Page 1

Instruction manual

DXA heater

pag

e 1

Inst

ruction manual

DXA Heater

Ver GB 50

3a

YOU MUST READ THIS DOCUMENT BEFORE COMMENCING INSTALLATION.

INSTRUCT THE USER ONCE TAKEN INTO USE AND KEEP THIS DOCUMENT

NEAR THE APPLIANCE

Date: 01

-09-

2009

Version: GB 50

3a

Appliances for GB

Natural gas, Propane, Butane, LPG

Page 2

Instruction manual

DXA heater

pag

e 2

Foreword

This installation and user

manual

is intended mainly for the gas, oil and electrical fitter. It also

provides instructions for the user and for the

maintenance of the air heater. To use this air

heater in a safe and effective way, it is strictly essential that this manual is used correctly.

Contents:

Pag

e

1

ABOUT THIS MANUAL

3

1.1

G

UARANTY

3

2

SAFETY INSTRUCTIONS AND PRECAUTIONS

3

2.1

K

EY TO SY

MBOLS

3

2.2

S

YMBOLS ON THE APPLIANCE

3

2.3

W

ARNINGS

3

2.4

PRE-

CHECK

. 4

2.5

S

AFETY PRECAUTIONS

4

2.6

W

ATER AND CHEMICAL SU

BSTANCES

5

2.7

U

SE IN A GREENHOUSE

5

2.8

U

SE IN A POULTRY SHED

5

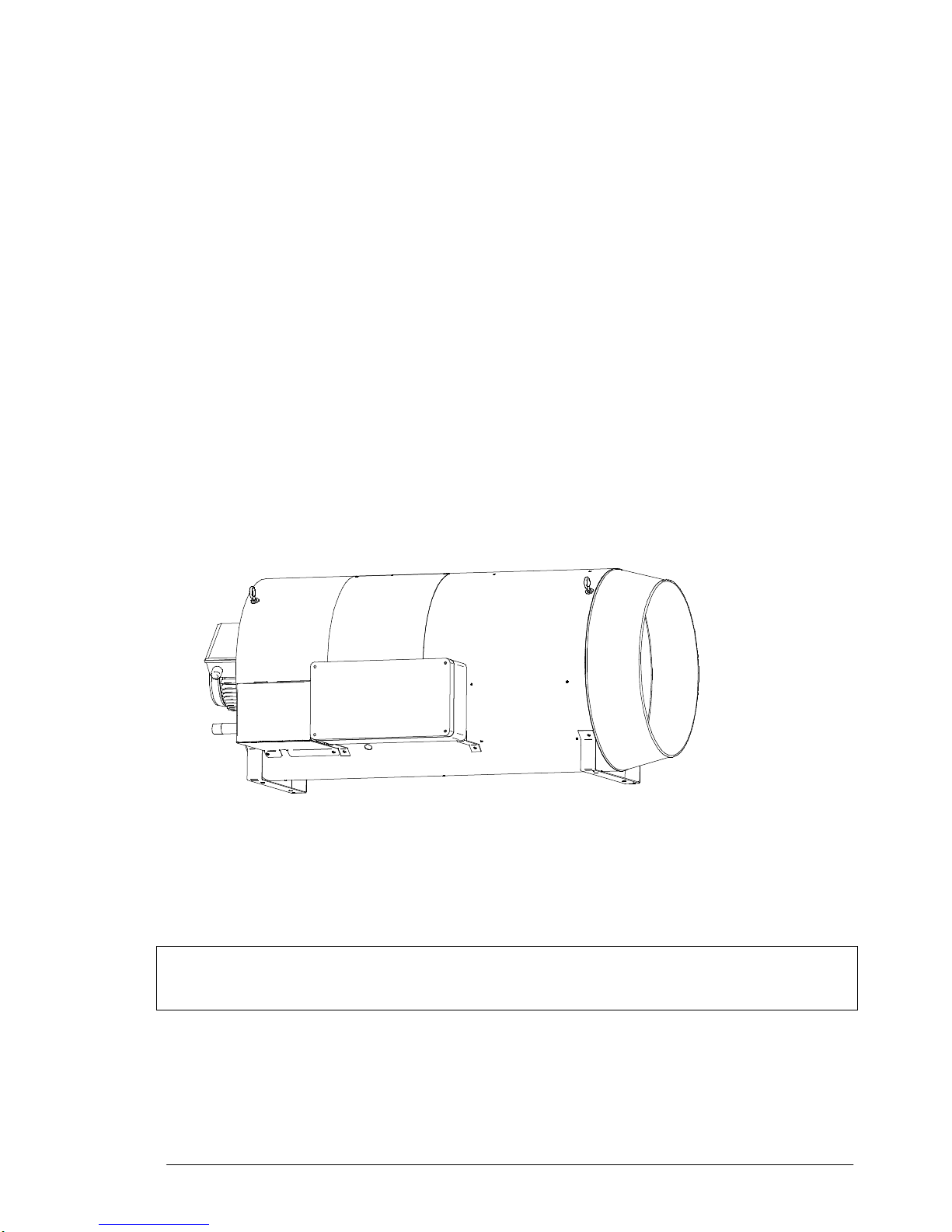

3 INTRODUCTION DXA HEA

TER

5

4

INSTALLATION

6

4.1

M

OUNTING THE HEATER

6

4.2

G

AS CONNECTION

6

4.3

E

LECTRICITY SUPPLY

7

4.4

I

NTERFACE UNIT

; 8

4.5

C

HECKS BEFORE TAKEN I

NTO OPERATION

8

5

FUNCTION OF THE HEATER 9

5.1

F

UNCTION BUTTON ON TH

E HEATER

9

5.2

H

EAT DEMAND

9

5.3

DELAYED START 9

5.4

V

ENTILATION

10

5.5

T

EMPERATURE LIMITER

10

5.6

A

IR TRANSPORT,

VANE SWITCH

10

5.7

M

INIMUM GAS PRESSURE

SWITCH 10

5.8

D

ESCRIPTION HEATER CO

NTROL

HC

10

5.9

G

AS CIRCUIT

11

5.10

M

EASURING AND ADJUSTI

NG THE BURNER PRESSURE 11

5.11

M

EASURING COMBUSTION

VALUES

12

6

MAINTAINING THE HEATER 12

6.1

G

ENERAL MA

INTENANCE

13

6.2

E

XTENSIVE MAINTENANCE

IN A POULTRY SHED

13

6.3

C

LEANING THE BURNER U

NIT

13

6.4

C

HANGING GAS TYPE

14

6.5

S

PARE PARTS

14

7

PROBLEM SOLVING

15

7.1

G

ENERAL

15

7.2

E

RROR CODES

15

8

WIRING DIAGRAM

17

9

SPECIFICATIONS

19

9.1 DXA H

EATER

75

19

9.2 DXA H

EATER

100

20

9.3 DXA H

EATER

120

21

Page 3

Instruction manual

DXA heater

pag

e 3

1

About this manual

In this manual you will find information on the DX Heater. One section of this is intended to

enable the user of the DX Heater to operate the appliance in a sensib

le and safe way. Another

section is intended to enable the fitter or service technician to fit, set up and maintain the DX

Heater, and to detect and resolve any malfunctions quickly and effectively.

This manual makes regular mention of a fitter or serv

ice technician. This refers to a qualified

fitter or service technician who is trained in the fitting, malfunction-free operation and

maintenance of the DX Heater. He is also competent to carry out work on a heater.

