The Communications Edge

TM

RF OUT

2 3

查询EC1019供应商

EC1019

InGaP HBT Gain Block Product Information

Product Features

x DC – 4 GHz

x +19 dBm P1dB at 1 GHz

x +34 dBm OIP3 at 1 GHz

x 20 dB Gain at 1 GHz

x 5.5 dB Noise Figure at 2 GHz

x Available in SOT-86, SOT-89

and lead-free / green SOT-89

Package Styles

x Internally matched to 50 :

Applications

x Mobile Infrastructure

x CATV / DBS

x W-LAN / ISM

x RFID

x Defense / Homeland Security

x Fixed Wireless

Specifications

(1)

Product Description

The EC1019 is a general-purpose buffer amplifier that

offers high dynamic range in a low-cost surface-mount

package. At 1000 MHz, the EC1019 typically provides 20

dB of gain, +34 dBm Output IP3, and +19 dBm P1dB.

The EC1019 consists of Darlington pair amplifiers using

the high reliability InGaP/GaAs HBT process technology

and only requires DC-blocking capacitors, a bias resistor,

and an inductive RF choke for operation. The device is

ideal for wireless applications and is available in low-cost,

surface-mountable plastic SOT-86 and SOT-89 packages.

The EC1019 is also available in a lead-free/green/RoHScompliant SOT-89 package. All devices are 100% RF and

DC tested.

The broadband MMIC amplifier can be directly applied to

various current and next generation wireless technologies

such as GPRS, GSM, CDMA, and W-CDMA. In addition,

the EC1019 will work for other various applications within

the DC to 4 GHz frequency range such as CATV and fixed

wireless.

