Wittkopp Primor FE, Primor RO, Primor FS, Primor 100, Primor 2000 Installation Instructions Manual

...

Installation instructions Primor

Content

1 General instructions _____________________________________________________________ 2

2 System overview

3 Installation input unit Primor RE ____________________________________________________ 3

4 Installation input unit Primor FE ____________________________________________________ 5

5 Installation input unit Primor RO ___________________________________________________ 7

6 Installation input unit Primor FL ___________________________________________________ 11

_________________________________________________________________ 2

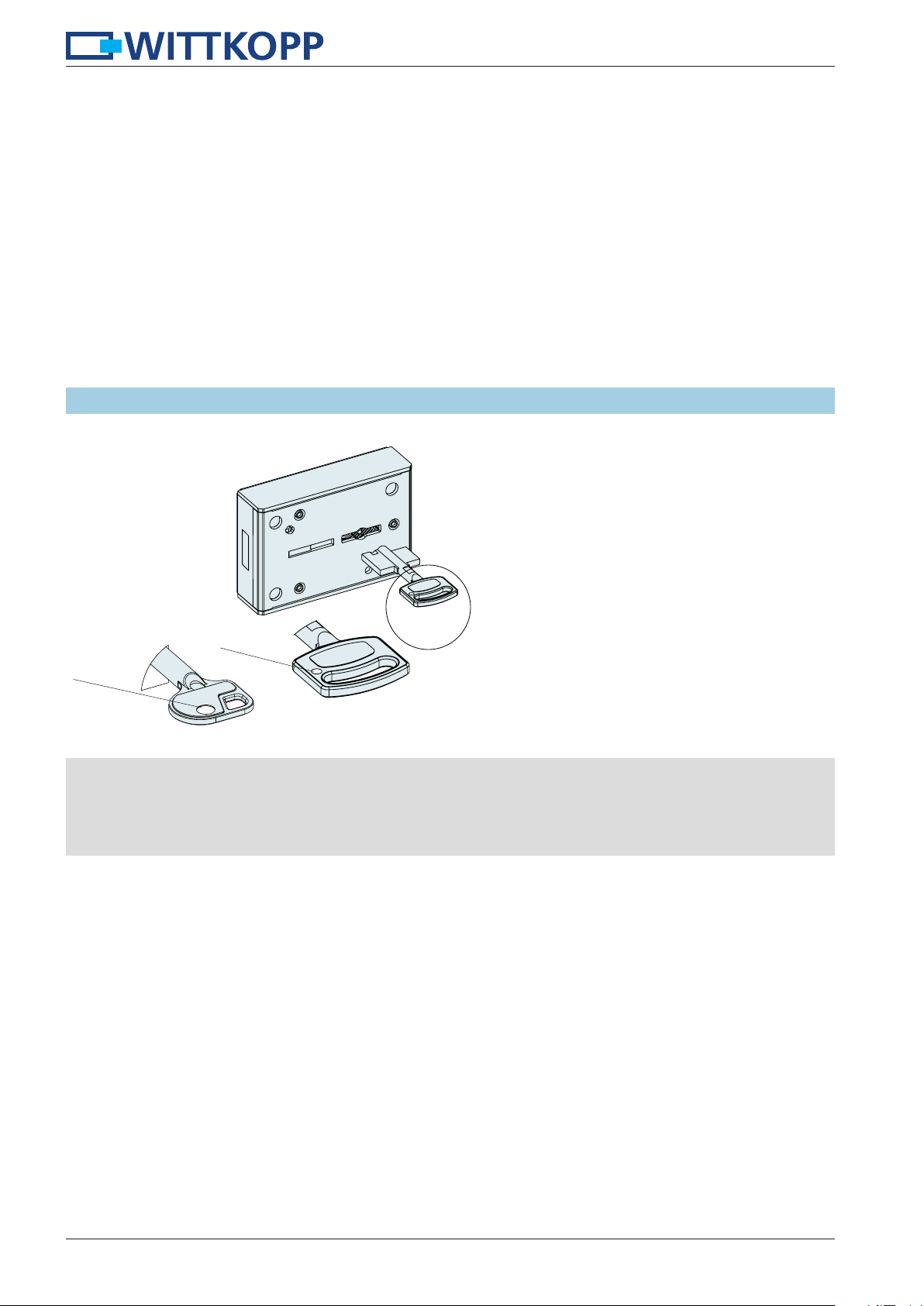

7 Installation input unit Primor FS ___________________________________________________ 13

8 Installation lock

9 Mounting lock Primor 100 _______________________________________________________ 15

10 Mounting lock Primor 1000 _____________________________________________________ 18

11 Mounting lock Primor 1000/2000/3000/3010/3011 ______________________________ 18

12 Plug positions

13 External power supply

14 Functional test

15 Testing the system

________________________________________________________________ 14

_________________________________________________________________ 21

__________________________________________________________ 21

________________________________________________________________ 22

_____________________________________________________________ 22

© Carl Wittkopp GmbH - Errors and omissions excepted

Rel. 1.6 06.02.2017 Installation instructions no 9999-154-0

Installation instructions Primor

1 General instructions

• Please read the installation instructions carefully, before activating the lock.

1.1 Liability notes

• The mounting of the electronic lock and the input unit has to be carried out according to the installation instruction.

• We point out that this installation instruction is part of the VdS-certification and non-compliance leads to the loss of this

certification.

