Operating Instructions

Vacuum based lifting device

for prefabricated glass and cladding elements

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Serial no.: A 810 772

Technical documentation

BA 000 101

07/2016

The present technical documentation corresponds to the status as per the date of issue.

WIRTH GMBH

INSTALLATION SYSTEMS DIVISION

Brehnaer Straße 1

D-06188 Landsberg

Phone: +49 (0) 34 602 / 70 88 - 0

Fax +49 (0) 34 602 / 70 88 - 111

www.wirth-gmbh.com

Original instructions

Proprietary notice as per ISO 16016

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 2 of 27

Page

Table of Contents 2

1 General information regarding the OKTOPUS® 4

1.1 Manufacturer’s information 4

1.2 Service workshop 4

1.3 Scope of application 4

2 Proper use of the OKTOPUS

®

5

2.1 Mode of operation and safety concept of the OKTOPUS

®

system 5

2.2 Safety instructions 6

2.3 Symbols and markings 7

2.4 Design and application of the OKTOPUS

®

8

2.5 Conditions and restrictions of application 11

2.6 Transport and storage 12

3 Instructions for use of the OKTOPUS® 13

3.1 Power supply 13

3.2 Vacuum supply 14

3.3 Control panel/switch 15

3.4 Start-up 15

3.5 Handling of glass and cladding elements 16

3.5.1 Handling of lying glass and cladding elements 16

3.5.2 Handling of glass and cladding elements standing upright 17

3.5.3 Rotating a load hanging in a vertical position with

the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with a crane arm 18

3.5.4 Rotating a load hanging in a vertical position with

the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring 18

3.5.5 Swivelling a load hanging in a vertical position with

the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with crane arm 19

3.5.6 OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 slung to the basic frame 20

3.6 Converting the OKTOPUS

®

into its different versions 20

3.6.1 Assembly of the guide ring 20

3.6.2 Mounting of the crane arm 21

3.6.3 Mounting of the extension arms (4 suction pads) 21

3.6.4 Mounting of the extension arms (6 resp. 8 suction pads) 22

4 Servicing and Maintenance 23

4.1 General 23

4.2 Mechanical components 23

4.3 Vacuum system 24

4.3.1 Cleaning the suction pads 24

4.4 Electrics and electrical components 25

5 Conduct in the event of hazardous incidents 27

6 Disposal and Recycling 27

Annex 1: Short summary of operating instructions

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800

Annex 2: Functional dimensions

Annex 3: EC Declaration of conformity

Annex 4: Test badge pursuant to the directive 2006/42/EU

Annex 5: Electrical Circuit Diagram

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 3 of 27

Page

Table of Figures

3

Fig. 1: OKTOPUS® GLASS-Jack GL-RN 400 with crane arm 8

Fig. 2: OKTOPUS

®

GLASS-Jack GL-RN 400 with crane arm and extensions 9

Fig. 3: OKTOPUS® GLASS-Jack GL-RN 600 with crane arm and extensions 9

Fig. 4: OKTOPUS

®

GLASS-Jack GL-RN 800 with crane arm and extensions 9

Fig. 5: OKTOPUS® GLASS-Jack GL-RN 400/600/800 with guide ring 9

Fig. 6: Load lifting attachment OKTOPUS® GLASS-Jack GL-RN 400/600/800 10

Fig. 7: Transport rack 12

Fig. 8: Charge indicator 13

Fig. 9: Vacuum gauge 14

Fig. 10: Control panel 15

Fig. 11: OKTOPUS

®

GLASS-Jack GL-RN 400 and 800 with glass element 17

Fig. 12: OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring resp. crane arm 18

Fig. 13: OKTOPUS® GLASS-Jack GL-RN 400/600/800 with guide ring, with crane arm,

and with crane arm and extension arms (6 or 8 suction pads respectively) 19

Fig. 14: OKTOPUS

®

GLASS-Jack GL-RN 800 during swivelling 19

Fig. 15: Guide ring mounting 20

Fig. 16: Mounting of the extensions (4 suction pads) 21

Fig. 17: Mounting of the extension arms (ex. 8 suction pads) 22

Fig. 18: Suction pad 24

Fig. 19: Battery charger (sample) 25

Fig. 20: Warning devices 27

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 4 of 27

1 General information regarding the OKTOPUS®

1.1 Manufacturer’s information

Manufacturer’s name and registered office:

WIRTH GMBH

Installation Systems Division

Brehnaer Straße 1

D-06188 Landsberg

Germany

Device characteristics:

Product description: OKTOPUS

®

GLASS-Jack GL-RN 400/600/800

Type: OKTOPUS® GLASS-Jack GL-RN 400/600/800 R M B24 P 110

Serial number: (see type plate)

Year of manufacture: (see type plate)

Weight:

approx. 55 kg (basic unit, crane arm, 4 suction pads)

approx. 60 kg (basic unit, crane arm, 4 suction pads, 4 extensions)

approx. 70 kg (basic unit, crane arm, 6 suction pads, 4 extensions)

approx. 80 kg (basic unit, crane arm, 8 suction pads, 4 extensions)

approx. 60 kg (basic unit, guide ring, 4 suction pads)

Working Load Limit: max. 300 kg (guide ring, 4 suction pads ∅ 400 mm)

max. 400 kg (crane arm, 4 suction pads ∅ 400 mm)

max. 600 kg (crane arm, 6 suction pads ∅ 400 mm)

max. 800 kg (crane arm, 8 suction pads ∅ 400 mm)

CE mark: pursuant to EC Declaration of conformity Annex 3

Test badge as per Annex 4 on the unit.

1.2 Service workshop

WIRTH GMBH Telefon: +49 (0) 34 602 / 70 88 - 0

Brehnaer Str. 1 Fax-Nr.: +49 (0) 34 602 / 70 88 - 111

D-06188 Landsberg E-Mail:

info@wirth-gmbh.com

1.3 Scope of application

The operating instructions on hand represent the state-of-the-art and the safety measures defined by the European Machinery Directive valid at the editing date of the manual.

Diverging or amending national regulations may not be considered eventually.

The user is exclusively responsible to observe such regulations.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 5 of 27

2 Proper use of the OKTOPUS®

2.1 Mode of operation and safety concept of the OKTOPUS® system

The devices of the OKTOPUS® system are „Load lifting attachments“ following the principle

of a „Vacuum lifter“. They are installed to a hoist or work as a stand-alone unit, and are used

for handling and positioning large-size construction elements.

The basic functions of the OKTOPUS

®

system comprise:

⇒ Controlled suction and release of large-size construction elements having sufficient inherent

stability by use of one or more vacuum suction pads of the OKTOPUS

®

,

⇒ transport and positioning of the sucked construction elements by manipulating the OK-

TOPUS,

⇒ fine positioning of the construction elements using the control of the OKTOPUS

®

-axes (if

available).

The OKTOPUS

®

system is offered in various types of design and models for different fields of

application. These differ depending on the used hoist, the loads to be lifted, the necessary positioning movements and the used controls.

For further information please do not hesitate to contact us (

www.wirth-gmbh.com).

Specific safety requirements, which have been taken into account during construction, execution, technical documentation and in drawing up the operating instructions for the OKTOPUS

®

system, arise due to the special function of the OKTOPUS system as a “load lifting attachment”.

Therefore, strict compliance with the instructions and information for proper and safe use of the

device given in the operating instructions is a prerequisite for the manufacturer’s warranties during the agreed warranty period.

The OKTOPUS

®

user is responsible for combining the OKTOPUS® system to a hoist. The user

himself is responsible for proper implementation of the relevant guidelines and instructions. The

information provided by the manufacturer of the OKTOPUS

®

system through these operating in-

structions shall be considered as an additional support for the user.

Before initial start-up of the system, skilled staff shall check at the user’s premises, whether the

combination of OKTOPUS

®

system / crane or hoist is suitable for use.

Moreover, the OKTOPUS® shall be subject to tests by an expert at regular intervals (please refer to pt. 4.1). Experts are persons who have sufficient knowledge in the field of load lifting attachments on account of their education and experience in the concerned subject and who are

being highly acquainted with the relevant safety-at-work instructions and safety precautions,

guidelines and generally accepted engineering standards, so that they can evaluate the state of

the load lifting attachments as being safe for operation.

Initial testing of the crane or lifting device/OKTOPUS

®

combination as well as the successful

completion of the annual test of the OKTOPUS® system by an expert shall be documented.

The manufacturer of the OKTOPUS® system offers expert testing as a service and documents

testing of the OKTOPUS® by placing the test badge on the test card in accordance with Annex 4

together with the indication of the date for the next test.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 6 of 27

2.2 Safety instructions

(1) Only employ cranes with a Working Load Limit that exceeds the live weight of the

OKTOPUS® GLASS-Jack GL-RN 400/600/800 in all working positions by at least 90 kg!

(2) Never use a damaged, not fully functioning or incomplete OKTOPUS

®

!

(3) Have your combination crane/OKTOPUS

®

tested and documented by an expert prior to

initial start-up!

(4) Operate the crane with an operating license only!

(5) Only operate the OKTOPUS

®

and the crane, if you are familiar with the operating and

display elements as well as with the operating instructions. You shall be aware of the

impact of a function on the entire unit!

(6) Before operating the OKTOPUS

®

and the crane, test the function of the operating and

display elements as well as the alarm unit!

(7) Make sure that the crane operator has a sufficient view over the sling and assembly site!

(8) Arrange hand signals with the installer and fitter for the necessary crane operations!

(9) It is absolutely necessary to observe the maximum Working Load Limit of the OKTOPUS

®

GLASS-Jack GL-RN 400/ 600/800 stipulated in section 2.3 Symbols and markings!

These specifications only apply to a working height up to 400m above sea level!

(10) If there are any protection hoods on the suction pads, remove them before initial start-up!

(11) Only work in wind strengths less than 30 km/h, otherwise the load will be endangered

by swinging uncontrollably!

(12) Check the suction pads daily for damage; if necessary replace with new pads

(13) Clean the suction surfaces on the elements. Do not place the suction pads on protective

film, instead, remove the film before – at least at the contact areas of the suction pads

(14) Never stand or walk under the suspended load!

(15) Ensure that nobody attempts to mount or ride on the OKTOPUS® GLASS-Jack GL-RN

400/600/800 or the suspended construction elements.

(16) Stop work immediately when the acoustic alarm sounds and/or the warning light

flashes up! In this case, danger of severe damage to the system exists, and the sucked

load might drop down. Carefully put down the OKTOPUS® together with the sucked load

by the used hoist until the load is rested safely. Find and remove the cause for the alarm.

If the defects cannot be removed, finish working with the OKTOPUS

®

immediately. The

OKTOPUS

®

has to be secured against further use!

(17) In the event of faults and during servicing and maintenance work, always switch off the

OKTOPUS

®

. Therefore, turn the main switch to the OFF position!

(18) Please note that low temperatures and humidity can cause freezing of the vacuum

system!

(19) Never use the OKTOPUS® within highly explosive ranges or within the range of ag-

gressive substances!

(20) Never attempt to lift damaged glass or cladding elements!

(21) Do not lift the load higher than necessary!

(22) Wet components must not be sucked, because

a. this reduces the safe work load capacity considerably and

b. the vacuum system and/ or the control system of the OKTOPUS

®

might be damaged!

(23) Protect the suction pads of the OKTOPUS

®

against damage by using protection hoods af-

ter use!

(24) Always wear suitable protection clothes, helmets, gloves and industrial safety shoes!

(25) Never leave a lifted load unsupervised!

(26) Never lift more than one glass or cladding element at the same time!

