Page 1

FCC ID: UXEMWSSTSR2 Report No. M060937_Cert_MWS_ST_SR

EMC Technologies Report Number: M060937_Cert_MWS_ST_SR

APPENDIX G

USER MANUAL

EMC Technologies Pty Ltd – 57 Assembly Drive, Tullamarine VIC 3043 Australia

www.emctech.com.au

Page 2

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

MWS

MWSMWS

MWS

----

ST/SR

ST/SRST/SR

ST/SR

----

2 DELUXE

2 DELUXE 2 DELUXE

2 DELUXE

SERIES

SERIESSERIES

SERIES

MICROWAVE LEVEL SWITCH

OPERATION MANUAL

MWS-ST-2 [TRANSMITTER]

DELUXE MODEL

MWS-SR-2 [TRANSCEIVER]

1

Page 3

TABLE of CONTENTS

This equipment has been tested and found to

comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

in a

This equipment

generates, uses and can radiate radio

frequency energy and, if not installed and used

in accordance with the instructions, may cause

ations.

However, there is no guarantee that

interference will not occur in a particular

installation. If this equipment does cause

harmful interference to radio or television

reception, which can be determined by turning

r is

to try to correct the interference by

Increase the separation between the

Connect the equipment into an outlet on a

t from that to which the

Consult the dealer or an experienced

OPERATION PRINCIPAL…... 3

FEATURES…………………… 4

SPECIFICATIONS…………... 5

APPLICATIONS………….….. 6

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

FCC Modification Warning

Any changes or modifications not expressively

approved by WADECO LTD. could void the

user's authority to operate this equipment.

NOTE:

protection against harmful interference

residential installation.

harmful interference to radio communic

HARDWARE OPTIONS….…. 9

DIMENSIONS & PART

NUMBERS……………………. 11

INSTALLATION &

MOUNTING…………………… 13

WIRING……………………….. 16

FUNCTION OF SWITCHES,

INDICATORS AND

RHEOSTATS…………………. 18

the equipment off and on, the use

encouraged

one or more of the following measures:

• Reorient or relocate the receiving antenna,

•

equipment and receiver,

•

circuit differen

receiver is connected,

•

radio/TV technician for help.

SENSITIVITY

ADJUSTMENT……………….. 19

GUARANTEE………………… 20

2

Page 4

OPERATION PRINCIPAL

ST/SR type microwave sensor is

ansmitter

)

The transmitter emits a continuous, low

power microwave beam towards the

and an output relay is released

The sensor has wide application across all

. The

sensor is generally used for process control

ing presence/absence of product,

flow conditions and point level

sensor may

also be used as a proximity switch for

detection of vehicles such as dump trucks

Harsh environments may result in a buildup

of contaminants on the sensing head;

however, the sensor is easily able to

enetrate such buildup thanks to the high

When microwaves transmitted through air

encounter an object, some will be reflected,

through the object. The amount of

e object

Generally speaking, microwaves cannot

Microwaves can easily pass through

s output is regulated to assure

compliance with FCC Rule 15, covering field

With low output power, the sensor’s power is

ST/SR level switch is the first of

heterodyne detection

obsolete, diode

The heterodyne detection method gives

detection output that is proportional to the

received power level, whereas the diode

t

is proportional to the square of the received

Therefore the heterodyne method allows

detection with a minimum received power

that is lower than that of the minimum level

This

erating

range/penetrability without any increase in

the power of the transmitted microwave

General

The MWSa level switch consisting of a tr

(MWS-ST-2) and a transceiver (MWS-SR-2

installed face-to-face.

transceiver

when the beam is obstructed.

areas of industry where highly reliable, noncontact level detection is required

by monitor

flow/no

detection in bins and silos. The

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

well below the American OSHA exposure

specifications as stated in Section 1910.97.

There are no health hazards to personnel

operating WADECO sensors: no license,

approval or caution sign posting is required.

Heterodyne vs. Diode Detection

The MWSits kind to utilize the

method rather than the, now

detection method.