• By opening the lock cover warranty of the manufacturer will be void.

• Take care that the input unit or the lock and the cables should not be damaged.

2 System overview

Primor RE Primor FE Primor RO Primor FL Primor FS

Primor 100

Primor 1000

Primor 2000

Primor

3000/3010/3011

* can serve simultaneously as boltwork actuator

• •

• •* • •

• •

• •* • •

2

Installation instructions Primor

205

30

A

A

Türlochbohrung

mind . ø10,6 - max. ø11,4

3 Installation input unit Primor RE

3.1 Input unit Primor RE 3.1.1 Dimensions Primor RE

3.2 Installation overview

3.2.1 Input unit Primor RE

83

O-ring

Axe profile

Cylinder screws

M5 x 18

Lever input unit

Black covering cap

Red covering cap

3.3 Axis length calculation input unit Primor RE

3.3.1 In connection with Primor 100 3.3.2 Panel hole spindle

Battery compartment

cover

Cylinder screws

M5 x 14

L

Spindle:

Debur the ends

L = A + 35 mm (tolerance -2 mm)

min. Ø 10.6 mm/max. Ø 11.4 mm

A

3

Installation instructions Primor

60 145

30

3.4 Mounting input unit

3.4.1 Drill pattern Primor RE (lock is closing towards the right) - (closing towards the left inversely)

Opening for cable

2 x Fixing position for

Ø 11,4

screws M5 x 14

15

2 x Fixing position

for screws M5 x 18

30

100

15

30

130

• From the front 4 threaded holes M5 with sufficient depth thread and 1 through-hole (opening for cable/Spindle)

have to be drilled into the safe door.

3.4.2 Cable guidance Primor RE 3.4.3 Cable guidance/Plug position Primor RE

Lock

O-ring

Spindle

• Lead the connection cable through the Spindle.

• Push the cable and the O-ring in the direction of the arrow until the inset.

• Connect the plug of the cable with the plug on the circuit board. Attention: Don’t put the connection cable under tensile stress.

• Fix the input unit from the front with the enclosed cylinder screws M5.

• Install covering caps and battery compartment cover (see 3.2.1).

4

Installation instructions Primor

156

4 Installation input unit Primor FE

4.1 Input unit Primor FE 4.1.1 Dimensions Primor FE

4.2 Installation overview

4.2.1 Input unit Primor FE

11,5

52,5

26

83

Cylinder screw

M5 x 18

Battery compartment cover

Black covering cap

Axe profile M5 x 14

5

Installation instructions Primor

11,5 100

4.3 Mounting input unit

4.3.1 Drill pattern Primor FE (lock is closing towards the right) - (closing towards the left inversely)

30

• From the front 3 threaded holes M5 with sufficient thread depth and 1 through-hole (opening for cable/Spindle)

have to be drilled into the safe door.

4.3.2 Plug position Primor FE

Lock

• Connect the plug of the cable with the plug on the circuit board. Attention: Don’t put the connection cable under tensile stress.

• Fix the input unit from the front with the enclosed cylinder screws M5.

• Install covering caps and battery compartment cover (see 4.2.1).

