Wintecronics TR68B User Manual

Model No . : L-TR68B

Install this behind the dashboard at the suitable position, near the ignition cylinder (within 60 cm

s moving parts]. Drill a hole of 1/8 in drill at the selected place and secure the siren using

During the security standby mode, this performs as a visual indicator against attempted theft and

s programming can be done using override switch as in the manual entry into valet mode,

1. The L-TR68B is a 2-way security system featured with remote engine start and can be

installed to work with any vehicle with its normal voltage of 12 volt.

2. The L-TR68B’s circuit is designed to suit both the manual gear and the auto-transmission

gear car for remote engine starting.

3. The L-TR68B has 2 different engine start time circuit for remote starting of both gasoline

engine and diesel engine.

Installation of the major components

Choice of place for main control module

from it) but far from the heat source and water tank.

l Siren

Choose its location in the engine compartment [far from the heat source and water tank, and free

from the

engine’

the mounting bracket, facing the siren downward or in the horizontal position.

l Hood switch

While in arm mode or remote engine running, this helps the main control module detect the

hood’s status .It must be installed on the grounded metal surface. Drill a hole of 1/4 inch at the

selected place and secure the hood switch and adjust it. [The switch must have negative output

when the hood is opened, and becomes neutral when the hood is closed.]

Dash LED Status indicator

also is the current status indicator of the system. During programming of system features, the

LED’s flashing pattern provides feedback as a confirmation for different active modes being

achieved. Mount the LED at a suitable area to ensure better visibility either from inside or

outside of the vehicle.

Override switch

System’

manual arm/disarm. It may not require concealment because the main system itself has other

multi-security features. Then connect it with the system’s modules for valet switch.

1

RF transmitter module/ call button

While in arm mode, this helps the main system detects impacts upon the vehicle. It must be fixed

the adjustment

This is integral part of the main system for transmitting / receiving and paging by push button.

Select its mounting place to insure the best transmission range. It is suggested to fix it on the left

or right upper area of the interior side of the windshield, using the double stick tape included. Be

sure not to block driver ’s view.

Anti –carjack switch

While ignition “ON”, entry and exit of anti-carjack mode can be done by this switch. Select the

mounting place within reach of the driver but must be a concealed place Drill a 5/32 inch hole

for mounting it. Connect one end of its wire to the system’s negative and the other to the anticarjack wire from the main system.

[This wire gets negative input to make the main system to enter anti-carjack mode]

Shock sensor

onto the chassis or stable metal surface.[ keeping far from heat source , water tank and vehicle’s

transmitter module ] .Adjust it for the optimal sensitivit y. While in arm mod twist

pole to the (+) direction to make it more sensitive and to the (-) direction for lesser sensitivity.

[Strike with your palms or shake the vehicle’s body and observe if the LED turns on in green

color during light impact and it turns on in red color during heavy impact.]

※

Wire installation guide

This is the 2-way security system with remote engine start features. While the system is action,

L-TR68B’s circuit interaction during remote controlling is the same situation with an ignition

key. As the starter circuit differs depending on the car manufacturers, the main system’s circuit

must be verified before wiring.

THE 6 PIN MAIN POWER HARNESS WIRE:

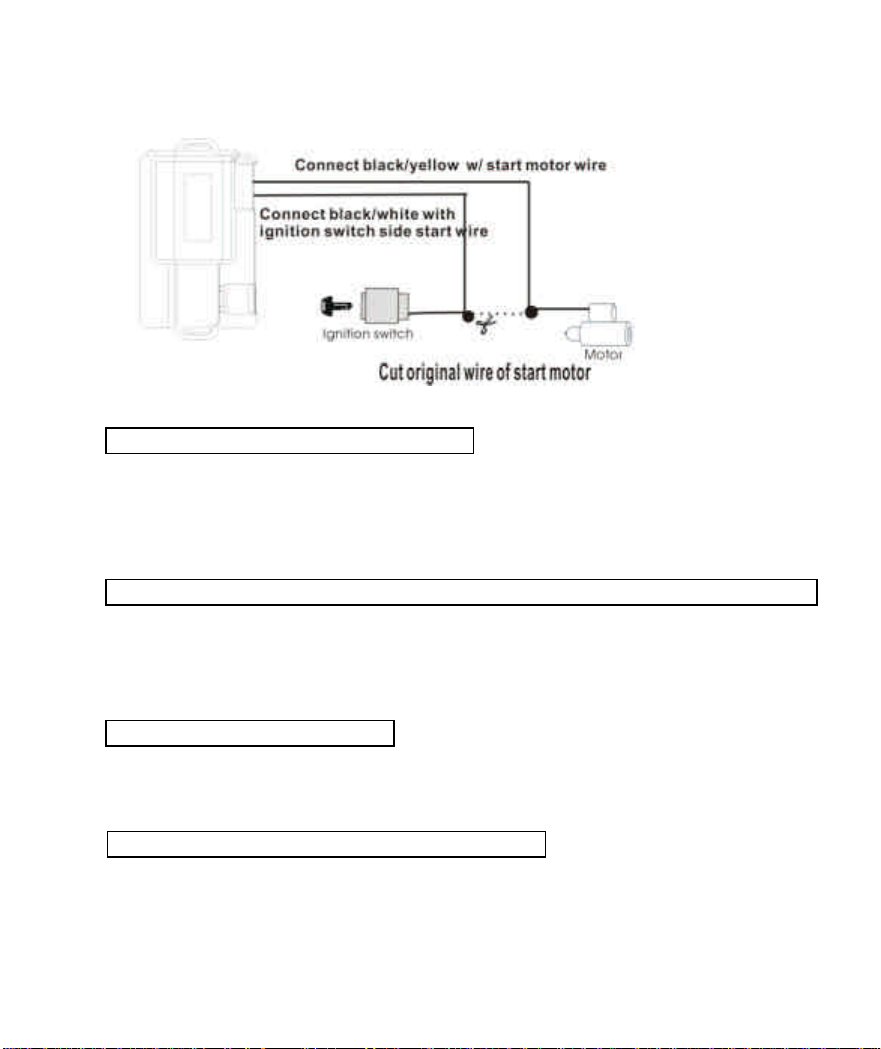

1. Black/yellow trace wire: Connect this to the wire from the start motor wire

Firstly locate the ignition switch wire which shows +12V when the ignition switch is turned to

“Start position ” . Cut this wire as in below illustration. Then connect the black/yellow trace wire

2

with wire from the start motor. The installing details are as below:

current ,regardless of position of the ignition key . This supplies power source

position.

※ This kind of connection will enable the start kill during alarm trigger.

2. Blue wire: output connecting wire for ACC

This provides the current needed by ACC. Locate the wire of the ignition switch area that shows

(+) 12 v when the ignition key is turned to “ACC” and “ ignition” position . Connect this wire

with the blue wire. But this wire must be “0” volts when the ignition key is turned to “ start”

position.

3. Black/white wire: Connect this wire from the ignition key switch start motor wire

Firstly locate the ignition switch wire which shows +12V when the ignition switch is turned to

“Start position ” . Cut this wire and connect the black/white trace wire with the

wire from wire of the ignition switch. Refer to the above illustration.

4. R ed wire: + 12 v power source # 1

Locate the 12v wire of the ignition switch and connect it with this. This supplies (+) 12V power

with over 40 amps

for ACC, ignition # 1 , ignition # 2 , start wires and their relays.

5. Yellow wire: output connecting wire for ignition # 1

This provides the current required for the running of engine. Locate the wire of the ignition

switch area that shows (+) 12 v when the ignition key is turned to “ignition” and “start”

Connect this wire with the yellow wire.

3

6. Green wire: output connecting wire for ignition # 2

volts while the engine is starting or cranking. But in

wire provides (-) 300mA current to turn the dome light on through the external relay. Installation

Locate the wire of the ignition switch area that shows (+) 12 v when the ignition key is turned to

“ ignition” and “start” . Connect this wire with the green wire.