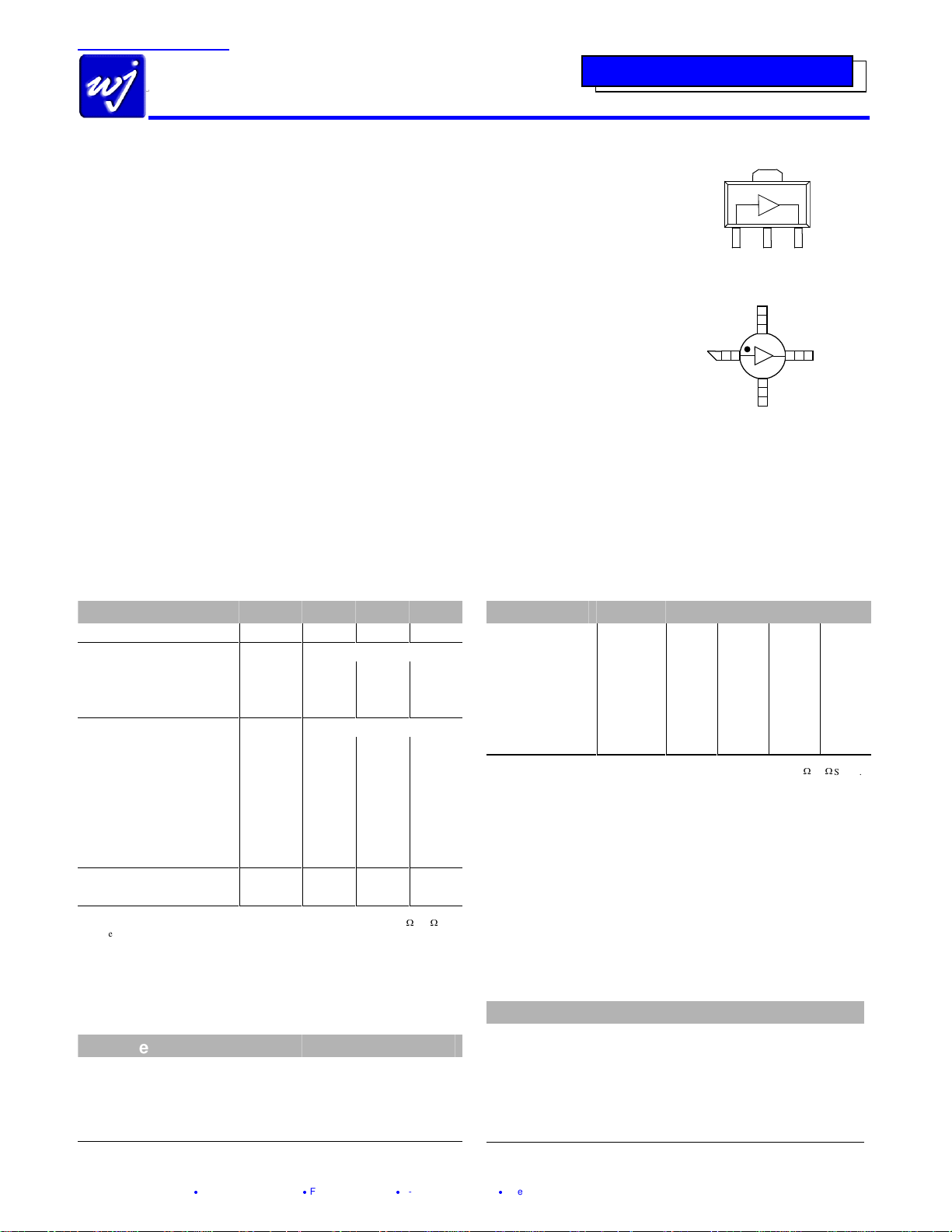

Typical Performance

Functional Diagram

GND

1

RF IN GND

4

EC1019B / EC1019B-G

RF In

GND

4

1

GND

3

RF Out

2

EC1019C

(4)

Parameter Units Min Typ Max

Operational Bandwidth MHz DC 4000

Test Frequency MHz 1000

Gain dB 19.8

Output P1dB dBm +19

Output IP3

Test Frequency MHz 2000

Gain dB 18

Large-signal Gain

Input Return Loss dB 19

Output Return Loss dB 15

Output P1dB dBm +19.5

Output IP3

Noise Figure dB 5.5

Device Voltage V 4.2 5.0 5.2

Device Current mA

1. Test conditions unless otherwise noted: 25º C, Supply Voltage = +6 V, Rbias = 16.5 , 50

System.

2. 3OIP measured with two tones at an output power of +4 dBm/tone separated by 1 MHz. The

suppression on the largest IM3 product is used to calculate the 3OIP using a 2:1 rule.

3. Large-signal gain is tested with an input power level of +4 dBm.

(2)

dBm +34

(3)

dB 14 15.5

(2)

dBm +31

70

Absolute Maximum Rating

Parameter Rating

Operating Case Temperature

Storage Temperature

Device Current 130 mA

RF Input Power (continuous) +12 dBm

Junction Temperature

Operation of this device above any of these parameters may cause permanent damage.

WJ Communications, Inc Phone 1-800-WJ1-4401 FAX: 408-577-6621 e-mail: sales@wj.com Web site: www.wj.com December 2004

-40 to +85 qC

-55 to +150 qC

+250 qC

Parameter Units Typical

Frequency MHz 500 900 1900 2140

S21 dB 21 19.8 17.5 16

S11 dB -17 -18 -19 -20

S22 dB -15 -15 -15 -15

Output P1dB dBm +19 +19 +19.5 +19

Output IP3

Noise Figure dB 3.8 4.0 4.8 5.5

4. Test conditions: T = 25º C, Supply Voltage = +6 V, Device Voltage = +5V, R

(2)

dBm +34 +34 +31 +30.5

= 16.5

, 50 System.

bias

Ordering Information

Part No. Description

EC1019B

EC1019B-G

ECG1019C InGaP HBT Gain Block (SOT-86 Pkg)

EC1019B-PCB 700 – 2400 MHz Fully Assembled Eval. Board

EC1019C-PCB 700 – 2400 MHz Fully Assembled Eval. Board

InGaP HBT Gain Block

(leaded SOT-89 Pkg)

InGaP HBT Gain Block

(lead-free/green/RoHS-compliant SOT-89 Pkg)

Specifications and information are subject to change without notice

The C

ommunications Edge

TM

Gain vs. Frequency

Gain (dB)

S11, S22 (dB)

Icc (mA)

OIP3 vs. Frequency

OIP3 (dBm)

