Installation and Operations Manual

Part Number 281-102471-201

February 2000

N2-4XE1

Wireless, Inc.

5452 Betsy Ross Drive

Santa Clara, CA 95054-1101

N2-4XE1 nstallation and Operation Manual

Notice

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of Wireless, Inc.

© Copyright 2000, Wireless, Inc. All rights reserved.

N2-4XE1™ and ACCESS™ Series are trademarks of Wireless, Inc.

ii

N2-4XE1 Installation and Operation Manual

Table of Contents

1.0 General Overview ................................................................................................................. 1

1.1 N2-Link Series Product Family .................................................................................. 1

1.2 Introduction to the N2-4XE1 ...................................................................................... 1

1.3 Regulatory Information .............................................................................................. 2

2.0 N2-4XE1 Product Profile ....................................................................................................... 3

2.1 General Overview ...................................................................................................... 3

2.2 Specifications ............................................................................................................ 7

2.3 User Interfaces ........................................................................................................ 10

2.4 ODU Performance Monitoring ................................................................................. 13

2.5 Theory of Operation ................................................................................................ 13

3.0 Equipment Installation and Commissioning ........................................................................ 20

3.1 Installation ............................................................................................................... 20

3.2 Install the IDU .......................................................................................................... 21

3.3 Outdoor RF Unit Installation .................................................................................... 22

3.4 Commissioning ........................................................................................................ 28

4.0 Maintenance and Troubleshooting ...................................................................................... 30

4.1 N2-4XE1 Maintenance ............................................................................................ 30

4.2 Identifying and Resolving Receive Signal Strength Issues ..................................... 31

4.3 Where to Get Further Assistance ............................................................................ 32

4.4 Return Procedure .................................................................................................... 33

Appendix A Grounding Practices and Lightning Protection Information....................................... A-1

Appendix B Installation Instructions .............................................................................................. B-1

Appendix C Adjustable Panel Antenna Mount ..............................................................................C-1

iii

N2-4XE1 Installation and Operation Manual

Figures

Figure 2.1 Typical Deployment of a N2-4XE1 in a Point-to-Point Configuration ........................ 5-6

Figure 2.2 N2-4XE1 Link IDU ......................................................................................................10

Figure 2.2a Outdoor Unit, Front View ............................................................................................ 12

Figure 2.2b Outdoor Unit, Back View ............................................................................................ 12

Figure 2.3 Block Diagram, IDU ....................................................................................................14

Figure 2.4 N2-4XE1 Block Diagram ....................................................................................... 18-19

Figure 3.1 N2-4XE1 Link Rack Mount ......................................................................................... 21

Figure 3.2 Outdoor Unit Mounting Hardware .............................................................................. 22

Figure 3.3 Mounting the Outdoor RF Unit to the Bracket ............................................................ 23

Figure 3.3a Mounting the Bracket Latch and Stand Mount Detail ................................................. 24

Figure 3.3b Locking the Mounting Hardware ................................................................................ 25

Figure 3.3c N-Type Antenna and Siamesed Ethernet/Power Connections .................................. 26

Figure 3.3d Ground Connection ....................................................................................................27

Figure B.1 Two Foot Diameter Antenna ..................................................................................... B-1

Figure B.2 Mount Configuration .................................................................................................. B-3

Figure B.3 Mounting Hardware Packed ...................................................................................... B-5

Figure B.4 Mounting Hardware Unpacked .................................................................................. B-5

Figure B.5 Parabolic Reflector .................................................................................................... B-8

Figure B.6 Unpacking the Radome ............................................................................................. B-8

Figure B.7 Antenna Mount Assembly ......................................................................................... B-9

Figure B.8 Antenna Mount Assembly ....................................................................................... B-10

Figure B.9 Elevation Rod Assembly ......................................................................................... B-10

Figure B.10 Feed Horn Installation ............................................................................................. B-11

Figure B.11 Feed Horn Polarization Markings ............................................................................ B-12

Figure B.12 Parabola Rear View Showing Polarization Reference Markers .............................. B-12

Figure B.13 Feed Horn Installation ............................................................................................. B-13

Figure B.14 Feed Horn Installation for Vertical Polarized Operation.......................................... B-13

Figure B.15 Azimuth Clamp/Shear Stop Assembly .................................................................... B-14

Figure B.16 Azimuth Adjustment Clamp Assembly ................................................................... B-14

Figure B.17 Hoisting the Antenna ............................................................................................... B-15

Figure B.18 Antenna Alignment using RSL Output while adjusting the antenna ....................... B-16

Figure C.1 Antenna Mount .......................................................................................................... C-1

Figure C.2 Azimuth and Elevation Planning ............................................................................... C-2

Figure C.3 Azimuth and Elevation Planning ............................................................................... C-3

Figure C.4 Flat Panel Antenna....................................................................................................C-4

Figure C.5 Adjustable Panel Antenna Mount ..............................................................................C-5

iv

N2-4XE1 Installation and Operation Manual

Tables

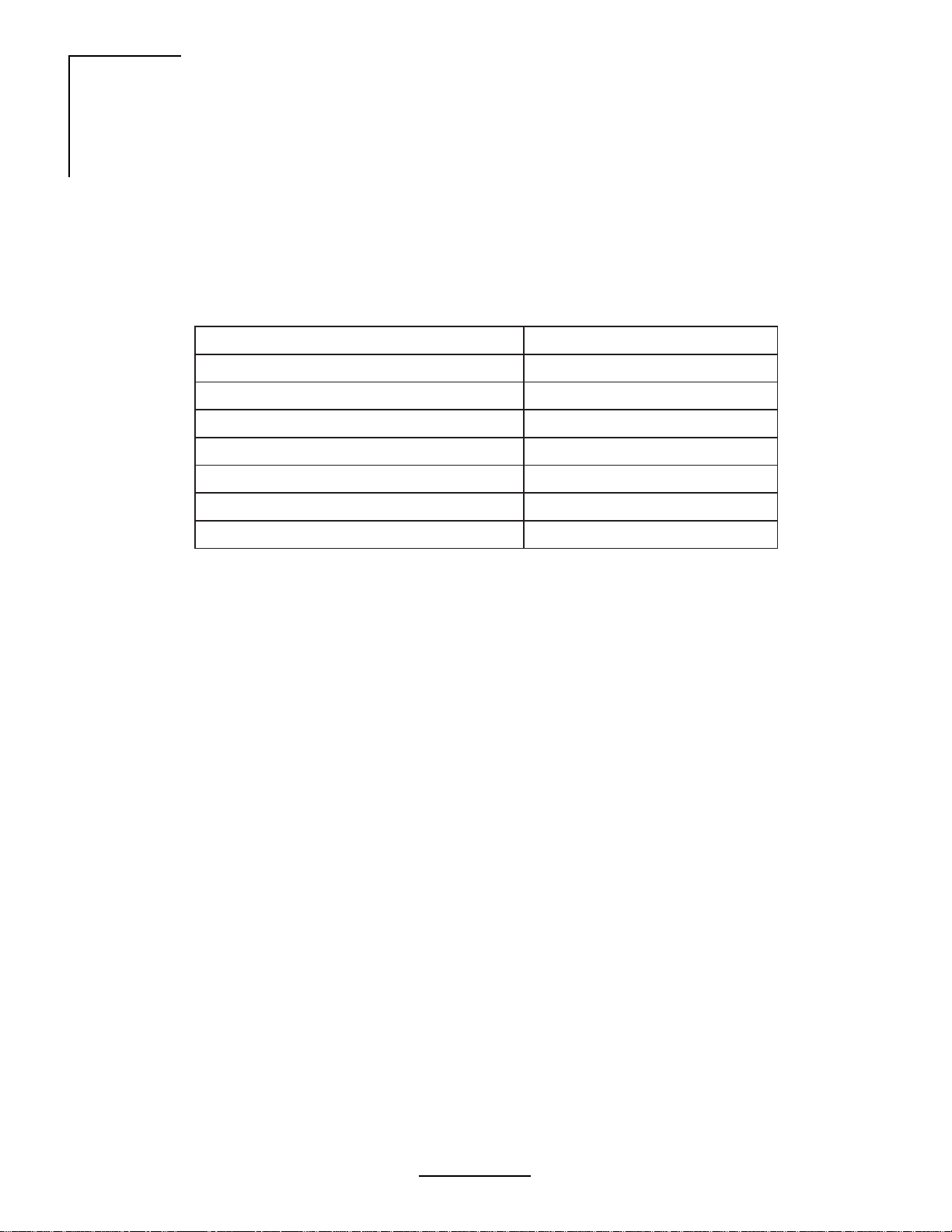

Table 1.1 FCC U-NII Bands ......................................................................................................... 2

Table 2.1 Recommended Antennas ............................................................................................. 8

Table 2.2 Features Available Through RS-232 Interface ........................................................... 11

Table 3.1 Inventory of Equipment and Installation Materials ..................................................... 20

Table 3.2 Installation Checklist................................................................................................... 28

Table 3.3 Approximation Table .................................................................................................. 29

Table 4.1 Frequencies ................................................................................................................ 31

v

N2-4XE1 Installation and Operation Manual

Welcome!

Welcome to the Wireless, Inc. N2-ACCESS™ Series product family. This manual is designed

to introduce you to the N2-4XE1

operate and maintain a N2-4XE1 wireless communication system.