6

Installation instructions Primor

Türlochbohrung

mind . ø10,6 - max. ø11,4

Türlochbohrung

Türlochbohrung

mind. ø9 - max. ø10,6

mind . ø10,6 - max. ø11,4

5 Installation input unit Primor RO

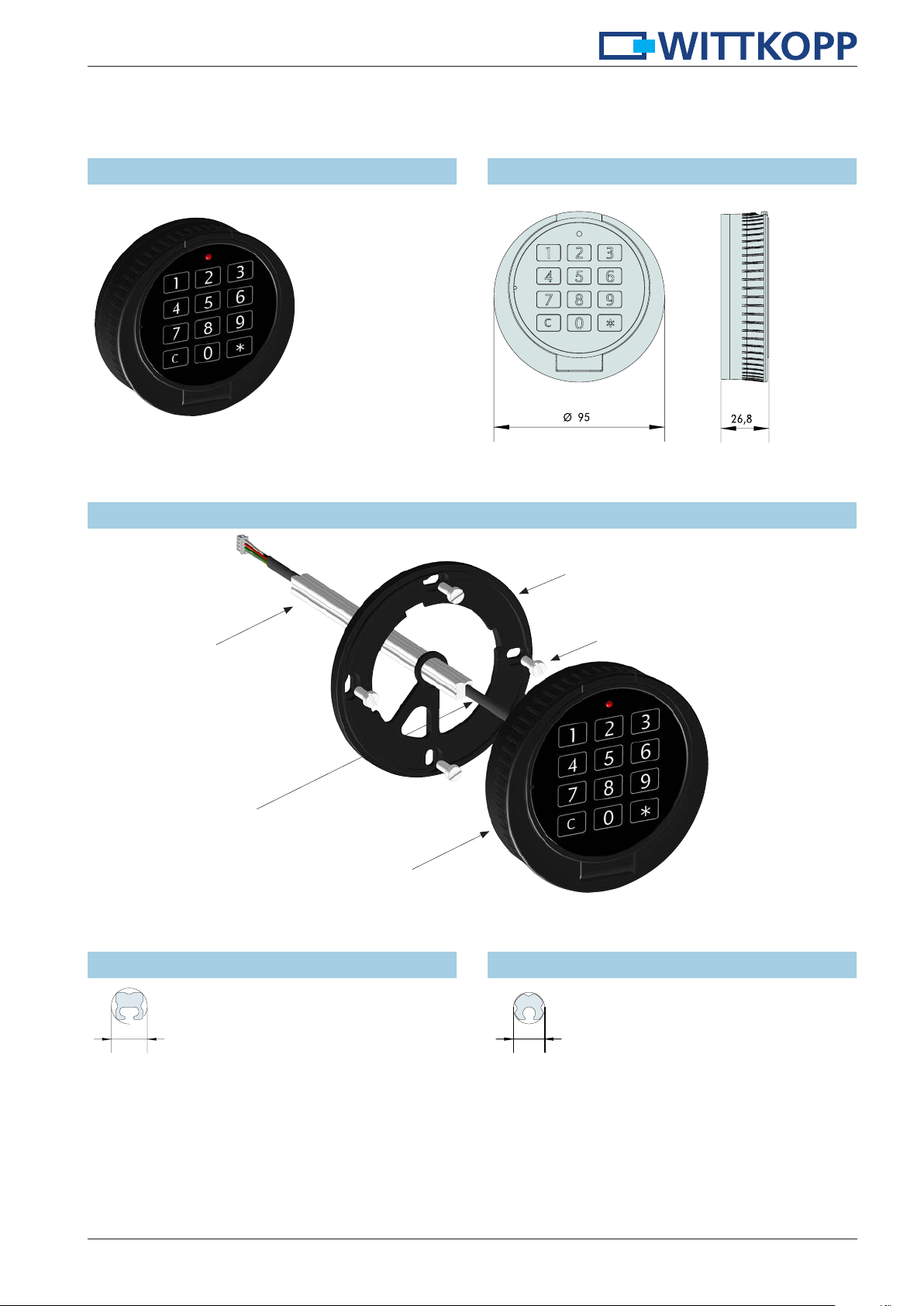

5.1 Input unit Primor RO 5.1.1 Dimensions Primor RO

5.2 Installation overview

5.2.1 Input unit Primor RO

Fixing ring for input unit

Spindle for

turnable input unit

Connection cable

Input unit

4 Cylinder screws M4 x 10

5.3 Panel hole Primor RO (turnable)

5.3.1 Spindle square 5.3.2 Spindle round

min. Ø 10.6 mm/max. Ø 11.4 mm

min. Ø 9 mm/max. Ø 11.4 mm

7

Installation instructions Primor

A

A

A

L

A

A15X

Achse in axialer Richtung

gegen verschieben sichern

A1

Achse in axialer Richtung

gegen verschieben sichern

5.4 Axis length calculation input unit Primor RO (drehbar)

5.4.1 In connection with Primor 100 5.4.2 In connection with Primor 2000

A

A

L

Spindle:

Debur the ends

L = A + 28 mm (tolerance -4 mm) L = A + 43 mm (tolerance -4 mm)

L

Spindle:

Debur the ends

5.4.3 In connection with boltwork

Secure the axis

against shifting in

axial direction

L

Spindle:

Debur the ends

L = X + A + 15 mm (+ axial hedge)