NF (dB)

P1dB vs. Frequency

P1dB (dBm)

EC1019

InGaP HBT Gain Block Product Information

Typical Device RF Performance

Supply Bias = +6 V, R

Frequency MHz 100 500 900 1900 2140 2400 3500 5800

S21 dB 20.4 20.0 19.8 18 17.5 16.8 14.2 10.3

S11 dB -17 -17 -18 -19 -20 -20 -19 -11

S22 dB -15 -15 -15 -15 -15 -15 -14 -7.7

Output P1dB dBm +19.4 +19.4 +19.4 +19.5 +19.0 +18.8 +16.2

Output IP3 dBm +33 +33.2 +33.6 +31 +31 +30.7

1. Test conditions: T = 25º C, Supply Voltage = +6 V, Device Voltage = 5.0 V, Rbias = 16.5 , Icc = 70 mA typical, 50 System.

2. 3OIP measured with two tones at an output power of +4 dBm/tone separated by 1 MHz. The suppression on the largest IM3 product is used to calculate the 3OIP using a 2:1 rule.

3. Data is shown as device performance only. Actual implementation for the desired frequency band will be determined by external components shown in the application circuit.

25

Noise Figure dB 3.4 3.5 3.5 3.8 3.8 3.9

S11, S22 vs. Frequency

0

= 14 :, Icc = 70 mA

bias

160

Icc vs. Vde

20

15

10

5

0

0 1 2 3 4 5 6

40

35

30

25

20

500 1000 1500 2000 2500 3000

Frequency (GHz)

25°C 85°C -40°C

Frequency (MHz)

-5

-10

-15

-20

-25

0 1 2 3 4 5 6

6

5

4

3

2

500 1000 1500 2000

S22

S11

Frequency (GHz)

Noise Figure vs. Frequency

Frequency (MHz)

120

80

25°C

40

0

0 1 2 3 4 5 6

24

20

16

12

500 1000 1500 2000 2500 3000

Vde (V)

25°C 85°C -40°C

Frequency (MHz)

WJ Communications, Inc Phone 1-800-WJ1-4401 FAX: 408-577-6621 e-mail: sales@wj.com Web site: www.wj.com December 2004