1.1

Gu

arant

y

Guaranty is only valid when the

appliances are used

and or installed according to thi

s manual.

2 Safety instructions and precautions

Always read the entire manual so that you are familiar with all the safety instructions and

precautions.

2.1 Key to symbols

Safety warning: warning of danger

of physical injury or (direct) damage to product, animals or

the environment.

Warning

Information

Tip

2.2 Symbols on the appliance

Warning which refers to the manual for information on the component on or next to which the

warning is positioned

.

Warni

ng of the potential hazard of electric shock.

Safety grounding

2.3

Wa

rnings

Keep this manual in a safe place near the heater so that you can consult the manual whenever

necessary

Incorrect use of the heater can result in physical injury. Therefore, follow

the instruction below

carefully:

•

Avoid physical contact with the motor or other hot parts of the heater.

•

Do not touch live parts of the heater.

•

Keep body parts, loose items of clothing, jewellery or hair away from rotating fan blades or

other movin

g parts of the heater.

•

Do not pl

ace articles in front or nearby

the heater because this can cause fire hazard.

The following conditions can lead to damage to the heater:

• •

Incorrect transportation or storage of the heater;

• •

Errors in the assembly of (

parts of) the heater;

• •

Excessively high or low oil pressure;

• •

Excessively high or low ambient temperature;

• •

Wear, ageing and metal fatigue in components of the heater.

• •

Moisture: the heater has IPX4D protection grade

.

Page 4

Instruction manual

DXA heater

pag

e 4

2.4 Pre-check.

Before unpacking and i

nstallation, please check (i.e. on the data badges) if the heater

corresponds to the order and if it is suitable for the local present provisions (gas type, gas

pressure, electrical supply etc.)

The installation must comply with all applicable local and n

ational standards.

The installation of the air heater must be in accordance with the relevant requirements of the

Gas Safety Regulations (for example in GB; The Institute of Gas Engineers IGE UP-1 and 2),

Building Regulations and the IIE Regulations also incorporating the gas safety (installation and

use) regulations. Other national and/or local regulations may apply (the Local Authority, Fire

Officer and Insurers)

The competent installer must make sure the heater operates correctly and must instruct the

user about the safe operation of the heater.

This heater is takes its combustion air from within the room in which it is located, the necessary

ventilation requirements must be followed for gas safety regulations.

The heater should not be installed in are

as containing corrosive or explosive vapours

. P

lease

consult your supplier;

otherwise the guarantee will become invalidated.

Make sure that the warm air can be blown out freely. There should absolutely be no (possibility

of) materials within 5m from the f

ront of the heater.

The heater has been tested in detail on safety and correct operating settings before leaving the

factory. It has been adjusted for the type of gas that is stated on the data badge. Should there

be any doubt, please contact your suppli

er.

2.5 Safety precautions

If the distance between hot flue gas coming from the outlet cover and people or animals is too

short, this may pose a danger to them. In addition, the heater is started automatically, which

may pose a risk to people or animals in the

vicinity of the heater. Therefore, you should always

observe the prescribed minimum distances between the heater and people, animals and crops

(refer to Mounting the heater)

O2 is

used during gas combustion and converted, amongst others, to CO2. Too much CO2 in

the air may be harmful to people, animals and crops. Therefore, you should always ensure

sufficient fresh air can enter the space where the heater has been placed, e.g. by way of open

windows or a separate fresh air intake.

When the CO2 concentrat

ion is too high, the heater will

not function properly. There may be incomplete combustion. (Danger of Carbon Monoxide CO)

The CO2 concentration may not exceed 1%. Minimal ventilation requirements 1000m3/h for

each 100kW installed power.

Observe the follo

wing precautions when using the heater:

•

Only start the heater if access panels and protective grill have been fitted.

•

Have the heater checked and serviced once a year by a service technician.

•

This appliance is not intended for use by persons (including

children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

•

Children should be superv

ised to ensure that they do not play with the appliance.

•

Children may only be present in the space where the heater has been placed if

supervised by an adult.

•

Ensure the socket outlet is located within a 2 m radius of the heater and that the plug can

be r

emoved easily and quickly from the socket outlet.

•

Leave the plug in the socket outlet even if you are not using the heater. This prevents

condensation of the print circuit board; this may lead to heater damage and/or

malfunctions.

•

Make sure the mains cabl

e does not get damaged. Replace a damaged cable

immediately.

Page 5

Instruction manual

DXA heater

pag

e 5

•

Do not connect the heater to an air duct, as this has a negative effect on the performance

of the heater.

•

Due to the presence of CO2 and the noise levels produced, you must obtain permission

f

rom the safety and health service before taking a heater into use that is to be placed

•

Minimal ventilation requirements 1000m3/h for each 100kW installed power.

•

In case of a malfunction, ensure the heater is free of electricity by removing the plug from

t

he socket outlet, in order to prevent damage to the heater.

2.6 Water and chemical substances

Observe the following measures if water or chemical substances that could be dangerous to

people, animals, and/or crops are used in the space where the heater has

been placed:

•

Switch off the heater.

•

Make sure the heater cannot be started automatically by removing the plug from the

socket outlet.

•

Close the gas tap.

•

Cover the heater.

2.7 Use in a greenhouse

Observe the following additional measures when using the h

eater in a greenhouse:

•

The CO2 level should not exceed 1% (10,000 ppm).

•

In completely enclosed greenhouses there must be at least 100 m3 fresh air per m3 of

gas and external atmospheric protection.

Or Minimal ventilation requirements 1000m3/h

for each

100kW installed power.

•

There must be at least two openings in the space to ensure adequate circulation of air if

no artificial ventilation is present.

•

Use the heater preferably in combination with one or more exhaust fans and a

CO2 meter

•

Do not use any su

lphurous fuels in the space where the heater has been placed, as these

contain high amounts of sulphur that could be harmful.

2.8 Use in a poultry shed

When cleaning and disinfecting a poultry shed in which a heater has been placed, or when

spreading sawdus

t, the following precautions should be taken. Failure to take these precautions

will give rise to a risk of explosion or fire.

Take the following into account when using the heater in a poultry shed:

•

The CO2

content must not exceed 0.3% (3,000 ppm).

•

If

no artificial ventilation is provided, there must be at least two openings in the space to

ensure sufficient circulation of air.

•

Cover or remove the heater when cleaning or disinfecting the poultry shed.

•

When spreading sawdust the heater must be covered

to prevent sawdust particles from

entering the heater and creating a fire hazard. Also make sure that the heater cannot be

started automatically by removing the plug from the socket outlet. Also close the gas

valve.

•

Clean the heater after every poultry s

hed clean-out to prevent the heater from becoming

dirty.

