Page 1

E SERIES BUILT-IN OVENS

INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

INSTRUCTIONS D’INSTALLATION

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLATIONSANWEISUNGEN

Page 2

ENGLISH 4

ESPÃNOL 22

FRANÇAIS 40

ITALIANO 58

DEUTSCH 76

3

Page 3

CONTACT

INFORMATION

Website:

wolfappliance.com

ORIGINAL

INSTRUCTIONS

As you follow these instruc tions, you will

notice WARNING and CAUTION symbols.

This blocked information is impor tant for the

safe and efficient installation of Wolf equipment. There are two types of potential

hazards that may occur during installation.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

WOLF®is a registered trademark of Wolf Appliance, Inc.

Page 4

WOLF E SERIES BUILT-IN OVENS

INSTALLATION REQUIREMENTS

IMPORTANT NOTE: This installation must

be completed by a qualified technician.

IMPORTANT NOTE:

Save these Installation

Instructions for the local inspector’s use.

Please read the entire Installation Instructions prior to installation.

Installer:

please retain these instructions

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep these

instructions for future reference and be sure

to read the entire Use & Care Information

prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with all local codes.

The correct voltage, frequency and amperage

must be supplied to the appliance from a dedicated, grounded circuit which is protected by a

properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and

amperage ratings are listed on the product

rating plate.

SITE PREPARATION

IMPORTANT NOTE:

A minimum 610 mm of

usable cabinet depth is required, or the back

panel of the cabinet may need to be removed

for proper installation. A minimum 635 mm of

usable cabinet depth is required for a flush

inset installation. The electrical box must be

flush with the back panel of the cabinet.

The installation opening must have a flat, level

base platform to support the oven. Single

ovens require a minimum base support of

113 kg and double ovens require a minimum

base support of 181 kg.

IMPORTANT NOTE:

Wolf built-in ovens are

designed and agency approved for installation

with Wolf cooktops, microwaves and warming

drawers only. The nominal width of the built-in

oven should match the nominal width of the

cooktop. A built-in oven cannot be installed

below a Wolf rangetop.

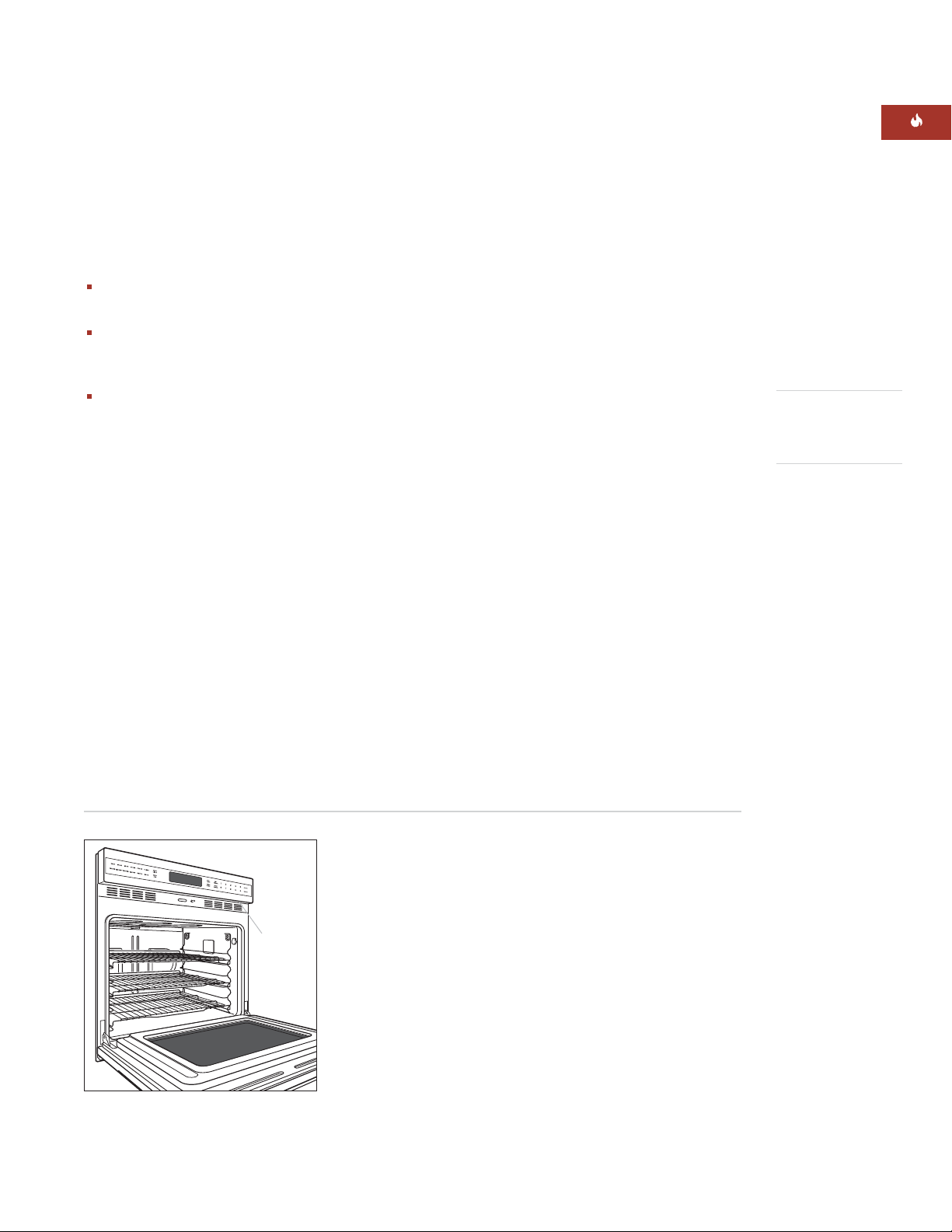

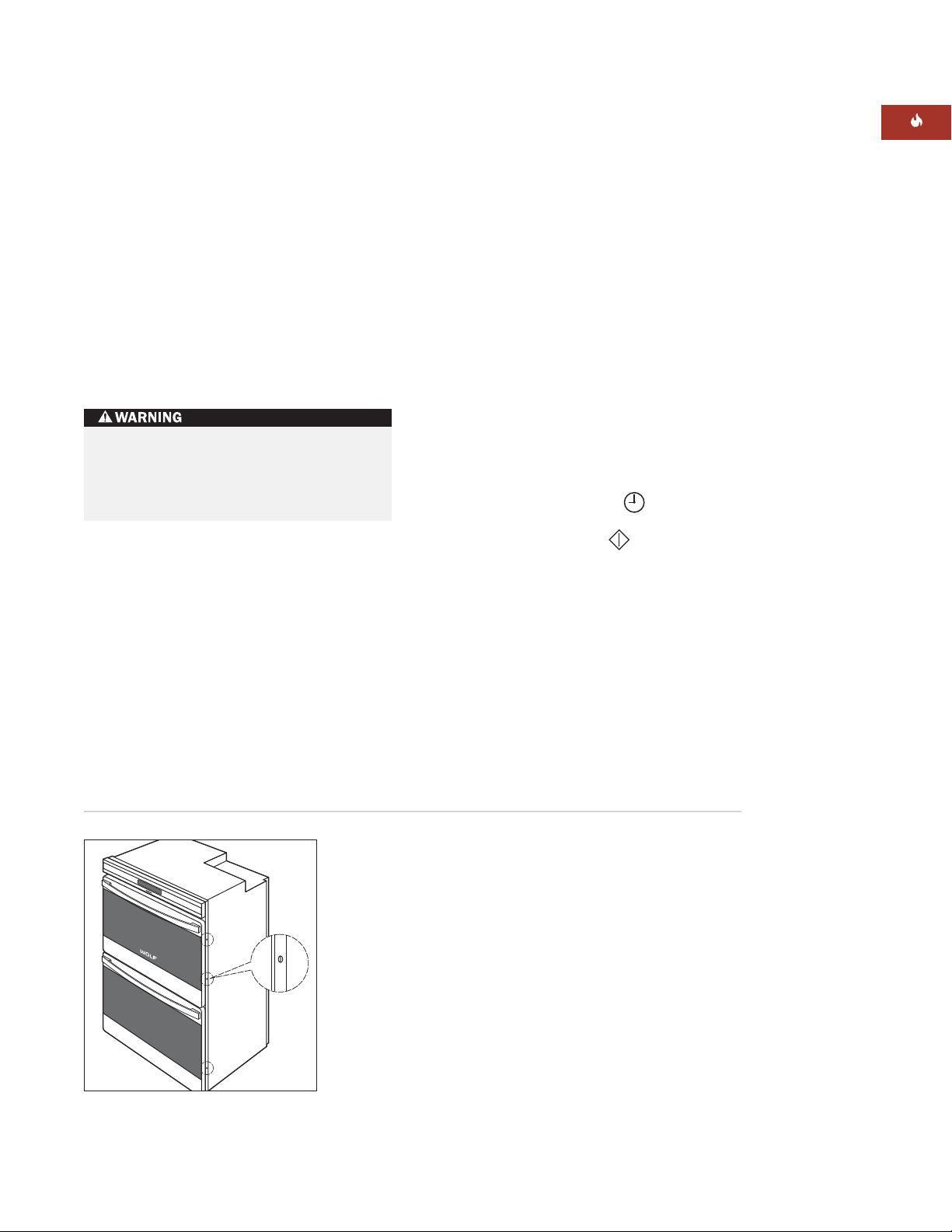

RATING PLATE

INFORMATION

Model Number

Serial Number

Record the model and serial numbers before

installing the built-in oven. Both numbers are

listed on the rating plate, located on the right

side of the oven trim, directly above the door.

Open the oven door to view the rating plate.

Refer to the illustration below.

Location

of rating

plate

Rating plate location

5

Page 5

WOLF E SERIES BUILT-IN OVENS

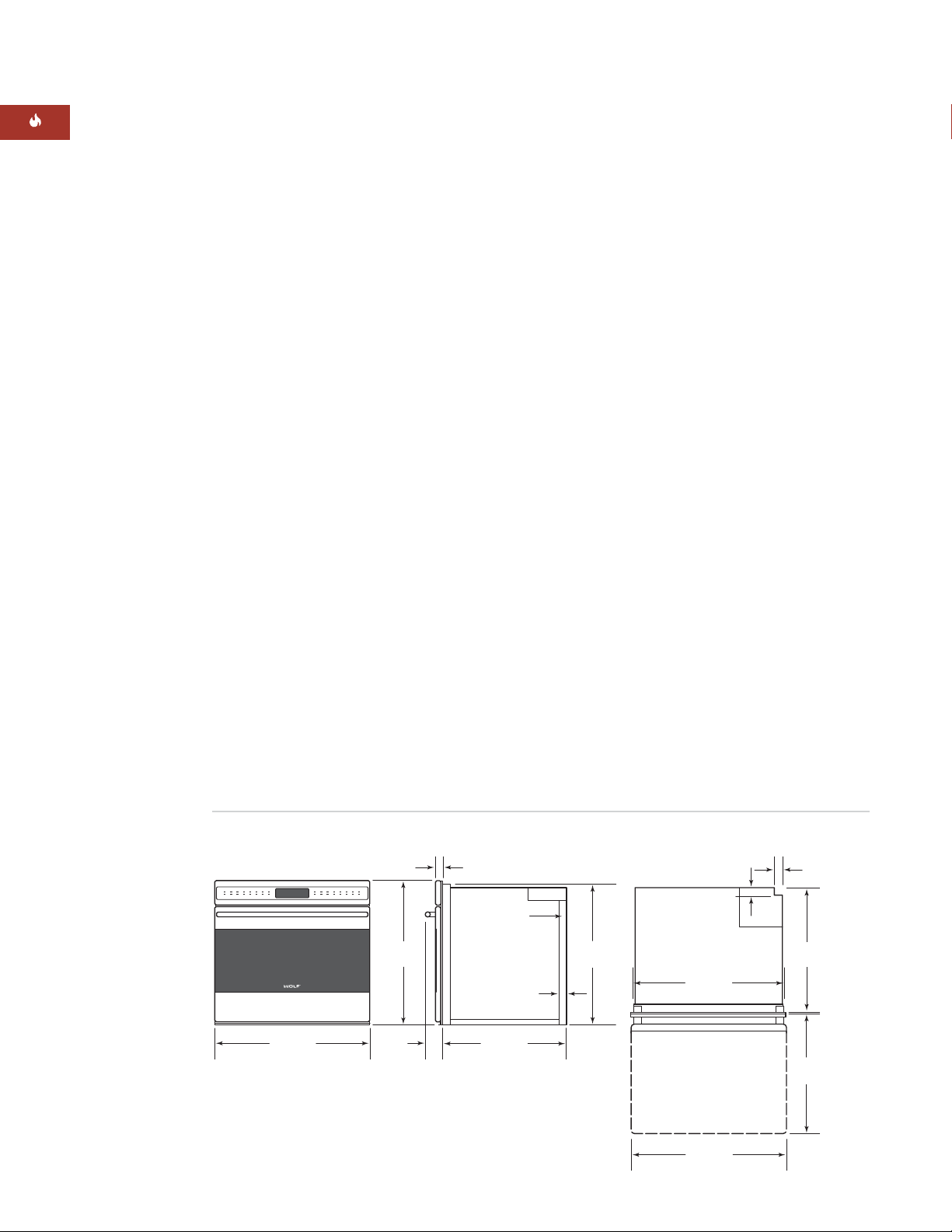

E SERIES BUILT-IN SINGLE OVENS

IMPORTANT NOTE:

A minimum 610 mm of

usable cabinet depth is required, or the back

panel of the cabinet may need to be removed

for proper installation. A minimum 635 mm of

usable cabinet depth is required for a flush

inset installation. The electrical box must be

flush with the back panel of the cabinet.

For ease of installation, Wolf recommends

using 838 mm wide cabinets with the E Series

single oven. A minimum 838 mm wide cabinet

is required for a flush inset installation. The

cabinet base platform must be able to support

113 kg.

