WinterGreen IM-90, IM-130, IM-220, IM-330 Owner's Manual

OWNER’S MANUAL

Installation and

Operating

Instructions for

Models:

IM-90, IM-130,

IM-220, IM-330

WinterGreen Wood Furnaces have been

tested and are certified to meet UL standard

391 for safety for Solid Fuel Burning Indoor

Heating Appliances

IMPORTANT. KEEP THESE INSTRUCTIONS. DO NOT THROW AWAY.

BE SURE TO READ THIS MANUAL AND KEEP FOR FUTURE REFERENCE.

WinterGreen Wood Furnaces

3015 West Main Street, Parish, NY 13131

Email us: sales@homegrownheat.com

Visit us at: www.homegrownheat.com

Version: 8/09

TABLE OF CONTENTS

Section Page

Furnace Serial Number – Recording Information 4

Warnings and Safety – Installation 5

Warnings and Safety – Operation 6

Risk of Fire - Explosion 7

Safety Label Locations 8

Furnace Introduction

Firebox technology 9

Combustion chamber 9

Heat exchanger 9

Water tube design 9

Wood gasification & Combustion Chamber 10

Furnace Unloading and Moving

Safety 11

Unloading furnace from pallet 11

Lifting the furnace from the Bottom 12

Lifting the furnace from the top with a spreader bar 13

Lifting the furnace from the top with slings 13

Floor requirements 14

Furnace Specifications 15

Furnace Component List 16

Furnace Installation – Location

Mounting on a cement or masonry base 17

Clearances to combustible surfaces 18

Connecting to existing ductwork 18

Chimney Installation

Chimney Regulations 19

Furnace connection to a factory built chimney 20

Furnace connection to a Masonry Chimney 21

General Rules for chimneys 22

Digital Temperature Controller

Feature description 23

Operation & setting temperature 24

Error messages, settings & alarms 25

Furnace Startup

Cold startup – checking the furnace 26

Cold startup fire 26

Factory setting for damper 27

Runaway Fire 27

Furnace – Primary Fire

Determining the appropriate fire size 28

Normal operating temperature 28

Furnace - Ash Disposal

Disposal of ashes 29

Access to ash pan 29

Loading the Furnace

Warnings 30

Wood loading procedure 31

Proper wood loading height in the furnace 32

Loading wood into the furnace 33

Furnace burning tips 33

Wood Selection

Efficiency 34

Best wood to burn 34

Harvesting 34

Wood selection chart 35

TABLE OF CONTENTS

Section Page

Draft Inducer and Barometric Damper

Draft Inducer location and installation 36

Draft Inducer-installation on stove pipe 37

Draft Inducer-Electrical outlet on furnace 38

Barometric Damper location and Installation 39

Maintenance 40

Draft Setup

What is draft 41

What is the Draft Inducer and Barometric Damper 41

Manometer and where to test 42

Barometric Damper setup 42

Draft Inducer setup 43

Measuring and adjusting the flue draft 44

Maximum draft setting 45

Negative Air – Make-up Air

Negative air problems 46

Supplying Make-up air 46

Determining the volume of fresh air 46

Confined and unconfined space 47

Plumbing Installation

System configurations 48

Filling the system 48

Closed System – basic plumbing configuration to furnace 49

Open System – basic plumbing configuration to furnace 50

Closed System – basic plumbing configuration to boiler 51

Side Arm Heat Exchanger (Hot water tank) 52

Furnace Plenum Heat Exchanger 53

Plumbing components and functions 54

Wiring and Controls

Basic wiring and controls 55

Wiring schematic 56

Furnace control panel 57

Power Failures – System Backup

Overheat protection during a power failure 58

Power outage instructions 58

Battery Backup power supply (Schematic) 59

Installing a back-up generator 60

System backup – Heat from main furnace or boiler 60

Thermal Spike Protection

Why have thermal spike protection 61

Thermal spike protection methods 61

Maintenance – Furnace

End of season and general maintenance 62

Flushing the system 62

Firebox refractory cracks 62

Maintenance – Chimney

Chimney inspection and cleaning 63

Creosote 63

Chimney Fire 64

Troubleshooting Guide 65

Warranty 66

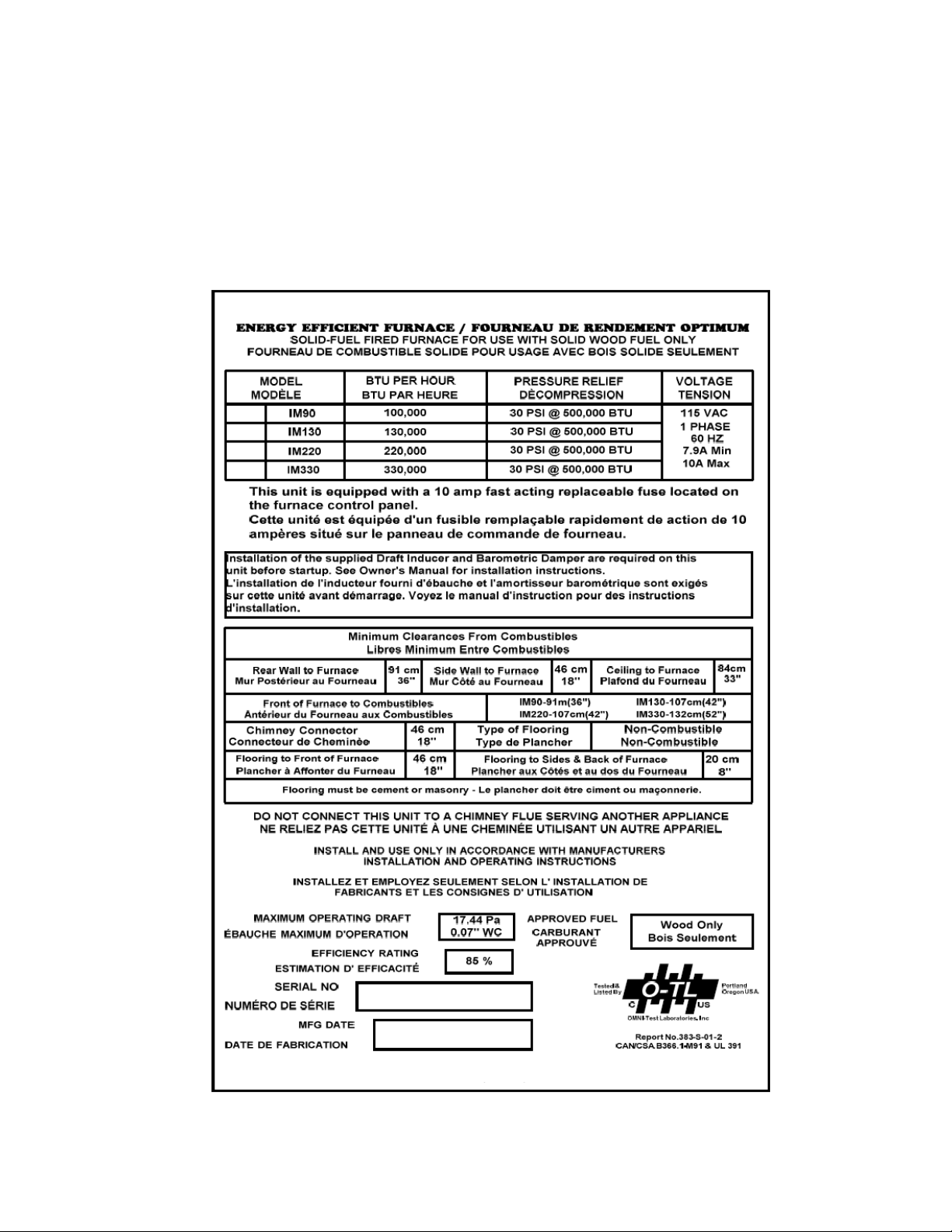

FURNACE SERIAL NUMBER

Locate the serial number and model number of your WinterGreen Furnace on the unit and record

them in the space provided in the label below. (See section: “Safety Label Locations”) for the

location of the Manufacturer’s Decal on the furnace.

Have this information available when contacting your WinterGreen Dealer for warranty, service

or technical information.

WinterGreen

Manufactured for WinterGreen Wood Furnaces by SJV Inc. Fort Kent, Maine, USA

WARNINGS & SAFETY

INSTALLATION

Read and understand all warnings, safety instructions and information provided in this

manual. If your Furnace is not installed properly a house or building fire may occur.