Specifications and information are subject to change without notice

The C

ommunications Edge

TM

Voltage

C3

0.018 µF

Bias

RF IN

Bypass

Capacitor

Blocking

Capacitor

EC1019

InGaP HBT Gain Block Product Information

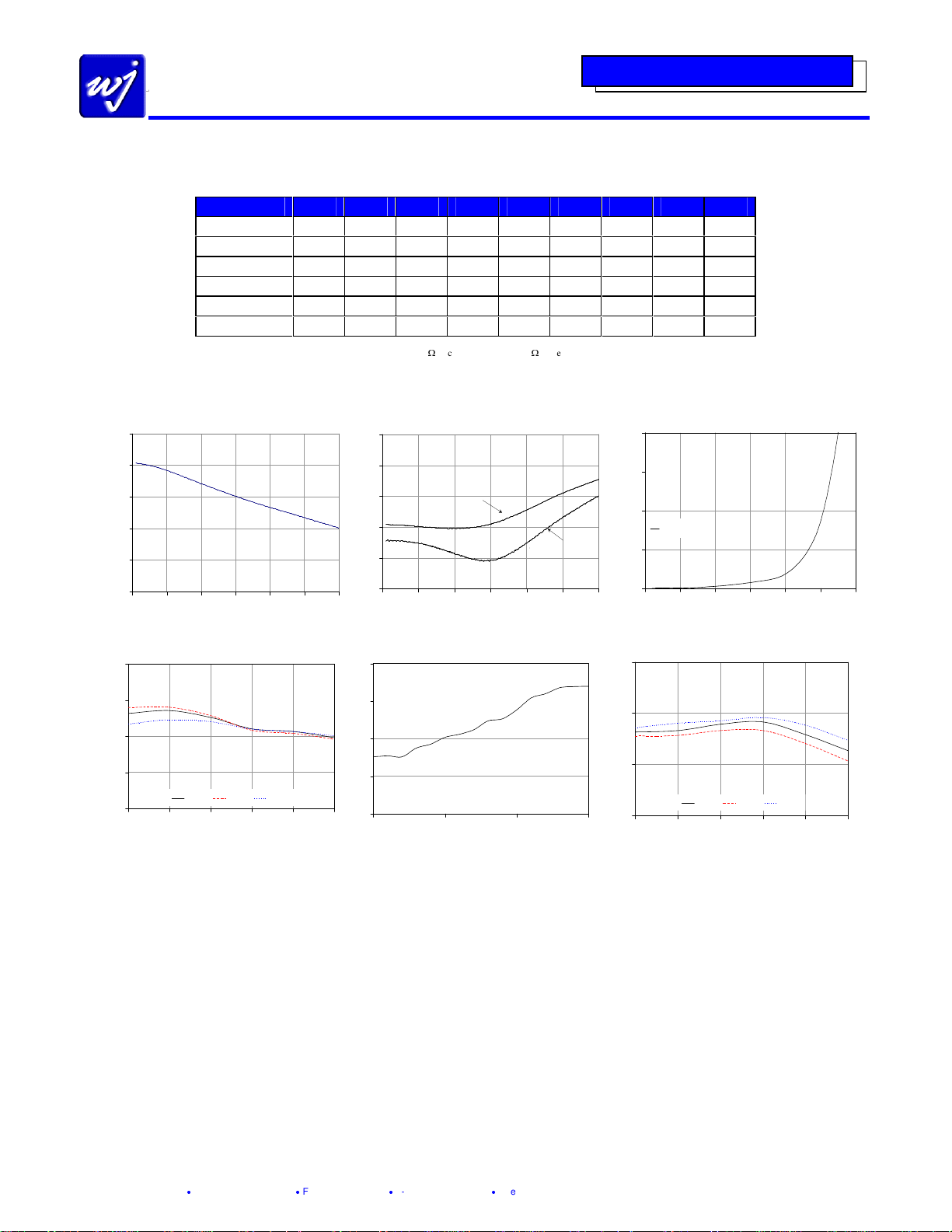

Recommended Application Circuit

EC1019

C1

Blocking

Capacitor

EC1019B-PCB EC1019C-PCB

Icc = 70 mA

R4

Resistor

C4

RF Choke

Vcc

L1

RF OUT

C2

Recommended Component Values

Reference

Designator

50 500 900 1900 2200 2500 3500

Frequency (MHz)

L1 820 nH 220 nH 68 nH 27 nH 22 nH 18 nH 15 nH

C1, C2, C4 .018 µF 1000 pF 100 pF 68 pF 68 pF 56 pF 39 pF

1. The proper values for the components are dependent upon the intended frequency of operation.

2. The following values are contained on the evaluation board to achieve optimal broadband performance:

Ref. Desig. Value / Type Size

L1 39 nH wirewound inductor 0603

C1, C2 56 pF chip capacitor 0603

C3

0.018 PF chip capacitor

0603

C4 Do Not Place

R4

14 : 1% tolerance

0805

WJ Communications, Inc Phone 1-800-WJ1-4401 FAX: 408-577-6621 e-mail: sales@wj.com Web site: www.wj.com December 2004

Specifications and information are subject to change without notice

Recommended Bias Resistor Values

Supply

R1 value Size

6 V 16.4 ohms 0805

7 V 30.7 ohms 1210

8 V 45 ohms 1210

9 V 59 ohms 2010

10 V 74 ohms 2010

12 V 102 ohms 2512

The proper value for R1 is dependent upon the supply

voltage and allows for bias stability over temperature.

WJ recommends a minimum supply bias of +6 V. A

1% tolerance resistor is recommended.

The C

ommunications Edge

TM

EC1019

InGaP HBT Gain Block Product Information

EC1019B (SOT-89 Package) Mechanical Information

This package may contain lead-bearing materials. The plating material on the leads is SnPb.

Outline Drawing

Product Marking

The component will be marked with an

“1019” designator with an alphanumeric lot

code on the top surface of the package.

Tape and reel specifications for this part are

located on the website in the “Application

Notes” section.