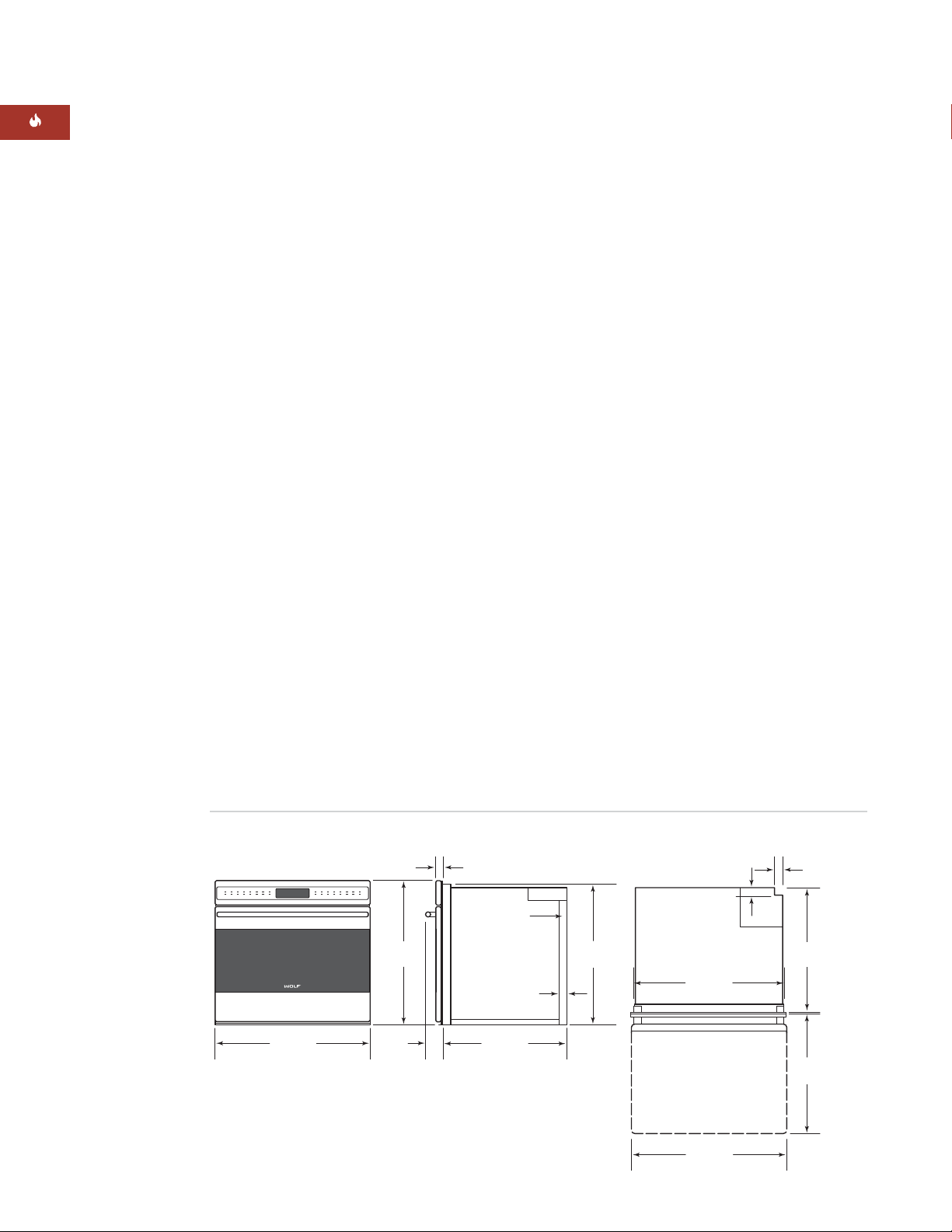

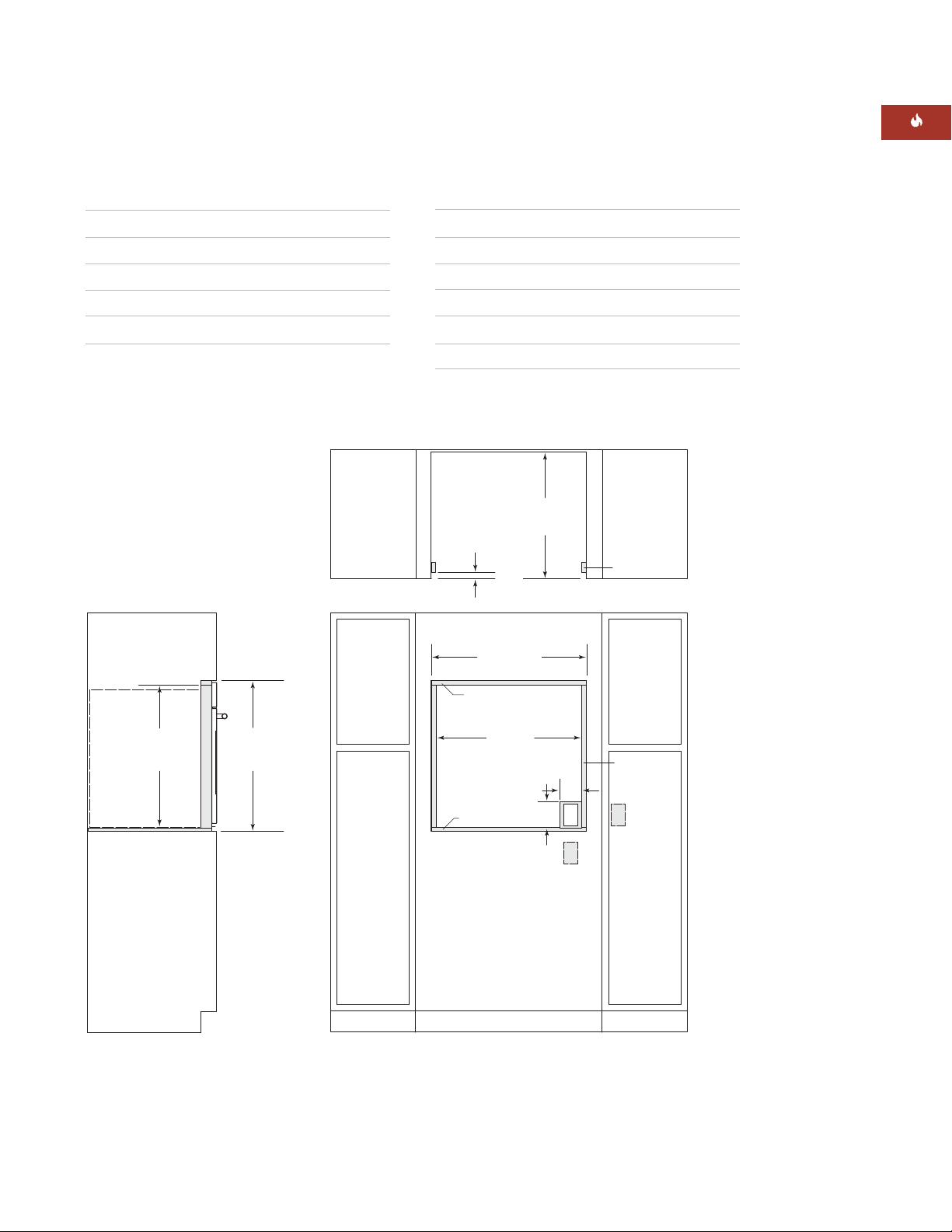

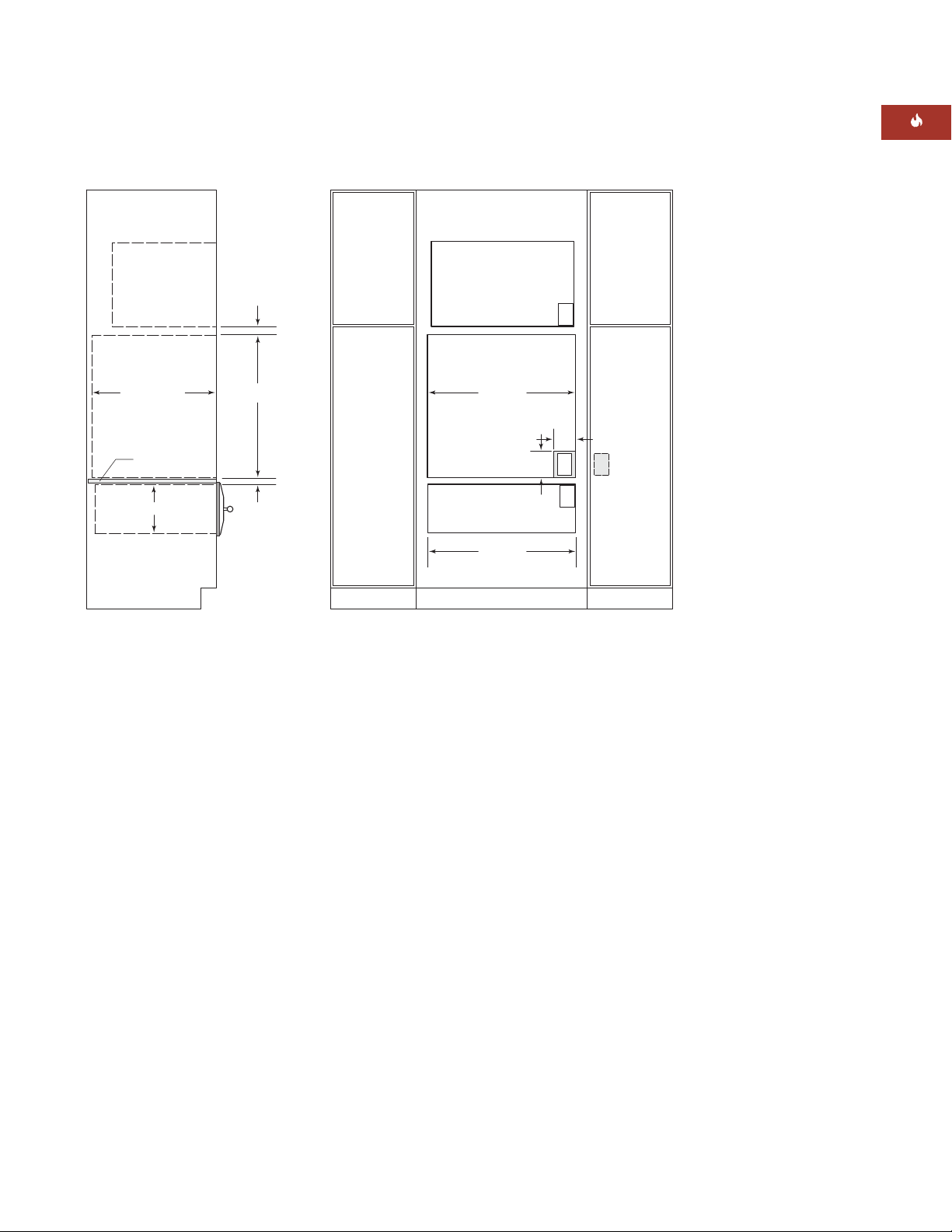

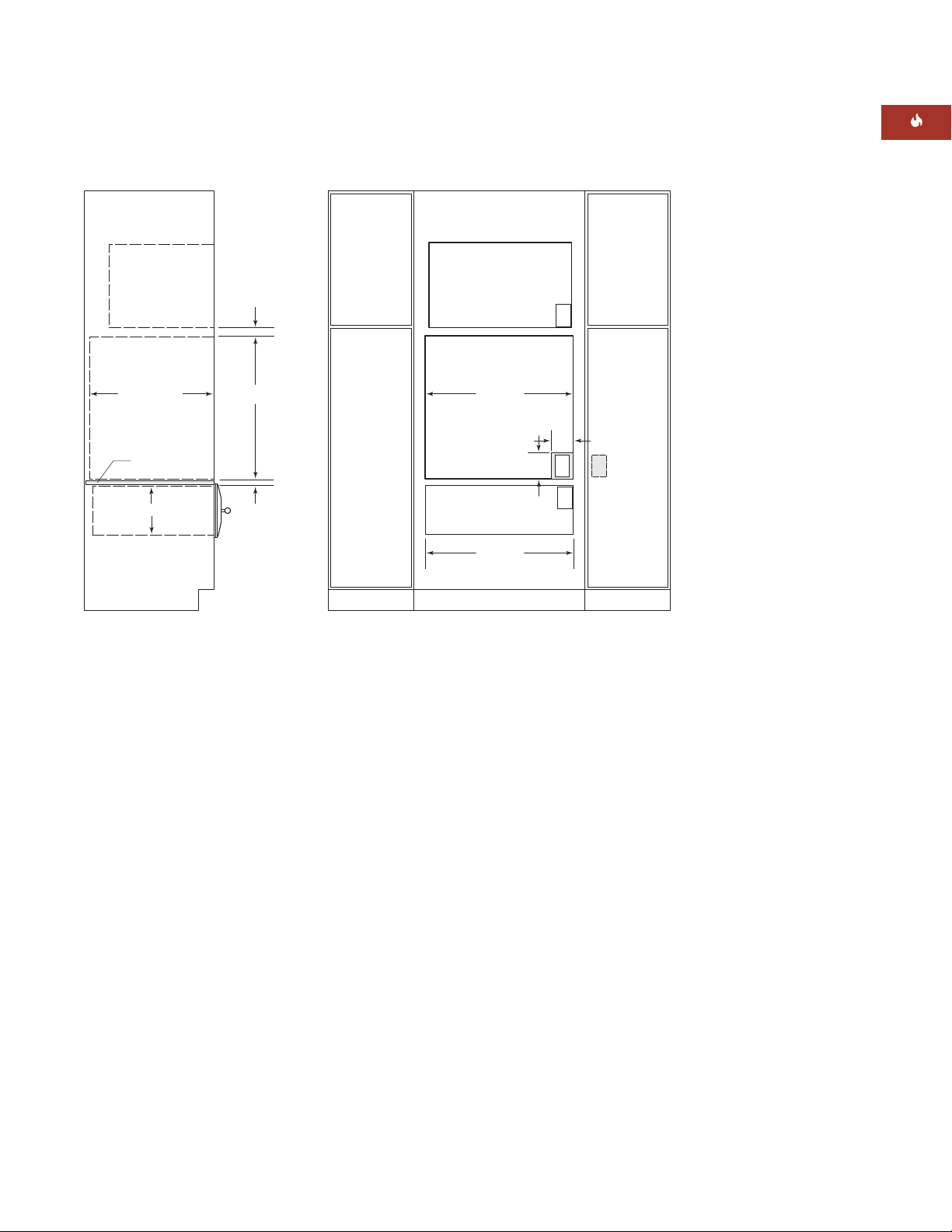

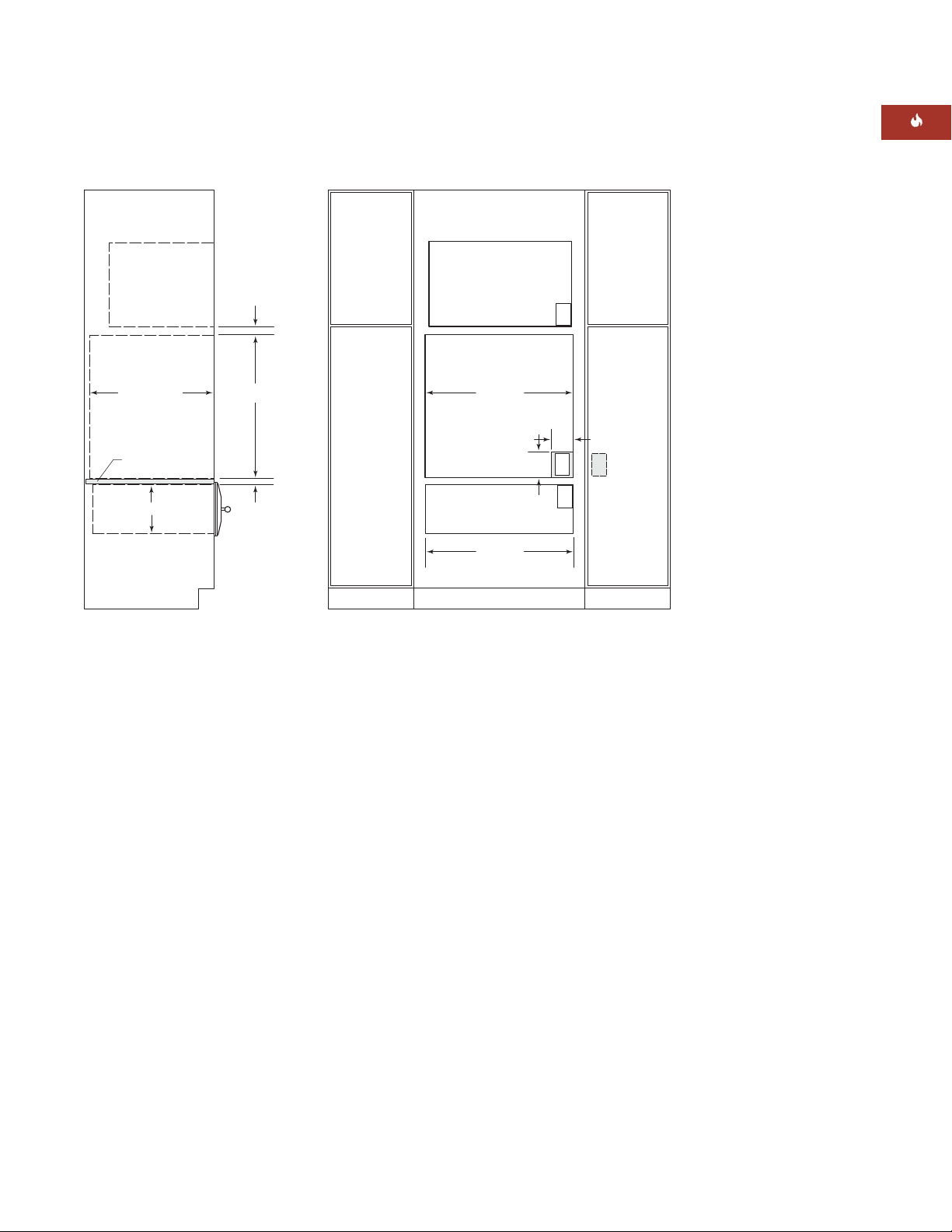

Refer to the following illustrations for overall

dimensions, installation specifications and

electrical location for the E Series single oven.

The E Series single oven requires a grounded

3-wire 220-240 V AC, 50 Hz electrical supply.

Refer to Electrical Requirements on page 16.

The oven is not supplied with an electrical

plug.

IMPORTANT NOTE:

Unless you are using

cabinets deeper than 610 mm for a standard

installation or 635 mm for a flush inset installation, it is recommended that the electrical

supply be placed in an adjacent cabinet.

Choose the location shown in the installation

illustrations on pages 8–9 that best suits your

installation.

OVERALL DIMENSIONS

25 mm*

708

mm

759 mm

*For black glass model, increase dimension by 6 mm.

Unframed Model ICBSO30-2U/S shown.

6

67*

mm

RIGHT SIDE VIEW

CONDUIT

CHANNEL

48 mm

603 mm

BEHIND FRAME

687

mm

TOP VIEW

48 mm

718 mm

OPEN OVEN DOOR

759 mm

32 mm

603*

mm

559

mm

Page 6

INSTALLATION INSTRUCTIONS

E SERIES BUILT-IN SINGLE OVENS

STANDARD INSTALLATION

IMPORTANT NOTE:

For standard installations,

a minimum 610 mm of usable cabinet depth is

required, or the back panel of the cabinet may

need to be removed for proper installation.

The electrical box must be flush with the back

panel of the cabinet.

For standard installations, the E Series built-in

oven is installed by inserting into cabinetry

from the front. The oven has a face trim on all

four sides and will overlap stiles and rails. The

trim overlaps 3 mm on the bottom, 8 mm on

the top and 19 mm on each side.

FLUSH INSET INSTALLATION

IMPORTANT NOTE:

For flush inset installations, a minimum 635 mm of usable cabinet

depth is required, 641 mm for black glass

models, or the back panel of the cabinet may

need to be removed for proper installation.

The electrical box must be flush with the back

panel of the cabinet.

COMBINATION INSTALLATIONS

The Wolf E Series single oven may be installed

below a Wolf 762 mm induction, electric or gas

cooktop. Unless you are using cabinets deeper

than 610 mm for a standard installation or 635

mm for a flush inset installation, it is recommended that the electrical supply be placed in

the base cabinet to the right of the oven. The E

Series single oven may also be installed below

a Wolf 914 mm induction, electric or gas

cooktop.

A Wolf E Series single oven may be installed

next to another E Series single oven. You must

allow for a 64 mm space between the oven

rough openings. Also, a separate inner wall is

required for each oven between openings.

The flush inset installation requires the built-in

oven to be recessed into the cabinet. A

minimum 838 mm wide and 635 mm deep

cabinet is needed if you want the front of the

oven to be flush with surrounding cabinetry.

IMPORTANT NOTE:

For flush inset installations, the inside edges of the rough opening

must be finished, as they will be exposed

when the oven door is open. These edges

should be stained instead of having a laminated surface, to avoid damage from high

temperatures during self-clean.

