Winterwarm HR10, HR20, HR30, HR60, HR80 Instruction Manual

...

INSTRUCTION MANUAL

PREMIX UNIT AIR HEATER

TYPE HR

Production from 2014

THIS DOCUMENT MUST ABSOLUTELY BE READ BEFORE STARTING THE

INSTALLATION.

INSTRUCT USER AND LEAVE THIS DOCUMENT WITH HEATER FOR

REFERENCE.

Instruction manual version GB 109g

Heaters for GB

date: 01-02-2018

heaters for natural gas G20 and Propane

Instructions condensing Air heaters type HR

Page 2/31

1 Introduction:

This installation and user manual is produced specifically for the gas, electrical and mechanical

installer , it also gives instructions how to use and maintain the heater.

2 Content:

Page

1 INTRODUCTION: 2

2 CONTENT: 2

3 GENERAL 3

3.1 G

UARANTEE

3

4 APPLICATION RESTRICTIONS 3

4.1 PRE-

CHECK

3

4.2 P

ROTECTION DEGREE

4

5 TECHNICAL DETAILS: 4

6 INSTALLATION 7

6.1 P

OSITIONING

7

6.2 G

AS CONNECTION

9

6.3 E

LECTRICAL CONNECTION

9

6.4 A

IR INTAKE / COMBUSTION PRODUCTS DISCHARGE

11

6.5 C

ONDENSATE DISCHARGE

13

7 FUNCTIONING OF THE UNIT 14

7.1 G

ENERAL

14

7.2 H

EAT DEMAND

14

7.3 D

ELTA

-T-

REGULATION (TEMPERATURE CONTROLLED DE-STRATIFICATION FAN

) 14

7.4 S

UMMER VENTILATION

14

7.5 H

IGH LIMIT PROTECTION

14

7.6 F

LUE TRANSPORT SUPERVISION

15

7.7 D

ESCRIPTION HEATER CONTROL

HC 15

8 PUTTING INTO OPERATION AND ADJUSTMENT 16

8.1 G

ENERAL

16

8.2 S

TART BY USING THE SERVICE-BUTTON

17

8.3 S

TART BY USING THE THERMOSTAT

17

8.4 T

O SIMULATE A LOCK OUT CONDITION

17

9 ADJUSTING THE GAS-CONTROL 18

10 PROBLEM SOLVING 18

10.1 G

ENERAL

18

11 MAINTENANCE / SPARE PARTS 21

11.1 G

ENERAL INSPECTION

21

11.2 I

NSPECTION OF THE HEATER

21

11.3 I

GNITION ELECTRODE

21

12 EXAMPLES ELECTRICAL INSTALLATION 22

12.1 T

HERMOSTAT CABLE

22

12.2 I

NSTALLATION WITH MODULATING ROOM THERMOSTAT

22

12.3 I

NSTALLATION OF MORE HEATERS ON ONE THERMOSTAT

22

Instructions condensing Air heaters type HR

Page 3/31

13 ELECTRICAL DIAGRAM 25

14 EXPLODED VIEWS AND SPARE PARTS 27

14.1 S

PARE PARTS

27

14.2 E

XPLODED VIEW

HR10-20 28

14.3 E

XPLODED VIEW

HR30-60 29

14.4 E

XPLODED VIEW

HR80-120 30

15 CE CERTIFICATE & DECLARATION 31

3 General

The premix unit air heater is provided with sophisticated control sequence to maintain a

comfortable room temperature and even air distribution.

It is paramount that that the installation and maintenance of this appliance are carried out by

qualified gas engineers, and strictly according to our instructions.

This is a condensing heater. This means a condensate water discharge system should be

installed according to local regulations. Never block this discharge.

3.1 Guarantee

The guarantee is invalidated when the air heaters are not installed in accordance with this

manual.

4 Application restrictions

Important!

The installation en maintenance of this air heater should be performed by an

authorized competent installer in accordance with this manual.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children may not play with this heater.

4.1 Pre-check

Before unpacking and installation, please check (i.e. on the data badge) if the heater is in

accordance with the order and if it is suitable for the local present provisions (gas type, gas

pressure, electrical supply etc.)

The Installation must comply with all applicable local and national standards.

The installation of the air heater must be in accordance with the relevant requirements of the

Gas Safety regulations (for example in GB; The Institute of Gas Engineers IGE UP-1 and 2),

building regulations and the IIE regulations also incorporating the gas safety (installation and

use) regulations. Other national and/or local regulations may apply (the Local Authority ,Fire

Officer and Insurers)

The competent installer must make sure the heater operates correctly and must instruct the

user about the safe operation of the heater.

A ventilation gap of 30 cm is required from the top and bottom of the heater to any flammable

materials.

If this heater is drawing its combustion air from within the room in where it is located, the

necessary combustion ventilation requirements must be followed for gas safety regulations.

The heater should not be installed in areas containing any corrosive or explosive vapours , in

high moisture or dust concentrations, at negative pressures or temperatures higher than 30°C ;

please consult Winterwarm or your supplier. The guarantee is then invalidated..

