Wittco 200-2R-BI-C-NA User Manual

INSTALLATION &

OPERATION MANUAL

DRAWER WARMER

NA

MODEL:

200-2R-BI-C-NA

(Unit Weight: 111 lbs. / 50.3488 kg )

CAUTION: Read the instructions before using the machine.

For additional information on WITTCO or to locate an authorized parts

and service provider in your area, visit our website at www.wittco.com

WITTCO FOOD SERVICE EQUIPMENT 7737 NORTH 81 STREET

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC MILWAUKEE, WI 53223

www.wittco.com © 2014 Wittco Foodservice Equipment F-41215 (02-14)

NA DRAWER WARMER F-41215 (02-14)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITYOF THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment,

alteration, service, or maintenance can

cause property damage, injury, or death.

Read the installation, operating and

maintenance instructions thoroughly

before installing or servicing equipment.

IN THE EVENT OF A POWER FAILURE,

DO NOT ATTEMPT TO OPERATE THIS DEVICE.

1

NA DRAWER WARMER F-41215 (02-14)

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

STAINLESS STEEL CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SERVICE & PARTS INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2

NA DRAWER WARMER F-4121 5 (02-14)

GENERAL

INTRODUCTION

WITTCO Drawer Warmers are produced

with quality workmanship and material.

Proper installation, usage, and

maintenance of your warmer will result

in many years of satisfactory

performance.

