Wixey WR550 User Manual

INSTRUCTIONS

+

+

+

+

+

+

+

Wixey

REMOTE PLANER READOUT

MODEL WR550

1- Slide the sensor onto the scale

NOTE

The sensor can only go on the scale one way. Be sure the

pattern on the sensor decal matches the pattern on the scale.

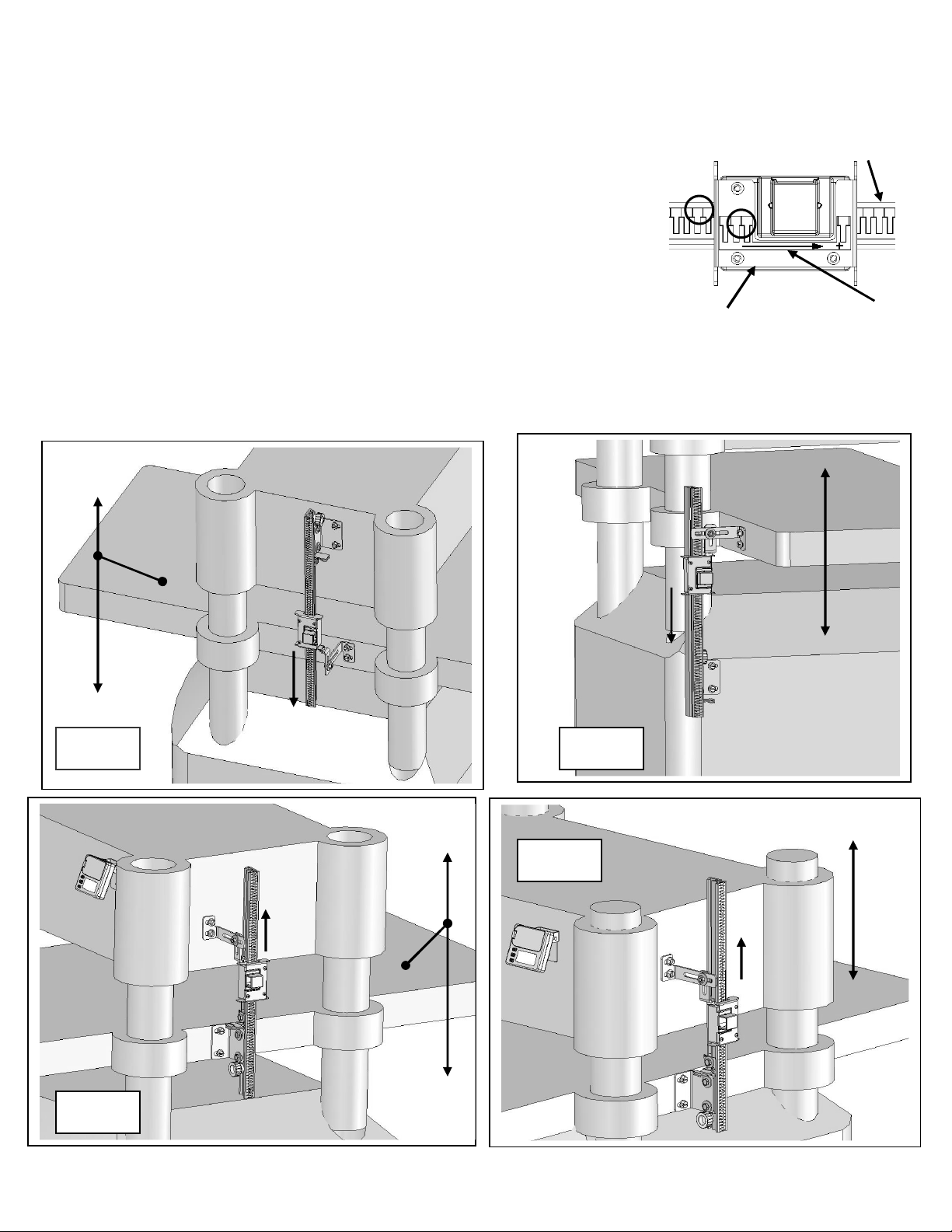

2- Select a mounting position

The WR550 can be mounted to a variety of machines in a number of different ways. Either the scale or the

sensor can be mounted to a non moving part of the machine as long as the travel direction of the sensor on

the scale is in the proper direction as indicated by the arrow and + sign on the sensor decal. (FIG 1-5).

