Page 1

1 Stationary RFID Portal Reader User’s Manual

1.1 Cover sheet

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 1

Page 2

1 STATIONARY RFID PORTAL READER USER’S MANUAL.........................1

1.1 Cover sheet........................................................................................................................................ 1

1.2 Introduction ...................................................................................................................................... 3

1.2.1 Contents of this Document ......................................................................................................... 3

1.2.2 Audience..................................................................................................................................... 3

1.2.3 RFID System Quickstart............................................................................................................. 3

1.2.4 Product Description .................................................................................................................... 4

1.2.5 Unpacking and Inspection .......................................................................................................... 4

1.2.6 Product Installation..................................................................................................................... 4

1.3 Installation and Operation of demonstration Graphical User Interface ..................................... 5

1.3.1 Minimum System Requirements ................................................................................................ 5

1.3.2 Installation .................................................................................................................................. 5

1.3.3 Using the Demonstration software ............................................................................................. 8

1.3.4 COM Port Enumeration............................................................................................................15

1.3.5 Changing Software Parameters and Reader Configuration ...................................................... 18

1.4 RFID overview................................................................................................................................ 20

1.4.1 RFID operating principles ........................................................................................................ 20

1.4.2 RFID vs. bar code..................................................................................................................... 22

1.4.3 RFID system components......................................................................................................... 23

1.4.4 RFID standards......................................................................................................................... 29

1.5 Stationary portal RFID Reader Theory of Operation................................................................. 39

1.6 Host-Reader Interface.................................................................................................................... 41

1.7 Troubleshooting / technical support .............................................................................................41

1.8 Technical specifications.................................................................................................................. 41

1.9 Notices.............................................................................................................................................. 42

1.9.1 RFID limitations....................................................................................................................... 42

1.9.2 Safety........................................................................................................................................ 42

1.9.3 Limitation of liability................................................................................................................ 42

1.9.4 Patents....................................................................................................................................... 42

1.9.5 Copyright notice ....................................................................................................................... 42

1.9.6 Comments and feedback...........................................................................................................43

1.10 Regulatory Compliance.................................................................................................................. 43

1.10.1 FCC Statement.......................................................................................................................... 43

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 2

Page 3

1.2 Introduction

1.2.1 Contents of this Document

This manual describes installation and operation of the WJ Communications UHF Stationary RFID Portal

Readers. A description of the installation and use of the demonstration Graphical User Interface is also

provided. The Application Programmer’s Interface to the Apollo-series devices using a serial

communications port is summarized; use of the Ethernet port to control the reader is described in a separate

document.

1.2.2 Audience

This manual assumes that the reader is generally familiar with Windows personal computers. An

introduction to RFID technology is provided for readers who are new to the field.

1.2.3 RFID System Quickstart

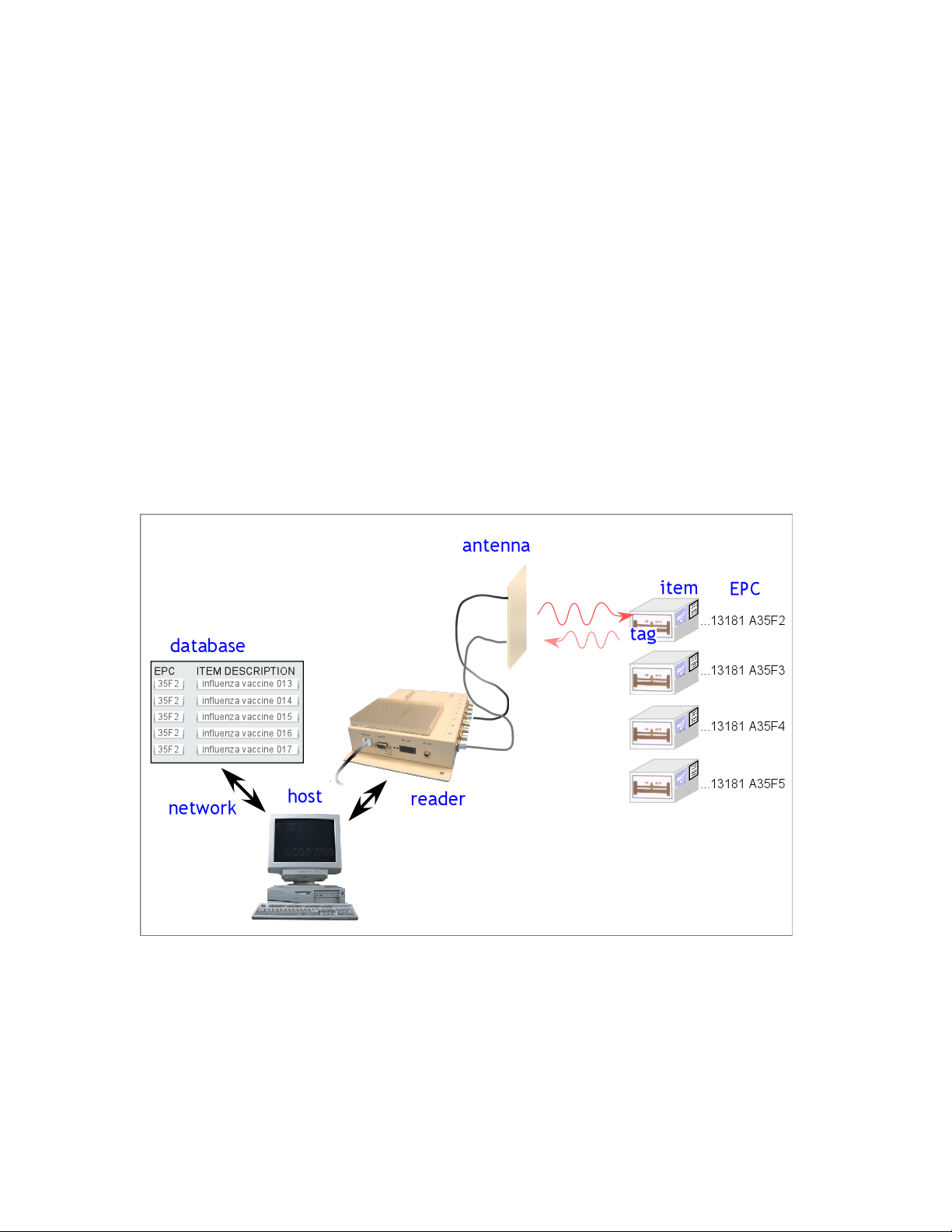

Radio Frequency Identification (RFID) uses electromagnetic waves to exchange information between a tag,

containing (at least) a number uniquely identifying that physical tag and by implication the object to which

it is attached, and a reader. RFID tags are analogous to bar codes, but can contain more information and

are more versatile.

The WJ Communications Stationary Portal Readers are UHF readers, operating at a frequency of roughly

902-928 MHz. These readers are compatible with EPCglobal Class 0 and EPCglobal Class 1 RFID tags,

as well as class 0+ tags and ISO 18000-B tags. They are not compatible with HF (13.56 MHz) tags

generally used in Smart Cards, or LF (125/134 KHz) tags generally used in animal identification. The

stationary portal readers are configured to use either an RS232 serial port or an Ethernet interface to

communicate with a host computer; direct optically-isolated I/O ports are also provided. With an

appropriate host and appropriate external antennas, a stationary portal reader can be used to acquire the

unique identification number (UID) of one or more compatible tags in its reading range. When multiple

tags are present in the field, collision resolution algorithms are applied to allow effectively simultaneous

reading of all the readable tags.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 3

Page 4

A more detailed discussion of RFID technology can be found in section 1.4.

1.2.4 Product Description

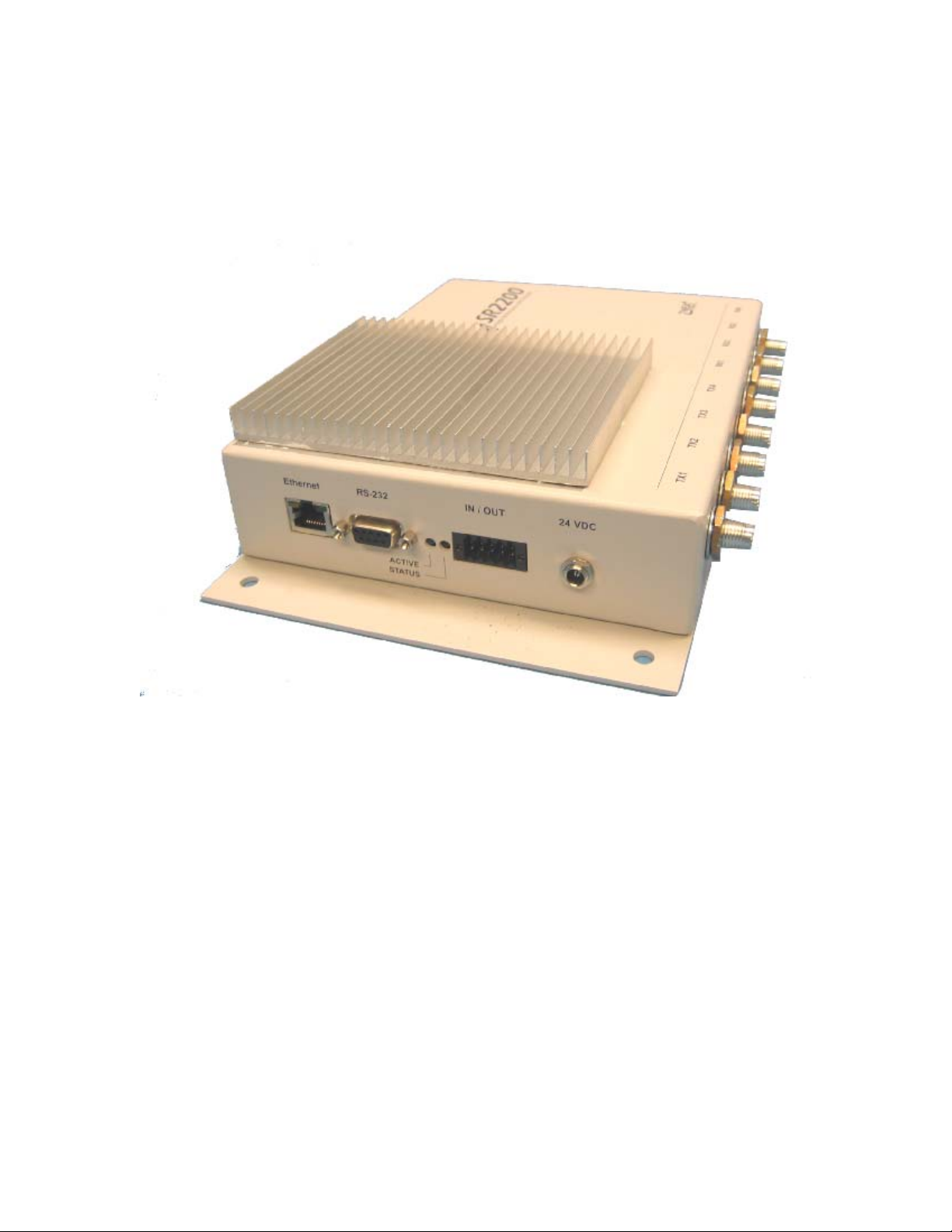

The Stationary portal reader is a self-contained RFID reader configured for use at 902-928 MHz. Eight

antenna connections using mini-UHF connectors, normally configured as four pairs of (transmit – receive),

are provided on the back of the unit. Each pair can be connected to a WJ Communications model AN-120

antenna pair, or to other approved antennas. Communications with a host controller is achieved through a

conventional RS232 serial port. Optically-isolated direct I/O, and an Ethernet interface using a

conventional RJ45 connector, are also available.