Instructions condensing Air heaters type HR

Page 4/31

Make sure that the warm air can be blown out freely. There should absolutely be (no possibility

of) materials within 5m from the front of the heater.

The heater has been tested in detail on safety and correct operating settings before leaving the

factory. It has been adjusted for the type of gas that is stated on the data badge. Should there

be any doubt , please contact the manufacturer.

4.2 Protection degree

The heater has a protection degree of IP20, this means for use in a dry and not very dusty

environment. This is also the case for the Winterwarm room-thermostat.

5 Technical details:

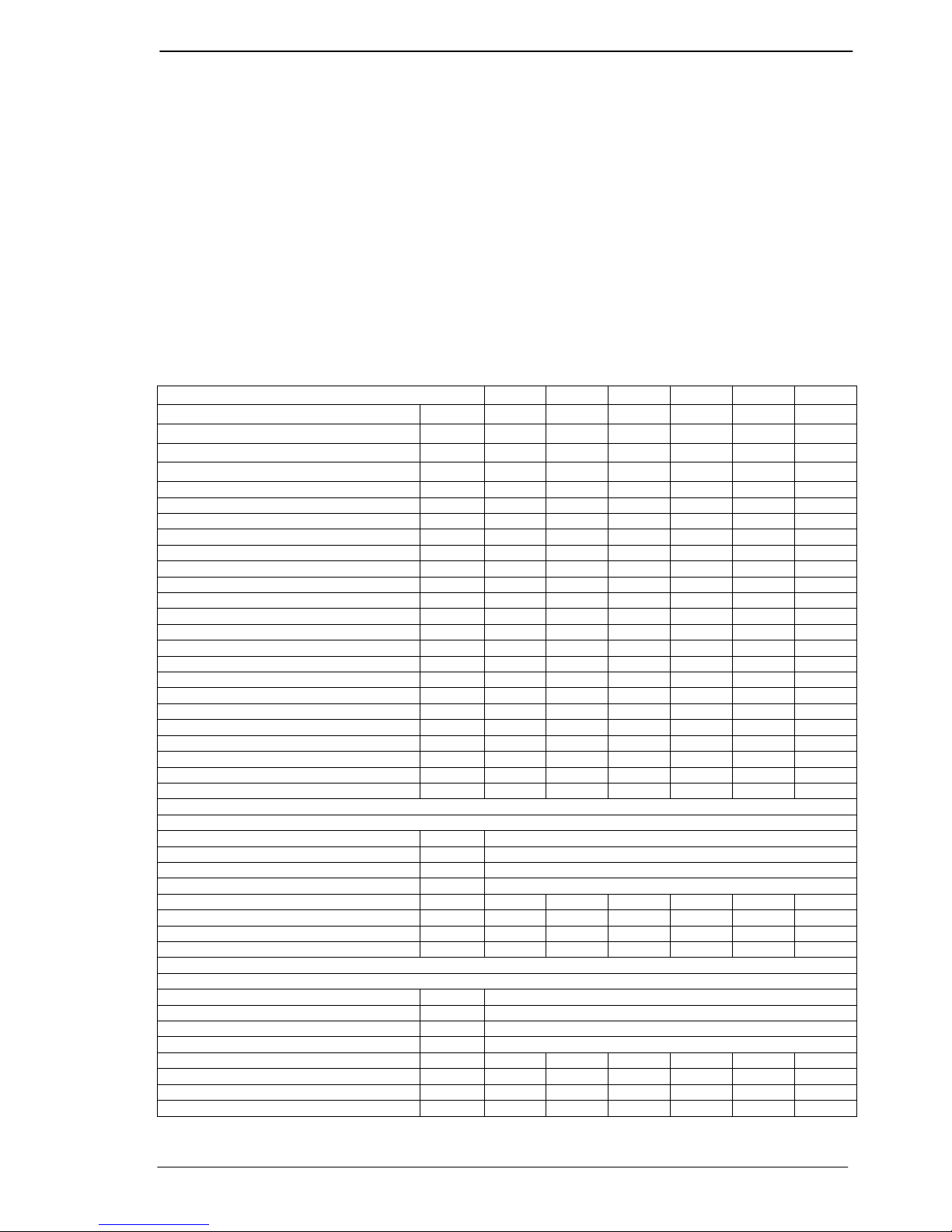

Type HR

10 20 30 40 50 60

Maximum nominal heat input (H.I.) kW 12,5 20,0 30,0 40,0 50,0 60,0

Minimum nominal heat input (H.I.) kW 4,0 6,0 9,0 12,0 15,0 18,0

Efficiency max. power % 96,0 96,0 96,5 97,0 96,5 96,6

Efficiency 30% power % 106,0 106,0 106,0 106,5 106,0 106,0

Maximum heat output kW 12,0 19,2 29,0 38,8 48,3 58,0

Minimum heat output kW 4,2 6,4 9,5 12,8 15,9 19,1

Max air output (warm) m3/hr 2.000 2.600 3.000 4.500 5.000 6.000

Throw horizontal (max) m 15 20 23 26 28 30

Gas connection G” ½” bin ½” bin ¾” bui ¾” bui ¾” bui ¾” bui

Electrical Voltage [50 Hz] V 230 230 230 230 230 230

Electrical power max. kW 0,250 0,250 0,250 0,450 0,450 0,600

Electrical power min.