•

Do not use water when cleaning the heater

3

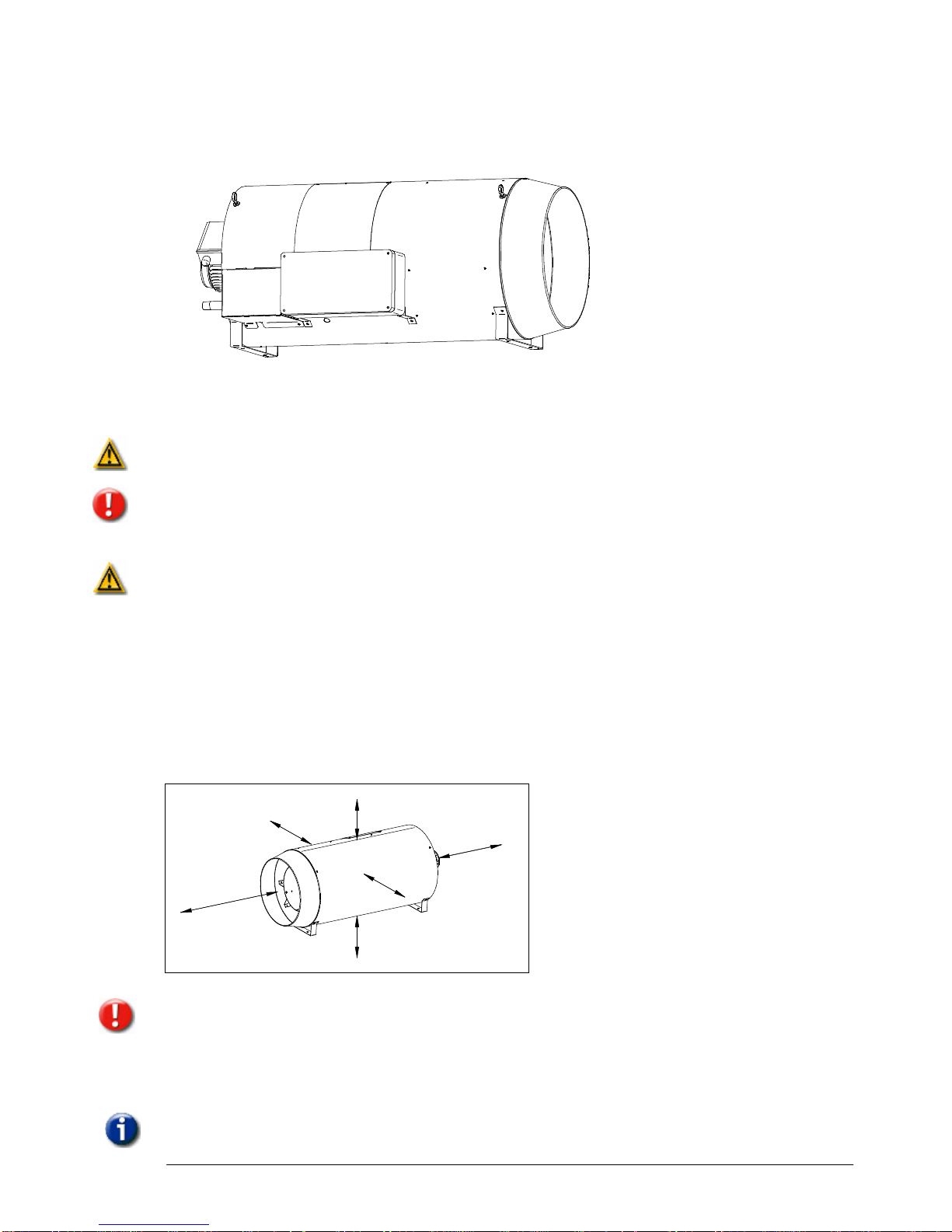

Introducti

on

DXA heater

The DX Heater is a direct fired heater designed specifically for greenhouses and poultry sheds.

The device is placed in the enclosed

space itself, which means that the heater displaces air only

and uses a small amount of energy to warm and ventilate the space. The large air capacity and

the unique shape of the heater also ensure that the device can distribute the air within the

space i

n the best possible manner.

The heater's design is aimed at straightforward installation, maintenance and safe use.

Ignition and combustion for example are controlled automatically and parts are easily accessible

for cleaning and maintenance.

Page 6

Instruction manual

DXA heater

pag

e 6

The heater

can be ordered for different gas types and fuel settings:

•

Natural gas

•

Propane

, Butane and LPG

•

Paraffin and Diesel

4

Installati

on

Read the chapter on Safety instructions and precautions first and observe all warnings and

precautions. Follow all instructio

ns in this chapter explicitly.

Only skilled installers or service technicians are permitted to install the heater.

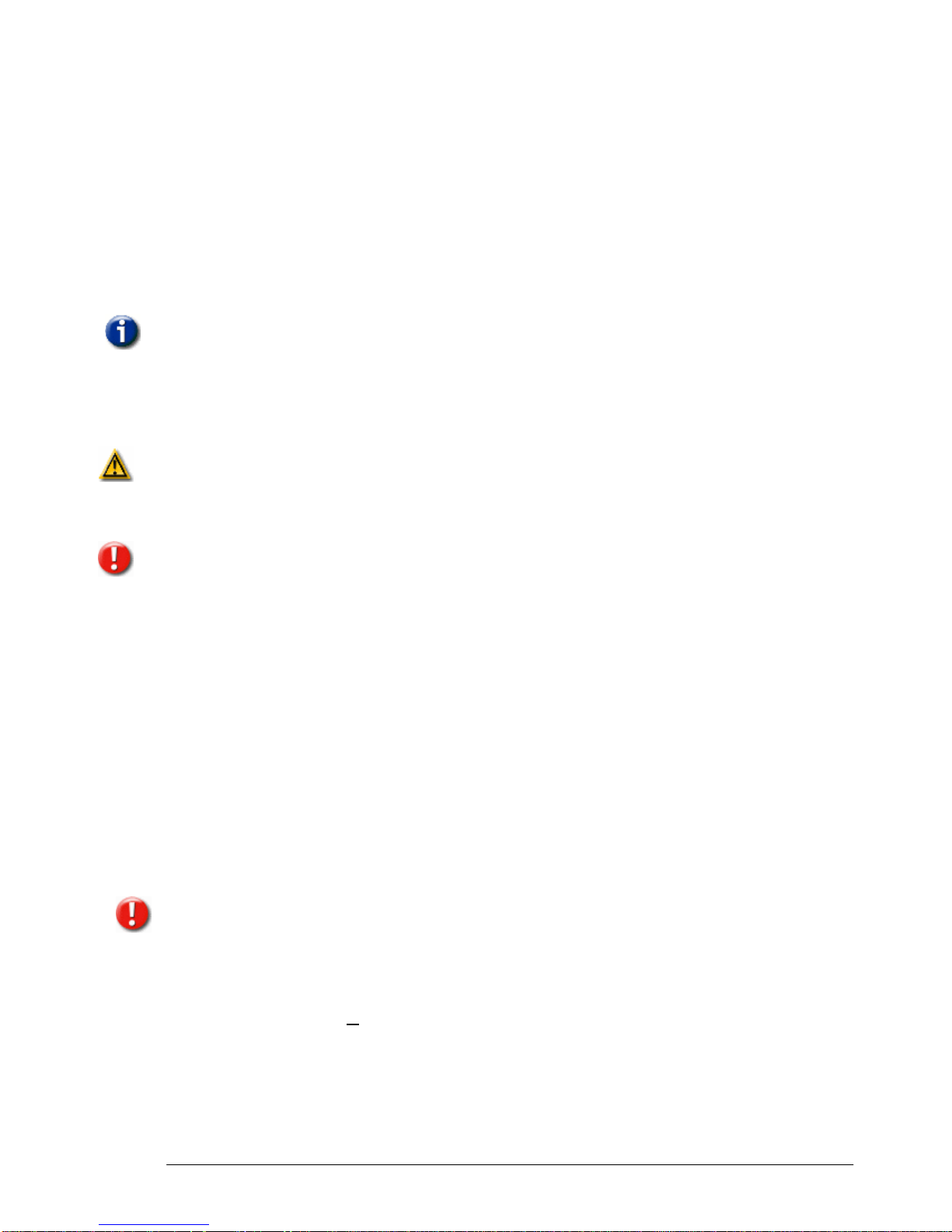

4.1 Mounting the heater

Mount the heater in a sturdy manner, taking into account the dynamic load and the weight of the

appliance (refer to

Specifications ).