7

Page 7

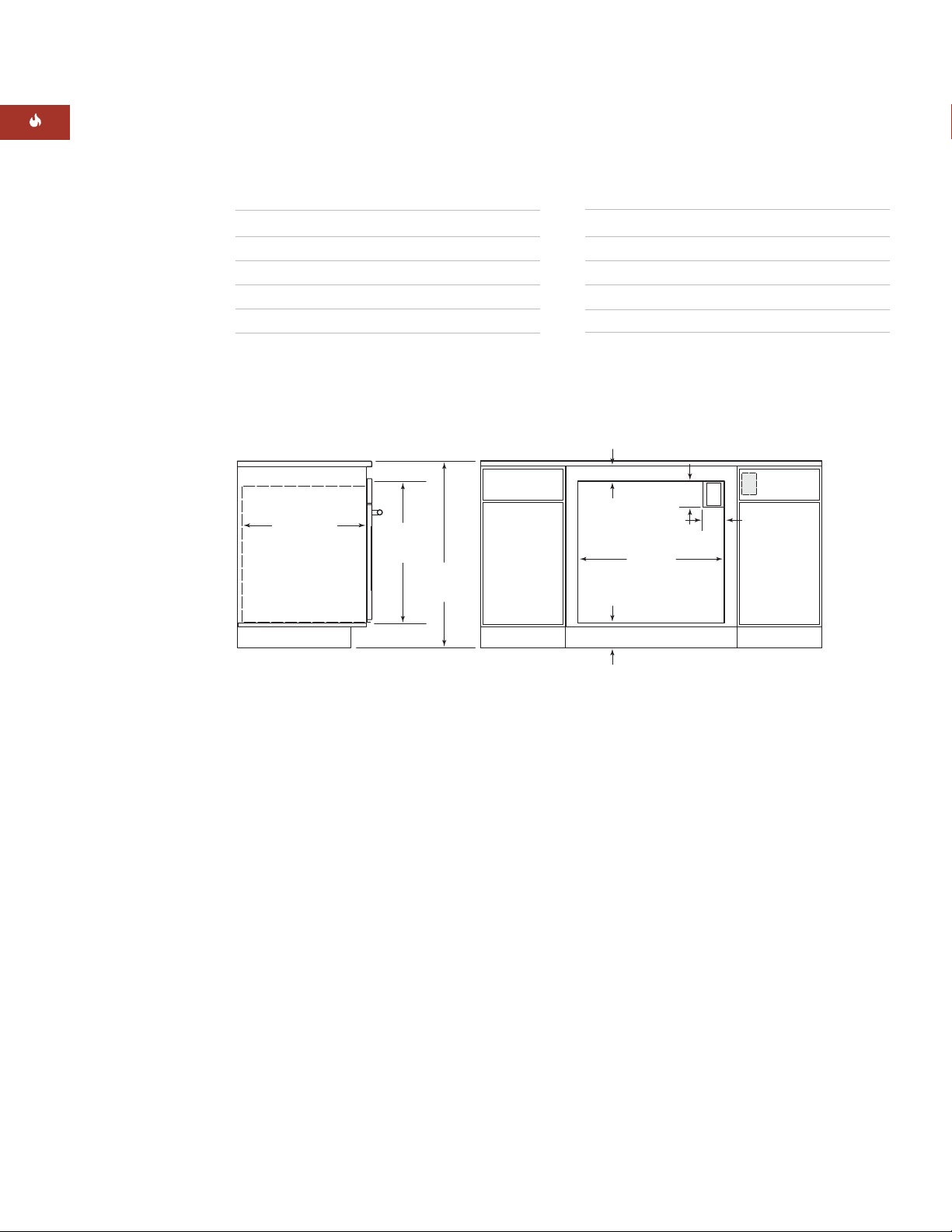

WOLF E SERIES BUILT-IN OVENS

E SERIES BUILT-IN SINGLE OVENS

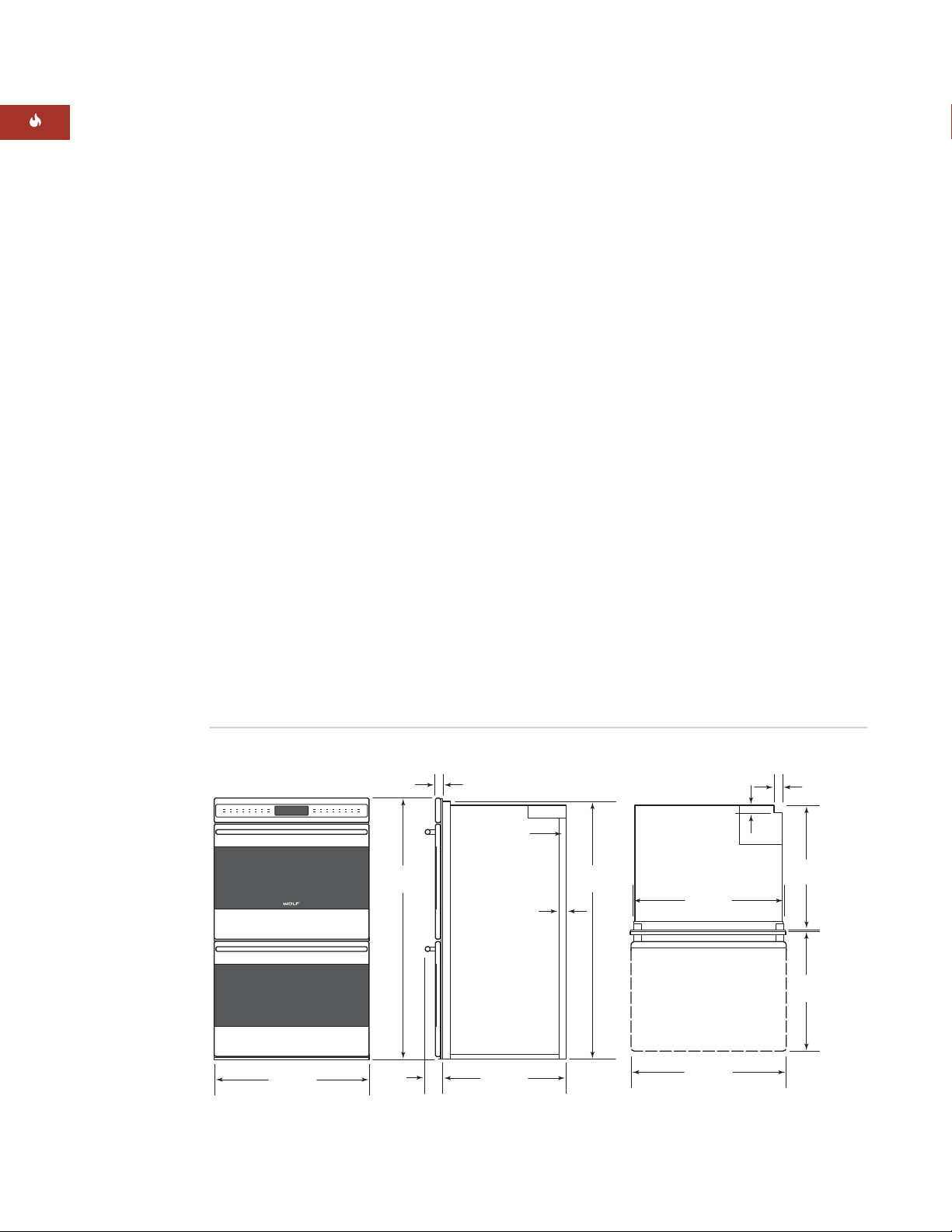

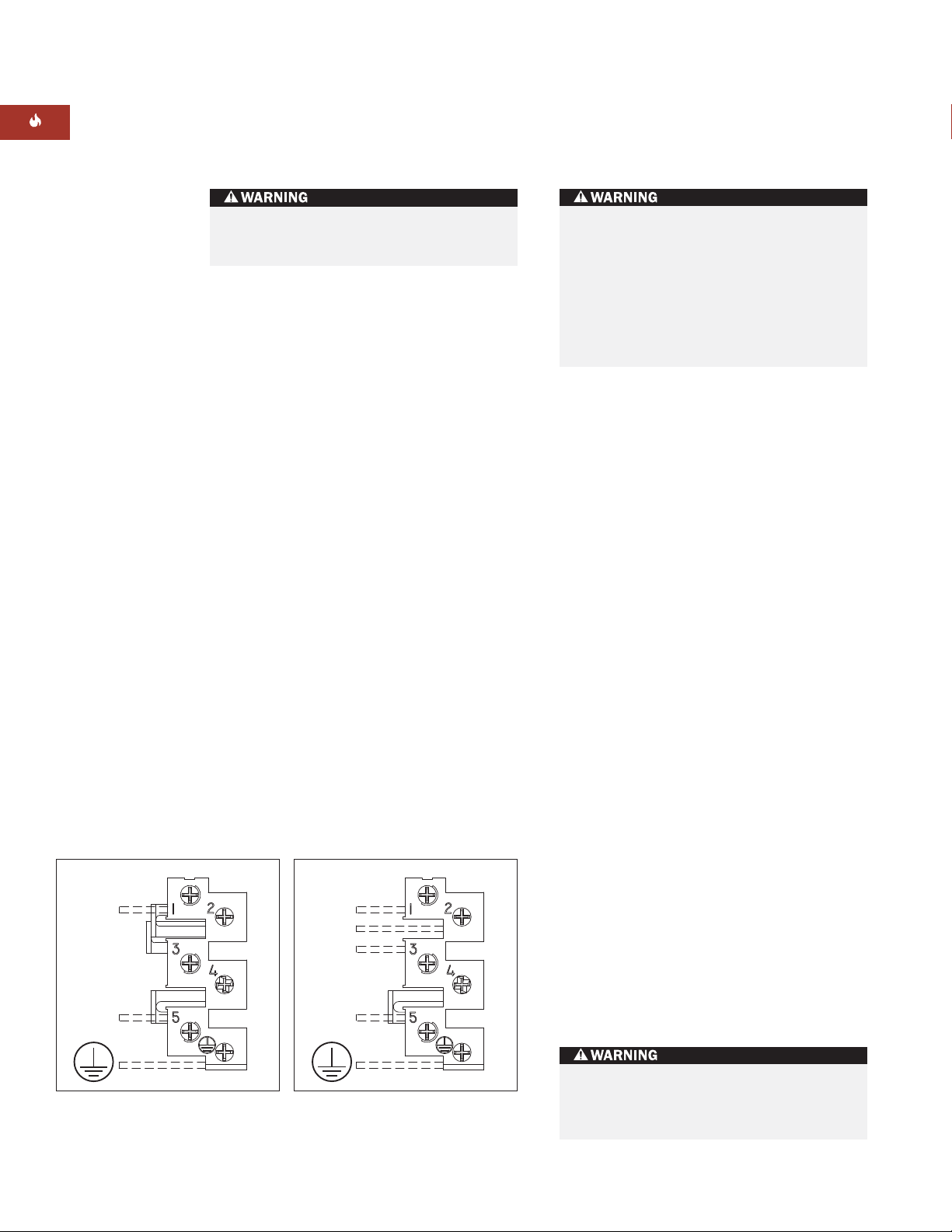

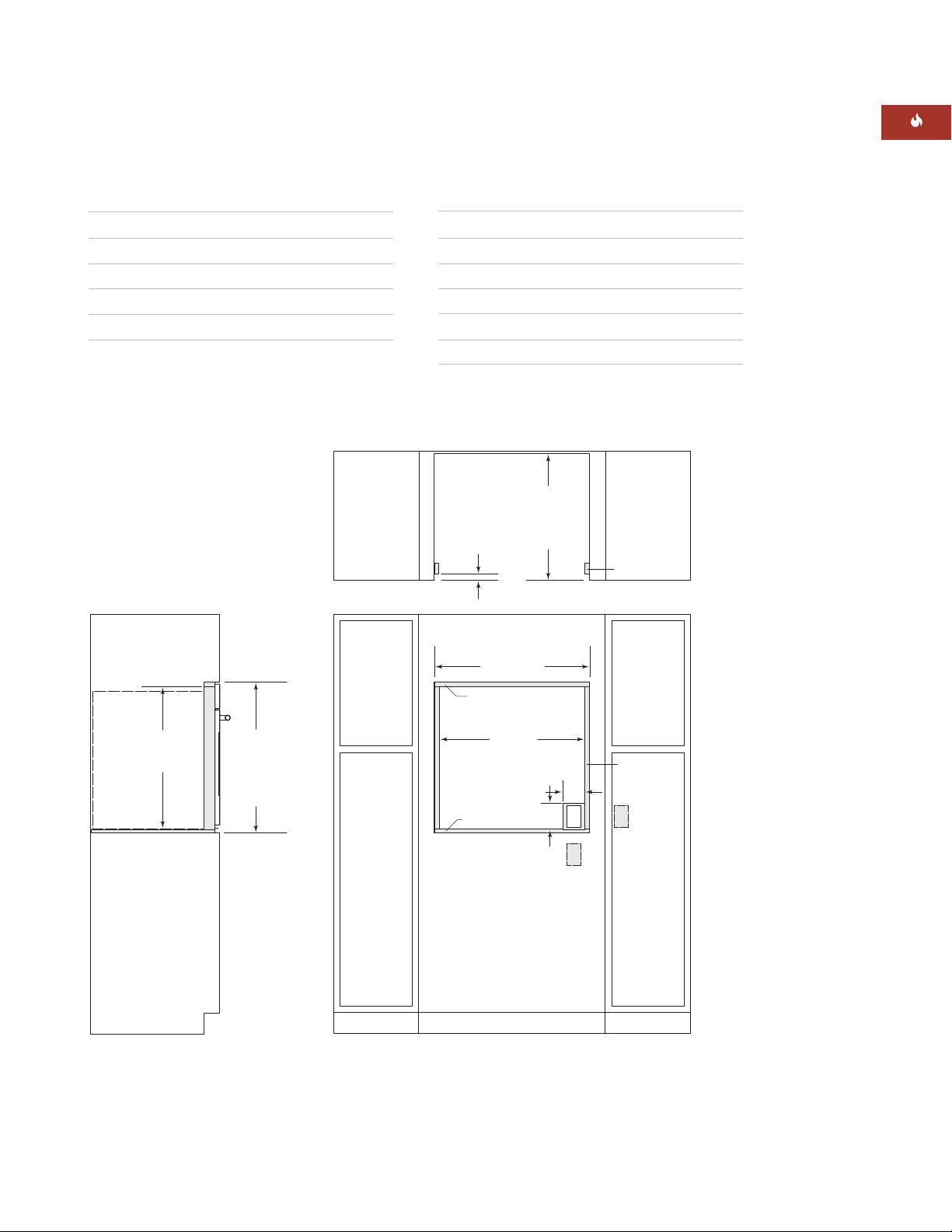

STANDARD INSTALLATION

Overall Oven Width 759 mm

Overall Oven Height 708 mm

Overall Oven Depth (behind frame) 603 mm

Open Door Clearance 559 mm

Recommended Cabinet Width 838 mm

STANDARD INSTALLATION

610 mm min

OPENING DEPTH

691 mm

OPENING

HEIGHT

914 mm

FLOOR TO

COUNTERTOP

Minimum Cabinet Width 762 mm

Minimum Cabinet (Opening) Depth 610 mm

Opening Width 724 mm

Opening Height 691 mm

Minimum Base Support 113 kg

DIMENSION WILL VARY*

724 mm

OPENING WIDTH

121 mm TYPICAL*

FRONT VIEWSIDE VIEW

127

mm

102

mm

E

E

*Dimension must accommodate height of oven trim.

NOTES: Location of electrical supply within opening may require additional cabinet depth.

Dashed line represents profile of unit.

8

Page 8

INSTALLATION INSTRUCTIONS

E SERIES BUILT-IN SINGLE OVENS

FLUSH INSET INSTALLATION

Overall Oven Width 759 mm

Overall Oven Height 708 mm

Overall Oven Depth (behind frame) 603 mm

Open Door Clearance 559 mm

Minimum Base Support 113 kg

FLUSH INSET INSTALLATION

Minimum Cabinet Width 838 mm

Minimum Flush Inset Depth 635 mm

Opening Width 724 mm

Minimum Flush Inset Width 772 mm

Opening Height 691 mm

Minimum Flush Inset Height 724 mm

TOP VIEW

629 mm* min

FLUSH INSET

DEPTH

25 mm*

SIDE CLEATS

772 mm min

FLUSH INSET WIDTH

22 mm TOP CLEAT

IMPORTANT

NOTE

For flush inset

installations, the

inside edges of the

rough opening

must be finished,

as they will be

exposed when the

oven door is open.

691 mm

OPENING

HEIGHT

*For black glass model, increase dimension by 6 mm.

NOTES: Minimum base support 113 kg.

Location of electrical supply within opening may require additional cabinet depth.

Cleats may be visible and should be finished to match cabinetry.

Dashed line represents profile of unit.