1.2.5 Unpacking and Inspection

Box Contents:

• SR2200 Stationary Portal Reader

• A CD containing this User’s Manual and Demonstration Software

• AC power adaptor

• RS232 Serial Cable

• USB-to-serial adaptor

• Ethernet cable

• 50 ohm mini-UHF terminators (6)

• I/O port terminator

• Mounting hardware

Contents may vary slightly depending on the model number and options purchased.

1.2.6 Product Installation

The Stationary portal reader should be installed in a location protected from physical impact. The reader

may support up to 4 transmit-receive antenna pairs. The antennas should not be located more than 5 meters

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 4

Page 5

(15 feet) from the reader. The reader should be securely mounted using the four mounting holes provided,

preferably in a vertical orientation allowing air to flow along the length of the cooling fins. At least 12 cm

(5 inches) of clearance should be provided in all directions from the reader. The reader and antennas

should not be located close to a strong source of RF interference such as a cordless telephone or 900-MHz

wireless local area network (WLAN) basestation. The antennas should not have any conductive (metallic)

obstructions within 50 cm in the direction in which tag reading is to be performed.

A possible installation sequence is as follows:

1. Mount the reader to a secure, stable surface, with adequate clearance and air flow.

2. Attach the antenna cables to the relevant mini-UHF connectors at the reader, and N-type

connectors at the antenna. Terminate unused mini-UHF connectors with 50 ohm loads.

3. Connect the RS232 serial control cable to the reader and the host computer.

4. Connect the 24 VDC power supply cable to the reader.

5. If the I/O port is not used, it must be terminated using the I/O terminator provided.

6. Place one or more appropriate RFID tags in front of one of the antenna pairs, within 1-2 meters.

It is important to note that transmit and receive antennas must be connected in pairs to corresponding

connectors. Thus, if only one antenna pair is employed, the transmit antenna may be connected to any of

the transmit connectors (e.g. TX1), but the receiving antenna must then be connected to the corresponding

receive connection (RX1 in this case). Antenna ports not used should be terminated with the 50 ohm

terminations provided. If separate transmit and receive antennas are employed, it is important that they be

oriented so as to view the same illuminated area, and preferably be coplanar so as to minimize coupling

between the antennas.

At this point the reader should be ready for operation using the demonstration graphical interface software,

or other custom control software.

1.3 Installation and Operation of demonstration Graphical User

Interface

The following description assumes the host computer is operating under Microsoft Windows XP; slightly

different screens will be visible if another operating system is employed.

1.3.1 Minimum System Requirements

This software requires a host computer running Microsoft Windows 98, NT, 2000 or XP, with a Pentiumcompatible PC and at least 128MB RAM, 50 MB available hard disk space, and 800x600 resolution or

higher. The configuration described presumes that an RS232-capable serial port or emulated serial port is

available. If the host computer is not equipped with a serial port connection, a USB-to-serial converter can

be employed. The converter may require additional driver software, not provided here.

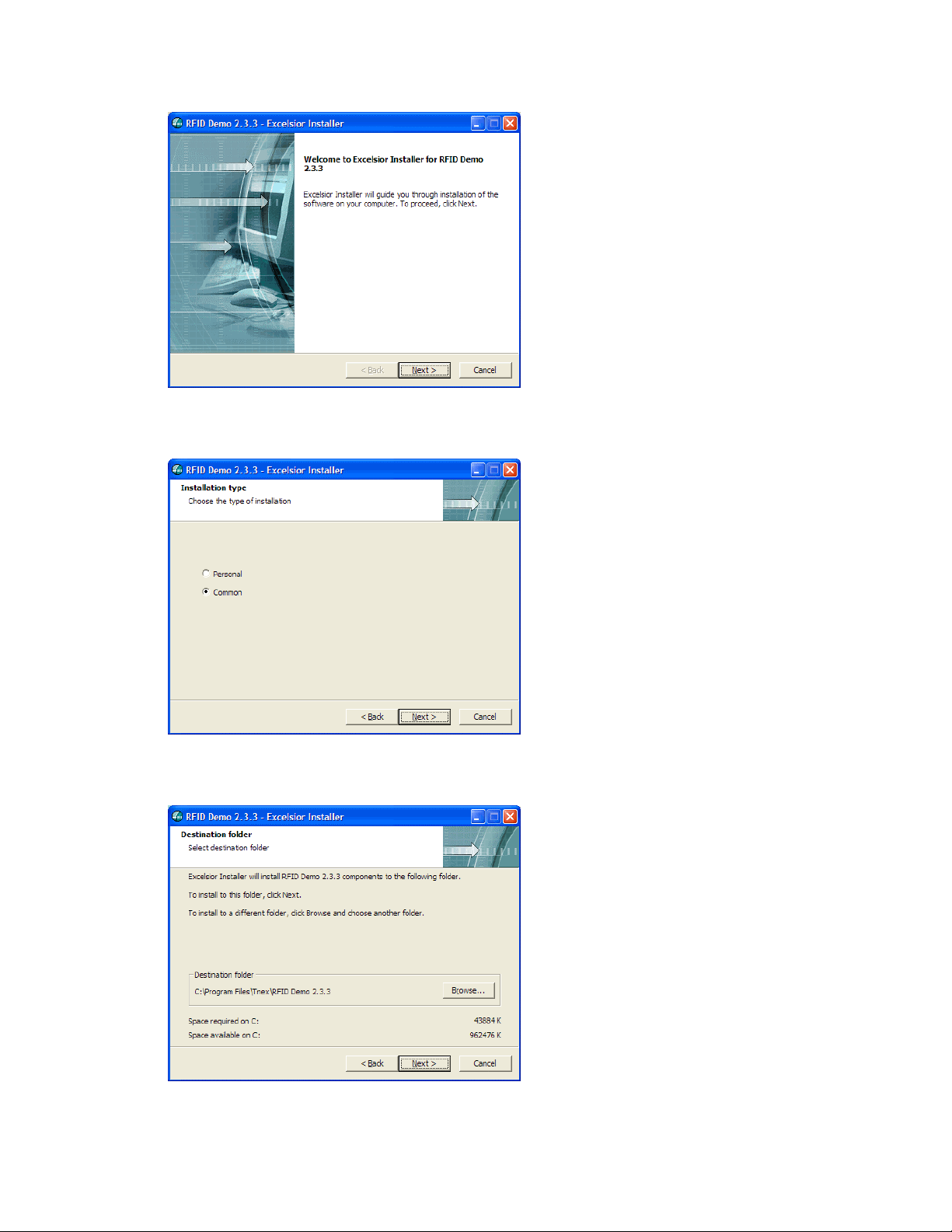

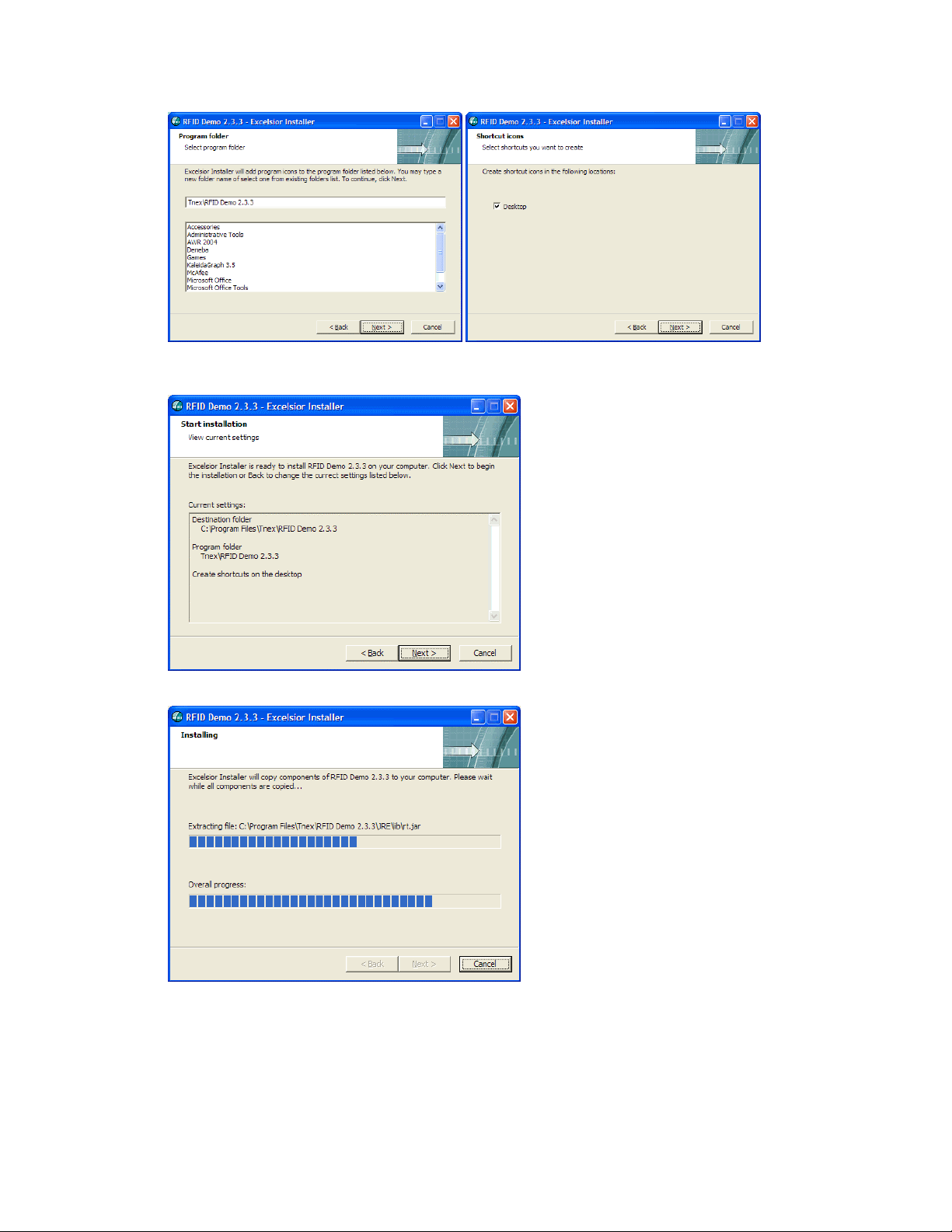

1.3.2 Installation

1. Double-click on the file ‘rfiddemo_2.3.3_setup.exe’ or run the file from the START menu ‘run’

selection.