Furnace installation must conform to National Fire Protection Association (NFPA) installation standards No.89M, 90B, 211, 70 (National Electrical Code) and local building and fire code standards.

Check with local authorities for the code requirements in your area.

Chimney installation must conform to National Fire Protection Association (NFPA) Standard 211

and local building and fire code requirements. Check with local authorities for the code requirements

in your area.

DO NOT CONNECT furnace to an aluminum “Type B” gas vent. This is unsafe. Use an approved

masonry or CSA/UL approved, "Class A" Residential Type Building Heating Appliance Chimney.

DO NOT USE A CHIMNEY CAP.

DO NOT connect furnace to a chimney flue shared with another appliance.

Ensure your chimney is safely constructed and in good repair. Have the chimney inspected by a

qualified technician.

Installation should be made by a qualified heating equipment installer (one who is engaged in and is

responsible for, or is thoroughly familiar with the installation and operation gas, oil and solid fuel

burning heating appliances; that is experienced in such work and familiar with all building requirements and/or fire codes of the authority having local jurisdiction.

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME. Install the Furnace outside in a covered

building and pipe the hot water heat into the home.

Always connect this furnace to an approved chimney and vent to the outside, never vent to another

room or inside a building.

Observe all clearances as specified in this manual, especially those for combustibles materials.

DO NOT operate the furnace while under the influence of alcohol or drugs.

The furnace has stainless steel and painted surfaces which are very durable, although rough handling or abuse will cause premature failure of their protective qualities. To maintain a long lasting

finish, handle with reasonable care. Clean surfaces regularly with soap and water or stainless steel

cleaner. ONLY WHEN THE FURNACE IS COOL! Paint discoloration will occur if the furnace is overfired.

While in operation, keep the feed door, ash tray door closed and secured at all times, except when

tending the fire.

Operate the furnace draft with no less than 0.005” WC or no more than 0.07” WC

FURNACES ARE HEAVY!

Models can be from 2400 lbs. to 3800 lbs. Check specifications and know the weight of your unit. In order to prevent personal injury, make sure you have the proper equipment and manpower to unload,

move and position your boiler safely.

Continued on next page…

WARNINGS & SAFETY

OPERATION

To prevent injury, always wear protective clothing, leather hearth

gloves and eye protection while tending the furnace fire. NEVER

TOUCH THE FURNACE WITH BARE SKIN

Do not over-fire the furnace. Over firing will occur if the feed door or

ash door is left open during furnace operation. A dangerous fire hazard condition may result!

Keep the furnace area clear and free from all combustible materials,

wood chips, gasoline and all other flammable vapors and liquids.

DO NOT any use chemicals, charcoal lighter fluid, gasoline or any

other type of flammable liquids to start the fire.

Do not burn coal, use only solid seasoned whole wood.

Do not allow ashes to accumulate higher than the bottom of the

draft holes in the firebox.

Open firebox door slowly when loading the furnace.

Do not install the warm air supply outlet (Heat Exchanger) of the furnace to the cold air return inlet of the central home furnace because

a possibility exists of components of the central furnace overheating and causing the central furnace to operate other than intended.

While the furnace is in operation, extreme care should be taken to

avoid contact with the unit as high surface temperatures may result

in a burn injury. Special care should be taken if children are present

in the area of the furnace, they should be kept a safe distance away

from the unit and supervised at all times. IT IS RECOMMENDED

THAT A CHILD PROOF BARRIER BE INSTALLED AROUND THE PERIMETER OF THE UNIT AT A SUITABLE DISTANCE TO ENSURE

THERE IS NO POSSIBILITY OF CONTACT OR POTENTIAL INJURY.

Continued on next page…

WARNINGS & SAFETY Continued:

RISK OF FIRE

NEVER OPERATE THE FURNACE WITH THE DRAFT DOOR

BLOCKED OPEN!

DO NOT OPERATE WITH THE FUEL LOADING OR ASH REMOVAL DOORS OPEN!

DO NOT STORE FUEL OR OTHER COMBUSTIBLE MATERIAL

WITHIN THE MARKED INSTALLATION CLEARANCES OF

FURNANCE.

INSPECT AND CLEAN FLUE AND CHIMNEY REGULARLY.

DO NOT OPERATE WITH FLUE DRAFT EXCEEDING .07” WATER

COLUMN.

RISK OF FIRE OR EXPLOSION

DO NOT BURN GARBAGE, GASOLINE, DRAIN OIL OR ANY

OTHER FLAMMABLE FLUIDS.

HOT SURFACES

KEEP CHILDREN AWAY FROM FURNACE.

DO NOT TOUCH HOT SURFACES DURING FURNACE OPERA-

TION. MAXIMUM DRAFT OF FURNACE IS MARKED ON MANUFACTURER’S NAMEPLATE.

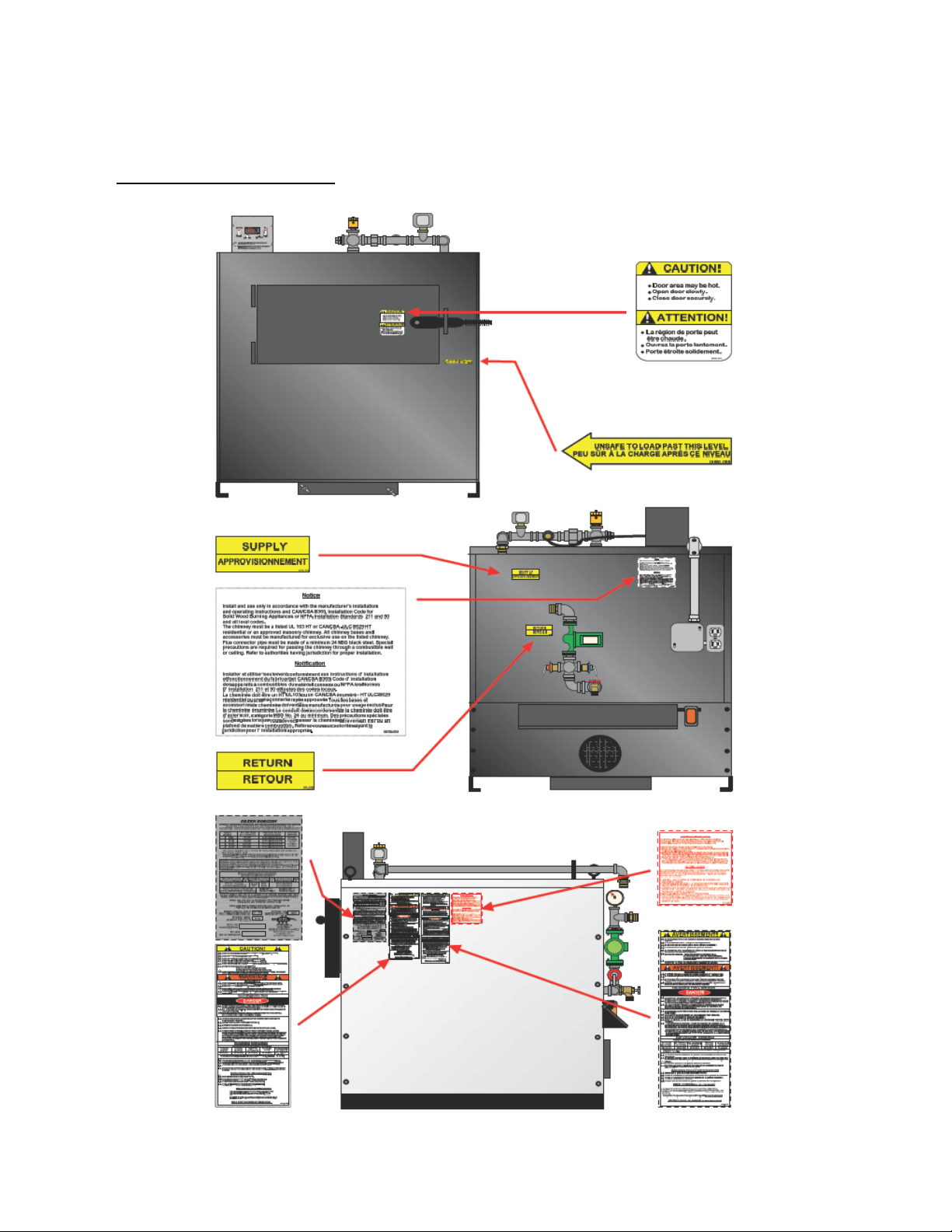

WARNINGS & SAFETY

SAFETY LABEL LOCATIONS:

FURNACE INTRODUCTION

Congratulations on your purchase of a new WinterGreen Hydronic Wood Furnace. The WinterGreen Furnace when properly installed and maintained will give you many years of dependable

wood burning service.

