISHED ROUGH OPENING WIDTH

457 mm min

TO COUNTERTOP

mm min TO

914 mm max

TO BOTTOMOF

VENTILATIONHOOD

600 mm min

COUNTERTOP

TO COMBUSTIBLE

MATERIALS

762mm min

FOR CHARBROILER

ISLAND INSTALLATIONS: 305 mm MINIMUM

CLEARANCE FROM BACK OF RANGE TO

COMBUSTIBLE REAR WALL ABOVECOUNTERTOP–

330 mm

max

1527 mm

OVERALLWIDTH

1064

mm

WITH

127 mm

RISER

1191

mm

WITH

254 mm

RISER

1445

mm

WITH

254 mm

RISER

1194 mm

616 mm

641 mm

699 mm

235

mm

749 mm

OVERALL DEPTH

LEGS AND CASTERS ALLOW

54 mm HEIGHT ADJUSTMENT

911

mm

937 mm

OVERALL

HEIGHT TO

COOKING

SURFACE

I N ST A L L AT I O N SPEC I F IC A T I O N S

O VERAL L D I M E N S I O N S

Overall Width 1527 mm

Overall Height

(to cooking surf ace) 937 mm

Overall Depth 749 mm

Opening Width 1530 mm

Dimensions may vary t o±3 mm.

1 52 4 m m DUA L F UE

I CBDF 6 0 6 C F

L R A N G E S

IMPORTANT NOTE: In non-island applications, a

minimum 254 mm ri s er is required for all 1524 mm

models installed against a combu s tible surface.

The is land trim and 127 mm riser may only be used

against a non- combustible surface.

NOTE

A

NOTE

B

Note A:

Side clearances. If the distance

measured from the periphery of the

nearest burner to any vertical surface

is less than 200 mm, the surface shall

be protected in accordance with

AS/NZ5601.

Note B:

The rangehood fitted above the

cooktop must be installed according

to the installation instructions for

the rangehood. A minimum

distance of 750 mm is required for a

range hood and 750 mm for an

exhaust fan

.

600

FC4 06FDBCI

50 mm TO NON-COMBUSTIBLE MATERIALS

Page 8

8

U NP A CK TH E R A N G E

Remove and discard a ll pack ing mat erials,

including cardboard a nd tape on the outside of

the range and inside the oven cavity.

Remove the box conta ining t he oven racks,

oven rack guides and broiler pan from in side

the oven cavity. Be sure to do this for both

oven cavities on the 1524 mm range.

Remove the burner gr ates an d styro foam of f

the top cooking surf ace. Be sure to remove the

burner caps packaged in styrofoam below t he

burner grates.

Do not discard the angle iron supplied w ith th e

range. This is the anti-tip bracket and must be

installed with the u nit. Re fer to anti-tip bracket

installation on page 11.

Carefully lift the r ange of f the pallet and

remove the styrofoam from the bottom of the

unit.

IMPORTANT NOTE:

Before moving the ra nge

into position, protec t any finished flooring with

appropriate materials to avoid damage to the

floor.

The rear of the rang e has rolling casters whic h

allows for easy move ment of the range by

picking up on the f ront of the unit. Refer to the

illustration below.

The dual fuel range comes from the facto ry at

an overall height of 911 mm from floor to the

top of the bullnose, before any height a djustment. The legs and c asters allow for 54 mm

height adjustment. Ref er to the illustration

below. Us e a 1 9 mm s ocket t o adjus t the rear

casters. Refer to th e insta llation specifications

illustration for your model on pages 4– 7 for

additional dimensions.

W O L F DU A L F UE L R A N GE S

Casters allow for 54 mm

height adjustment

Rolling casters.

Do not lift the r ange by the oven door

handle(s). Th is wil l dam age t he ov en do or

and hinges.

The dual fuel ra nge i s ver y hea vy. Use

caution when l ifting and moving th e uni t.

Secure oven do or(s) closed before

moving the uni t.