724 mm min

FLUSH INSET

HEIGHT

724 mm

OPENING WIDTH

11 mm

BOTTOM CLEAT

FRONT VIEWSIDE VIEW

127

mm

102

mm

E

E

25 mm

SIDE CLEATS

E

9

Page 9

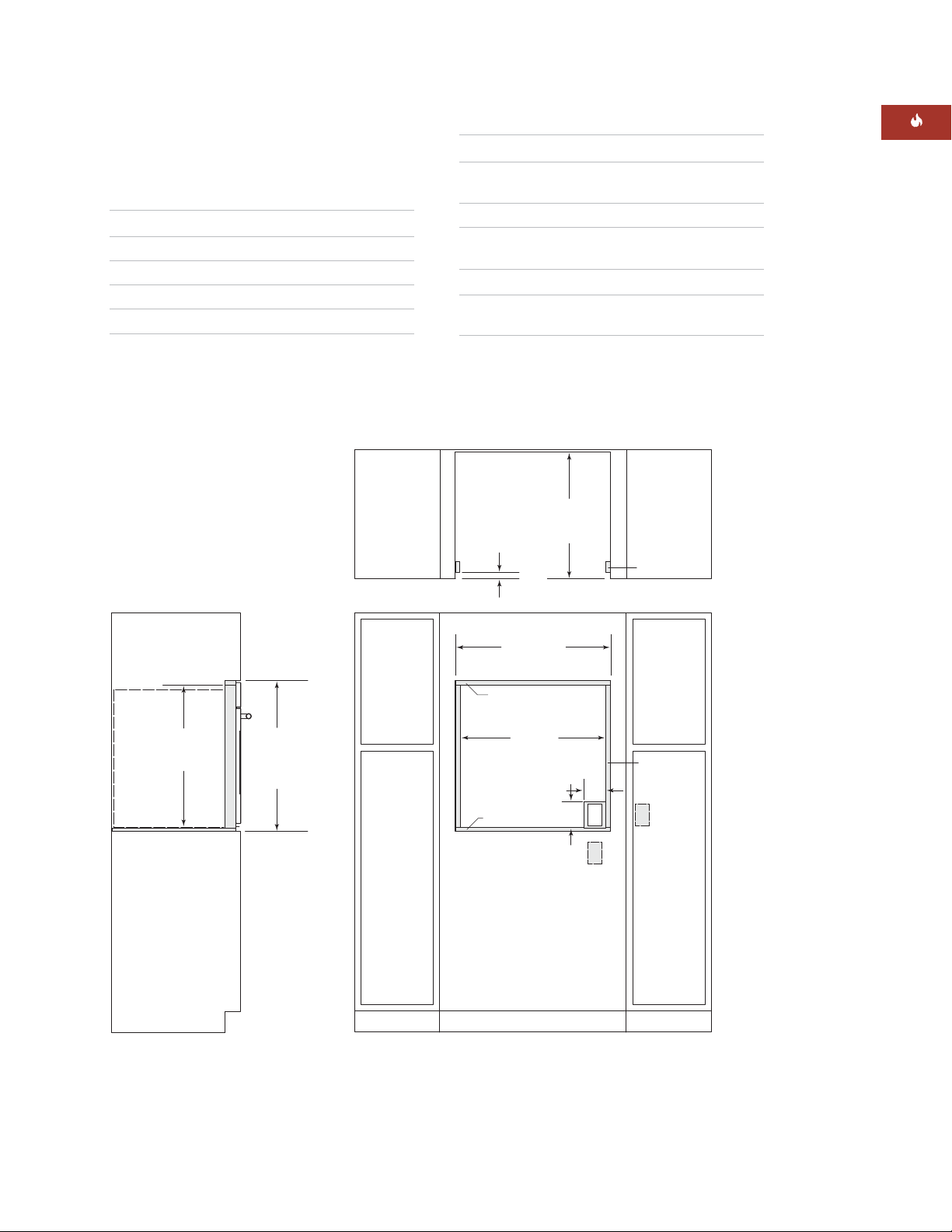

WOLF E SERIES BUILT-IN OVENS

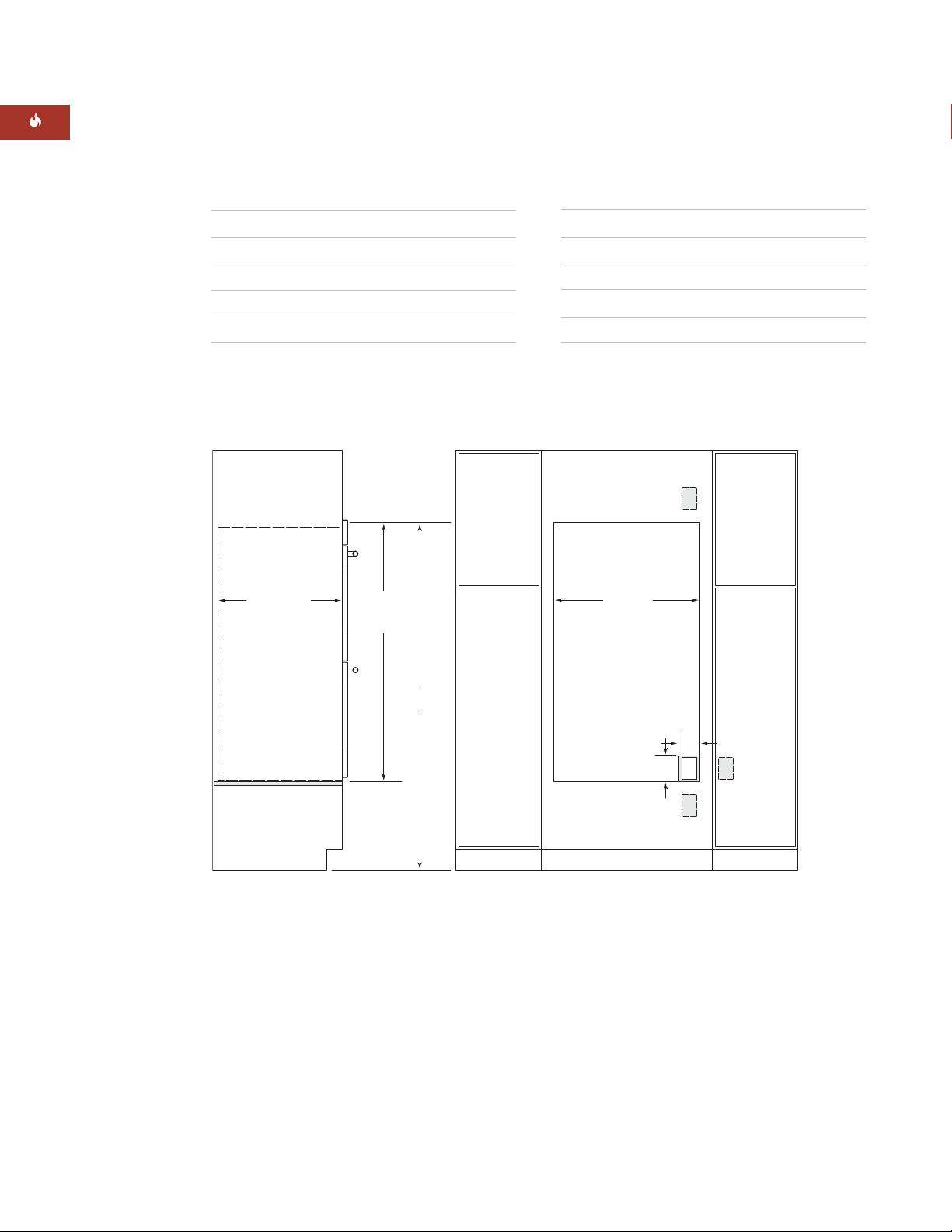

E SERIES BUILT-IN DOUBLE OVENS

IMPORTANT NOTE:

A minimum 610 mm of

usable cabinet depth is required, or the back

panel of the cabinet may need to be removed

for proper installation. A minimum 635 mm of

usable cabinet depth is required for a flush

inset installation. The electrical box must be

flush with the back panel of the cabinet.

For ease of installation, Wolf recommends

using 838 mm wide cabinets with the E Series

double oven. A minimum 838 mm wide

cabinet is required for a flush inset installation.

The cabinet base platform must be able to

support 181 kg.

Refer to the following illustrations for overall

dimensions, installation specifications and

electrical location for the E Series double oven.

The E Series double oven requires a grounded

3-wire 220-240 V AC, 50 Hz electrical supply.

Refer to Electrical Requirements on page 16.

The oven is not supplied with an electrical

plug.

IMPORTANT NOTE:

Unless you are using

cabinets deeper than 610 mm for a standard

installation or 635 mm for a flush inset installation, it is recommended that the electrical

supply be placed in an adjacent cabinet.

Choose the location shown in the installation

illustrations on pages 12–13 that best suits

your installation.

10

OVERALL DIMENSIONS

25 mm*

1280

mm

759 mm

*For black glass model, increase dimension by 6 mm.

Unframed Model ICBDO30-2U/S shown.

67*

mm

RIGHT SIDE VIEW

CONDUIT

CHANNEL

48 mm

603 mm

BEHIND FRAME

1257

mm

TOP VIEW

48 mm

718 mm

OPEN OVEN DOOR

759 mm

32 mm

603*

mm

559

mm

Page 10

INSTALLATION INSTRUCTIONS

E SERIES BUILT-IN DOUBLE OVENS

STANDARD INSTALLATION

IMPORTANT NOTE:

For standard installations,

a minimum 610 mm of usable cabinet depth is

required, or the back panel of the cabinet may

need to be removed for proper installation.

The electrical box must be flush with the back

panel of the cabinet.

For standard installations, the E Series built-in

oven is installed by inserting into cabinetry

from the front. The oven has a face trim on all

four sides and will overlap stiles and rails. The

trim overlaps 3 mm on the bottom, 8 mm on

the top and 19 mm on each side.

FLUSH INSET INSTALLATION

IMPORTANT NOTE:

For flush inset installations, a minimum 635 mm of usable cabinet

depth is required, 641 mm for black glass

models, or the back panel of the cabinet may

need to be removed for proper installation.

The electrical box must be flush with the back

panel of the cabinet.

The flush inset installation requires the built-in

oven to be recessed into the cabinet. A

minimum 838 mm wide and 635 mm deep

cabinet is needed if you want the front of the

oven to be flush with surrounding cabinetry.

IMPORTANT NOTE:

For flush inset installations, the inside edges of the rough opening

must be finished, as they will be exposed

when the oven doors are open. These edges

should be stained instead of having a laminated surface, to avoid damage from high

temperatures during self-clean.

11

Page 11

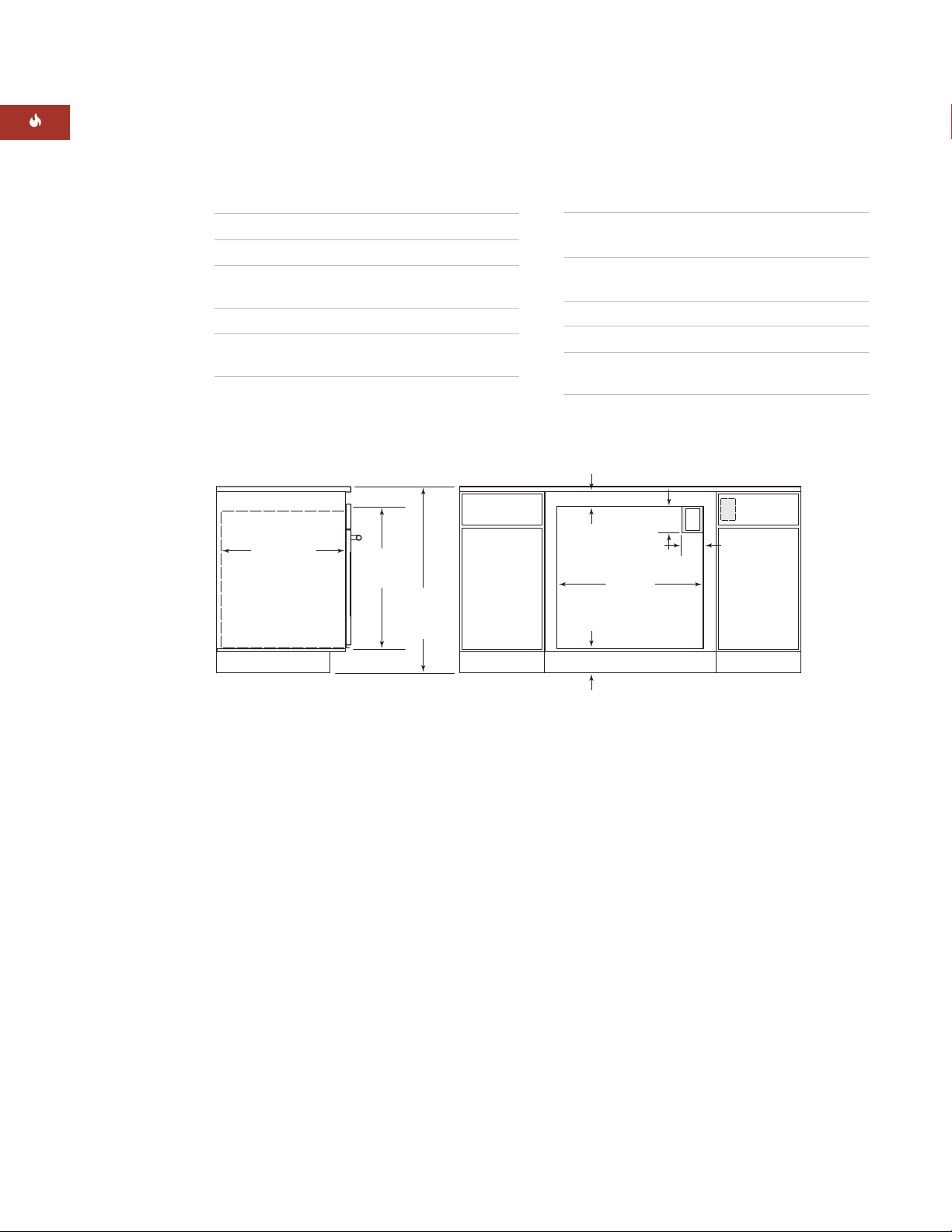

WOLF E SERIES BUILT-IN OVENS

E SERIES BUILT-IN DOUBLE OVENS

STANDARD INSTALLATION

Overall Oven Width 759 mm

Overall Oven Height 1280 mm

Overall Oven Depth (behind frame) 603 mm

Open Door Clearance 559 mm

Recommended Cabinet Width 838 mm

STANDARD INSTALLATION

610 mm min

OPENING DEPTH

1260 mm

OPENING

HEIGHT

Minimum Cabinet Width 762 mm

Minimum Cabinet (Opening) Depth 610 mm

Opening Width 724 mm

Opening Height 1260 mm

Minimum Base Support 181 kg

E

724 mm

OPENING WIDTH

1702 mm

TYPICAL*

*Dimension must accommodate height of oven trim.

NOTES: Location of electrical supply within opening may require additional cabinet depth.

Dashed line represents profile of unit.

102

mm

127

E

mm

FRONT VIEWSIDE VIEW

E

E

12

Page 12

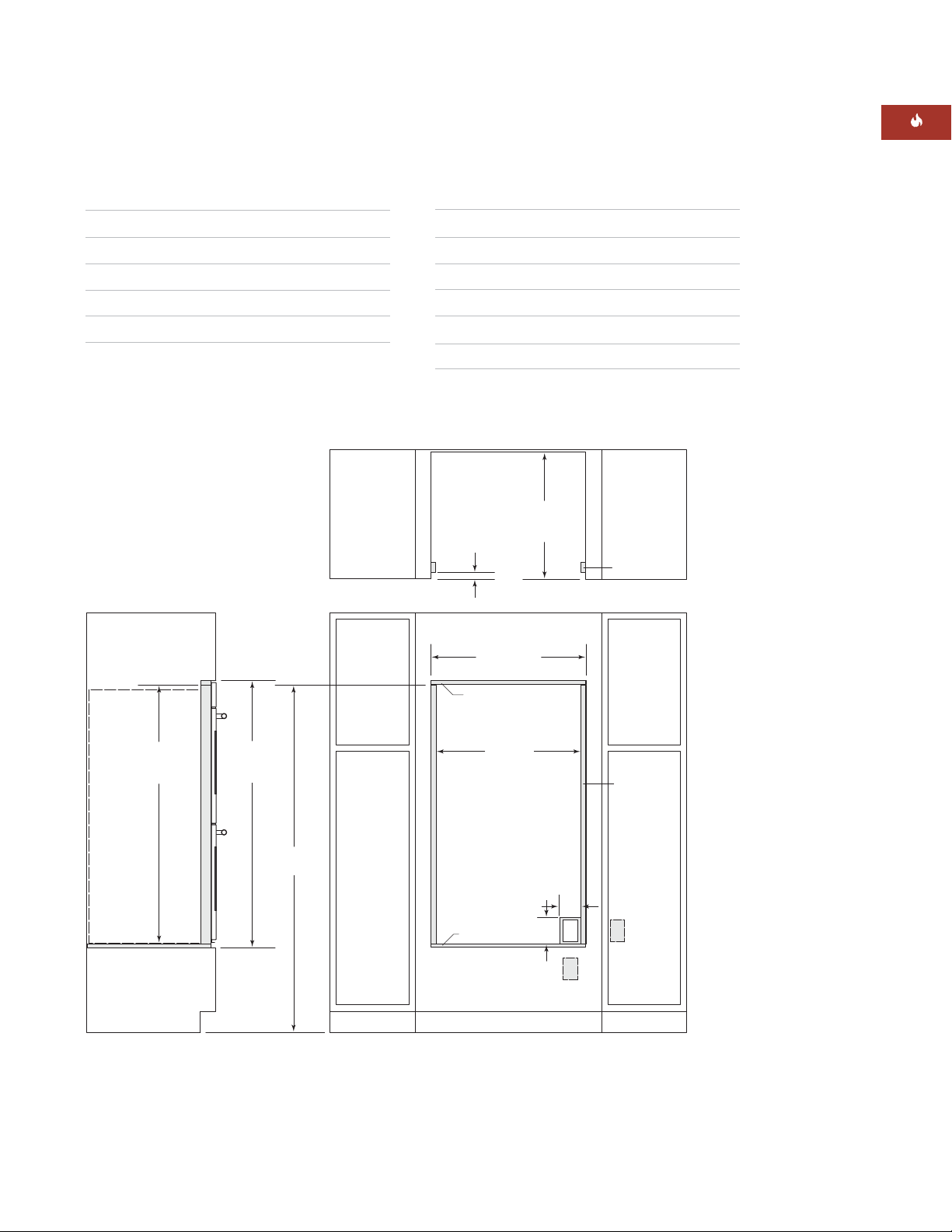

INSTALLATION INSTRUCTIONS

E SERIES BUILT-IN DOUBLE OVENS

FLUSH INSET INSTALLATION

Overall Oven Width 759 mm

Overall Oven Height 1280 mm

Overall Oven Depth (behind frame) 603 mm

Open Door Clearance 559 mm

Minimum Base Support 181 kg

FLUSH INSET INSTALLATION

Minimum Cabinet Width 838 mm

Minimum Flush Inset Depth 635 mm

Opening Width 724 mm

Minimum Flush Inset Width 772 mm

Opening Height 1260 mm

Minimum Flush Inset Height 1294 mm

TOP VIEW

629 mm* min

FLUSH INSET

25 mm*

772 mm min

FLUSH INSET WIDTH

22 mm TOP CLEAT

DEPTH

SIDE CLEATS

IMPORTANT

NOTE

For flush inset

installations, the

inside edges of the

rough opening

must be finished,

as they will be

exposed when the

oven doors are

open.

1260 mm

OPENING

HEIGHT

*For black glass model, increase dimension by 6 mm.

NOTES: Minimum base support 181 kg.

Location of electrical supply within opening may require additional cabinet depth.

Cleats may be visible and should be finished to match cabinetry.

Dashed line represents profile of unit.