To ensure a safe and proper installation of your WinterGreen Hydronic Furnace, you should:

1) Have your furnace installed by a reputable contractor that has experience with the installation of this

type equipment, has knowledge with Solid Fuel Heating Appliances and be familiar with all local fire

and building codes.

2) Read carefully and use the information that is provided in this manual.

How the WinterGreen Hydronic Wood Furnace Works

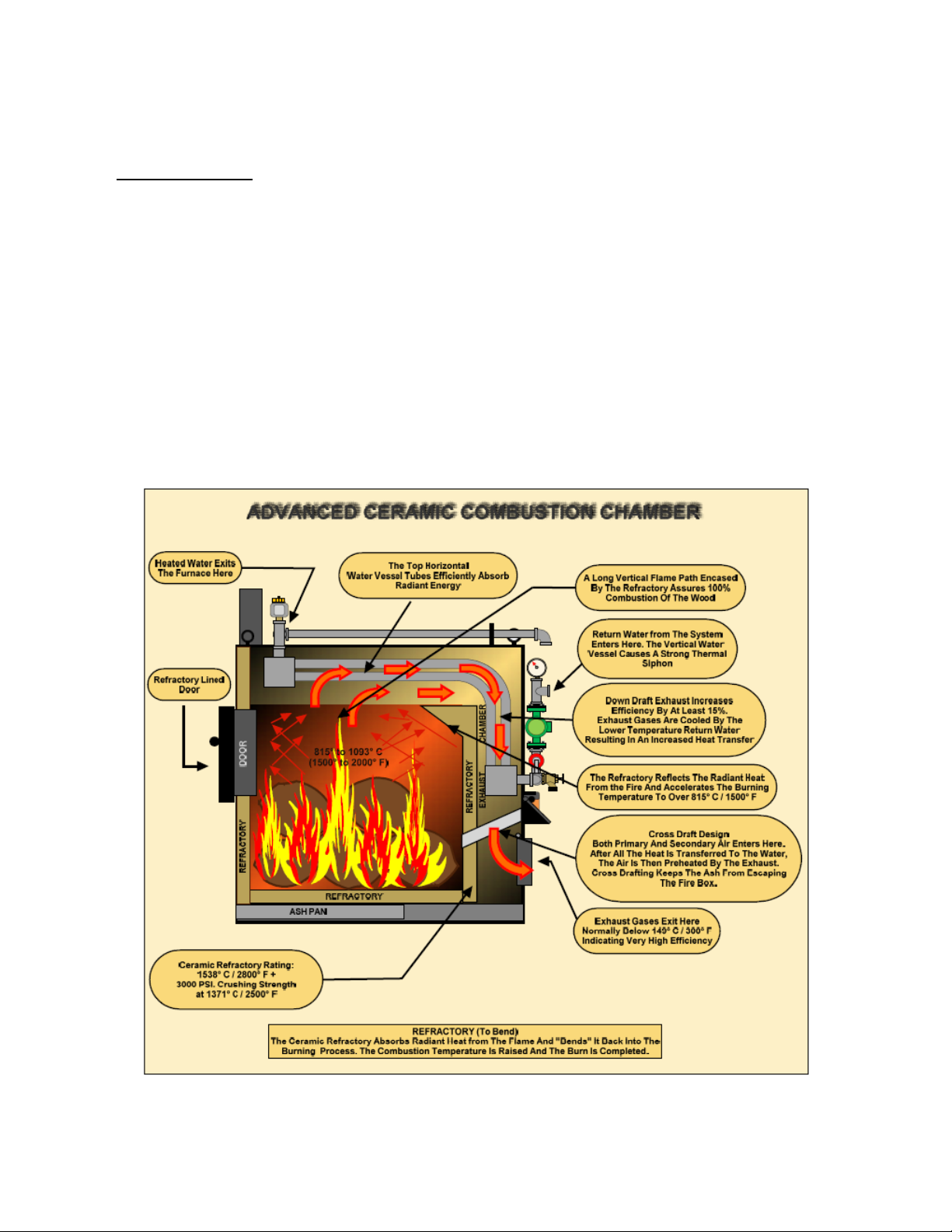

Firebox Technology:

As wood burns, it begins boiling out moisture at 100˚C/212˚F. The wood starts to change its chemistry at

400-600˚F and begins releasing volatile gases as it breaks down. Those gases contain 50-70% of available energy from the wood. Most furnace designs allow those gases to escape out of the stack, wasting

energy. Our Wood Furnaces are manufactured with a refractory fire chamber surrounded by three

inches of high temperature insulation and an airtight stainless steel “skin”. The fire box temperature exceeds 1500˚F and “skin” temperature is less than 100˚F. The water tube pressure vessel removes both

radiant and convective heat. The heat must travel down past the vessel to the exhaust port, heating the

incoming combustion air on the way. The exhaust temperature is below 300˚F. Once the fluid reaches

the set temperature, the draft is closed and the fire is completely extinguished; it does not smolder. Because the thermal mass in the refractory stays above the flash point the fire always re-ignites when the

furnace calls for heat again.

Combustion Chamber:

These Wood Furnaces have several unique features that enable them to achieve higher efficiency and

cleaner burns than other wood Furnaces. The refractory combustion chamber ensures a very high combustion temperature and a long flame path with enough turbulence to complete the burning of all gases.

Once the wood gases are completely burned, the hot gases enter the heat exchange area.

Heat Exchanger:

The heat exchanger is a down draft system where the exhaust exits the unit below the entrances of the

cold water and the draft air supply. Because of the differential between the incoming cold water temperature and the exhaust temperature, thermal transfer is increased. The heat in the exhaust is transferred to the water and warms it as it enters the unit, while also decreasing the exhaust temperature. As

the exhaust continues downward, the I coming draft air is also heated after all the available heat has

already been put into the water. The heate draft air increases the combustion temperature in the refractory chamber without taking heat from the combustion process.

Water Tube Design:

The Furnaces have a water tube design (Pressure Vessel) which absorbs much more heat per square

inch than fire tube furnaces, withstands much more pressure, and also holds much less water so it responds more quickly. Because of limited water storage, water tube furnaces are much safer than fire

tube furnaces.

Continued on next page…

FURNACE - INTRODUCTION Continued:

Wood Gasification

Wood gasification is the process of heating wood in an oxygen-limited chamber until volatile gases

(carbon monoxide, hydrogen, and oxygen) are released from the wood and combusted. Heating the

wood to the temperature range of 400-600 degrees releases most of the gases. The emitted wood

gases are then superheated and mixed with air for complete combustion, leaving little or no ash, and the

heat produced is transferred to the boiler for heating.

This process takes place in two stages, through the cross draft combined with the very high temperatures of the refractory (1500-2000 degrees). The extreme radiant energy from the refractory raises the

wood temperature for gasification, while limiting the oxygen in the primary zone. As the gases rise, the

preheated draft air combines with them and completes the combustion. The long flame path combined

with the turbulence and reverse flow assures complete combustion. During each off-cycle the radiant

heat from the refractory combined with the lack of oxygen prepares the wood for the next cycle.

FURNACE – UNLOADING & MOVING

To Prevent Personal Injury, WinterGreen Recommends:

The use of a suitable Forklift Truck with a capacity rating of at least 5000lb with 5-6 ft forks and is

capable of unloading, lifting and transporting the furnace unit to the determined installation location

safely.

That you have sufficient manpower and proper equipment available to assist in moving and installation of the furnace.