Take the following into account when installing the heater:

•

Attach chains to the four hook eyes and suspend the heater.

•

Make sure the heater is positioned horizontally otherwise it will not operate (properly).

•

Do not connect the heat

er to an air duct, as this has a negative effect on its performance.

•

Take into account the minimal distances between the heater and people, animals and

crops:

• 5

m on the outlet side;

•

3 m on the inlet side;

•

1 m on the other sides.

5

m

1m

1

m

1m

1

m

3

m

The same minim

um distances apply between the heater and walls, glass and other objects, with

the exception of the outlet side. The minimum distance on this side must be equal to the throw

that the heater is capable of producing. This depends on the type of heater (refer

to

Specifications ).

4.2 Gas connection

To connect the heater to the gas network, your supplier

can

supply a gas connection set that

consists of a ball plug valve, (reducing) nipples, gas filter, gas pressure regulator and gas hose.

A set is available for ev

ery type of gas.

Page 7

Instruction manual

DXA heater

pag

e 7

Keep the following in mind when connecting the heater to the gas network

.

The gas supply line has to meet the national valid requirements and possibly the local

requirements of the building inspector, police or fire brigade. (

For example in GB it must comply

with Gas Engineers publication UP-1 and UP-2 together with BS 6891.)

A manual isolation valve in the supply line must be placed within reach of the heater, and all gas

lines must be mounted without any mechanical tension.

When testin

g the supply lines with pressures above 60 mbar, this manual valve at the heater

must be closed.

The working and standing supply pressure must be between 17mbar and 50mbar, measured at

the inlet pressure nipple of the gas control in the heater.

The burner

pressure is pre-adjusted (see technical details). The burner pressure can be

measured on the P-out measure point on the gas valve.

There is a kit available for changing the

gas type

. (from natural gas to propane / butane or vice

versa) The gas

nozzle

ha

s to be exchanged and the

burner pressure

readjusted. Look into the

specifications for the exact adjustments. Instructions can be found in this manual.

4.3 Electricity supply

4.3.1 230Vac

supply

The installation must comply with local and national requirements, (as well as IEE regulations).

The unit heater is delivered completely internally wired. Where controls of any type are to be

added (e.g. room thermostat), the relevant wiring diagrams must be followed. Never use a room

thermostat to interrupt the electrical s

upply to the heater!

The supply is 230Vac 50Hz with earth. When the

supply

voltage is lower than 195V and higher

than 255V the correct functioning of the heater is not

guarantied.

A mains cable including plug is supplied with the heater. The wires

of t

he cable

must

be connected to the

clamps in the connection box. Make sure you do not damage the mains

cable. Replace a damaged cable immediately.

When the heater is connected without a plug, m

ake provisions to completely isolate the heater

for maintenance

purposes. This can be an isolation switch (min. 3mm contact opening gap).

The switch should not interrupt earth.

Ensure the plug or switch is located within a 2 m radius of the heater and the plug can be

removed easily and quickly from the socket

4.3.2 Thermost

at connection

The heater can be controlled in various ways. It can be controlled by a simple ON / OFF signal,

but it can also be controlled by an external print.

4.3.3 Thermostat cable

In all cases the communication between the heater and the thermostat is base

d on a two wire,

low-voltage connection. (see also electrical wiring diagram).

Cable specification: signal cable, 1x2x0,8 (shielded and twisted)

Maximum length 200m.

If the chosen cable is too thin, the signal will be too weak and heater will not work

. I

f the cable is

not shielded and twisted the signal might become disturbed in an EMC unfriendly environment.

Keep the thermostat cable separated from mains cables. Connect the earth shield of the cable

only to the earth terminal in the heater.

If these gui

delines are not followed it may result in malfunction of the installation or worse, it

could damage the thermostat or the electronics in the heater.

4.3.4 Simple ON / OFF contact

(standard configuration)

The heater can be connected to a potential free ON/OFF co

ntact.

Page 8

Instruction manual

DXA heater

pag

e 8

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

0

1

S2

S3

0

1

0

1

PE

N65

L

Neutal

L (230V AC)

Heater 1

Neutal

L (230V AC)

Heater 2

Neutal

L (230V AC)

Heater 3

Neutal

L (230V AC)

Heater 8

Max. 8 Hea

ter

s

Communication bus:

2 wires; low voltage

T

On Of

f thermostat

PE

N65

L

PE

N65

L

PE

N65

L

Neutal

L (230V AC)

Heater 1

Neutal

L (230V AC)

Heater 2

Neutal

L (230V AC)

Heater 3

22°C

The heater will only react on the heat demand. Remote reset or the ventilation signal can only

be made on the heater itself.

The following (Standard) settings on the main board in the heater

have to be actual.

•

The

S2

micro switches on the main boa

rd have to be set to

OFF, see example.

•

The switch S3 has to be set to 1.

•

The thermostat has to be connected to the clamps 5 and 6 in the heater.

•

In the case that more than 1 heater is connected to 1 thermostat, do not exchange clamp

5 with clamp 6 between

the heaters. This will result in permanent burning of the heaters.

Any changes too these switches must be performed with the power off, otherwise any changes

made will not take effect.

4.4 Interface Unit;

Special designed module to connect t

he heaters to external

climate computers. This unit has connections for Burner ON /

OFF, Ventilation

, Reset function in case of faults and some

outputs are available (faults for example) The unit can control

up to 8 heaters.

When this unit is used the set

tings in the heater have to change.

Each heater needs its own unique number to recognise the heater

by the room thermostat. The number of the heater can be set by

the micro switch S2 on the heater control in the heater. The

number at the upper position of

the switch is the given number for

that heater. Make sure that each heater has is own unique number.

If more than one heater has the same number the system does not

work.

Any changes too these switches must be performed with the power

off, otherwise any ch

anges made will not take effect.

The switch S3 has to be set to 0 (off)

It is possible you may have the incorrect settings with the system still working! However if this is

the case, you will ultimately damage the equipment. So every care should be take

n to ensure

the switches are set correctly!

4.5

C

hecks before taken into operation

Perform the following checks before taking the heater into

operation

.

•

Wiring

, Ensure the heater is free of electricity by removing the plug from the socket outlet.

Now check th

at the connection is OK and that the wiring is connected properly

.

•

Gas

soundness, Open the gas valve and check if the heater is gas-tight, using a leak

detector spray for example

.

1 2 3 4 5 6 7 8

ON

10

S3

S2

Page 9

Instruction manual

DXA heater

pag

e 9

•

Supply

voltage; check

if the supply voltage is sufficient.

•

Transport and com

bustion air flow, Check if the transport and combustion air exhaust is

free from any obstacles. In this way, you will prevent the heater from continuing to

operate while the air exhaust is blocked

.