2. The installer should display the startup-screen:

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 5

Page 6

Click “NEXT”.

3. The installation-type screen gives you the option of installing the software so that it is available to

all users of the host computer (‘Common’), or only to the login name under which the installation

is performed (‘Personal’).

4. The installer asks where you would like to install the program. The default location is on the local

C disk in the Program folder. If you change the location of the program it is important to note

where it is installed, as you will need to access this folder to make modifications to the reader

configuration.

5. You are provided with the option of installing a demo icon in the Program folder, and a shortcut

on the desktop.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 6

Page 7

6. The installer then provides a summary of the selected parameters for you to review prior to actual

installation of the software. Click ‘Back’ if you decide to change any of the settings. Click ‘Next’

to begin the installation.

7. The installer copies the requisite files; progress is displayed in the installer window. This process

may take a few minutes.

8. When the installer is finished the Installation Complete screen appears. Click ‘Finish’ to exit the

installer.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 7

Page 8

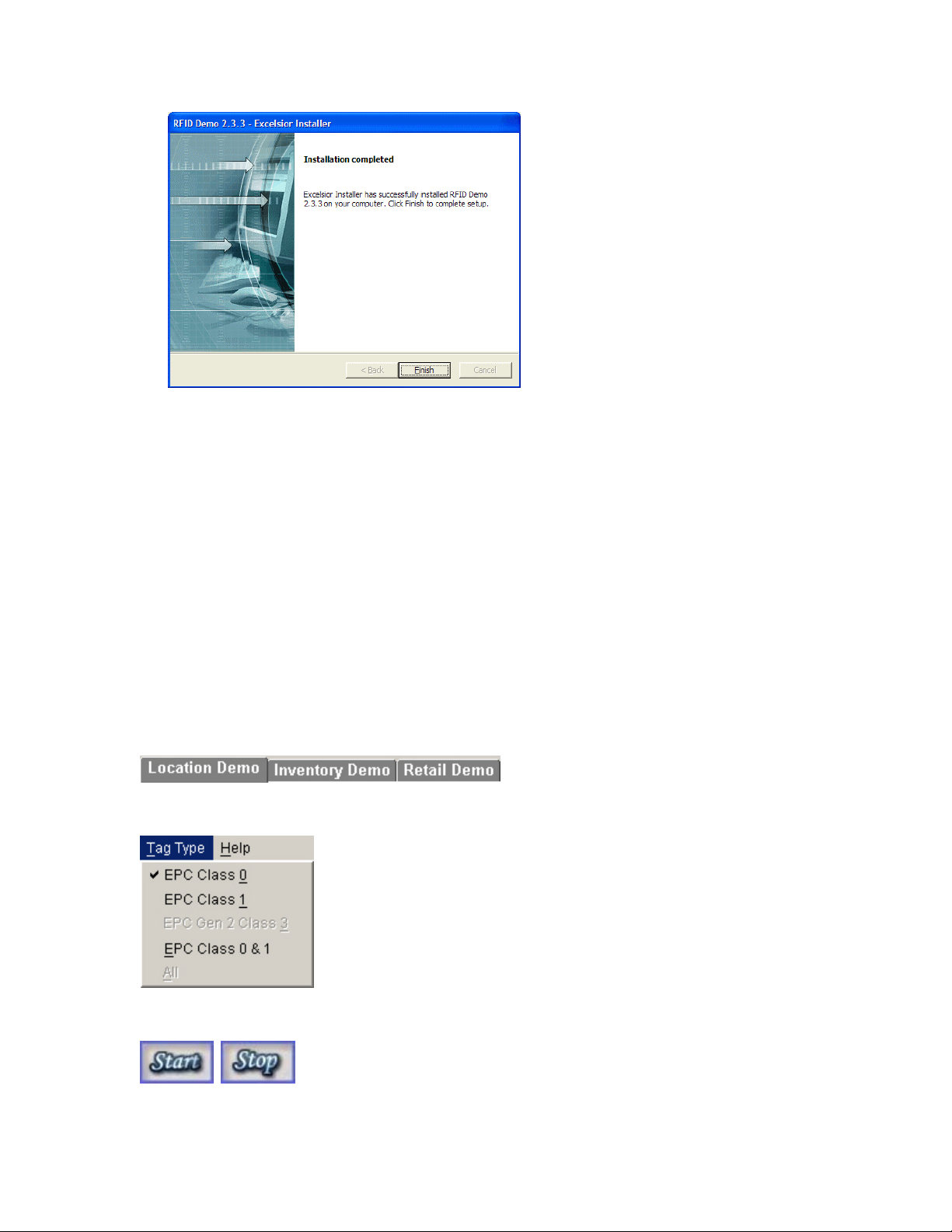

1.3.3 Using the Demonstration software

Introduction

The RFID Demo is an application for demonstrating the capabilities of the RFID hardware and Java API.

The demo consists of three individual demonstration modules: a Location Demo, an Inventory Demo, and

a Retail Demo. Each demo demonstrates different aspects and areas where the RFID hardware and API

can be applied. More details concerning each demo are described in later sections.

Running the Demos

Before starting the software, ensure that the reader is powered up and connected to one or more pairs of

antennas. Any antenna ports that are not used should be terminated by a 50-ohm load. The reader serial

port should be connected to the physical or emulated serial port on the host computer.

Start the demo software from the START menu or the desktop shortcut. Select the demo to run from the

tabs.

Select the tag type to read from the menu bar.

Press the 'Start' button to start the demo and begin reading tags. Press ‘Stop’ to stop tag reading.

Press the 'Clear' button to clear the data for the current demo. Press the 'Exit' button to exit the application.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 8