O VE N D O OR RE M O V A L

If removal of the ov en door (s) is necessary, a

hinge pin, supplied w ith th e range , will need to

be inserted in the appropriate hinge arm. For

each oven door, only one hinge arm is spring

loaded, requiring use of the hinge pin f or

removal of the oven door. The h inge pi n will

be found taped to t he insi de of the oven door.

For 762 mm and 914 mm ranges, the hinge pin

will be inserted thro ugh th e hole in the right

hinge arm (facing th e unit) . On 1 219 mm and

1524 mm ranges, the spring hinges are l ocated

on the outer edges of the unit. On thes e units ,

the left oven door will have the spring hinge

on the left side an d the right oven door will

have the spring hing e on t he righ t side. Refer

to the illustrations below for the locati on of the

spring hinge(s) for your model.

Place Hinge Pin on

Spring Hinge Side of Door

Place Hinge Pins on

Spring Hinge Side of Door

Spring hinge locati on for 762 mm

and 914 mm ranges.

Spring hinge locati ons for 12 19 mm

and 1524 mm ranges.

Failure to ins ert t he hi nge pi n in t he

appropriate h inge a rm wi ll ca use d amage

to the range. Mi nor i njuries may occur.

IMPORTANT NOTE:

The oven door(s) sho uld

not be removed unles s it i s neces sary to fit the

range through a tight doorway. Door remov al

should only be done by a qualified servi ce

technician or installe r. Door removal an d reinstallation may cause damage to the oven

porcelain interior.

Page 9

9

O VE N D O OR R E M O VA L

If removal of the oven door(s) is necessary,

follow thes e steps:

1)

Remove the low er kickplate assembly to

access the low er hinge retainer mount ing

screws.

2)

Open the oven door to its f ully opened

position and r emove both upper and lower

hinge retainer moun ting screws. The oven

gasket may hav e to be moved sl ightly to

access the bot tom screws.

3)

After removing the mounting screws, move

the hinge reta iner plate forward sli ghtly.

The hinge reta iner plate will re main on the

door hinge ass embly after the m ounting

screws have b een removed.

4)

Insert the sup plied door hinge p in through

the hole in t he app

ropriate hinge arm . Refer

to the illustr ation below.

5)

Carefully close the oven door to about a

60° angle from horizontal and lif t the door

away from the oven. A sligh t rocking

motion may be required for r emoval.

6)

For 1219 mm a nd 1524 mm ranges ,

complete these step s for both oven doors

IMPORTANT NOTE:

The dual fuel range must

be connected t o a regulated gas supply.

The rating pla te, located rear of r emovable

lower panel, h as information on the type of

gas that shoul d be used. If thi s information

does not agree with the type of gas avail able,

check with the local gas su pplier. A duplicate

pl

ate can be at tached to the insi de top of an

adjacent cupboard.

This appliance appl iance must be ins talled in a

position with the proper level o f ventilation. Do

not obstruct t he flow of combust ion and ventilation air.

The gas pressu re regulator supplied with the

appliance must be installed in l ine with the gas

pipe. (N.G. on ly).

If the applian ce cannot be adjus ted to perform

correctly contact Multyflex or t he local gas

utility. For service con tact telephone number

please refer p age 13.

For pressure t esting in excess of 3 .5 kPa (1/2”

psig) the appl iance and its indi vidual shut-off

va

lve must be d isconnected from the g as

supply piping syste m. For pressure t esting of

the gas piping system at pr essures equal to or

less than 3.5k Pa (1/2”psig) the appli ance must

be isolated fr om the gas supply system by

closing its in dividual shut off valv e during any

pressure testing.

The appliance shoul d not be connecte d to a

combustion product evacuation system.

Instruct the u ser in the operat ion of the appliance before le aving..

EXPLOSION HAZARD —

Securely tight en al l gas c onnections.

Failure to do so can result in ex plosion,

fire or death.