5X

8

Installation instructions Primor

78

78

4,3

4,3

41,5

41,5

4

4,3

78

4

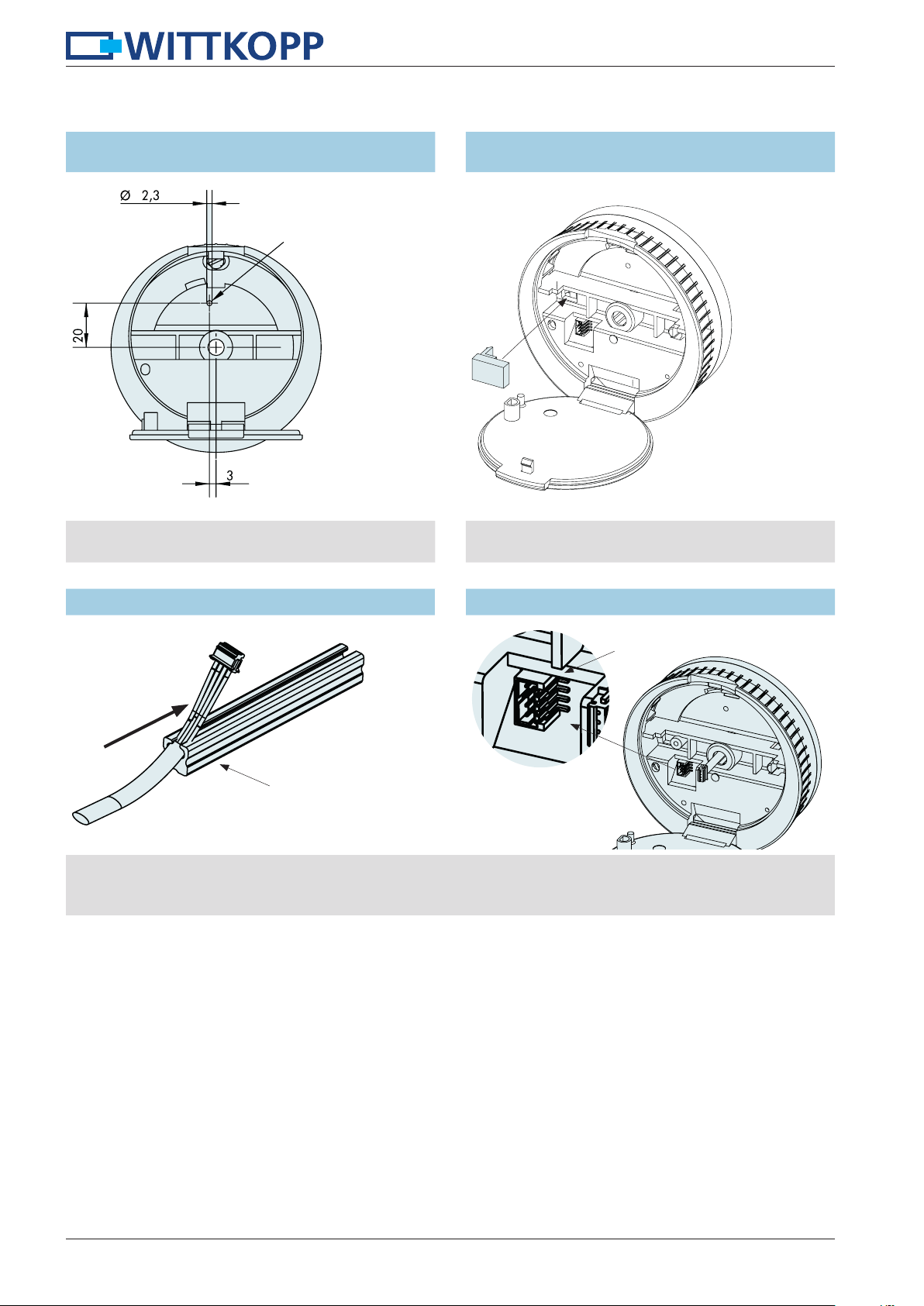

5.5 Mounting input unit

5.5.1 Drill pattern fixing with 4 threaded holes Primor RO

4 x Fixing position for M4

Hole center congruent with middle

axis of nut of the electronic lock

Opening for cable

• From the front 4 threaded holes M4 with sufficient thread depth and 1 through-hole (opening for cable/Spindle)

have to be drilled into the safe door.

• From the front the fixing ring has to be fixed with the enclosed cylinder screws M4 x 10.

5.5.2 Drill pattern fixing with 8 threaded holes Primor RO

41,5

4 x fixing positions for

screws M4

4,3

4,3

4,3

- oprionally Ø 41.5 mm

or Ø 78 mm

78

41,5

Hole center congruent with middle

axis of nut of the electronic lock

Opening for cable

• From the front 4 threaded holes M4 with sufficient depth thread and 1 through-hole (opening for cable/Spindle)

have to be drilled into the safe door.

• From the front the fixing ring has to be fixed with the enclosed cylinder screws M4 x 10.

5.5.2 Mounting input unit Primor RO

20°

Position 1

• Position 1: Mount the input unit with an angle of approx. 20° to the fixing ring.

Position 2

• Position 2: Turn the input unit to the right into position. The turning has to happen easily.

9

Installation instructions Primor

5.5.3 Input unit Primor RO (fixed)

Fixing ring with 4 threaded holes

Drill-hole Ø 3,4

mm in the safe door

to fix the input unit

• Fit input unit of approx. 20° (see 5.5.2), adjusting and

insert grub screw M3 x 6 or arrest pin.

5.5.4 Input unit Primor RO (fixed)

Fixing ring with 8 threaded holes

• Fit input unit of approx. 20° (see 5.5.2), adjusting and

insert clip.

5.5.5 Cable guidance Primor RO (drehbar) 5.5.6 Plug position Primor RO

Lock

Spindle

• Lead connection cable through the input unit.

• Insert the Spindle into the input unit from behind.

• Lead connection cable through the input unit and connect the plug.

10

Installation instructions Primor

82

6 Installation input unit Primor FL

6.1 Input unit Primor FL

(fixing on the inside)

6.2 Mounting input unit

6.2.1 Drill pattern Primor FL

Opening for cable:

Drill-hole min. Ø 8 mm/max. Ø 11.4 mm in

the safe door for connection cable

6.1.2 Input unit Primor FL

(fixing on the front)

6.1.3 Dimensions Primor FL

Emergency

Fixing position:

- Fixing on the inside: Through-hole

for screws M5

- Fixing on the front: Thread M3

• Fixing on the inside: 2 through-holes for screws M5 and 1 through-hole (opening for cable) have to be drilled into the safe door.

Fix the input unit with 2 screws M5 from behind.

• Fixing on the front: From the front 2 threaded holes M3 with sufficient depth and 1 through-hole (opening for cable) have to

be drilled into the safe door. Fix the input unit with 2 screws M5 from the front.

6.3 Mounting battery compartment

6.3.1 Battery compartment 6.3.2 Drill pattern battery compartment

78

41

36

47,5

• The battery compartment has to be fixed to the inside of the door. It is recommended to fix it in a way that it is accessible

without unscrewing the interior of the door.

• To avoid a short circuit/independent discharge, no connection between the inputs of the battery compartment and other

components may occur.

• Battery compartment can be fixed with the double sided tape or with the screws, which are included in the scope of delivery.

11

Installation instructions Primor

3

24

29

60

3

24

6.3.3 Battery sliding compartment 6.3.4 Drill pattern battery sliding compartment

29

43

53

60

• The battery sliding compartment has to be fixed to the inside of the door. It is recommended to fix it in a way that it is

accessible without unscrewing the interior of the door.