kW 0,250 0,250 0,250 0,450 0,450 0,600

Electrical power standby

kW 0,004 0,004 0,004 0,004 0,004 0,004

Electrical current A 1,1 1,1 1,2 2,0 2,6 2,6

Emission efficiency, (ηs,flow) % 97,6 96,4 94,6 95,0 94,8 94,6

Seas. space heating efficiency % 90,4 90,1 88,7 89,9 89,2 89,4

NOx emission (GCV) mg/kWh 30 21 33 40 31 44

NOX class 5 5 5 5 5 5

Flue amount max. kg/hr 19,4 31,1 48,3 64,2 80,2 96,2

Thermostat bus system (low voltage) Ja Ja Ja Ja Ja Ja

Sound level (average @ 4 meter) dBA 45 45 45 47 48 49

Suspension height horizontal throw min. m 1,7 1,7 1,7 1,7 1,7 1,7

Flue length max. m 9 9 9 9 9 9

Weight m 45 50 75 85 105 110

Natural gas G20, heater version 3.3

Nominal supply pressure G20 mbar. 20

Supply pressure (min-max) G20 mbar. 17-25

Gas category Cat. I2H

Class Class. B23, C13, C33

Max gas consumption G20 m3/hr 1,3 2,1 3,2 4,2 5,3 6,3

CO2 High G20 % 9,5 9,5 9,2 9,2 9,2 9,2

CO2 Low G20 % 9,0 9,0 8,8 8,8 8,8 8,8

CO (@ 0%O2) mg/kWh 4 5 1 1 3 3

Propane, G31, heater version 3.4

Nominal supply pressure G31 mbar. 30-50

Supply pressure (min-max) G31 mbar. 25-50

Gas category Cat. I3P

Class Class. B23, C13, C33

Max gas consumption G31 kg/hr 1,0 1,6 2,4 3,2 4,0 4,8

CO2 High G31 % 10,7 10,7 11,0 11,0 11,0 11,0

CO2 Low G31 % 10,3 10,3 10,5 10,5 10,5 10,5

CO (@ 0%O2) mg/kWh 13 8 3 1 1 1

Instructions condensing Air heaters type HR

Page 5/31

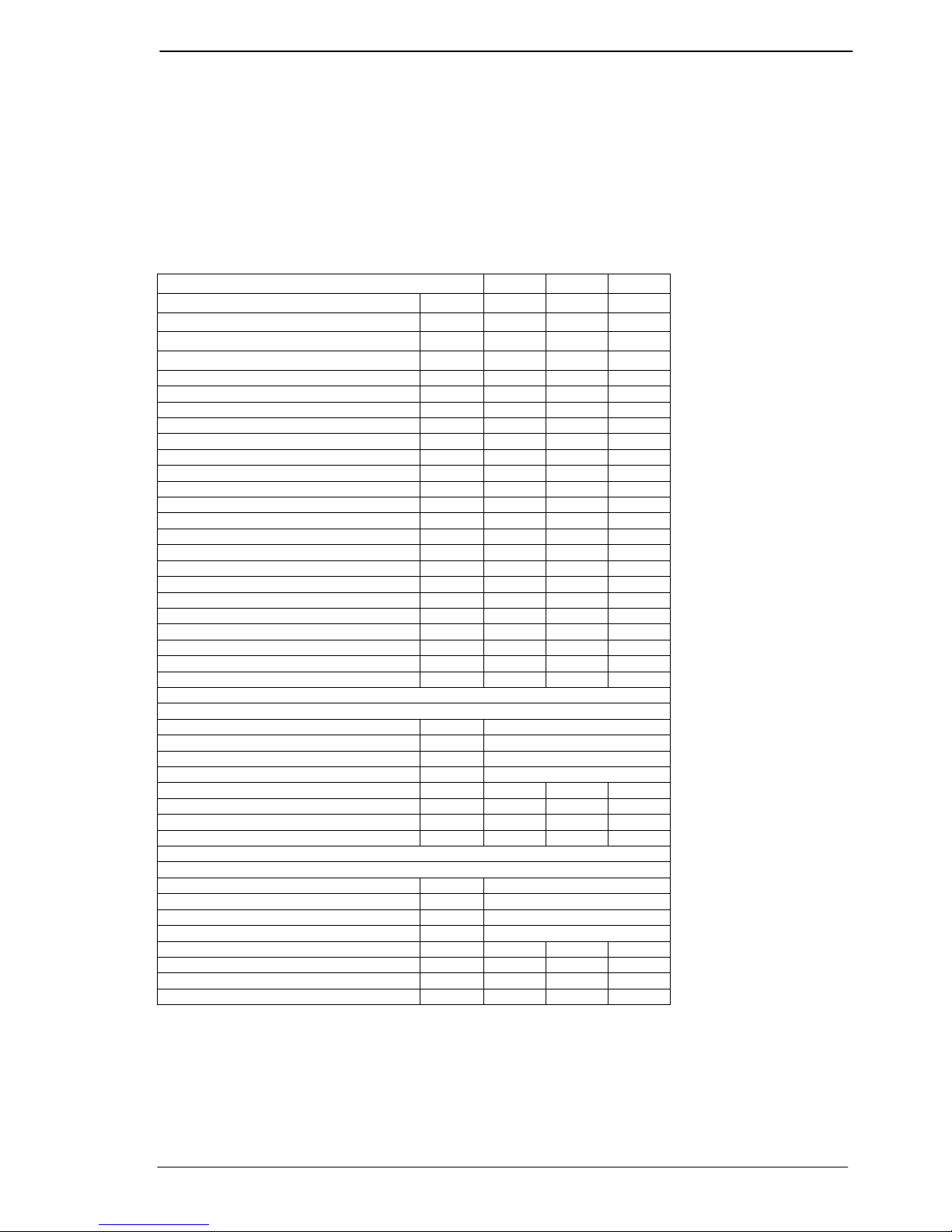

HR80, 100, 120

The HR80 & 100 & 120 heaters are respectively 2 x HR40, 50 & 60 heaters been placed on top

of each other in cascade in one casing with 1 gas connection, 1 combined air inlet, 1 combined

flue outlet, 1 electrical connection, 1 thermostat connection and 1 condensate drain. For the

proper functioning and to prevent interaction between the two burners, a gravity check valve

has been placed between the premix burner fan and the burner.

Please note that when more then only this heater is connected to one thermostat the micro

switches on the print boards in the heaters have to be set different.

See section 12.3 multiple heaters on 1 room thermostat.

Type HR

80 100 120

Maximum nominal heat input (H.I.) kW 80,0 100,0 120,0

Minimum nominal heat input (H.I.) kW 24,0 30,0 36,0

Efficiency max. power % 97,0 96,8 96,5

Efficiency 30% power % 105,0 105,0 105,0

Maximum heat output kW 77,6 96,8 115,8

Minimum heat output kW 25,2 31,5 37,8

Max air output (warm) m3/hr 8.500 10.000 12.000

Throw horizontal (max) m 30 30 33

Gas connection G” 1” int. 1” int. 1” int.

Electrical Voltage [50 Hz] V 230 230 230

Electrical power max. kW 0,900 1,000 1,050

Electrical power min.

