Wixey WR525 User Manual

TM

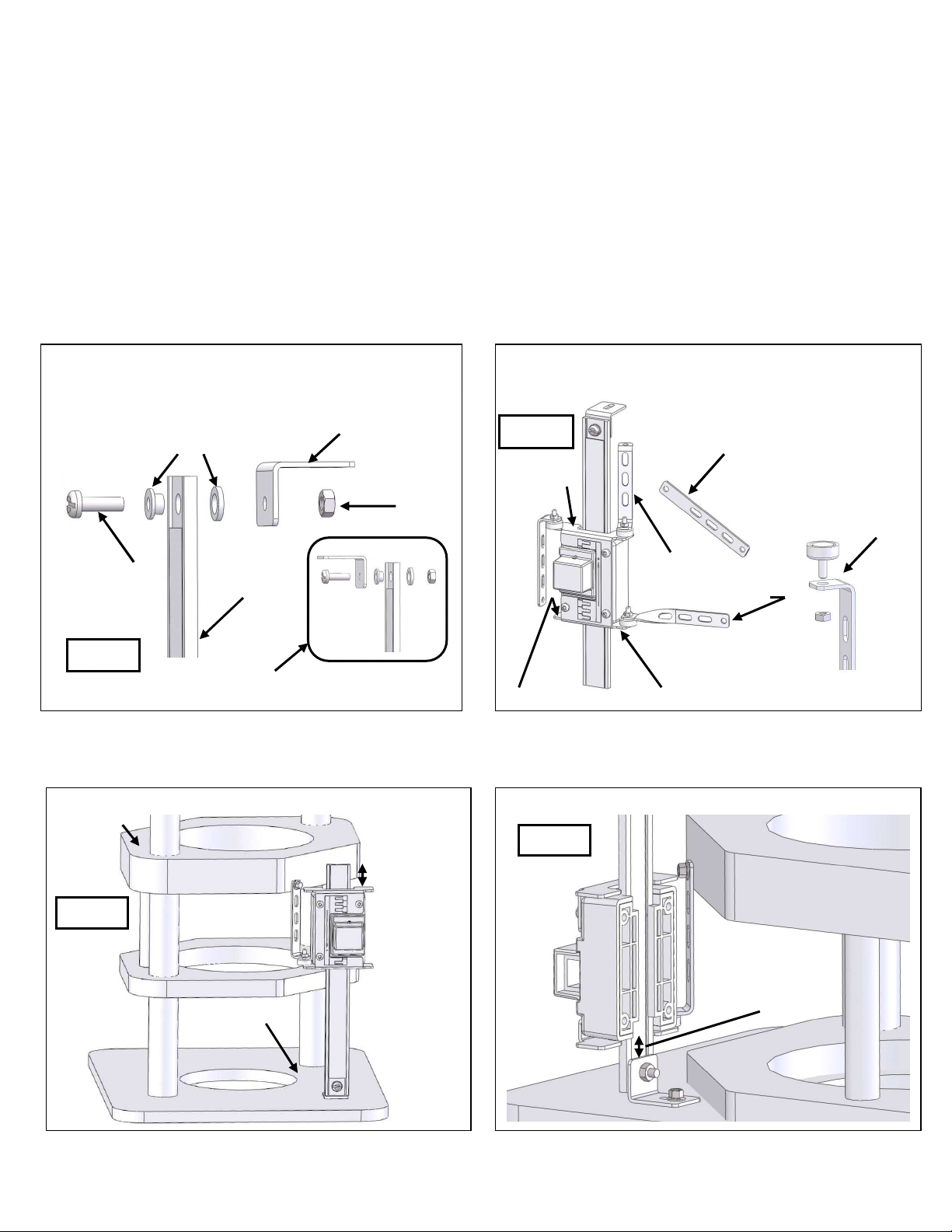

FIG 1

FIG 2

FIG 3

not bottom out

Wixey

REMOTE ROUTER READOUT

INSTRUCTIONS

NOTE

:

• Always turn off the power and unplug your

machine before installing the WR525

MODEL WR525 Type 2

1- Select the best mounting location

The WR525 can be mounted to a variety of machines in a number of different ways. These instructions

demonstrate the WR525 mounted to a router lift that is laying upside down on its top plate.

The “L” bracket and the magnet bracket can be attached the scale and sensor in many different ways

(FIG 1-2). Determine the best way for your particular situation.

The “L” bracket attaches to the top of the Scale

as shown:

Select a position to attach the magnet and bend

one of the straight magnet brackets as needed.

Plastic bushing

and washer

“L” bracket

Straight magnet bracket

(2 spares are included)

M4 pan head

screw

M4 Hex Nut

Scale

Sensor

Attach the magnet

using the M3 Hex Nut

There are many possible

ways to bend and attach

the magnet bracket

Alternate bracket position

There are 8 possible magnet attachment points

Before attaching the scale and sensor to your lift check the travel with the carriage both fully extended and

tight against the top plate (FIG 3-4).