Detection output

and rail cars.

Penetrability of Microwaves

p

penetrability of microwaves.

some absorbed and the rest will pass

microwaves passing through th

depends on its composition.

penetrate metals and are reflected; water

absorbs the most microwaves.

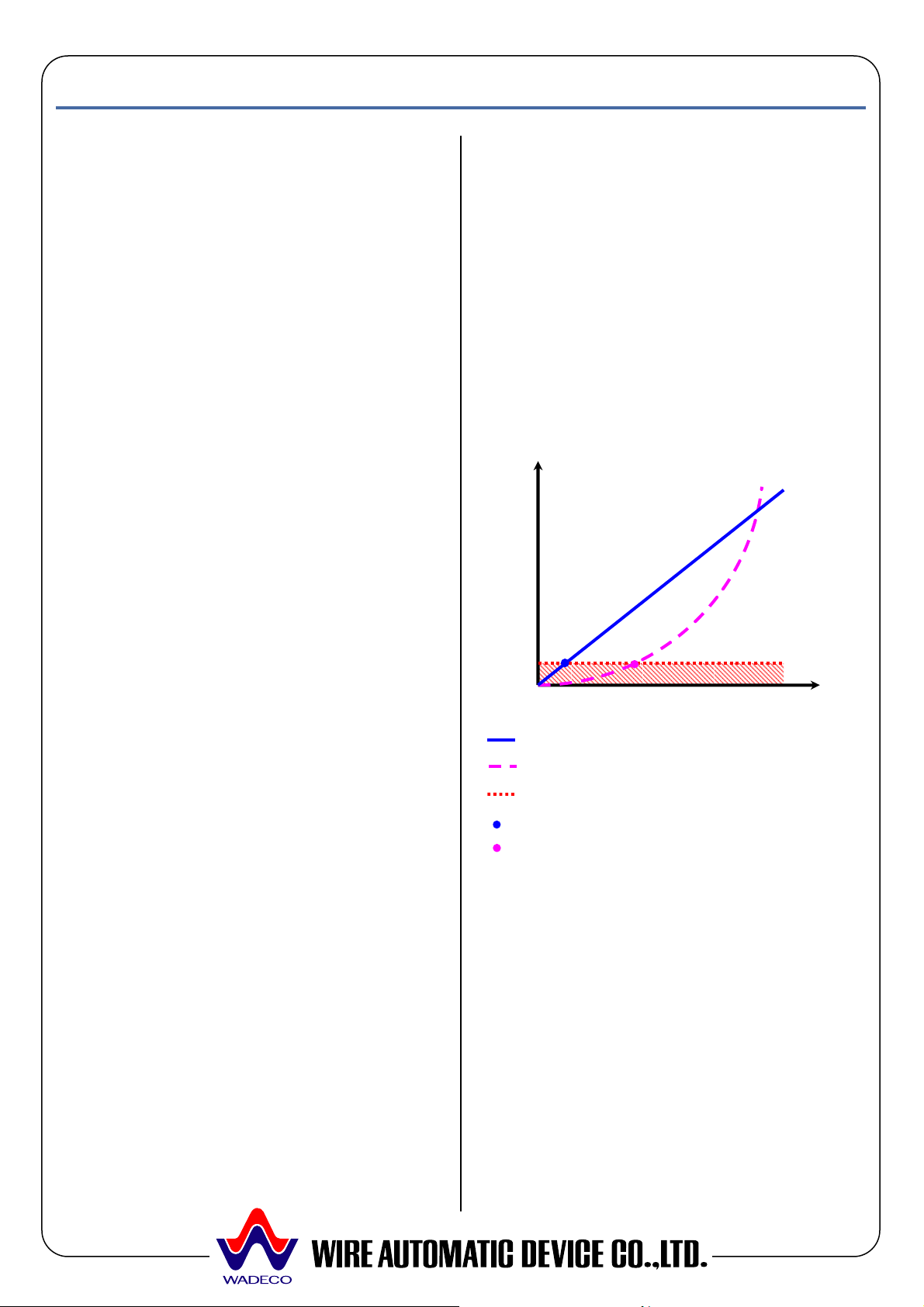

Received power level

Heterodyne method (WADECO)

Diode method (commonly used)

Noise level

Minimum received power: -70dBm

Minimum received power: -50dBm

detection method gives detection output tha

power level.

plastics, glass, ceramic, paper etc.