The N2-4XE1 is intended for professional installation only. This manual, however, is also

designed for personnel who plan, operate and administrate the N2-4XE1 communication

system. Please review the entire manual before powering up or deploying any N2-4XE1 .

Updates to this manual will be posted on the Wireless, Inc. Customer Service Website at

http://www.wire-less-inc.com. Registered Wireless customers can access Wireless’ on-line

information and support service, available 24 hours a day, 7 days a week. Our on-line service

provides users with a wealth of up-to-date information, with documents being added or updated

each month.

™, and to provide you with information necessary to plan, install,

Radiation Warnings

Microwave Radio Radiation Warning

Under normal operating conditions, N2-4XE1 radio equipment complies with the limits for

human exposure to radio frequency (RF) fields adopted by the Federal Communications

Commission (FCC). All Wireless, Inc. microwave radio equipment is designed so that under

normal working conditions, microwave radiation directly from the radio is negligible when

compared with the permissible limit of continuous daily exposure recommended in the United

States by ANSI/IEEE C95.1-1991 (R1997), Safety Levels with Respect to Human Exposure to

Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

Microwave signal levels that give rise to hazardous radiation levels can exist within transmitter

power amplifiers, associated RF multiplexers, and antenna systems.

Never look into the open end of a Waveguide as eyes are particularly vulnerable to radiation.

Do not disconnect RF coaxial connectors, open microwave units, or break down any

microwave screening while the radio equipment is operating.

vi

N2-4XE1 Installation and Operation Manual

Microwave Antenna Radiation Warning

Designed for point-to-point operation, an N2-4XE1 microwave radio system will use directional

antennas to transmit and receive microwave signals. These directional antennas are usually

circular or rectangular in shape, are generally located outdoors, and are usually mounted on a

tower or mast.

Referencing OET Bulletin 65 (Edition 97-01, August 1997) from the Federal Communication

Commission’s Office of Engineering & Technology, limits for maximum permissible exposure

(MPE) to microwave signals have been adopted by the FCC for both Occupational/Controlled

environments and General Population/Uncontrolled environments. These limits are 5.0 mW/

2

cm

and 1.0 mW/cm2, respectively, with averaging times of six-minutes and thirty-minutes,

respectively.

The closer you are to the front center-point of a microwave antenna, the greater the power

density of its transmitted microwave signal. Unless you are very close, however, microwave

exposure levels will fall far below the MPE limits. To determine how close to a microwave

antenna you can be and still remain below the MPE limits noted above, “worst case” predictions

of the field strength and power density levels in the vicinity of an N2-4XE1™ microwave antenna

can be made from the following calculations. The equation is generally accurate in the far-field

of an antenna, and will over-predict power density in the near-field (i.e. close to the antenna).

S = PG/4πR

2

where: S = power density (in mW/cm2)

P = power input to the antenna (mW)

G = power gain of the antenna in the direction of interest relative to an isotropic

radiator

R = distance to the center of radiation of the antenna (cm)

Note that G, the power gain factor, is usually expressed in logarithmic terms (i.e., dB), and must

be converted using the following equation:

G = 10

dB/10

For example, a logarithmic power gain of 24 dB is equal to a numeric gain of 251.19.

Assuming (1) maximum output power from the N2-4XE1 (+3.5 dBm [2.238 mW]), (2) no signal

loss in the cable connecting the N2-4XE1 to the antenna, and (3) the use of a 27 dBi gain

parabolic antenna, the 5.0 mW/cm2 and 1.0 mW/cm2 MPE power density limits would be

reached at distances of approximately 4.22 cm and 9.44 cm, respectively.

Wireless, Inc. fully supports the FCC’s adopted MPE limits, and recommends that personnel

maintain appropriate distances from the front of all directional microwave antennas. Should you

have questions about N2-4XE1™ microwave signal radiation, please contact the Wireless, Inc.

Customer Service Department.

vii

N2-4XE1 Installation and Operation Manual

Notice Regarding Operation pursuant to FCC part 15 Rules

This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

viii

N2-4XE1 Installation and Operation Manual

1.0 General Overview

1.1 N2-Link Series Product Family

All N2-4XE1 radios are members of the N2-ACCESS Series radio product family. The N2ACCESS Series is designed to provide an economical wireless solution for local access

telecommunication requirements.

This manual addresses, in detail, the operation of the N2-4XE1. For detailed information on

other members of the N2-ACCESS Series, please refer to the appropriate Operation Manual(s).

1.2 Introduction to the N2-4XE1

The N2-4XE1 is a digital radio using BPSK modulation techniques and is designed for use as

a point-to-point communications system. The N2-4XE1 is used in the following applications:

point-to-point (building to building), ISPs, CLECs, Wireless Local Loop (WLL), Backup

Solutions and Temporary Links.

The N2-4XE1 radio is designed for operation in two of the Unlicensed National Infrastructure

at frequencies of 5.250 - 5.350 GHz or 5.725 - 5.825 GHz.

Each N2-4XE1 is comprised of an indoor unit which provides the means to connect system

power, formatted data, SNMP interface and RS-232 ports to monitor and control the link. An

outdoor pole mounted RF unit is supplied as part of the system. Each link is powered by means

of a DC power supply which is fed to the unit through a power/data cable. The system has a data

total transmission capacity of 8.448 Mb/s. Refer to the N2-4XE1 data sheets for detailed

information relating to product offerings and specifications.

1

N2-4XE1 Installation and Operation Manual

1.3 Regulatory Information

In January 1997, the FCC made available 300 MHz of spectrum for Unlicensed National

Information Infrastructure (U-NII) devices. The FCC believes that the creation of the U-NII band

will stimulate the development of new unlicensed digital products which will provide efficient and

less expensive solutions for local access applications.

The U-NII band is divided into three sub bands at 5.15 - 5.25, 5.25 - 5.35 and 5.725 - 5.825 GHz.

The first band is strictly allocated for indoor use and is consistent with the European High

Performance Local Area Network (HIPERLAN). The second and third bands are intended for

high speed digital local access products for “campus” and “short haul” microwave applications.

Table 1.1 - FCC U-NII Bands

ycneuqerF zHG52.5ot51.5zHG53.5ot52.5zHG528.5ot527.5

)xaM(rewoP PRIEsttawillim002PRIEttaw1)PRIE(sttaw4

1dnaB2dnaB3dnaB

*

esUdednetnI ylnOesUroodnIsupmaCselim01xorppA

.dnabIIN-U528.5-527.5ehtnittaw1

swolla8991,42enuJnodesiver)00M(redrodnanoinipomudnaromemCCFtnecerA:etoN*

forewoptuptuorettimsnartmumixamadnaniagiBd32htiwannetnalanoitceridafoesueht

609772LW

2

N2-4XE1 Installation and Operation Manual

2.0 N2-4XE1 Product Profile

2.1 General Overview

The N2-4XE1 series of microwave radio products provides digital capacities for 4XE1 data rates

for short-haul applications up to 10 km. The radio terminal operates in the Unlicensed National

Information Infrastructure (U-NII) spectrum with a revolutionary Split Modulation system

architecture that provides full duplex operation in the 5.3/5.7 GHz U-NII frequency bands.

The N2-4XE1 series provides the unique advantage of a very robust digital transmission

scheme employing advanced Forward Error Correction (FEC) techniques to reduce data

errors.

The product uses two separate 100 MHz bands within the U-NII frequency spectrum. Within

these bands, the N2-4XE1 series operates in one of many independent channels providing for

frequency reuse and network flexibility, ideal for dense network applications.

Synthesized RF channel selection is field configurable, as are the power output options for the

selection of antenna sizes. Frequency coordination and installation guidelines are provided in

the appendix section of this manual.

Complying with all aspects of FCC Rules Subpart 15.401-15.407, the transmission characteristics of the N2-4XE1 series are ideally suited to meet the peak power spectral density

requirements of the U-NII 5.250 - 5.350 and 5.725 - 5.825 GHz bands.

The N2-4XE1 has been designed for easy access to all interfaces, controls, and displays.

Information in this manual will familiarize you with all of these items. Figure 2.1 illustrates two

(2) N2-4XE1 terminals in a point-to-point configuration.