G AS S U P PL Y R E Q U I RE M E N TS G AS S U P PL Y C O N N E CT I O N

I NS T A L L AT I O N I N S T R U C T I O N S

Hinge

Retainer

Plate

Upper Mounting

Screw

Hinge

Pin

Kickplate

Oven door removal.

Do not lift or car ry th e ove n door by the

door handle.

Never test for a gas leak with a ma tch o r

other flame.

Gas connection:

The cooktop is adjusted to o perate on the gas

type specified on t he gas type label located on

the bottom of the unit. If in doubt as to the

type of gas a vailable contact the net work

operator or ga s supplier for co nfirmation of

gas type.

The cooktop mu st be

connected to t he gas

supply with up stream

connection of a n isolation valve in accordance

with the respe ctively

valid regulations. We

recommend that the

isolation valve be fitted

prior to the cooktop to

enable isolation of the cooktop f rom the gas

supply. The valve m ust be easily acce ssible at

all times.

Thi

s appliance ma y be connected with a hose

assembly, class B o r class D in accordance to

AS/NZS 1869. If connected with a hose assem bly ensure that th e gas

supply connection p oint is accessible

with the appli ance installed.

The position o f the inlet connect ion is

measured from botto m RH rear of unit ,

75 mm centre line from rear and 300 mm

centre line fr om RH side.

Fit regulator (N.G.) or Propane fi tting (Propane)

directly to th e R1/2” connection. dire ction for

gas flow is in dicated on the rea r of the regulator.

Check correct operat ion of each burner individually and in combination. Burner flames should

be clear blue, with no yello w tipping. If the

burners show a ny abnormality check tha t

burner heads ar e correctly located and refer to

the ‘trouble sh ooting’ guide on p age 26 & 27 o f

the Use and Ca re manual. If sati sfactory

performance can not be obtained, contac t

Multyflex or t he local gas utili ty. For service

contact number refer page 13 of t his booklet.

Note: These bur ner have no aerati on adjustme

nt.

It should be e xpressly noted that we cannot

accept any liab ility for direct or in direct damage

caused by wron g connection or im proper installation. When b eing repaired, the appl iance must

always be

disconnected

from the main

gas and electri city supply; if

required,notify

our customer

service.

Page 10

10

WOLF DU AL FUEL RA NG ES

IMPO RTANT NOTE

Be aware of local codes and ordinances

when installing your service.

ELECTRICAL REQUIREMENTS

GAS RATING

GAS RATIN G

Refer to page 13

REQUIRED POWER SUPPLY

Single phase: 220-240V AC; 50/60 Hz

3phase: 380-415V AC; 50/60 Hz

MAXIMUM CONNECTED LOAD

762 mm and 914 mm Dual Fuel ranges:

Single phase: 19 amps

3phase: 18 amps

1219 mm Dual Fuel ranges:

Single phase: 35 amps

3phase: 18 amps

1524 mm Dual Fuel ranges:

Single phase: 38 amps

3phase: 18 amps

Refer to the wiring diagram showing the connections

for each lead to the terminal box on the unit.

The complete appliance must be properly

grounded at all times when electrical power is

applied.

NOTE: Improper connection can result in a

re

hazard.

Before obtaining access to terminals, all supply

circuits must be disconnected.

Verify that power is disconnected from the

electrical box before proceeding.

Open the terminal box to expose the screws with

corresponding numbers. Run the cord through the

strain relief hole and into the terminal box.

For Single Phase Install (Line, Neutral, Ground):

Loosen the 1, 5, and ground screws. Attach the

Neutral wire to the number 5 position. Line should be

attached to the 1 postion and attach the ground to

the corresponding ground screw.

For 3phase Install (L1, L2, L3, Neutral, Ground):

Loosen the 1, 2, 3 and remove the copper bars.

Loosen 5 and ground screws. Attach L1 to position

1. L2 to position 2. L3 to position 3. Neutral wire to

position 5 and attach the ground to the corresponding ground screw.