Safety of Microwaves

The sensor’

disturbance devices.

required by the diode detection method.

greatly increases the op

radiation.

3

Page 5

FEATURES

100m Range with heterodyne detection

27mm

antenna, thanks to the Heterodyne

process buildup on

antenna, firebrick, refractory etc., thanks to

is unaffected by surface

contaminants, flames, steam, vapor or

Easy initial beam alignment at installation,

Either broken beam (BLOCK) or unbroken

beam (UNBLOCK) detection method may

0.1~10secs.,

prevents instantaneous detection of falling

icator array displays the

point, allowing for visual sensitivity

e (CH1~4),

nterference. The sensor can also

operate in regular single channel mode by

The received power level may be output

The received power level and the

point are easily seen,

TRANS

CEIVER

CONTROLS

Beam obstructed

Approx. 100m range with a Ø

detection method.

High penetration

Easily penetrates

the increased operating range.

Unaffected by adverse environments

The sensor

airborne particles.

Simple beam alignment

thanks to the wide beam angle.

Selectable detection mode

be selected.

On delay time rheostat

On delay time, adjustable

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Transceiver

Transmitter

Beam unobstructed

Sensitivity-set-point

Relay OFF

material whist filling.

15 LED indicator bank

A 15 LED ind

received power level and the sensitivitysetadjustment and maintenance.

No set-to-set interference

Four channels are availabl

selectable by rotary switch, eliminating setto-set i

selecting CH0.

Analog output (optional)

as a 4 ~ 20mA analog signal.

Inspection window (optional)

sensitivity-setwithout removing the controller cover.

Received power levels

Relay ON

4

Page 6

SPECIFICATIONS

Type

NOTE: Phase of power supply must be the

Note: Operating distance may vary from

sensor to sensor and according to

ule 15 and

OSHA exposure specification stated in

Section 1910.97. Caution sign posting not

perate in single channel mode

by selecting CH0; doing so will disable the

(angle in half of receiving

On delay function

Output occurs on change of state, but only

after any delay period has past. Output

wave noise from noise simulator

: 1

ormal and

common modes), with the frequency of the

Note: Optional hardware is available for

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Transmitter : MWS-ST-2

Transceiver : MWS-SR-2

Power supply

AC100~120V ±10% 50/60Hz &

AC200~240V ±10% 50/60Hz

same for both transmitter and transceiver.

Operating distance

<80 meters

installation.

Frequency & transmission power

Approx. 24GHz, less than 10mW

Note: Complies with FFC Title R

required.

Number of channels

Single Channel Mode (CH0): 1

Multi Channel Mode (CH1~4): 4

Note: May o

multi channel function.

Received power level

Indicated by 1 of 15 LED indicators

Note: Indicator is fully illuminated

Sensitivity-set-point

Indicated by 1 of 15 LED indicators

Note: Indicator is half illuminated

Radiation angle

Approx. ±20°

value)

Output contact (on receiver)

1C relay contacts AC250V, 3A (COSØ=1)

Response time

25msec (when in multi channel mode)

10msec (when in single channel mode)

0.1 ~ 10sec

Condition of output function

relay is unexcited during output state.

Delay time from power on to function

Transmitter : Approx. 50msec.

Receiver : Approx. 5sec

Power consumption

Transmitter : 2VA

Receiver : 2VA

Noise tolerance

Square

(Rising time: 1 nanosecond, Width

microsecond), ±1.5KV (n

power supply in the 0º ~ 360º phase.

Operating ambient temperature

-10ºC ~ +55ºC

high temperature applications up to 600ºC.