1294 mm min

FLUSH INSET

HEIGHT

1702 mm

TYPICAL

724 mm

OPENING WIDTH

11 mm

BOTTOM CLEAT

FRONT VIEWSIDE VIEW

127

mm

102

mm

E

E

25 mm

SIDE CLEATS

E

13

Page 13

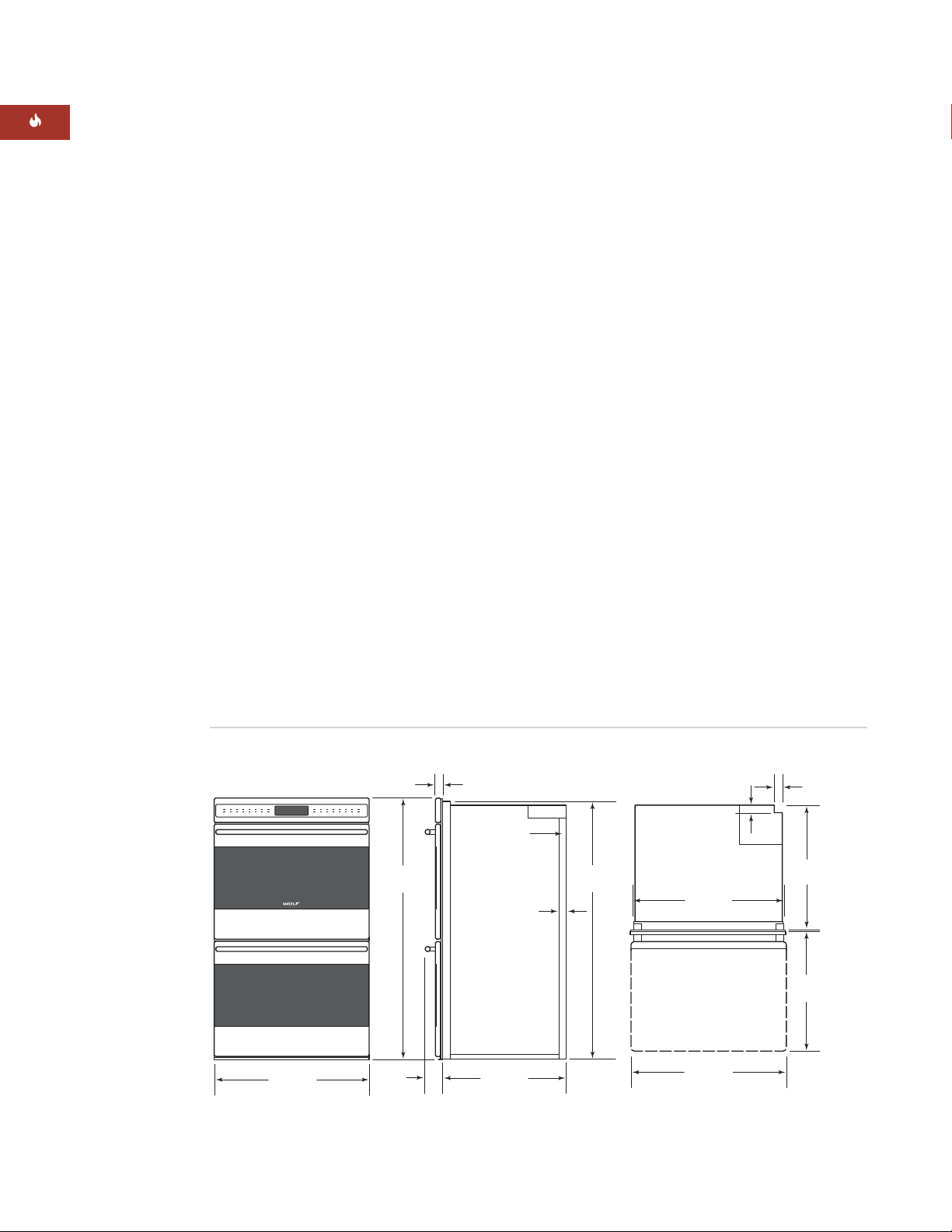

WOLF E SERIES BUILT-IN OVENS

STANDARD INSTALLATION

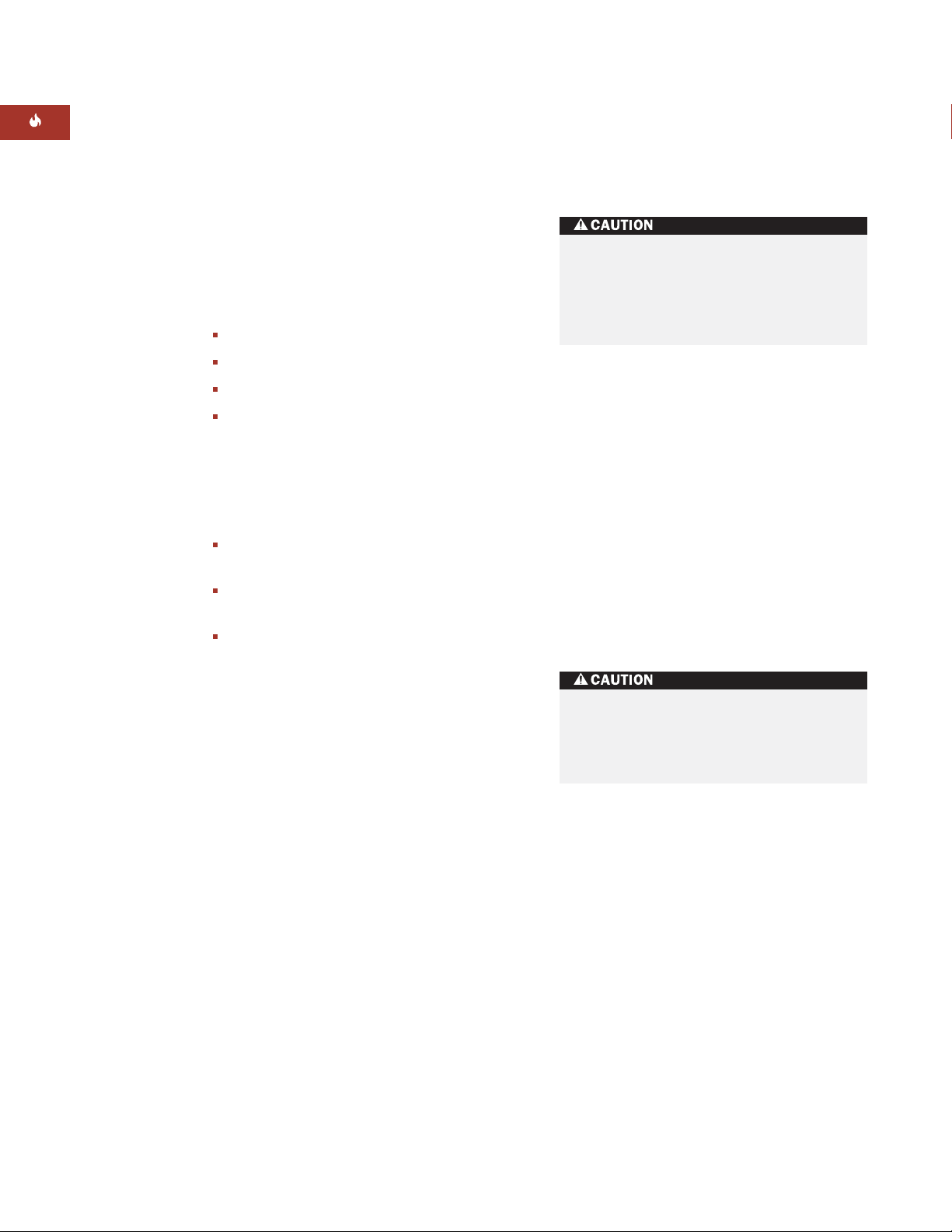

OPTIONS

E SERIES BUILT-IN SINGLE OVEN

The Wolf E Series single oven may be installed

in combination with a Wolf convection or nonconvection microwave oven with 762 mm

E Series trim kit, and a Wolf warming drawer

with E Series stainless steel drawer front or

integrated drawer front. Refer to the illustration below, and pages 6–9 for installation specifications for E Series single ovens.

Keep in mind that the size of the custom

panel for the warming drawer with integrated

drawer front will vary according to the

specific installation. Refer to the installation

instructions provided with the microwave trim

kit and warming drawer front for detailed

specifications. Dimensions will vary according

to the specific installation.

14

Page 14

INSTALLATION INSTRUCTIONS

STANDARD INSTALLATION

38 mm

min

MICROWAVE

OPENING

E

610 mm min

OPENING DEPTH

NTI-TIP

A

691 mm

724 mm

OVEN OPENING WIDTH

127

mm

102

mm

E

E

E

232 mm

NOTES: Minimum base support for oven 113 kg.

Location of electrical supply within opening may require additional cabinet depth.

Dashed line represents profile of unit.

19 mm

min

727 mm

WARMING DRAWER

OPENING WIDTH

FRONT VIEWSIDE VIEW

Single oven installed with convection microwave with 762 mm E Series trim and warming drawer with

E Series stainless steel drawer front.

15

Page 15

WOLF E SERIES BUILT-IN OVENS

ELECTRICAL REQUIREMENTS

IMPORTANT

NOTE

Be aware of local

codes and ordinances when

installing your

service.

L1

˜

N

Verify that power is disconnected from

the electrical box before proceeding.

E SERIES SINGLE OVENS

Required power supply:

Single phase: 220-240V AC; 50 Hz

3phase: 380-415V AC; 50 Hz

Maximum connected load:

Single phase: 4.4 kW

3phase: 4.4 kW

Total amps:

Single phase: 19 amps

3phase: 19 amps

E SERIES DOUBLE OVENS

Required power supply:

Single phase: 220-240V AC; 50 Hz

3phase: 380-415V AC; 50 Hz

Maximum connected load:

Single phase: 7.4 kW

3phase: 5.1 kW

Total amps:

Single phase: 32 amps

3phase: 22 amps

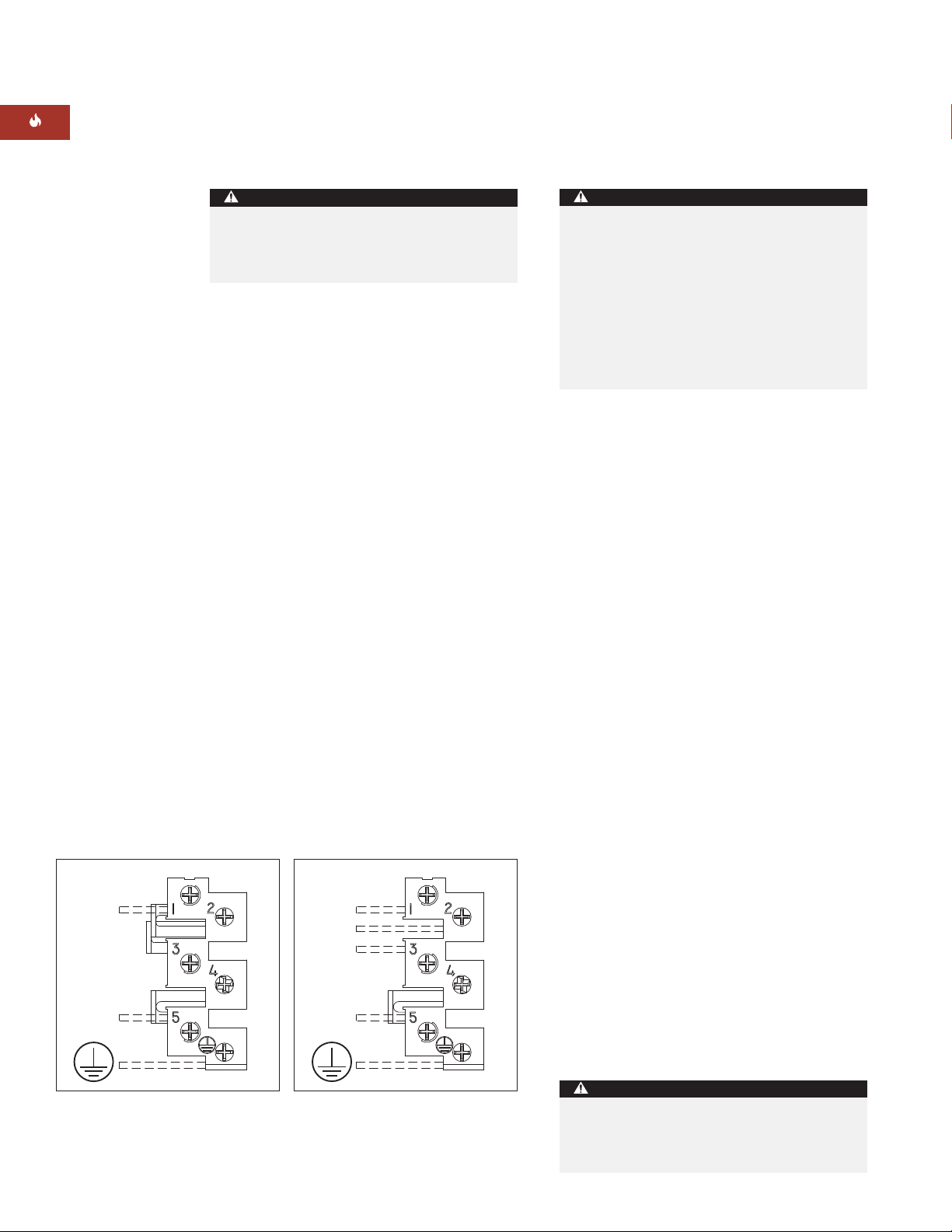

Refer to the wiring diagram showing the

connections for each lead to the terminal box

on the unit.

3N

˜

L1

L2

L3

N

The complete appliance must be properly

grounded at all times when electrical

power is applied.

NOTE: Improper connection can result in

a fire hazard.

Before obtaining access to terminals, all

supply circuits must be disconnected.

Open the terminal box to expose the screws

with corresponding numbers. Run the cord

through the strain relief hole and into the

terminal box.

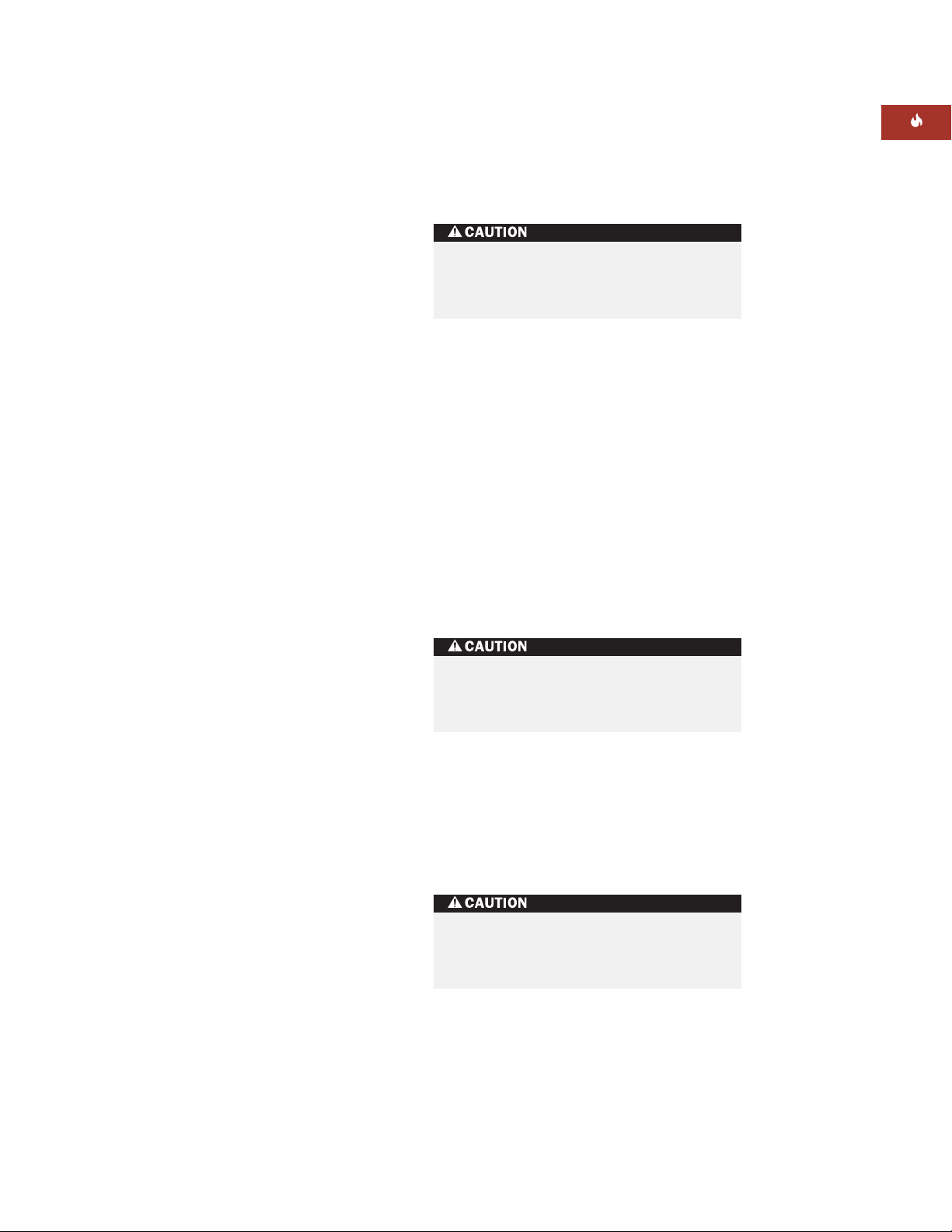

For Single Phase Install (Line, Neutral,

Ground):

Attach the Neutral wire to the number 5

position. Line should be attached to the 1

postion and attach the ground to the corresponding ground screw.

For 3phase Install (L1, L2, L3, Neutral,

Ground):

copper bars. Loosen 5 and ground screws.

Attach L1 to position 1. L2 to position 2. L3 to

position 3. Neutral wire to position 5 and attach

the ground to the corresponding ground screw.

After tightening the screws, tighten down the

cord strain relief and close the cover to the

terminal box without pinching any of the wires.

IMPORTANT NOTE:

ance should be through a fused connection

unit or a suitable isolator, which complies with

national and local safety regulations. The

on/off switch should be easily accessible after

the appliance has been installed. If the switch

is not accessible after installation (depending

on country) an additional means of disconnection must be provided for all poles of the

power supply. When switched off there must

be an all pole contact gap of 3 mm in the

isolator switch. This 3 mm contact disconnect

gap must apply to any isolator switch, fuses

and/or relays according to EN60335.

Loosen the 1, 5, and ground screws.

Loosen the 1, 2, 3 and remove the

Connection of this appli-

Single phase wiring diagram

16

3phase wiring diagram

Copper bars must be removed from positions 1, 2, and 3 when connecting to

3phase power.

Page 16

INSTALLATION INSTRUCTIONS

ELECTRICAL REQUIREMENTS

With the oven positioned directly in front of

the cabinet opening, feed a minimum 105°C

rated cord attached to the oven terminal box

through the opening in the cabinet platform

(where applicable). Then, depending upon

local codes, utilize one of the following techniques to connect the appliance to the electrical power supply.

INSTALLING THE OVEN

UNPACK THE OVEN

Oven is not mounted to the shipping

base. Do not remove banding until the

oven is at the point of installation.

Cut the plastic straps and remove the two

V-boards. Remove the four top foam corners

and the corner posts. Remove the carton

sleeve by lifting the sleeve up and over the

appliance.

Remove all oven racks, oven rack guides and

accessories from inside the oven cavity. For

the double oven, be sure to do this for both

the upper and lower ovens.

Remove the four bottom corners. Use caution

as the oven is not mounted to the shipping

base. Keep the bottom foam in place when

moving or carting the oven. The bottom foam

also protects the factory-installed trim.

Do not remove the bottom foam until

oven has been positioned next to the

installation opening.

IMPORTANT NOTE:

Before moving the oven,

protect any finished flooring with appropriate

materials to avoid damage to the floor.

Remove and discard all packing materials,

including cardboard and tape on the outside of

the oven and inside the oven cavity.

Do not lift the unit by the oven door

handle(s). This will damage the oven door

and hinges.

17

Page 17

WOLF E SERIES BUILT-IN OVENS

INSTALLING THE OVEN

OVEN DOOR REMOVAL

To reduce the weight of the oven and ease

installation, removal of the oven door(s) is an

option.

To Remove Oven Door:

Open oven door all the way.

Flip down the hinge latch on each side.

Close the oven door as far as it will shut.

While holding the oven door on each side

with both hands, lift the oven door up.

Continue to push the oven door closed and

pull it away from the oven frame.

To Reinstall Oven Door:

Insert both hanger arms into the oven

frame openings.

Open the oven door. You should hear a

”click” as the door is set into place.

Move the hinge levers back to the locked

position. Ensure that the door is free to

open and close. If not, repeat the removal

and reinstallation procedures.

POSITION THE OVEN

The oven is very heavy—use caution

when lifting. It is recommended that two

people lift and position the oven into the

opening. Wear gloves to protect hands

from any sharp edges.

Holding the oven by the upper edge and

bottom side of the oven chassis, carefully lift

the oven up to the cabinet opening.

Resting the oven on the cabinet base platform,

slide the oven into the opening until it is

approximately 152 mm from full insertion. If

applicable, ensure that the installer supplied

cable slides through the opening in the cabinet

platform as the oven is slid into place.

IMPORTANT NOTE:

The installer supplied

cable must be placed in the recessed area

located along the right rear vertical edge of the

oven. Make sure that the cable is not trapped

between the oven and the inner cabinet wall.

Do not block the oven air exhaust located

at the bottom of the oven. Blocking the

exhaust may cause cabinet damage and

poor baking performance.