•

Burner pressure

, The heater will not operate if the burner

pressure is too high or too low;

refer to Measuring the burner pressure

•

Flame detection

, Flame

detection is by means of ionisation. The ionisation probe is placed

inside the flame. When the flame does not

touch

the pen or the probe is polluted the

heater

will

not function.

•

CO-value and

CO2-readings in the combustion air

too

high a level of CO and/or CO2 in

an enclosed space can be harmful to people, animals and crops. You should therefore

always verify that the CO value and the CO2 content in the flue gas

comply with the

requirements; refer to Measuring combustion values

•

General heater operation

.

5 Function of the heater

5.1

Functi

on button on the heater

O

n the control panel on the heater there is a function button. T

his button has several functions:

When the b

utton is pushed once (1X) the heater will start to burn. When the button is pushed

again the heater will stop. The heater will remain in the burn mode for maximal 24 hour. Every

hour the heater will perform a safety shutdown and will automatically restart.

When the button is pushed twice (2X shortly) the heater will start to ventilate (without burning).

The heater will stop to ventilate when the button is pushed again.

When the heater is in error, it can be reset by pushing this button once.

5.2 Heat demand

The heat demand can be generated by means of the room thermostat or

manually

by pushing

the function button on the heater.

If the

re is

heat demand, the following cycle will start:

1. Internal checks: The heater performs several checks before there happens

anything.

2. Gas pressure

check. The heater will check if the minimum gas pressure switch is closed.

If not the heater wil generate an E7 error. This error resets itself when the gas pressure

is back.

3. Pre purge

: The electronic circuit board acknowledges the h

eat-demand and the

fan

will

start running for 15 seconds. (Display print

1)

4. Ignition

: After 15 seconds of pre purge, the electrode will spark for max. 5 seconds, the

gas

valve is opened and the

gas air

mixture will ignite. (Display print

2)

5. Burn

: When

the flame is detected (Display print b) the unit will go into burn mode.

6. End of heat demand:

When the heat demand ends, the burner will switch off and the

system fan will continue to run for ca. 1

minute

in order to cool the unit down (Display

print

P)

.

The unit will try to ignite

5 times

before lockout on flame fault.

In the case of flame failure during operation, the heater will attempt one restart.

When the heater is in lockout you see in the display intermittent A1. On the display of the room

thermo

stat you see failure 1.

Every hour the heater performs a safety shut down. After this shutdown the heater wil restart

automatically.

5.3 Delayed start

Often more than one heater are

connected to one control unit. When all the units are starting on

at the s

ame time, a pressure drop in the gas supply can occur. This may result in some heaters

Page 10

Instruction manual

DXA heater

page 10

not starting. To prevent this there is a random waiting time before the heater starts. In this

manner the pressure drop in the gas supply stays to a minimum.

5.4 Ventilati

on

By means of the optional external interface board, the fan in the heater can start

without the

burning from the heater. The

symbol

F

will

be displayed on the heater.

The fan can also be operated manually by pushing the function button twice.

This manu

al ventilation setting will remain maximum 24 hour.

5.5 Temperatu

re limiter

The temperature from the combustion chamber is mea

sured by a NTC sensor. When the

temperature

from this sensor becomes too high the heater will stop burning. (Display E / 1) The

hea

ter will start if the sensor is cooled again.

When the temperature becomes much too hot the heater will stop, and will be locked. The

heater will only start after a manual reset. (Display A / 2).

5.6 Air transport, vane switch

In

the air stream inside the hea

ter a vane

switch

is mounted. When the fan is running this switch

should

be made. If not, Error E8. The heater will perform a retry for 5 times. When

the vane

switch is still not closed the heater will lock with error A8 and has to be reset

manually

.

When

during one heat demand the

vane

switch opens more than 5 times the heater will also

stop. Error A8.

When the heater is in standby and the

vane

switch is closed, the heater will

give

error E8

until

the switch is open again.

5.7 Minimum gas

pressure switch

The

gas supply pressure during standby and operation should be between certain values.

For natural gas it should be between 17 and 30 mbar and for propane it should be between 25

and 57 mbar.

When the supply pressure is too low, the heater will not operate an

d will generate an error E7.

The setting from the pressure switch is shown in the specifications.

Attention, this is a safety issue. When the pressure becomes too low the safe combustion

becomes an issue. The combustion gasses may become

harmful

for man,

animals and crop.

It is normal that during the start of the heater the pressure drops a bit. The heater will not react

on this

. Only when before and during burning the pressure is stays to low for a longer period the

heater will stop, and automatically r

estart when the pressure is available again.

5.8 Description heater control HC

The heater control HC controls the unit and communicates with the room thermostat.

Functions integrated in the heater control HC are:

-

Two

wire communication with room thermostat

-

ionisation flame guard on burner

-

controlling the gas valve

-

guarding the temperature of the heat exchanger

-

LED signals status of heater, heat demand: green, failure: red

-

Status of heater on 8 segment display on heater control HC

-

reset of heater

-

servic

e mode function

Page 11

Instruction manual

DXA heater

page 11

1

2

3

6 7

8

9

10

5

4

4

Lay-out print board

J2

Fuse 5AT

J4

J8

U11

S1 J12

J6

S2

S3

J9

T2

J15

J7

0

1

123 4

5 6 7 8

on

Argus vision

J2

Main power connection 230V

J4

Connection for gas valve and

the N for

system fan relay

J6

Connection for room thermostat, appliance recognition

J7

Earth burner

J8 Fase for

system fan

rellay

and ignition transformer

J9

Not used

J12

Connections for Temperature sensors, vane switch and gas pressure switch

J15

Ionisation

F1

&

F2

Fuses 2x 5AT

U11

Status display

S1

Reset service button

S2

Micro switch heater no. Standard all on OFF

S3

Power supply thermostat standard

S3 op 1

T2

not used

5.9 Gas circuit

The

gas circuit

from the DXA has the following parts:

1. Gas connection

¾”

pipe thread

2. Minimum gas

pressure switch

3. Gas

valve

4. Nut with

mechanical union

22mm

5. Gas

pipe

22mm

6. Nozzle

7. Flame stabilizer

8. Ignition electrode

9. Connection

boot

2x

10. Ignition cable

2x

5.10 Measuring and adjusting the burner pressure

Right on the measuring

point (

1) the

minimum gas pressure switch is mounted.

(1)

Measuring

point gas supply pressure

(2)

Measuring

point burner pressure

(3)

Adjusting

the burner pressure

1. Switch off the heater.

2. Unscrew and remove the screw of the measuring nipple (2).

3. Connect a pressure gauge to the measuring nipple.

Page 12

Instruction manual

DXA heater

page 12

4. Switch on the heater and start heating manually by pressing the button on the operating

panel.

5. Check whether the b

urner pressure is equal to the nominal burner pressure for the

corresponding heater type (refer to

Specifications).

6. Record the measured value as a reference for the next measurement.

7. If the burner pressure does not correspond with the specified value:

a.

T

urn the adjusting screw (3) either to the right or the left until the specified value

is indicated on the gauge.

b. Check the burner pressure again following the steps outlined above.

8. Switch off the heater and allow the heater to cool.

9. Remove the pressure g

auge and retighten the screw of the measuring nipple (2).