Non-function ambient temperature

-20ºC ~ +70ºC

Continuous maximum pressure

0.5MPa

Note: Optional hardware is available for

high pressure applications.

Enclosure rating

IP65 Equivalent

Enclosure construction

Diecast aluminum

Color

Metallic silver grey

Weight

Transmitter : 1kg

Receiver : 1kg

5

Page 7

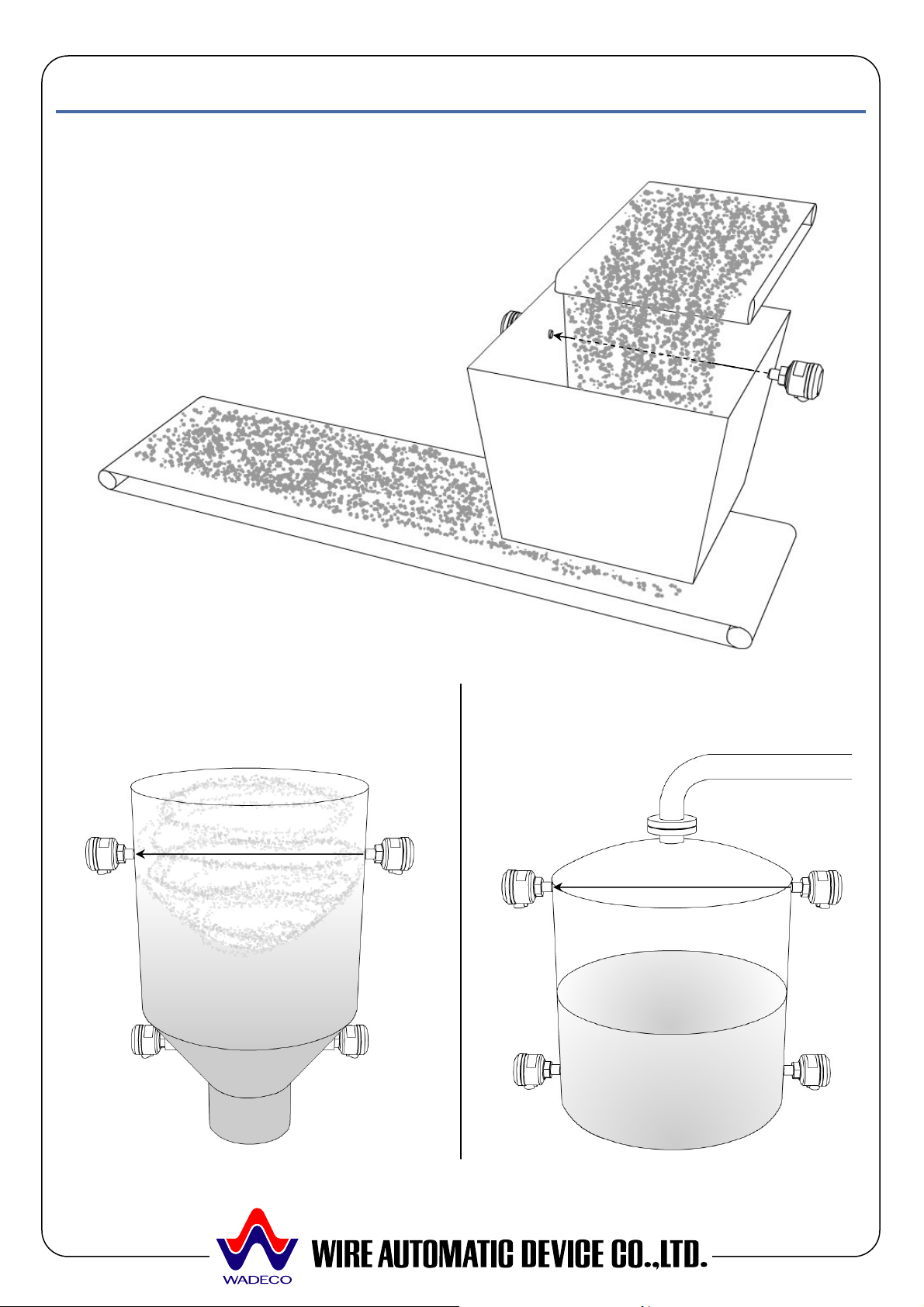

APPLICATIONS

Hi/low level of liquids in tanks,

Standard Applications

Blocked Chute Detection

Note: Install the sensors behind the

material flow to avoid false

detection.