3

N2-4XE1 Installation and Operation Manual

This Page Left Blank Intentionally

4

N2-4XE1 Installation and Operation Manual

Figure 2.1 (WL272904) goes here

5

N2-4XE1 Installation and Operation Manual

Figure 2.1 (WL272904) goes here

6

2.2 Specifications

2.2.1 General Specifications

Frequency Band: Full-duplex operation in the Unlicensed National

Regulations: Complies with FCC Ruling Part 15, Subpart E (U-NII)

Frequency Range: 5,250 - 5,350 MHz and 5,725 - 5,825 MHz

Capacity Options: 4xE1

2.2.2 Digital Interface

Type: Based on 4 E-1 inputs

Line rate: 4 x 2.048 Mb/s

Line Code: HDB3

Interface: 75

Connectors: BNC (75

2.2.3 Transmitter

Frequency Range: 5,250 - 5,350 MHz 5,725 - 5,825 MHz

Output Power (maximum): 0 dBm 0 dBm

2.2.4 Receiver

N2-4XE1 Installation and Operation Manual

Information Infrastructure

ITU-T/E1

Ω unbalanced or optional 120Ω unbalanced

Ω) or RJ-48C (120Ω)

5.3 GHz (Low Band) 5.7 GHz (High Band)

+4 dBm +4 dBm

+8 dBm +8 dBm

+12 dBm +12 dBm

Type: Coherent Detection Coherent Detection

Sensitivity, BER 10

-6

Typical: 85.5 dBm 85.5 dBm

Maximum RF Input: -20 dBm -20 dBm

7

N2-4XE1 Installation and Operation Manual

2.2.5 Antennas

Flat Panel: 6” (15.24 cm) 18 dB 35 dB

Parabolic: 2’ (.61 m) 28 dB 38 dB

Forward Gain Front/Back Ratio

12” (.30 m) 23.5 dB 41 dB

24” (.61 m) 27 dB 45 dB

4’ (1.22 m) 34 dB 46 dB

Table 2.1 - Recommended Antennas

epyTrebmuNtraPdnarerutcafunaM

iBd5.82,dezireloPenalP,hsidretemaid'2IRA25-2PSSleirbaG

iBd5.82,dezireloPlauD,hsidretemaid'2IRA25-2DSSleirbaG

iBd5.33,dezireloPenalP,hsidretemaid'4*A25-4PSSleirbaG

iBd5.33,dezireloPlauD,hsidretemaid'4*A25-4DSSleirbaG

iBd81,dezireloPenalP,lenaPtalF"625-5.SPFDleirbaG

iBd5.32,dezireloPenalP,lenaPtalF"2125-1SPFDleirbaG

2.2.6 Diagnostics

Front Panel Indicators: Power (normally On)

Alarms: Major Alarm On

External Alarm Inputs: Two separate TTL level inputs, ground inputs to alarm

Performance Monitoring: Receive Signal Strength Indicator (RSSI)

2.2.7 Power

Input Voltage Range: ±20 to 72 VDC

Power Consumption: 21 watts maximum

2.2.8 Environmental

Temperature Range: -10°C to +50°C -30°C to +60°C

Altitude: 4,500 meters (15,000 ft) 4,500 meters (15,000 ft)

Humidity: 95% non-condensing Outdoor, all weather

iBd5.82,dezireloPenalP,lenaPtalF"4225-2SPFDleirbaG

.tnailpmocCCFtoneradna,ylnoASUehtedistuoesuroferasannetnahsidtoof-4ehT*

LED

Minor Alarm Blinks

(DB9 connector)

Indoor Unit Outdoor Unit

enclosure

709772LW

8

2.2.9 Mechanical

Dimensions (HxWxD): 44 x 483 x 240 mm 310 x 351 x 73 mm

Weight: 2.9 kg (6.6 lbs) 5.2 kg (11.5 lbs)

2.2.10 FCC Information (US Only)

This device has not been authorized as required by the rules of the Federal Communications

Commission. This device is not, and may not be, offered for sale or lease, or sold or leased, until

authorization is obtained.

Notes: 1. N2-4XE1 is intended for professional installation only

2. Specifications subject to change without notice

N2-4XE1 Installation and Operation Manual

Indoor Unit Outdoor Unit

(0.72 x 19.0 x 9.4 in) (12.2 x 13.8 x 2.88 in)

9

N2-4XE1 Installation and Operation Manual

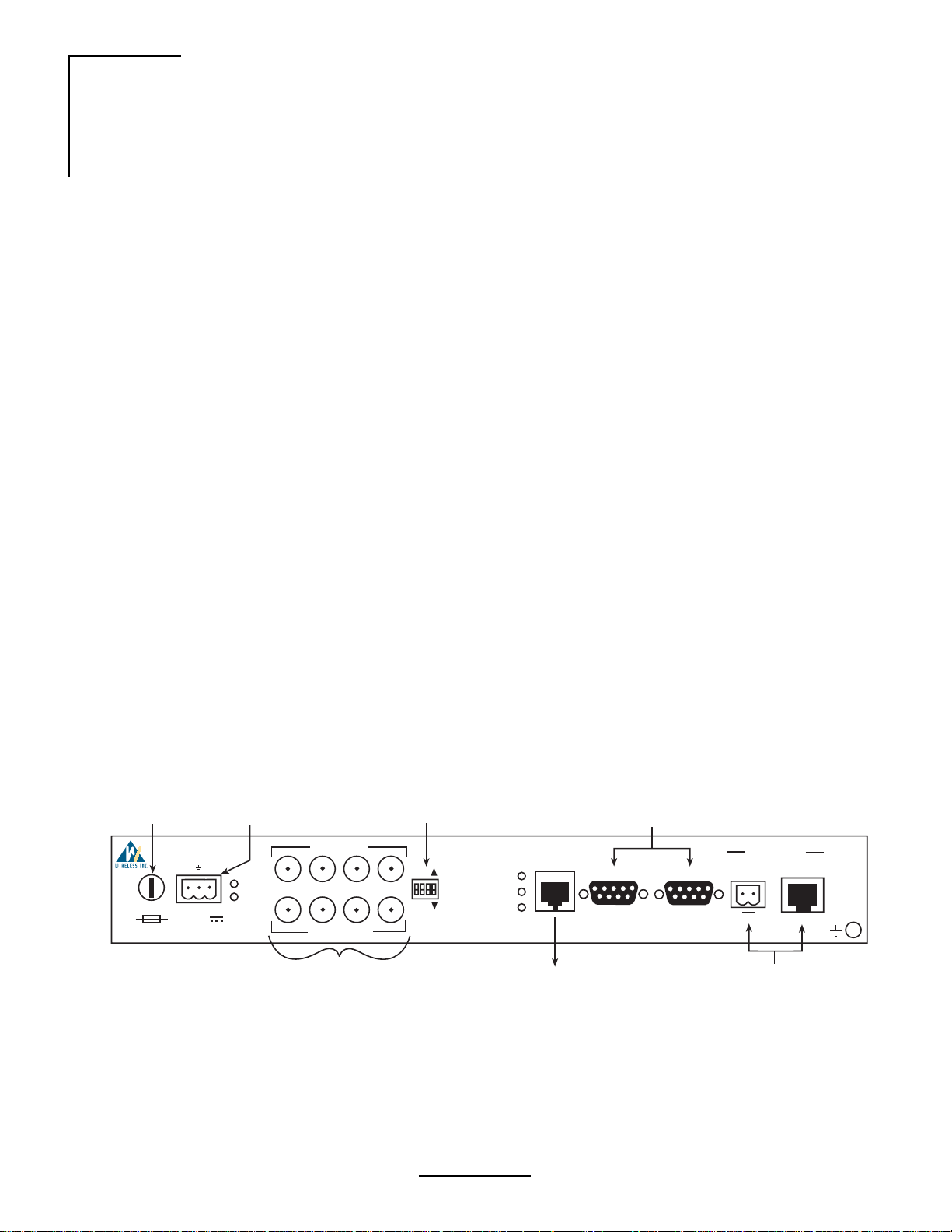

2.3 User Interfaces

The N2-4XE1 provides user interfaces for fused DC power connection, electrical grounding,

radio frequency (RF) antenna connection, E1 Data connection, configuration and RSSI output.

The following provides information on each interface. Figure 2.2 shows the locations of each

connection to the indoor unit.

Indoor Unit, Connections

• 21-56 VDC Power Input - provided by customer, each terminal consumes 21 Watts

• 4xE1 Input/Output BNC type - E1 data conforming to the G.703 standard

(Optional RJ-48C Connection)

• NMS-Port - RJ-48C - SNMP interface for existing NMS systems

• Aux Port 1-RS-232 Connection, DB9 - provides local and remote control over terminals

• Aux Port 2-RS-232 Connection, DB9 - provides local and remote control over terminals

• ODU Power Interface - Category 3 Siamesed cable provided in the install kit

• ODU Data Interface - Category 3 Siamesed cable provided in the install kit

Indoor Unit, Controls and Indicators

• Fuse/On-Off Switch - Fuse holder containing a 250 V, 3 amp fuse for protection of the

system. The fuse can be rotated counterclockwise to disable the system, clockwise to

enable.

• LEDs, Status and Alarm - The status LED confirms the system is on. The alarm LED

indicates an alarm condition exists. The fault can be determined by means of the local RS232 interface on the IDU and a VT-100 terminal.

• G.703 Ground Switch - Enables the customer to configure the ground requirements of the

E1 unbalanced connections according to the G.703 standard.

• LEDs, Link, TX and RX - Provide a visual indication of the status of the link, transmitter and

receiver.

Fuse -250V 3A

N2 -

250V 3A

21-56V

+

Link

-

21-56 VDC

Input

TM

Status

Alarms

Figure 2.2 - N2-4XE1 Link IDU

G.703 Ground

Digital Input

1234

Digital Output

4xE1 Data Input/Output

BNC-Type Connections

Switch

DC

AC

10

NMS Port

Link

Tx

Rx

NMS - SNMP

Interface, RJ-48c

RS 232 Interface,

DB-9 Connector

AUX Port 1

AUX Port 2

ODU Interface

+

-

Data

Siamesed Cat 3

Data/Power

To/From ODU

WL272903

Outdoor Unit

• Date/Power Cable - Siamesed cat - 3 Data and power cables.

• RSSI - BNC type connector used for RSSI measurement.

• Antenna (RF) Connector - N-type connector used for connection with antenna.