TABLE MOVES UP AND DOWN

FIG 1

FIG 3

TABLE MOVES UP AND DOWN

:

• Always turn off the power and unplug your

machine before installing the WR550

Scale

TABLE MOVES UP AND DOWN

Sensor Sensor decal

+

FIG 2

HEAD MOVES UP AND DOWN

FIG 4

1

+

+

TABLE MOVES UP AND DOWN

FIG 5

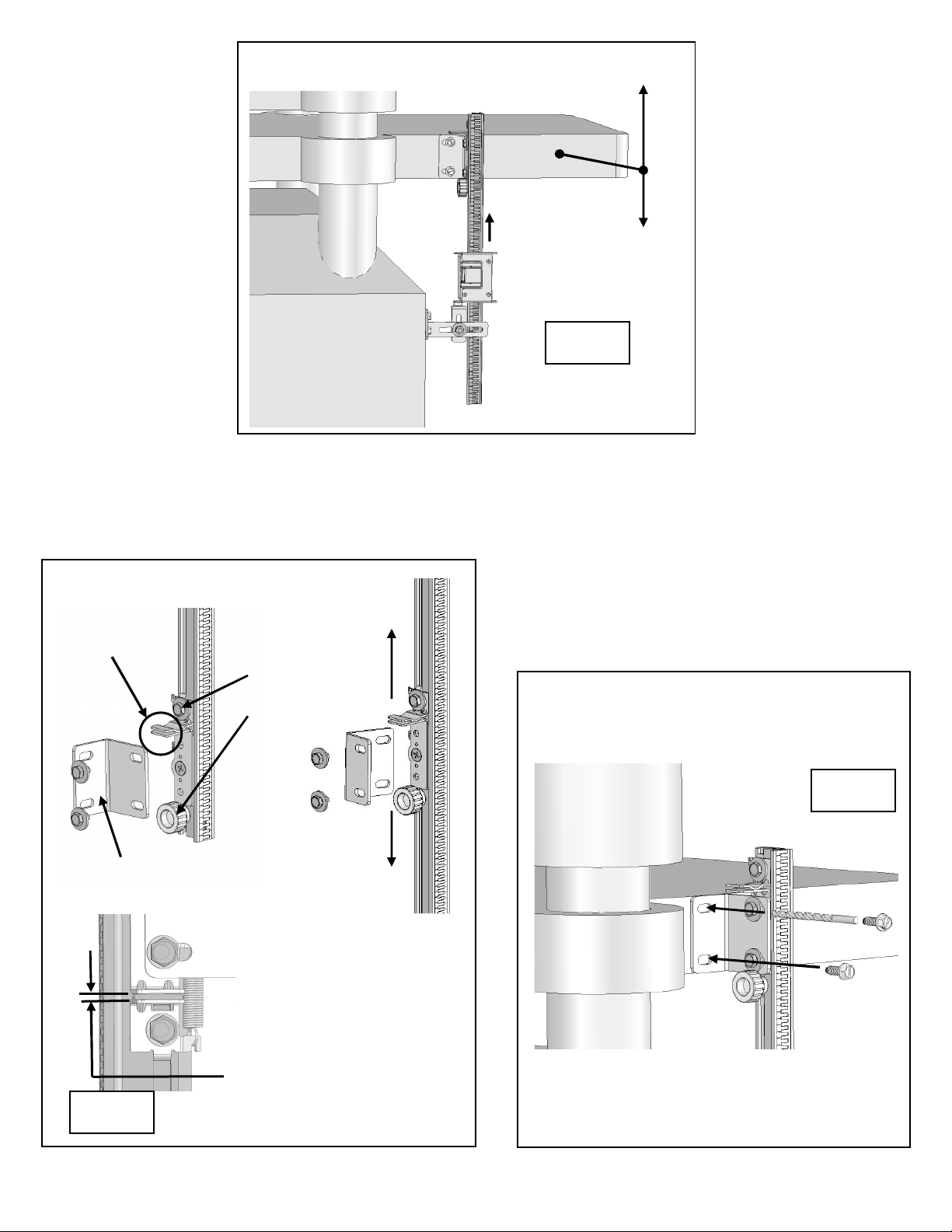

3- Mounting the Scale

The scale mounting assembly can be located at any position along the scale. The “L” bracket can be

removed and re-attached to the assembly in different positions (steps 1-3 in FIG 6). The slots in the “L”

bracket are used to adjust the scale perpendicular to the table surface (FIG 7).

SCALE MOUNTING ASSEMBLY

JAWS

1. LOOSEN

BOLT

AND

LOCK KNOB

USING THE 5.5mm DRILL AND 2-M6 x 12mm

LONG THREAD FORMING SCREWS ATTACH

THE L-BRACKET TO THE MACHINE.

FIG 7

L-BRACKET

FIG 6

2. SLIDE THE

SCALE MOUNTING

ASSEMBLY TO

ANY POSITION ON

THE SCALE.

(REMOVING THE

SPRING MAY

MAKE THIS STEP

EASIER)

3. TIGHTEN THE BOLT AND

LOCK KNOB. BE SURE THE

JAWS ARE ALIGNED FLAT

WHEN DONE. REPLACE THE

SPRING IF IT WAS REMOVED.

PUT A DROP OF OIL ON THE END OF THE

SCREWS. USE A DRILL DRIVER OR

RACTHET WRENCH AND PUSH THEM INTO

THE HOLE WHILE TURNING SLOWLY

2

4- Mounting the Magnet Connector

There are 4 tabs on the sensor where the Magnet can attach. There are also a number of possible positions

to assemble the Support Arm, Magnet Connector, and Magnet (FIG 8-9).

SUPORRT

ARM

FIG 8

M6

CARRIAGE

BOLT,

NUT AND

WASHER

USING THE 5.5mm DRILL AND 2-M6 x 12mm LONG

THREAD FORMING SCREWS ATTACH THE

SUPPORT ARM TO THE MACHINE.