18

Page 18

INSTALLATION INSTRUCTIONS

INSTALLING THE OVEN

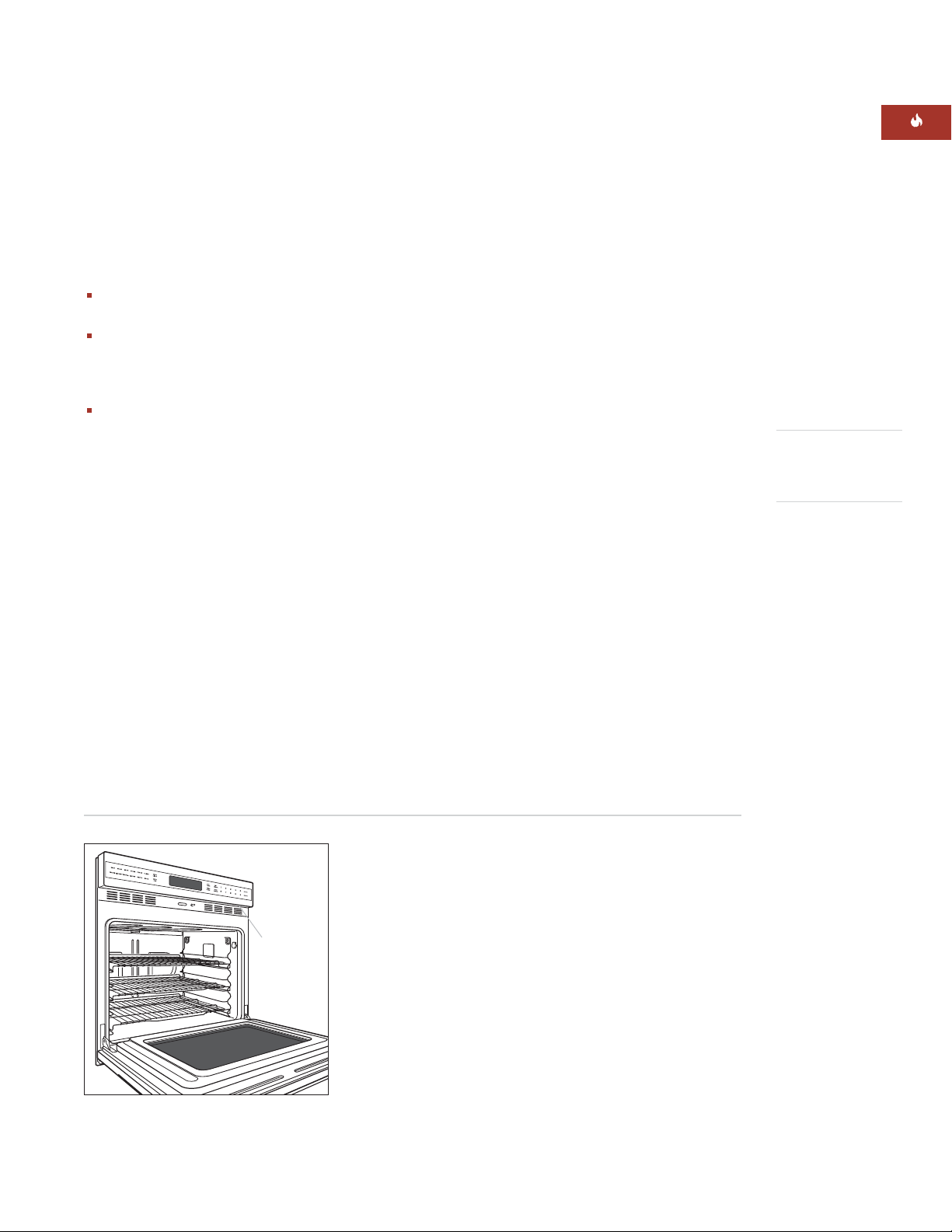

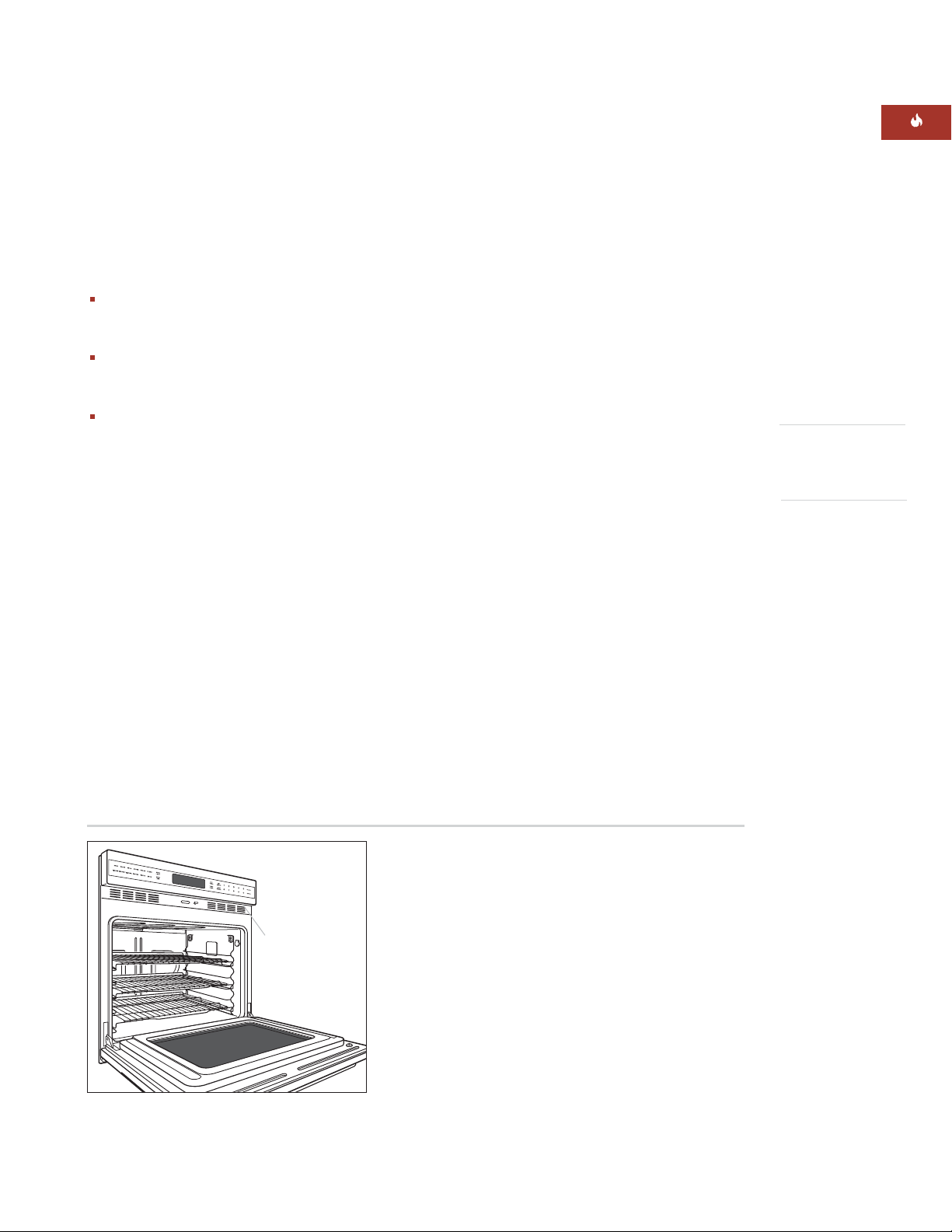

MOUNT OVEN TO CABINETRY

Once the oven is fully inserted into the cabinet

opening, locate the mounting holes on the

oven side trim. There will be four mounting

holes for a single oven and six for a double

oven. Refer to the illustration below. Use a

2 mm drill bit to drill pilot holes into the

cabinet. Use the provided wood screws to

secure the oven to the cabinet through the

oven mounting holes.

Failure to install the mounting screws

may cause the oven to move or tip

forward during use. This may result in

damage to the oven or personal injury.

OVEN OPERATION

IMPORTANT NOTE:

Prior to operating the

oven, be sure to read the entire Wolf E Series

Built-In Ovens Use & Care Information

included with the oven for important safety

information.

Unpack the box containing the oven components found in each oven cavity. Install the

oven rack guides onto the shoulder screws

located on the interior side walls of the oven.

Slide the oven racks onto the support racks

within the oven. There are three racks per

oven. Place the broiler pan and grid on a rack

within the oven, if desired.

Turn on the power supply to the oven. Set the

time of day by pressing the

SET CLOCK

touch pad, input the desired time by using the

number pads, then touch

ENTER

.

Select any of the ten cooking modes on the

control panel. Verify that the oven is coming

up to temperature. For the double oven, be

sure to verify operation of both ovens.

IMPORTANT NOTE:

A small amount of smoke

and odor may be noticed during the initial

break-in period. Refer to the Use & Care

Information for additional information.

Location of mounting holes

19

Page 19

WOLF E SERIES BUILT-IN OVENS

CONTACT

INFORMATION

Website:

wolfappliance.com

TROUBLESHOOTING

IMPORTANT NOTE:

If the built-in oven does

not operate properly, follow these troubleshooting steps:

Verify that power is being supplied to the

oven.

Check the electrical connections to ensure

that the installation has been completed

correctly.

Follow troubleshooting procedures as

described in the Wolf E Series Built-In

Ovens Use & Care Information.

If the oven still does not work, contact a

Wolf authorized service center. Do not

attempt to repair the oven yourself. Wolf

is not responsible for service required to

correct a faulty installation.

WIRING DIAGRAM

IF YOU NEED SERVICE

For service in your area, contact either your

Wolf dealer or visit the Showroom Locator

section of our website, wolfappliance.com

to find the regional distributor by country.

When calling for service, you will need the

built-in oven model and serial numbers.

Both numbers are listed on the product

rating plate, located on the right side of the

oven trim, directly above the door. Open

the oven door to view the rating plate.

Refer to the illustration on page 5 for

location of the rating plate.

The wiring diagram covering the control circuit

is located on the top of the oven in a sealed

plastic bag.

20

Page 20

The information and images in this book are

the copyright property of Wolf Appliance, Inc.,

an affiliate of Sub-Zero, Inc. Neither this book

nor any information or images contained herein

may be copied or used in whole or in part

without the express written permission of Wolf

Appliance, Inc., an affiliate of Sub-Zero, Inc.

©Wolf Appliance, Inc. all rights reserved.

21

Page 21

INFORMACIÓN

DE CONTACTO

Página Web:

www.sub-zero.eu.com

INSTRUCCIONES

GENERALES

Cuando consulte las instrucciones que

aparecen en esta guía, encontrará símbolos

de AVISO y PRECAUCIÓN. Esta información

en recuadros es importante para instalar el

equipo de Wolf de forma segura y eficaz.

Existen dos tipos de posibles riesgos que

pueden producirse durante una instalación.

PRECAUCIÓN

indica una situación en la que se pueden

sufrir heridas leves o provocar daños

secundarios al producto si no se siguen

las instrucciones.

AVISO

indica peligro de que se produzcan

heridas personales graves o incluso puede

provocar la muerte si no se siguen las

precauciones especificadas.

Otro tipo de anotación que es importante

resaltar es la que se incluye en NOTA

IMPORTANTE: En esta nota se resalta la

información que resulta especialmente

importante para que la instalación se

realice sin problemas.

WOLF®es una marca comercial registrada de Wolf Appliance, Inc.

Page 22

HORNOS INTEGRABLES SERIE E DE WOLF

REQUISITOS DE INSTALACIÓN

NOTA IMPORTANTE: Esta instalación debe ser

realizada por un técnico cualificado.

NOTA IMPORTANTE:

Guarde estas instrucciones

de instalación para que el inspector local pueda

utilizarlas.

Lea las instrucciones de instalación antes de

llevar a cabo la instalación.

Instalador:

guarde estas instrucciones para

que el inspector local pueda utilizarlas como

referencia y, a continuación, entréguelas al

propietario del aparato.

Propietario:

lea y guarde estas instrucciones

para que pueda utilizarlas como referencia en

el futuro y asegúrese de leer la guía de uso y

mantenimiento antes de utilizar el aparato.

NOTA IMPORTANTE:

Este aparato debe instalarse

siguiendo todas las normativas nacionales

correspondientes. Se debe aplicar al aparato

el voltaje, la frecuencia y el amperaje adecuados

desde una instalación eléctrica resistente con

toma de tierra protegida por un fusible de retardo.

El voltaje, la frecuencia y el amperaje se muestran

en la placa de datos del producto.

Apunte la referencia del modelo y los números

de serie antes de instalar el horno integrable.

Encontrará estos números en la placa de datos,

situada en el lado derecho del borde del horno,

justo encima de la puerta. Abra la puerta del

horno para verla. Observe la siguiente ilustración.

PREPARACIÓN DEL

NOTA IMPORTANTE:

SITIO

Es necesario dejar un fondo

mínimo de 610 mm utilizables, si no, podría ser

necesario quitar el panel trasero del armario para

que el horno quede bien instalado. En el caso de

una instalación empotrable, es necesario dejar un

fondo mínimo de 635 mm utilizables. La caja de

conexiones debe empotrarse con el panel trasero

del armario.

La apertura de la instalación debe tener una

plataforma con una superficie nivelada y plana

para aguantar el horno. Los hornos sencillos

necesitan un apoyo de superficie mínimo de

113 kg mientras que los hornos dobles

necesitan que este apoyo sea de 181 kg.

NOTA IMPORTANTE:

Los hornos integrables

Wolf están diseñados y aprobados por el

organismo regulador correspondiente para que

se puedan instalar solamente con placas,

microondas y cajones calentadores de Wolf. El

ancho nominal del horno integrable debe coincidir

con el ancho nominal de la placa. No se puede

instalar un horno integrable debajo de una cocina

de gas de Wolf.

INFORMACIÓN

DE LA PLACA

DE DATOS

Referencia del

modelo

Número de serie

Ubicación de la placa de datos

Ubicación

de la

placa de

datos

23

Page 23

HORNOS INTEGRABLES SERIE E DE WOLF

HORNOS SENCILLOS INTEGRABLES

SERIE E

NOTA IMPORTANTE:

Es necesario dejar un fondo

mínimo de 610 mm utilizables, si no, podría ser

necesario quitar el panel trasero del armario para

que el horno quede bien instalado. En el caso de

una instalación empotrable, es necesario dejar un

fondo mínimo de 635 mm utilizables. La caja de

conexiones debe empotrarse con el panel trasero

del armario.

Para facilitar la instalación, Wolf recomienda

utilizar un armario con un ancho de 838 mm

para el horno sencillo Serie E. En el caso de

una instalación empotrable, es necesario que

el armario tenga 838 mm de ancho como mínimo.

La plataforma base del armario debe aguantar un

peso de 113 kg.

Vea las siguientes ilustraciones para conocer las

medidas totales, las especificaciones de instalación

y la ubicación de los componentes eléctricos del

horno sencillo de la Serie E.

El horno simple de la serie E necesita un suministro eléctrico trifásico con toma a tierra de 220240 V CA, 50 Hz. Consulte la sección Requisitos

eléctricos en la página 34. El horno no se entrega

con un enchufe eléctrico.

NOTA IMPORTANTE:

A menos que utilice armarios

con un fondo superior a 610 mm para una

instalación estándar o con un fondo superior a 635

mm para una instalación empotrable, se recomienda

que la toma eléctrica se coloque en un armario

contiguo. Elija la ubicación entre las que se

muestran en las ilustraciones de instalación en las

páginas 26-27 que mejor se adapte a su instalación.

24

MEDIDAS TOTALES

25 mm*

CONDUCTO PARA

708

mm

759 mm

*Para el modelo en vidrio negro, aumente el tamaño en 6 mm.

67*

mm

DETRÁS DEL MARCO

VISTA LATERAL DERECHA

CANAL DEL

CABLES

48 mm

603 mm

687

mm

VISTA SUPERIOR

48 mm

718 mm

PUERTA DEL HORNO ABIERTA

759 mm

32 mm

603*

mm

559

mm

Page 24

INSTRUCCIONES DE INSTALACIÓN

HORNOS SENCILLOS INTEGRABLES

SERIE E

INSTALACIÓN ESTÁNDAR

NOTA IMPORTANTE:

estándar, es necesario dejar un fondo mínimo

de 610 mm utilizables, si no, podría ser necesario

quitar el panel trasero del armario para que

el aparato quede bien instalado. La caja de

conexiones debe empotrarse con el panel

trasero del armario.

Para las instalaciones estándar, el horno integrable

Serie E queda instalado al insertarlo en el armario

desde la parte delantera. El horno tiene un

contramarco frontal en cada uno de los cuatro

lados que va superpuesto sobre los raíles y

montantes. El contramarco sobresale 3 mm en

la parte inferior, 8 mm en la parte superior y 19

mm a cada uno de los lados.

Para las instalaciones

INSTALACIÓN EMPOTRABLE

NOTA IMPORTANTE:

trables, es necesario dejar un fondo mínimo de

635 mm utilizables y de 641 mm para los modelos

en vidrio negro; si no, podría ser necesario quitar

el panel trasero del armario para que el aparato

quede bien instalado. La caja de conexiones debe

empotrarse con el panel trasero del armario.

La instalación empotrable exige que el horno

integrable quede bien acoplado dentro del

armario. Si desea que el frente del horno quede

empotrado respecto al mobiliario circundante,

necesitará un mueble con un ancho mínimo de

838 mm y un fondo mínimo de 635 mm.

NOTA IMPORTANTE:

empotrables, los bordes internos de la cavidad

deben estar acabados, ya que quedarán expuestos

cuando la puerta del horno esté abierta. Estos

bordes deberían estar teñidos en vez de tener

una superficie laminada con el fin de evitar que

las altas temperaturas de la limpieza automática

los dañen.

Para las instalaciones empo-

En las instalaciones

INSTALACIONES COMBINADAS

Los hornos sencillos Serie E de Wolf se pueden

instalar debajo de una vitrocerámica, una placa

de gas o de inducción de 762 mm de Wolf. A

menos que utilice armarios con un fondo superior

a 610 mm para una instalación estándar o con un

fondo superior a 635 mm para una instalación

empotrable, se recomienda que la toma eléctrica

se coloque en el armario base situado a la derecha

del horno. Los hornos sencillos Serie E también se

pueden instalar debajo de una vitrocerámica, una

placa de gas o de inducción de 914 mm de Wolf.

Además, existe la posibilidad de instalar un horno

sencillo Serie E de Wolf al lado de otro horno

sencillo Serie E. Debe dejar un espacio de 64 mm

entre las cavidades del horno. También es

necesario dejar una pared interior separada

entre las cavidades de cada uno de los hornos.

25

Page 25

HORNOS INTEGRABLES SERIE E DE WOLF

HORNOS SENCILLOS INTEGRABLES

SERIE E

INSTALACIÓN ESTÁNDAR

Anchura total del horno 759 mm

Altura total del horno 708 mm

Fondo total del horno (marco posterior) 603 mm

Margen de apertura de la puerta 559 mm

Anchura del armario recomendada 838 mm

INSTALACIÓN ESTÁNDAR

610 mm min

FONDO DE LA CAVIDAD

691 mm

ALTURA DE

LA CAVIDAD

DEL SUELO

A LA ENCIMERA

914 mm

Anchura mínima del mueble 762 mm

Fondo mínimo del armario (apertura) 610 mm

Anchura de la cavidad 724 mm

Altura de la cavidad 691 mm

Soporte mínimo de la base 113 kg

LA MEDIDA PUEDE VARIAR*

724 mm

ANCHURA DE LA CAVIDAD

121 mm TÍPICO*

VISTA FRONTALVISTA LATERAL

127

mm

102

mm

E

E

*Las medidas deben coincidir con la altura del borde del horno.

NOTAS: la ubicación de la toma eléctrica en la cavidad puede exigir un armario de mayor profundidad.