• Main Power - The N2-4XE1 is designed to work from a power input of 20 to 56 VDC.

• Grounding Connector - The front panel of the N2-4XE1 is equipped with an M5 ground

screw and associated washers. This ground screw serves as the proper chassis-ground

connection point for an external ground source. The N2-4XE1 must be grounded in

accordance with the electrical codes, standards, and practices governing the local

installation.

The following alarm configuration features are possible using the RS-232 interface:

N2-4XE1 Installation and Operation Manual

Table 2.2 - Features Available Through the RS-232 Interface

tinUnoitpircseD

smralAUDI tsoLataDUDO,mralAxumeD,mralALLP,4-1SIA

noitarugifnoCUDIsehctiwS,noitarugifnoC,dnuorG,307-G

smralAUDOrezisehtnyS,domeD,evieceR,CLA

noitarugifnoCUDO noitceleSycneuqerF,noitaunettAFR,kcabpooLelbaC

209772LW

11

N2-4XE1 Installation and Operation Manual

Figure 2.2a - Outdoor Unit, Front View

Mounting

Studs

WL272910

Figure 2.2b - Outdoor Unit, Back View

Antenna Connection

(N Type, Female)

Receive Signal Level (RSL)

Output (BNC Type, Female)

Siamesed Category 3

Ethernet and

Power cables

ODU

Ground Connection

12

WL272905

N2-4XE1 Installation and Operation Manual

2.4 ODU Performance Monitoring

RSSI - A voltage provided through a BNC connector on the outside of the ODU. The RSSI port

is used for antenna alignment during installation and for periodic measurement of Receiver/

Path performance. The RSSI voltage is related to Rx BER from -30 dBm to -90 dBm.

2.5 Theory of Operation

General Overview

The N2-4XE1 is a point to point Wireless Extension operating in the 5.3/5.7 GHz UNII band as

authorized in rule sections 15.401 through 15.407. The unit is enclosed in a weather proof

outdoor enclosure and is intended to provide data links over distances up to 10 km. The radio

in the unit operates full duplex, transmitting and receiving data at the rate of 8.448 Mbps. The

radio is modulated using BPSK.

2.5.1 N2-4XE1 Indoor Unit

Circuit Description

The following circuit description is intended to explain the operation of the indoor and outdoor

units at the block diagram level. This text is written with the idea that the reader has the block

diagram readily available, as it will aid in understanding the signal flow in the radio.

Four E1 rate tributaries are time division multiplexed and input to the IDU protection circuit by

means of four panel mounted BNC type connectors. The LIU (Line Interface Unit) converts the

4xE1 data stream from a bipolar HDB3 signal which is input to the Mux/Demux and converts

the 4E1 signal to an aggregate signal. The FGPA scrambles the data into a pseudo random

pattern which passes the data back to the mux and through an E2 rate line interface to and from

the ODU. The microcontroller acts as the processing core to manage all external and internal

functions of the IDU/ODU. This includes monitoring the ODU, IDU for alarm conditions, as well

as providing SNMP and RS-232 control over the terminal. See Figure 2.3.

13

J16

Status

Lead

R

J

1

N2-4XE1 Installation and Operation Manual

Figure 2.3 - Block Diagram, IDU

IDU Board

5V DC-DC

CS2

Converter

3.3V

SCC2

SCC3

Ether

SCC1

RASO

Reg

EEPROM

2K

Modem

Driver

Addr

Data

PIO

PIO

CSO

Power

Supervisor

CS1

Reset

CPU

68EN302

RS232

XCVR

Ethernet

XCVR

Fuse

J15

J

2

3

Front

Panel

Board

Aux 2

Aux 1

OTPROM

E2

LIU

Data

Addr

Boot

512K

Flash1

512K

Addr

Decode

De-Scrambler

Flash2

512K

E1 / E2

MUX

Status

Regs

Cntrl

Regs

Radio

Sync

Scrambler

303V

XCVR

FPGA

TAO

addr

data

DRAM

8M

E1

LIU1

E1

LIU2

E1

LIU3

Ether

Link Leds

UNI/BI SW

E1 BNC

TX RX

14

E1

LIU4

WL055001

N2-4XE1 Installation and Operation Manual

2.5.2 N2-4XE1 Outdoor Unit, Transmitter

The data is differentially encoded and scrambled before it is routed through the transmit

baseband filter to provide spectral shaping. The baseband filter is a five pole low pass filter.

After amplification, the baseband signal is fed to the modulator consisting of a doubly balanced

mixer. The modulator is running directly at the transmitter frequency of 5.775 GHz ± 50 MHz.

The local oscillator signal of the mixer is supplied from the frequency synthesizer section, with

the frequency dependant on the RF channel selected. Operation of the frequency synthesizer

will be detailed later in this document.

From the output of the modulator, the signal is amplified and then passed through a 150 MHz

wide bandpass filter to remove any local oscillator products from the output spectrum. After

filtering, the signal is passed through a series of amplifier and attenuator stages that are used

to control the output power level. With a combination of fixed and variable attenuation the output

power can be set to one of four different levels to accommodate different antennas used with

the product.

The power setting is maintained by an active ALC circuit that samples the transmitter output

power and then adjusts the variable attenuator to keep the output power constant over the

operating temperature of the unit. The power level is controlled to within ±1 dB of the set point.

Following the attenuators the signal is fed through additional amplification to bring the output

level to a maximum of +13 dBm at the output of power amplifier. A lowpass matching section

follows the power amplifier to aid in filtering harmonics of the signal. After passing through the

duplexer, the power level at the antenna port is a maximum of +11 dBm.

15

N2-4XE1 Installation and Operation Manual

2.5.3 N2-4XE1 Outdoor Unit Receiver

The receiver in the N2-4XE1 is a conventional dual conversion design with IF frequencies of

474.88 MHz and 70 MHz.

From the receive port of the duplexer, the low level input signal is passed through a low noise

preamplifier that provides 25 dB of gain. Following the preamplifier the signal is passed through

a 200 MHz wide bandpass filter to provide image rejection for the first mixer.

The signal is then mixed with the first LO to convert the signal to 474.88 MHz. Following further

amplification the signal is passed through a five pole, 20 MHz wide bandpass filter. This filter

provides image filtering for the second mixer, and also helps attenuate signals on the adjacent

receive channels. After filtering, the signal is further amplified and then passed through a

variable attenuator stage before it is applied to the second mixer.

The output of the second mixer is at 70 MHz. The 70 MHz IF stages provide additional gain along

with two sections of variable attenuation for the AGC function. The primary adjacent channel

filtering is also at 70 MHz where the signal is passed through a 12 MHz wide SAW filter. The

combination of filters provide a minimum of 47 dB of attenuation at the adjacent receive

channels (± 10.24 MHz).

At the end of the 70 MHz IF chain the signal is fed into a quadrature demodulator. The carrier

recovery loop consists of a four quadrant multiplier that multiplies I and Q baseband signals to

create an error voltage. This error voltage is then amplified and fed back to the 70 MHz VCO.

This forms a phase locked loop that is locked to the received carrier frequency.

The 70 MHz output is also fed into a wide band logarithmic amplifier that provides a DC voltage

output proportional to the 70 MHz signal strength. The DC voltage is then integrated and fed

back to the variable attenuator stages to form an AGC control loop. This control loop keeps the

signal level at the input to the demodulator chip constant over the entire operating range of the

receiver.

Data recovery from the I baseband signal begins by passing the I signal through a slicer. The

output of the slicer is a digital signal that contains both data and clocking information. A clock

recovery circuit recovers receive timing information that is needed to clock the data through the

descrambler, and differential decoder.

16

2.5.4 Synthesizer

The FPGA provides four 22-bit streams in a serial format loaded to the synthesizer. This data

provides all of the possible frequencies at which the system can operate. Depending upon the

dip switch settings selected, the actual frequency being used is selected. When the reset button

is pressed, the FPGA will reload this data to the synthesizer.

Frequency Synthesis

The local oscillator frequencies used in the RF Unit are all synthesized from a 19.2 MHz, ± 2.5

PPM reference oscillator. The overall frequency stability of the radio is ±2.5 PPM, directly

reflecting the reference oscillator stability.

A dual frequency synthesizer chip is used to control both the first and second local oscillator

loops. This chip supports one high frequency oscillator, up to 1.5 GHz, and one lower frequency

oscillator to be used as a second LO.

The first local oscillator VCO operates at one half the transmitter output frequency, and changes

with the transmit channel selected. The first LO consists of a bipolar VCO operating at 2.887

GHz ±25 MHz. The output of this VCO is buffered and then passed through a X2 prescaler chip

before being fed back to the synthesizer chip. The phase comparison frequency for the first LO

is 320 kHz.

N2-4XE1 Installation and Operation Manual

After amplification the 2.887 GHz signal is passed through a frequency doubler to create the

5.775 GHz signal that is applied to the mixer stages.

The second local oscillator consists of a VCO that is phase locked to 404.88 MHz. This auxiliary

synthesizer is operating with a phase comparison frequency of 240 kHz.

17

N2-4XE1 Installation and Operation Manual

This Page Left Blank Intentionally

18

N2-4XE1 Installation and Operation Manual

Figure 2-4 (WL272902) goes here

19

N2-4XE1 Installation and Operation Manual

Figure 2-4 (WL272902) goes here

20

N2-4XE1 Installation and Operation Manual

3.0 Equipment Installation and Commissioning

3.1 Installation

The N2-4XE1 has been specifically designed for ease of installation. The following installation

instructions should be followed.