MSL / ESD Rating

Land Pattern

ESD Rating: Class 1A

Value: Passes between 250 and 500V

Test: Human Body Model (HBM)

Standard: JEDEC Standard JESD22-A114

MSL Rating: Level 3 at +235

Standard: JEDEC Standard J-STD-020

C convection reflow

Mounting Config. Notes

1. Ground / thermal vias are critical for the proper

performance of this device. Vias should use a .35mm

(#80 / .0135” ) diameter drill and have a final plated

thru diameter of .25 mm (.010” ).

2. Add as much copper as possible to inner and outer

layers near the part to ensure optimal thermal

performance.

3. Mounting screws can be added near the part to fasten

the board to a heatsink. Ensure that the ground /

thermal via region contacts the heatsink.

4. Do not put solder mask on the backside of the PC board

in the region where the board contacts the heatsink.

5. RF trace width depends upon the PC board material

and construction.

6. Use 1 oz. Copper minimum.

7. All dimensions are in millimeters (inches). Angles are

in degrees.

WJ Communications, Inc Phone 1-800-WJ1-4401 FAX: 408-577-6621 e-mail: sales@wj.com Web site: www.wj.com December 2004

Specifications and information are subject to change without notice

The C

ommunications Edge

TM

EC1019

InGaP HBT Gain Block Product Information

EC1019B-G (Green / Lead-free SOT-89 Package) Mechanical Information

This package is lead-free/Green/RoHS-compliant. It is compatible with both lead-free (maximum 260qC reflow temperature) and leaded

(maximum 245qC reflow temperature) soldering processes. The plating material on the leads is NiPdAu.

Outline Drawing

Product Marking

The component will be marked with an

“ 1019G” designator with an alphanumeric lot

code on the top surface of the package.

Tape and reel specifications for this part are

located on the website in the “ Application

Notes” section.

MSL / ESD Rating

Land Pattern

ESD Rating: Class 1A

Value: Passes between 250 and 500V

Test: Human Body Model (HBM)

Standard: JEDEC Standard JESD22-A114

MSL Rating: Level 3 at +260 C convection reflow

Standard: JEDEC Standard J-STD-020

Mounting Config. Notes

1. Ground / thermal vias are critical for the proper

performance of this device. Vias should use a .35mm

(#80 / .0135” ) diameter drill and have a final plated

thru diameter of .25 mm (.010” ).

2. Add as much copper as possible to inner and outer

layers near the part to ensure optimal thermal

performance.

3. Mounting screws can be added near the part to fasten

the board to a heatsink. Ensure that the ground /

thermal via region contacts the heatsink.

4. Do not put solder mask on the backside of the PC board

in the region where the board contacts the heatsink.

5. RF trace width depends upon the PC board material

and construction.

6. Use 1 oz. Copper minimum.

7. All dimensions are in millimeters (inches). Angles are

in degrees.

WJ Communications, Inc Phone 1-800-WJ1-4401 FAX: 408-577-6621 e-mail: sales@wj.com Web site: www.wj.com December 2004

Specifications and information are subject to change without notice

The C

ommunications Edge

TM

EC1019

InGaP HBT Gain Block Product Information

EC1019C (SOT-86 Package) Mechanical Information

Outline Drawing

Product Marking

The component will be marked with a two-

digit numeric lot code followed by an “ A”

designator on the top surface of the package.

Tape and reel specifications for this part are

located on the website in the “ Application

Notes” section.

MSL / ESD Rating

Land Pattern

ESD Rating: Class 1A

Value: Passes between 250 and 500V

Test: Human Body Model (HBM)

Standard: JEDEC Standard JESD22-A114

MSL Rating: Level 1 at +235

Standard: JEDEC Standard J-STD-020

C convection reflow

Mounting Config. Notes

1. Ground / thermal vias are critical for the proper

performance of this device. Vias should use a .35mm

(#80 / .0135” ) diameter drill and have a final plated

thru diameter of .25 mm (.010” ).

2. Add as much copper as possible to inner and outer

layers near the part to ensure optimal thermal

performance.

3. Mounting screws can be added near the part to fasten

the board to a heatsink. Ensure that the ground /

thermal via region contacts the heatsink.