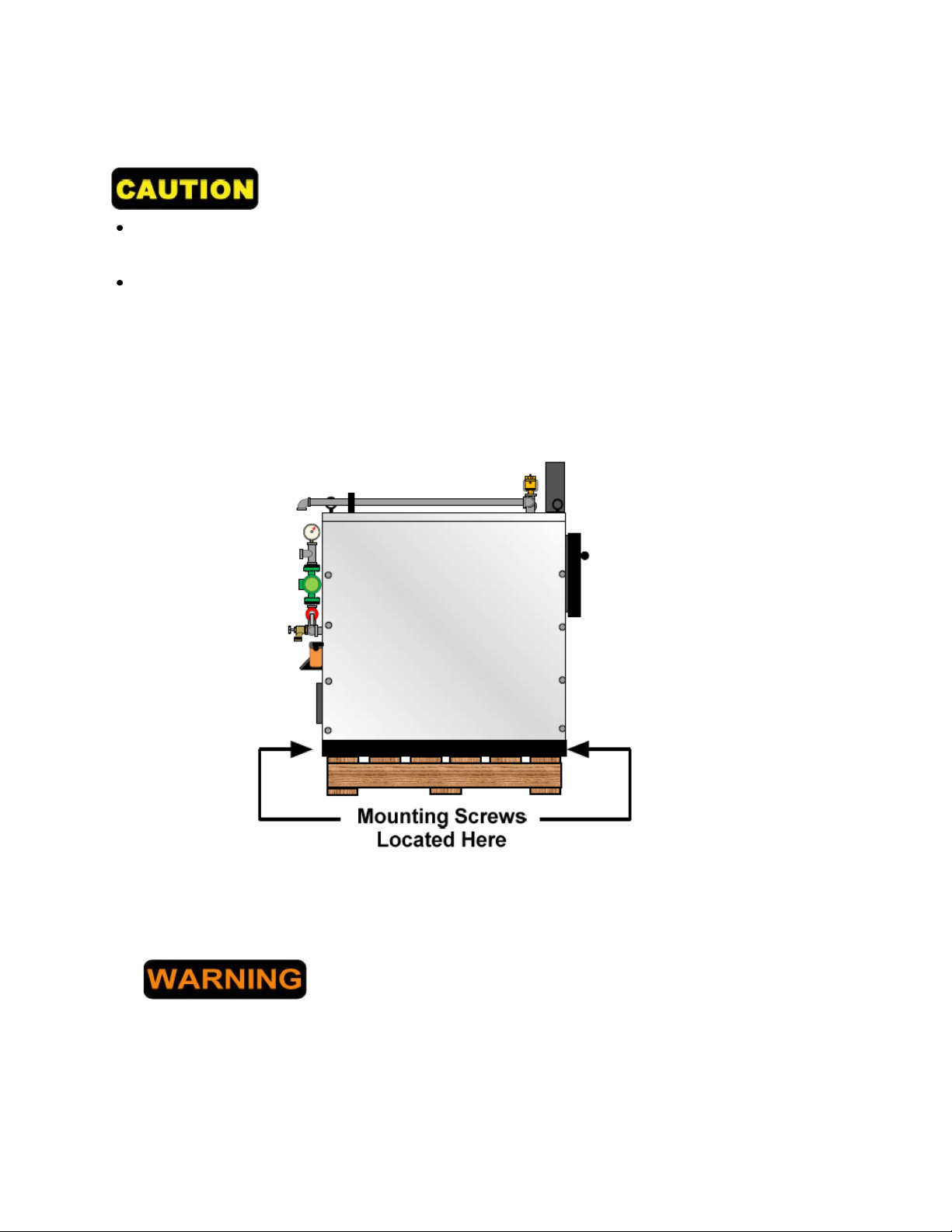

The WinterGreen Furnace comes mounted on a wooden pallet to protect it during shipping. To detach

the furnace from the pallet, remove the 4 (four) anchoring screws located on each corner of the base of

the unit that secure it to the pallet.

WinterGreen Furnaces are heavy, be sure you know the weight your going lift.

WinterGreen recommends that the furnace be moved by a professional equipment mover who is knowledgeable and experienced in

the rigging and moving of heavy equipment. Damage can occur to

the furnace refractory if the unit is dropped. An experienced professional can ensure the installation will be safe and damage free.

Continued on next page…

FURNACE – UNLOADING & MOVING Continued:

Methods of moving the Furnace

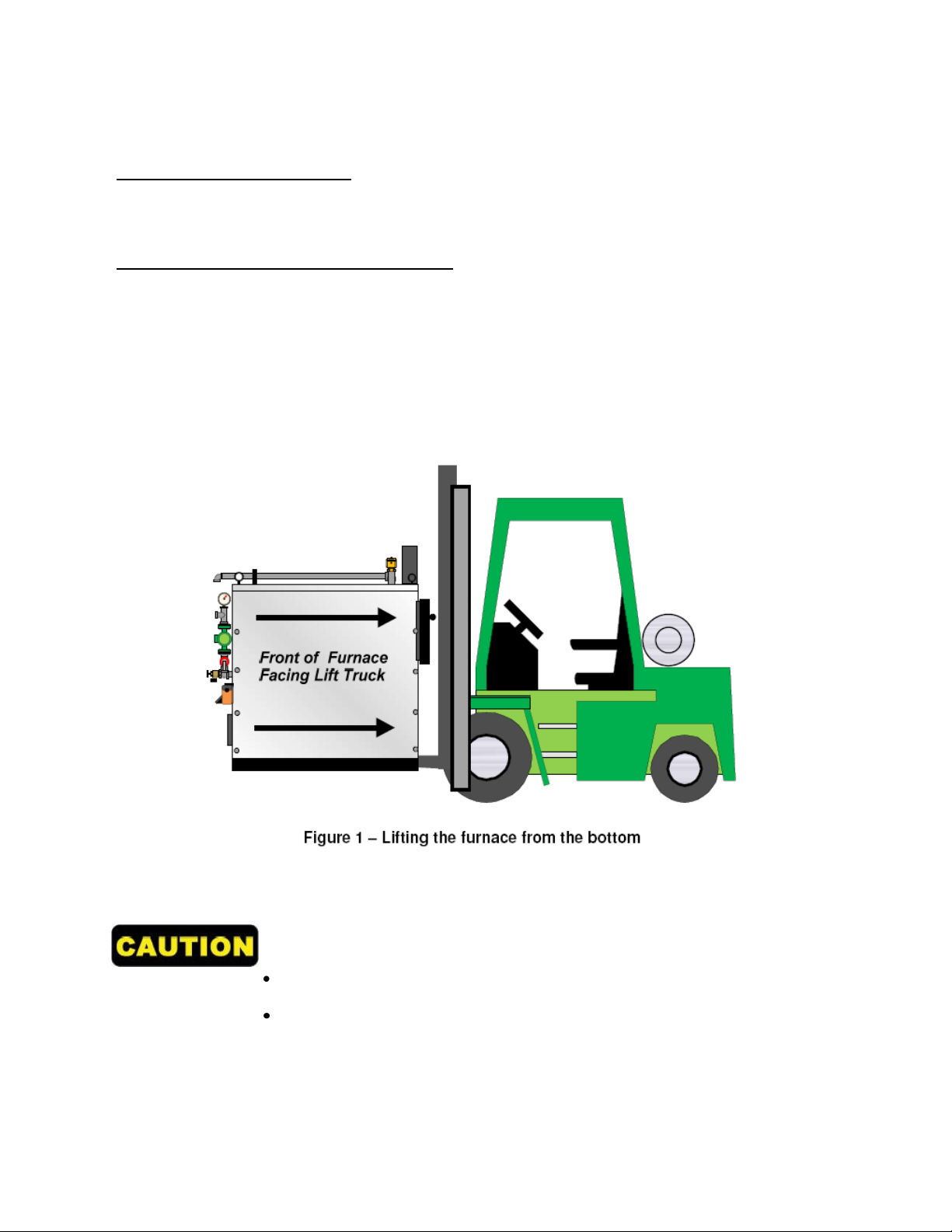

The furnace has been designed it to be lifted and transported using a fork lift truck utilizing 2 (two) different methods.

Method 1: Lifting the furnace from the bottom

When moving the furnace from the bottom it is important that the forks be spread as wide as possible to

fit between the base plates .The unit should be centered on the forks so as the load is safely distributed

and the furnace is stable. To prevent damage to the piping and components mounted on the back of the

furnace, the front of the furnace (Loading door side) should face the lift truck. (See figure 1) This is important should the furnace contact the lift truck during the installation. Keep the load level while lifting

and only raise the unit as high as necessary to allow safe movement. Avoid any sudden jerky movements and maneuvers, drive slowly and make any turns with caution.

Never stand under or in the path of the load while moving the furnace!

The operation of a fork lift truck should be performed by a professional

driver who has been trained in the safety and handling of this type of

vehicle.