IMPORTANT NOTE:

Connection of this appliance

should be through a fused connection unit or a

suitable isolator, which complies with national and

local safety regulations. The o

switch should

be easily accessible after the appliance has been

installed. If the switch is not accessible after installation (depending on country) an additional means of

disconnection must be provided for all poles of the

power supply. When switched

there must be an

all pole contact gap of 3 mm in the isolator switch.

This 3 mm contact disconnect gap must apply to

any isolator switch, fuses and/or relays according to

EN60335.

Copper bars must be removed from positions 1,

2, and 3 when connecting to 3phase power.

Single phase wiring diagram

3phase wiring diagram

Page 11

DRYWALL APPLICATIONS

After properly positioning the anti-tip bracket, use wall

anchors to fasten it to the wall. Using a Philips screwdriver

or a low rpm screw gun, drive the anchor into the surface

of the wallboard until the two cutting blades penetrate the

surface. Use gentle forward pressure to rotate the collar until

flush with the surface of the wall. Refer to the illustrations

below. Use #8 screws and flat washers to fasten the anti-tip

bracket to the wall.

IMPORTANT NOTE:

Pre-drill holes if difficulty is encountered during installation of the wall anchor. For hard wallboard or double-board construction, use a 6 mm drill bit. For

solid plaster, use a 11 mm drill bit.

WOOD FLOOR APPLICATIONS

After properly positioning the anti-tip bracket, drill 5 mm pilot

holes through the floor. Use #12 screws and flat washers to

secure the bracket to the floor.

C ONCRETE FLOOR APPLICATIONS

After properly positioning the anti-tip bracket drill 10 mm

holes into the concrete a minimum of 38 mm deep. Use 10

mm wedge anchors to secure the bracket to the floor.

ANTI-TIP BOLT ADJUSTMENT

Once the bracket is secured in place, adjust the

anti-tip bolt

at the back of the range so the top of the washer is 22 mm

maximum from the floor. Slide the range into the opening and

verify the anti-tip bolt is engaged. Refer to the illustrations

below.

IMPORTANT NOTE:

The top of the range must be level.

Use the adjustable front legs and the rear casters to level

the range.

Raise the unit to its desired height by adjusting the front

legs and rear casters. The legs and casters allow for 54 mm

height adjustment. Use a 19 mm socket to adjust the rear

casters. The front legs are adjusted by rotating the bottom

hexagonal portion of the leg.

The anti-tip bracket can be installed by securing it to the wall

or floor using the supplied hardware.

Refer to the chart and illustration below to determine the

proper distance from the left side of the opening to the

anti-tip bracket. This will ensure the anti-tip bolt properly

engages the bracket.

MODEL A

762 mm Range 5 mm

914 mm Range 14 mm

1219 mm Range 5 mm

1524 mm Range 8 mm

ANTI- TIP BRACKET INS TALLATI ON

O VEN DOOR REINSTALLATION

IMPORTANT NOTE:

The oven door(s) should not be removed

unless it is necessary to fit the range through a tight

doorway. Door removal should only be done by a qualified

service technician or installer. Door removal and reinstallation may cause damage to the oven porcelain interior.

A

ANTI-TIP

BRACKET

Anti-tip bracket location.

ANTI-TIP

BRACKET

WALL

ANCHOR

Wall anchor installation.

22 mm MAX

ANTI-TIP

BOLT

Anti-tip bolt adjustment.

ANTI-TIP

DEVICE

ENGAGED

Anti-tip bolt engaged.

Hinge

Retainer

Plate

Upper Mounting

Screw

Hinge

Pin

Kickplate

Oven door reinstallation.

If oven door(s) have been removed, follow these steps to

reinstall:

1)

Hold the oven door on both sides and position it with

door hinges aligned with openings in the oven frame.

2)

Holding the oven door at an approximate 30° angle from

vertical, slide the hinges into the openings until the

bottom hinge arms drop fully into the hinge receptacles.