1. Plan the installation - Decide where each component of the N2-4XE1 will be placed prior

to commencement of any installation activity. Installation considerations for each component in general are as follows:

a. Indoor Unit - Install in floor or rack mount configuration.

b. Outdoor RF Unit - Mount as close as practical to the Antenna assembly. The maximum

distance is determined by the included interconnect cable which is 1 meter in length.

Determine pole mounting details for the Outdoor Unit and Antenna. Adjust output power

according to Table 3.1.

c. Antenna Unit - See Appendix B.

2. Inventory your equipment and installation materials.

To install one (1) terminal you should have the items shown in Table 3.1.

3. The following tools should be on hand:

Tool Purpose

Wire Stripper/Cutter General wire stripping and cutting purposes

Hand-Held Voltmeter (DMM) Confirm magnitude, polarity, continuity

with standard probes

2 Adjustable Wrenches Antenna mounting, Outdoor Unit up to 1.5 cm

#2 Philliips Screwdriver Outdoor Unit Grounding

Table 3.1 - Inventory of Equipment and Installation Materials

ytQnoitpircseD

1UDIX4-2N

1tiKllatsnIUDIX4-2N

1UDOX4-2N

1srenetsafdetaicossadnatekcarBtnuoMllaWroeloP

1elbaCrewoPylppuSCDV84/ataDdesemaiS

1ylbmessAelbaClaixaoCelaM-NotelaM-N

309772LW

21

N2-4XE1 Installation and Operation Manual

3.2 Install the IDU

1. Choose either a desktop or rack mount mounting location.

• For a desktop mount configuration, the unit can be installed directly out of the box.

• For rack mounting the IDU, installation kit contains rack mounting brackets for flush or

projection mounting. See Figure 3.1 for IDU Install Kit. Remove the desktop mounting

feet and install the rack mount brackets.

2. Make the following connections to the IDU:

• 21-56 VDC Input

• 4xE1 Data Input/Output BNC-Type Connections

• G.703 Ground Switch

• NMS - SNMP Interface, RJ-48C

• Aux 1 (DB-9, Terminal Interface, RS-232)

• Aux 2 (DB-9, Aux Serial port or Alarm Input)

• Siamesed Cat. 3 Data/Power To/From ODU

Figure 3.1 - N2-4XE1 Link Rack Mount

12 x 24

Rack Screws

4 Places

250V 3A

N2 -

21-56V

Status

Alarms

Digital Input

1 2 3 4

Digital Output

NMS Port

AUX Port 1

DC

Link

Tx

AC

Rx

AUX Port 2

ODU Interface

+

-

Data

TM

Link

+

-

WL272911

22

N2-4XE1 Installation and Operation Manual

3.3 Outdoor RF Unit Installation

General

The outdoor unit is installed by means of a pole mount adaptor bracket (wall mount optional)

that is secured to the pole using two metal hose type clamps. Figure 3.1 shows the hardware

provided to mount the Outdoor RF Unit.

1. Install the outdoor unit pole mount adaptor bracket using the supplied metal hose type

clamps. See Figure 3.2.

2. Align the four mounting studs on the outdoor unit with the bracket holes (See figure 3.3)

and secure to the bracket by pushing down the latches as shown in Figures 3.3a and 3.3b.

3. Connect the Siamesed Category 3 Data/power cable, the N-type antenna and the ground

connections as shown in Figures 3.4a and 3.4b.

Figure 3.2 - Outdoor Unit Mounting Hardware

Pole Mount

Bracket Fasteners

Wall Mount Bracket

(Optional)

Pole Mount Bracket

Siamesed Catagory 3

Ethernet and Power Cable

for IDU to ODU Interconnection

23

N-Male to N-Male

ODU to Antenna

Coaxial Cable Assembly

WL272909

N2-4XE1 Installation and Operation Manual

Figure 3.3 - Mounting the Outdoor RF Unit to the Bracket

Outdoor Unit

Pole Mount

Bracket

24

WL272912

N2-4XE1 Installation and Operation Manual

Figure 3.3a - Mounting Bracket Latch and Stud Mount Detail

Detail of Latch Mechanism

for Securing the Outdoor Unit

to the Pole Mount

(4 Places on Bracket)

Outdoor Unit

Mounting Studs

placed through

this hole

WL272913

25

N2-4XE1 Installation and Operation Manual

Press locking latches

down to secure the ODU

to the pole mount bracket

Mounting

Studs x 4

Figure 3.3b - Locking the Mounting Hardware

26

WL272906

N2-4XE1 Installation and Operation Manual

Figure 3.3c - N-Type Antenna and Siamesed Ethernet/Power Connections

N-Type

Antenna

Connector

Siamesed Category 3

Data/Power Cable

WL272907

27

N2-4XE1 Installation and Operation Manual

Figure 3.3d - Ground Connection

Ground Cable

(not supplied)

WL272908

28

N2-4XE1 Installation and Operation Manual

3.4 Commissioning

1. Visually verify that the N2-4XE1 is properly mounted.

2. Verify that the DC power input to the N2-4XE1 is on.

Refer to Table 3.2.

3.4.1 Configuring N2-4XE1 System Antennas

The antennas used on an N2-4XE1 radio system are generally configurable for either vertical

or horizontal polarization. It is extremely important to verify that both antennas are configured

for the same polarization, and that the appropriate antenna polarization has been selected for

the specific radio link.

Table 3.2 - Installation Checklist

tsilkcehCnoitallatsnI

?eruceserawdrahgnitnuomkcarehtsI

?dednuorgylreporptinuehtsI

?detcennocylreporpannetnaehtsI

?tcerrocdnaecalpnisnoitcennocatadehterA

809772LW

3.4.2 Aligning the N2-4XE1 System Antennas

With the N2-4XE1 at each site properly configured for operation, antenna alignment must be

performed at both sites. Proper antenna alignment is crucial to the proper operation of an N24XE1 radio system, and should only be accomplished by experienced professionals.

The N2-4XE1 is equipped with a ODU mounted BNC-(f) RSSI connector to which an analog or

digital voltmeter can be connected. The voltage range at the test point, between the center

conductor of the connector and ground, varies from approximately two VDC to four VDC,

serving as a receive signal strength indicator (RSSI). The stronger the receive signal, the higher

the RSSI voltage.

Emanating from a microwave antenna is a main beam (or lobe) of RF energy, surrounded by

RF side lobes. The beamwidth of the main beam varies with the size and type of antenna, as

well as the specific frequency of the RF signal, and is generally defined by the nominal total width

of the main beam at the half-power (-3 dB) points. Side lobes surround the main beam at specific

angle distances, and will be lower in power than the main beam.

When aligning an antenna system, it is extremely important to verify that the antennas are both

aligned on the main beam, not on a side lobe. Referencing Table 3.3, the first side lobe will

generally be located at an angle slightly less than twice the antenna beamwidth.

Following the course alignment of an antenna system, a common practice when performing a

fine alignment is to slowly swing each antenna (one at a time!) in both vertical (elevation) and

horizontal (azimuth) planes to verify that the main beam and first side lobe can be accurately

identified. This insures that accurate alignment of the antenna system on the main beam has

been accomplished.

29

N2-4XE1 Installation and Operation Manual

Each N2-4XE1 is shipped with an RSSI test sheet, showing the relationship between the receive

signal strength level (in dBm) and the RSSI level (in VDC). These RSSI test sheets are often

referred to as AGC Curves. The RSSI test sheets can be used to verify that the calculated

receive signal levels match up with the actual receive signal levels. Substantial differences

between calculated and actual levels could point to transmission system problems, side lobe

alignment, path obstructions, etc.

Table 3.3 - Approximation Table

elytSdnaretemaiDannetnA)iBd(niaG)seerged(htdiwmaeBBd3

cilobaraptoof-25.821.6

*cilobaraptoof-42.031.3

lenaptalftoof-15.324.9

lenaptalftoof-25.827.4

.tnailpmocCCFtoneradna,ylnoASUehtedistuoesuroferasannetnahsidtoof-4ehT*

909772LW

30

N2-4XE1 Installation and Operation Manual

4.0 Maintenance and Troubleshooting

The N2-4XE1 contains static sensitive components, and has no user-serviceable parts.

4.1 N2-4XE1 Maintenance

The N2-4XE1 is designed to operate with no scheduled maintenance activities. From a

precautionary perspective, a regular check of power supply input voltages and RSSI voltages

should be planned by the user.

4.1.1 RSSI Voltage

The Wireless Customer Service department recommends a monthly check of the N2-4XE1’s

RSSI voltage. Variations in the RSSI voltage could be an indicator of antenna or antenna feed

movement, loose or improper RF cabling or connectorization, path obstructions or reflections,

etc.

31

N2-4XE1 Installation and Operation Manual

4.2 Identifying and Resolving Receive Signal Strength Issues

There are a great number of items which can affect the transmission of a microwave signal from

one site to another. Every microwave path is unique, and must be evaluated for performance

before a radio link is installed.

Outside of radio equipment issues, antenna alignment, RF signal blockage, and multipath

fading are among the most common transmission problems experienced in the field.

