Page 1

DIU:

BIG

PARTS

SERVICE

6th

Edition,

SERVICE

MOTOR ROTATION

'0'

AND

MANUAL

Published

INSTRUCTIONS

Keep the

When

Before

clockwise

be

To

p.!lii[•l:l

and damage

July

2008

This

is a hazardous

nect electrical connector

Be

sure

machine

in

the

path

of

ble

operator

ling

ordering

placing

checked

rever5e

during

clothing

machine

direction

the

operation

should

and

clean

replacement

three phose mo<:hlnes ifl

when

by

o flash

direction,

Should the machine be

machine.

type

of

machinery

before

is

properiy

machine

remove

persons

and

contact

interchange two wires (not ground wire)

Single phose machines always

and

completely

all

properly

ports

looking

grounded.

when

loose

with

be

ot

at

performing

Ws

in

fitting

long

hair

odiusted,

sure

to

service

the

nameplate

the

electrical

run

and

should

repairs,

Never

place

service.

down

when

jewelry,

should

as

this

give

Port

be sure the

connedor

in the wrong

be

Keep

not

shouldn't

cover

will add

No.,

side

of

rotate

hands

used

adjustments or

the front

In

use.

or pull it

de$Criptlon

the

with

direction

in

with

care.

or

any

part

guard

as

For

personal

wear

loose

back.

to

ih

life

and

knife

rotates

machine.

at

the proper

The

the

switch

electrical

ports could unscrew

direction.

Always

discon·

maintenance.

of

your

person

low

as

possi·

safety

or

baggy

and

efficiency.

machine

size.

in a counter-

rotation

turned

connector.

the

fit·

con

on.

LUBRICATION

TO

SHARPEN KNIFE

TO

REMOVE KNIFE

TO

REMOVE GEAR

w

1st/Since

The

grease

cup

in

of cup

greose.

To

oil sharpener journals, remove screw

from

oil and

good

surface,

It

is

most e:.sentiol

lmures

clean

odjusted.

toward

mode by releasing screws

to

on

times.

To

nut

of

To

greose cop with pin

gear

they

Becovse

the

knife to ovoid long

the proper pc!Sition. Corn should

knife.

A good bevel

remove

to

left.

slot.

Be

remove knife geor 1 hove knife on

con

then

adjwt

THE

the standard should be

grease.

knife,

When knife

sure to tighten screws

the mesh

Ta

or 5pray with

that o keen

and

easy

of

the weor

place

wrench.

be

lifted

of

WOLF

5570 Creek Road • Cincinnati, OH 45242 • USA

Phone: 513-791·5194 • FAX 513-791-0925

1888

TOLL

e-mail: info@wclfmachine.com • Web Site: www.wclfmachine.ccm

FREE 1-800-543-WOLF

do

this~

remove emery

Keep-M-Kieen

cutting.

of

wea!'$

off.

the

cutting

To

obtain

of

knife and emery

bevel.

damping

pin in hole through

the threaded

be

l/8"

makes o good

move

1

that

Remove knife

Be

sure not

geon.

When

geor.

MACHINE

half

in

end

solution (Order

edge

this,

Wheel11

taken

that

cutting

toeplote

secure

toeplote.

Then

and

to

lose

replacing,

filled

with

grease.

of

bushing shaft and

and

rub wheels

be

kept

the

must touch knife

journob.

standard.

bock so

cop.

any

an the knife

grinding wheel:. must

wheels,

it

the emery wheels

put

The journals can then be futned

edge.