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 7 of 27

(27) Always stick to the prescribed maintenance instructions:

• daily visual and functional test (charge level of the battery, vacuum gauges, suction

cups, warning light, signal light, acoustic alarm, manual control)!

• depending on the operating conditions, at least annually, inspection by a qualified ex-

pert !

(28) Never modify the OKTOPUS

®

in such a way, that its safety is impaired. Otherwise the

manufacturer's warranty is rescinded!

(29) Never remove information signs, safety signs and test card (with test badge) from

the OKTOPUS

®

! Otherwise the manufacturer's warranty is rescinded!

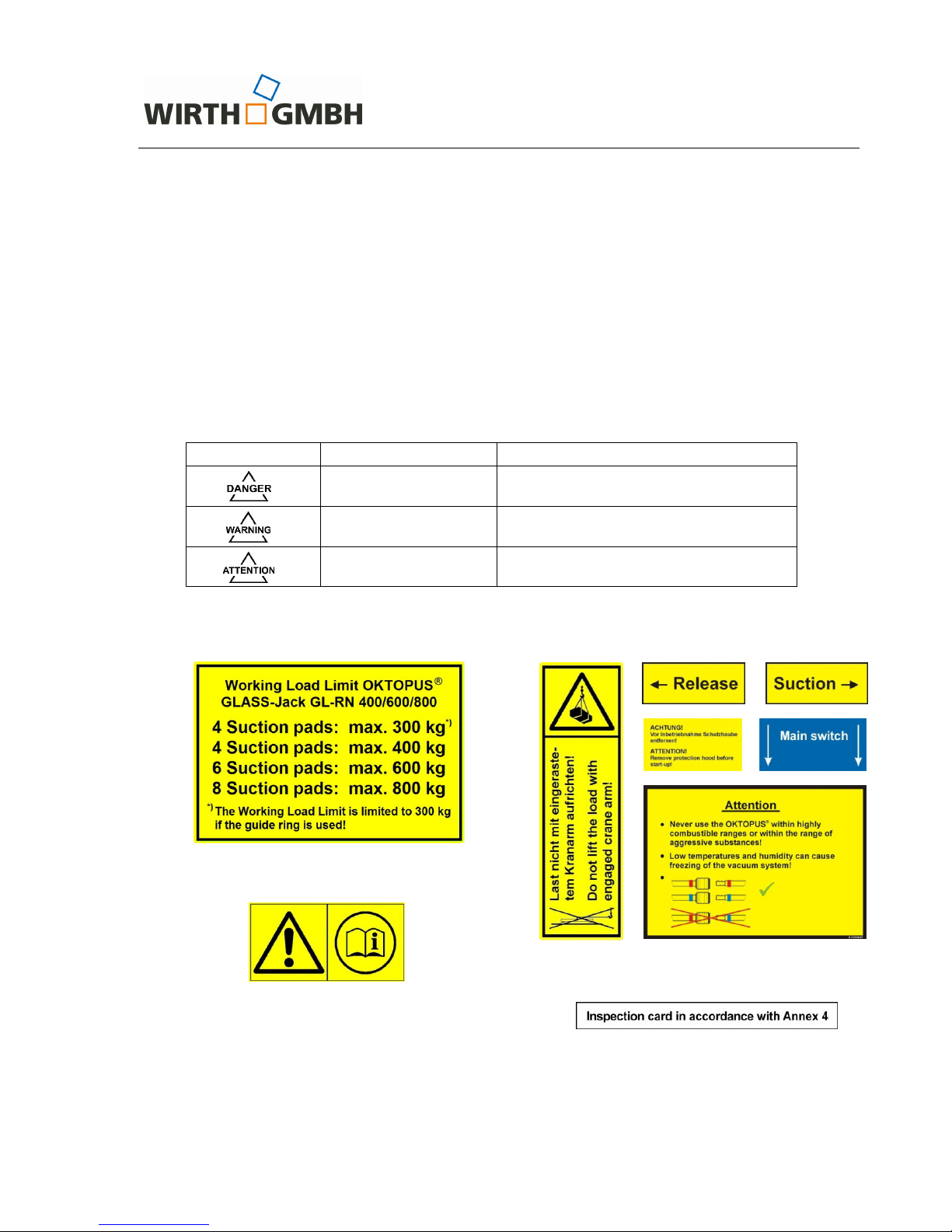

2.3 Symbols and markings

Signal word Meaning Consequences of non-compliance

Warns of imminent

threat of danger

Death or serious injury or substantial

material damage as consequence.

Warns of potential

threat of danger

Death or serious injury or substantial

material damages are possible.

Warns of possibly

dangerous situation

Light injury or material damages are

possible.

Next to the type plate the following safety-related signs and pictographs are attached to the

OKTOPUS®:

(Inspection card)

(Working Load Limit OKTOPUS

®

)

(Before operating, r

ead and comply

with operating manual as well as

safety instruction!)

(Warning signs / General information)

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 8 of 27

2.4 Design and application of the OKTOPUS®

The OKTOPUS® GLASS-Jack GL-RN 400/600/800 is a load lifting attachment of modular design for large glass and cladding elements of sufficient inherent stability with a surface that is, at

least on one side, partially smooth and airtight. It is designed for wall and roof assemblies on

building sites.

The OKTOPUS

®

is equipped with a load lifting eye to be hooked into a lifting device provided by

the customer. The basic frame can be rotated manually by 360° and swivelled by 90°.

By dismounting the crane arm the overall height of OKTOPUS

®

is minimized to 140 mm only.

The low overall height allows - in combination with the guide ring optionally available - the installation of elements weighing up to 300 kg in clearances of normally max 300 mm only between

the building front and the scaffolding in front of it. The arrangement of the guide ring allows rotating the lifting attachment with the sucked load by 360°.

Depending on the load class the following OKTOPUS

®

models are distinguished:

Max. Working Load Limit 400 kg: OKTOPUS

®

GLASS-Jack GL-RN 400

(4 suction pads on the unit)

Max. Working Load Limit 600 kg: OKTOPUS® GLASS-Jack GL-RN 600

(6 suction pads on the unit)

Max. Working Load Limit 800 kg: OKTOPUS

®

GLASS-Jack GL-RN 800

(8 suction pads on the unit)

Each of the models mentioned above can be equipped with a guide ring. In case of using the

guide ring, the Working Load Limit of the OKTOPUS® is limited to 300 kg.