Hi/low level of solids in cyclone

bins, hoppers, silos etc.

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Transceiver

MWS-SR- •

Transmitter

MWS-ST- •

and other storage vessels.

Transceiver

MWS-SR- •

Transceiver

MWS-SR- •

Transmitter

MWS-ST- •

Transmitter

MWS-ST- •

Transmitter

MWS-ST- •

Transceiver

MWS-SR- •

Transmitter

MWS-ST- •

Transceiver

MWS-SR- •

6

Page 8

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

High Pressure Applications

NP Type

Polypropylene plug with flange mounting.

Note: See HARDWARE OPTIONS for more details.

Transmitter

MWS-ST- • -NP

Transceiver

MWS-SR- • -NP

Mounting detail

High pressure flange

Polypropylene

‘top hat’ plug

7

Page 9

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

High Vibration & Hazardous Applications

Isolated, Non-invasive Mounting

Sensors may be protected from high temperatures, hazardous materials, vibration and shock

by providing detecting windows through which the microwaves can pass.

Detecting windows should be made of ceramic, glass, Teflon or polypropylene materials having

no water content, through which there is minimal loss of microwave energy.

The detecting windows should be al least 60mm in diameter as microwaves pass more easily

through larger apertures. The distance between the window and the antenna should be less

than 200mm.

The sensors should be fixed to an isolated support structure to protect against high vibration.

8

Page 10

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

HARDWARE OPTIONS

Standard: Diecast Aluminum Antenna Head with Teflon Antenna cover

The standard enclosure is suitable for most applications that do not exceed the general

specifications (temperature, pressure, vibration etc).

Standard (as above) with Optional Flange Mounting

Threaded flanges are available in most standards (JIS, DIN, ANSI etc).

Rubber packing

SUS Lock nut

SUS Lock nut

SUS Flange

9

Page 11

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Optional NP Type: Polypropylene Head and Flange

The NP type is useful for applications where the process material is conductive and tends to

buildup, impairing the microwaves; the polypropylene plug should be placed into the standoff

portion preventing material from entering the standoff.

The NP type, when combined with a high pressure flange/seal, is also suitable for high pressure

applications. Threaded flanges are available in most standards (JIS, DIN, ANSI etc).

SUS Lock nut

Polypropylene head

SUS Flange

10

Page 12

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

DIMENSIONS & PART NUMBERS

Note: Hardware dimensions are same for both the transmitter and transceiver.

Standard

Flange Mounting

NOTE: Other flange sizes are available upon request.

11

Page 13

NP Type

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Part Number Example: NP-56-075 = 5K65A Flange with 75mm long polypropylene head.

NOTE: Other flanges and polypropylene head lengths are available upon request.

12

Page 14

INSTALLATION & MOUNTING

The transmitter emits liner polarized

microwaves; as such it is necessary to align

the transmitter and its corresponding

ceiver in the same plane. The cable

ceiver

n the same direction, or be

If the units are installed with the cable

entries at 90º to each other they will not

The sensors should be mounted with the

me

Note that the sensors do not have to be

perfectly aligned, thanks to the wide beam

angle, however suitable care should be

taken.

Set-to-set interference

ceiver sets are

installed in close proximity to each other,

one set should be mounted at 90º to the

2 comes with 4 channels, selectable

set

interference. As such, installation of multiple

so as

to minimize material buildup on the antenna.