kW 0,900 1,000 1,050

Electrical power standby

kW 0,010 0,010 0,010

Electrical current A 3,9 4,4 4,7

Emission efficiency, (ηs,flow) % 95,5 95,6 95,5

Seas. space heating efficiency % 88,8 89,0 89,1

NOx emission (GCV) mg/kWh 38 33 36

NOX class 5 5 5

Flue amount max. kg/hr 128,4 160,4 192,4

Thermostat bus system (low voltage) Ja Ja Ja

Sound level (average @ 4 meter) dBA 50 51 52

Suspension height horizontal throw min. m 1,7 1,7 1,7

Flue length max. m 9 9 9

Weight m 180 195 205

Natural gas G20, heater version 3.3

Nominal supply pressure G20 mbar. 20

Supply pressure (min-max) G20 mbar. 17-25

Gas category Cat. I2H

Class Class. B23, C13, C33

Max gas consumption G20 m3/hr 8,4 10,6 12,6

CO2 High G20 % 9,2 9,2 9,2

CO2 Low G20 % 8,8 8,8 8,8

CO (@ 0%O2) mg/kWh 1 3 3

Propane, G31, heater version 3.4

Nominal supply pressure G31 mbar. 30-50

Supply pressure (min-max) G31 mbar. 25-50

Gas category Cat. I3P

Class Class. B23, C13, C33

Max gas consumption G31 kg/hr 6,4 8,0 9,6

CO2 High G31 % 11,0 11,0 11,0

CO2 Low G31 % 10,5 10,5 10,5

CO (@ 0%O2) mg/kWh 1 1 1

Instructions condensing Air heaters type HR

Page 6/31

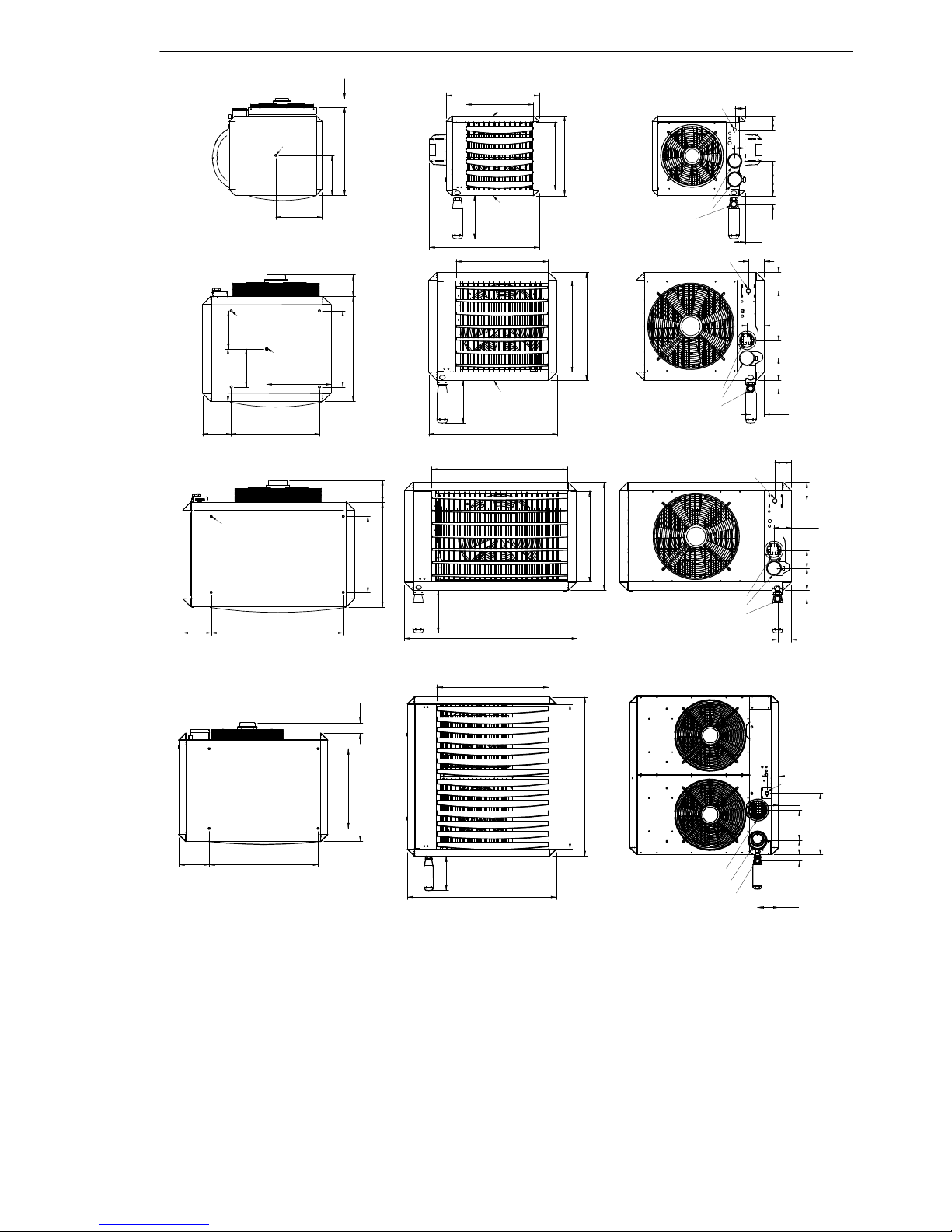

490 125

285

245

M10

420

495

420

680

M10

M10

100 110 85

65

65

85

35

O

40

IN O80

OUT O80

Gas 1/2"

Type 10 & 20

575

795

670

565

575

650 125

470

545

M10

4x M10

M10

115140 110

100

105

Gas 3/4" ext.

INO80

OUTO80

325

400

180

=

=

35

85

180 815

470

650 125

4X M10

565

670

1065

Gas 3/4" ext.

100

115

105

11014035

85

IN O80

OUT O80

O

40

O

40

Type 30 & 40

Type 50 & 60

280

280

280

840

815227

600

812 75

280

1115

1090

1195

840

87

462

11045

158

158

Gas 1" int.