FIG 9

MAGNET

CONNECTOR

MAGNET

MAGNET

ATTACHMENT

TABS

PUT A DROP OF OIL ON THE END OF THE

SCREWS. USE A DRILL DRIVER OR RACTHET

WRENCH AND PUSH THEM INTO THE HOLE

WHILE TURNING SLOWLY

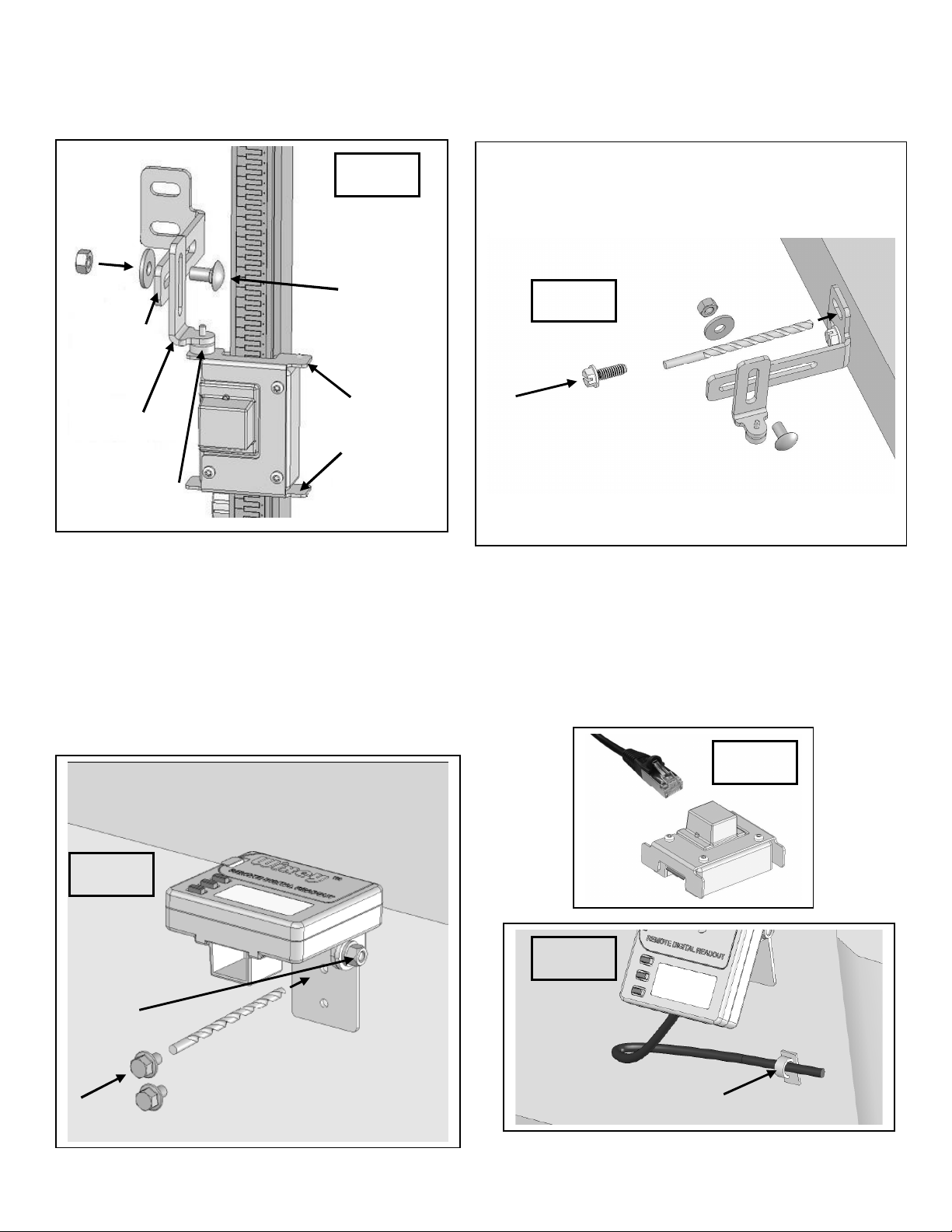

5-Mount the display and connect the Cat 5E cable

Find a suitable location to mount the display (FIG 10). After it is mounted, connect one end of the Cat 5E

cable to the display and the other end to the sensor (FIG11). Carefully route the cable using the 4 adhesive

backed cable clips. Be sure to use a solvent to clean the surface before applying each clip (FIG12).

NOTE: If you purchase a shorter Cat 5E cable to use be sure that is a shielded style noted by the

metal encased plug.

USING THE 3.6mm DRILL AND 2- M4 x 8mm LONG

THREAD FORMING SCREWS ATTACH THE

DISPLAY MOUNTING BRACKET TO THE

MACHINE.

FIG 11

FIG 10

LOOSEN

NUTS TO

ADJUST

VIEWING

ANGLE

FIG 12

PUT A DROP OF OIL ON THE

END OF THE SCREWS. USE A

NUT DRIVER AND PUSH THEM

INTO THE HOLE WHILE

TURNING SLOWLY

CABLE CLIP

3

Loading...

Loading...