• To avoid a short circuit/independent discharge, no connection between the inputs of the battery sliding compartment and

other components may occur.

6.3.5 Plug position Primor FL

Lock

Battery

• The two 4-pin plug connection must be accessible at all times.

12

Installation instructions Primor

5,1

7 Installation input unit Primor FS

7.1 Input unit Primor FS 7.1.1 Dimensions Primor FS

7.2 Mounting input unit

7.2.1 Drill pattern Primor FS

Fixing position for screws M5

23

Opening for cable:

Drill-hole min. Ø 8 mm/max. Ø 11,4 mm for connection

5

46

• From the front 2 threaded holes M5 with sufficient depth and 1 through-hole (opening for cable) have to be drilled into

the safe door.

• Fix the input unit with the enclosed cylinder screws M5 from the front.

7.2.2 Cable guidance Primor FS 7.2.3 Plug position Primor FS

Connection cable lock

cable has to be drilled into the safe door

BatteryLock

Fixing screw

Bottom of case

Battery clip

Folding unit

• Lead connection cable of the lock and connection cable

of the battery behind the bottom of the case of the input unit.

13

Installation instructions Primor

17,3

41

66,5

17,3

41

66,5

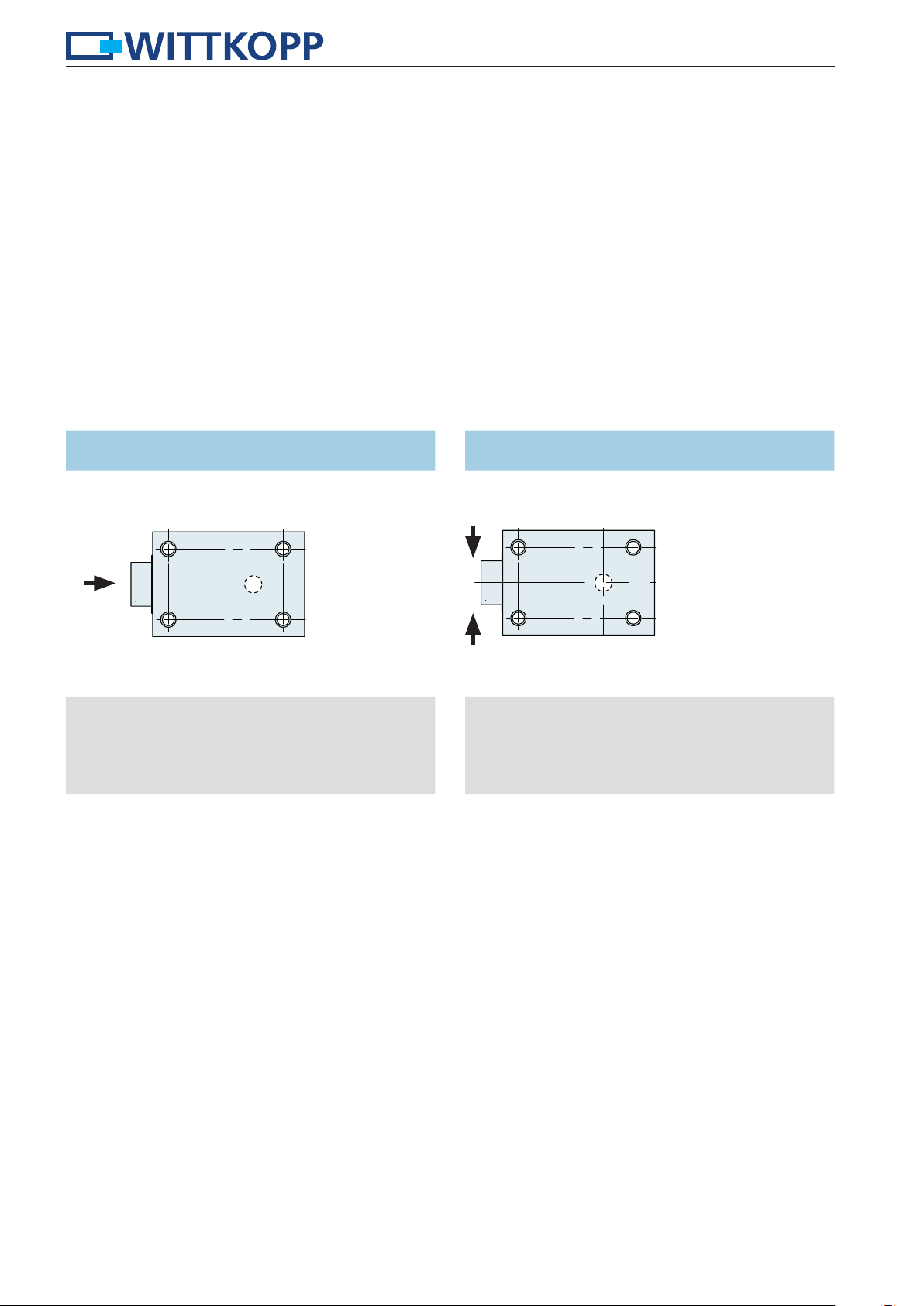

8 Installation lock

Before mounting the lock the input unit has to be installed (see chapter 3 to 7).