Use knife wrench and

thot

pin in knife ond stondord ond loosen

Then remove screw and washer. The

washen

be sure

Use only a good grade

oil.

together

12l00600).

is

necessary

Emeries

knife

that

the

until they show a

at

evenly.

do

nat

mU$t

Is

about

may

be

screw and

Keep emery free

oil

be

to

go

under

COMPANY

Hmes,

os

kept

properly

adjust

emerie<s:

Adjustment is

too

fordawo

spin free

l/16"

at

tum

knife

from

bearing~

cop

are

tight.

this

all

end

as

Page 2

~-------

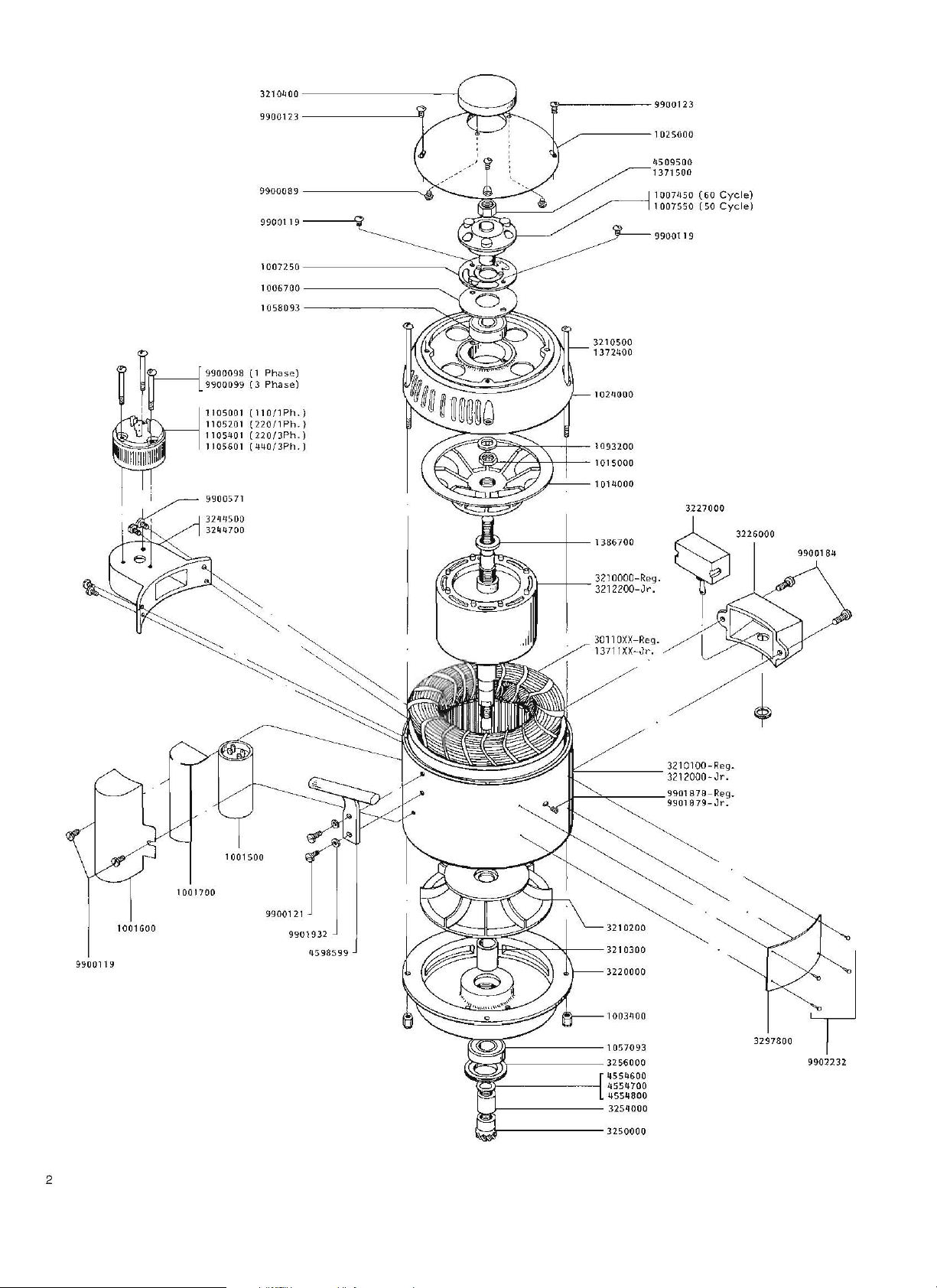

9900123

1105001

1105201

1105401

1105&01

9900119

1006700

1

058093

(110/1Ph.}

(220/1Ph.)