4. Do not put solder mask on the backside of the PC board

in the region where the board contacts the heatsink.

5. RF trace width depends upon the PC board material

and construction.

6. Use 1 oz. Copper minimum.

7. All dimensions are in millimeters (inches). Angles are

in degrees.

WJ Communications, Inc Phone 1-800-WJ1-4401 FAX: 408-577-6621 e-mail: sales@wj.com Web site: www.wj.com December 2004

Specifications and information are subject to change without notice

The C

ommunications Edge

TM

EC1019

InGaP HBT Gain Block Product Information

S-Parameters (V

Freq (MHz) S11 (dB) S11 (ang) S21 (dB) S21 (ang) S12 (dB) S12 (ang) S22 (dB) S22 (ang)

50 -38.22 -0.60 21.22 176.90 -23.21 0.43 -24.92 -6.19

500 -28.54 -69.70 20.70 151.10 -22.91 1.81 -20.21 -75.88

1000 -23.03 -116.73 19.85 125.62 -22.19 1.88 -15.95 -118.31

1500 -19.80 -149.18 18.77 102.16 -21.39 -0.54 -13.31 -148.47

2000 -16.95 -175.69 17.78 81.09 -20.49 -4.57 -11.44 -173.35

2500 -14.97 161.78 16.64 60.78 -19.66 -10.52 -10.17 164.24

3000 -13.14 141.18 15.54 42.33 -18.91 -17.61 -8.90 144.05

3500 -11.43 120.25 14.52 24.29 -18.40 -26.33 -7.88 125.10

4000 -9.78 100.23 13.50 6.80 -17.96 -35.09 -6.74 107.67

4500 -8.16 82.20 12.43 -10.58 -17.71 -44.95 -5.73 90.92

5000 -6.60 65.82 11.31 -27.02 -17.58 -54.92 -4.75 76.11

5500 -5.40 50.97 10.10 -42.90 -17.72 -64.25 -3.97 61.95

6000 -4.36 38.35 8.93 -58.04 -17.94 -73.51 -3.35 49.09

= +5 V, ICC = 70 mA, T = 25C, calibrated to device leads)

device

Typical Device S-Parameters – EC1019C

Typical Device S-Parameters – EC1019B/EC1019B-G

S-Parameters (V

Freq (MHz) S11 (dB) S11 (ang) S21 (dB) S21 (ang) S12 (dB) S12 (ang) S22 (dB) S22 (ang)

50 -17.33 -1.31 20.43 177.50 -22.79 -0.64 -14.48 -3.98

500 -17.25 -10.41 19.97 155.09 -22.66 4.13 -14.68 -34.98

1000 -17.56 -23.16 19.18 132.71 -22.29 7.47 -14.89 -66.22

1500 -18.41 -38.16 18.15 112.72 -21.69 9.85 -15.11 -93.82

2000 -19.28 -59.40 17.14 94.96 -20.89 10.97 -15.17 -120.65

2500 -20.21 -85.13 16.08 78.76 -20.18 10.33 -15.08 -144.97

3000 -20.40 -116.07 15.09 64.36 -19.45 8.87 -14.49 -168.42

3500 -19.31 -148.51 14.19 50.13 -18.76 5.64 -13.50 169.49

4000 -17.60 -175.60 13.37 36.77 -18.13 1.90 -12.22 151.45

4500 -15.46 161.94 12.54 23.49 -17.57 -2.80 -10.85 136.31

5000 -13.33 142.40 11.78 10.37 -17.10 -8.33 -9.46 123.24

5500 -11.61 126.05 10.94 -2.97 -16.77 -14.35 -8.31 111.67

6000 -9.93 111.47 10.05 -15.41 -16.55 -20.52 -7.23 100.94

= +5, ICC = 70 mA, T = 25C, calibrated to device leads)

device

Device S-parameters are available for download off of the website at: http://www.wj.com

WJ Communications, Inc Phone 1-800-WJ1-4401 FAX: 408-577-6621 e-mail: sales@wj.com Web site: www.wj.com December 2004

Specifications and information are subject to change without notice

Loading...

Loading...