This is especially important if the process

material contains moisture. Microwaves are

able to penetrate most surface

containments; however it is recommended

that you optimize the installation to gain

Microwaves are able to penetrate walls

conductive materials such

as refractory/firebrick, ceramic, plastic, glass

etc. Microwaves can not penetrate metallic

or conductive wall linings: a hole must be

made and a suitable process connection

The ambient temperature between the

should not vary

General Guidelines

Mounting angle

trans

entry of both the transmitter and trans

should be facing i

180º opposite each other.

Transmitter

Transmitter

function.

Transmitter

Elevation angle

antennas facing each other on the sa

horizontal axis.

Transceiver

Transceiver

Transceiver

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

If two transmitter trans

other to eliminate set-to-set interference.

Transmitter 1

Transmitter 2

Transceiver 1

Transceiver 2

Note that the Deluxe Level Switch MWSST/SRby rotary switch, to eliminate set-to-

sets as shown above may not be necessary.

Mounting flush

It is desirable to mount the units flush

maximum reliability.

Penetrability of walls

made from non-

welded to the vessel.

Temperature Variation

transmitter and transceiver

by more that 10ºC.

13

Page 15

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Mounting

Standard Mounting

Transmitter or transceiver

The sensor is threaded into an internal half connector welded to the wall. The sensor should be

mounted flush with the inside of the vessel and the SUS lock nut used to fix the sensor in position.

Apply liquid sealant into screw hole and/or any gaps.

Optional Flange Type Mounting

SUS lock nut

SUS Flange User’s flange

Flanges are optionally available in most standard sizes. The sensor’s flange is bolted to the

process connection flange supplied by the user.

Installation on sloped walls may be accomplished with a pipe and Teflon window as shown above.

Note: The length and diameter of the pipe are critical to ensure optimal performance; consult

your representative or the factory before deciding on these dimensions, we will advise you

on the most appropriate dimensions for your application.

G1 (1”) threaded coupling

SUS lock nut

Teflon window

Pipe

14

Page 16

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Optional NP Type Mounting

SUS lock nut

Polypropylene head

SUS Flange User’s flange

The polypropylene head is placed in the stand-off portion of the pipe and mounted flush with the

inside of the vessel.

The polypropylene head is not fixed to the sensor; rather it is sandwiched between the two flanges.

Use suitable gaskets for high pressure applications.

15

Page 17

WIRING

!

!

!

!

!

Do not disconnect the wires connected to ground, either inside or

outside the sensor. If they are disconnected it may cause electrocution

or damage the circuits.

Do not touch live terminals of the sensor as high voltages may be

present.

Do not disassemble any part of the sensor’s electronics.

Turn off the power before connecting to any terminals. If this is not

done electrocution or damaged circuits may result.

To prevent electrocution, ensure that the ground terminal of the sensor

is connected to ground before turning on the power.

If there are problems with grounded wires, or if other protective

functions are absent, do not turn on the power.

Before turning on the power, confirm that the rated voltage of the

controller is compatible with the voltage of the power supply.

Ensure that the ground wire is connected to earth before connecting

any other wires to the controller.

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Warning

!

16

Page 18

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Terminal Connection for AC Power Supply Type MWS-ST/SR-2

**AC 100V~120V ±10%, 50/60Hz

**AC 200V~240V ±10%, 50/60Hz

Note:

• The MWS-ST/SR-2 is not available with DC24V power supply.

• The phase of the power supply must be the same for both transmitter and transceiver.