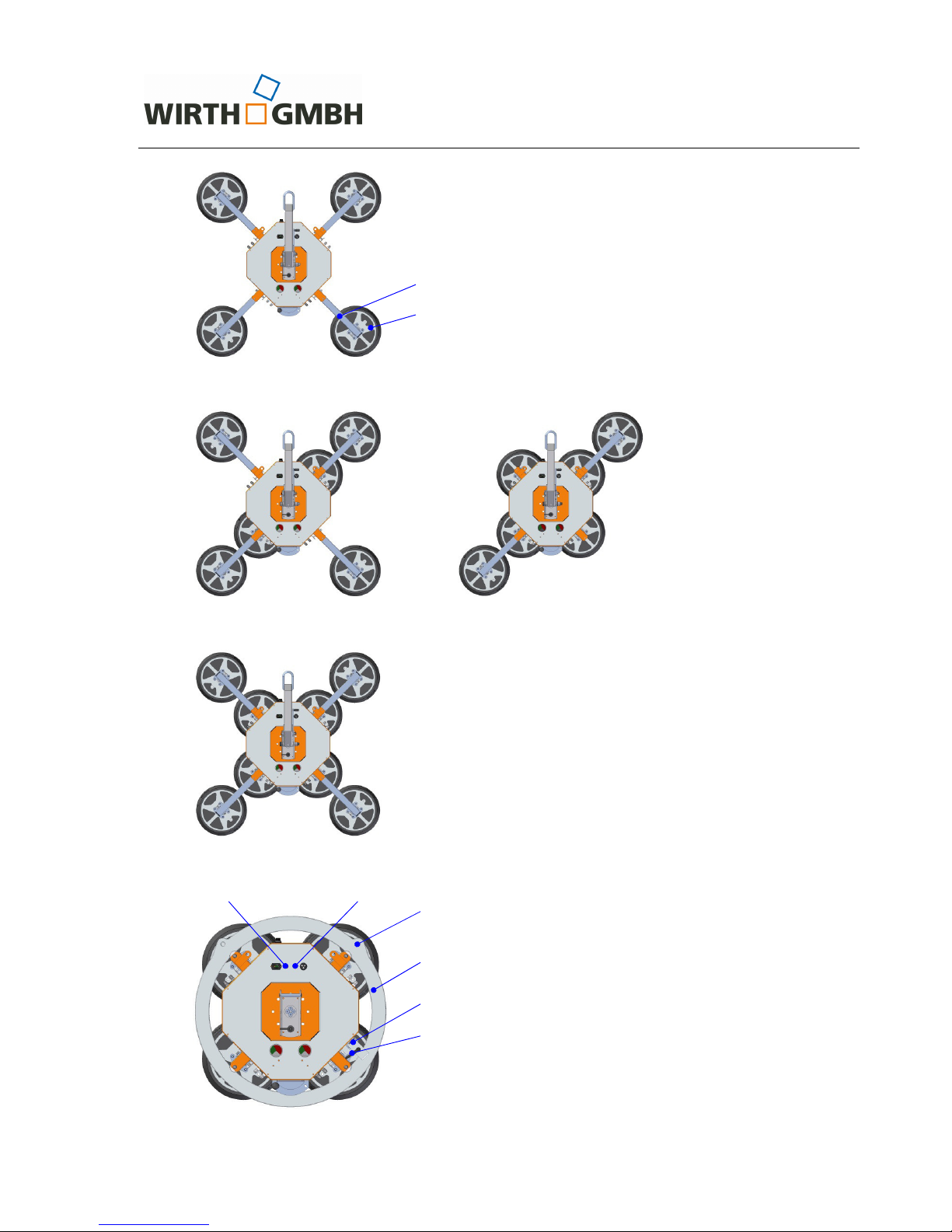

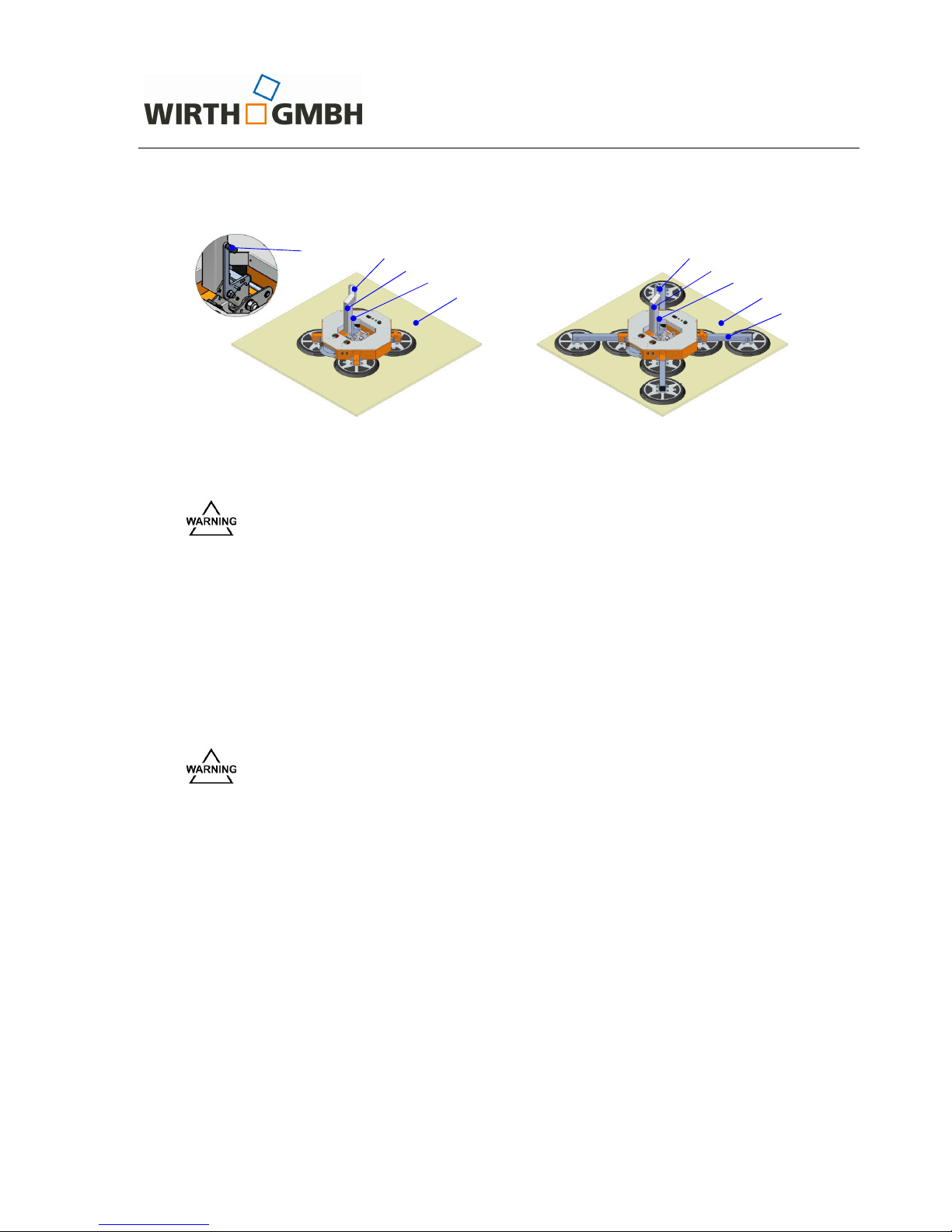

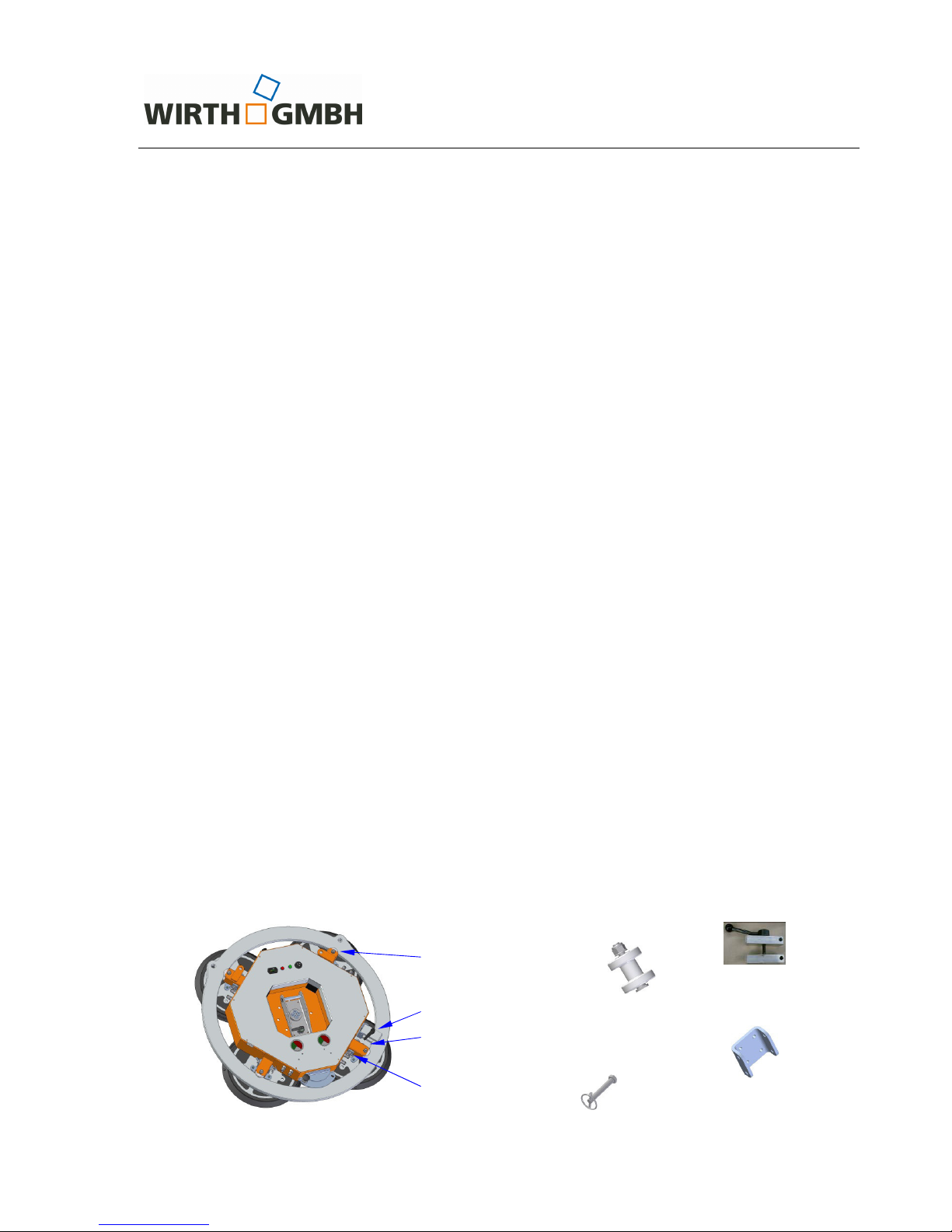

The functional main groups of components are (see fig. 1 to 5):

− the crane eyes (1, 12, 19) to connect the OKTOPUS

®

to the crane,

− the red signal light (17) indicating hazardous situations and the green signal light (18) defin-

ing the working area,

− the vacuum gauge (7) indicating the vacuum level,

− the basic frame (5) and the extension arms (17) with the suction pads fixed thereto (8),

− the charge indicator (11) permanently showing the actual charge of battery,

− the main switch (10) for switching on and the switch „Suction/Release“ (15) to operate the

OKTOPUS®.

Fig. 1: OKTOPUS

®

GLASS-Jack GL-RN 400 with crane arm

1 Crane eye of the crane arm

2 Crane arm

3 Release „Swivelling“

4 Alarm buzzer

5 Basic frame

6 Swivel joint

7 Vacuum gauge

8 Suction pad

9 Cover sheet

10 Main switch

11 Charge indicator

12 Crane eye basic frame

13 Release „Rotating“

14 Battery charge socket

15 Switch „Suction/Release“

16 Button “Blow-off“ (optional)

1

2

3

4

6

7

8

9

11

10

12

13

14

15

5

16

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 9 of 27

Fig. 2: OKTOPUS

®

GLASS-Jack GL-RN 400 with crane arm and extensions

Fig. 3: OKTOPUS

®

GLASS-Jack GL-RN 600 with crane arm and extensions

Fig. 4: OKTOPUS

®

GLASS-Jack GL-RN 800 with crane arm and extensions

Fig. 5: OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring

17

8

17 Extension arm

18 Signal light red

19 Signal light green

20 Crane eye guide ring

21 Guide ring

22 Shoe brake

23 Locking lever guide ring

19 18

21

20

22

23

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 10 of 27

The load lifting attachment OKTOPUS® GLASS-Jack GL-RN 400/600/800 is designed as an attachment and is mounted to the crane as per fig. 6.

Fig. 6: Load lifting attachment OKTOPUS

®

GLASS-Jack GL-RN 400/600/800

Applying the load lifting attachment system OKTOPUS

®

will have the following effects on the in-

stallation of large-size glass and cladding elements:

• rapid, efficient and effective assembling procedure,

• small-sized assembly team,

• high process quality through material-preserving handling,

• low physical stress for the assembler as heavy carrying and lifting works is avoided,

• high occupational safety.

Crane arm

Lifting device

Suction pad

OKTOPUS® GLASS-Jack GL-RN 400/600/800 OKTOPUS® GLASS-Jack GL-RN 400/600/800

with crane arm

slung at the basic frame

Lifting device

Lifting device

Guide ring

OKTOPUS® GLASS-Jack GL-RN 400/600/800

with guide ring

Glass/cladding

element

Suction pad

Glass/cladding

element

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 11 of 27

2.5 Conditions and restrictions of application

The glass and cladding elements to be processed with the OKTOPUS® GL-RN 400/600/800

have to fulfil the following criteria in the suction areas:

•

they have to be airtight,

• they must have a smooth, dry, oil-free and clean surface and

• they must not be equipped with a protective plastic film.

The OKTOPUS® shall be delivered with suction pads for smooth glass and cladding elements.

Generally, no statements can be made on the length and the width of the elements to be in-

stalled with the OKTOPUS

®

, as this depends - upon observing of the safe work load criteria almost exclusively on the inherent rigidity and the deformation behaviour of the construction elements connected thereto.

The suction of oil, water, vapours or aggressive gases shall be avoided. The ambient temperature shall be min 0 °C and may be max 40 °C (valid for 1013 mbar and sea level). At low temperatures the capacity of the batteries in use is reduced. The airborne sound deriving from the

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 is < 70 dB(A), vibrations are at < 2.5 m/s2, so

that no special protective measures are required.

Limitations of application arise from the limited Working Load Limit of the OKTOPUS® GLASS-

Jack GL-RN 400/600/800 (see section 2.3 Symbols and markings) as well as from the capacity

data, the conditions of application of the crane to be used and the building site conditions. Furthermore, it shall be taken into account that the element to be installed should be of sufficiently

inherent stability and appropriate for mounting by vacuum lifting attachments (to be clarified with

the elements‘ manufacturer if so).

Due to the large number of the elements existing in the market and their surface coatings, we

cannot take over liability in case of possible material incompatibilities between suction pad and

surface coating.

The maximum Working Load Limit stipulated on the OKTOPUS® only applies to the use of the

original suction pads and a working height of maximum 400 m above sea level. Employing the

OKTOPUS

®

in heights above 400 m leads to a decreased Working Load Limit of the OKTOPUS® on the one hand, on the other hand the OKTOPUS® control system needs to be adjusted. If you want to employ the OKTOPUS

®

in heights above 400 m, please contact the Wirth

Service Team beforehand.

Employing the OKTOPUS

®

at heights above 400 m leads to a decreased Work-

ing Load Limit! The Working Load Limits stipulated on the OKTOPUS

®

and in

this operating manual do not apply in this case!

Never carry out unauthorized adjustments at the control system of the OK-

TOPUS® as it may lead to serious malfunctions of the device! It means danger

to life and limb! Consult with the OKTOPUS

®

manufacturer if it is necessary to

adjust the control system of the OKTOPUS®, e.g. for height adjustment.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 12 of 27

2.6 Transport and storage

The OKTOPUS® may be moved only by a suitable lifting device/means of transport of appropriate Working Load Limit.

Shut down the OKTOPUS

®

for transport! Turn the main switch to the OFF po-

sition!

Protect the rubber lip of the suction pad from pollution and damage by protec-

tion covers!

To avoid damage to the batteries by deep discharge during storage, the OK-

TOPUS

®

shall be charged every two weeks at least.

Transport rack

The transport rack shown in figure 7 is optionally available. It allows:

⇒ space-saving storage of the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 and

⇒ protecting the suction pads, especially the rubber lip during transport and storage.

Fig. 7: Transport rack

Always completely secure the OKTOPUS

in the transport rack using the

screws, washers and locking bolts with lynch pins provided in the delivery!

