Wixey WR365 User Manual

TM

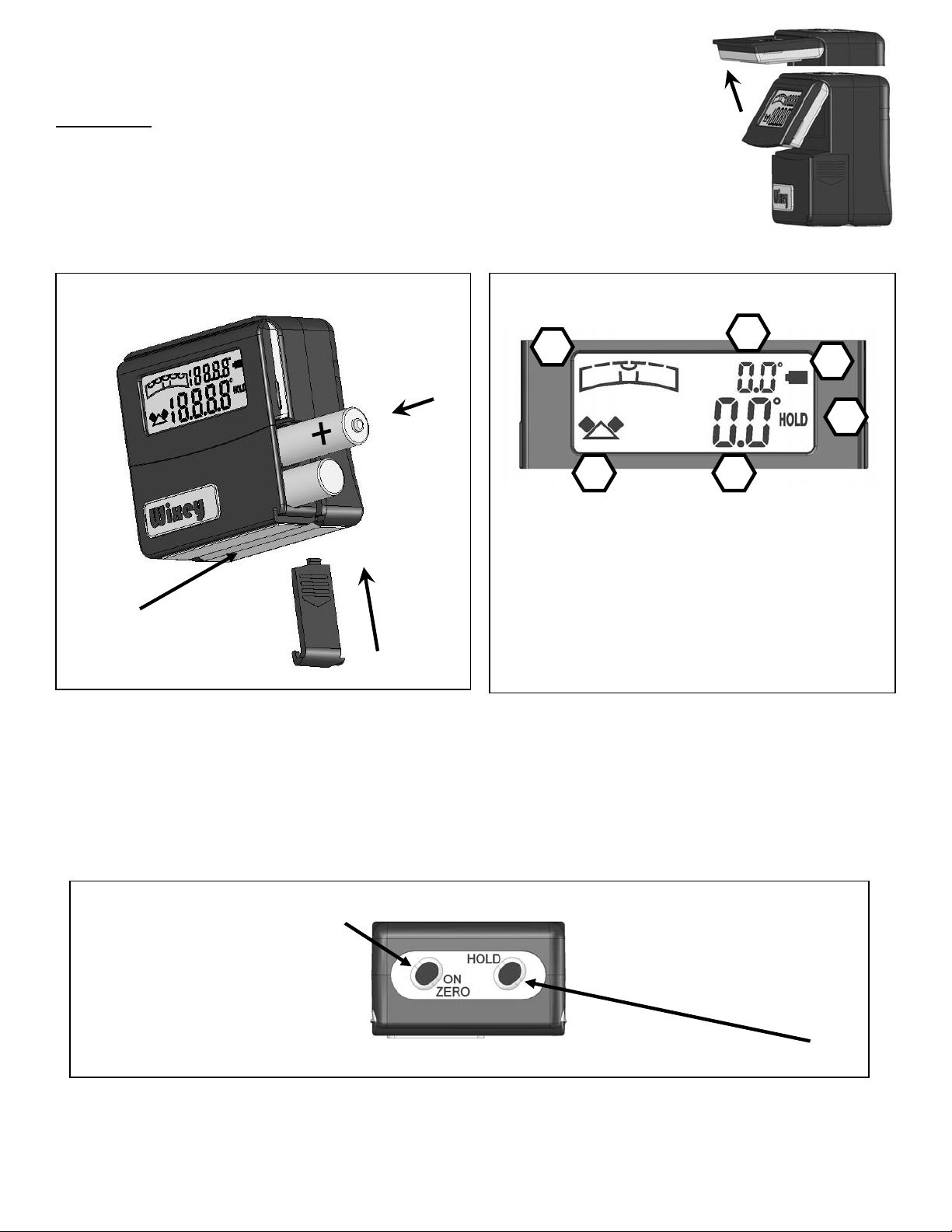

ON/ZERO

:

A.

Press once to turn

ON

disp

lay. B.

Press again to set relative angle to 0.0

°.

Wixey

Instructions

Model WR365 Digital Angle Gauge

with Level Patent Pending

Exclusive

flip-up

display

SAFTEY FIRST

• Always turn off the power and unplug power tools before using any gauge.

• Never use power tools without properly installed blade guards. Guards

may not be shown for clarity.

Basic Use

Install two AAA Batteries

FIG 1

READING THE DISPLAY

Note the super strong

magnetic base with “V”

groove for use on pipe

A. Bubble icon permanently set Dead Level

B. Tilt of gauge compared to Dead Level

C. Low battery indicator

D. Indicates the display is in HOLD mode

E. Relative angle reading

F. Indicates direction of tilt from relative 0.0°

*

Dead Level

TM

refers to absolute level with respect to the center of the earth. This

is what is shown with a tradition bubble level when the bubble is in the exact

center of the vial. Our Dead Level

TM

technology consists of a permanently

calibrated level setting which is always being displayed by both the bubble level

icon and the small digital angle reading in the upper right corner of the display.