Selection of Detection Mode and Relay Configuration

Transmitter Transceiver

Detection Mode Beam broken BLOCK

Beam unbroken

UNBLOCK

Terminal Number 4 & 5 5 & 6 4 & 5 5 & 6

Unpowered state Closed Open Closed Open

Powered

state

Non-detecting

state

Detecting state Closed Open Closed Open

Open Closed Open Closed

17

Page 19

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

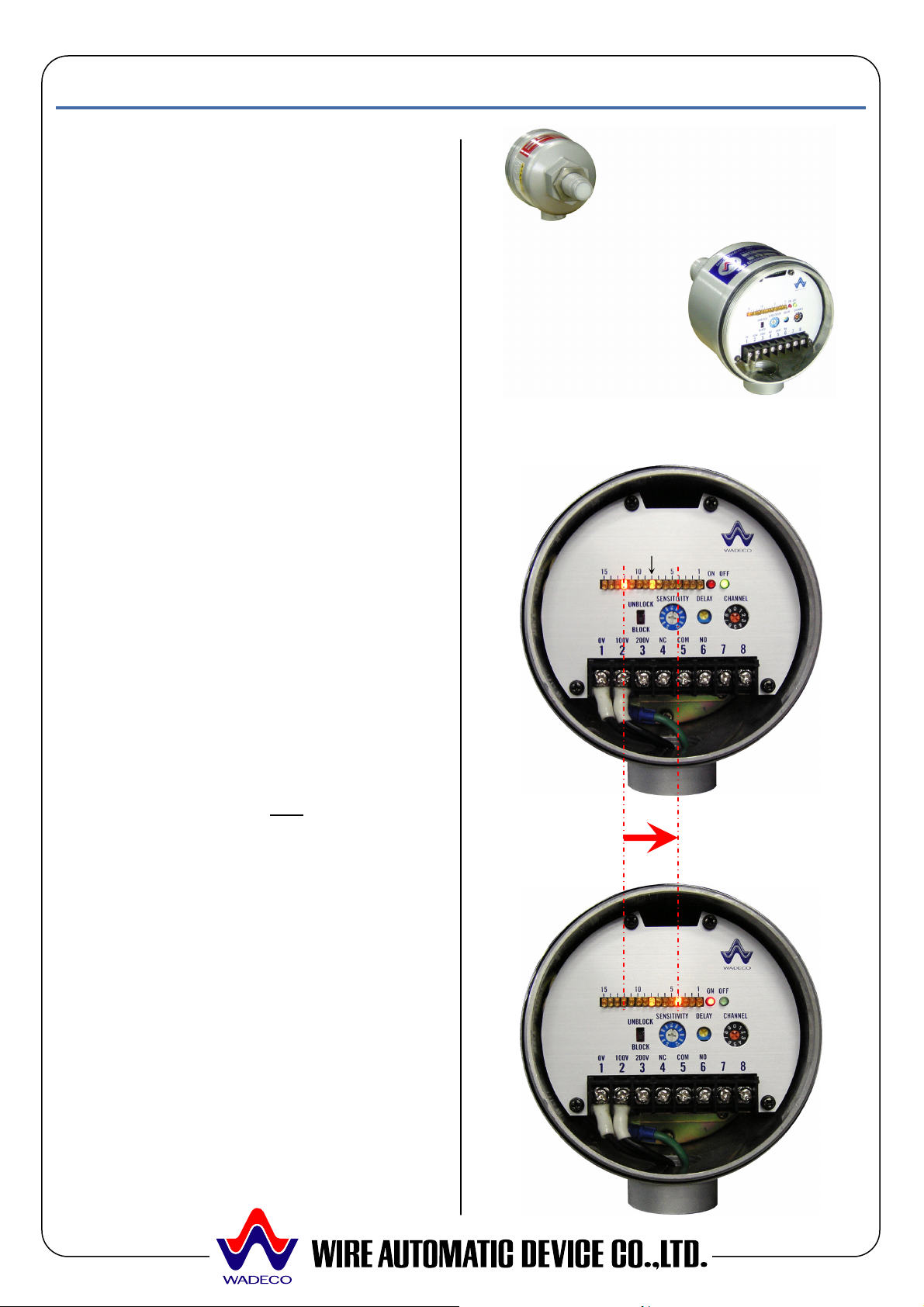

FUNCTION OF SWITCHES, INDICATORS AND RHEOSTATS

Transmitter MWS-ST-2

Part name Description

Power indicator

①

②

Channel selector

Block button

③

④

Terminals

⑤

Ground

Transceiver MWS-SR-2

Part name Description

①

Mode selection switch

Sensitivity rheostat

②

Delay time rheostat 0.1 ~ 10sec. delay period after state changes

③

④

Channel selector

⑤

Received power level indicators

Output indicator ON (red): Illuminates on output

⑥

Output indicator OFF (green): Illuminates on no output

⑦

Terminals Power supply (terminals 1 ~ 3) and relay contacts (4~6)