Page 9

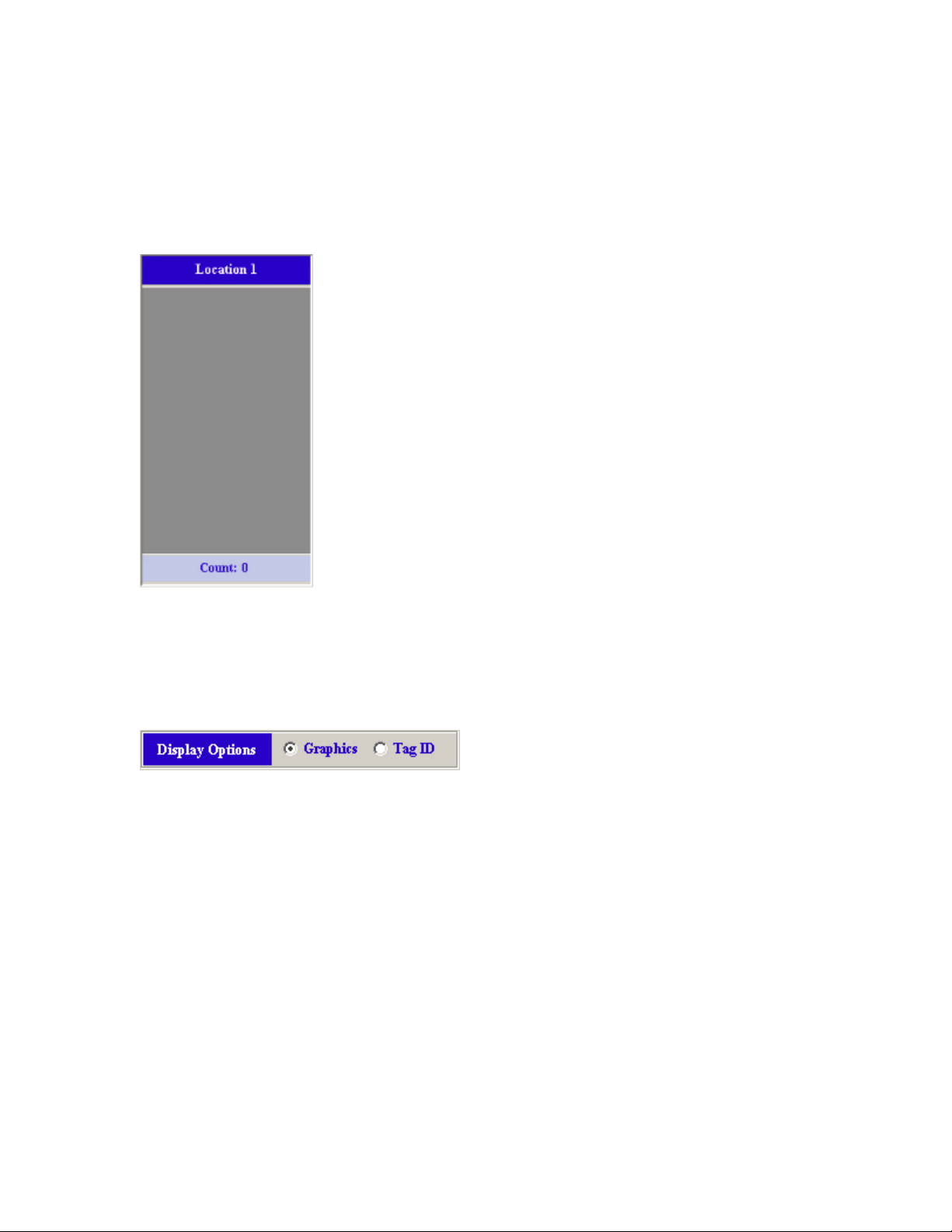

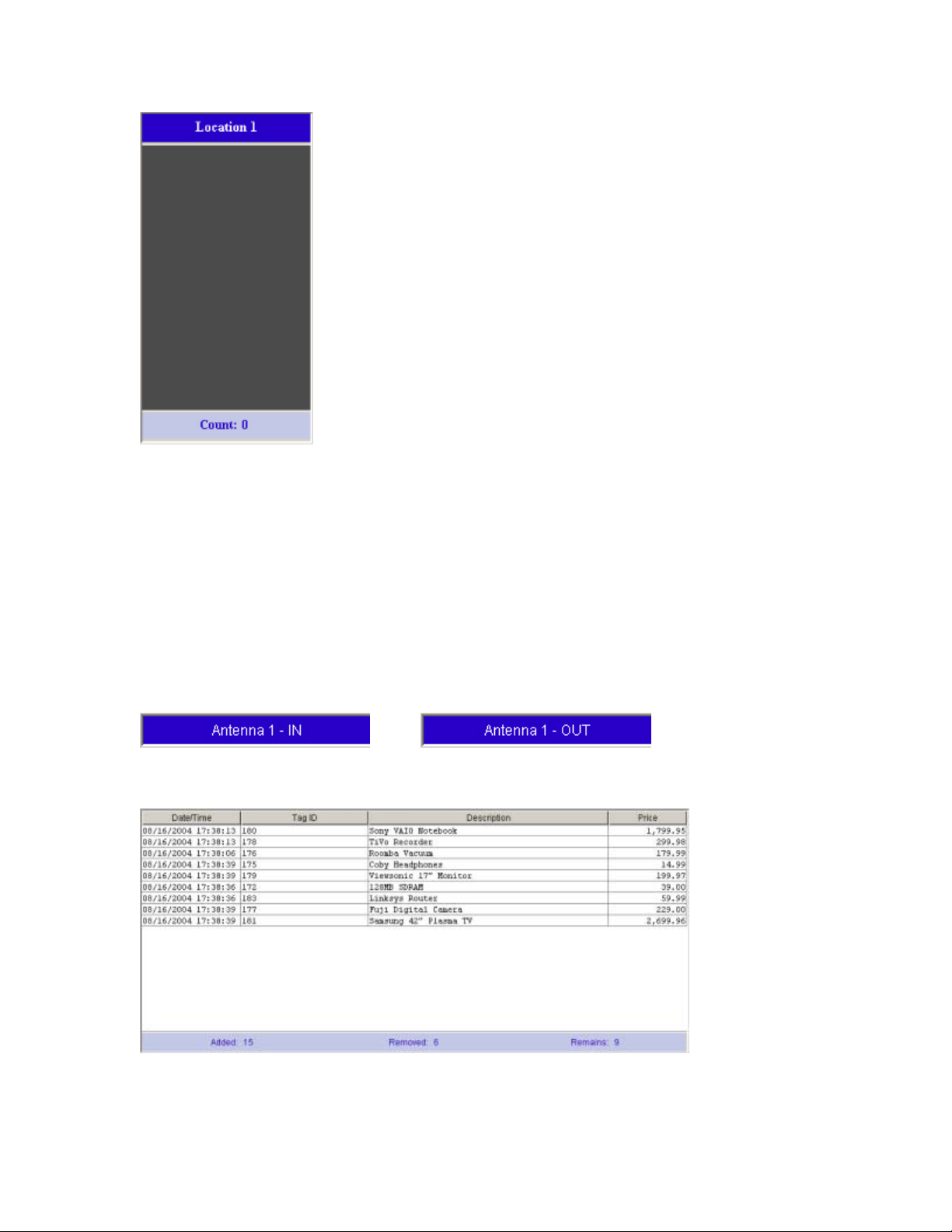

Location Demo

The Location Demo is for demonstrating basic RFID functionality. It consists of four panels, which each

represent a location (typically configured as a pair of antennas; thus there are four possible locations

corresponding to the four antenna pairs supported by the unit). For this demo, one location directly

correlates to one antenna pair.

The top bar contains the location name (Location 1-4). It will show 'No Location' if that location is not set

for the selected reader. The bottom bar contains the count of tags being read.

The middle section displays the tags read either in graphic or text format, which can be selected from the

display options in the lower left corner of the application. The options are disabled if the demo is currently

running.

When the 'Graphics' option is selected, the panel will display one box for each tag read at that location. A

sample is shown below with three tags read.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 9

Page 10

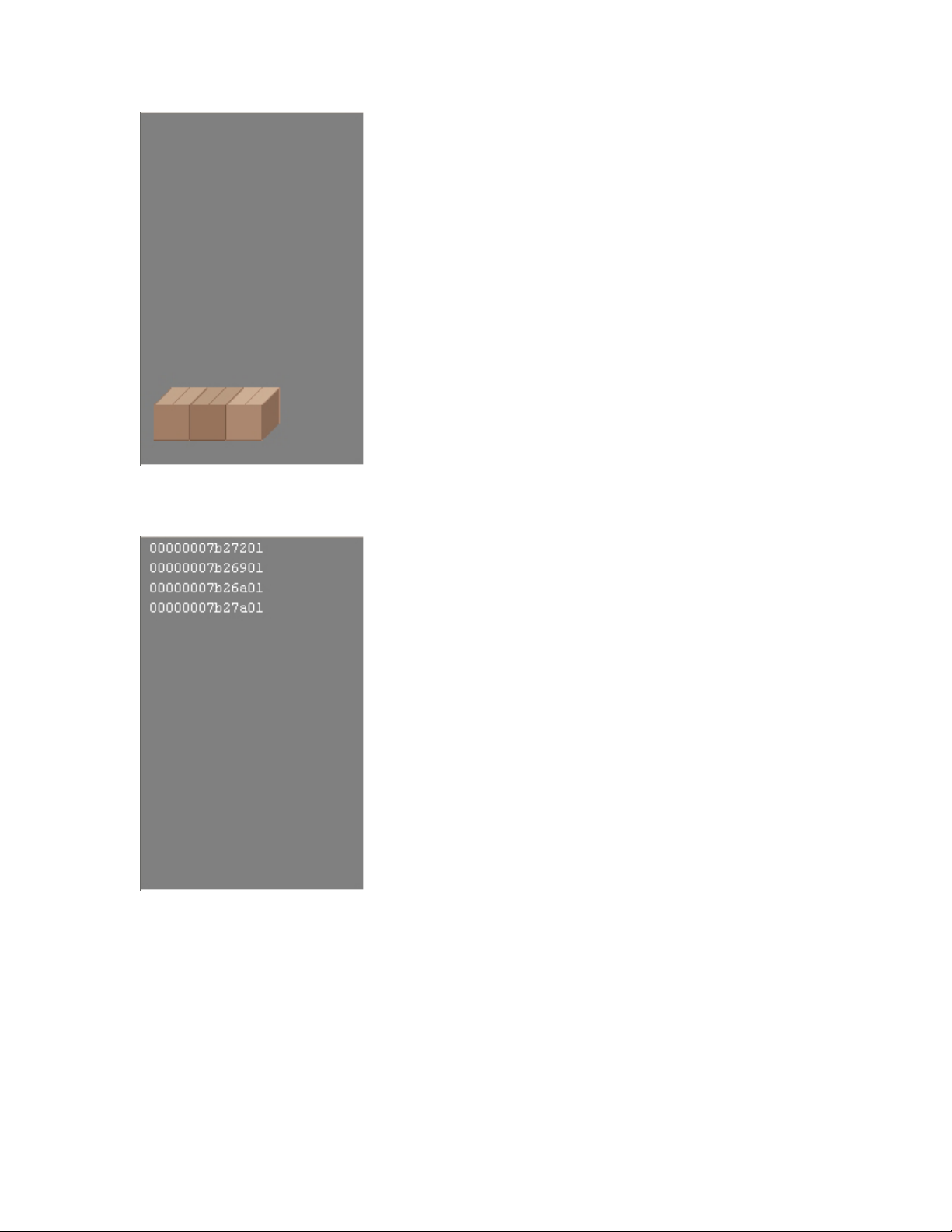

When the 'Tag ID' option is selected, the panel will display a list of all tag IDs that are being read. A

sample is shown below.

When the middle section is dark gray as shown below, there is no communication between the application

and antenna. Either an antenna fault or response error has occurred.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 10

Page 11

Inventory Demo

The Inventory Demo simulates an inventory supply of incoming and outcoming goods. It demonstrates the

pairing of antennas as two locations: IN & OUT. Tags read at an IN location are added to the inventory.

Tags read at an OUT location are removed from the inventory. The demo consists of three areas.

The top bar displays the four antennas and their respective location IN or OUT. The antenna background

will be blue if the antenna is responding. It will be black if the antenna is not responding. 'No Location' will

be displayed if that antenna is not set for the selected reader.

Next to the antenna name is the location type. When an antenna section is pressed, it will switch that

antenna from IN to OUT and vice versa as shown below.

>>

When a tag is read at an IN location, an item is added to the inventory table for that tag as shown below.

When a tag is read at an OUT location, the item corresponding to that tag is removed from the inventory

table as shown below.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 11

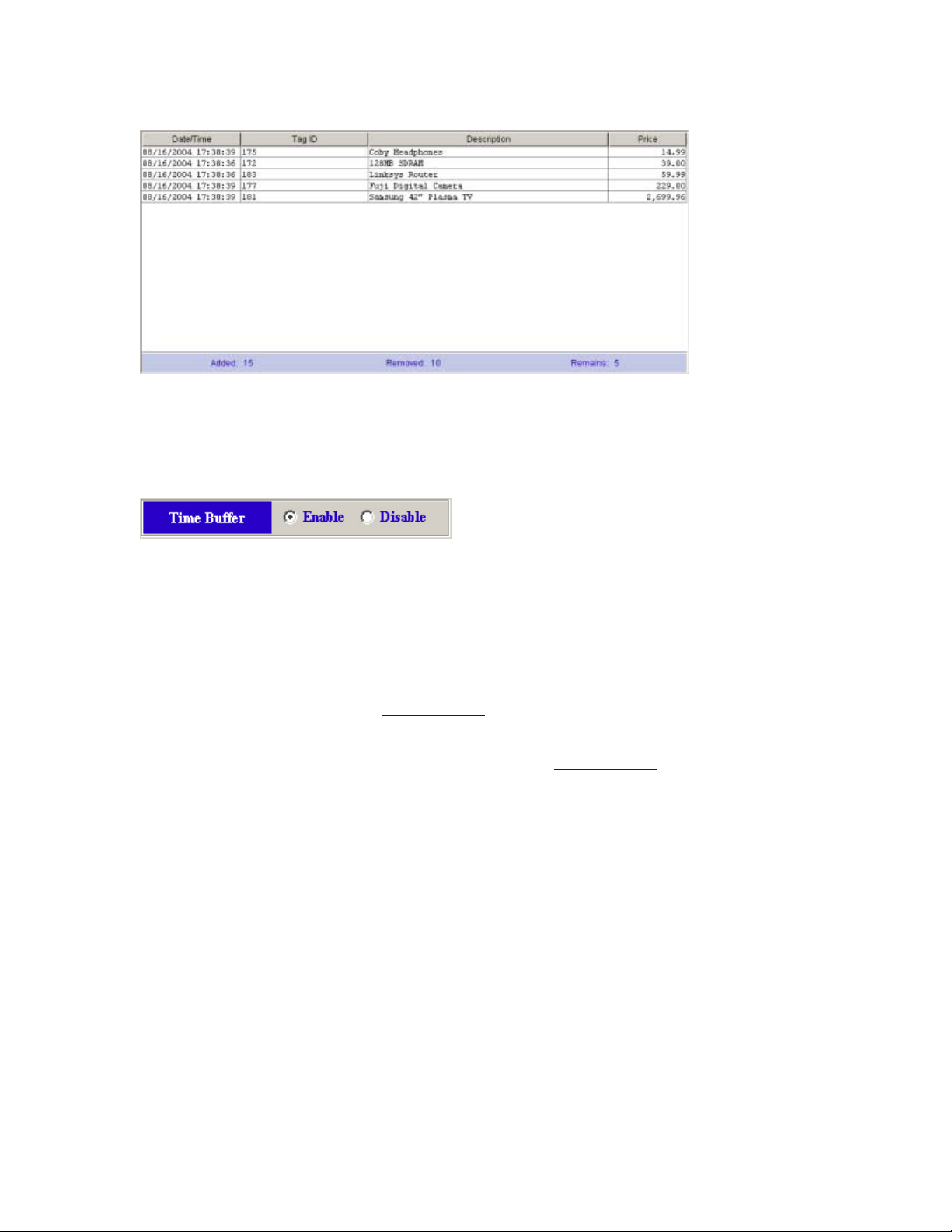

Page 12

The bottom bar displays the inventory counters. It displays the overall count of items that have been added

to and removed from the inventory. It also displays the current count of items that still remain in inventory.