3)

Open the oven door to its fully opened position. Remove

the hinge pin from the appropriate hinge arm. Refer to

the

illustration below.

4)

Reinstall the hinge retainer plate with upper and lower

mounting screws.

5)

Open and close the door completely to ensure that it is

properly installed.

6)

For 1219 mm and 1524 mm ranges, complete these steps

for both oven doors.

7)

Reinstall the lower kickplate assembly.

IMPORTANT NOTE:

Fully extend the hinge claw which is

opposite the hinge pin location and insert into the hinge

pocket prior to inserting opposite side. This will ease the

installation of the oven door.

This range can tip. Injury to persons could result.

Install the anti-tip bracket supplied with the range.

Do not lift or carry the oven door by the door handle.

INSTALLATION INS TRUCTIONS

Page 12

12

W O L F DU A L F UE L R A N GE S

R EM O V I NG T H E R A N G E

If removing the dual fuel range is neces sary fo r

cleaning or service, shut off the gas su pply.

Disconnect the gas s upply an d elec trical

connections to the u nit, th en remo ve the

range. Reinstall in the reverse order and be

sure to check the g as conn ection for leaks.

Refer the Wolf dual fuel ranges use & care

information included w ith the range for

cleaning recommendatio ns.

T RO U B L ES H O O T I N G

IMPORTANT NOTE:

If the dual fuel ran ge

does not operate prop erly, follow the se

troubleshooting steps:

Verify that power is being supp lied to the

range.

Check the gas supply and electrical

connections to ensure that the installatio n

has been completed c orrectly.

Check that gas valve s are turned to the ON

position.

Follow troubleshooting procedures as

described in the Wolf dual fuel ranges

use & care informati on.

If the range still does not work, contac t a

Wolf dealer. Do n ot atte mpt to repair the

range yourself. Wolf

is not responsible fo r serv ice req uired t o

correct a faulty ins tallation.

Be sure to disco nnect the gas suppl y and

electrical co nnections before re moving

the range.

V ER I F Y R A N G E O P E R A T I O N

IMPORTANT NOTE:

Prior to operating

the range, be sure to read the entire

Wolf dual fuel ranges use & care information included with the range for

important safety and service information.

Install the oven rac k guide s onto the

shoulder screws locat ed on the interior

side walls of the o ven. Sl ide the oven

racks onto the suppor t rack s withi n the

oven. There are thre e racks per oven,

except for the 457 m m oven which has

two racks. Place the broiler pan and gri d

on a rack within th e oven, if desired.

Turn on the p ower su pply to the range.

The control panel sh ould be closed (no

visible control pads) . Touch and slightly

depress the flame gra phic o n the hidden

control panel to ope n.

Set the time of day by pressing the

touch pad, scroll to the desired time by

using the or arrows, then touch

. After setting the time, the hidden

control panel can be closed. The control

panel does not have to be open to

operate the oven.

Select any of the ei ght co oking m odes

by using the oven c ontrol knob bezel

and turning to the d esired mode. Once

the mode has been s elected, the temperature can be adjuste d by t urning the

temperature readout k nob clo ckwise to

increase the temperat ure or counterclockwise to decrease the temperature.

Verify that the oven is coming up to

temperature. For a 1 219 mm or 1524 mm

range, follow this p rocedure for the both

ovens.

IMPORTANT NOTE:

A small amount of

smoke and odor may be noticed during

the initial break-in period. Refer to the

use & care informati on for additional

information.

C OO K T O P O P E R A T I O N

The cooktop burner use s an e lectronic igniter in

place of a standing p ilot. W hen the cooktop control

knob is pushed in and turned to the position,

the system creates a spark to light the bu rner. This

sparking continues for 4 seconds or until the electronic ignition senses a flame, which ever comes

first. If the igniter fails to ignite the gas in 4 seconds,

the gas safety shutoff valve will close, e liminating

the gas flow for 5 s econds. The valve will reopen

after the purge time of 5 seconds, and the igniter

will automatically atte mpt to re-ignite the gas. T his

cycle of events is at tempted 3 times. After the th ird

attempt, in order for gas to flow to the burner once

again, the user must return the knob to th e

position and then turn the knob to the

position.