(220/3Ph.)

(440/3Ph.)

-------',~

-----------....

---------------

--------

1

025000

4509500

1371500

1007450 ( 60

1

007550

(50

3227000

Cycle)

Cycle)

9900119

1001600

1001700

1001500

9900121

9901932

4598599

1----+-

- 3210000

IF-------

-Reg.

3212200

-Jr.

30110XX-Reg.

13711 XX-Jr.

3210100-Reg.

3212000

u--,::,_,,..----m:

-Jr.

~;t~~?·

~~~9)}---------1057093

m-~r--------

lC:>}----------l

L.J---------

n 5&ooo

~554600

4554

700

4554800

3254ooo

2

990H32

Page 3

See back cover

for part numbers

and descriptions.

9901560

i1580000

4577300

4532000

9900592

'--------9801866

------,li

Sh<lrpener

Bracket

mounls

of

the

Bottom

413220000.

Grinder

#3277100,

to

underside

Head

9901932

9900121

4561100

4561600

4555200

___

1386060

J

9900573

3277059

3285259

3298100 - 10"

1!.567200

- 8"

9900819

"--------

14315701431970-

3264000

10"

99001

8"

21

3285

299

ft--

.....___

3286559

9901595

3266550

Includes

3266260

3

Page 4

(

Part

1001500

1001600 Capacitor Cover 3277059 Grinder Frame Complete

1001700 Capacitor Insulator 3277100

t003400

t006700

1007250 Inner Breaker

t007450

t007550

t014000

1015000 Lock Nut

1024000

1025000 Cover

1057093 Bearing for Bottom Head 4548300

1058093 Bearing for Top

1081100 Pin for Lifter Spring 4548693 1/4"

1081593 Lifter Spring 4548700 Emery Wheel Shaft

1082200 Hinge Pin 4548800

1083099 Lifter 4554600 Shim

t093200

110500t

1105201 Male

1105401 Male Twist Lock

1t05601 Male Twist Lock Plug - 3 Phase

1371101 Stator

1371104 Stator

13711t6

1371500

1372400

1386060 Handle

1386700 Rear Fan Spacer 4561600 Left Hand Screw

1431570

1431671

1431970

1432071 8" Knife Blade - High Speed 4576400 8" Shoulder Screw (Not shown)

1504800 Grinder Shaft

t505500

3011001

3011004

3011016

For any other

3210000

3210100 Motor Case 7230693 Hardened Screw

3210200 Bottom Fan 7230893 Hardened Screw

3210300 Bottom Fan Spacer 9801866 Set Screw

3210400

3210500

3212000

3212200

3222000 Bottom Head 9900119 Round Head Screw

3226000 Switch Box 9900121 Round Head Screw

3227000 Switch 9900123 Round Head Screw

3244500

3244700

3250000

3251000

3252000 Knife

3252093

3254000 Aligning Collar 9900573 Screw

3256000

3262069 Filler Block 9900592 Filester Head Screw 4

3264000 Knife Nut 9900819 Screw

3265300

3265500

3266000 Cover for Double

3266260 Rear Knife Guard

3266550

3266800

3266900 1 0" OSHA Plastic Guard 9902232

3266960 1 0" OSHA Guard with Bracket

3269060

3269200

PART NUMBERS and DESCRIPTIONS for ENTIRE MACHINE. Listed

No. Description

Capacitor-

Acorn

Insulator

Outer

Outer

Fan-

Top Head 4532000

Bearing Spacer 4554700 Shim .003

Male Twist Lock

Stator

NutMotor

1 0" Knife Blade - Carbon