Ø40

Type 80, 100 & 120

225

IN Ø130

OUT Ø130

Instructions condensing Air heaters type HR

Page 7/31

6 Installation

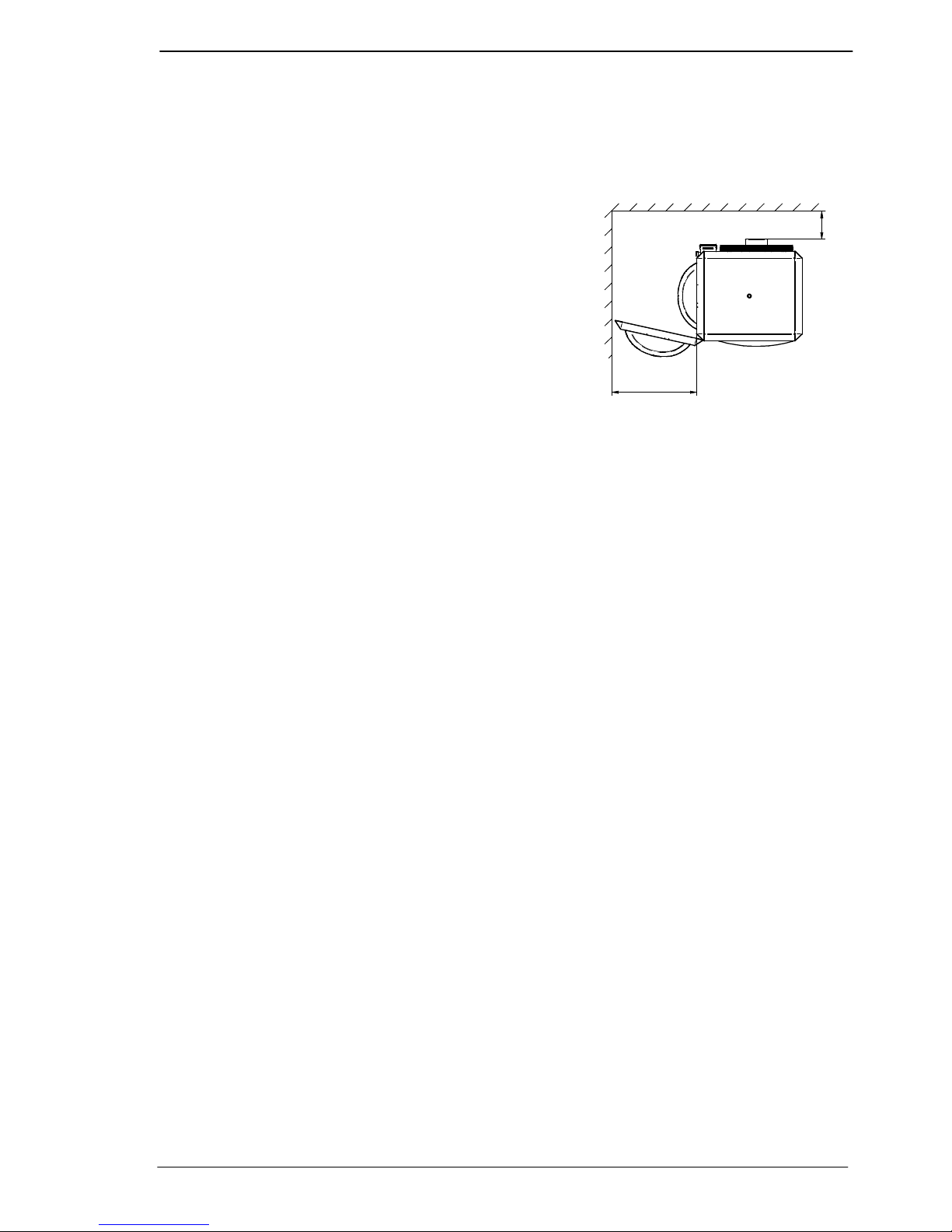

6.1 Positioning

• Check that the support is solid enough.

• The heater is designed as free hanging. The heater

should be able to blow the warm air free from any

ducting or obstacles. Also the air intake should be

free.

• Keep sufficient distance between the heater and any

obstruction , in connection with safety and access for

service and maintenance. Pay particular attention to

any flammable materials. Please take into account

the possibility to open the door of the heater for the

necessary service and maintenance work . Make

sure the air flow to and from the heater is unhindered. Any obstacles should be a minimum

of 5 metres away from the front of the heater.

• The heater can be installed horizontally or on an angle of maximum 45 degrees downwards.

• The heaters type 10 and 20 are provided with 2 off M10 threaded sockets as fixing points

(see the dimension diagram).

• The types 30 and 40 have in the middle a M10 socket and also 4 sockets on the top corners

of the heater

• The types 50 and 60 have on the top and bottom 4 M10 sockets. (see drawings)

• Use preferably the Winterwarm suspension kits.

• Make sure that after fitting, there is no mechanical tension on any connecting gas or electric

supplies.

• If the heater is installed with the air stream vertical downwards the maximum suspension

height is 8 meters. Otherwise the warm air will not reach the floor.

Attention:

See the application-restrictions in this manual (Chapter 4) for further installation restrictions.