⑧

Ground Connected to chassis

⑨

Green when power is on

Multi channel mode: CH 1 ~ 4

Single channel mode: CH 0

Blocks transmission

Power supply (1~3)

Connected to chassis

BLOCK: Outputs on broken beam

UNBLOCK: Outputs on unbroken beam

For sensitivity adjustment

Multi channel mode: CH 1 ~ 4, Single channel mode: CH

0

Received power level: indicated by one of 15 LEDs

Sensitivity-set-point: indicated by one of 15 LEDs

18

Page 20

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

Before adjusting the sensitivity:

to 0 (single channel

f you are installing more

3 or 4

The phase of the power supply to must be the same for both the transmitter(s) and the

Set the mode selection switch to BLOCK. Turn sensitivity rheostat fully counter clockwise

The received power level

Turn the

ay between the

from above, a suitable delay time must be

late the beam

SENSITIVITY ADJUSTMENT

• Ensure that there is a clear line of sight between the transmitter and transceiver,

• Set the CHANNEL selector on both the transmitter and transceiver

mode) if you are installing one transmitter/transceiver set only: i

than one transmitter/transceiver set, in close proximity, then select channel 1, 2,

(multi channel mode) to prevent set-to-set interference.

•

transceiver(s).

Transmitter MWS-ST-2

• Apply power to the unit. The green POWER indicator will illuminate.

Transceiver MWS-SR-2

• Apply power to the unit. Either the red ON or the green OFF indicator will illuminate.

•

(minimum).

• Turn the delay time rheostat fully counter clockwise (minimum).

• The red output indicator ON will illuminate.

• The sensitivity is adjusted visually using the 15LED indicator array.

and sensitivity-set-point are indicated on the receiver by a bank of 15 LEDs.

sensitivity rheostat clockwise until the sensitivity-set-point is located halfw

received power level in the BEAM UNOBSTRUCTED and the BEAM OBSTRUCTED states.

BEAM UNOBSTRUCTED BEAM OBSTRUCTED

Received power level Received power level

Sensitivity-set-point

• For an application where material is introduced

provided to avoid instantaneous detection of falling material.

• To use UNBLOCK output mode, switch the mode selection switch to UNBLOCK.

• When adjusting the delay time, use the TEST button on the transmitter to simu

being blocked.

19

Page 21

WADECO MICROWAVE LEVEL SWITCH MWS-ST/SR-2 DELUXE MODEL

GUARANTEE

Guarantee Period

The guarantee period is for 1 year from the date of delivery.

Conditions

Any sensor that malfunctions during the guarantee period, as a result of a manufacturing fault, will

be repaired free of charge once it has been returned to the factory.

The cost of freight will be borne by the buyer. This guarantee does not cover any malfunction

resulting from conditions listed below:

1) When used under conditions or in environments not stated in the manufacturer's

specifications or brochures.

2) When the cause of the malfunction is not the result of the operation of the unit itself.

3) When repairs or adjustments have been performed by anyone other than the manufacturer.

4) When used for purposes other than for what it was intended.

5) When the cause of the malfunction was not predictable at the time of delivery or within the

scientific know-how of that time.

6) When the cause of the malfunction is due to a natural disaster.

The guarantee is not transferable to any second party.

Service

On site service and/or experimentation by WADECO personnel/technicians is not included in the

unit's price. If requested WADECO will provide an estimate of the cost for such services.

Wire Automatic Device Co., Ltd. (WADECO Ltd.)

1-9-27 Jokoji, Amagasaki-shi, Hyogo-ken 660-0811, JAPAN.

Tel: +81-6-6482-3838, Fax: +81-6-6481-6321

Email: sales@wadeco.co.jp

Web: http://www.wadeco.co.jp

20

Loading...

Loading...