Continued on next page…

FURNACE – UNLOADING & MOVING Continued:

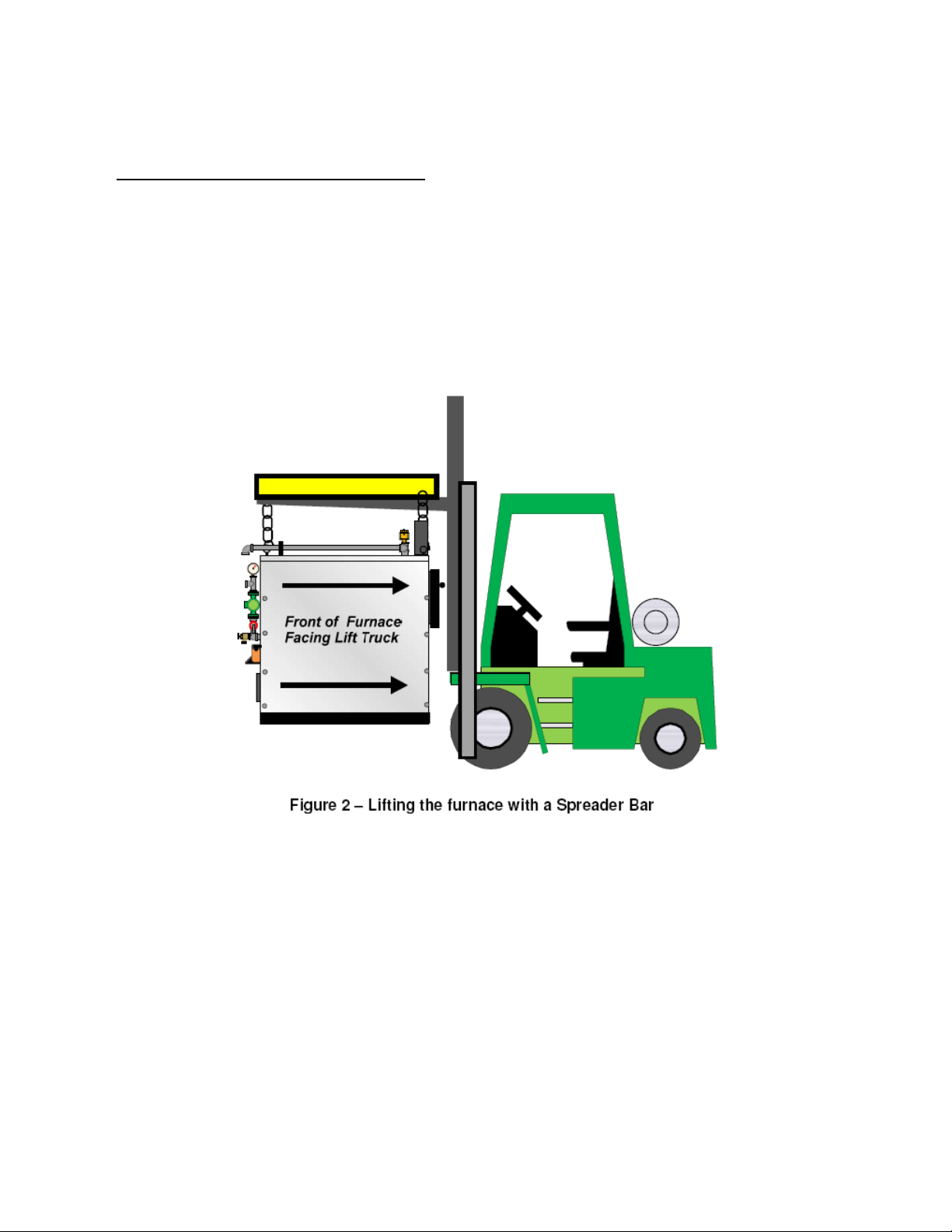

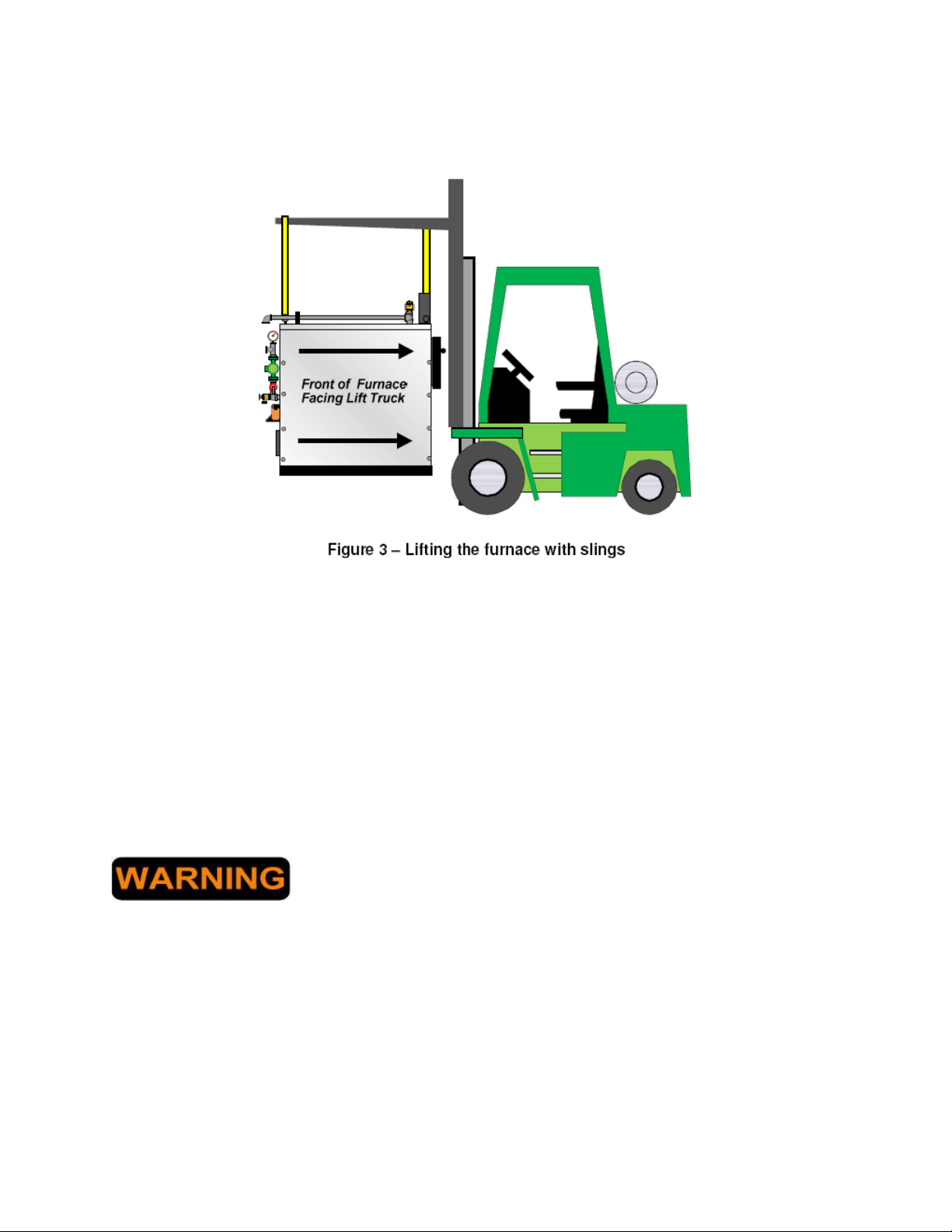

Method 2: Lifting the furnace from the top

Spreader Bar:

The WinterGreen furnace comes with 2 (two) lifting eyelets located on opposing top corners of the unit.

One method of lifting the unit can be the use of a spreader bar. The spreader bar can have either lifting

slings or chains. Place the bar diagonally across the forks of the lift truck and attach the chains or lifting

slings so as they are directly in line with eye hooks. (See figure 2) It is important that when the unit is

lifted there s no side pull on the eyelets as this will cause damage to the unit and possible personal injury.

Slings:

To use just nylon lifting slings to lift the furnace, first slide one end of the sling through an eyelet until

both end sare of equal length. Do the same with the other eyelet. Both slings should be equal in length.

Adjust both forks on the lift truck so the center of each fork is directly centered to each eyelet. Slide each

sling over a separate fork. One sling will be to the back of one fork and the other sling will be to front of

opposite fork. Slowly lift the forks until there is tension. Check to see if there is any side pull on the eyelets. Several re-adjustments may have to be made before the sling position is correct. (See figure 3) Be

sure not to lift if there is any side pull, damage to the furnace will occur.