Locking bolt with

lynch pin

Screw M16,

washer

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 13 of 27

3 Instructions for use of the OKTOPUS®

3.1 Power supply

The electrical power is provided by a battery 24 V / 7 Ah (two 12-V batteries in series connection).

The charge level is controlled by a charge indicator according to fig. 8. After switching on the

OKTOPUS

®

, light-emitting diodes (LED) in the signal colours green, yellow and red indicate the

current charging level.

The charge indicator shows the following charging status:

⇒ If one of the green LED lights up, the battery is charged. Now you can work with the OK-

TOPUS

®

.

⇒ If the third LED from the left (yellow LED) lights up, the battery should be charged.

⇒ If the second LED from the left (yellow LED) lights up or if the second LED from the left

and the red LED are alternately flashing, the battery shall be charged immediately to avoid

a deep discharge and damages.

The charge indicator is arranged according to fig. 1.

Fig. 8: Charge indicator

Do not use the OKTOPUS

®

, if the yellow LED flashes or the yellow and the red

LED are flashing alternately. An eventually sucked load should be lowered.

The OKTOPUS

®

should be immediately charged to avoid a deep discharge and

damages.

The user shall ensure that the battery of the OKTOPUS® is sufficiently charged

while operating the OKTOPUS®.

The charge indicator only shows the current voltage level of the battery that

shall not be considered as a reliable qualitative indication in terms of the batteries’ capacity.

The charge indicator reacts/responds slowly. To judge the actual voltage level

after charging (see point 4.4), the vacuum pump of the attachment needs to

run for approx. 2 minutes. The indicated charging level of the batteries allows

you to decide about the use of the attachment.

If this green LED lights up, the

battery is fully charged.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 14 of 27

3.2 Vacuum supply

The vacuum supply is provided by a vacuum pump, which is powered by electricity and supplied

by the battery. Starting from the vacuum pump, the OKTOPUS® GLASS-Jack GL-RN

400/600/800 is developed as a dual circuit system. That means, all the following vacuum modules, like non-return valve, vacuum reservoir, pressure controller, vacuum gauge and suction

pads exist twice (2 vacuum circles).

At the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 the 2 vacuum circles are marked by different colours, one colour per vacuum circuit (usually blue and red). Please note, that only vacuum hoses and vacuum hose couplings of the same colour shall be interconnected.

Mounted to the crane, the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 is ready for operation

as soon as sufficient vacuum is provided in both vacuum reservoirs. The current vacuum level is

constantly indicated via two vacuum gauges (fig. 9).

The green scale sector is the

permissible working range from -0.65 bar to -0.9 bar

Fig. 9: Vacuum gauge

During operation the vacuum is monitored by two pressure control devices. If the vacuum is in

both vacuum circles in the working area, the green signal light shines. The OKTOPUS® is ready

for use. If the vacuum descends in one or both vacuum circles below the prescribed level (pressure exceeding the -0.65 bar mark = red sector), an alarm is automatically activated:

⇒ the acoustic alarm sounds,

⇒ the red warning light flashes up.

Only interconnect vacuum hoses and couplings of the same color! Non-

compliance with these instructions could, in case of a breakdown of a vacuum

circuit, lead to the load suddenly dropping due to uneven load distribution.

If the alarm is activated, stop working instantly and evacuate the hazard zone,

as the sucked element could disengage suddenly. Never stand or walk under

the OKTOPUS

®

or the suctioned element!

The alarm remains active until the vacuum pressure is restored within its

permitted limits.

Green

sector

The OKTOPUS®

may only be operated

within this range.

Red

sector

The OKTOPUS®

must not be operated in

this range.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 15 of 27

3.3 Control panel/switch

The OKTOPUS® GLASS-Jack GL-RN 400/600/800 is operated by a control panel according to

fig. 10.

Fig. 10: Control panel

3.4 Start-up

Proceed as follows to start the operation of the OKTOPUS®:

• Place the suction pads of the OKTOPUS

®

onto the element to be sucked!

• Turn the main switch to the "ON“ position.

• Slightly lift the switch SUCTION / RELEASE, and then push it towards SUCTION!

• Check the charge level of the battery on the charge indicator,

⇒ The operational readiness is indicated through the luminescence of a green LED.

⇒ If the second LED from the left (yellow LED) flashes or the second LED from the left

(yellow LED) and the red LED flash alternately, the battery needs to be charged!

• Check the vacuum on the vacuum gauges,

⇒ if the needle of both gauges are in the green range, the unit is ready for operation!

⇒ if one or both needles are in the red range, the alarm will be activated, and the vacuum

must be built up first.

− Vacuum is built up to -0.73 bar, the red warning light goes out and the green signal

light goes on.

• Slightly lift the switch SUCTION / RELEASE and slide it towards RELEASE.

Switch

Suction/Release

Release

Main switch

Suction

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 16 of 27

3.5 Handling of glass and cladding elements

First of all the OKTOPUS® GLASS-Jack GL-RN 400/600 /800 has to be coupled to the crane as

a load lifting attachment in order to get it ready for operation.

The assembly of the OKTOPUS

®

shall be carried out while the crane is immobile and the OK-

TOPUS

®

is switched off.

The assembly of the building elements is carried out as follows:

Make sure that the load is placed properly to the OKTOPUS®. Unbalanced

loads can tilt or turn unexpectedly.

3.5.1 Handling of lying glass and cladding elements

⇒ In order to suck a lying load, you need the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800

in the version with a crane arm or with a crane arm and extensions (see fig. 11, ex. OKTOPUS

®

GLASS-Jack GL-RN 400 and 800).

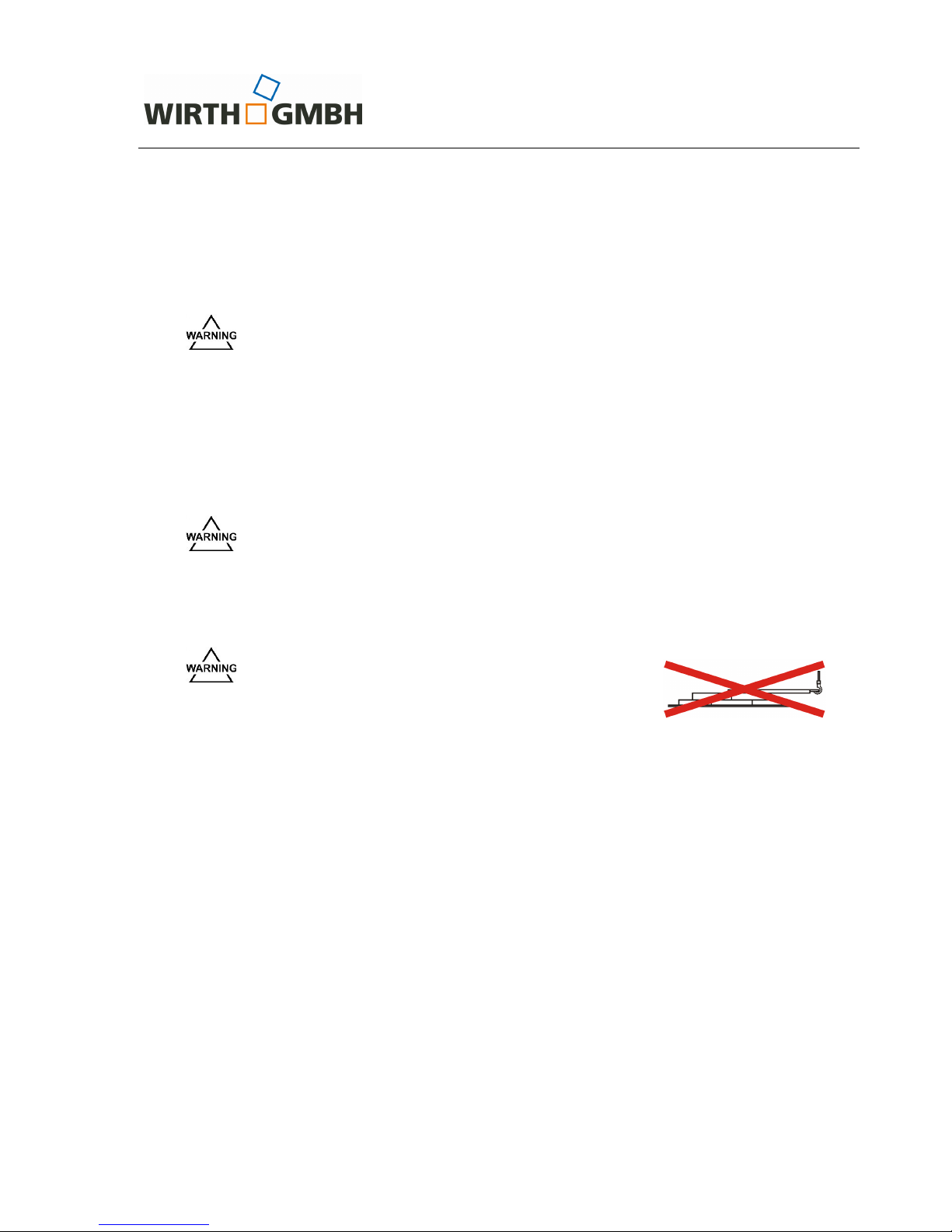

Never use the OKTOPUS

®

with a mounted guide ring for putting up or lifting a

horizontally lying load!

⇒ Unlock the release "Swivelling" (see fig. 11) and move the crane arm with the mounted

OKTOPUS® GLASS-Jack GL-RN 400/600/800 to the elements. Place the OKTOPUS® on

the topmost element.

Never attempt to lift a horizontally lying load

if the pivoting of the crane

arm is latched!

⇒ Place the OKTOPUS

®

above the centre of mass (±5 cm) of the load.

⇒ Slightly lift the switch SUCTION / RELEASE and push it towards SUCTION (see fig. 10)

until it snaps into place.

⇒ After the warning light and the buzzer have both gone out, the vacuum gauge indicates

that the working range has been reached (see fig. 9) and you have made sure, that no

one stays in the danger area, you can lift the load.

⇒ Only lift the load as high as necessary!

⇒ After the element has been placed at the assembly location, fasten it completely to avoid

any danger after release!

⇒ After that, the building element is detached. For release, again raise the switch SUCTION

/ RELEASE a bit and push it towards RELEASE. Raising the switch is an additional safety

feature against unintentional faulty operation.

If your OKTOPUS

®

is equipped with the optional blow-off function, subsequently press the

button “Blow-off“ (see fig. 1, pos. 16). Keep the button pressed until all suction pads have

completely disengaged from the load. In this case the suction pads are supplied with

compressed air which ensures that the suction pads are released quicker from the load.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 17 of 27

Fig. 11: OKTOPUS

®

GLASS-Jack GL-RN 400 and 800 with glass element

Due to the dead weight of the OKTOPUS

®

, a residual vacuum remains even after ventilating the suction pads by the evacuated system. Jerky rising of the

OKTOPUS

®

strengthens this effect. Therefore, take the equipment always

slowly and steadily off from the elements shifted.

3.5.2 Handling of glass and cladding elements standing upright

⇒ Move the crane with the attached OKTOPUS

®

GLASS-Jack GL-RN 400/600 /800 to the

elements. Place the OKTOPUS

®

onto the topmost element.

⇒ Position the OKTOPUS

®

onto or above the centre of mass of the load (max. ±5 cm)!

In order to avoid unintended load rotation, make sure that the sliding lever

„Rotation“ (see fig. 12) is locked. The sliding lever „Swivelling“ shall be released and the crane arm be vertical !

⇒ Slightly lift the switch SUCTION / RELEASE and push it towards SUCTION (see fig. 10)

until it snaps into place.