0"'

1

Knife Blade

8"

Grinder Handle - 1 0" only

Stator·

StatorStator

Stator Voltages, Please Specify. 4598599 Carrier Handle

Rotor 7230593 Hardened Screw

Rotor Knob Cover 9802033 Roll Pin

Motor Bolt

Motor Case Big

Rotor Big

Inlet

Inlet

Pinion

Double Gear

Gear

Lock Nut for Bottom Bearing

Standard - 6"

Standard

1 0" OSHA Guard Complete 9901879 Set Screw

1 0" OSHA Plastic Guard Bracket

Rear Knife Guard

8" OSHA Plastic Guard (not shown)

11

OV

Nut

BreakerBreaker-

Top

Twist Lock

JuniorJuniorJunior-

Junior

Bolt-

Knife

- 220/3/60

60

50

Head

PlugPlugPlug-

110/1/60 4560300 Shim .003

220/1/50 4560400

22013160 4560500 Shim .010

Junior 4560700 Shim .002

Blade·

High Speed

-Carbon

110/1/60 4580000 Grinder Spring

220/1/50 4598582 Pivot Bushing and Screw

'0'

'0'

Junior

Box Twist-Lock 1 Phase Plug

Box Twist-Lock 3 Phase Plug

Gear

Gear

Pin 2 9900571 Screw to secure Connector Box 4

- 1 0"

Gear

Bracket-

Bracket-

Quantity

if

Cycle

Cycle 3297800

1 Phase,

1 Phase, 220V 4555200 Bearing Lock Nut

3 Phase, 220V 4559293 Knife Bearing

Junior

11

OV

440V

1 0" 9901878

8"

used

more

than

4 3279200 8" Pull Rod (not shown)

4

2

Part

No.

1

3269550 8"

3285259

3285299

3286559

3298100

4509500

4548050

4548593

4554800 Shim .005

4560200 Shim .001

4560600 Shim .032

4561t00

4567200 Toe

4567300 Screw

4576000 8" Grinder Trigger (Not shown)

4577200

4577300

4598571 Guard

9900089 Round

9900098 Screw to secure Twist Lock Plug 1 Phase

9900099 Screw to secure Twist Lock Plug 1 Phase

9900184

9900307 Flat

9900355 Flat Head Screw 2

9900338 Locking Screw 2

9900339 Screw to secure Plastic Guard

9900574 Screw - 1 0" only

9901560 Screw

9901595

9901675

9901932

9902256 Screw to secure Journal 2

9902325

Description

OSHA

Guard Complete (not shown)

Grinder

Bracket-

Footplate Complete

Footplate

Roller Complete 4

Name

Plate

Toe Plate - 1

Nut

Grease

Cap

Emery Wheel and Shaft Complete 2

Emery

Wheel

Emery

Wheel

Nylon

Washer

Grinder

Journal

.001

Shim .005

Lock Washer

Plate-

to secure

Grinder

Frame

Grinder

Frame Cap

Head

Round Head Screw

Head Screw 4

to

secure Rear Knife Guard

to

Round Head Screw to secure Rollers

Nut

Set Screw

Lock

Escutcheon Pin 4

Washer

secure Spring

Washer

0"

8"

in

numerical order.

Quantity

if

more than 1

1 0"

Washer

Toe

Plate

Screw 2

2&2

2. 3 &4

2,

3&

)

used

2

2

2

2

2

2

2

2

2

3

2

3

3

2

2

2

2

8

4

4

2

THE

WDU::

4

Phone:

WOLF

513·791·5194 •

MACHINE

FAX

513·791·0925 •TOLL

COMPANY

FREE

1·800·543-WOLF •

•

5570

Creek Road • Cincinnati.

e-mail:

info@wolfmachine.com •Web

OH

45242 • USA

Site:

www.wolfmachine.com

Loading...

Loading...