The time buffer filters consecutive tag events between IN and OUT locations. This is to demonstrate the

filtering of invalid reads between close proximity antennas.

When the time buffer is enabled, a tag read at an IN location will be ignored at an OUT location until a

span of 3 seconds has elapsed without being read again at the IN location. The time buffer is reset to 3

seconds every time the tag is read again at an IN location within the time window. Once the time buffer for

a tag has expired, the tag will not be ignored if read again at an OUT location. The same concept applies to

tags read first at an OUT location.

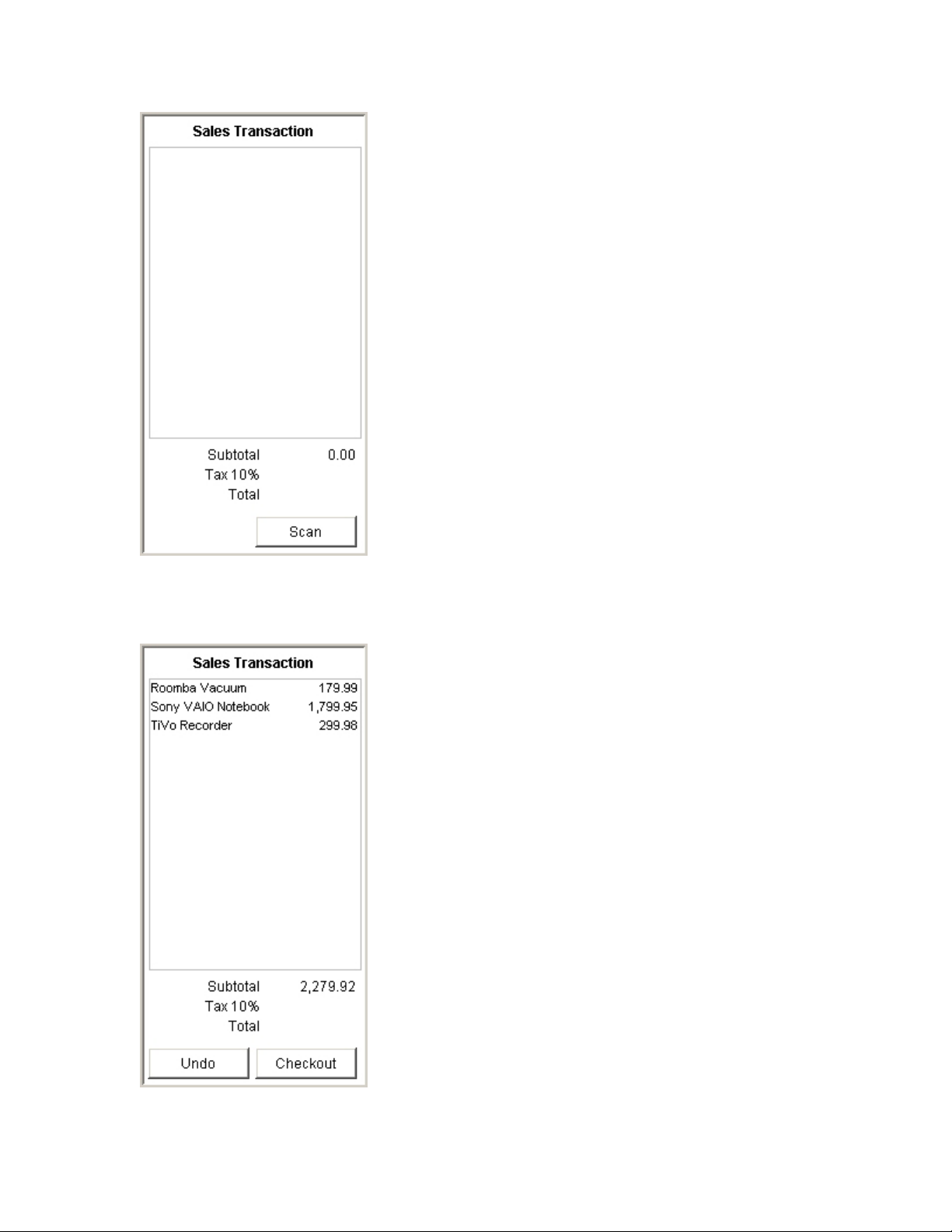

Retail Demo

The Retail Demo is very similar to the Inventory Demo

. It also simulates an inventory supply of incoming

and outgoing goods. The difference is that outgoing goods leave via the sales transaction checkout station.

The left section containing the table works almost exactly like the Inventory Demo

. Tags read at an IN

location are immediately added to the inventory. The difference is with tags read at an OUT location, which

is described below.

The right section or sales transaction section represents a retail checkout station. Tags read at an OUT

location are ignored until the 'Scan' button is pressed (shown below).

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 12

Page 13

When the 'Scan' button is pressed, the sales transaction buttons will become 'Undo' and 'Checkout' as

shown below. Now when a tag is read at an 'Out' location, the item corresponding to that tag is removed

from the inventory and added to the sales transaction list also shown below.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 13

Page 14

The 'Undo' button will return all items in the sales transaction list back to the inventory table. Items can

also be returned from the transaction list back to the inventory by reading the corresponding tag at an IN

location.

The 'Checkout' button will complete the sales transaction. It will turn the sales transaction off and calculate

the tax and total of the transaction as shown below.

There is no time buffer for the Retail Demo.

Troubleshooting

Below are listed some common error conditions and means to correct them.

ERR001 - Communication Port Not Found

The serial port isn’t working, or has enumerated to a COM port different from what the software expects.

See sections 1.3.4 and 1.3.5 below for instructions on how to diagnose and correct these problems.

ERR002 - Communication Port in Use

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 14

Page 15

The communication port is being use by another application.

- Close the application that is using the port.

ERR010 - Communication Response Error

There is no communication between the application and the reader.

- Restart the application.

- Check that the all connections are correct.

- Check that reader has power.

- Reset the reader by powering it off, waiting, and then powering it back on.

1.3.4 COM Port Enumeration

The default method for communication with the Stationary portal reader employs a serial port or emulated

serial port. In a Windows environment, serial ports are denoted by the word COM and a one-or-two-digit

number; thus the first port is COM1, the second COM2, and so on. The demo software assumes that the

reader is present on the COM1 port. If the host computer is equipped with a single physical serial port

(typically a D-sub-9 connector on the back of the unit, often labeled ‘COM’ or ‘COM1’), this port will

typically be COM1 and can be used to connect the host to the Stationary portal reader using a conventional

serial cable.

If a physical serial port is not available but a USB (universal serial bus) connection is, it is possible to

employ any one of a number of commercially-available converters that provide translation between the

USB and RS232 protocols. It may be necessary to install driver software in the host computer for the

converter employed. Once the converter is installed and running, it will appear to the host computer as a

serial port, but not necessarily as COM1. To find out which port the emulator has enumerated to, go to the

START menu and select Control Panel. In the Control Panel, select System.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 15

Page 16

In the System panel, click on the Hardware tab and select the Device Manager:

In the Device Manager, scroll down if necessary to find the list of ‘Ports (COM and LPT)’. You may need

to click on the [+] heading to see the list. The USB-to-serial device should be displayed, showing which

COM port it has been assigned to. In this case, a ‘Prolific USB-to-Serial’ converter has been assigned to

COM3. Your display may differ slightly depending on the brand of converter used.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 16

Page 17

If the port you wish to use to communicate with the reader is not assigned to COM1 you need to take one

of two approaches: you can reassign the port to COM1, or you can reconfigure the software to use the port

to which your reader cable has been assigned (COM3 here). Reassignment, described below, may not be

possible depending on the configuration of the host computer. Software configuration is described in

section 1.3.5.

To change the port assignment, double-click on the port (‘Prolific USB-to-Serial’ in the example shown) to

bring up the configuration screen for this port. Select the ‘Port Settings’ tab and click on ‘Advanced’.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 17

Page 18

In the resulting control window, select the pull-down menu for the COM port. If the COM port you want

(for example, COM1) is not in use you can reassign that number to the current port. However, if it is in use

you may need to reconfigure the demo software (section 1.3.5).

1.3.5 Changing Software Parameters and Reader Configuration

Changes to the COM port assignment, RF power level, delay between inventory operations, or other

parameters, you need to edit the text file RfidConfig.xml, located in the director \properties\ in the folder in

which the software was installed. If you did not change the default configuration, this folder will be found

in C:\Program Files\Tnex\RFID Demo 2.3.3. If you installed the software in a different location, you must

navigate to this location using Windows Explorer or the DOS window. The text file can be edited in any

environment that can edit and save pure text files. Typical word processors like Microsoft Word will not

save text files unless specifically instructed to do so. If you save to a pure text file from Word or another

standard word processor, ensure that the file name has not been changed, and in particular that the

extension remains ‘.xml’ and not, for example, ‘.txt’. It may be necessary to reconfigure Windows

Explorer to display filename extensions. The file consists of a series of XML statements; an excerpt is

shown below:

<?xml version="1.0"?>

<RIC>

<location class="com.tnex.services.common.location.LocationService">

<locationProp name="LocationName" type="String">a0</locationProp>

<locationProp name="ttl" type="Integer">2</locationProp>

</location>

<location class="com.tnex.services.common.location.LocationService">

<locationProp name="LocationName" type="String">b0</locationProp>

<locationProp name="ttl" type="Integer">2</locationProp>

</location>

…

COM Port Reassignment:

In the segment:

<protocol

class="com.tnex.services.common.protocols.sr2000.ProtocolService">

<protocolProp name="PortNumber" type="String">COM1</protocolProp>

<protocolProp name="TimeOut" type="Integer">3000</protocolProp>

<protocolProp name="BaudRate" type="Integer">57600</protocolProp>

<protocolProp name="DataBits" type="Integer">8</protocolProp>

<protocolProp name="StopBits" type="Integer">1</protocolProp>

<protocolProp name="Parity" type="String">NONE</protocolProp>

<protocolProp name="Delay" type="Integer">200</protocolProp>

<reader

class="com.tnex.services.common.datasources.rfreaders.sr2000.Sr2000Reade

rService">

change ‘>COM1<’ to whatever port your serial connection to the reader has been assigned to. In the

example of the previous section (1.3.4) the text would become:

<protocolProp name="PortNumber" type="String">COM3</protocolProp>

Save the file (make sure it has the same filename!) and restart the demonstration software.

RF Power:

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 18

Page 19

In the segment

<antennaProp name="id" type="String">00</antennaProp>

<antennaProp name="power" type="Integer">255</antennaProp>

<antennaProp name="singulation" type="Byte">02</antennaProp>

change the value of “power” as appropriate. The power is entered as a decimal integer; the minimum value

is 0 (not very useful!), and the maximum value is 255. For example, to reset the power to a value of 200,

you can change the text to:

<antennaProp name="power" type="Integer">200</antennaProp>

Then save the file and restart the demonstration software.