4.2.1 N2-4XE1 Equipment Issues

Frequency Selection

1. Verify the transmit/receive frequency selection for each N2-4XE1 radio is set appropriately, and that a “matched pair” of radios has been selected for the system. Each N2-4XE1

terminal can be set to the frequencies listed in Table 4.1.

2. To reduce the possibility of co-adjacent channel interference, proper frequency coordination and antenna polarization is used to isolate each channel. The concept is to achieve

maximum RF isolation between link channels by means of frequency spacing and antenna

polarization. In a “star” configuration an optimum frequency and antenna polarization plan

is provided to demonstrate an example of maximum isolation between links (See Figure

4.1).

Table 4.1 - Frequencies

.oNlennahCycneuqerF

18062.5

'1865337.5

240172.5

'229547.5

382182.5

'361657.5

425192.5

'44667.5

567103.5

'546677.5

600213.5

'688687.5

742223.5

'721797.5

884233.5

'863708.5

32

019772LW

N2-4XE1 Installation and Operation Manual

4.3 Where To Get Further Assistance

Your primary source of assistance is the support staff of the organization from which you

purchased this product. The Wireless, Inc. support staff should only be contacted directly if you

purchased this product directly from Wireless, Inc., or if you are unable to obtain sufficient

assistance from your primary support contact.

General Product and Company Information

Wireless, Inc.

5352 Betsy Ross Drive

Santa Clara, CA 95454-1101

USA

Tel: +408 727 8383

Fax: +408 727 1259

E-mail: info@wire-less-inc.com

Website: www.wire-less-inc.com

Detailed Product Information, Sales, Pricing Information and Pre-Sales

Technical Support

Wireless, Inc.

Sales Department

5352 Betsy Ross Drive

Santa Clara, CA 95454-1101

USA

Tel: +408 727 8383

Fax: +408 727 0990

E-mail: info@wire-less-inc.com

Website: www.wire-less-inc.com

Post-Sales Technical Support (Customer Service)

To assist you with field issues and, if necessary, to arrange for repair services, Wireless, Inc.’s

Customer Service department can be reached via telephone, facsimile, e-mail, mail, or through

our Website.

33

N2-4XE1 Installation and Operation Manual

4.4 Return Procedure

All material returned to Wireless, Inc. must be accompanied by a Return Material Authorization

(RMA) number from Wireless, Inc.'s Customer Service department. If you purchased your

Wireless, Inc. product through a distributor, the Wireless RMA number should be obtained

through the distributor. An RMA number is necessary to assure proper tracking and handling

of returned material at the factory. Wireless, Inc. reserves the right to refuse shipments not

accompanied by an RMA number. Refused shipments will be returned to the shipper via collect

freight.

To obtain an RMA number, contact Wireless, Inc. as follows:

Telephone: +408 727 8383

Fax: +408 727 1259

E-mail: customerservice@wire-less-inc.com

The following information will be required to issue an RMA number:

• Part Number

• Serial Number

• Failure Description

• Contact person, telephone, and fax numbers

• Ship-to address

• Bill-to address*

• Customer purchase order* (P.O.) or reference number

* Required for non-warranty repair services. For non-warranty repair services, an RMA

number will be issued when Wireless, Inc. acknowledges the purchase order.

Important - All non-U.S. returns must include 5 copies of proforma/customs invoice for each

shipment which lists:

• RMA number

• Value of items

• Description of items (including the Wireless model or part number)

Please send all returns to:

Wireless, Inc.

Attn: RMA Department

5452 Betsy Ross Drive

Santa Clara, CA 95054-1101

USA

RMA No. __________

The customer is responsible to properly label and package repairs and prepay shipping to

Wireless, Inc. If possible, the original packaging material should be used to return electronic

parts. The RMA number must be visible on the outside of all packages returned. Unless other

arrangements have been made, all repairs are shipped back to the customer prepaid via ground

carrier.

34

N2-4XE1 Installation and Operation Manual

Appendix A Grounding Practices and Lightning

Protection Information

General

Good grounding (“earthing”) practices, when used in telecommunications, have some direct

benefits which can help you maximize the up time of your system as well as ensure the safety

of those people working on the system. Among these benefits are:

1. Protection of personnel from electric shock and fire hazards.

2. Reduction of radiated and conducted electromagnetic susceptibility.

3. Improved system tolerance to discharge of electrostatic energy and lightning interference.

4. Minimized service interruptions and service damage.

There is no practice or formula which can completely eliminate the above risks, but we at

Wireless, Inc. believe that good grounding and bonding practices can significantly reduce the

risk of many of these hazards. We have included a bibliography at the end of this appendix which

contains several publications that are readily available and contain detailed information on

many aspects of grounding systems and their design, implementation, measurement, and

maintenance.

Please note that every telecommunication site is unique, and must be evaluated accordingly.

The following information is provided for generic reference and educational purposes only. The

grounding plans and practices for a given site should only be established and accomplished by

trained professionals, working in accordance with local practices and regulations.

Ground Connections

There should be a grounding plan designed at the outset of site design in order to provide the

best grounding procedures and to minimize ground loop currents. This should be achieved by

connecting the outer conductors of the cables through a large section copper strap to a central

grounding point and the size of the conductor should be increased as each branch path is

added. The final conductor should be connected directly to the grounding system. For a radio

site a single copper grounding rod is insufficient because its impedance is likely to be too high.

Lightning Protection

Radio sites can be particularly prone to lightning strikes by virtue of their normally exposed

locations and the presence of relatively tall antenna support structures.

It is not possible to provide and guarantee complete protection from the effects of lightning;

however, they can be significantly reduced by careful attention to grounding, protection

devices, and the layout of the site itself.

Reference should also be made to various publications, some of which are listed in the

Bibliography. Where any site owner or user is in doubt about the protection requirements for any

particular location, the appropriate authority should be consulted.

A-1

N2-4XE1 Installation and Operation Manual

Protection Arrangements

The purpose of any protection arrangement should be to provide a suitable path to ground for

the lightning current, to ensure adequate bonding between structures and all metalwork on the

site and the common grounding system in order to reduce the side flashing, and to attempt to

prevent the entry of flashes or surges into the building.

The resistance to ground should be kept to a minimum and a value of less than 10-ohms is

recommended. The most important feature is that the system should ideally be at equal

potential across the entire site.

Certain authorities and service providers have their own particular practices which have to be

followed where applicable.

Arrangements will vary considerably from very simple sites to complicated sites with multiple

buildings, antenna support structures and associated equipment, and may involve integration

with existing systems. Such systems may require upgrading.

Lightning Conductors

Down conductors, bonding interconnections, ground rings and radial tapes should be of copper

cable or solid copper tape with a minimum cross section according to local practice with all

connections protected by non reactive paste.

Protected test points should be included if appropriate, and sacrificial ground lugs should be

clearly marked and easily accessible for periodic inspection.

Grounding of Antenna Support Structures

A structure will generally act as its own lightning conductor and therefore will not require an

additional conductor from the top to the base. A lightning rod may be required to extend the zone

of protection to protect equipment mounted on the top of the structure. The lightning rod should

extend 2.5-meters above the highest equipment.

Ground mounted support structures should be connected at their base to a ground ring via

sacrificial ground lugs. Towers should have a connection from each leg.

A ground ring should consist of copper cable or solid copper tape with ground rods equally

spaced at 2-meter intervals around the base of the structure as close to it as possible, buried

approximately 0.6-meters deep where soil conditions allow. An alternative method using radials

rather than rings is detailed in “The ‘Grounds’ for Lightning and EMP Protection”, second

edition, published by PolyPhaser Corporation.

The ground ring should be connected to the main building ground by the most direct route,

buried as appropriate.

Roof mounted structures should be connected to the main building ground by the most direct

route using sacrificial lugs and copper cable or tape as appropriate. Tower guy wires should be

directly bonded at their lowest point to a suitable ground electrode or connected to the site

ground by the most direct route.

A-2

Grounding of Feeders

All antenna feeders should be bonded to the tower at the upper and lower ends and grounded

at the point of entry into the building. Weatherproof grounding kits are available from antenna

manufacturers.

Note: Many of the cables used by Wireless, Inc. have braided rather than solid outer

conductors; this type of grounding is not appropriate. In these cases we recommend the

use of Wireless, Inc. approved lightning arrestors. For information on lightning arrestors,

please contact Wireless, Inc.’s Customer Service department.

Grounding of Buildings

A ground ring ideally should surround the building and be connected to individual grounds

associated with feeder entry, antenna support structure, building lightning conductor, equipment room, main AC supply and other facilities. Each connection should be made by the most

direct route in order to minimize interaction between the different grounding functions.

The ground ring should consist of copper cable or tape with electrodes 2- meters or greater in

length, buried to a depth of 0.6-meters and at a distance from the building not to exceed 1-meter.

N2-4XE1 Installation and Operation Manual

Buildings may require lightning rods where they are not within the zone of another protected

structure.

Bibliograpy

ITU - T K.40 Protection against LEMP in telecommunications centres

ITU - T K.27 Bonding configurations and earthing inside a telecommuni-

ITU - T K.35 Bonding configurations and earthing at remote electronic

ITU - T K.39 Risk assessment of damages to telecommunications sites

ITU - T Lightning Handbook The protection of telecommunication lines and equipment

IEEE Emerald Book - Powering and Grounding

The Grounds for Lightning and EMP Protection, second edition

Published by PolyPhaser Corporation

cation building

sites

due to lightning discharges

against lightning discharges

A-3

N2-4XE1 Installation and Operation Manual

A-4

N2-4XE1 Installation and Operation Manual

Appendix B Installation Instructions

Read the instructions completely before assembling or installing the antenna. This installation

can be dangerous and requires qualified personnel familiar with microwave assembly and

installation.