5.11

Measuring combustion values

Probe

Heater with probe

CO2 percentage (approximate

)

Nominal

CO2 percentage (airtime 20°C)

Gas type

DXA 75

DXA 100

DXA 120

H

igh

calori

fic gas

(G20)

7,5%

7,5%

7,5%

Low

calori

fic gas

(G25)

7,7%

7,7%

7,7%

Butane (G30)

8,5%

8,5%

8,5%

Propane (G31)

8,5%

8,5%

8,5%

LPG

8,

0%

8,

0%

8,

0%

1. Switch off the heater.

2. Place the probe (1) on the heater (refer to figure

DX Heater with probe

) and connect the

(calibrated) flue gas anal

ysis equipment.

3. Switch on the heater and start heating manually by pressing the button on the operating

panel.

4. Allow the heater to heat for about 5 minutes.

5. Measure the CO value.

6. Measure the

CO2 percentage

in the flue gas.

7. Record the CO value reading

and the

CO2 percentage

as a reference for the next

measurement.

8. If the CO value exceeds 15 ppm, or if the CO2 percentage does not correspond to the

specified percentage, refer to theCO2 percentages (average ambient temperature 20°C)

a. Check CO2 percentage

if

deviates by more than 1 %,

check the burner pressure

air inlet openings of the system fan

.

b. Measure the burner pressure; refer t

o Measuring the burner pressure.

c. Check whether the gas pipe diameter

(gas pressure to low).

d. Check the CO value and the CO2

percentage again following the steps outlined

above.

9. Switch off the heater.

Allow the heater to cool down and then remove the probe and the flue gas analysis equipment

6

Maintaining the heater

It is recommended to have the heater checked and serviced by

a service technician every

year to guarantee reliable and safe operation. Heaters used in poultry sheds must be serviced

more often and more extensively due to high levels of dust and dirt in these types of spaces.

Page 13

Instruction manual

DXA heater

page 13

6 7

8

9

10

4

6.1 General maintenance

The heater must

be free of electricity during servicing. Remove the plug from the socket outlet.

Do not use water when cleaning the unit.

Perform the following activities during general maintenance:

•

Open the body access panel and especially clean the body, fan blades, f

an motors, vane

swi

tch, maximum thermostat

and swirl ring.

•

Grease any parts and bolts that are loosened regularly for maintenance.

•

Check whether the wiring, nuts and bolts are all properly tightened.

•

Open the gas valve and check whether the heater and t

he gas hose are gas-tight.

6.2 Extensive maintenance in a poultry shed

The heater must be free of electricity during servicing. Remove the plug from the socket outlet.

Do not use water when cleaning the heater.

Clean and check heaters used in poultry sh

eds after every shed clean-out and before spreading

sawdust. To do this, carry out the following actions:

1. Use compressed air to blow the parts clean, especially the inside and outside of the body,

fan blades, fan motor, vane switch and the maximum thermos

tat.

2. Remove all dust from the motor as the layer of dust acts as insulation, which can cause

the motor to overheat.

3. Use a brush to remove any caked on dust.

4. Clean the burner unit (refer to Cleaning the burner unit).

5. Put the Power back on and let the he

ater heat for a while so that if any dust particles have

remained behind, they are now burnt.

6. Stop heating and cover the heater once it has fully cooled off.

7. Make sure the heater is free of electricity by removing the plug from the socket outlet.

8. Disinf

ect the poultry shed and spread the sawdust.

9. Remove the cover from the heater.

To ensure the instructions below are carried out safely, it is recommended having these

carried out exclusively by a service technician.

Perform the following checks after

cleaning the heater:

•

Open the gas valve and check whether the gas hose is gas-tight.

•

If the heater has been moved, check whether the gas hoses are connected properly.

Connections that slip off or that are improperly mounted can create a fire hazard.

•

Ch

eck that the wiring is properly secured.

Finally, carry out all the checks that are performed during heater installation (refer to Performing

checks :

1.

Measure

the burner pressure;

2.

Measure

combustion values;

3

.

General

heater operation.

Place

and close the access panels once you have completed all checks. The heater may now

be used again.

6.3 Cleaning the burner unit

The burner unit can easily be removed out of the heater.

•

Open

the inspection hatch

•

Remove the gas pipe by unscrewing the 2 nuts

wit

h mechanical union 22mm.

•

Remove the 2 connecting boots from the ignition

electrode by pulling gently at the cables

.

•

Unscrew the 4 nuts where the burner unit connects

to the air inlet.

•

Take the burner unit out the heater

Page 14

Instruction manual

DXA heater

page 14

6 7

8

9

10

4

The burner unit has the following

parts:

4

Nut with mechanical union 22mm

5 Gas pipe 22mm

6 Nozzle

7 Flame stabilizer

8 Ignition electrode

9 Connection boot 2x

10 Ignition cable 2x

Clean the various parts with a soft brush ,a coth or compressed air.

Pay attention to dirt building up on

the stabilizer and the ignition pen.

The distance between the electrodes should be 3 mm.

6.4 Changing

gas type

The heater is suited for different types of gas, natural gas or propane / Butane

.

To change from natural gas to propane or butane (or vice versa) th

e nozzle (6) has to be

changed.

To ensure the instructions below are carried out safely, it is recommended having these carried

out exclusively by a service technician.

•

Open the inspection hatch

•

Remove the gas pipe by unscrewing the 2 nuts with mechani

cal union 22mm.

•

Remove the 2 connecting boots from the ignition electrode by pulling gently at the cables.

•

Unscrew the 4 nuts where the burner unit connects to the air inlet.

•

Take the burner unit out the heater

Disassemble the burner unit

:

•

Remove the sta

bilizer (7) from the Nozzle (6)

•

Remove the flange from the nozzle by unscrewing

the nut from the nozzle.

Take the new injector and assemble everything again.

Look at the table with the technical details in the back of

this manual for the proper diameters

from the nozzles

and the right burner pressure.

When

everything is assembled again, make the following

checks:

Perform the following checks after cleaning the heater:

•

Open the gas valve and check whether the gas hose is gas-tight.

•

If the heater has be

en moved, check whether the gas hoses are connected properly.

Connections that slip off or that are improperly mounted can create a fire hazard.

•

Check that the wiring is properly secured.

Finally, carry out all the checks that are performed during heater installation (refer to Performing

checks :

1.

Measure

the burner pressure;

2.

Measure

combustion values;

3

.

General

heater operation.

Place and close the access panels once you have completed all checks. The heater may now

be used again.

6.5 Spare Parts

Name

75

100

120

Page 15

Instruction manual

DXA heater

page 15

Gas

valve

Fan

motor

Fan blade

Ignition electrode

Ionisation

electrode

Ignition cable

Ignition

transformer

V

ane switch assembly

Stabilizer

Control unit

Minimum Gas

pressure switch

Fan relay

Tempe

rature sensor

Propane Kit

Natural gas Kit

7

Problem solving

7.1 General

When it turns out that the problem is

not

caused by the external circumstances (i.e. no electric

supply power or no gas), please take the following instructions into account. Please remembe

r

the built in waiting times of the heater (do not react too soon!) and the code on the display on

the electronic circuit board.

To simplify the investigation of the failing heater please check first:

•

the fuses as well as the wires and plugs in the heater

for possible loose contacts.

•

Use first the service-button to put the heater in run mode, try later the room thermostat.