An example relationship between the continuous-wave (CW) output power and the power setting for an

Stationary portal reader is shown below to provide rough guidance in the use of the power setting

parameter. Note that your reader may not produce exactly the same results as shown.

35

30

25

20

CW output power (dBm)

15

0 50 100 150 200 250 300

power setting

Delay between inventory commands:

To reset the inventory delay, edit the value of ‘Delay’ in the segment (the delay is given in milliseconds):

<protocol

class="com.tnex.services.common.protocols.sr2000.ProtocolService">

<protocolProp name="PortNumber" type="String">COM3</protocolProp>

<protocolProp name="TimeOut" type="Integer">3000</protocolProp>

<protocolProp name="BaudRate" type="Integer">57600</protocolProp>

<protocolProp name="DataBits" type="Integer">8</protocolProp>

<protocolProp name="StopBits" type="Integer">1</protocolProp>

<protocolProp name="Parity" type="String">NONE</protocolProp>

<protocolProp name="Delay" type="Integer">200</protocolProp>

For example, the following text would change the delay from 200 to 100 milliseconds:

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 19

Page 20

<protocolProp name="Delay" type="Integer">100</protocolProp>

Note that the settings for the serial port can also be reset in this file. The default values are:

- Port Number: COM1

- Baud Rate : 57600

- Data Bits : 8

- Stop Bits : 1

- Parity : NONE

1.4 RFID overview

1.4.1 RFID operating principles

Radio-frequency identification (RFID) is an auto-identification technology, similar in concept to other

common auto-identification technologies such as bar code scanners, magnetic strip readers, or magnetic ink

readers. Like other auto-ID techniques. RFID associates an identifying number with a physical object. In

RFID, the unique identifying number (UID or, as will be explained below, EPC) is incorporated in a

special system, an RFID transponder (often simply known as a tag). An RFID Interrogator (usually

known as a reader) is used to obtain the UID from the tag using electromagnetic waves. The tag is usually

attached to a physical object that is to be identified, such as a carton, a pallet, or a container filled with a

product.

In order to reduce the cost of the tag, most tags do not incorporate a battery or other source of power, but

instead operate using DC power derived from the radio frequency signal they receive from the reader. In

addition, low-cost tags do not incorporate a radio transmitter, but instead use varying reflection of the

received signal from the reader to communicate back to it. Such tags are known as passive tags. Since

passive tags are the most common type, the description below will assume their use. Variants are also

available: semi-active tags incorporate a battery to power the integrated circuit, but still use reflected

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 20

Page 21

waves (backscattering) to communicate with the reader. Active tags incorporate both a battery and a radio

transmitter, and are much more costly than passive tags, but also more versatile.

RFID systems can operate at different radio frequencies. The frequency chosen has important effects on

the way tags and readers interact and on what applications are appropriate.

Low-frequency (LF) tags and readers typically operate at 125 or 134 KHz. This is a very low frequency,

with a wavelength of about 2.4 kilometers (1.5 miles). Low-frequency radiation is very effective at

penetrating water and living tissues, so that LF tags can be used to identify livestock. However, because

the tags and readers are very much smaller than a wavelength, they cannot radiate effectively, so LF readers

and tags depend on inductive coupling to operate. In effect, the reader and tag form the primary and

secondary windings of a transformer. The tag must be in close proximity to the reader antenna to be read;

read ranges are comparable to the size of the reader antenna, typically a few 10’s of cm (5-10 inches) for a

small reader antenna. Because the induced voltage per coil winding is also very small at these frequencies,

the tags are composed of many turns of wire, often wound around a ferrite core to increase coupling. Since

there is no radiated power, there is usually very little issue with regulatory compliance in using LF tags and

readers.

High-frequency (HF) tags and readers operate at 13.56 MHz. This frequency is available for industrial use

in most jurisdictions worldwide. The wavelength is about 20 meters (60 feet), still larger than most reader

or tag antennas, so inductive coupling is used as in LF tags and readers. However, the higher frequency

provides a larger induced voltage, so the reader usually uses a single-turn coil, and transponders typically

incorporate 3-5 turns of wire. HF transponders can be readily constructed on a flat plastic substrate the

size of a credit card, forming Smart Cards widely used as identification badges and credit cards with

enhanced functionality. Typical read range varies from a few cm to a meter or so (a few inches to 3 feet),

again dependent on reader antenna size.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 21

Page 22

When long read range is required, ultra-high-frequency (UHF) tags and readers are appropriate. The

Apollo-series are UHF RFID readers. UHF systems typically operate at frequencies between 860 and 960

MHz, depending on the regulatory jurisdiction. In the United States, unlicensed operation is allowed in the

Industrial, Scientific, and Medical (ISM) band at 902-928 MHz. The wavelength at these frequencies is

about 33 cm (13 inches), so the reader and tags are roughly comparable in size to the wavelength. The

reader antenna creates a radiated electromagnetic wave, which can propagate long distances. UHF tags and

readers can thus exploit radiative coupling to achieve read ranges not available for LF or HF devices.

Read range for passive UHF tags can be as much as 10 meters (30 feet) with an appropriate directional

antenna; longer ranges are achievable using semi-passive tags.

RFID readers and tags operating in the microwave ISM band at 2.4-2.45 GHz are also widely used. The

2.4-2.45 GHz band is available for unlicensed operation in most jurisdictions worldwide. At this frequency

the wavelength is about 12 cm (5 inches). Very small tags can be used in the 2.45 GHz band, but because

of the consequent small antennas, the amount of power collected by a tag is reduced in comparison to UHF

tags. Passive 2.4 GHz tags have typical read ranges of around 1 to 3 meters (3 to 10 feet).

1.4.2 RFID vs. bar code

RFID tags and readers perform functions similar to those of bar codes and bar code scanners. How do they

differ? When should one use bar codes and when should RFID tags be employed? There are four key

distinctions to keep in mind:

• COST: bar codes can be printed on the surface of many existing packages at very low cost.

Separate bar-coded tags with adhesive backing are also inexpensive. Bar code scanners of various

types are widely available at modest cost, as is software to integrate bar code scanning into

standard business processes and enterprise planning. RFID (particularly at UHF and microwave

frequencies) is a relatively less widespread technology, and RFID tags are manufactured objects

containing an integrated circuit and antenna structure. RFID tags today cost significantly more

than bar codes, the exact value depending on type and quantity, though the cost of RFID tags is

falling rapidly as economies of scale are applied. Low-cost readers such as the MPR5000 are just

becoming available, but most readers are still expensive proprietary devices. When cost is the

only or a dominant issue, bar codes should be used.

• INFORMATION: Bar codes usually contain very limited information. Bar codes printed on

mass-produced packaging inevitably identify only the type of product and not the unique

individual package in hand. Bar codes containing unique identifying information such as serial

numbers can be used, but must be individually printed, raising cost, and separate codes are usually

needed to identify model number and the particular instance of the model. RFID tags generally

allow a 64-bit or 96-bit UID, the latter being more than adequate to identify manufacturer, model

or part number, and the specific physical instance of the model to which the tag is attached. More

advanced tags can contain additional user memory, which can be written to in the field, allowing

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 22

Page 23

for versatile storage of information conveniently attached to an object when necessary. When

information storage capacity is a concern, RFID tags may be superior to bar codes.

• AUTOMATION: Bar codes require an optical line of sight between the reading device and the

code, and may also require that the code or reader be properly oriented. In many cases this means

that individual objects or tags must be handled by a human being in order to be reliable read.

UHF RFID tags can be read from a relatively long distance, and the path between the reader and

the tag can be visually obstructed (though certain obstructions will also affect radio frequency

devices, as will be discussed in more detail below). Bar codes are normally read one at a time,

particularly on randomly-oriented or stacked objects, whereas tens to hundreds of RFID tags can

be simultaneously present in the field of the reader and read ‘simultaneously’ from the viewpoint

of the user. RFID techniques permit automated information handling to a much greater extent

than bar codes.

• ROBUSTNESS: Bar codes cannot be read if the printed code becomes dirty, defaced, or

excessively bent or curled. RFID tags are robust to dirt, paint, ink, and to some extent mechanical

damage, and can be read (albeit with reduced range) when misoriented or mechanically distorted.

RFID tags are tougher than bar codes.

1.4.3 RFID system components

An RFID system is composed of (at least) a reader, one or more antennas, and one or more compatible

tags. In many applications it may be necessary or helpful to create human-readable labels incorporating

RFID tags; in this case an RFID tag printer is also very useful. While standalone RFID systems are

appropriate in some circumstances, more commonly the RFID reader is just a sensor that needs to interact

with a larger information system in order to be useful. Middleware is used to enable the interaction

between the reader and the network, and to filter and aggregate the large amounts of data the reader collects

into a more useful compendium provided to the network.

1.4.3.1 Reader

A UHF RFID reader is a radio transmitter and receiver. Most readers are capable of interrogating passive

tags, and are equipped with certain features uniquely suited to use for communicating with passive RFID

tags. A reader reading passive tags simultaneously communicates with the tag population and provides

power to operate the integrated circuits contained in the tags. During transmission, the reader transmits an

amplitude-modulated signal that is received by tags within range. The transmit power is generally limited

by regulatory requirements; for example, in the United States, no more than 1 watt average RF power may

be transmitted. Modulation rate varies depending on the standard employed, but is typically a few tens of

kilobits per second for UHF tags. Special coding of the transmitted data is employed to maximize the

power available to the tags.

Once the tags have been powered up and received their instructions from the reader, they take turns

responding with their UID. Because of the unique requirements of the backscatter radio system used by

passive and semi-passive tags, the reader must continue to transmit a non-modulated (continuous-wave or

CW) signal while it listens for tag responses. The tags employ the CW signal to continue to provide power

to the tag electronics, and modulate the impedance of their own antennas in order to vary the signal

reflected back to the reader. The reader must extract the very small tag reflections from all the other

reflected signals it encounters. The default configuration of the Stationary portal readers uses one antenna

to transmit, and a second (typically physically adjacent) antenna to receive the backscattered signal. Up to

four such pairs can be connected to the reader. The reader can switch from one antenna pair to the other in

order to cover differing physical regions, such as the high and low portions of a doorway, or to avoid

missing tags because of local losses of signal strength – fading – that are sensitive to the exact position of

the antenna and other objects. Any signal from the transmitting antenna that leaks into the receiving

antenna will compete with the small reflected signal from the tag; that is, it is desirable to have good

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 23

Page 24

isolation between the transmit and receive antennas. Isolation will be degraded if conductive (metallic)

objects are placed close to the antennas. For best results, antennas should always be mounted in

accordance with manufacturer’s recommendations, and free of obstructions for at least 1 meter in the read

direction.