Site Planning

1. For antenna mounting and planning dimensions, see Figure B.1 and Table B.1.

2. The antenna is normally assembled with an elevation adjustment range of +50 degrees to

-5 degrees. By inverting the mount, it can be assembled with a +5 degree to -50 degree

range. In either configuration, the antenna centerline can be offset right or left, relative to

the vertical mast pipe (See Figure B.2) by inverting the Horizontal Tube Assembly.

Figure B.1 - Two Foot Diameter Antenna

J

K

H

P

B

A

G

Q

D

C

WL035927

B-1

N2-4XE1 Installation and Operation Manual

Table B.1 - Two Foot Diameter Antenna Dimensions

noisnemiDnoitpircseDannetnA)m6.0(.tf2

AhtgneLtnuoM)mm075("4.22

BtnioPtoviP)mm501("2.4

CtesffOeniLretneC)mm521("0.5

DturtStnuoMlatnoziroHA/N

EturtStnuoMlacitreV.tP.tvP)mm571("8.8

FturtSediSdexiFlatnoziroHA/N

GenilretneCannetnA)mm543("6.31

HhtgneLrotcelfeR)mm513("3.21

htgneLduorhStrohS)mm023("5.21

J

htgneLduorhSgnoL)mm583("1.51

KretemaiDannetnA)mm016("0.42

L)dradnatS(htgneLemodaR)mm043("4.31

NhtpeDturtStnuoMA/N

PxetreVrotcelfeR)mm091("6.7

retemaiDtsaM)mm511-06("5.4"4.2

Q

egnaRelbatsujdAhtumizA °5±

segnaRtnemtsujdAnoitavelE °5-/°05+

829530LW

B-2

3/8” (10mm)

Round Head

Screw Lockwasher

and Nut (4)

ø 2.4”- 4.5”

(60-115mm)

Shear Stop

Collar

N2-4XE1 Installation and Operation Manual

Figure B.2 - Mount Configuration

Elevation

Plate

WL035929

B-3

N2-4XE1 Installation and Operation Manual

Unpacking and Preparation

1. Carefully unpack the reflector, mount, shroud (if any), radome (if any) and feed from the

crate. For correct antenna performance, handle all components with care. Set aside the

packaged feed and any shroud or radome. See Figures B.3 through B.6.

Caution: The reflector spinning has been formed to a very close-toleranced parabolic shape.

Careful handling and assembly is required to avoid denting or deforming the reflector,

which would degrade the antenna's performance.

2. Inspect for any damaged parts. See Tables B.2a-B.2d for an inventory of the parts and

hardware shipped with the antenna.

Shroud Attachment

Attach the shroud assembly that is provided with high-performance antennas to the reflector.

The installation procedure is covered by another instruction sheet supplied with the shroud.

Note: Some models have the shroud factory installed.

Table B.2a - Contents List, Reflector Assembly

rebmuNtraPnoitpircseD.ytQkcehC

3-23832A2-nepO'2ES.yssA.lfeR1

039530LW

Table B.2b - Contents List, Feed Assembly

rebmuNtraPnoitpircseD.ytQ

1-63752pmalCgnitnuoMdeeF4

305-61762058.5-052.5A/SdeeF1

0715TDA071SSD'04x8//7x61/3lytuBkcarTRR1

0500XWF560.x437.0W"4/1rehsaW4

122-IIsnoitcurtsnInoitallatsnI1

0600XUNtuNxeH4

0500XWSrehsaWtilpS4

139530LW

B-4

Feed Horn

Assembly

Mounting

Hardware

N2-4XE1 Installation and Operation Manual

Figure B.3 - Mounting Hardware Packed

WL035932

Figure B.4 - Mounting Hardware Unpacked

B-5

WL035933

N2-4XE1 Installation and Operation Manual

Table B.2c - Contents List, Mount Assembly

rebmuNtraPnoitpircseDytQ

105-57652ylbmessAepiPlatnoziroH 1

505-52752ylbmessAgnipmalCtsaM 1

2-61322vlaGdoRdedaerhT2

5-52542"1flaHpmalCtsaM1

0210GWFvlaGrehsaW2

1210GUNvlaGrehsaW6

0900GWSvlaGrehsaWtilpS4

905-52732yssAgnipmalCtsaM 1

2-61322vlaGdoRdedaerhT2

8-52542flaHpmalCtsaM1

0210GWFvlaGrehsaW2

0210GUNtuNxeH6

0900GWSvlaGrehsaWtilpS4

405-72752yssApotSraehS 1

3-58232doRdedaerhT2

2-52542trohS-flaHpmalCZA2

0310XUNtuNxeH6

0900GWSvlaGrehsaWtilpS4

305-03752yssAdoRnoitavelE 1

6-11632doRnoitavelE1

105-24832yssAtkrBdoRnoitavelE1

1-66652elgnAtroppuSnoitavelE1

0800GOBvlaGtloBxeH1

0210GWFvlaGrehsaW1

0410GWFvlaGrehsaW1

0210GUNvlaGtuNxeH1

5910XUNSStuNxeH4

0900GWSvlaGrehsaWtilpS1

0010GWSvlaGrehsaWtilpS1

439530LW

B-6

N2-4XE1 Installation and Operation Manual

Table B.2d- Contents List, Mount Assembly

rebmuNtraPnoitpircseD.ytQ

105-33752 tiKerawdraHtnuoM1

45-94701.vlaGtloB-U2

2-16532recapS2

5000MDAebuT.zo1ezieS-itnA1

1290XOBtloBxeH6

0210GWFrehsaW4

05000XWFrehsaW21

0210GUN.vlaGtuNxeH4

0600XUN.vlaGtuNxeH6

0900GNPtunlaP4

0500XWS.vlaGrehsaWtilpS6

1-09562 etalPnoitavelE1

1-19562 etalPhtumizA1

6811XOB wercSDHDNR4

0310XUN tuNxeH4

0800XWS rehsaWtilpS4

232-II snoitcurtsnInoitallatsnI1

539530LW

B-7

Parabolic

Reflector

N2-4XE1 Installation and Operation Manual

Figure B.5 - Parabolic Reflector

WL035936

Figure B.6 - Unpacking the Radome

B-8

WL035937

Mount Assembly and Attachment

1. The reflector should be placed face down, either on the shroud or blocked up on packing

lumber. Locate the Top and Bottom markings stenciled onto the back of the reflector.

2. Loosely attach Top Support Angles to the Horizontal Tube Assembly as shown in Figure

B.7 and B.8.

3. For desired mount configuration (refer to Figure B.2), attach the Vertical Tube Assembly

to the Horizontal Tube Assembly as shown in Figure B.7 and B.8.

4. Verify proper assembly of the elevation rod hardware as shown in Figure B.9. Remove

outer hardware and insert rod through elevation plate.

Important: For elevation angles grater than ±20°, Beveled Washers, shown in Figure B.9,

must be used. However, beveled washers may be used for elevation angles greater than

±10°.

5. Carefully place mount assembly onto antenna backring, taking care not to damage the

reflector. Loosely fasten the Top Support Angles and the Elevation Support Angle to the

antenna backring using 1/2” hardware as shown in Figure B.7.

6. Verify alignment of the Vertical Assembly with the vertical axis of the reflector and secure

the Top Support Angles and the Elevation Support Angle to the ring.

N2-4XE1 Installation and Operation Manual

3/8” (10mm)

Round Head

Screw Lockwasher

and Nut (4)

ø 2.4”- 4.5”

(60-115mm)

Shear Stop

Collar

Elevation

Plate

Figure B.7 - Antenna Mount Assembly

B-9

WL035938

N2-4XE1 Installation and Operation Manual

Figure B.8 - Antenna Mount Assembly

WL035939

Figure B.9 - Elevation Rod Assembly

Secure Antenna to Mast

Pipe using large and

small Mast Clamps

Attach Shear Stop

Collar on Mast Pipe so

that it will be Under

Azimuth Plate

Position Elevation Plate

on the Mast so elevation

screw is horizontal when

Antenna is aligned

WL035940

B-10

Feed Installation

Following the instructions provided with the feed assembly, install the feed in the reflector. Refer

to Figures B.10 through B.14.

Hex Nut,

Lockwasher,

Flat Washer

N2-4XE1 Installation and Operation Manual

Figure B.10 - Feed Horn Installation

Feed

Support

Clamp

Reflector

V

H

Vertical

V

Graphite

Grease

1/4”-20

Hex Nut

H

Horizontal

WL035941

B-11

N2-4XE1 Installation and Operation Manual

Figure B.11 - Feed Horn Polarization Markings

Feed Horn

Polarization

Markings

WL035942

Figure B.12 - Parabola Rear View Showing Polarization Reference Markers

Horizontal

Polarization

Marking

Vertical

Polarization

Marking

WL035943

B-12

N2-4XE1 Installation and Operation Manual

Figure B.13 - Feed Horn Installation

WL035944

Figure B.14 - Feed Horn Installation for Vertical Polarized Operation

WL035945

B-13

N2-4XE1 Installation and Operation Manual

Radome Installation

Molded Radomes (normally optional on standard antennas) should be installed following the

instructions provided.