To check operatio n of th e cookt op burn er, push in

and turn the control knob to the position. The

flame should light wit hin fou r secon ds.

If the burner does no t light properly, turn the c ontrol

knob to the position. Check that the burner

head is in the proper position. Check that the power

supply cord is plugged in and that the cir cuit br eaker

or house fuse has not blown.

Check operation again; If flame is not est ablished

within the ignition cy cle tim e, rele ase the knob, open

a door and wait 1 mi nute bef ore att empting a new

ignition procedure.

If the flames are ext inguished - for any reason

whatever - turn OFF t he cont rol kno b and w ait at

least 1 minute before retrying to ignite t he burne r.

Ensure that the flames do not extinguish w hen you

reduce to low flame q uickly. Check co rrect op eration

of each burner indivi dually and in combination.

F LA M E H E IG H T A ND AP P EA R A N CE

The flame on natural gas should be blue wi th a

deeper blue core. and no yellow tipping. I f burner s

show any abnormality check that burner head s are

correctly located and refer to the ‘ troubl e shoot ing

guide’ on this page. If satifactory perform ance can

not be obtained, cont act Mult yflex. For service

contact number refer page 13 of this bookle t.

IMPORTANT NOTE:

Initial lighting of the surface

burners may take sli ghtly l onger, as air in t he

system must be purge d befor e gas can be supplied

to the burner.

Page 13

13

W IR I N G D I A G R A M

The wiring dia gram covering the con trol circuit

is located rea r of the removabl e lower panel.

The information and im ages in th i s book are th e

copyright proper ty of Wolf App liance, Inc., an

affiliate of Sub-Ze ro, Inc . Neith e r this boo k nor any

information or imag es cont ained he rein ma y be

copied or used in whole or in part w i thout t he

express wri tte n pe rmission of Wolf Appliance, Inc .,

an affiliate of Sub-Ze ro, Inc .

©Wolf Applian ce, Inc . all righ ts reser ve

d.

I NS T A LL A T I O N I N S T R U C T I O N S

S ER V I C E I N FO R M AT I O N

When requesting in formation, literature,

replacement parts or service, al ways refer to

the model and serial number of your dual fue l

range. This in formation is found on the

product rating plat e located rear of the removable lower pan el. Refer to the illustration below.

Record the rat ing plate information

below for futu re reference.

Model Number

Serial Number

Installation Date

Wolf Dealer and Phon e

B E FO R E C A L L IN G F O R SE R V I C E

Before calling y

our Wolf dealer, refer t o the

troubleshooting guid e on page 12. Che ck

the household fuse or circuit b reaker to see if it

has been blown or tripped a nd that the elect rical connection to the appliance has not been

disconnected. A po wer outage may als o have

caused a disru ption in service.

For service c all:

1300 808 859

C O N T A C T

I N F O R M AT I O N

Website:

www.multyflex.com. au

I M P O RT E D &

D I ST R I B U T E D B Y :

MultyFlex

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in ac cordance with

AS/NZS3100 240 V AC, 4.5 kW/19 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF304

Serial No:

Gas

type

NG LPG

Test point p ress. (kPa) 1.0 2.75

Injector sizes (mm)

RHF

RHR

LHF

LHR

1.80

1.80

1.80

1.35

1.09

1.09

1.09

0.89

Total Consumption (MJ/h) 51.0 51.1

MF027

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in a ccordance with

AS/NZS3100 240 V AC, 4.5 kW/19 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF366

Serial No:

Gas

type

NG LPG

Test point press. (kPa) 1.0 2.75

Injector sizes (mm)