Wittkopp electronic locks of the Primor series have got standard fixing points and can be mounted in all 4 directions (right-hand,

left-hand, up, down).

• The lock can be installed in all conventional safes.

•

Depending on the model there can be optional used more locking elements (e.g. angle with bolts) additional to the existing

holes of the bolt. Please make sure that the lock and the connections operate properly.

•

The electronic lock is maintenance free in normal domestic and office surroundings. After approx. 10,000 closures it is re-

commended to carry out a security and functional test of the electronic lock.

• For safety reasons it is not allowed to locate the electronic lock in the area where openings are (except Primor 100/2000).

• The electronic lock has to be protected against external attacks.

• It is recommended to protect all security relevant components of the high-security lock against tempering even when the

door is opened.

• Do not insert any lubricants or other substances into the electronic lock.

8.1 Constant bolt load

Primor 100/2000/3000/3010/3011

F

• The maximum and constantly bolt load against bolt

closing direction may not exceed the following limits::

Primor 100 2.5N

Primor 2000 2.5N

Primor 3000/3010/3011 2.5N

8.2 Bolt support load

Primor 100/2000/3000/3010/3011

F= 1000 N

F= 1000 N

• The load on the bolt must not exceed 1000 N.

14

Installation instructions Primor

Hub/Stroke 12

27

Platzbedarf/Required space

25

41

78

110

78

112,5

142

25

78

78

112,5

142

25

78

9 Mounting lock Primor 100

9.1 Dimensions lock Primor 100

60,7

Ø

4,5

25,4

15

9,1

58

88

66,5

25

41

Middle-axis of the nut has to be

congruent with the middle-axis of the

input unit

22

14 +12mm

9.1.1 Option extension latch 9.1.2 Option lock cover - screwed

6,5

Ø

142

25

9.1.3 Option lock cover - welded

(without anti-drilling plate)

110

9.1.4 Option lock cover - welded

(with anti-drilling plate)

66,5

112,5

If the lock is mounted without its lock case further installation guidelines have to be considered. Non-observance leads to

loss of VdS certification. A separate installation instruction no 9999-139-1 can be found on www.carl-wittkopp.com.

15

Installation instructions Primor

Hub/Stroke 12

102

Required space for bolt throw

9.2 Mounting lock Primor 100 - Schlossdecke anschraubbar

9.2.1 Dimensions lock Primor 100 - lock cover screwed

25

9,1

66,5

8

6,5

Ø

Platzbedarf für Riegelhub /

142

60,7

41

25,4

27

15

4,5

Ø

22

7

2,5

13

58

110

115

3

9

• 4 threaded holes M6 or 1/4" with depth min. 5 mm for fixing the key lock have to be drilled into the safe door.

•

Optional: Insert extension latches into the guiding pins at the back of the lock in the right direction and pull up the extension

latch that closes to the top.

• The lock case is put on top of the electronic lock.

• Lead the connection cable of the input unit through the square nut of the lock.

Attention: Don’t put the connection cable under tensile stress.

•

Afterwards the lock has to be stuck onto the spindle of the input unit that is already inside the door.

• The electronic lock has to be fixed with the screws included in the scope of delivery or cylinder screws M6 or 1/4" (at least

property class 8.8). The screw length should be 30 mm or longer so that a minimum thread length of 5 mm is achieved.

•

Independent loosening of the screws has to be avoided. Recommendation: put lock washers underneath the screw’s head.

• Turn the screws with a maximum turning force of 3.5 – 5 Nm.

• After mounting the bolt/extension latch must not be under tension.

• After the installation the lock’s bolt may not be loaded.

16

Installation instructions Primor

Hub/Stroke 12

102,1

Required space for bolt throw

Hub/Stroke

102

w

9.3 Mounting lock Primor 100 - lock cover welded

9.3.1 Dimensions lock 100 - lock cover welded

(without anti-drilling plate)

97027

8

25,4

78

15

60,7

7

4,5

Ø

22

13

58

110

115

2,5

25

Platzbedarf für Riegelhub /

142

3

9

9.3.2 Dimensions lock Primor 100 - lock cover welded

(with anti-drilling plate)

27

12

78

25,4

15

4,5

Ø

7

2,5

23

14

8

58

112,5

115

25

Platzbedarf für Riegelhub /

Required space for bolt thro

142

3

10

• Before welding the lock cover, the lock case has to be removed.

• When positioning keep the middle of the Spindle congruent with the input unit RO/RE.

•

Weld the lock case (if so with hardened manganese steel plate) with 4 welding seams, length 15-20 mm (position of the

welding seams on the corners of he lock case) to the inside of the safe door. Make sure that the lock cover (possibly with

hardened manganese steel plate) is fixed tightly onto the door.

• Welding distortion has to be avoided.

• Lead the connection cable of the input unit through the square nut of the lock.

Attention: Don’t put the connection cable under tensile stress.

•

The lock then has to be plugged onto the Spindle of the input unit, which is already in the safe door.

• Optional: Insert extension latches into the guiding pins at the back of the lock in the right direction and pull up the extension

latch that closes to the top.

•

The electronic lock has to be fixed with the 4 enclosed flat-headed screws M6 x 12 with the designated drillings of the lock

case in order that permanent foothold is guaranteed

• Turn the screws with a maximum turning force of 3.5 – 5 Nm.

• After mounting the bolt/extension latch must not be under tension.