INSTALLATION

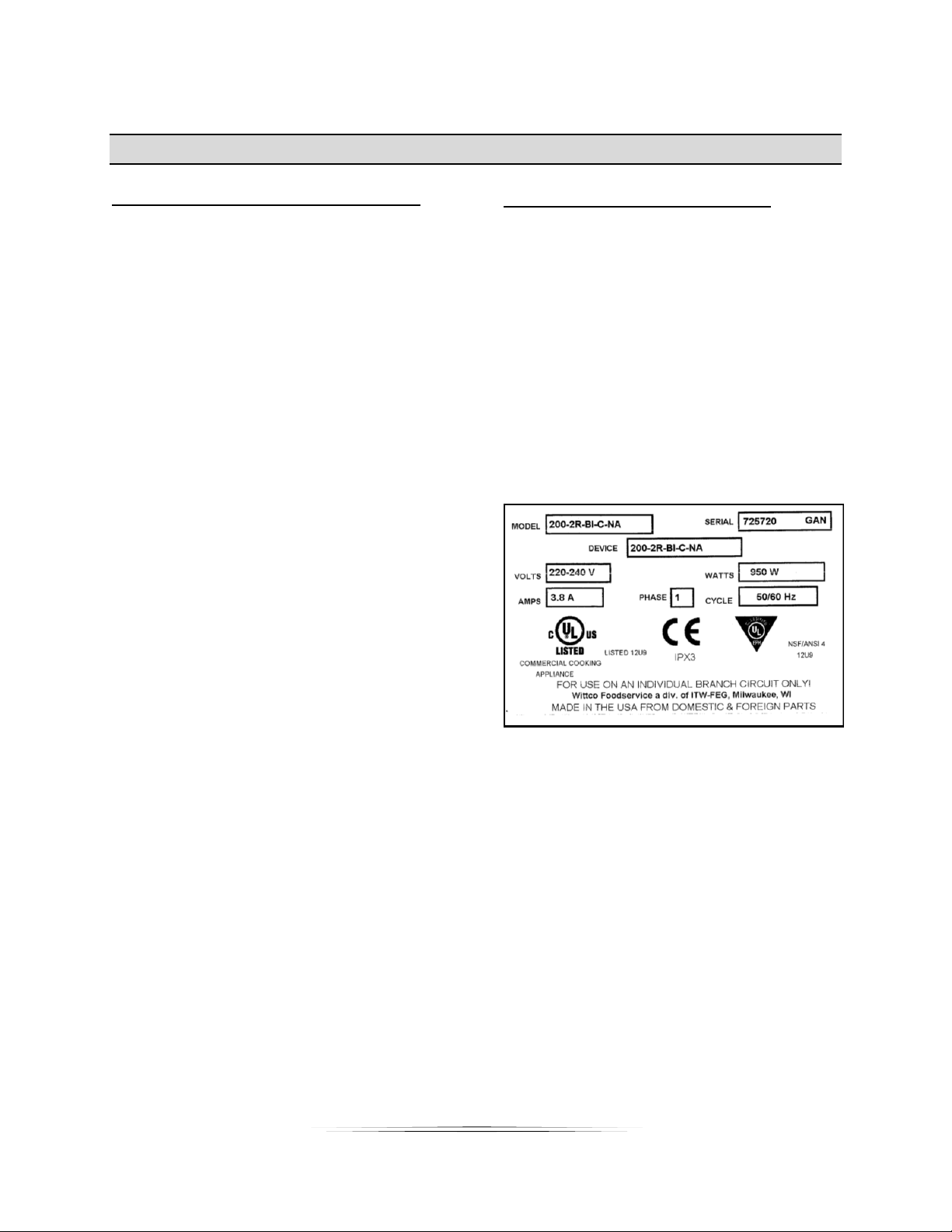

Before installing, verify that the electrical

service agrees with the specifications on

the rating plate located on the lower

back corner of the warmer. If the supply

and equipment requirements do not

agree, do not proceed with unpacking

and installation. Contact your WITTCO

Customer Service Department

immediately.

UNPACKING:

The Warmer was inspected before

leaving the factory. The transportation

company assumes full responsibility for

safe delivery upon acceptance of the

shipment. Immediately after unpacking,

check for possible shipping damage to

the warmer.

If the warmer is found to be damaged, save

the packaging material and contact the

carrier within 15 days of delivery.

Carefully unpack warmer and place in a

work accessible area.

1. Remove banding holding the

carton to the pallet.

2. Carefully remove warmer from

carton and place on floor or table.

3. Remove legs from drawer of

warmer.

It is suggested that you thoroughly read

this entire manual and carefully follow all

of the instructions provided.

The WITTCO Drawer Warmers provide

an efficient means of holding a variety of

prepared hot food products at proper

temperatures until serving.

4. Secure legs to the bottom of

warmer by screwing legs into the

holes provided.

5. Remove any and all packaging

materials in drawers.

6. Peel off vinyl protection film.

7. Thoroughly clean the warmer as

described in the cleaning instruct-

ions.

8. Connect Equipotential bonding

conductor that is located

in the rear of the unit.

CLEANING:

The warmer should be thoroughly

cleaned prior to putting into service.

Use a mild soap and water solution to

clean the interior drawer inserts of the

unit. Never use harsh chemicals or

abrasive pads to clean the unit.

LOCATION:

For efficient warmer operation, choose a

location that will provide easy loading

and unloading without interfering with

the final assembly of food orders.

The installation location must allow

adequate clearances for servicing and

proper operation.

3

NA DRAWER WARMER F-4121 5 (02-14)

ELECTRICAL REQUIREMENTS

ELECTRICAL CODES & STANDARDS:

The warmer must be installed in

accordance with:

In the United States of America:

1. State and Local Codes.

2. National Electrical Code, ANSI/

NFPA-70 (latest edition.) Copies

may be obtained from: The

National Fire Protection

Association, Batterymarch Park,

Quincy, MA 02269.

In Canada:

1. Local Codes.

2. Canadian Electrical Code, CSA

C22.1 (latest edition.) Copies

may be obtained from: The

Canadian Standard Association,

178 Rexcale Blvd., Etobicoke,

Ontario, Canada M9W 1R3.

In United Kingdom:

1. Local codes.

ELECTRICAL CONNECTIONS:

The warmer is factory wired for

220–240 V, single phase operation.

Refer to wiring diagram in the back of

this manual

Verify that the power source matches

the Serial Data Plate located on the

lower back corner of the warmer and

the plug configuration before the

connection is made.

.

(Fig. 1)

SERIAL DATA PLATE

Fig. 1

4

NA DRAWER WARMER F-41215 (02-14)

OPERATION

CONTROLS

The Warmer and its

parts are hot. Be very careful when

operating, cleaning, or servicing the

warmer.

HEATING INDICATOR LIGHT:

The Drawer Warmer Control Panel

contains a Heating Indicator Light. The

Heating Indicator Light lights up when

the heating elements are engaged.

When the drawer warmer reaches

factory set temperature, this light will go

out.

(Fig.2)

LIGHTED SWITCH:

The lighted switch energizes the unit.

(Fig. 2)

Fig. 2

.

OPERATING INSTRUCTIONS

The Warmer and its

parts are hot. Be very careful when

operating, cleaning, or servicing the

warmer.

Once the drawer warmer has been

connected to the appropriate power

source, the warmer is ready for

operation.

The warmer has two drawers. Each

drawer has a Heating Indicator light and

a lighted switch.

The operator should always monitor the food product to insure that it remains at

proper temperatures.

Push the Lighted Switch to the ON

position. This will cause the heating

element to start heating. When this

occurs, the Heating Indicator Light will

illuminate. This light will stay on as long

as the heating element is engaged.

Once the factory set temperature is

achieved, the heating element will begin

to cycle. During this period, the

Heating Indicator Light will turn on and

off as the heating elements cycle

.

5

Loading...

Loading...