Las líneas discontinuas representan el perfil de la unidad.

26

Page 26

INSTRUCCIONES DE INSTALACIÓN

HORNOS SENCILLOS INTEGRABLES

SERIE E

INSTALACIÓN EMPOTRABLE

Anchura total del horno 759 mm

Altura total del horno 708 mm

Fondo total del horno (marco posterior) 603 mm

Margen de apertura de la puerta 559 mm

Soporte mínimo de la base 113 kg

INSTALACIÓN EMPOTRABLE

Anchura mínima del mueble 838 mm

Fondo mínimo de

instalación empotrable 635 mm

Anchura de la cavidad 724 mm

Anchura mínima de

instalación empotrable 772 mm

Altura de la cavidad 691 mm

Altura mínima de

instalación empotrable 724 mm

VISTA

SUPERIOR

629 mm* min

FONDO DE

INSTALACIÓN

25 mm*

EMPOTRABLE

LISTONES

LATERALES

NOTA

IMPORTANTE

En las instalaciones

empotrables, los

bordes internos de la

cavidad deben estar

acabados, ya que

quedarán expuestos

cuando la puerta del

horno esté abierta.

772 mm min

ANCHURA DE INSTALACIÓN

EMPOTRABLE

22 mm

LISTÓN SUPERIOR

691 mm

ALTURA DE

LA CAVIDAD

*Para el modelo en vidrio negro, aumente el tamaño en 6 mm.

NOTAS: Soporte mínimo de la base 113 kg.

La ubicación de la toma eléctrica en la cavidad puede exigir un armario de mayor profundidad.

Los listones pueden ser visibles y deberán acabarse para que coincidan con los muebles.

Las líneas discontinuas representan el perfil de la unidad.

724 mm min

ALTURA

DE

INSTALACIÓN

EMPOTRABLE

ANCHURA DE LA CAVIDAD

11 mm

LISTÓN

INFERIOR

VISTA FRONTALVISTA LATERAL

724 mm

127

mm

102

mm

E

E

25 mm

LISTONES

LATERALES

E

27

Page 27

HORNOS INTEGRABLES SERIE E DE WOLF

HORNOS DOBLES INTEGRABLES

SERIE E

NOTA IMPORTANTE:

Es necesario dejar un fondo

mínimo de 610 mm utilizables, si no, podría ser

necesario quitar el panel trasero del armario para

que el horno quede bien instalado. En el caso de

una instalación empotrable, es necesario dejar un

fondo mínimo de 635 mm utilizables. La caja de

conexiones debe empotrarse con el panel trasero

del armario.

Para facilitar la instalación, Wolf recomienda

utilizar un armario con un ancho de 838 mm

para el horno doble Serie E. En el caso de una

instalación empotrable, es necesario que el

armario tenga 838 mm de ancho como mínimo.

La plataforma base del armario debe aguantar un

peso de 181 kg.

Vea las siguientes ilustraciones para conocer las

medidas totales, las especificaciones de instalación

y la ubicación de los componentes eléctricos del

horno doble de la Serie E.

El horno doble de la serie E necesita un suministro

eléctrico trifásico con toma a tierra de 220-240 V

CA, 50 Hz. Consulte la sección Requisitos eléctricos

en la página 34. El horno no se entrega con un

enchufe eléctrico.

NOTA IMPORTANTE:

A menos que utilice

armarios con un fondo superior a 610 mm para

una instalación estándar o con un fondo superior

a 635 mm para una instalación empotrable, se

recomienda que la toma eléctrica se coloque en

un armario contiguo. Elija la ubicación entre las

que se muestran en las ilustraciones de instalación

en las páginas 30-31 que mejor se adapte a su

instalación.

28

MEDIDAS TOTALES

25 mm*

1280

mm

759 mm

*Para el modelo en vidrio negro, aumente el tamaño en 6 mm.

67*

mm

Se muestra el modelo ICBDO30-2U/S sin marco

VISTA LATERAL DERECHA

CANAL DEL

CONDUCTO

PARA CABLES

DETRÁS DEL MARCO

48 mm

603 mm

1257

mm

VISTA SUPERIOR

48 mm

718 mm

PUERTA DEL HORNO ABIERTA

759 mm

32 mm

603*

mm

559

mm

Page 28

INSTRUCCIONES DE INSTALACIÓN

HORNOS DOBLES INTEGRABLES

SERIE E

INSTALACIÓN ESTÁNDAR

NOTA IMPORTANTE:

estándar, es necesario dejar un fondo mínimo

de 610 mm utilizables, si no, podría ser necesario

quitar el panel trasero del armario para que

el aparato quede bien instalado. La caja de

conexiones debe empotrarse con el panel

trasero del armario.

Para las instalaciones estándar, el horno integrable

Serie E queda instalado al insertarlo en el armario

desde la parte delantera. El horno tiene un

contramarco frontal en cada uno de los cuatro

lados que va superpuesto sobre los raíles y

montantes. El contramarco sobresale 3 mm en

la parte inferior, 8 mm en la parte superior y 19

mm a cada uno de los lados.

Para las instalaciones

INSTALACIÓN EMPOTRABLE

NOTA IMPORTANTE:

trables, es necesario dejar un fondo mínimo de

635 mm utilizables y de 641 mm para los modelos

en vidrio negro; si no, podría ser necesario quitar

el panel trasero del armario para que el aparato

quede bien instalado. La caja de conexiones debe

empotrarse con el panel trasero del armario.

La instalación empotrable exige que el horno

integrable quede bien acoplado dentro del

armario. Si desea que el frente del horno quede

empotrado respecto al mobiliario circundante,

necesitará un mueble con un ancho mínimo de

838 mm y un fondo mínimo de 635 mm.

NOTA IMPORTANTE:

empotrables, los bordes internos de la cavidad

deben estar acabados, ya que quedarán expuestos

cuando las puertas del horno estén abiertas. Estos

bordes deberían estar teñidos en vez de tener

una superficie laminada con el fin de evitar que

las altas temperaturas de la limpieza automática

los dañen.

Para las instalaciones empo-

En las instalaciones

29

Page 29

HORNOS INTEGRABLES SERIE E DE WOLF

HORNOS DOBLES INTEGRABLES

SERIE E

INSTALACIÓN ESTÁNDAR

Anchura total del horno 759 mm

Altura total del horno 1.280 mm

Fondo total del horno (marco posterior) 603 mm

Margen de apertura de la puerta 559 mm

Anchura del armario recomendada 838 mm

INSTALACIÓN ESTÁNDAR

610 mm min

FONDO DE LA CAVIDAD

1260 mm

ALTURA DE

LA CAVIDAD

Anchura mínima del mueble 762 mm

Fondo mínimo del armario (apertura) 610 mm

Anchura de la cavidad 724 mm

Altura de la cavidad 1.260 mm

Soporte mínimo de la base 181 kg

E

724 mm

ANCHURA DE LA CAVIDAD

1702 mm

TÍPICO*

VISTA FRONTALVISTA LATERAL

Las medidas deben coincidir con la altura del borde del horno.

*

NOTAS: la ubicación de la toma eléctrica en la cavidad puede exigir un armario de mayor profundidad.

Las líneas discontinuas representan el perfil de la unidad.

127

mm

102

mm

E

E

E

30

Page 30

INSTRUCCIONES DE INSTALACIÓN

HORNOS DOBLES INTEGRABLES

SERIE E

INSTALACIÓN EMPOTRABLE

Anchura total del horno 759 mm

Altura total del horno 1.280 mm

Fondo total del horno (marco posterior) 603 mm

Margen de apertura de la puerta 559 mm

Soporte mínimo de la base 181 kg

INSTALACIÓN EMPOTRABLE

Anchura mínima del mueble 838 mm

Fondo mínimo de

instalación empotrable 635 mm

Anchura de la cavidad 724 mm

Anchura mínima de

instalación empotrable 772 mm

Altura de la cavidad 1.260 mm

Altura mínima de

instalación empotrable 1.294 mm

VISTA

SUPERIOR

629 mm* min

FONDO DE

INSTALACIÓN

25 mm*

EMPOTRABLE

LISTONES

LATERALES

NOTA

IMPORTANTE

En las instalaciones

empotrables, los

bordes internos de

la cavidad deben

estar acabados,

ya que quedarán

expuestos cuando

las puertas del

horno estén

abiertas.

772 mm min

ANCHURA DE

INSTALACIÓN EMPOTRABLE

22 mm

LISTÓN SUPERIOR

1260 mm

ALTURA DE

LA CAVIDAD

*Para el modelo en vidrio negro, aumente el tamaño en 6 mm.

NOTAS: Soporte mínimo de la base 181 kg.

La ubicación de la toma eléctrica en la cavidad puede exigir un armario de mayor profundidad.

Los listones pueden ser visibles y deberán acabarse para que coincidan con los muebles.

Las líneas discontinuas representan el perfil de la unidad.

1294 mm min

ALTURA DE

INSTALACIÓN

EMPOTRABLE

1702 mm

TÍPICO

ANCHURA DE LA CAVIDAD

11 mm

LISTÓN

INFERIOR

VISTA FRONTALVISTA LATERAL

724 mm

127

mm

102

mm

E

E

25 mm

LISTONES

LATERALES

E

31

Page 31

HORNOS INTEGRABLES SERIE E DE WOLF

OPCIONES DE INSTALACIÓN

ESTÁNDAR

HORNO SENCILLO INTEGRABLE

SERIE E

El horno sencillo Serie E de Wolf se puede instalar

en combinación con un horno microondas de

ventilación o sin ventilación de Wolf con el kit de

marco de 762 mm de la Serie E, así como con un

cajón calentador de Wolf con el frente de cajón de

acero inoxidable o integrado de la Serie E. Vea la

siguiente ilustración y las páginas 24–27 para

conocer las especificaciones de instalación

de los hornos sencillos de la Serie E.

Recuerde que el tamaño del panel fabricado a

medida para el cajón calentador con frente

integrado puede variar según cada instalación.

Consulte las instrucciones de instalación que

se proporcionan con el kit de marco de horno

microondas o el frente del cajón calentador

si desea obtener información más detallada.

Las medidas pueden variar dependiendo de

cada instalación.

32

Page 32

INSTRUCCIONES DE INSTALACIÓN

INSTALACIÓN ESTÁNDAR

3

8 mm

min

CAVIDAD DEL

MICROONDAS

E

610 mm min

FONDO DE LA CAVIDAD

ANTIVUELCO

691 mm

724 mm

ANCHURA APERTURA

DE HORNO

127

mm

102

mm

E

E

E

232 mm

NOTAS: Soporte mínimo de la base para el horno 113 kg.

La ubicación de la toma eléctrica en la cavidad puede exigir un armario de mayor profundidad.

Las líneas discontinuas representan el perfil de la unidad.

19 mm

min

727 mm

FONDO DE APERTURA

DEL CAJÓN CALENTADOR

VISTA FRONTALVISTA LATERAL

Horno sencillo instalado con horno microondas de ventilación con el marco de la Serie E de 762 mm y el cajón calentador

con el frente de acero inoxidable de la Serie E.

33

Page 33

HORNOS INTEGRABLES SERIE E DE WOLF

REQUISITOS ELÉCTRICOS

NOTA

IMPORTANTE

Deberá cumplir la

normativa eléctrica

nacional al instalar

el aparato.

L1

˜

N

AVISO

Compruebe que la unidad está

desconectada de la caja de

conexiones antes de continuar.

HORNOS SENCILLOS DE LA SERIE E

Alimentación eléctrica requerida:

Monofásica: 220-240 VCA; 50 Hz

Trifásica: 380-415 VCA; 50 Hz

Carga máxima conectada:

Monofásica: 4,4 kW

Trifásica: 4,4 kW

Amperaje total:

Monofásica:

Trifásica:

HORNOS DOBLES DE LA SERIE E

Alimentación eléctrica requerida:

Monofásica: 220-240 VCA; 50 Hz

Trifásica: 380-415 VCA; 50 Hz

Carga máxima conectada:

Monofásica: 7,4 kW

Trifásica: 5,1 kW

Amperaje total:

Monofásica:

Trifásica:

Vea el cuadro de conexiones que muestra las

conexiones de cada cable a la caja de cables

en la unidad.

19 amperios

19 amperios

32 amperios

22 amperios

3N

˜

L1

L2

L3

N

AVISO

El aparato debe estar conectado a tierra

de manera correcta siempre que esté

conectado a la red eléctrica.

NOTA: Si la conexión no se realiza de

manera correcta, existe riesgo de que se

produzca un incendio.

Antes de tener acceso a los terminales,

se deben desconectar todos los circuitos

de suministro.

Abra la caja de terminales para ver los tornillos

con los números correspondientes. Pase el cable

por el agujero aliviador de tensión e introdúzcalo

en la caja de cables.

Para la instalación monofásica (línea, neutro,

tierra): Afloje los tornillos 1, 5 y el tornillo de

conexión a tierra. Conecte el cable neutro en la

posición número 5. El cable de línea debe conectarse en la posición número 1 y el cable de

conexión a tierra en el tornillo de conexión a

tierra correspondiente.

Para la instalación trifásica (L1, L2, L3, neutro,

tierra): Afloje 1, 2 y 3 y quite las barras de cobre.

Afloje 5 y los tornillos de conexión a tierra. Conecte

L1 a la posición 1. L2 a la posición 2. L3 a la posición

3. El cable neutro a la posición 5 y conecte la tierra al

tornillo de conexión a tierra correspondiente.

Una vez que haya apretado los tornillos, apriete

el aliviador de tensión del cable y cierre la tapa

de la caja de cables asegurándose de que los

cables no quedan enganchados.

NOTA IMPORTANTE:

debe realizarse a una unidad de conexión con

fusibles o a un aislador adecuado, que cumple con

las normativas de seguridad nacionales y locales.

El interruptor de encendido/apagado debe encontrarse en un lugar accesible después de haber

instalado el aparato. Si no es posible acceder al

interruptor después de la instalación (según el

país), se deberá brindar un medio de desconexión

adicional para todos los polos de la alimentación

eléctrica. Al estar desconectado, deberá existir una

separación de contacto entre todos los polos de 3

mm en el interruptor del aislador. Esta separación

de 3 mm de desconexión de los contactos deberá

aplicarse a cualquier interruptor, fusibles o relés

del aislador según la norma EN60335.

la conexión de este aparato

Diagrama de cableado monofásico

34

Diagrama de cableado trifásico

AVISO

Las barras de cobre deben quitarse de las

posiciones 1, 2 y 3 al conectar a la corriente trifásica.

Page 34

INSTRUCCIONES DE INSTALACIÓN

REQUISITOS ELÉCTRICOS

Con el horno colocado justo delante de la abertura

del armario, introduzca el cable de 105 °C nominales mínimos conectado a la caja de terminales

del horno a través de la plataforma del armario

(donde proceda). Después, según la normativa

nacional, utilice una de las siguientes técnicas para

conectar el aparato al suministro eléctrico.

INSTALACIÓN DEL HORNO

DESEMBALAJE DEL HORNO

PRECAUCIÓN

El horno no está montado sobre la base

de envío. No retire las cintas hasta que

el horno se encuentre en su lugar

de instalación.

Corte las correas de plástico y retire los dos

esquineros. Quite las cuatro esquinas de espuma

superiores y los postes esquineros. Levante la hoja

de cartón y sáquela por encima del aparato para

retirarla.

Saque del interior del horno todas las bandejas,

las guías de éstas y accesorios. En el caso del

horno doble, asegúrese que saca estos accesorios

de los dos hornos.

Retire las cuatro esquinas inferiores. Tenga

cuidado, ya que el horno no está montado en la

base de envío. Deje la espuma inferior en su lugar

cuando vaya a mover o desplazar el horno en un

carro. La espuma inferior también protege el

contramarco instalado de fábrica.

PRECAUCIÓN

No retire la espuma inferior hasta que el

horno se haya colocado junto a la

apertura de instalación.

NOTA IMPORTANTE:

proteja el acabado del suelo con lo que resulte

adecuado para evitar dañarlo.

Quite y y tire todo el material de embalaje,

incluido el embalaje de cartón y la cinta que

envuelve la parte exterior del horno y el interior

de éste.

Antes de desplazar el horno,

PRECAUCIÓN

No utilice el tirador de la puerta para

levantar el horno. Podría dañar la puerta

y las bisagras del horno.

35

Page 35

HORNOS INTEGRABLES SERIE E DE WOLF

INSTALACIÓN DEL HORNO

RETIRADA DE LA PUERTA DEL

HORNO

Para reducir el peso del horno y facilitar su

instalación, puede optar por retirar la(s) puerta(s)

del horno.

Para retirar la puerta del horno:

Abra la puerta del horno por completo.

Gire hacia abajo el pasador de la bisagra

de cada lado.

Cierre la puerta del horno todo lo que pueda.

Mientras sujeta la puerta del horno por ambos

lados con las dos manos, levante la puerta del

horno hacia arriba. Siga empujando la puerta

del horno cerrada y tire de ella para sacarla

del marco del horno.

Para volver a colocar la puerta en el horno:

Inserte los brazos de soporte en las aperturas

del marco del horno.

Abra la puerta del horno. Debería escuchar

un ”clic” cuando la puerta quede colocada

en su sitio.

Mueva las palancas de las bisagras hacia la

posición de bloqueo. Asegúrese de que la

puerta puede abrirse y cerrarse con facilidad.

Si no es así, repita los procedimientos de

retirada y de recolocación.

COLOCACIÓN DEL HORNO

PRECAUCIÓN

El horno pesa mucho—tenga cuidado

al levantarlo. Se recomienda levantarlo

y colocarlo en la abertura entre dos

personas. Utilice guantes para proteger

las manos de los bordes afilados.

Sujete el horno por el borde superior y el lado

inferior del bastidor y levante el horno con

cuidado hasta la abertura del armario.

Una vez que el horno está apoyado en la

plataforma base del armario, deslícelo en

la abertura hasta que falten 152 mm

aproximadamente para insertarlo por completo.

Si es necesario, asegúrese de que el instalador

ha suministrado el sistema de deslizamiento de

cable a través de la abertura en la plataforma

del armario cuando el horno se desliza y coloca

en su sitio.

NOTA IMPORTANTE:

instalador debe estar colocado en el área acoplada

situada a lo largo del borde vertical trasero

derecho del horno. Asegúrese de que el cable no

queda atrapado entre el horno y la pared interna

del armario.

El cable suministrado por el

PRECAUCIÓN

No bloquee la salida de aire del horno

situada en la parte inferior del horno. Si

se bloquea esta salida de aire, se puede

dañar el armario y el horneado puede

resultar deficiente.

36

Page 36

INSTRUCCIONES DE INSTALACIÓN

INSTALACIÓN

DEL HORNO

MONTAJE EN EL MOBILIARIO

Cuando el horno se encuentre totalmente

insertado en la abertura del armario, localice los

agujeros de montaje en el contramarco lateral del

horno. Los hornos sencillos tienen cuatro agujeros

de este tipo mientras que los hornos dobles tienen

seis. Observe la siguiente ilustración. Utilice una

broca de 2 mm para taladrar agujeros guía en

el armario. Utilice los tornillos para madera

proporcionados para fijar el horno al armario

a través de los agujeros de montaje.