min 250

10 t/m 30 min. 500 mm

40 t/m 60 min 660 mm

Instructions condensing Air heaters type HR

Page 8/31

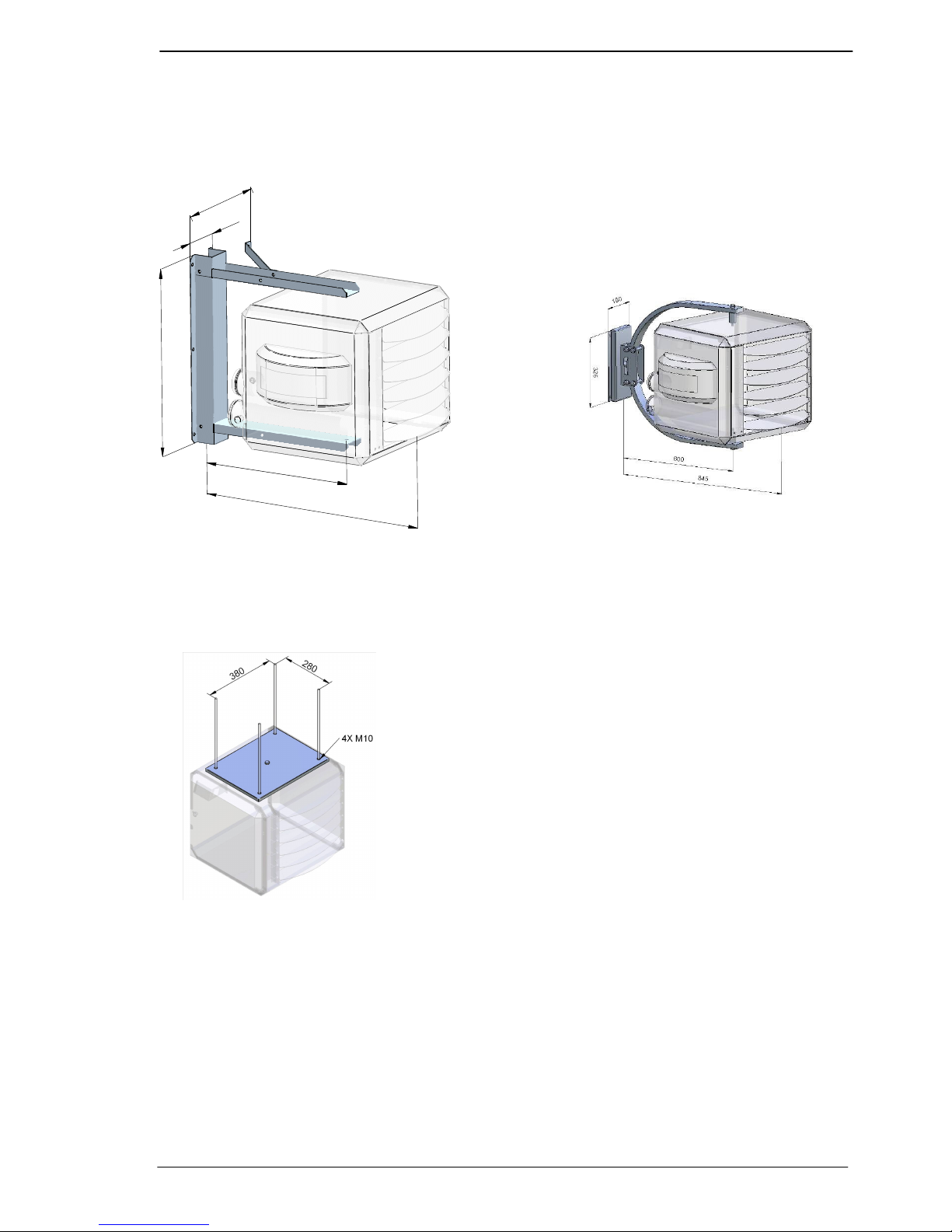

B

1

5

0

3

9

0

A

C

XR10-30 XR40-60

HR10-20 HR30-40

A 550 665

B 640 815

C 800 990

Available suspensions:

Standard bracket for type HR10 to 40 Design bracket type HR10 and 20

Horizontal horizontal

Suspension adapter for type HR10 and 20

M10 threaded bar

Instructions condensing Air heaters type HR

Page 9/31

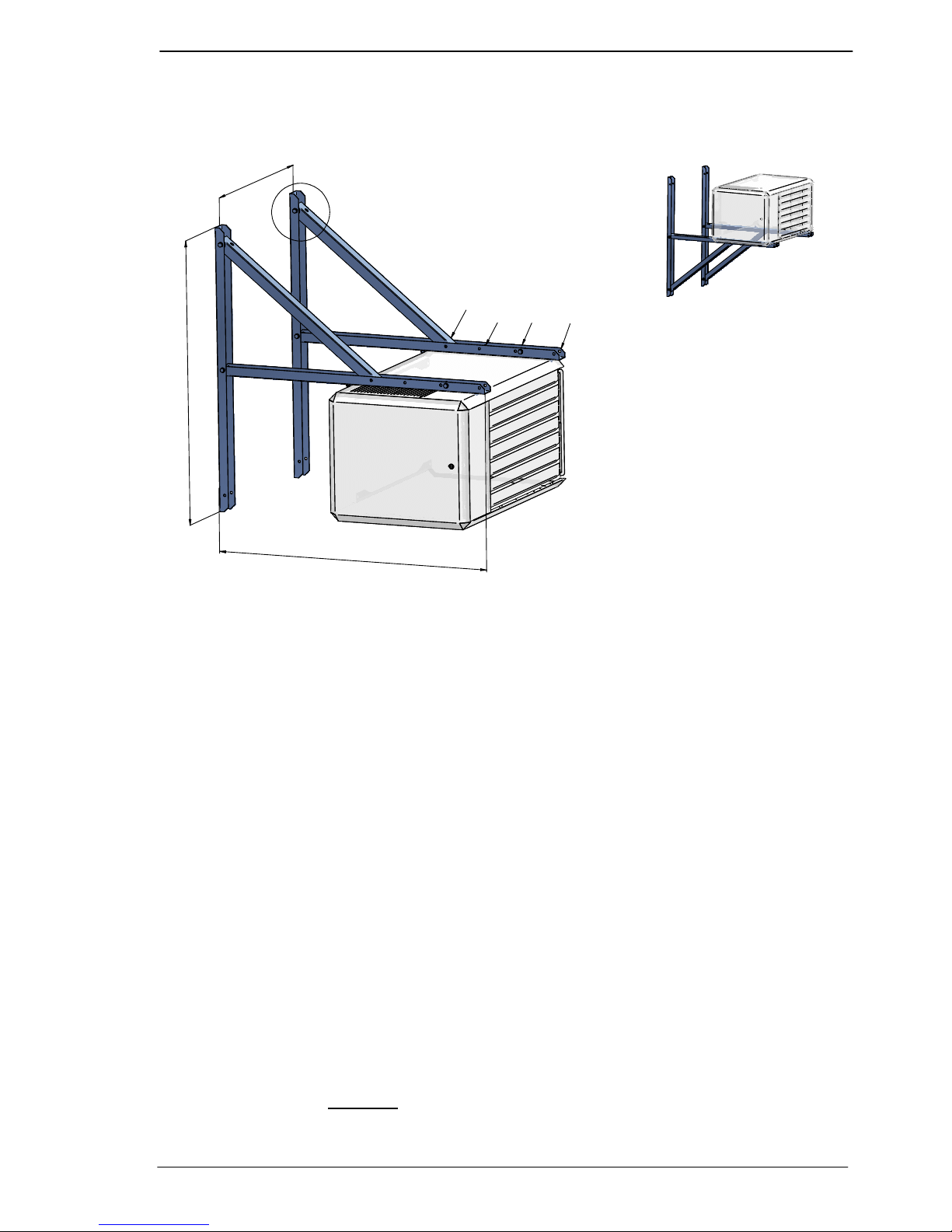

Wall console set HR30 up to 120

Art. Nr. : GA8580

1

2

0

0

1

2

0

0

S

e

e

i

n

s

t

a

l

l

a

t

i

o

n

m

a

n

u

a

l

45°

15° & 30°

Horizontal

15°

30°

45°

Horizontal

6.2 Gas connection

The gas supply line has to meet the national valid requirements and possibly the local

requirements of the building inspector, police or fire brigade. (In GB it must comply with Gas

Engineers publication UP-1 and UP-2 together with BS 6891.

A manual isolation valve in the supply line must be placed within reach of the heater, and all gas

lines must be mounted without any mechanical tension.

When testing the supply lines with pressures above 60 mbar, this manual valve at the heater

must be closed.

The working and standing supply pressure must be a minimum of 17 mbar, and a maximum of

30 mbar ,measured at the inlet pressure nipple of the gas control in the heater .

6.3 Electrical connection

6.3.1 230Vac supply

The installation must comply with local and national requirements, ( as well as IEE regulations)

The unit heater is delivered completely wired internally, where controls of any type are to be

added (e.g. room thermostat) , the relevant wiring diagrams must be followed to. Never use a

room thermostat to interrupt the electrical supply to the heater!

Make provisions to completely isolate the heater for maintenance purposes. This can be an

isolation switch (min.3mm contact opening gap) , a power plug or a non-switched fuse spur.

The wiring diagram for the heater can be found towards the end this manual.

The supply is 230Vac. with earth

. The control circuit is a two wire low voltage Argus-link bus

communication.

HR30 - 60

HR30 - 60

HR30 - 120 HR30 - 120

Instructions condensing Air heaters type HR

Page 10/31

6.3.2 Room thermostat

The heater can only be controlled by special modulating Winterwarm room thermostats:

The Multi Therm Comfort; modulating digital clock thermostat with optimiser. It can control 1 to

8 air heaters HR10 up to HR60 or 1 to 4 air heaters HR80 up to 120.

The Multi Therm Standard; modulating digital thermostat. It can control 1 to 8 air heaters