⇒ After the warning light and the buzzer have both gone out, the vacuum gauge indicates

that the working range has been reached (see fig. 9) and you have made sure, that no

one stays in the danger area, you can lift the load.

⇒ Only lift the load as high as necessary!

⇒ After the element has been placed at the assembly location, fasten it completely to avoid

any danger after release!

⇒ After that, the building element is detached. For release again raise the switch

SUCTION/RELEASE a bit and push it towards RELEASE. Raising the switch is an additional safety feature against unintentional faulty operation

If your OKTOPUS

®

is equipped with the optional blow-off function, subsequently press the

button “Blow-off“ (see fig. 1, pos. 16). Keep the button pressed until all suction pads have

completely disengaged from the load. In this case the suction pads are supplied with

compressed air which ensures that the suction pads are released quicker from the load.

1

OKTOPUS® GLASS-Jack GL-RN 400

with glass element

1 Crane eye 4 Glass element

2 Crane arm 5 Extension arm

3 Release „Swivelling“

OKTOPUS® GLASS-Jack GL-

RN 800 with

glass element and extension arms

2

3

4

1

2

3

4

5

3

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 18 of 27

Fig. 12: OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring resp. crane arm

Due to the dead weight of the OKTOPUS

®

, a residual vacuum remains even after ventilating the suction pads by the evacuated system. Jerky rising of the

OKTOPUS

®

strengthens this effect. Therefore, take the equipment always

slowly and steadily off from the elements shifted.

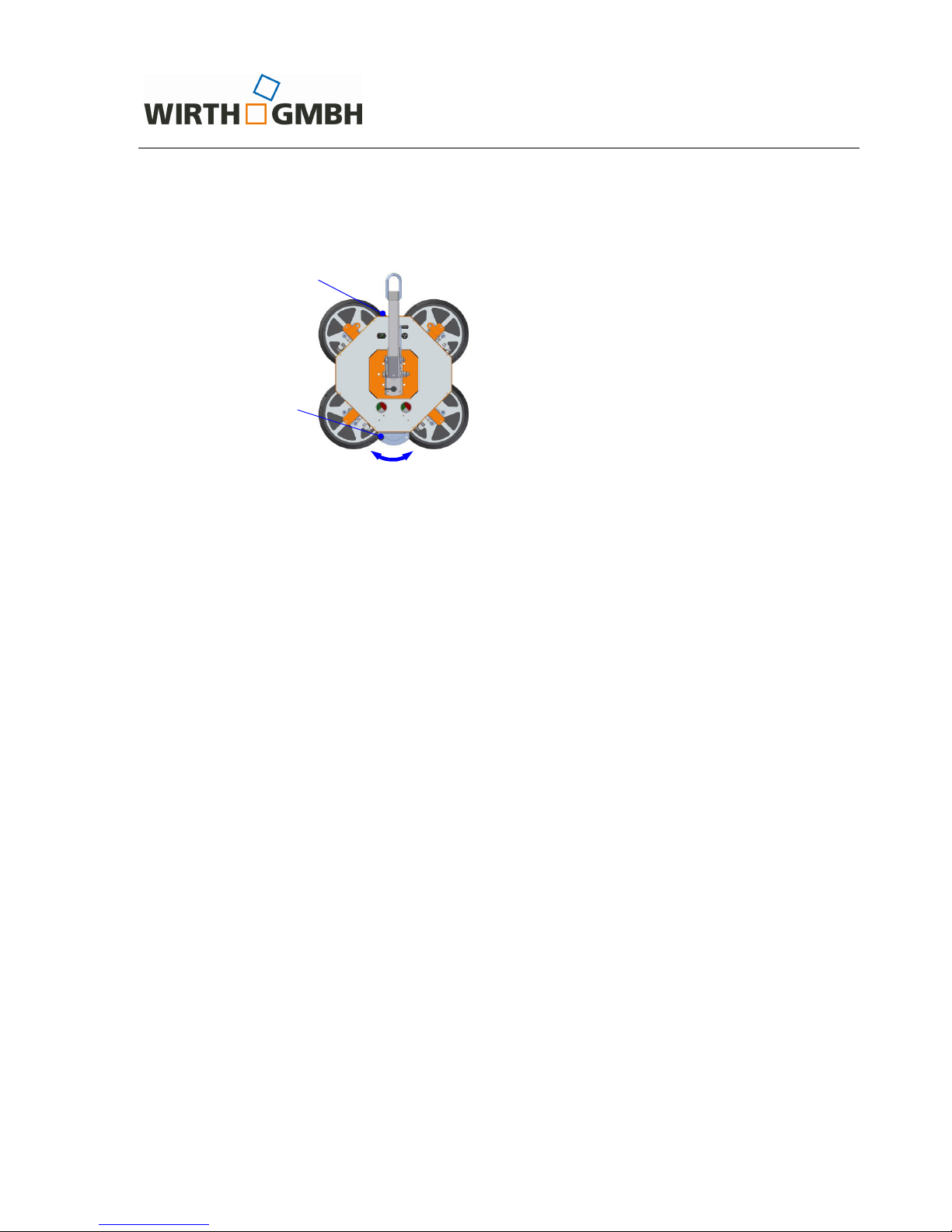

3.5.3 Rotating a load hanging in a vertical position with the

OKTOPUS® GLASS-Jack GL-RN 400/600/800 with a crane arm

⇒ Suck the element as described in 3.5.2!

Never unlock the release ’’Rotation“ and ’’Swivelling“ at the same time! Un-

locking both the releases may cause damages to the attachment and/or the

load!

⇒

Before rotating the load, make sure that there is enough space available. Ensure that the

load does not strike anything during rotation!

⇒

Unlock the release ’’Rotation“ (see fig. 12) and turn the load into the appropriate position.

After that relock the sliding lever.

3.5.4 Rotating a load hanging in a vertical position with the

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring

⇒

Suck the element as described in 3.5.2!

⇒

Position the OKTOPUS® above the centre of mass of the load (max. ±5 cm).

To avoid unintended load rotation, make sure that upon use of the version

GLASS-Jack GL-RN 400/600/800 with guide ring, the eccentric lever guide ring

(see fig. 12) shall be tightened!

⇒

Before rotating the load, make sure that there enough space is available. Ensure that the

load does not strike anything during rotation!

⇒

Slowly release the eccentric lever guide ring (see. fig. 12)!

⇒

Turn the load into the appropriate position.

⇒ Engage the clamping again by moving the eccentric lever!