7.2 Error codes

Volatile lock out : Can only be reset by hand

A/0

Blinking

Internal failure

Defective print board

A/1

Blinking

No flame

Wi

thin 5 sec flame, then flame failure: Cause 1

No flame: Cause 2

A/2

Blinking

Exchanger too hot

Heater stops because the temperature of the heat exchanger is

too high: Cause 3

A/3

Blinking

Sensor error

Temperature sensor on heat exchanger error: Cause 4

A/4

Blinking

Too many flame

failures

Too many flame failures on ionization: Cause 1, 5

A/5

Blinking

Internal error

Too many problems with power supply. Try other Fase if

possible. Control unit defective, change control unit.

A/6

Blinking

Internal error

Too many problems with power supply. Try other Fase if

possible. Control unit defective, change control unit.

A/7

Blinking

Flame

Flame detection when there should not be a flame

A/8

Blinking

V

ane switch / Fan

Fan does not run: Cause 6

Fan runs: Cause 7

Non volatile lockout:

will disappear when the error is cleared.

E/0

Blinking

Internal defect

Defective print board

Page 16

Instruction manual

DXA heater

page 16

E/1

Blinking

1st temperature

safety

Heater stops because the temperature of the heat exchanger is

too high. When the heater is cooled down, the heater will

restart: Cause 3

E/2

Blinking

Selection

resistance

Heater recognition does not work: Cause 8

E/3

Blinking

Selection

resistance

Heater recognition does not work: Cause 8

e/7

Blinking

Gas

pressure

switch

Gas supply pressure too low, che

ck gas supply pressure

.

e/8

Blinking

Fan / V

ane switch

Fan does not run: Cause 6

Fan runs: Cause 7

E/9

Blinking

Reset error

Too many switches on reset button: Cause 9

Cause 1:

Within 5 sec flame, then flames failure.

•

The flame is not detected. Check

the ignition cable and electrode. (cable resistance 1K

ohm

•

The heater has electrically a poor earth.

•

The print board is defective.

Cause 2:

•

There is not enough gas pressure.

•

The burner pressure is too low, adjust the gas valve

•

The gas valve does not open

, check during ignition on 230V on the valve.

•

Check whether the ignition electrode sparks, replace cable, electrode

Cause 3:

Heat exchanger too hot

•

Check if the system fan blows enough air.

•

Check the setting of the gas valve, the heater may be overloaded.

Cause 4:

Temperature sensor on heat exchanger error.

•

The sensor has internally 2 sensors. These differ too much. Measure the resistance from

each sensor, the resistance should be 20K at 25° en 25K at 20°. If the measured values

differ too much, replace sen

sor.

•

Rotate the sensor ¼ turn, so that the contact point is different on the sensor housing.

Cause 5

: Too many flame failures while burning

•

Bad earth connection on the heater

•

Burner pressure fluctuates, is too low.

•

CO2 concentrati

on is too high (lack of o

xygen)

Cause 6: System

Fan is not running

•

The v

ane switch is not in the rest position at start.

•

The Fan has no power or is blocked.

Cause 7: System

fan runs

•

Check if the fan is

dirty

• C

heck if the v

ane switch can move freely

• C

heck the wiring from the v

ane

switch

• C

heck if the heater is extremely

dirty

• C

heck if the supply voltage to the heater is sufficient

Case 8

: Selection resistance error

•

Check the appliance recognition part, replace if necessary

Case 9

: Reset button error

•

Too many switches on reset butto

n in a short period of time. These error will disappear

after some time, or if the main power is disconnected for a while.

Heater starts but other problems

.

a)

C

heck the heater by firing it up with the service button. Push it one time and the heater fires

up

, push it again and the heater stops. If the button is pushed twice shortly after

each other

,

the system Fan will run. Push it again and the

heater stops. Try to operate the heater wit

another room thermostat.

Page 17

Instruction manual

DXA heater

page 17

8

Wiring diagram

N

L

PE

1

2 3

J2

2

10

4

12

5

7 1

3

9

8

J4

8

3

4

5

9

1

1

5

2

6

3

7

4

8

-T

20K@25°C

-T

20K@25°C

5 61211 13 14

5

6

22°C

4

7

J6

J12

J8

1 2 3 1098

166-W2-DX

Get: MF

Date: 01-07-2009

Auth:

Ver: A

Title:

Nr.:

P003

DXA 75, 100

(fan direct)

J7

1 2 3 4 5 6 7 8

ON

F2

F1

2 x 5AT

Thermostat (bus)

green/yellow

blue

black

GB

10

2

6

7

10

black

15

16

green/yellow

blue

black

R2

J15

11

6

green

yellow

brown

white

S3

S2

R3

Temperature

sensors on heat

exchanger

Micro switches S2 standard all OFF, and S3 to 1.

When more heaters on one thermostat, do not

change clamps 5 and 6 between heaters.

blue

Apliance

recognition

13

14

21

M1

43

P

Function / Reset

1 2 3

4

10

11

1 2

3 4

PE

L

N

5

6 10

LD RT

N

L

230 Vac

LN

L

N L

N

11 12

13 14 15

16

17

Clamps

Brown

Fan

gas valve

Temperature

sensors on heat

exchanger

Gas press. sw.

Fane switch

Ignition

Transformer

Ionisation probe

Page 18

Instruction manual

DXA heater

page 18

N

L

PE

1

2

3

J2

2

10

4

12

57 1

3

9

8

J4

8

3

4

5

9

1

1

5

2

6

3

7

4

8

-T

20K@25°C

-T

20K@25°C

5 61211 13 14

5

6

22°C

4

7

J6

J12

J8

1 2 3 1098

166-W2-DX

Get: MF

Date: 01-07-2009

Auth:

Ver: A

Title:

Nr.:

P002

DXA 120 series

(fan relay)

J7

1 2 3 4 5 6 7 8

ON

F2

F1

2 x 5AT

Thermostat (bus)

green/yellow

blue

brown

black

white

puple

GB

10

2

6

7

10

black

15

16

green/yellow

blue

black

R2

J15

11

6

green

yellow

brown

white

S3

S2

R3

blue

Apliance

recognition

13

14

21

K1

14

11

M1

A2

A1

43

P

Function / Reset

1

2 3

4

10

11

1 2

3 4

PE

L

N

5

6

10

LD RT

N

L

230 Vac

L

N

L

N L

N

11 12

13

14

15 16

17

Clamps

Fan

gas valve

Fan relay

Micro switches S2 standard all OFF, and S3 to 1.

When more heaters on one thermostat, do not

change clamps 5 and 6 between heaters.

Temperature

sensors on heat

exchanger

Gas press. sw.

Fane switch

Ignition

Transformer

Ionisation probe

Page 19

Instruction manual

DXA heater

page 19

9

Specifica

ti

ons

9.1 DXA Heater 75

General

G20

G25

G30

G31

Nominal input

Qn(Hi) is

output

75 kW

75 kW

75 kW

75 kW

Air volume

6000 m³/h

6000 m³/h

6000 m³/h

6000 m³/h

Throw

40 m

40 m

40 m

40 m

weight

40 kg

40 kg

40 kg

40 kg

Dimensions

(b x d x h)

650 x 1200 x 530

mm

650 x 1200 x 530

mm

650 x 1200 x 530

mm

650 x 1200 x 530

mm

Permissible ambient temperature

0 - 45 °C

0 - 45 °C

0 - 45 °C

0 - 45 °C

Noise level

79 dB(A)

79 dB(A)

79 dB(A)

79 dB(A)

Fan diam / angle

.