Continued on next page…

FURNACE – UNLOADING & MOVING Continued:

Note: The furnace should be placed on a non-combustible floor made of concrete or masonry. Consid-

eration should be made when deciding a location for the furnace, it should be close to a chimney, a

power source and have easy accessibility to your wood supply. If your WinterGreen furnace is to be lo-

cated in a garage, National Codes require that the lowest point of ignition be at least 46cm/18” from the

floor. If the furnace is to be installed in a separate enclosed space where combustion air is taken from

outside the garage, this rule does not apply.(See Page 17 – Mounting on a Cement or Masonry Base)

Although Your WinterGreen furnace is certified for minimal clearance from combustible surfaces, it is

advisable to verify local authorities for all clearances before the installation begins.

READ THE SECTION “FURNACE INSTALLATION –LOCATION” in the Owner’s Manual.

The installation location must have provisions to shelter the furnace from weather and protect it

from freezing intake air.

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME OR TRAILER.

INSTALL A CARBON MONOXIDE DETECTOR AND SMOKE ALARM IF

THE NSTALLATION IS IN A HOME, GARAGE OR AN ENCLOSED AREA.

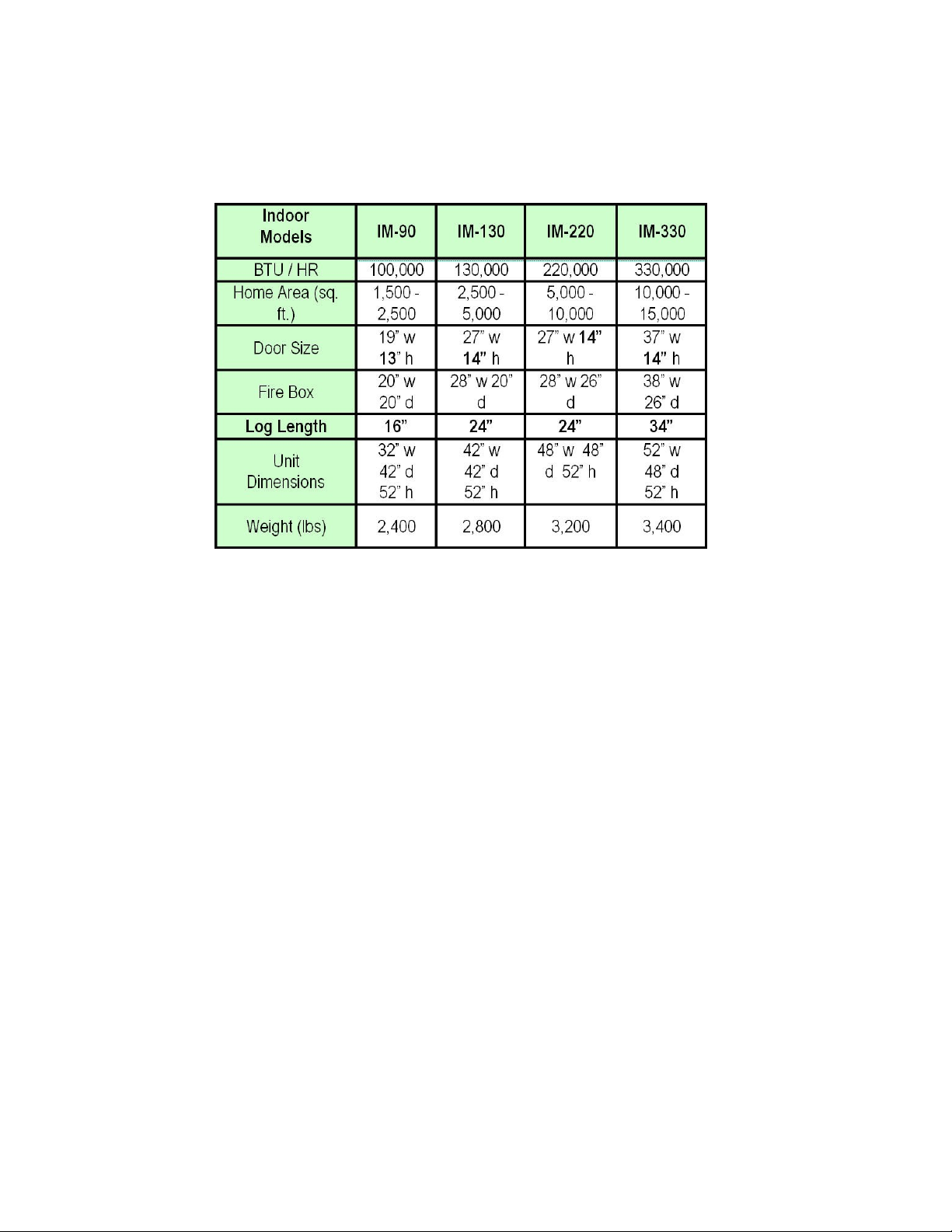

FURNACE - SPECIFICATIONS

General Furnace Specifications:

Note that many factors must be considered to determine “Heating Capacity” including the de-

sign of your home, how well your home is built, construction quality, insulation properties, climate in your area and what type of wood you are burning.

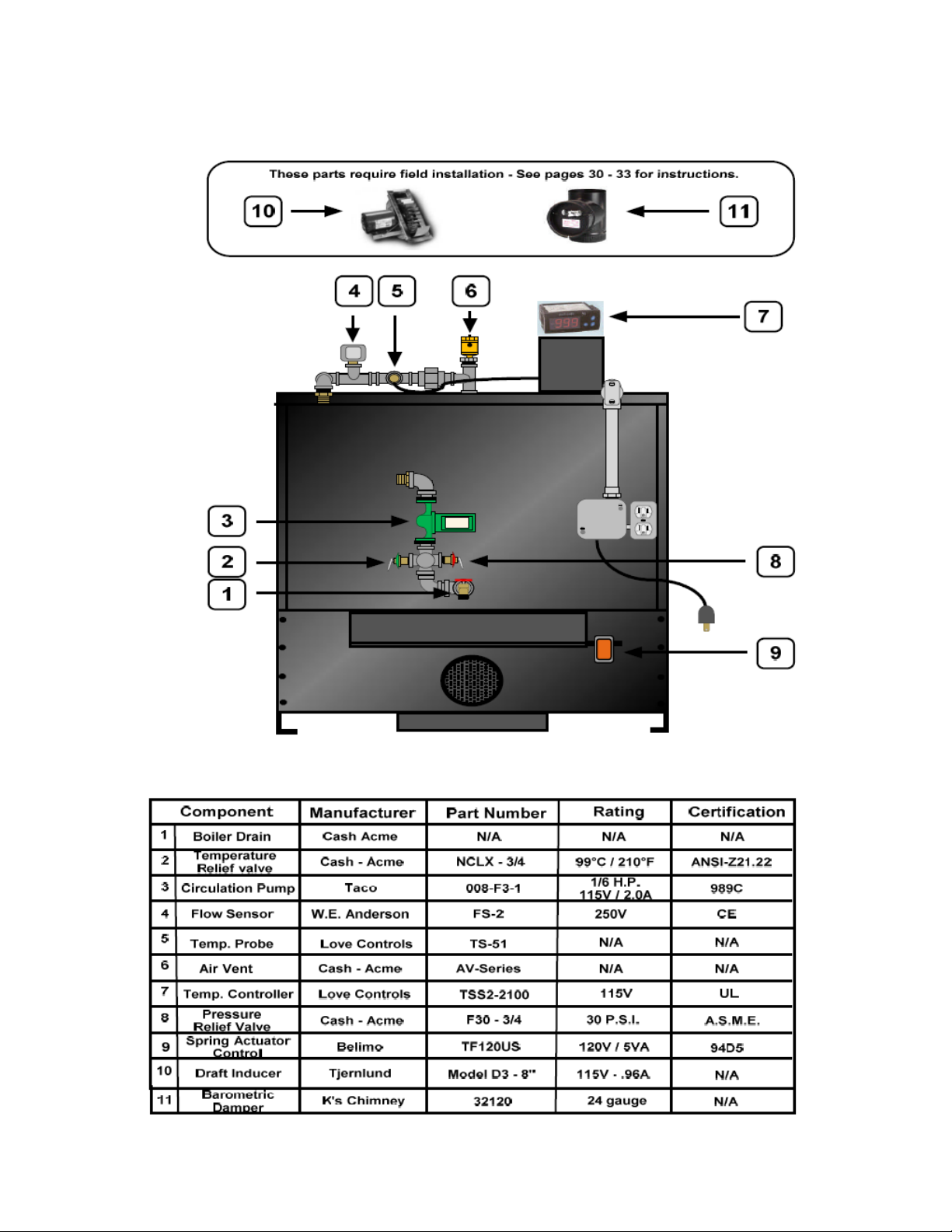

FURNACE – COMPONENT LIST

FURNACE INSTALLATION - LOCATION

It is very important to adhere to the installation clearances and restrictions stated in this

manual.