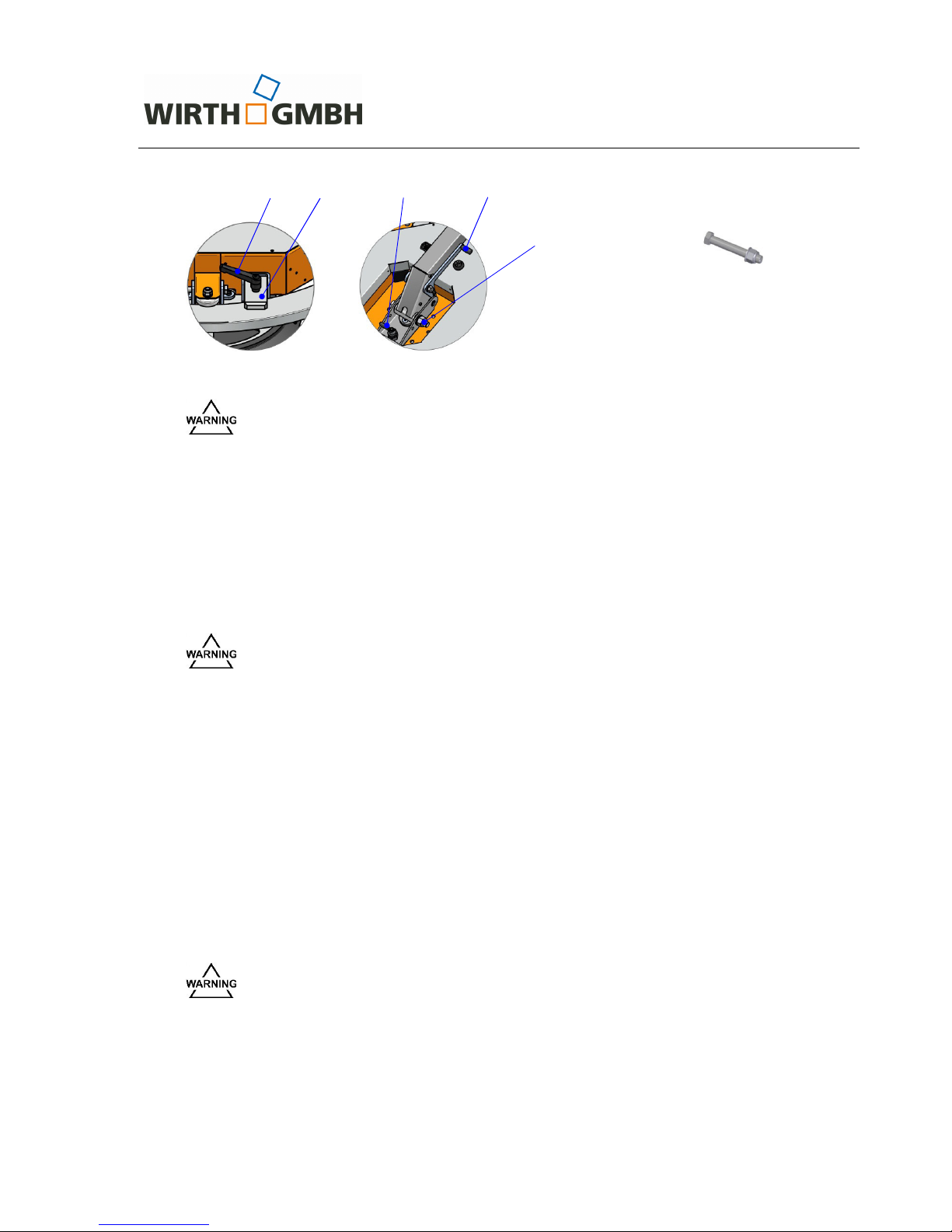

1 Eccentric lever guide ring

2 Show brake

3 Release „Rotation“

4 Release „Swivelling“

Hexagon bolt M20 x 140,

washer, lock nut

1 2 3 4

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 19 of 27

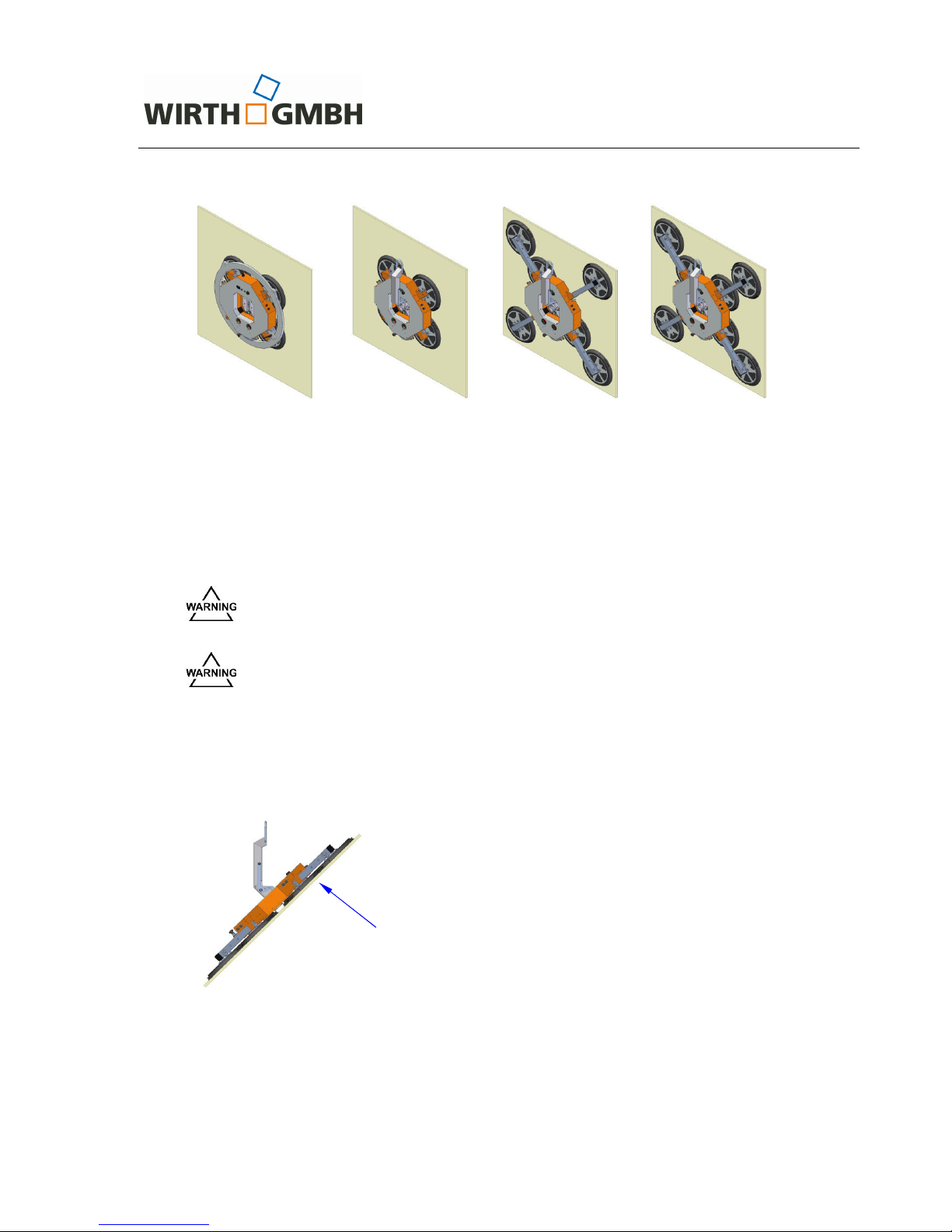

Fig. 13: OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring, with crane arm, and

with crane arm and extension arms (6 or 8 suction pads respectively)

3.5.5 Swivelling a load hanging in a vertical position with the

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with crane arm

⇒ Suck the element as described in 3.5.2!

Never attempt to unlock release “Swivelling“ (see fig. 12), if it carries a load.

This would cause uncontrollable “downward tilting” of the load.

In order to swivel the load from a vertical into a horizontal position, at least 3

persons are needed. Two persons have to secure and guide the load, while

the third person has to release the interlock!

⇒ Before swivelling the load you have to take into account that the swivelled load needs

more horizontal space. Make sure that the load does not strike anything during swivelling!

⇒ Unlock the release “Swivelling“ (see fig. 12) and move the load into a horizontal position.

Fig. 14: OKTOPUS

®

GLASS-Jack GL-RN 800 during swivelling

Glass element

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 20 of 27

3.5.6 OKTOPUS® GLASS-Jack GL-RN 400/600/800 slung to the basic frame

As for handling standing glass and cladding elements the OKTOPUS

®

GLASS-Jack GL-RN

400/600/800 may directly be slung to the basic frame (see fig. 6). However, in this case the load

can neither be rotated nor swivelled.

3.6 Converting the OKTOPUS® into its different versions

3.6.1 Assembly of the guide ring

⇒ Place the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 in a flat position on a clean and

even surface (suction pads are pointing down).

⇒ Dismount the crane arm. To do so remove the hexagon bolt (see fig. 12).

⇒ Dismount the extension possibly installed and any suction pads from the attachment. Re-

move the clip pin and the locking bolt to which the extensions /suction pads are fixed to

the basic frame.

⇒ Mount the guide roll completely (see fig. 14). For this use a roller pin M10, a washer and a

lock nut enclosed in the scope of supply. Insert the roller pin from bottom-up.

⇒ Push the remaining 3 guide rolls loosely into the remaining roller seats.

⇒ Put the guide ring over the basic frame and insert it into the slot of the first firmly mounted

guide roll.

⇒ Lift the guide ring and position the roll being opposite the first mounted guide roll that way,

so that it runs in the slot of the guide ring. Fix the second guide roll by means of a roller

pin M10, a washer and a lock nut.

⇒ Mount the remaining 2 guide rolls.

⇒ Mount the brake being part of the scope of supply (see fig. 12 and 15) as follows:

- If the holding plate has not yet been installed, then mount it by using the bolts M6,

washers and lock nuts forming part of the scope of supply.

- Fix the preassembled brake to the holding plate. Use the bolts, washers and lock nut

likewise enclosed in the scope of supply.

⇒ Mount the four suction pads by using the locking bolts (scope of supply). Secure each

suction pad with a clip pin.

⇒ Check again the proper seat of the guide ring, the roller seats, and the guide rolls as well

as the fixing material!

Fig. 15: Guide ring mounting

Guide roll, roller pin M10,

washer and lock nut

Locking bolts with clip pin

Brake

Brake pre-

assembled

Holding plate

brake

Roller seat

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 21 of 27

Please note that after the alteration works to the OKTOPUS® any mounted

parts are always secured entirely through fixing material licensed by the manufacturer!

3.6.2 Mounting of the crane arm

⇒ Place the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 in a flat position on a clean and

even surface (suction pads are pointing down).

⇒ In case the guide ring is mounted, dismount it as well as the 4 guide rolls and the brake.

⇒ Mount the crane arm (see fig. 1) by means of the hexagon bolt M20 X 140, the washer

and the lock nut being part of the scope of supply (see fig. 12).

⇒ Mount the tension spring between the release „Swivelling“ and the crane arm.

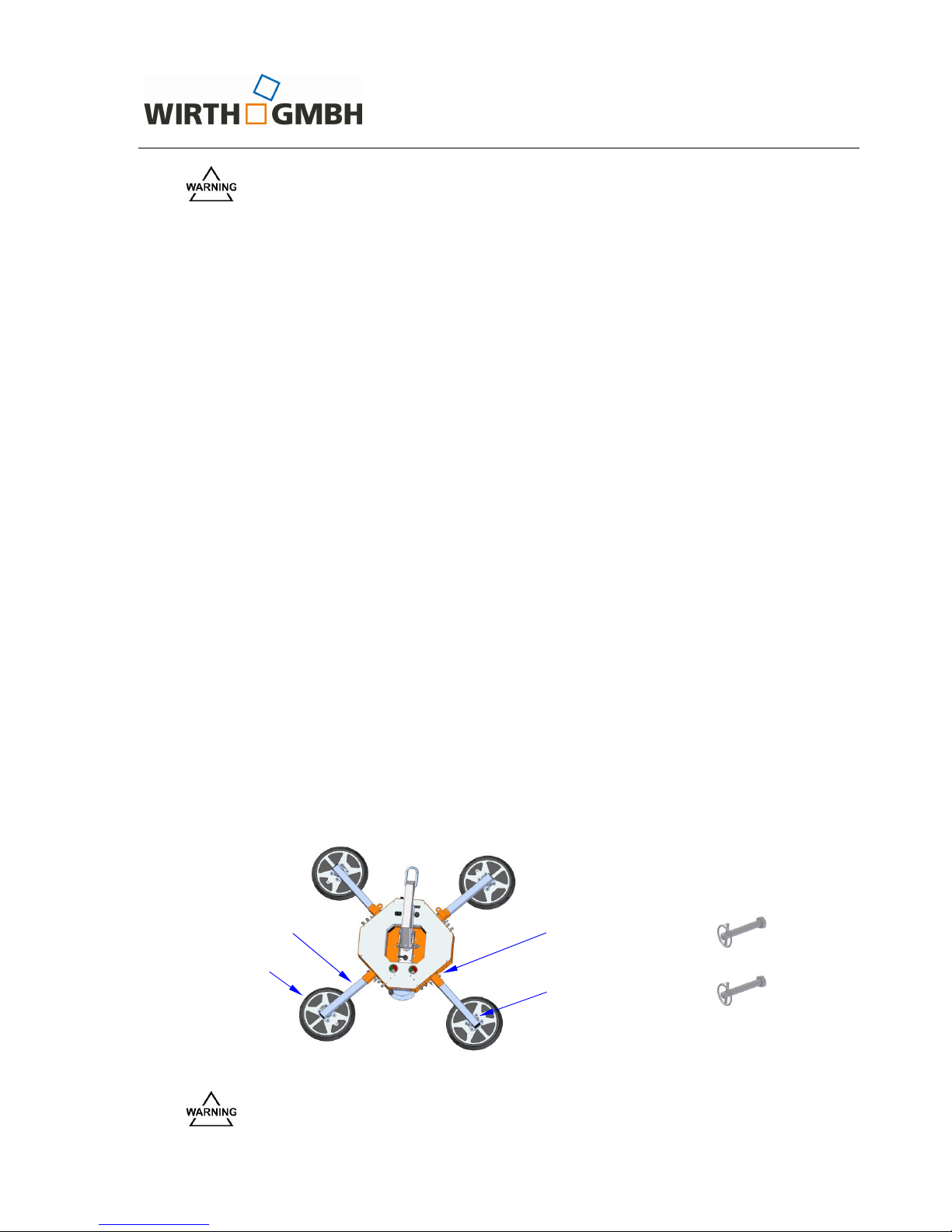

3.6.3 Mounting of the extension arms (4 suction pads)

⇒ Place the OKTOPUS® GLASS-Jack GL-RN 400/600/800 in a flat position on a clean and

even surface (suction pads are pointing down).

⇒ In case the guide ring is mounted, dismount it as described in pt. 3.6.2.

⇒ Carry out one after another the following working steps applying to each of the four exten-

sions:

- Dismount a suction pad from the basic frame. For this disconnect it from the vacuum system by releasing the quick coupling and remove the clip pin as well as the associated

locking pin.

- Push an extension arm into the basic frame and lock it by a locking pin belonging to the

scope of supply. Secure the locking pin by a clip pin enclosed in the scope of supply, either.

- Now install the suction pad removed before to the extension arm by using the locking pin

removed before. Secure the locking pin with a clip pin.

- Couple the suction pad placed onto the extension arm to the vacuum system by inserting

the quick coupling.

Fig. 16: Mounting of the extensions (4 suction pads)

Connect only vacuum hoses resp. couplings of the same colour!

Locking pin with clip pin

Locking pin with clip pin

Extension arm

Suction pad

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 22 of 27

Make sure that the locking pins are always secured entirely by the clip pins

supplied by the manufacturer!

The dismounting of the extension arms is done in reversed order.