Fully extended carriage position

Carriage

The sensor

must stay

on the

scale

Carriage positioned tight against the top plate

Make sure the

sensor does

Top plate

1

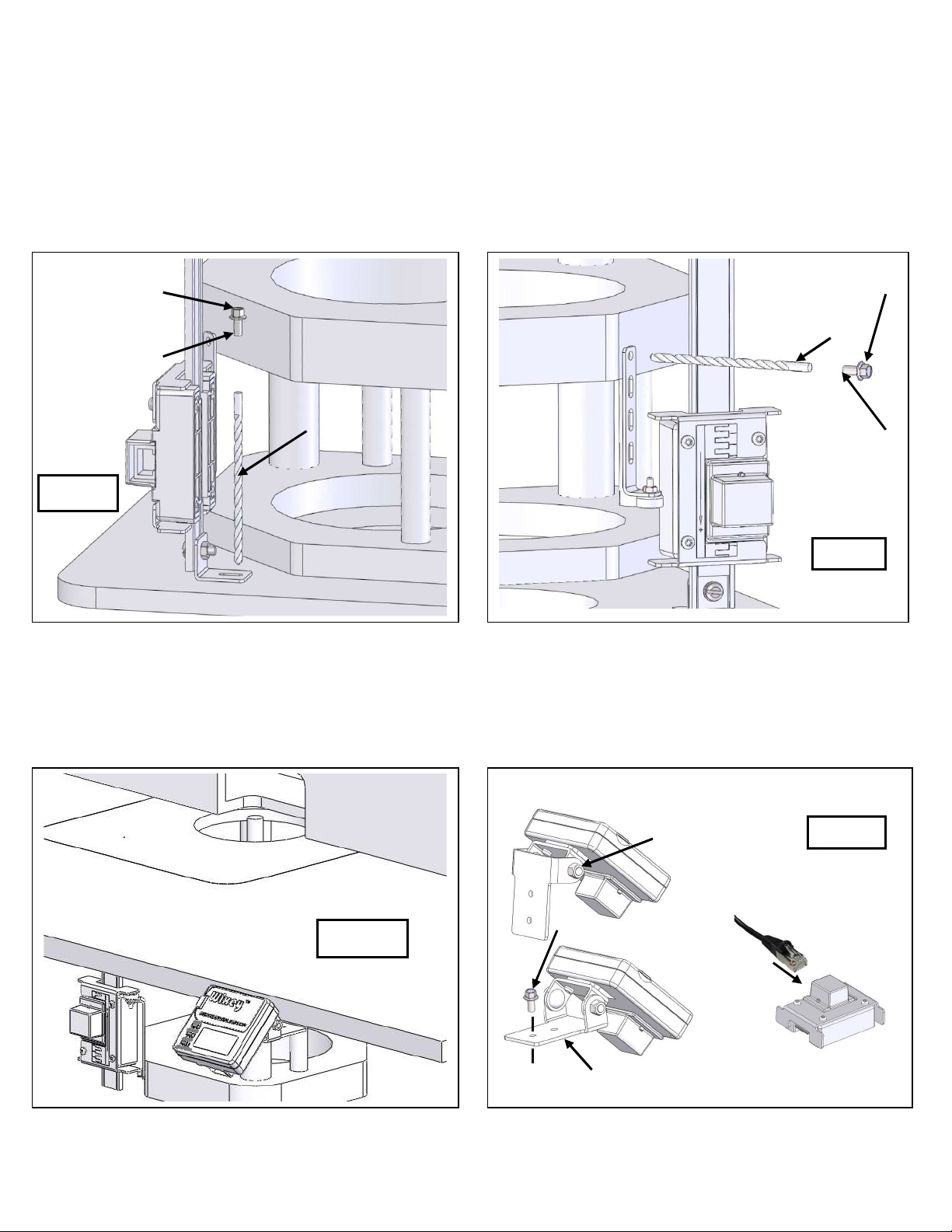

FIG 8

2- Permanently attached the scale and sensor to the lift

Center punch the screw locations and use the 3.6mm drill bit and the M4 x 8mm long thread forming

screws to attach the scale to the top plate (FIG 5) and the magnet bracket to the carriage (FIG 6). Put a

drop of oil on the end of the screws and use a nut driver to force the screws into the holes while turning

slowly.

Using a square make sure the scale is perpendicular to the top plate. If needed you may have to carefully

bend the “L” bracket to get perfect alignment. Fully tighten all screws to hold the system in position.

M4 x 8 thread

forming screw

M4 x 8 thread

forming screw

Add drop of oil

3.6mm drill

3.6mm drill

Add drop of oil

FIG 5

3- Mount the display and connect the Cat 5E cable

Find a suitable location to mount the display (FIG 7). You can use the 3.6mm drill bit and the M4 x 8mm

long thread forming screws to attach display. Connect the Cat 5E cable to the sensor and display and route

the cable using the cable clips.

Position the display mounting bracket

FIG 7

Attach using M4 X 8mm

thread forming screws

Loosen nuts to

adjust angle

Connect the Cat 5E

cable to the sensor

and display

Alternate bracket position

2

Loading...

Loading...