WinterGreen Furnaces are certified to be installed in most indoor applications, garage, and basements or out buildings that are sheltered.

DO NOT INSTALL FURNACE INSIDE A MOBILE HOME OR TRAILER! The furnace must be installed outside in a suitable sheltered building such as a shed or garage and pipe the hot water into

the mobile home.

The clearances provided are minimum dimensions determined by the manufacturer’s testing facility.

Installation of this furnace must comply with either the following Canadian or U.S. applicable regulations:

Installation is to be in accordance with National Fire Protection Association installation standards 90, 211, 70 (National Electrical Code) and Uniform Mechanical Code 913, 6-4 in applicable

states. Check with local building and fire code officials for regulations required for your area.

Provisions should be made for accessible power for the furnace.( See: ”Furnace Wiring” section )

WARNING: Wood storage must be kept a minimum of 1.5m (5 ft) from the furnace.

BEFORE installing the WinterGreen Furnace as an “add on to any existing installation, a thorough in-

spection and approval must be made of the existing systems by a qualified inspector. Any additional procedures shown in the installation instructions provided with the unit must be followed.

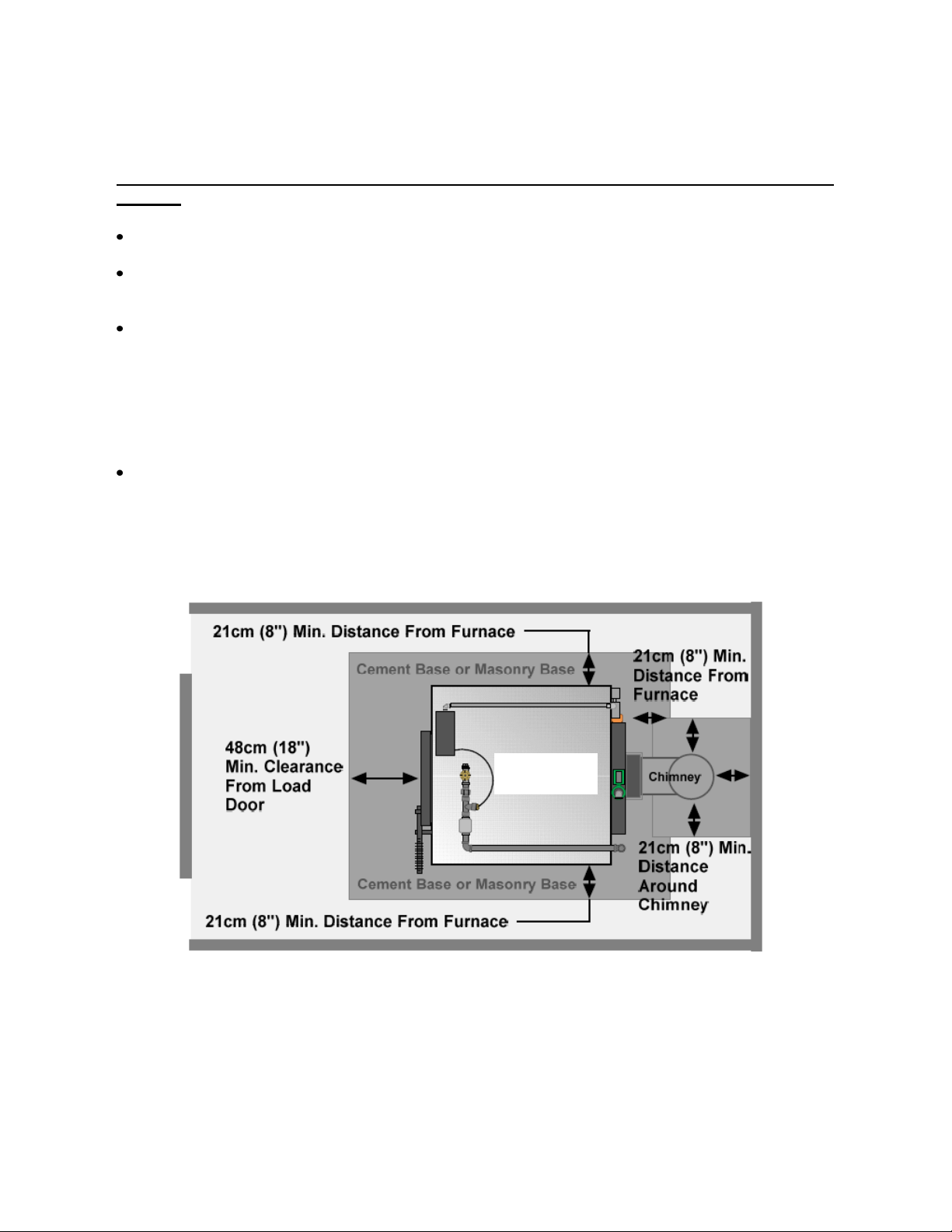

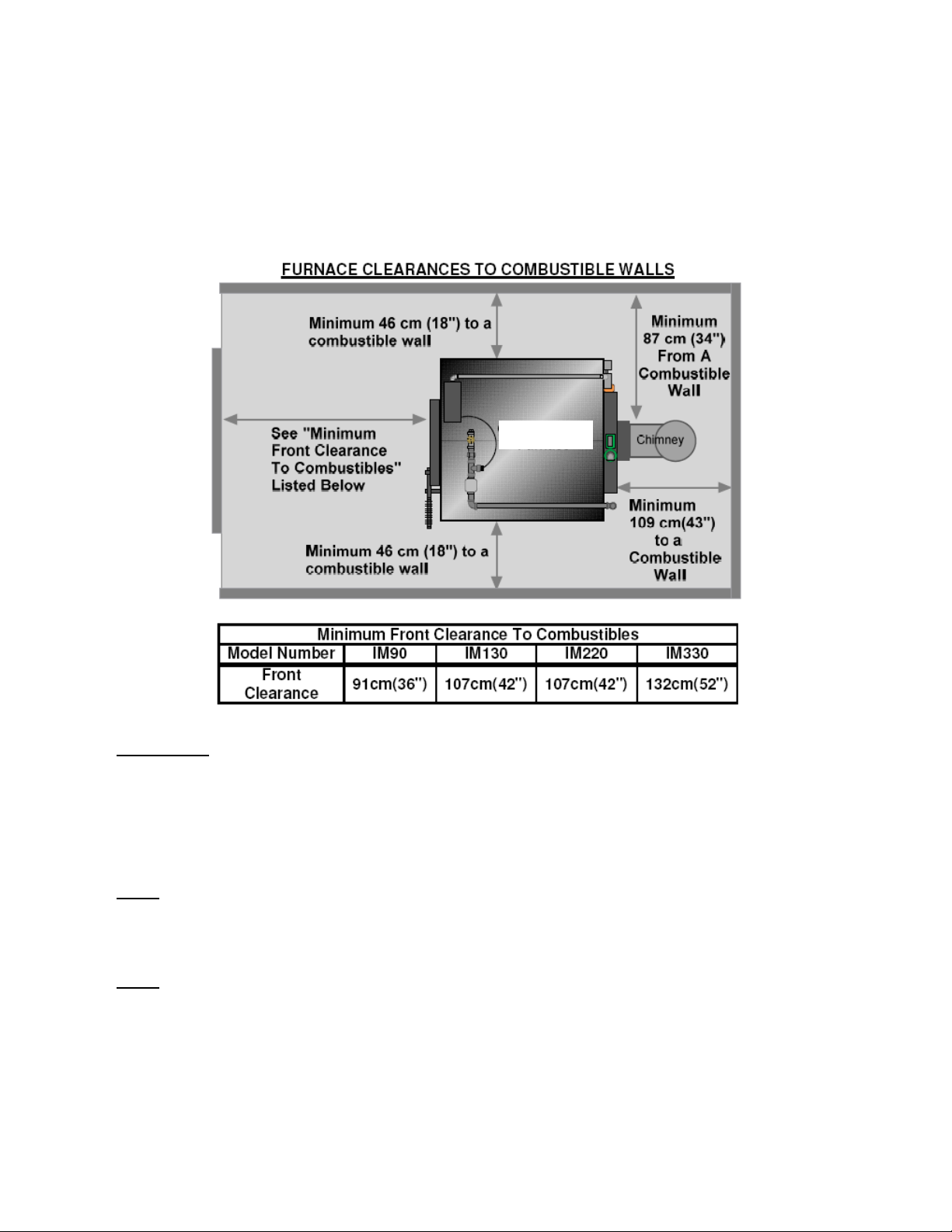

Top View

The WinterGreen Furnace must be installed on a solid concrete floor or 3 ½” thick masonry base.