Azimuth Adjustment Clamp/Shear Stop Installation

1. Verify proper assembly of the azimuth clamp/shear stop clamp as shown in Figure B.15

and B.16. Securely attach the shear stop clamp to the mast pipe as shown, orienting it as

nearly as possible to the antenna boresight direction, and square to the mast axis. Note

that the shear stop clamp used on the two foot antennas also provides the azimuth

adjustment.

2. Refer to Figure B.1 for the position of the antenna centerline relative to the shear stop

clamp. The clamp must be mounted to provide support during installation and azimuth

adjustment.

Figure B.15 - Azimuth Clamp/Shear Stop Assembly

3/8” (10mm)

Round Head

Screw Lockwasher

and Nut (4)

ø 2.4” - 4.5”

(60-115mm)

Figure B.16 - Azimuth Adjustment Clamp Assembly

WL035946

B-14

WL035947

Antenna Hoisting and Installation

1. Attach a hoist strap around the vertical assembly or the horizontal assembly as shown in

Figure B.17. Do not hoist by the elevation rod. Make sure that the vertical assembly is

unobstructed where it will mount against the mast pipe.

2. Attach tag lines and carefully lift the antenna into position, resting the vertical assembly on

the shear stop clamp.

3. Fasten the mount to the mast pipe with 1/2” U-bolts. The antenna must be free to rotate

during azimuth adjustment, so tighten only enough to close the gap between the mast and

vertical channel. Do not leave the antenna loose for any extended period of time, i.e.

overnight.

Figure B.17 - Hoisting the Antenna

N2-4XE1 Installation and Operation Manual

B-15

5”

(127mm)

WL035948

N2-4XE1 Installation and Operation Manual

General Antenna Alignment Procedures

Normally the antenna is aligned by performing azimuth and elevation adjustments and

elevation adjustments as necessary until the peak signal is obtained. It may be helpful to repeak one adjustment before finalizing or locking down the other.

Warning: Damage to the antenna can occur if azimuth or elevation adjustments are

attempted without loosening the proper connections as described in the following steps.

Azimuth Adjustment

1. Be sure the mast pipe U-bolts are just loose enough to allow mount rotation while

maintaining complete contact between the mount and the mast pipe.

2. Turn the long stainless steel azimuth screws against the mounting channel. By alternately

turning one azimuth adjustment screw out and the other in, the antenna can be rotated to

the desired azimuth angle. Approximately 1 turn changes the azimuth direction by 1°. Avoid

adjusting the antenna beyond the ±5° provided by the azimuth clamp as this can damage

the adjusting hardware. Fasten the antenna to the mast pipe and reposition the clamp if

needed.

Note: By securing the mount to the mast pipe and realigning the azimuth clamp with the

antenna boresight, more reliable and precise azimuth adjustments can be achieved.

After all adjustments are made, tighten both of the azimuth screws against the channel and

secure with the lock nuts provided.

3. Tighten the mast pipe U-bolts while maintaining the peak signal by alternating from left to

right in 1/4 turn intervals.

Elevation Adjustment

1. Insure that both of the bolts connecting the mount to the Top Support Angles and the

pivoting Elevation Angle (refer to Figures B.7 and B.9) are just loose enough to allow

resisted rotation.

2. Back the outer nuts on the elevation rod away from the bottom mount plate to allow some

fine adjustment range.

3. Turn the inside nut (with flat washer) on the elevation rod to adjust the elevation angle.

Approximately 5 turns changes the elevation by 1°. Remember, for elevation greater than

20°, install the two beveled washers as shown in Figure B.9.

4. After all adjustments are made, lock the nut against the bottom mount plate. Tighten the

angle pivot bolt and support bracket bolts.

Important: Be sure to tighten all hardware after final adjustments and insure that split

lockwashers, palnuts, or jam nuts are used where provided.

B-16

N2-4XE1 Installation and Operation Manual

Inspection and Maintenance

1. Before leaving the installation, check that all hardware on the mount, shroud, radome, and

feed is tight and that nuts are locked in place.

2. Inspection of the antenna should be performed at lease once a year to check its condition

and to insure safe operation and maintenance. Qualified personnel, knowledgeable and

experienced in antenna installations, are required for this inspection.

Supplemental Information

Table B.3 is provided for installers unfamiliar with adequate nut tightening procedures for use

on stainless steel bolts, U-bolts, galvanized bolts or any bolts without the ASTM-”A325” marking

on the head. Disregard these recommendations when specific tightening requirements are

given.

Note: It is not recommended to reuse a palnut that has already been fully tightened or

deformed in any way. It should be replaced by a new palnut.

Weather Proofing the Type N Female Connector on Feeds

Remove the protective cover from the end of the feed and mate the connectors, screwing the

male connector firmly onto the feed.

Important: After connecting the coaxial cable, wrap the Type N connector with the gray butyl

rubber, squeezing it firmly around all joints to make a continuous seal. Finish the

weatherproofing by wrapping the butyl rubber with several layers of black PVC tape (not

supplied).

Table B.3 - Nut Tightening Procedures

eziStloBlanimoNeuqroTtuNeuqroTtunkcoLtunlaP

"4/1.bl/.ni05.bl/.ni04

"61/5.bl/.ni201.bl/.ni06

"8/3.bl/.tf51.bl/.ni58

"61/7.bl/.tf42.bl/.tf51

"2/1.bl/.tf73.bl/.tf61

"8/5.bl/.tf47.bl/.tf82

"4/3.bl/.tf571.bl/.tf44

"8/7.bl/.tf212.bl/.tf15

"1.bl/.tf813.bl/.tf95

B-17

059530LW

N2-4XE1 Installation and Operation Manual

B-18

N2-4XE1 Installation and Operation Manual

Appendix C Adjustable Panel Antenna Mount

Assemble the panel mount according to Figure C.1. Orient Antenna using instructions supplied

with the antenna. Antenna models used with this mount may be circular, square or diamond

shaped. To change the offset of the antenna, unbolt the mount from the antenna, invert the

mount and reattach to the antenna.

Figure C.1 - Antenna Mount

Side View

Top View

2 3/8” (60mm)

DIA Mast

(2) 1/4” U-Bolt w/

Washer, Lockwashers

and Nuts

Azimuth Adjustment

Slots

Elevation

Adjustment

Slots

Rear View

Offset Left

Optional Mast Clamp Kit

for 1.9” (48mm) DIA thru

4.5” (114mm) DIA Masts

Rear View

Offset Right

C-1

WL035951

N2-4XE1 Installation and Operation Manual

Loosen the azimuth or elevation locking hardware while maintaining sufficient friction to prevent

unwanted slippage. See Figure C.2.

Insert flat blade screw driver into slot “B” and pry in direction of the arrow or into slot “A” and pry

in opposite direction, as shown in Figure C.2. Stop prying approximately as new overlapping

slot in bottom plate becomes sufficiently visible when viewed through slot “A”.

Figure C.2 - Azimuth and Elevation Planning

Top View

A

A

Sectional View

B

B

Top View

B

A

B

A

Sectional View

WL035952

C-2

N2-4XE1 Installation and Operation Manual

Insert Screw Driver into slot “A” and pry in direction of the arrow, as shown in Figure C.3. Stop

prying approximately as new slot in bottom plate becomes sufficiently visible when viewed

through slot “B”. Continue alternating slots and prying in either direction until desired alignment

is obtained. Lock down hardware securely before leaving the site.

Figure C.3 - Azimuth and Elevation Planning

Top View

B

A

B

A

Sectional View

Top View

A

A

Sectional View

B

B

WL035953

C-3

N2-4XE1 Installation and Operation Manual

Attach the antenna to the mount as shown in Figure C.4. For antenna polarization, assemble

the antenna to the mount using four sets of nuts and washers after desired polarization is

selected. In horizontal polarization the arrow sticker should be pointed in a horizontal direction.

Likewise, in vertical polarization the arrow sticker should be pointed in a vertical position.

Important: After cable connection is completed, wrap connection with Butyl or other

waterproof tape, supplied by the customer.

Each panel antenna has four factory sealed drain holes located on the back of the antenna. After

orienting the antenna to its proper polarization, the lower most sealed drain hole(s) must be

punctured with a pointed tool. See Figure C.4.

Caution: Do not allow the tool to protrude into the drain hole more than 1/4” (7mm) or damage

to the antenna may result.

Figure C.4 - Flat Panel Antenna

Antenna

Polarization

using Nuts

and Washers

Polarization

Arrow

Drain

Holes

WL035954

C-4

N2-4XE1 Installation and Operation Manual

Aim the antenna according to Figure C.5. Orient the antenna using instructions supplied with

the antenna. Antenna models used with this mount may be circular, square or diamond shaped.

To change the offset, unbolt the mount from the antenna, then invert the mount and reattach

in the antenna.

Figure C.5 - Adjustable Panel Antenna Mount

Side View

1/4” Carriage Bolts

w/ Washers, Lockwashers

and Nuts (2)

Elevation

Adjustment

Clamp Kit for

1.9 (48mm) DIA

Thru 4.5 (114mm)

DIA Masts

Rear View

Right Offset

Rear View

Left Offset

C-5

WL035955