• After the installation the lock’s bolt may not be loaded.

17

Installation instructions Primor

Hub/Stroke 12

66,5

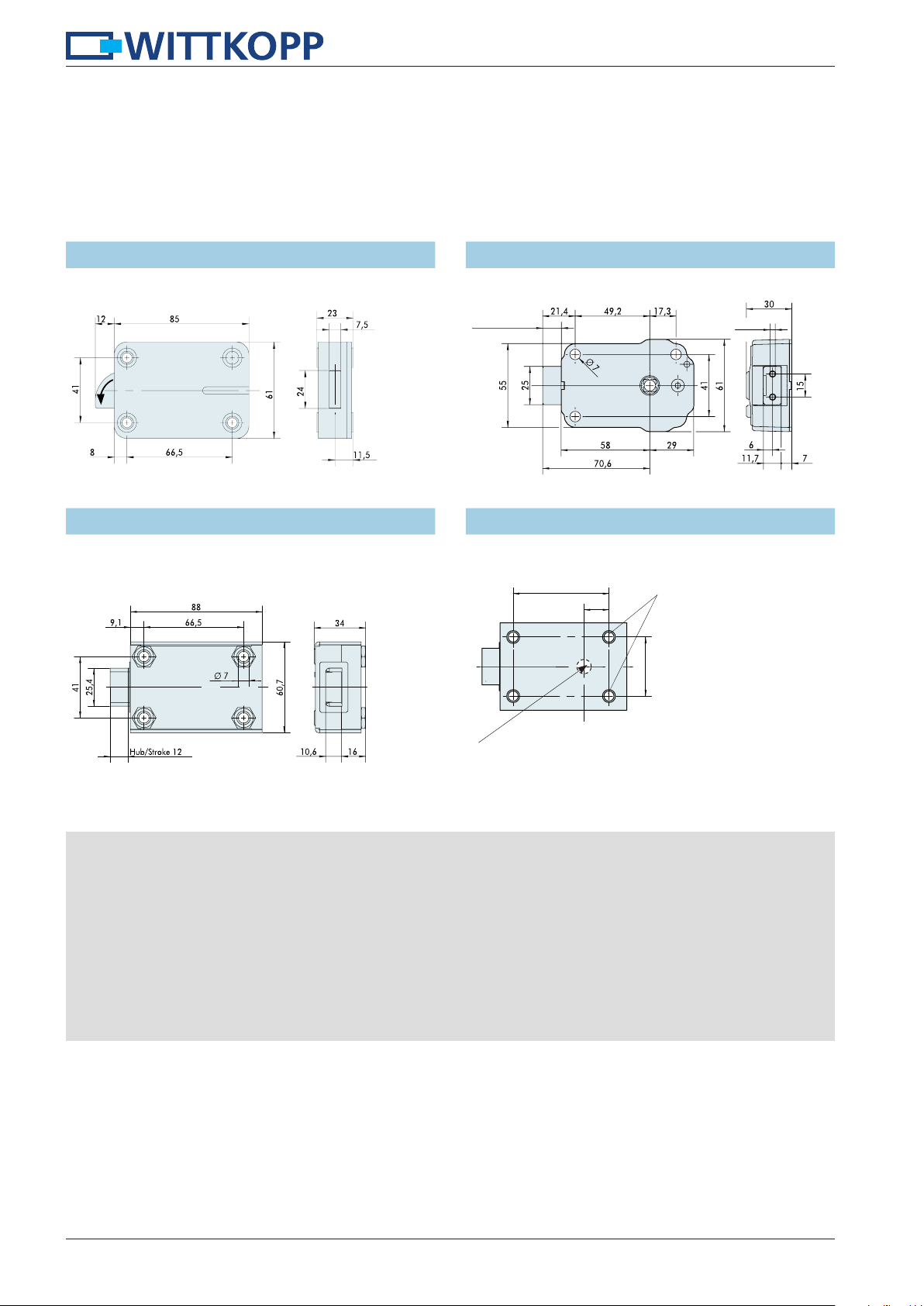

10 Mounting lock Primor 1000

• When the swing bolt lock is used with another lock, the boltwork has to be set up, so that the swing bolt lock inevitably locks first.

11 Mounting lock Primor 1000/2000/3000/3010/3011

11.1 Dimensions lock Primor 1000 11.1.1 Dimensions lock Primor 2000

M4

11.1.2 Dimensions lock Primor 3000/3010/3011 11.1.3 Drill pattern locks Primor-Serie

Primor 1000/2000:

17,3

one drill-hole not necessary

41

Primor 2000:

Middle axis of nut of the electronic lock congruent with middle

of the input unit (Primor RO)/middle input unit lever (Primor RE)

• 4 threaded holes M6 or 1/4" (Primor 1000/2000 - 3 threaded holes) with depth min. 5 mm for fixing the key lock have to

be drilled into the safe door.

• The electronic lock has to be fixed with the screws included in the scope of delivery or cylinder screws M6 or 1/4" (at least

property class 8.8). The screw length should be 30 mm or longer so that a minimum thread length of 5 mm is achieved.

• Primor 2000: Lead connection cable through the lock and adjust the electronic lock on the spindle.

•

Fixing the lock with screws M6 or a comparable inch thread. Length and material application of the screw has to be selected

such as a secure long-term stability is guaranteed

• Turn the screws with a maximum turning force of 3.5 - 5 Nm.