HR10 up to HR60 or 1 to 4 air heaters HR80 up to 120.

The Interface printboard; special designed interface module for connecting the air heaters with

Building Mangagement Systems. (0-10V (modulating input) signal, high/low signal,

external reset and other different in and outputs.

ON/OFF thermostat

The heater can not be controlled with a simple on/off thermostat.

In all cases the communication between heater and thermostat is based on a two wire, lowvoltage connection. In the appliance the wire for the thermostat has to be connected to

connection 4 and 5 (see also electrical wiring diagram) Attention: This also needs a change in

the settings on the print board, see chapter 11

When mounting the thermostat, take attention to the following items:

• Mount the thermostat in a place where the air can circulate free pass the thermostat. Take

notice that the sun does not shine directly upon the thermostat (in the winter). Do not

place the thermostat on a cold wall. Place the thermostat on an inner wall free from

draught.

Never place the thermostat within the throw of the heater.

6.3.3 Thermostat cable

In all cases the communication between the heater and the thermostat is based on a two wire,

low-voltage connection. In the appliance the wire for the thermostat has to be connected to

connection 4 and 5 (see also electrical wiring diagram).

Cable specification: signal cable, 1x2x0,8 (shielded and twisted)

Maximum length 250m.

If the cable is chosen too thin, the signal will become too poor. If the cable is not shielded and

twisted the signal might become disturbed in an EMC unfriendly environment.

Keep the thermostat cable separated from mains cables. Connect the earth shield of the cable

only to the earth terminal in the heater.

If these guidelines are not followed it may result in malfunction of the installation or worse, it

could damage the thermostat or the electronics in the heater.

Never mount the thermostat near aerials of internal communication networks.

These emit radiation that could lead to disturbance of the thermostat. Always keep

some meters distance.

6.3.4 Fuses

On the heater control HC there are two fuses. See electrical wiring diagram.

F1 and F2 are in the power supply of the heater. Replace the fuse only by a fuse of the same

type, 5AT

Loading...

Loading...