RHF/CF

RHR/CR

LHF

LHR

1.80

1.80

1.80

1.35

1.09

1.09

1.09

0.89

Total Consumption (MJ/h ) 79.0 79.1

MF022

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in a ccordance with

AS/NZS3100 240 V AC, 4.5 kW/19 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF364C

Serial No:

Gas

type

NG

LPG

Test point press. (kPa) 1.0 2.75

Injector sizes (mm)

RHF

RHR

Grill

LHF

LHR

1.80

1.80

1.78

1.80

1.35

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h ) 66.0 66.1

MF028

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in a ccordance with

AS/NZS3100 240 V AC, 4.5 kW/19 amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF364G

Serial No:

Gas

type

NG LPG

Test point press. (kPa) 1.0 2.75

Injector sizes (mm)

RHF

RHR

Griddle

LHF

LHR

1.80

1.80

1.70

1.80

1.35

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h ) 66.0 66.1

MF018

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in acc ordance with

AS/NZS3100 240 V AC, 8.4 kW/35 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF484CG

Serial No:

Gas

type

NG

LPG

Test point press. (kPa) 1.0 2.75

Injector sizes (mm)

RHF

RHR

Grill

Griddle

LHF

LHR

1.80

1.80

1.78

1.70

1.80

1.35

1.09

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h) 81.0 81.1

MF016

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in ac cordance with

AS/NZS3100 240 V AC, 8.4 kW/35 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF484F

Serial No:

Gas

type

NG

LPG

Test point press. (kPa) 1.0 2.75

Injector sizes (mm)

RHF

RHR

French top

LHF

LHR

1.80

1.80

1.80

1.80

1.35

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h) 65.0 65.1

MF017

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in ac cordance with

AS/NZS3100 240 V AC, 8.4 kW/35 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF486C

Serial No:

Gas

type

NG LPG

Test point press. (kPa) 1.0 2.75

Injector sizes (mm)

RHF

RHR

Grill

LHF/CF/CR

LHR

1.80

1.80

1.78

1.80

1.35

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h) 94.0 94.1

MF029

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in ac cordance with

AS/NZS3100 240 V AC, 8.4 kW/35 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF486G

Serial No:

Gas

type

NG LPG

Test point press. (kPa) 1.0 2.75

Injector sizes (mm)

RHF/CF

RHR/CR

Griddle

LHF

LHR

1.80

1.80

1.70

1.80

1.35

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h) 94.0 94.1

MF030

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in acc ordance with

AS/NZS3100 240 V AC, 9.1 kW/ 38 Amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF604CF

Serial No:

Gas

type

NG

LPG

Test point p ress. (kPa) 1.0 2.75

Injector sizes (mm)

RHF

RHR

Grill

French top

LHF

LHR

1.80

1.80

1.78

1.80

1.80

1.35

1.09

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h) 80.0 81.1

MF026

Made in USA

GSCS20230

SAI GLOBAL

AS4551

Electrical compliance: in acc ordance with

AS/NZS3100 240 V AC, 9.1 kW/38 amps, 50 Hz

Imported &

distributed

by

Suite 1, 151 Barkley Avenue. Burnley VIC 3121

t: +61 3 9421 0232

Model

No:

ICBDF606CG

Serial No:

Gas

type

NG LPG

Test point p ress. (kPa) 1.0 2.75

Injector sizes (mm)

RHF/CF

RHR/CR

Grill

Griddle

LHF

LHR

1.80

1.80

1.78

1.70

1.80

1.35

1.09

1.09

1.09

1.09

1.09

0.89

Total Consumption (MJ/h) 109.0 109.1

MF023

Page 14

14

W i r i n g d i a g r a m

Page 15

15

W i r i n g d i a g r a m

Page 16

16

W i r i n g d i a g r a m

Page 17

17

W i r i n g d i a g r a m

Page 18

Page 19

Page 20

Imported&distribute d by Multyfle x

www.multyfl ex.com.au

MF038

Loading...

Loading...