AVISO

Si no se han fijado correctamente los

tornillos de montaje, el horno podría

moverse o inclinarse hacia delante

durante su funcionamiento. Esto podría

provocar daños en el horno o heridas en

el usuario.

FUNCIONAMIENTO DEL HORNO

NOTA IMPORTANTE:

horno, asegúrese de que lee la guía de uso

y mantenimiento que se facilita con los hornos

empotrables Serie E de Wolf, para conocer la

información de seguridad importante relacionada

con el horno.

Desembale la caja que contiene los componentes

del horno y que se encuentra en el interior del

horno. Instale las guías de las bandejas del horno

sobre los tornillos de resalto situados en las

paredes laterales del interior del horno. Deslice

las bandejas sobre los soportes dentro del horno.

Existen tres bandejas por horno. Si lo desea,

coloque la bandeja para asar y la rejilla en una

bandeja en el horno.

Encienda el suministro eléctrico del horno. Ajuste

la hora del día; para ello pulse el botón

CLOCK

, introduzca la hora deseada con las

teclas numéricas y, después, pulse

En el panel de mandos, seleccione uno de los diez

modos de cocción. Compruebe que la temperatura

del horno va subiendo. En el caso de un horno

doble, compruebe el funcionamiento en ambos

hornos.

NOTA IMPORTANTE:

algo de humo y de olor durante el período de

arranque inicial. Consulte la guía de uso y

mantenimiento para obtener más información.

Antes de utilizar el

SET

ENTER

.

Es posible que se produzca

Ubicación de los agujeros de montaje

37

Page 37

HORNOS INTEGRABLES SERIE E DE WOLF

INFORMACIÓN

DE CONTACTO

Página Web:

www.sub-zero.eu.com

SOLUCIÓN DE PROBLEMAS

NOTA IMPORTANTE:

no funciona correctamente, siga estos pasos

de localización y solución de problemas:

Compruebe que el horno está conectado a la

red eléctrica.

Compruebe las conexiones eléctricas para

asegurarse de que la instalación se ha llevado

a cabo de manera correcta.

Realice los procedimientos de solución de

problemas tal y como se describe en la guía de

uso y mantenimiento de los hornos integrables

Serie E de Wolf.

Si el horno sigue sin funcionar, póngase en

contacto con el centro de asistencia técnica

de Wolf. No intente realizar usted mismo

ninguna reparación en el horno. Wolf

no se hace responsable de las tareas de

mantenimiento que deban realizarse para

corregir una instalación defectuosa.

Si el horno integrable

CUADRO DE CONEXIONES

SI NECESITA ASISTENCIA TÉCNICA

Para buscar el servicio técnico más cercano,

póngase en contacto con su distribuidor

de Wolf o visite la página Web,

www.sub-zero.eu.com, para buscar el

distribuidor más cercano.

Cuando solicite asistencia técnica, deberá tener

localizado el número de serie y el modelo del

horno integrable. Encontrará estos números

en la placa de datos del producto, situada en

la parte derecha del borde del horno, justo

encima de la puerta. Abra la puerta del horno

para verla. Consulte la ilustración de la página

23 para ubicar la placa de datos.

El cuadro de conexiones correspondiente

al circuito de control se sitúa en la parte superior

del horno en una bolsa de plástico sellada.

38

Page 38

La información y las imágenes que se

incluyen en esta guía son propiedad de Wolf

Appliance, Inc., una filial de Sub-Zero, Inc.

Este documento junto con la información y

las imágenes que en él se incluyen no

pueden copiarse ni utilizarse, total ni parcialmente, sin el consentimiento por escrito de

Wolf Appliance, Inc., una filial de Sub-Zero,

Inc.

©Wolf Appliance, Inc. se reserva todos los

derechos.

39

Page 39

CONTACT

Site Internet :

wolfappliance.com

INSTRUCTIONS

D’ORIGINE

Vous remarquerez tout au long de ce

manuel d’instruc tions les mentions

ATTENTION et MISE EN GARDE destinées à

fournir des recommandations importantes

afin d’assurer la sécurité et

l’efficacité de l’installation de l’équipement

Wolf. Deux types de dangers potentiels

peuvent se présenter pendant l’installation.

MISE EN GARDE

signale un danger qui pourrait causer

une blessure mineure ou endommager

le produit si vous ne suivez pas

les instructions.

ATTENTION

signale un danger qui pourrait causer des

blessures graves voire fatales si vous ne

prenez pas certaines précautions.

De plus, la mention REMARQUE IMPORTANTE met l’accent sur un renseignement

particulièrement important pour assurer

une installation parfaite.

WOLF®est une marque déposée de Wolf Appliance, Inc.

Page 40

FOURS ENCASTRABLES WOLF SERIE E

EXIGENCES RELATIVES

A L’INSTALLATION

REMARQUE IMPORTANTE : L’installation doit

être effectuée par un poseur qualifié.

REMARQUE IMPORTANTE :

Conservez ces

instructions d’installation pour le technicien local.

Veuillez lire les instructions d’installation

dans leur intégralité avant de procéder

à l’installation.

Poseur :

veuillez conserver ces instructions

afin que le technicien puisse s’y reporter, puis

laissez-les au propriétaire.

Propriétaire :

veuillez lire et conserver ces

instructions pour pouvoir vous y reporter

ultérieurement et assurez-vous de lire le Guide

d’utilisation et d’entretien dans son intégralité

avant d’utiliser votre appareil.

REMARQUE IMPORTANTE :

Cet appareil

ménager doit être installé conformément à tous

les codes locaux. La tension, la fréquence et

l’ampérage appropriés doivent être fournis à cet

appareil à partir d’un circuit spécial, mis à la terre

et protégé par un disjoncteur ou un fusible à

fusion temporisée adapté à l’intensité de courant

requise. La tension, la fréquence et l’ampérage

requis sont indiqués sur la plaque des caractéristiques du produit.

Consignez les numéros de modèle et de série

avant d’installer le four encastrable. Ces deux

numéros figurent sur la plaque des caractéristiques du produit située sur le côté droit de la

moulure du four, juste au-dessus de la porte.

Vous devez ouvrir la porte du four pour voir

la plaque des caractéristiques. Reportez-vous

à l’illustration ci-après.

PREPARATION DE L’EMPLACEMENT

REMARQUE IMPORTANTE :

Vous devez prévoir

une profondeur utilisable d’élément de cuisine de

610 mm minimum. Sinon, vous devrez peut-être

enlever le panneau arrière de l’élément pour

pouvoir réaliser une installation adéquate. Pour

une installation avec panneau d’affleurement,

la profondeur utilisable d’élément de cuisine

nécessaire est de 635 mm minimum. Le coffret

électrique doit affleurer au panneau arrière de

l’élément de cuisine.

L’ouverture dans laquelle sera insérée le four doit

être pourvue d’une plate-forme plate et de niveau

sur laquelle reposera le four. Cette plate-forme

doit pouvoir supporter un poids minimum de

113 kg pour les fours simples et de 181 kg pour

les fours doubles.

REMARQUE IMPORTANTE :

Les fours

encastrables Wolf sont étudiés et approuvés

pour être installés avec des plaques de cuisson,

des fours micro-ondes ou des tiroirs chauffants

de marque Wolf uniquement. La largeur nominale

du four encastrable devrait correspondre à la

largeur nominale de la plaque de cuisson. Un

four encastrable ne peut pas être installé sous

un entablement Wolf.

INFORMATIONS

FIGURANT SUR

LA PLAQUE DES

CARACTERISTIQUES

Numéro de modèle

Numéro de série

Emplacement de la plaque des

caractéristiques

Emplacement de

la plaque des

caractéristiques

41

Page 41

FOURS ENCASTRABLES WOLF SERIE E

FOURS ENCASTRABLES

SIMPLES SERIE E

REMARQUE IMPORTANTE :

Vous devez prévoir

une profondeur utilisable d’élément de cuisine

de 610 mm minimum. Sinon, vous devrez

peut-être enlever le panneau arrière de l’élément

pour pouvoir réaliser une installation adéquate.

Pour une installation avec panneau d’affleurement,

la profondeur utilisable d’élément de cuisine

nécessaire est de 635 mm minimum. Le coffret

électrique doit affleurer au panneau arrière de

l’élément de cuisine.

Pour faciliter l’installation, Wolf recommande

d’utiliser des éléments de cuisine de 838 mm

de largeur avec le four simple Série E. Pour une

installation avec panneau d’affleurement, la largeur

minimum d’élément de cuisine nécessaire est de

838 mm. La plate-forme de l’élément de cuisine

doit pouvoir supporter un poids de 113 kg.

Reportez-vous aux figures suivantes pour consulter

les dimensions hors-tout et les spécifications

d’installation et pour repérer l’emplacement des

raccordements électriques du four simple Série E.

Le four simple Série E requiert une alimentation

électrique à trois fils mise à la terre de 220 - 240 V

c.a. et 50 Hz. Reportez-vous à la section Configuration électrique page 52. Le four est fourni sans

prise de courant.

REMARQUE IMPORTANTE :

Il est recommandé

de placer l’alimentation électrique dans un

élément de cuisine adjacent, sauf si vous utilisez

des éléments de cuisine d’une profondeur de plus

de 610 mm pour une installation standard ou de

plus de 635 mm pour une installation avec

panneau d’affleurement. Choisissez dans les

figures pages 44 et 45 l’emplacement le mieux

adapté à votre installation.

42

DIMENSIONS HORS TOUT

25 mm*

708

mm

759 mm

*Pour le modèle en verre noir, rallongez de 6 mm.

Modèle ICBSO30-2U/S sans cadre illustré

67*

mm

VUE COTE DROIT

PASSAGE

DU CONDUIT

48 mm

603 mm

DERRIERE LE CADRE

687

mm

VUE EN PLAN

48 mm

718 mm

PORTE DE FOUR OUVERTE

759 mm

32 mm

603*

mm

559

mm

Page 42

INSTRUCTIONS D’INSTALLATION

FOURS ENCASTRABLES

SIMPLES

SERIE E

INSTALLATION STANDARD

REMARQUE IMPORTANTE :

installations standard, vous devez prévoir une

profondeur utilisable d’élément de cuisine de

610 mm minimum. Sinon, vous devrez peut-être

enlever le panneau arrière de l’élément pour

pouvoir réaliser une installation adéquate. Le

coffret électrique doit affleurer au panneau

arrière de l’élément de cuisine.

De plus, dans le cas des installations standard, le

four encastrable Série E est inséré dans l’élément

de cuisine, de l’avant. Le four est pourvu d’une

moulure frontale sur les quatre côtés qui empiète

sur les montants et les rails. La moulure empiète

de 3 mm sur le bas, de 8 mm sur le dessus et de

19 mm de chaque côté.

Dans le cas des

INSTALLATION AVEC PANNEAU

D’AFFLEUREMENT

REMARQUE IMPORTANTE :

installations avec panneau d'affleurement, vous

devez prévoir une profondeur utilisable d'élément

de cuisine de 635 mm minimum, 641 mm pour les

modèles en verre noir. Sinon, vous devrez peutêtre enlever le panneau arrière de l'élément pour

pouvoir réaliser une installation adéquate. Le

coffret électrique doit affleurer au panneau arrière

de l’élément de cuisine.

De plus, dans le cas d’une installation avec

panneau d’affleurement, le four doit être encastré

dans l’élément de cuisine. Un élément de cuisine

d’une largeur minimum de 838 mm et d’une

profondeur minimum de 635 mm est requis si

vous souhaitez que la façade du four affleure

aux éléments de cuisine adjacents.

REMARQUE IMPORTANTE :

panneau d’affleurement exige que les bords

intérieurs de l’ouverture soient finis car ils seront

visibles lorsque la porte du four sera ouverte.

Afin d’éviter les dommages causés par les

températures élevées pendant l’autonettoyage

du four, ces bords devraient être teintés plutôt

que laminés.

Dans le cas des

L’installation avec

INSTALLATIONS COMBINEES

Il est possible d’installer un four simple Wolf

Série E sous une plaque de cuisson à induction,

électrique ou au gaz Wolf de 762 mm. Il est

recommandé de placer l’alimentation électrique

dans un élément de cuisine inférieur, à droite du

four, sauf si vous utilisez des éléments de cuisine

d’une profondeur de plus de 610 mm pour une

installation standard ou de plus de 635 mm pour

une installation avec panneau d’affleurement. Il

est possible d’installer un four simple Wolf Série E

sous une plaque de cuisson à induction, électrique

ou au gaz Wolf de 914 mm.

Vous pouvez également installer deux fours

simples Wolf Série E côte à côte. Vous devez

alors prévoir un espace de 64 mm entre les

ouvertures ménagées pour les fours. De plus,

un mur intérieur distinct est requis pour chaque

four entre les ouvertures.

43

Page 43

FOURS ENCASTRABLES WOLF SERIE E

FOURS ENCASTRABLES

SIMPLES SERIE E

INSTALLATION STANDARD

Largeur hors tout du four 759 mm

Hauteur hors tout du four 708 mm

Profondeur hors tout du four

(derrière le cadre) 603 mm

Dégagement de la porte du four 559 mm

Largeur d’élément de

cuisine recommandée 838 mm

INSTALLATION STANDARD

610 mm min

PROFONDEUR

D'OUVERTURE

691 mm

HAUTEUR

D'OUVERTURE

914 mm

DU SOL

AU PLAN

DE TRAVAIL

Largeur minimum de

l’élément de cuisine 762 mm

Profondeur minimum de

l’élément de cuisine (ouverture) 610 mm

Largeur d’ouverture 724 mm

Hauteur d’ouverture 691 mm

Capacité minimum de

support de la base 113 kg

LES DIMENSIONS VARIERONT*

102

mm

E

E

724 mm

LARGEUR D'OUVERTURE

121 mm EN GÉNÉRAL*

127

mm

VUE DE FACEVUE LATERALE

*Les dimensions doivent laisser suffisamment d'espace pour la moulure du four.

REMARQUES : L'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'élément de cuisine plus importante.

La ligne en pointillés représente le contour de l'appareil.

44

Page 44

INSTRUCTIONS D’INSTALLATION

FOURS ENCASTRABLES

SIMPLES

INSTALLATION AVEC PANNEAU

D’AFFLEUREMENT

SERIE E

Largeur minimum de

l’élément de cuisine 838 mm

Profondeur minimum du

Largeur hors tout du four 759 mm

Hauteur hors tout du four 708 mm

Profondeur hors tout du four

(derrière le cadre) 603 mm

Dégagement de la porte du four 559 mm

Capacité minimum de support

de la base 113 kg

panneau d’affleurement 635 mm

Largeur d’ouverture 724 mm

Largeur minimum du

panneau d’affleurement 772 mm

Hauteur d’ouverture 691 mm

Hauteur minimum du

panneau d’affleurement 724 mm

INSTALLATION AVEC PANNEAU D’AFFLEUREMENT

VUE EN PLAN

D’AFFLEUREMENT

25 mm*

629 mm* min

HAUTEUR DU

PANNEAU

TASSEAUX

LATÉRAUX

REMARQUE

IMPORTANTE

L’installation

avec panneau

d’affleurement

exige que les

bords intérieurs

de l’ouverture

soient finis car

ils seront visibles

lorsque la porte

du four sera

ouverte.

772 mm min

LARGEUR DU PANNEAU

D’AFFLEUREMENT

22 mm

TASSEAU

SUPÉRIEUR

691 mm

HAUTEUR

D'OUVERTURE

*Pour le modèle en verre noir, rallongez de 6 mm.

REMARQUES : Capacité minimum de support de la base : 113 kg

L'emplacement de l'alimentation électrique dans l'ouverture peut exiger une profondeur d'élément de cuisine plus importante.

Les tasseaux peuvent être visibles et doivent être finis pour être assortis aux éléments de cuisine.

La ligne en pointillés représente le contour de l'appareil.

724 mm min

HAUTEUR

DU PANNEAU

D’AFFLEUREMENT

724 mm

LARGEUR D'OUVERTURE

11 mm

TASSEAU

INFÉRIEUR

VUE DE FACEVUE LATERALE

127

mm

102

mm

E

E

E

25 mm

TASSEAUX

LATÉRAUX

45

Page 45

FOURS ENCASTRABLES WOLF SERIE E

FOURS ENCASTRABLES

DOUBLES

SERIE E

REMARQUE IMPORTANTE :

Vous devez prévoir

une profondeur utilisable d’élément de cuisine

de 610 mm minimum. Sinon, vous devrez peutêtre enlever le panneau arrière de l’élément pour

pouvoir réaliser une installation adéquate. Pour

une installation avec panneau d’affleurement,

la profondeur utilisable d’élément de cuisine

nécessaire est de 635 mm minimum. Le coffret

électrique doit affleurer au panneau arrière de

l’élément de cuisine.

Pour faciliter l’installation, Wolf recommande

d’utiliser des éléments de cuisine de 838 mm

de largeur avec le four double Série E. Pour une

installation avec panneau d’affleurement, la

largeur minimum d’élément de cuisine nécessaire

est de 838 mm. La plate-forme de l’élément de

cuisine doit pouvoir supporter un poids de 181 kg.

Reportez-vous aux figures suivantes pour

consulter les dimensions hors-tout et les

spécifications d’installation et pour repérer

l’emplacement des raccordements électriques

du four double Série E.

Le four double Série E requiert une alimentation

électrique à trois fils mise à la terre de 220 - 240 V

c.a. et 50 Hz. Reportez-vous à la section Configuration électrique page 52. Le four est fourni sans

prise de courant.

REMARQUE IMPORTANTE :

Il est recommandé

de placer l’alimentation électrique dans un

élément de cuisine adjacent, sauf si vous utilisez

des éléments de cuisine d’une profondeur de plus

de 610 mm pour une installation standard ou de

plus de 635 mm pour une installation avec

panneau d’affleurement. Choisissez dans les

figures pages 48 et 49 l’emplacement le mieux

adapté à votre installation.

46

DIMENSIONS HORS TOUT

25 mm*

1280

mm

759 mm

*Pour le modèle en verre noir, rallongez de 6 mm.

Modèle ICBDO30-2U/S sans cadre illustré.

67*

mm

VUE COTE DROIT

PASSAGE

DU CONDUIT

48 mm

603 mm

DERRIERE LE CADRE

1257

mm

VUE EN PLAN

48 mm

718 mm

PORTE DE FOUR OUVERTE

759 mm

32 mm

603*

mm

559

mm

Page 46

INSTRUCTIONS D’INSTALLATION

FOURS ENCASTRABLES

DOUBLES

SERIE E

INSTALLATION STANDARD

REMARQUE IMPORTANTE :

installations standard, vous devez prévoir une

profondeur utilisable d’élément de cuisine de