Ø 508 mm / 20°

Ø 508 mm / 20°

Ø 508 mm / 20°

Ø 508

mm / 20°

RPM Fan

1400 rpm

1400 rpm

1400 rpm

1400 rpm

CE-marking

norm(s) against which the heater has been

tested

EN 12669 (safety of hot air blowers)

EN 60335-1; 2002

EN 60335

-2-

102

; 2006

EN 55014 and EN-IEC 61000 (EMC)

EN-IEC 60529 (IP code)

EN-IEC 61558 (safety of transformers, power supply units and similar)

guidelines the heater complies with

Low Voltage Directive

2006/95/EC

EMC Directive

2004/108/EC

Gas Appliances Directive 90/396/EEC

CE declaration

Upon request

Safety settings

minimum gas pressure switch

15 mbar

maximum thermostat (NTC)

110 °C

Gas

G20

G25

G30

G31

nominal gas consumption

7.9 m³/h

8,9

m³/h

10,2 l/h

6,0

kg/h

11,7 l/h

5,9

kg/h

nominal gas supply pressure

20 mbar

25 mbar

30 / 50 mbar

30 / 37 / 50 mbar

Appliance

category

II2EL3P

II2

L3P

II2L3B/P

II2L3P

minimum gas supply pressure

17 mbar

18 mbar

20 mbar

25 mbar

maximum gas supply pressure

25 mbar

30 mbar

57,5 mbar

57,5 mbar

nominal burner pressure

8,0 mbar

11,5 mbar

10,0 mbar

13,0

mbar

gas pipe diameter

3/4"

3/4"

3/4"

3/4"

nozzle diameter

8.5 mm

8.5 mm

6,0 mm

6,0 mm

Electricity

mains voltage

230 V

Frequency

50 Hz

maximum current requirement

2.8 A

Rated power

550 W

910

910

410

220

540

Gas 3/4"

660

1230

Page 20

Instruction manual

DXA heater

page 20

9.2

DXA Heater 100

General

G20

G25

G30

G31

Nominal input Qn(Hi) is output

100 kW

100

kW

100 kW

100 kW

Air volume

6,000 m³/h

6,000 m³/h

6,000 m³/h

6,000 m³/h

Throw

40 m

40 m

40 m

40 m

weight

40 kg

40 kg

40 kg

40 kg

Dimensions (b x d x h)

650 x 1200 x 530

mm

650 x 1200 x 530

mm

650 x 1200 x 530

mm

650 x 1200 x 530

mm

Permissible ambien

t temperature

0 - 45 °C

0 - 45 °C

0 - 45 °C

0 - 45 °C

Noise level

79 dB(A)

79 dB(A)

79 dB(A)

79 dB(A)

Fan diam / angle.

Ø 508 mm / 20°

Ø 508 mm / 20°

Ø 508 mm / 20°

Ø 508 mm / 20°

RPM Fan

1400 rpm

1400 rpm

1400 rpm

1400 rpm

CE-marking

norm(s

) against which the heater has been

tested

EN 12669 (safety of hot air blowers)

EN 60335-1; 2002

EN 60335

-2-

102

; 2006

EN 55014 and EN-IEC 61000 (EMC)

EN-IEC 60529 (IP code)

EN-IEC 61558 (safety of transformers, power supply units and similar)

guidel

ines the heater complies with

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

Gas Appliances Directive 90/396/EEC

CE declaration

Upon request

Safety settings

minimum gas pressure switch

15 mbar

17 mbar

15 mbar

15 mbar

maximum thermostat

(NTC)

110 °C

Gas

G20

G25

G30

G31

nominal gas consumption

10,5 m³/h

11,8 m³/h

13,6 l/h

8,0 kg/h

15,6 l/h

7,9 kg/h

nominal gas supply pressure

20 mbar

20 / 25 mbar

30 / 50 mbar

30 / 37 / 50 mbar

Appliance category

II2EL3P

II2L3P

II2L3B/P

II2L3P

minimu

m gas supply pressure

17 mbar

18 mbar

20 mbar

25 mbar

maximum gas supply pressure

25 mbar

30 mbar

57,5 mbar

57,5 mbar

nominal burner pressure

7,0 mbar

10,0 mbar

10,0 mbar

13,0 mbar

gas pipe diameter

3/4"

3/4"

3/4"

3/4"

nozzle diameter

10,5 mm

10,5 mm

7,0 mm

7,0 mm

Electricity

mains voltage

230 V

Frequency

50 Hz

maximum current requirement

2.8 A

Rated power

550 W

910

910

410

220

540

Gas 3/4"

660

1230

Page 21

Instruction manual

DXA heater

page 21

9.3 DXA Heater 120

General

G20

G25

G30

G31

Nominal input Qn(Hi) is output

120 kW

120 kW

120 kW

120 kW

Air volume

7,000 m3/h

7,

000 m3/h

7,000 m3/h

7,000 m3/h

Throw

45 m

45 m

45 m

45 m

weight

45 kg

45 kg

45 kg

45 kg

Dimensions (b x d x h)

650 x 1235 x 530

mm

650 x 1235 x 530

mm

650 x 1235 x 530

mm

650 x 1235 x 530

mm

Permissible ambient temperature

0 - 45 °C

0 - 45 °C

0 - 45 °C

0 - 45 °C

Noise level

81 dB(A)

81 dB(A)

81 dB(A)

81 dB(A)

Fan diam / angle.

Ø 508 mm / 25°

Ø 508 mm / 25°

Ø 508 mm / 25°

Ø 508 mm / 25°

RPM Fan

1420 rpm

1420 rpm

1420 rpm

1420 rpm

CE-marking

norm(s) against which the heater has been

tested

EN 12669 (safety of hot air blowers)

EN 60335-1; 2002

EN 60335

-2-

102; 2006

EN 55014 and EN-IEC 61000 (EMC)

EN-IEC 60529 (IP code)

EN-IEC 61558 (safety of transformers, power supply units and similar)

guidelines the heater complies with

Low Voltage D

irective 2006/95/EC

EMC Directive 2004/108/EC

Gas Appliances Directive 90/396/EEC

CE declaration

Upon request

Safety settings

minimum gas pressure switch

15 mbar

17 mbar

15 mbar

15 mbar

maximum thermostat (NTC)

110 °C

Gas

G20

G25

G30

G31

nomina

l gas consumption

12,6 m³/h

14,2 m³/h

16,3 l/h

9,5 kg/h

18,7 l/h

9,5 kg/h

nominal gas supply pressure

20 mbar

20 / 25 mbar

30 / 50 mbar

30 / 37 / 50 mbar

Appliance category

II2EL3P

II2L3P

II2L3P/B

II2L3P

minimum gas supply pressure

17 mbar

18 mbar

20

mbar

25 mbar

maximum gas supply pressure

25 mbar

30 mbar

57,5 mbar

57,5 mbar

nominal burner pressure

7,0 mbar

10,0 mbar

8,8 mbar

12,0 mbar

gas pipe diameter

3/4"

3/4"

3/4"

3/4"

nozzle diameter

12,0 mm

12,0 mm

8,0 mm

8,0 mm

Electricity

mains volt

age

230 V

Frequency

50 Hz

maximum current requirement

3,8 A

Rated power

800 W

910

910

410

220

540

Gas 3/4"

660

1230

Loading...

Loading...