In the United States, readers are required by law to hop randomly from one frequency channel to another

when operating within the ISM band, residing for no longer than 0.4 seconds at any one frequency. In

addition, regulations forbid coordination of hopping patterns between collocated transmitters. When

configured for US operation, the Apollo series uses 50 channels separated from one another by 500 KHz,

and operates in each channel for 50 to 400 milliseconds. During hops from one channel to another, the RF

output is turned off.

1.4.3.2 Antennas

Antennas are the intermediaries between the voltages sent and received by the reader, and the

electromagnetic waves used to provide power to and communicate with the tags. Three critical

characteristics of antennas used in RFID systems are their maximum directive gain, polarization, and

match.

Electromagnetic radiation consists of a traveling electric and magnetic field. The electric field has a

direction at any point in space, normally perpendicular to the direction of propagation of the wave; this

direction is the polarization of the wave. For linearly polarized radiation, the direction of the electric field

is constant as the wave propagates in space. Configurations can also be constructed in which the direction

of the electric field rotates in the plane perpendicular to the direction of propagation as the wave

propagates: this is known as circular polarization.

The best power transfer between antennas is obtained when their polarizations match. Thus the best read

range is obtained from e.g. a vertically polarized reader antenna transmitting to a vertically polarized tag

antenna. This is an excellent scheme to employ when the orientation of the tag during reading can be

controlled. However, if the orientation of the tag can vary, the tag could accidentally be perpendicular to

the polarization of the reader antenna – a horizontal tag with a vertically polarized signal in shown in the

diagram below – in which case very little power is received, and the tag will not be read. When the tag

orientation is unknown or uncontrollable, a circularly polarized reader antenna should be used. Vertical

tags, horizontal tags, and tags rotated to intermediate angles can then be read with equal facility. However,

this versatility is not without cost. A circularly polarized signal can be regarded as the combination of a

horizontal and vertical signal, each containing half of the transmitted power. A linearly polarized tag

antenna only receives its own polarization, and thus half the transmitted power, being of the wrong

polarization, is wasted. The read range of a circularly polarized antenna with a linearly polarized tag is

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 24

Page 25

reduced from what could be obtained with a linearly polarized reader antenna, if the tag orientation is

known.

In discussing antennas, it is often convenient to speak of an isotropic antenna that radiates power equally in

all directions, but no such antenna actually exists. Real antennas always transmit more effectively in some

directions than others. The ratio of the power density in the direction of highest power to the average

power radiated in all directions is the maximum directive gain, often simply referred to as the gain of the

antenna. It is important to note that antennas are passive devices and don’t actually add any power to the

signal provided by the reader: gain in this context refers to the increased power received by a device in the

best direction relative to the average of all directions. Gain varies tremendously for different antenna

designs. A very common antenna, the dipole antenna, is fairly close to an isotropic radiator: the dipole

sends no radiation along its axis, but transmits equally in all directions perpendicular to the axis and nearly

as well to directions at more than a few degrees away from the axis. The gain of a dipole antenna – the ratio

of the power density along the direction of maximum radiated power to the average of all directions – is

only about 1.7:1 or 2.3 dB

1

. Note that gain is often reported as ‘dBi’, the ‘i’ denoting the use of an ideal

isotropic antenna as the reference. A dipole antenna is a good choice when all tags in any direction along a

plane are to be read. Radiation from a dipole is polarized along the axis of the dipole; thus, a tag whose

antenna is also a dipole should be oriented in the same direction as the reader antenna in order to be read

effectively.

1

dB = deciBel is a method of logarithmically describing the ratio of two power levels; P21 (dB) = 10 log10

(P

). Thus 10 dB represents a factor of 10 in power.

2/P1

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 25

Page 26

The recommended antenna antenna for the Stationary portal reader, WJCI model AN120, provides a pair of

circularly-polarized panel antennas in a single package, with excellent transmit-receive isolation and return

loss. This antenna provides about 6 dBi of gain on both transmit and receive.

In principle, antenna gain could be increased to increase read range. However, in most jurisdictions, the

maximum gain employed in unlicensed operation is limited by regulation. For example, in the United

States, the FCC limits the effective isotropic radiated power (EIRP, the product of the actual power and the

antenna gain) to 4 watts. The Stationary portal reader, which is rated at 1 Watt output, cannot use an

antenna with more than 6 dBi of gain.

Note that the recommended antennas have been specifically approved for use with the Stationary portal

reader in the United States by the FCC. FCC regulations (title 47 part 15) require that antennas be

approved for use with specific radio communications devices, unless they are installed by a professional

installer, and that in all cases the combination of antenna and radio device must operate within regulatory

constraints.

External antennas are generally connected to the reader using flexible coaxial cables and connectors. It is

important to select these cables and connectors appropriately for the application. The stationary portal

readers use mini-UHF connectors on the reader; the recommended AN120 antennas are equipped with

type-N connectors. Both are mechanically robust and convenient. When the antenna must be mounted a

long distance from the cable (more than 3 meters), a large-diameter low-loss cable, such as RG-213 or

RG214 should be used.

The electrical impedance presented by an antenna is a complex function of the frequency, the antenna

shape, and the near-antenna environment. Antennas are carefully designed so that the electrical impedance

of the antenna is well-matched to the impedance of the device to which they are connected. For example,

the Stationary portal readers will generally employ a cable with 50 ohm characteristic impedance to

connect the reader to the antenna. In order for the power from the reader to be effectively transferred to the

antenna, the antenna must have an electrical impedance close to 50 ohms, with little capacitance or

inductance, at the frequency of operation. As noted previously, conductive objects or some other materials

such as aqueous liquids placed close to an antenna will change its impedance and thus degrade its match to

the cable. For best read range, keep such obstructions away from the antenna in directions of maximum

directive gain.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 26

Page 27

1.4.3.3 Tags

A UHF RFID tag typically consists of a specialized integrated circuit (IC) attached to an antenna structure

fabricated on an inexpensive flexible plastic substrate. The antenna and substrate designs vary

considerably to meet the needs of specific applications. Tags may be configured to respond primarily to

one linear polarization, to have some response to both orthogonal directions, or to provide multiple

antennas with capability for switching the IC to the best direction at any given moment.

The natural size for an antenna structure for a given wavelength λ of electromagnetic radiation is about half

of the wavelength: λ/2. Since the wavelength is about 33 cm at 915 MHz, the natural size for a simple

antenna is about 16 cm (6.5 inches). Half-wave antennas radiate and receive effectively, and tend to have

convenient nearly-resistive impedances: they are resonant. However, for many applications such an

antenna is excessively large. Many tags are designed with antennas that are smaller than λ/2. While such

antennas may be configured to provide good impedance matching, some coMpromise in radiation

efficiency is inevitable: in general, smaller antennas will not perform as well as half-wavelength antennas.

Tag antennas may be bent or curved to conserve space and allow some response to multiple linear

polarizations; however, in this case only the regions of the antenna that are along the polarization direction

contribute to the received signal, so again the received power is reduced. Note that most tag antennas are

incorporated onto a flat plastic substrate and are thus themselves in a plane; like a dipole, the tag antenna

does not transmit and cannot receive signals whose direction of propagation lies in this plane. A tag cannot

be seen by the reader when it is viewed on edge.

Tag antennas are also sensitive to their local environment, a fact that is of particular import since tags are

meant to be attached to objects. Many common materials, such as paper and most plastics, have little effect

on microwave propagation; tags can be attached readily to cardboard or plastic boxes or containers without

affecting their operation. However, large metal objects have important effects both on the local electric

fields and the impedance of nearby antennas. Tag antennas cannot be attached directly to metal plates or

boxes without suffering degraded performance. Tag antennas spaced 5 mm to 1 cm (0.2 to 0.4 inch) from a

metal surface can perform acceptably, particularly if designed for near-metal service. Aqueous fluids

(water and water-containing materials such as milk, juices, most cleaning fluids, etc.) also have a strong

effect on local field intensity and may affect tag antenna impedance as well, depending somewhat on the

tag design. Again the best operation of a tag will be obtained if it is kept at least 1-2 cm from bodies of

aqueous fluid.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 27

Page 28

The received signal from a tag antenna is connected to an integrated circuit. Tag IC’s are very small (to

keep the cost of manufacturing low), and are typically embedded in a plastic coating for mechanical

protection. The IC contains a rectifying circuit to convert the received 900 MHz signal to a DC voltage

used to power the remainder of the IC. Variations in the received power are converted to variations in a

DC voltage, providing the IC with a method of sensing information transmitted by the reader. The IC can

also modify the impedance it presents to the antenna, by using a transistor as a switching element, thus

causing a variation in the signal reflected back to the reader and enabling the tag to communicate back to

the reader without needing its own radio transmitter.

The necessity of powering the tag is an important limitation on the read range. Tags require a few 10’s of

microwatts of RF power to operate, limiting the range to about 10 meters with the recommended antenna

pair. When linearly-polarized reader antennas are used, read range may be degraded by misorientation of

the tag. Most indoor environments have very complex propagation characteristics, with the transmitted

signal reflecting off numerous obstacles such as walls, floors, other tagged objects, people, vehicles, desks,

tables, etc. As a consequence, the signal strength can vary by a factor of 10 or more between two

neighboring locations separated by about a half-wavelength (16 cm or 5 inches): this phenomenon is known

as fading, and is encountered in most wireless communications systems. A tag with the misfortune to find

itself in a fade may fail to power up, while a tag farther from the reader but happily located in a region of

maximum signal strength responds readily. Thus there is no reliable simple correlation between tag

location the likelihood of reading a tag. The exact signal strength is sensitive to the positions of all

reflecting / diffracting objects in proximity to the read region (including people and their tools and toys) to

an accuracy of much less than a wavelength, and thus in practice is impossible to predict or control.

The best approach to deal with fading is the use of diversity: intentional variations in the propagation

environment to ensure that each tag finds itself in a region of decent signal strength at some point.

Diversity can be achieved by alternately employing two antennas in slightly different positions (displaced

by at least a half a wavelength); the Stationary portal readers can be operated in this fashion by the four

antenna pairs in succession. Alternatively, the location of the tags relative to the reader antenna(s) can be

varied; this beneficial effect occurs naturally when the tags to be read are moving on a conveyorized belt,

or are rotated as a pallet of boxes is wrapped with plastic in preparation for transport.

1.4.3.4 System integration

An RFID reader can collect large amounts of data, often much more than would have been obtained by a

human being employing a bar code reader. To convert this data into knowledge may require considerable

filtering. For example, if a fork lift driver moves a pallet out of a door, then returns to the facility to correct

an error in some paperwork, and finally drives out through the door to the truck again, the reader may take

three inventories of the same pallet, but it is rarely desirable to treat the resulting information as suggesting

that the same items were shipped three times. On the other hand, if the pallet is returned by a hand truck,

and the operator’s colleague stands in front of the reader antenna during the transfer, the reader may fail to

record some or all of the tags. A successful RFID implementation requires the integration of appropriate

procedures for human workers to follow in placing and using tags and objects carrying them, careful

installation of reader hardware, and the right middleware to convert the raw data from the reader into

information useful for operating the business.