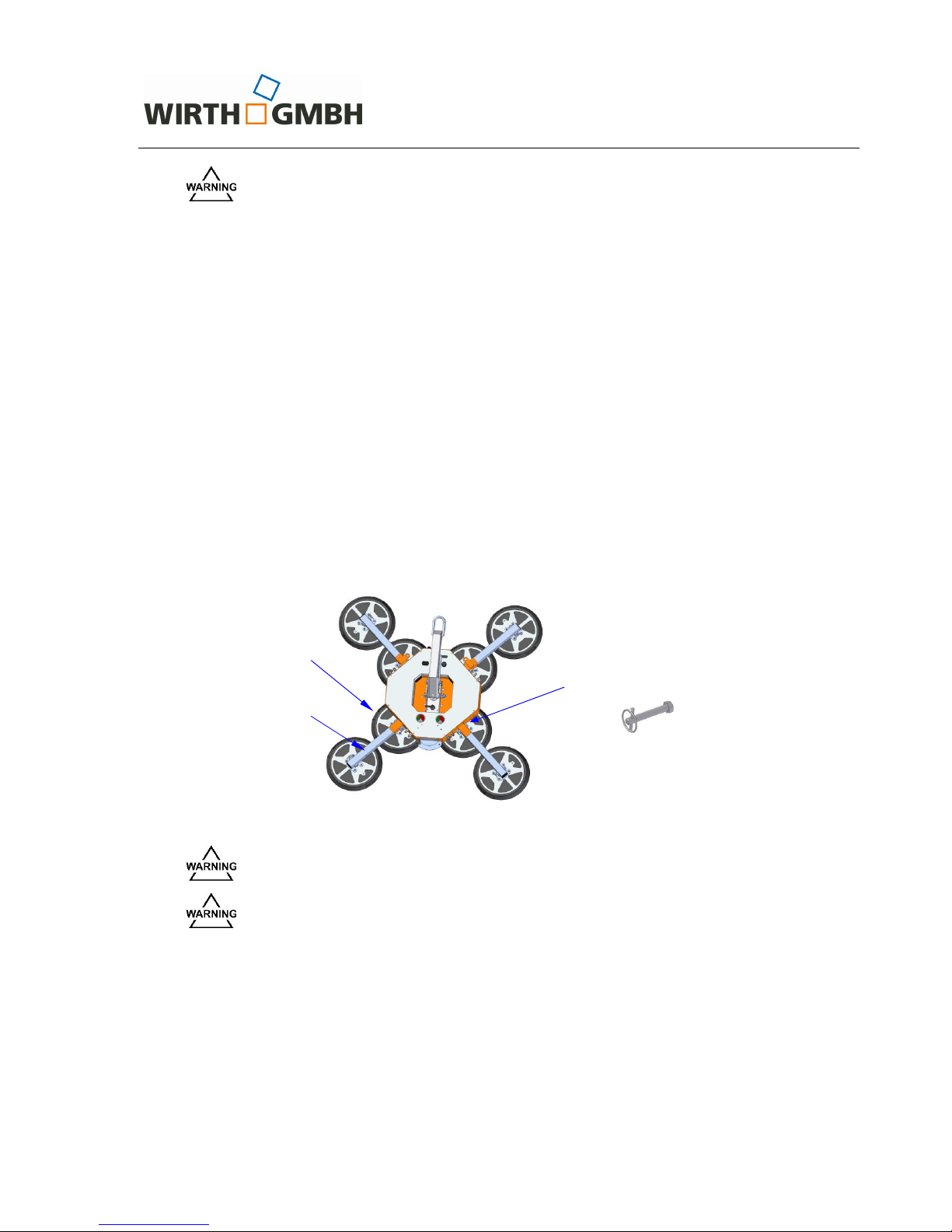

3.6.4 Mounting of the extension arms (6 resp. 8 suction pads)

⇒ Place the OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 in a flat position on a clean and

even surface (suction pads are pointing down).

⇒ In case the guide ring is mounted, dismount it as described in pt. 3.6.2.

⇒ Carry out one after another the following working steps which apply to each of the four ex-

tensions:

- Dismount the clip pin as well as the associated locking pin of one of the suction pads

fixed to the basic frame.

- Push one extension arm with suction pad into the basic frame.

- Lock the extension arm, thus locking the suction pad placed on the basic frame at the

same time with the locking pin removed before as well as with the clip pin.

- Couple the suction pad placed onto the extension arm to the vacuum system by insert-

ing the quick coupling.

Fig. 17: Mounting of the extension arms (ex. 8 suction pads)

Connect only vacuum hoses resp. couplings of the same colour!

Make sure that the lock pins are always secured entirely by the folding safe-

guard plugs supplied by the manufacturer!

The dismounting of the extension arms is done in reversed order.

Locking pin with clip pin

Suction pad

Extension arm with

suction pad

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 23 of 27

4 Servicing and Maintenance

4.1 General

As the OKTOPUS® system is a load lifting attachment, the manufacturer and operator bear

great responsibility for ensuring a high standard of safety during the entire operation of the unit.

For this reason, servicing and maintenance are of prime importance.

In order to maintain a high level of operational safety the OKTOPUS

®

GLASS-Jack GL-RN

400/600/800 must be inspected by the service centre of Wirth GmbH or a specially qualified

technician:

⇒ at least every 12 months or at shorter time intervals, if required by national standards or

regulations or

⇒ after any special incidents.

Any operative and scheduled servicing, maintenance and repair work exceeding this inspection

should be carried out by trained and skilled staff only.

Servicing and repair work should only be carried out when the machine is out of operation.

Before performing any repair or maintenance work on the OKTOPUS

®

switch

the entire unit off. Turn the main switch to the “OFF” position.

For the exchange of faulty parts only original spare parts shall be used. These will be supplied

after consulting the service centre of the OKTOPUS manufacturer upon request. The manufacturer will not accept any liability in the event of installation of anything but original spare parts.

Only use suitable tools to perform repair and maintenance work.

Always carry out a functional test after completing repair works.

In case of faults, which cannot be remedied by in-house personnel, please contact the Wirth

GmbH service centre.

4.2 Mechanical components

The mechanical components are sturdy and provided with a surface protection. Maintenance

work on your side comprises:

⇒ daily inspection of the mechanical components of the OKTOPUS

®

GLASS-Jack GL-RN

400/600/800 to detect any damage before starting the operation of the unit.

The OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 is a load lifting attachment. Therefore, re-

pairs to the mechanical function components can only be carried out by the OKTOPUS

manu-

facturer.

Never carry out any repair work on the mechanical function components!

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 24 of 27

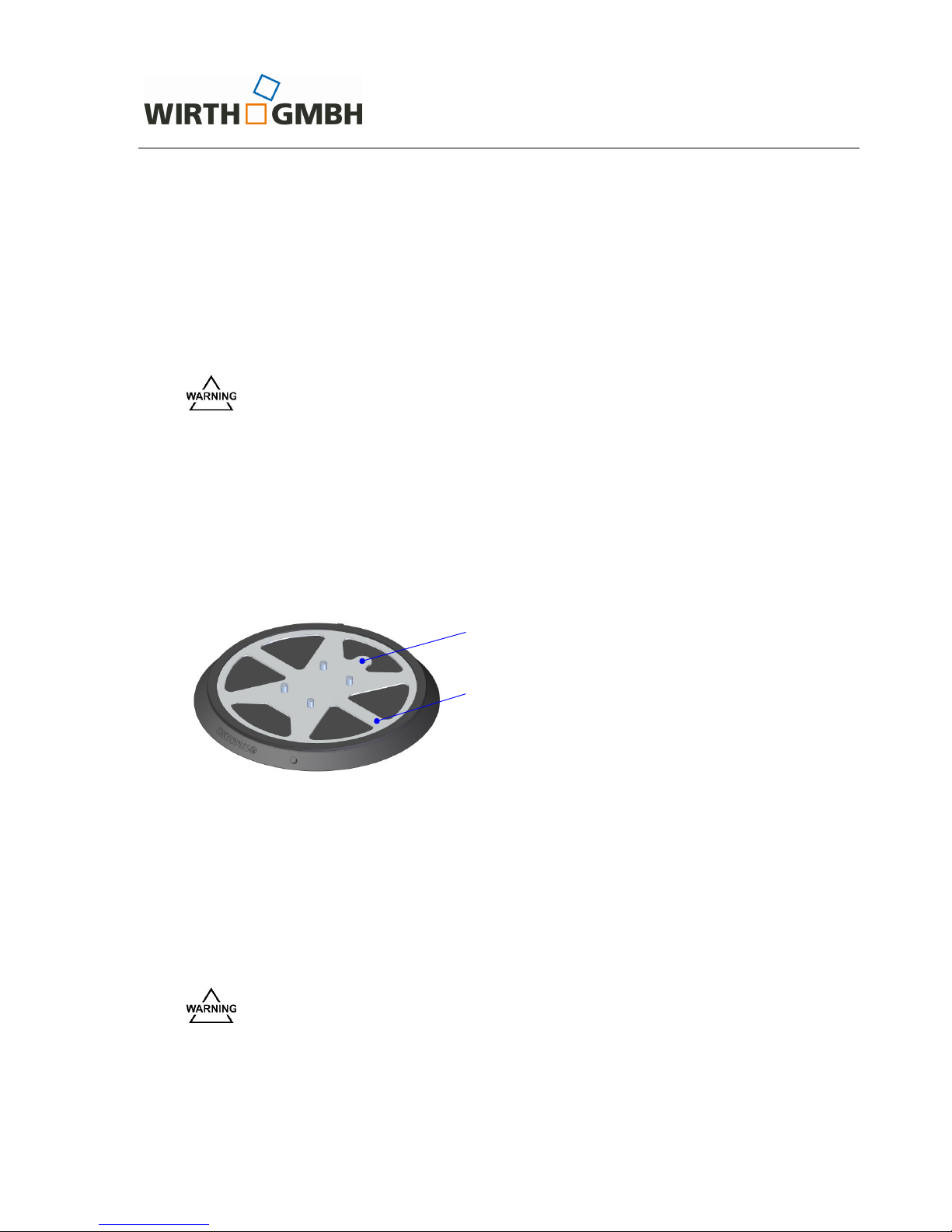

4.3 Vacuum system

Vacuum components, which are subject to wear and relevant to safety, must be inspected on a

regular basis. For this purpose:

⇒ Daily check the components in terms of their correct position and mechanical damages, in

particular:

• the suction pads (replace suction pad(s) if so),

• the hoses,

• the vacuum gauges.

Replace the suction pads and the hoses immediately if these have mechanical

damages (cracks, cuts, etc.)! These damages could lead to a reduced Working

Load Limit of the OKTOPUS

®

.

The vacuum pump runs completely oil-free. The robust design allows a maintenance-free operation.

The infiltration of dust into the vacuum pump is prevented by a filter screwed in into each individual suction pad. Therefore, maintenance of the vacuum system is focused on this component.

⇒ Slightly lift the OKTOPUS

®

without the load. The filter is in the through-hole to the connec-

tion of the vacuum hose. Dirty filters shall be cleaned.

Fig. 18: Suction pad

4.3.1 Cleaning the suction pads

Always clean the suction pads prior to every operation of the OKTOPUS

®

, if the suction areas

are soiled (dirt, dust, oil, etc.). Dirt could cause leakages and leave marks on the manipulated

elements.

For cleaning the suction pads we recommend to use water, if necessary add some detergent.

Do not use chemical solvents, petrol, diesel oil or similar in any case.

Never use solvents, petrol or aggressive chemicals for cleaning the suction

pads! Otherwise this may result in damaging the suction pads, which could

endanger the operator as well as others.

Ensure that fluids cannot enter the vacuum system during the cleaning process by positioning

the suction pads or by covering the suction opening. Give the suction pads a sufficient amount

of time to completely dry before operating the OKTOPUS

®

.

Filter (connection vacuum hose)

Suction pad

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 25 of 27

4.4 Electrics and electrical components

The OKTOPUS® GLASS-Jack GL-RN 400/600/800 is running with a maintenance-free lead-gel

battery (acidic). The battery casing is hermetically sealed.

Maintenance focuses on:

⇒ daily inspection of the external electrical functions and alarm devices:

• Alarm signal,

• Signal light,

• Alarm buzzer.