See the above diagram showing minimum distance requirements that the floor must extend past

the furnace, flue and chimney pipe. DO NOT INSTALL THE WINTERGREEN FURNACE ON A

COMBUSTIBLE FLOOR

Cement or Masonry Base Clearances for the WinterGreen Furnace

Continued on next page…

FURNACE INSTALLATION – LOCATION Continued:

When installing your WinterGreen Furnace it is important to adhere to the clearance dimensions

to combustible surfaces as shown below. Note that these are minimum clearances and your furnace should never be located any closer than the dimensions stated.

Top View

IMPORTANT:

The installation of this furnace must comply with the latest edition of NFPA 211 for Reduced

Clearances and/or your local building codes, whichever minimum clearances are greater.

Installation should be made by a qualified heating equipment installer (one who is engaged and

is responsible for, or is thoroughly familiar with the installation and operation of gas, oil and

solid fuel burning appliances; who is experienced in this type of work and familiar with all the

building code requirements and/or fire codes of the authority having local jurisdiction.)

NOTE: Any connections to an existing ductwork system of a forced air heating system must

comply with NFPA 90B, 2-1.1 and have plenums constructed of metal in accordance with NFPA

90B, 2-1.3. Contact your local H.V.A.C. professional for determining compatibility of the

WinterGreen Furnace to your existing heating system prior to installation.

NOTE: The furnace should be placed on a non-combustible floor made of concrete or masonry.

Consideration should be made when deciding a location for the furnace; it should be close to a

chimney, a power source and have easy accessibility to your wood supply. If your WinterGreen

furnace is to be located in a garage, National Codes require that the lowest point of ignition be at

least 18” from the floor. If the furnace is to be installed in a separate enclosed space where com-

bustion air is taken from outside the garage, this rule does not apply.

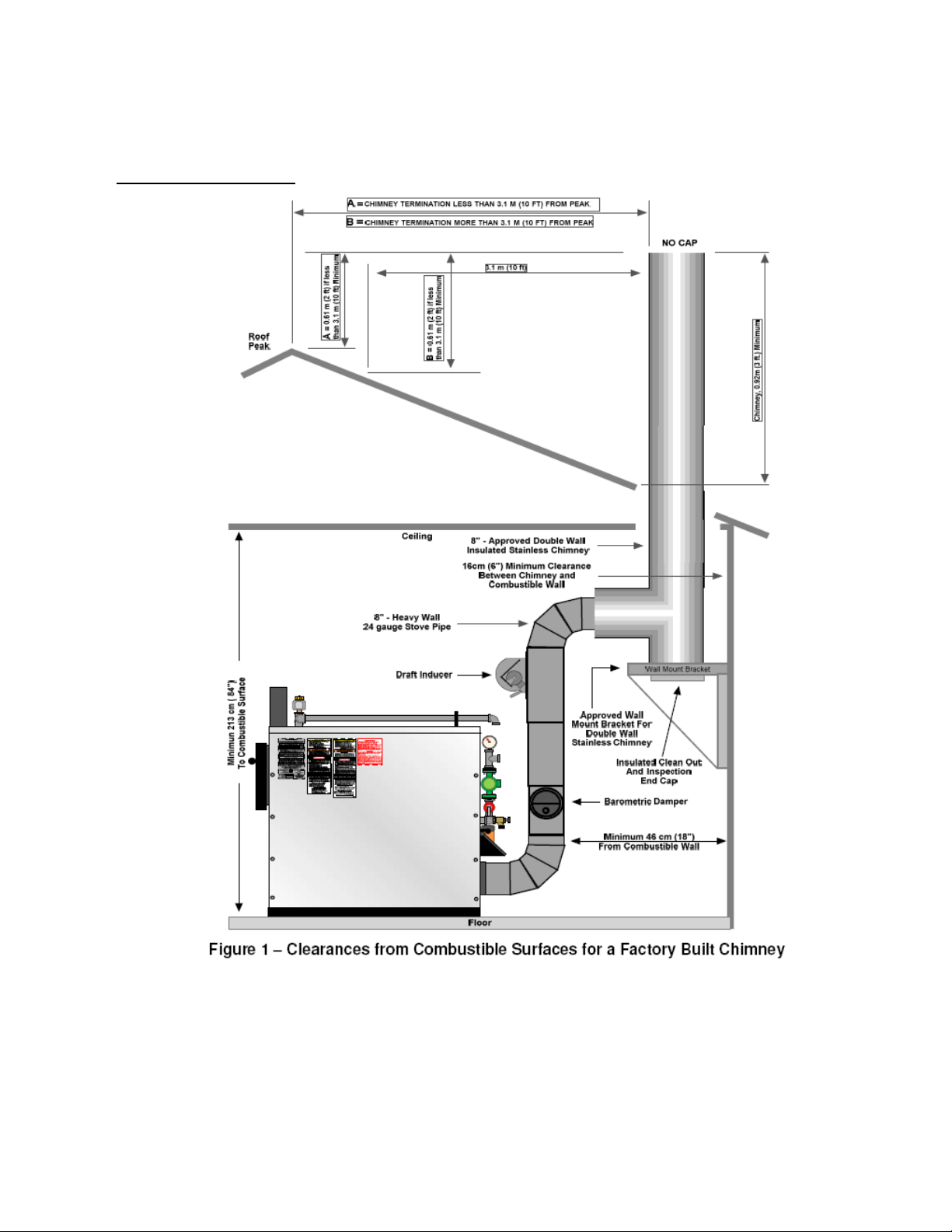

CHIMNEY - INSTALLATION

IMPORTANT: The following chimney instructions are for reference and guideline purposes only.

Chimney installation should be performed by a qualified chimney installer.

Be sure to read, understand and adhere to the installation clearances and restrictions stated in

this manual.

Masonry Chimneys: The use of an existing masonry chimney should only be considered if it has been

thoroughly inspected and approved for use with this furnace. The chimney must conform to State or National Building Codes. Consult local building code and fire code authorities for the proper requirements

in your area.

NOTE: WinterGreen does not recommend using a masonry chimney.

Factory Built Chimneys: New factory built chimneys must conform to type HT (High Temperature) re-

quirements of UL-103 for factory built chimneys and comply with the requirements of Chapter 11 of

NFPA 211 Standard for Chimneys, Fireplaces, Vents and Solid Fuel-Burning Appliances. Consult local

building code and fire code authorities for the proper requirements in your area.

Never connect to an aluminum Type B gas vent. As this is not approved

for the WinterGreen Furnace and is dangerous.

DO NOT USE A CHIMNEY CAP!

Do not connect furnace to a chimney flue serving any other appliance.

DO NOT SIDE VENT A SOLID WOOD BURNING FURNACE

Stove Pipe: The stove pipe and elbows used to connect from the WinterGreen Furnace to either a fac-

tory chimney or a masonry chimney must be black, heavy wall (24 gauge) thickness with a melting point

of not less than 2000˚F and conform to UL Standard S641 for flue pipes.

IMPORTANT: The flue connection between the furnace and chimney cannot have more than a

combined total of 180˚ in elbow connectors. (Example: 2 x 90˚ elbows or 1 x 90˚ and 2 x 45˚ el-

bows) The maximum straight length of flue pipe is 3 m (10 ft.) total and have an upwards slope

toward the chimney of 1/4” per foot to allow condensation to drain towards the furnace. All connections must have at least 1 3/16” overlap and a minimum of 3 fastening screws to prevent

separation. Provisions must be for visual inspection and cleaning either by cleanouts in the fluepipe or by removal of the flue pipe. Longitudinal seams of the pipe are to be located on the underside in horizontal runs.

Continued on next page… 19

CHIMNEY – INSTALLATION Continued:

Factory Built Chimneys:

Note: The top of the chimney must extend at least 0.9 m (3 ft) above the highest point where it exits the

roof and be at least 0.6 m (2 ft) higher than any other point of the roof within 3.1 m (10 ft).

For draft proper operation, the chimney should be at least 3.6 m (12 ft) to 4.6 (15 ft) in tall.

When installing the new chimney, observe all building code requirements. Be sure to carefully

follow all the manufacturers installation instructions supplied with your chimney.

Continued on next page…

Loading...

Loading...