Page 1

Installation instructions

Remote 3000 / 3010

Content

1 General instructions __________________________________________________________ 2

1.1 Liability notes _________________________________________________________________ 2

2 Lock installation ______________________________________________________________ 2

2.1 Installing the lock ______________________________________________________________ 3

2.2 Connection external control/lock _________________________________________________ 3

3 Schematic _____________________________________________________________________ 4

4 Terms and definitions _________________________________________________________ 4

5 Technical data ________________________________________________________________ 5

6 Functional test ________________________________________________________________ 5

© Carl Wittkopp GmbH - Errors and omissions excepted

Rel. 1.0 07.10.2013 Installation instructions no. 9999-137-0

Page 2

Installation instructions Remote 3000 / 3010

1 General instructions

• Please read the operating instructions carefully, before activating the lock.

1.1 Liability notes

• The mounting of the electronic lock has to be carried out according to the installation instruction.

• By opening the lock case and by exceeding the thresholds, the manufacturer’s warranty will be void.

• The electronic lock has to be protected against external attacks.

• Do not insert any lubricants or other substances into the electronic lock.

• Only controlled mains adapters may be used for power supply.

• Durable operation with increased bolt load shortens the operating life of the lock’s mechanics.

2 Lock installation

The electronic lock has got standard fixing points and can be mounted in all 4 directions (right-hand, left-hand, up, down). In

order to fix the electronic lock, 4 threaded holes M6 have to be drilled according to the figure below.

Fig. 1: Installation dimensions Remote 7219

Hub/Stroke 12

Fig. 2: Installation dimensions Remote 7219 with optional mech. opening

2

Page 3

Installation instructions Remote 3000 / 3010

2.1 Installing the lock

• The electronic lock has to be fixed with 4 x M6 screws in the prepared drillings in order to ensure a permanent hold.

• An independent loosening of the screws has to be avoided. It is recommended to put lock washers underneath the screw’s

head. To avoid malfunctions, turn the screws with a maximum turning force of 3.5 – 5 Nm.

• After the installation the lock’s bolt may not be loaded. The maximum bolt load is 2.5 N.

• The electronic lock is maintenance free in normal domestic and office surroundings. After approx. 10,000 closures it is

recommended to carry out a security and functional test of the electronic lock.

2.2 Connection external control/lock

• Plug single conductors cable into the connecting terminal plate on the lock from/to the external control and check fixing

(see fig. 2).

• Ensure enough traction relief to the signal lead.

• To loosen single conductors push in the corresponding clutch fork (orange) with an appropriate tool.

• Keep cable away from sharp edges and moving boltwork components and fix it permanently.