•

Independent loosening of the screws has to be avoided. Recommendation: put lock washers underneath the screw’s head

• After mounting the bolt must not be under tension.

• After the installation the lock’s bolt may not be loaded.

18

Installation instructions Primor

60,7

Platzbedarf/required space

10,6

116

Hub / Stroke 12

11.2 Primor 3010 and 3011 with emergency lock

• Only emergency locks with the VdS class 2 may be installed.

• If electronic locks Primor 3010/3011 are installed without emergency locks, the installation has to be checked with the corresponding testing institute.

• For a safe functioning of the emergency opening the emergency locks should have a stroke of 12 mm.

• The emergency locks have to be protected from attacks from the outside.

11.2.1 Dimensions lock Primor 3010 - short unlocking lever with mechanical emergency lock

Installation example

9,1

41

25,4

66,5

Ø

7

Hub/stroke 12

Primor 3010

150

25,5

41

66,5

7

Ø

13

Mechanical emergency lock

N-1821

• If the emergency lock N-1821 is not used, the electronic lock Primor 3011 has to be used.

11.2.2 Einbaumaße Primor 3011 - short unlocking lever with mechanical emergency lock

Installation example

9,1 66,5

13,5

41

60,7

25,4

88

7

Ø

Primor 3011

34

+ 12 mm

6,8

4

M

15

34

58,3

41

60,7

66,5

88

• This installation has to be checked with the corresponding testing institute.

7

Ø

(X)

Mechanical

emergency lock

3

Area around the

unlocking lever

mustbe protected

especially.

25

19

Installation instructions Primor

11.2.3 Security notes Primor 3010/3011 – emergency lock

• For the emergency locks the general installation notes as described under point 8 apply.

• Due to security reasons it is recommended not to leave the key unattended in the lock.

• The keys have to be stored at a safe place and may only be accessible by authorized persons.

• When losing the key exchange the lock immediately.

• Make sure after each locking if the safe is locked.

11.2.4 Operating notes Primor 3010/3011 – emergency lock

• The lock may only be operated with the according keys. The insertion and opening attempts with other keys can lead to

internal damage.

• Never use force.

11.2.5 Operating the lock

Index

Index

• Insert key so that the marking on the key head is pointing towards the lock’s bolt

•

When using right-hand locks (turning axis towards the right) the key has to be turned clockwise. With left-hand locks

counter-clockwise.

•

Removing of the key is only possible when lock is closed. The key has to be turned to a tight end.

• When turning the key do not use force (no auxiliary means). If jamming occurs contact qualified personnel. .

20

Installation instructions Primor

12 Plug positions

12.1 Primor 100 12.2 Primor 1000

Input unit

Battery compartment/

signalbox

Input unit

12.3 Primor 2000 12.4 Primor 3000/3010/3011

Battery compartment/

Signalbox

signalbox

2

Input unit

• Connect the plug from/to the input unit into the outer plug position on the lock and check fixation. To loose the plug, carefully

lift and pull out.

•

Keep the connection cables away from sharp edges and moving parts of the boltwork, then fix them permanently.

• Plug the connection cables of the signal box (optional) into the position „signal box“ on the lock. For further installation notes

please see the separate installation instruction PrimorSignal/PrimorSignalPlus.

1

Input unit

13 External power supply

• The locks Primor 1000/2000/3000/3010/3011 can be power supplied externally by PrimorSignal plus.

• When using mains adapter as primary power supply, there is no voltage control of the inserted battery.

• Emergency power supply (optional): insert 1 x 9V block Alkaline.

13.1 PrimorSignal 13.1.2 PrimorSignal Plus

• Further Installation instructions and circuit diagram see separate installation instruction PrimorSignal/PrimorSignal Plus.

21

Installation instructions Primor

14 Functional test (when the door is open)

• Connect the power supply: connect the battery 9V block with the battery clip in the input unit or switch on the external power

supply.

• Enter the factory code:

Lock Primor 100:

1 – 2 – 3 – 4 – 5 – 6

Lock Primor 1000/2000/3000/3010/3011:

Level 5: 1 – 2 – 3 – 4 – 5 – 6

Level 15: 1 – 2 – 3 – 4 – 5 – 6 – 7

Re-enter the factory code when the power was switched off.

Primor 100/2000:

• Turn the input unit (Primor RO) or the opening lever (Primor RE) within 3 seconds into opening position. The lock is opened.

• Turn the handle into opening position.

• Closing shall be performed in reverse order.

Primor 1000:

• Within 3 seconds turn the boltwork’s handle into the opening position. The bolt swings in (has to happen easily). The lock is

opened.

• Turn the boltwork’s handle into the locking position. The swing bolt automatically folds out and locks. The lock is closed.

Primor 3000/3010/3011:

• The lock’s bolt opens automatically (has to happen easily). The lock is opened.

Turn the handle within 3 seconds into opening position.

• Turn the handle into locking position. The lock’s bolt closes automatically and blocks. The lock is closed.

15 Testing the system (programme 5)

Press every number once. A functional key will be confirmed by a double signal. A key that was not identified is confirmed by a long signal and the functional test is aborted. The system has to be checked.

1. Press and hold the key “5“ until the red LEDs flash permanently.

2. Press every key in its order of appearance.

5

123.......90

22

Installation instructions Primor

23

Installation instructions Primor

24

Loading...

Loading...