Procedures are intimately connected with the planned usage for the RFID tags. Are the tags attached to

individual items, boxes, or a pallet or other large container? Are the items to be inventoried on a shelf,

counted as they move along a conveyorized transport belt, or tracked through a door? Can the orientation

of objects to be read be controlled or must the reader account for randomly-oriented tags, and does this

include tags placed end-on to the reader? What is the desired read range? Do the objects to be labeled

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 28

Page 29

contain metals or aqueous fluids, and if so can the tags be placed sufficiently far from these disturbing

influences to be read? Is the necessary read reliability 90%, 99%, or 99.9%? Given the answers to such

questions, the implementer can then develop procedures to ensure that the desired reliability is achieved.

As might be inferred from the discussion in section 1.4.3.2, selection and placement of reader antennas is a

critical consideration for a successful installation. The stationary portal readers can be connected to up to

four external antenna pairs; these antennas should be configured to reliably cover the region over which

tags are to be read. For example, at a doorway, one directional antenna may be placed < 1 meter (3 feet)

from the ground and the other around 2 meters (6 feet) high, thus providing good coverage of the whole

door area. When many readers are used in close proximity, consideration should be given to minimizing

interference between readers; for example, configurations in which one reader antenna looks directly at a

neighboring reader’s antenna should be avoided. It may be useful to provide reflective or absorbtive

shielding between reader installations.

The lower levels of middleware, dealing directly with the reader population, must incorporate very specific

knowledge about the use procedures and environment in which the tags are being read, and are likely to be

highly customized for each application. This software must provide filtering and aggregation capabilities

to ensure that the data that is forwarded to the enterprise information systems is correctly categorized and

representative of what is happening to the physical inventory of objects being tracked. Once this has been

accomplished, the integration of a properly filtered and aggregated dataset with a standard enterprise

resource planning package such as those available from vendors like Oracle or SAP is a reasonably wellestablished function, with the necessary customization provided by a large number of third-party vendors.

1.4.4 RFID standards

Bar codes for commercial products are standardized worldwide under the auspices of the Uniform Code

Council and EAN International. In September of 2003, these organizations joined with the AutoID Labs

headquartered at the Massachusetts Institute of Technology to form EPC Global Inc., chartered with the

standardization of a generalization of the bar code system, the Electronic Product Code (EPC), as well as

the creation of software and hardware standards to support the use of RFID systems in implementing

identification of objects by means of EPC’s. This work is intended to complement existing and ongoing

activities at the International Standards Organization (ISO), where many standards for the operation of

LF and HF RFID systems have already been defined.

1.4.4.1 EPC Global

EPC Global is creating a set of standards intended to provide a robust infrastructure for the proliferation of

RFID technology:

• EPC Tag data: the standards define various formats for the unique identifier (EPC) for each tag, to

be consistent with existing EAN/UCC standards: serialized version of the EAN.UCC Global Trade

Item Number (GTIN®), the EAN.UCC Serial Shipping Container Code (SSCC®), the EAN.UCC

Global Location Number (GLN®), the EAN.UCC Global Returnable Asset Identifier (GRAI®),

the EAN.UCC Global Individual Asset Identifier (GIAI®), and a General Identifier (GID).

• UHF Tags: partial specifications for first-generation ‘class 0’ (factory-write-only) and ‘class 1’

(field-write allowed) tags are public. A second-generation standard for class 1 tags is in progress

at the time of this writing.

• Physical Markup Language: In order to provide a standardized framework for exchange of EPC

data between organizations, EPC Global is defining a physical markup language (PML) based on

the popular extended markup language (XML) widely employed in web communications. In

addition, standards for object name servers (ONS), analogous to the domain name servers

employed to facilitate communications over the Internet, are being defined. Finally, specifications

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 29

Page 30

for the EPC Information Service (EPCIS) that will provide modular, standardized RFID

middleware functions are also being defined.

Tags compliant with the class 0 and class 1 EPC standards, manufactured by such vendors as Alien

Technology, Matrics (now a division of Symbol Technologies), and Impinj, are already in common

commercial use. Stationary portal readers will read both class 0 and class 1 and can write to class 0+ and

class 1 tags. Firmware upgrades will allow the stationary portal readers to read and write secondgeneration class 1 tags once they become available. Firmware upgrades will also support ISO1800-6B tags

(described below).

1.4.4.1.1 EPC Class 0 Summary

In this section we provide a very brief introduction to the operation of class 0 tags. Further information

may be obtained from the document “Draft protocol specification for a 900 MHz Class 0 Radio Frequency

Identification Tag”, dated 2/23/03, available from the EPC Global Inc. web site.

Class 0 tags are factory-programmed and thereafter read-only. Each tag contains a nominal 64-bit EPC and

a 16 bit cyclic redundancy check (CRC) in non-volatile memory. (Tags with 96-bit EPC’s are also

allowed, and are provided for in the Apollo-series firmware.) The CRC is independently re-calculated by

the reader when the EPC is read, and checked against that provided by the tag to check for errors in the

read.

When more than one tag is in the field of the reader, the reader employs a binary-tree traversal to resolve

possible collisions and individually address each tag (singulation). The traversal starts at the beginning of

an ID string and chooses one of the two possible branches (first bit = 0 or first bit = 1). All tags whose first

bit agrees with the reader’s choice remain in the traversal, while those with the opposite bit become

temporarily inactive waiting for the next traversal. When only one tag responds at any stage of the

traversal, that tag can be read. Proceeding in this fashion over the whole ID string (if necessary), the reader

must inevitably find all tags in the field if their ID’s are unique and all the tags are able to follow the

traversal.

In general, there are much less than 2

64

tags in the field in most practical cases. Thus it is often

unnecessary and wastefully slow to use the 64-bit EPC to aid in singulation. The protocol requires each tag

to provide two other ID’s in addition to the 64-bit EPC. These ID’s, known as ID0 and ID1, are both

pseudo-random 16-bit numbers. ID0 is generated by each tag upon request by the reader. ID1 is

programmed into each tag at the time of manufacture. In this nomenclature, the EPC is known as ID2.

During traversal, each tag still in the traversal backscatters the next bit of its active ID to the reader, and

listens for the reader to confirm that bit before remaining in the traversal. This procedure provides some

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 30

Page 31

simple error checking. However, if the EPC (ID2) is being used for singulation, it has the consequence that

the reader sends some or all the bits of each tag’s EPC. Since it is much easier to intercept high-powered

reader transmissions than the low-power tag reflections, if security of tag EPC’s is a concern, ID2 should

not be used for singulation. Note that once a tag is singulated, the EPC can be read without echo by the

reader.

The protocol also allows for filtering, in which the inventory process is performed only on tags whose ID2

contains a fixed bit string provided by the reader. Filtering can be used to inventory only tags assigned to a

particular manufacturer or a particular product type.

Amplitude-modulation is used to transmit information from the reader to the tag. In order to maximize the

power simultaneously provided to the tag, special coding is employed to ensure that the reader power is

high most of the time. The particular scheme employed here is known as pulse-interval modulation. In

each symbol, a short low-power pulse (1/4 of the bit time) denotes a binary 0, and a longer low-power pulse

(half of the total bit time) denotes a binary 1. Thus the average transmitted power for a string with an equal

number of 1’s and 0’s is 5/8 of the CW power. A long low-power pulse (3/4 of the bit time) denotes a

special ‘NULL’ character, which appears infrequently and thus has little effect on the average power

delivered to the tag. In the United States, a data rate of 80 kilobits per second (Kbps) is used. In Europe,

a lower 16 Kbps rate is employed in order to operate within a narrower allowed channel.

Communication from the tag to the reader employs a sub-carrier modulation, in which the tag inverts states

at a rate much faster than the data rate. In the particular scheme used in this protocol, the tag sends a 2.25

MHz backscattered signal for a binary 0, and 3.25 MHz for a binary 1. Tag backscatter is performed on the

‘high’ portion of each reader bit. Sub-carrier signaling has two benefits: the reader need only detect

transitions of the tag state without regard to the direction of the transition (up or down), and if two or more

tags simultaneously backscatter binary 1 and binary 0, the presence of both symbols can be detected by the

reader, allowing it to gather some information about the tag population even when collisions are present.

Each time power is turned on, the reader proceeds through a set of steps to initialize the tag IC timing.

First, the reader transmits a RESET consisting of 800 µs of CW power. A tag’s “ID’d” flag (telling it that

it was already read by the reader) may survive a RESET, but in other respects the tag returns to its default

state. After the RESET, 8 pulses are used to calibrate the tag internal oscillator to the 2.2 MHz sub-carrier

frequency. Finally, a set of pulses of varying length is transmitted to set the thresholds for distinguishing

between 0, 1, and null, and to signal the tag when to begin its transmission.

Copyright© 2005 by WJ Communications Inc. Subject to change without notice. This information is provided “as is,”

and WJ makes no claims of fit for purposes intended, merchantability or other. All trademarks, service marks, trade

names and logos are used in good faith and remain the property of their rightful owners.

page 31

Page 32

In the United States, communications devices operating in unlicensed bands must either use directsequence or frequency-hopping spreading techniques. The Apollo series products use pseudo-random

hopping from one frequency to another. The Class 0 protocol does not require the reader to power down

during hops, but the Apollo series stationary reader does in order to minimize spurious radiation.

Therefore, a RESET / calibration sequence is necessary after each hop. The time between hops is available

for the user to adjust, although regulations require that the transmitter remain on any given frequency for no

longer than 400 ms at a time. In Europe, revised regulations allowing 10 channels have been promulgated

and it is anticipated that with the passing of time frequency-hopping operation will become the normal

means of operation in most European jurisdictions. European regulations will require that the reader listen

before talking: that is, the reader must check each putative channel for other active transmitters before

beginning its own transmission. Note that the MPR5000/6000/7000 operate at 902-928 MHz and are not

approved for use in Region 1 (European) jurisdictions.

Tags have 10 possible states, roughly corresponding to [startup / calibrate], [global commands], [binary tree

traversal], and [singulated commands]. Each command is 8 bits long, with an additional parity bit provided

for error checking. The tag echoes each bit it receives in order to provide a simple error check and

acknowledgement function. Mandatory commands are:

• ResetIDFlag: resets the identified flag to NOT READ; that is, it forces tags to forget whether they

have been previously inventoried.

• SetNegotiationPage: this curious terminology is used to describe the choice of ID (ID0, 1, or 2)

used for singulation during binary tree traversal.

• SegRegionofOperation: sets the backscatter parameters according to whether the device is

operating under FCC or European regulations.

• ForceDormant: tags receiving this command immediately enter the Dormant state. The Dormant

state is the default tag turn-on state, exited when a RESET is received.

• ForceMute: tags receiving this command immediately enter the Mute state. In the Mute state, the

tags receive data but do not respond until a NULL is received. Tags that have been bypassed

during traversal reside in the Mute state until the next traversal begins.

• Read: Read ID1 or ID2 (ID0, being randomly generated at the time of request, has no enduring

interest and need not be read from the tag).