Connecting terminal

Fig. 3: Connecting terminal plate electronic lock

min. 10 mm

Fig. 4: Stripping length

3

Page 4

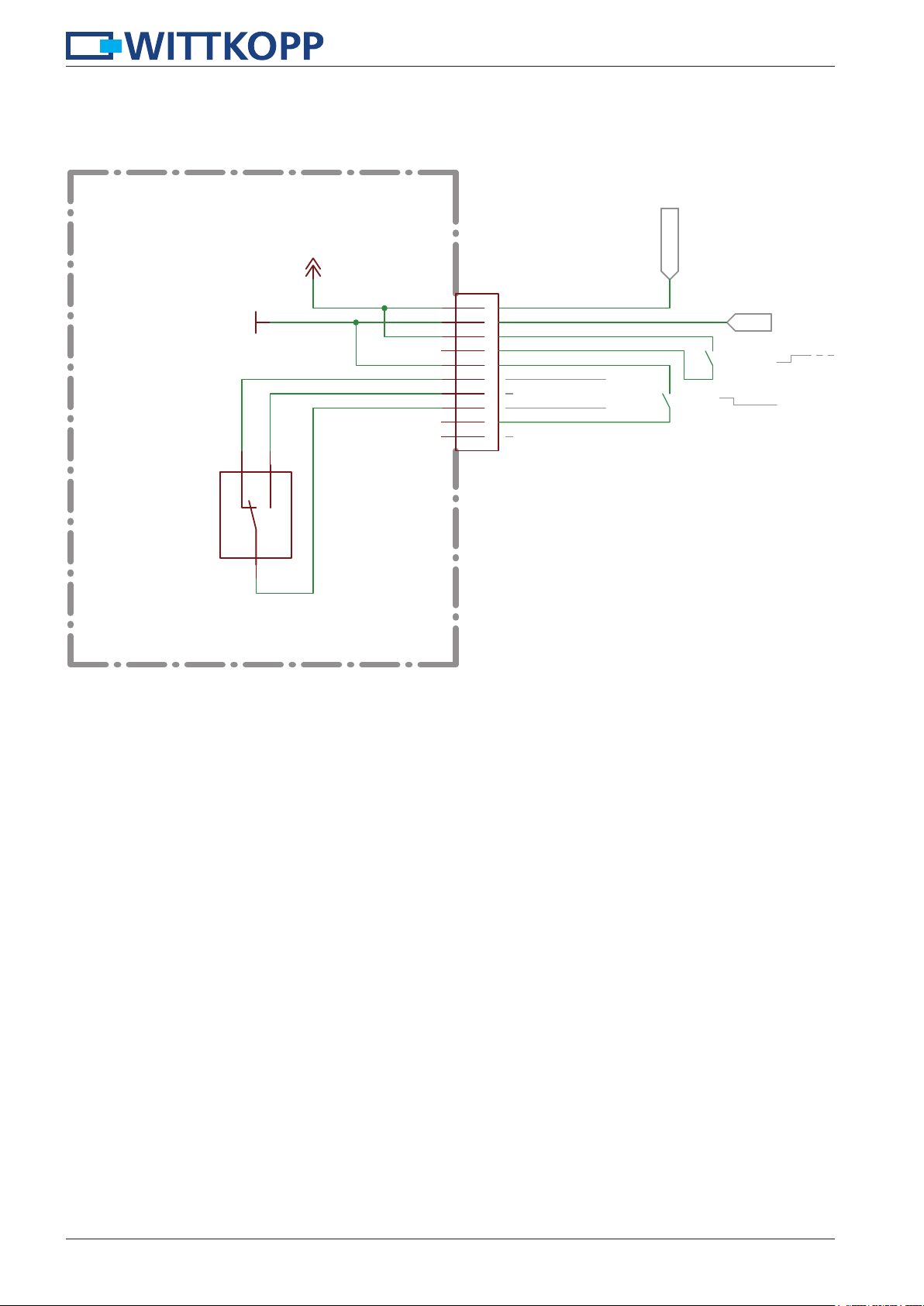

3 Schematic

NC

GND

NO

+12V

Installation instructions Remote 3000 / 3010

9-12VDC

X101

Vcc

1

power supply

2

3

4

5

6

7

secure / not secure

8

9

n.c.

10

RIACON-AST072-10

GND

open/close

blocking

not secure

S1

DH2CC6PA

COM

Abb. 4: Schematic

4 Terms and definitions

Pulse mode:

A closed lock can be opened by a single impulse and closed again by a succeeding one.

Hold mode:

If the opening signal is not turned off before the bolt reaches the opening position, the lock stays opened until the signal is

removed again. When the signal is then removed, the lock closes automatically.

Opening and closing is carried out by a signal input. The lock can be operated in pulse or hold-mode via this signal input.

4

Page 5

Installation instructions Remote 3000 / 3010

5 Technical data

Technical data

Dimensions lock (mm)

Material

Ingress protection

Temperature (°C)

Rel. humidity (%)

Operation conditions

Power supply

Voltage

Current consumption (standby *1)

Current consumption control inputs

- Open/close (mA)

- Blocking (mA)

Voltage levels control inputs

- Open/close

- Blocking

(always with reference to ground)

Output

- „Secured“

Terminal block wire gauge

(standby *1) supply voltage 12VDC, only power supply without any

(load *2) 7.5 N bold force, supply voltage 12VDC

(bold blocked *3) supply voltage 12VDC

(Vcc) 9-12 VDC +/- 10%

(load *2)

(max. *3)

BxHxT, see fig. 1 page 2

zinc plated steel sheet

IP30

5-40

10-75 % not condensating

control contacts

typ. 1 µA

< 300 mA

< 700 mA

< 0.5 mA

< 0.1 mA

5V – 12 V (max. Vcc)

0-5 V

5-500mA@30V

(data sheet Cherry DH)

0.13 – 0.5 mm² respectively AWG 26-20

• The blocking input allows to inhibit lock openings. Closing or accordingly extending the bolt, is still possible.

• The lock electronically checks at the beginning of every opening cycle, whether a blocking signal is active. To combine multiple locks like a double door system, only one common signal line is necessary (easier cabling).

• The condition „secure“, when the bolt is in closed position and retained, is signalized by switching contacts directly connected

to the terminal block (dry-contact).

6 Functional test (when the door is open)

• Carry out a functional test after installing the lock.

• Trigger the control signal.

• The lock bolt moves in automatically (has to happen easily). The lock is opened.

• After triggering another control signal (pulse mode) or after switching off the control signal (hold mode) the lock bolt moves

out automatically and locks. The lock is closed.

• Keep enough clearance to the locking point.

5

Loading...

Loading...