⇒ checking the charging level of the battery on the charge indicator (see fig. 8).

⇒ battery charging

A 24 V / 5 A charger for charging the battery is supplied by the OKTOPUS

®

system manu-

facturer (see fig. 19).

Fig. 19: Battery charger (sample)

Before connecting the charger to the power supply, check whether appropri-

ate! The respective data of capacity you will find on the charger.

In case you want to use a charger other than the one belonging to the OK-

TOPUS

®

scope of supply, it becomes essential to contact the Wirth Service

Team in advance!

The battery has to be charged as follows:

• Switch off the OKTOPUS

®

. For this turn the main switch to „OFF“ position!

• Connect the charger plug to the battery socket for charging OKTOPUS

®

.

• Connect the power plug of the charger to the power supply via socket to start the

charging procedure.

• The charging is finished as soon as the yellow LED lights up permanently.

• Proceed as follows to disconnect the charger from the OKTOPUS

®

:

1. Disconnect the charger from the power supply,

2. Separate the connection between charger and battery.

1 2 3 4 5

1 Charge plug charger

2 Yellow LED

3 Green LED

4 Battery charger

5 Main plug

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 26 of 27

LED display

⇒ The green LED will be on when the charger is connected to the mains supply.

⇒ The yellow LED will flash at a fast rate during bulk charge and at a slower rate during ab-

sorption charge. The yellow LED will be continuously on after the charging is complete.

Please contact the Wirth service centre for maintenance and in the event of failure of the

charger.

The sealed lead-gel battery entails the absolute observation of the charging

instructions!

In order to prevent the battery from destruction caused by deep discharging,

the OKTOPUS

®

should be recharged at least every two weeks.

The charger shall be protected against splash and installed in such a position

that the ventilator and the ventilation slots are not covered and cannot be

penetrated by sharp objects.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 27 of 27

5 Conduct in the event of hazardous incidents

In the event of hazardous incidents the acoustic alarm sounds and the red warning lamp lights

up. The total failure of the electric power supply is signalled by a fading sound of the alarm

buzzer.

Fig. 20: Warning devices

In case the alarm buzzer sounds and/or the red warning light flashes, immediately leave the

danger area, since the sucked elements could suddenly drop down. The cause for the alarm

should be found and removed. In case the defects cannot be removed, stop working with the

OKTOPUS

®

immediately. After releasing a possibly sucked element the OKTOPUS® shall be

secured against further use.

In case of faults that cannot be remedied, working with the OKTOPUS

®

shall

be stopped immediately. Der OKTOPUS

®

shall be secured against further use.

If there is no indication is given on the charge indicator when the OKTOPUS

®

is switched on,

always contact the Wirth GmbH service centre of immediately.

6 Disposal and Recycling

For the packaging of the OKTOPUS®, materials like wood, cardboard, paper and film are used.

These materials shall be recycled according to national regulations.

To dispose the OKTOPUS

®

, hand it in to a waste management company. If you have any ques-

tions, please do not hesitate to contact Wirth GmbH.

For environmental reasons hand over the OKTOPUS

®

for disposal to a waste

management company being fully aware and observing the national regulations!

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Annex 1

Abridged operating instruction

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800

1 Assembly

(1) Configurate the OKTOPUS® in correspondence with the application, and fix to the crane

hook.

2 Start-up of the OKTOPUS®

(1) Place the OKTOPUS® onto the element to be sucked.

(2) Turn the main switch to ON position.

(3) Slightly lift the switch „Suction/Release“ and push towards „Suction“.

(4) Check the charging status of the battery via charge indicator.

• the green LED shows readiness for operation,

• when the third LED from the left (yellow LED) lights up, the battery should be charged,

• when the second LED from the left (yellow LED) flashes or the second LED from the left

(yellow LED) and the red LED light up in turns, the battery must be charged.

(5) Check vacuum pressure at the vacuum gauge (permissible green sector -0.65 to -0.9 bar):

• In case pressure in one or in both gauges is in the red sector, the alarm will be activated

and vacuum needs to be built up.

• If pressure in both vacuum gauges is in the green area, the OKTOPUS

®

is ready for op-

eration; the red signal light switches off and the green signal lamp turns on.

3 Instruction for use

(1) Preparation of the elements:

• Check the surface of the element: The surface shall be smooth, airtight, clean and dry

at least at the suction spots. There must not be any protection film in the suction area.

(2) Lifting the element:

• Place the OKTOPUS

®

onto the element.

• Slightly lift the switch „Suction/Release“ and push towards „Suction“.

(3) Positioning the element:

• Erect/lift the element by crane lifting movement,

• Positioning of the element by crane driving and lifting movement together with simulta-

neous manual guidance of the element by the installer.

• Fixation of the element to the installation point.

(4) Detaching the element

• Slightly lift the switch „Suction/Release“ and push towards „Release“.

4 Shutdown

• Lower the crane.

• Separate the connection OKTOPUS

®

/ crane.

• Turn the main switch of the OKTOPUS

®

to OFF position.

• In case of shutdown over a longer period, the batteries of the OKTOPUS

®

shall be

charged at least every 2 weeks.

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Annex 2

Functional dimensions

1450 mm

1890 mm

230 mm

860 mm

1050 mm

230 mm

140 mm

860 mm

1050 mm

WIRTH

MBH

e

NG

Operatino

I nstructions

OKTOPUöC

GLASSJacK

GL-RN 400/600/800

.

Technical Documentation

BA

000 101

Annex 3

Declaration

of Conform

ity

Pursuant

to Appendix ll A

of the EU

machinery

directive 20061421EC

Manufacturer:

WIRTH

GMBH

Vacuum

lifting technology

division

Brehnaer

Straße 1

D-06188

Landsberg

Germany

Herewith

we

declare

that the machine hereinafter

described is in

conformity with any

provisions

relevant

to the

EU machinery

directive20Q6l42lEC:

Productdescription:

OKTOPUS@GLASS-JackGL-RN400/600/800

Type:

oKTOPUS@

ctnss-Jack

GL-RN 400/600/800

R M F,24 p 110

Serial number:

A

L{o

}+Z

Yearof

manufacture:

O"

lZoÄ-l

In

addition

the

partly

completed machinery is

in

conformity with

the

EC

directive concerning

the minimum

safety

and health

requirements

for

the use

of work

equipment by work-

ers

at

work

2O09l104lEC,

the EG

directive

on

product

safety 2001/95/EC

and

the

EC

di.

rective

on electromag

netic com

patibi

lity 201 4130/E

U.

Harmonized

standards

applied :

DrN

EN tSO 12100

(03/11)

Safety

of machines

-

General

principles

of Design

-

Risk

assessment

and Risk reduction

DrN EN tSO

13857

(06/08)

Safety of

machinery

-

Safety distances

to

prevent

hazard

zones

being reached

by upper

and

lower

limbs

DIN EN

60204

Part

,|

(06107)

Electrical

equipment

of machines

-

General requirements

DtN

EN 13{55

(08/09)

Crane

-

Safety

-

Non-fixed load

lifting

attachment

Authorized

staff

to compile the

relevant technical

documents:

Mr.

Sven Röthe,

Brehnaer

Straße 1, D-06188

Landsberg

This

declaration

solely corresponds

to the machine

in

the status as

put

on the market; any

parts

additionally installed

and/or

modifications

additionally

carried

out by the

end user shall

be unconsidered.

This

declaration will

become invalid,

in

case the

product

should be

modi-

fied without

our approval.

Landsberg,

at

.

O

0.2oa7

.11

r.-

.

L

r\.

Holger

Schadwinkel

(Managing

Director)

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS

®

GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Annex 4

Test badge for the

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800

Pursuant to the Directive 2006/42/EU

Plate dimensions: 80 x 40 mm

Background: blue

Foreground: white

Script: white on blue

Badge dimensions: diameter 30 mm

Background: depending on the year

Foreground: depending on the year

201

7

O p e r a t i n g I n s t r u c t i o n s

OKTOPUS® GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

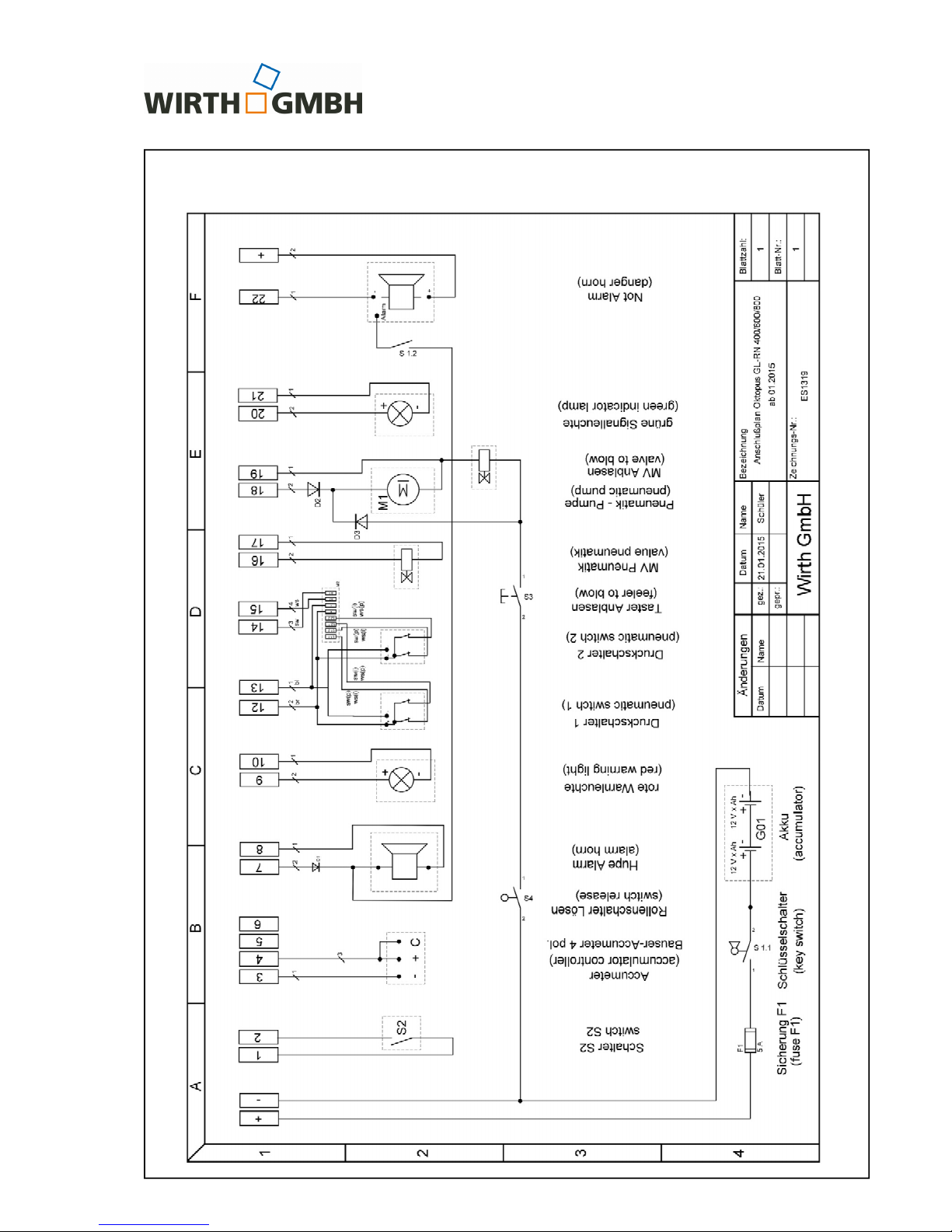

Annex 5

Electrical Circuit Diagram

Loading...

Loading...