FIG 2

TM

*

TM

C. Press and hold to turn off.

FIG 3

HOLD Press once to HOLD displayed reading -Press again to return to measuring mode

1

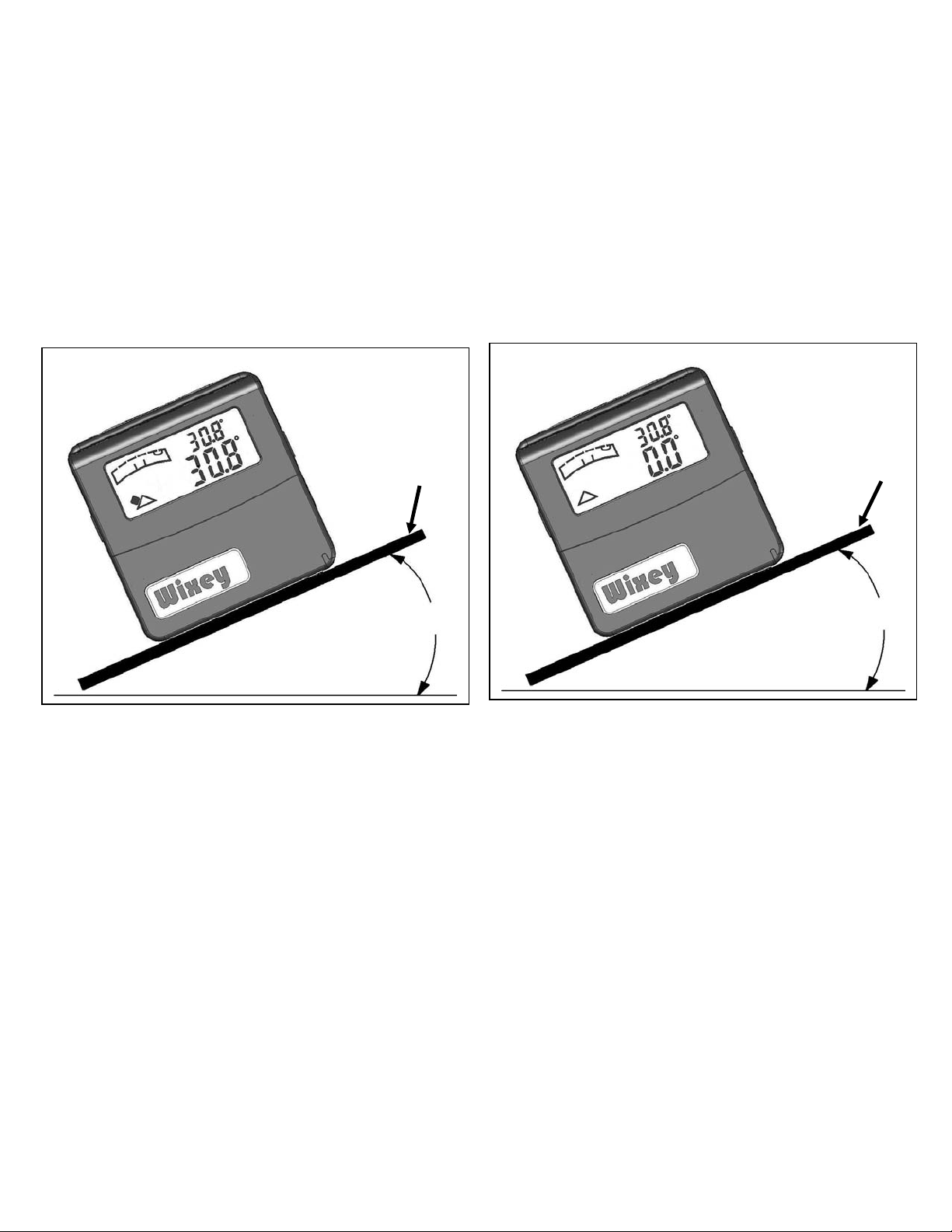

If the relative angle has been set to 0.0 on a level

surface and then placed on a non level reference

surface, both the relative angle measurement and

TM

the Dead Level

display will be the same FIG 4

FIG 4

Reference

surface

30.8°

Level surface

Pressing the ON/ZERO button calibrates the

relative angle to the reference surface and

displays 0.0. The Dead Level

continues to measure the FIG 5

TM

display

Reference

surface

30.8°

Level surface

FIG 5

Proper Measuring

1. Set the gauge flat on a reference surface such as a table saw, miter saw,

or jointer table. On a band saw or drill press the blade or bit will be the

reference surface. Keep the back of the gauge in a plane perpendicular to

the surface being measured. FIG 6

2. Turn on and press the ON/ZERO button to set the gauge to 0.0 degrees

which calibrates the reference surface.

3. Attach to the saw blade or jointer fence using the imbedded magnets. The

back of the gauge must always be kept in the same plane perpendicular to

the reference surface for all measurements. FIG 7

2

Loading...

Loading...