Note:In some vehicles, this wire shows “0”

some vehicles, this provides +12 v current. Program this as required. [ Refer to RF

Features Program Table 1, line 7th ] 。

l THE 18 PIN INPUT/OUTPUT HARNESS WIRE

1. R ed wire: system power 12 V (+) 15 A input

This wire supplies power to the system main module locate the 12v wire of the ignition switch

and connect it with this. This supplies (+) 12V power with over 15 amps current connect this

wire to the positive .

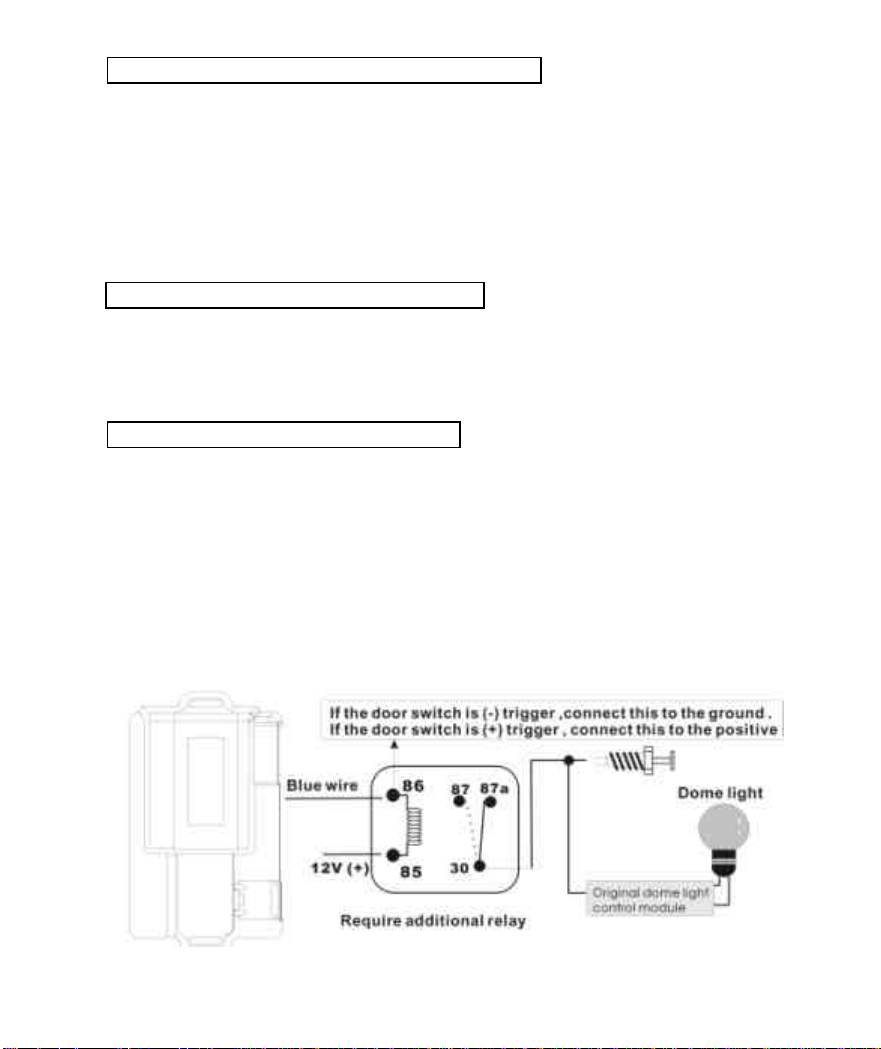

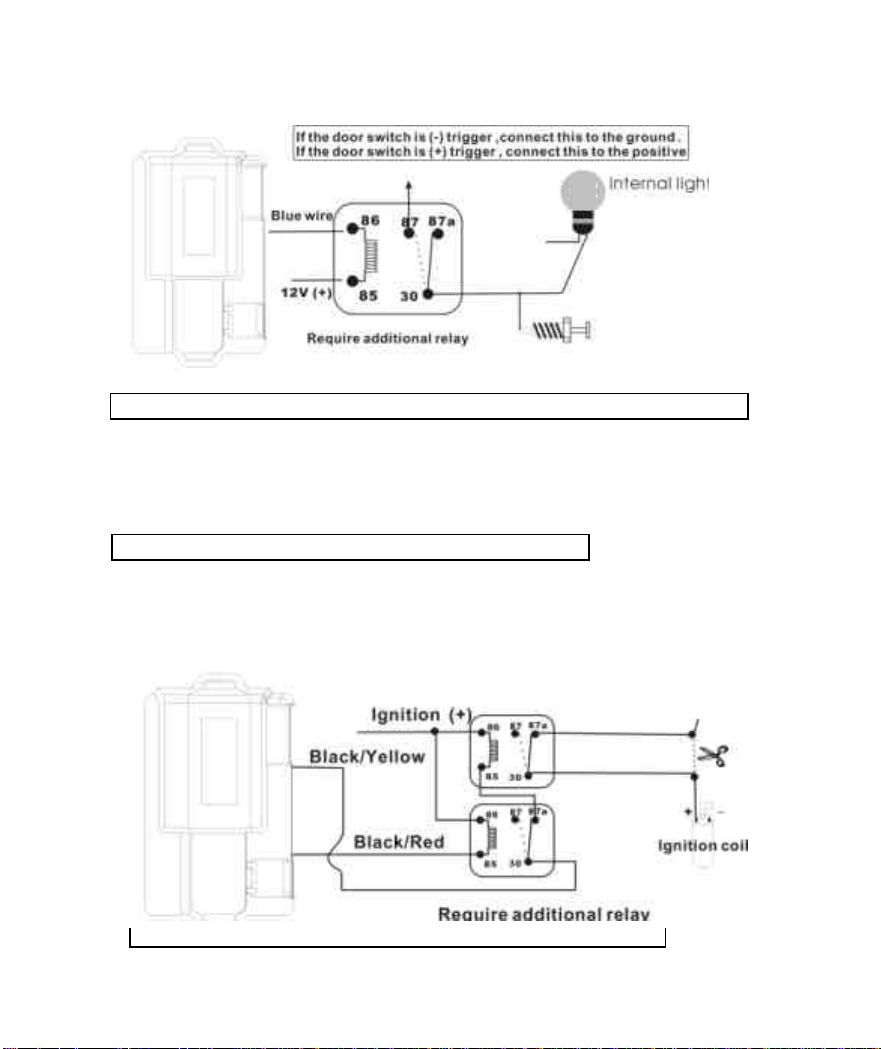

2 Blue wire: dome light (-) output at 300ma

Dome light trigger: While the main system from arm to disarm or “alarm run away” modes, this

differs depending on the types of vehicles.

A TYPE: This installation of this wire is not needed for vehicle with a dome light controlled by

door lock/unlock action.

B TYPE: An additional relay is required for vehicle with original dome light whose device is

controlled by driver door switch trigger. The installing details are as below. [Refer to

feature program table, item 14 with setting at 0.8 sec]

4

C TYPE: For the vehicle with no dome light, an additional relay is required. The installing

details are as below .[Refer to RF Feature Program Table, line 14th for setting at 6sec]

3 Black w/ Red trace wire: ignition # 3 or bypass V.A.T.S. (-)output at 300ma

While the system is in remote engine start mode; this feeds (-) 300ma current. Some vehicles

need this circuit for the engine running .If there is no such device, an additional relay is required

for the control of light.

4 Black w/ Yellow trace wire: start killer (-) output 300ma

When the main system is armed and remote start engine running time this feeds (-)pulse of

300ma which. If this circuit will be used to kill ignition or disrupt the gas pump, a 3 pin

black/red and 2 external relays are required .Refer to the following installation guide.

5 Y ellow w/ Red trace wire: Active channel # 2 ,output (-) 300ma

5

When the remote transmitter activates this channel, this feed (-) 300ma output which, needs an

In the case that the main system diagnoses the engine running by means of RPM signal, refer

crank time of 3000ms ( = 3 sec ). This indicates that the RPM wire happens to be connected

additional relay, to control the device as required.

Note: Refer to RF Features Program Table , line 4th for programming.

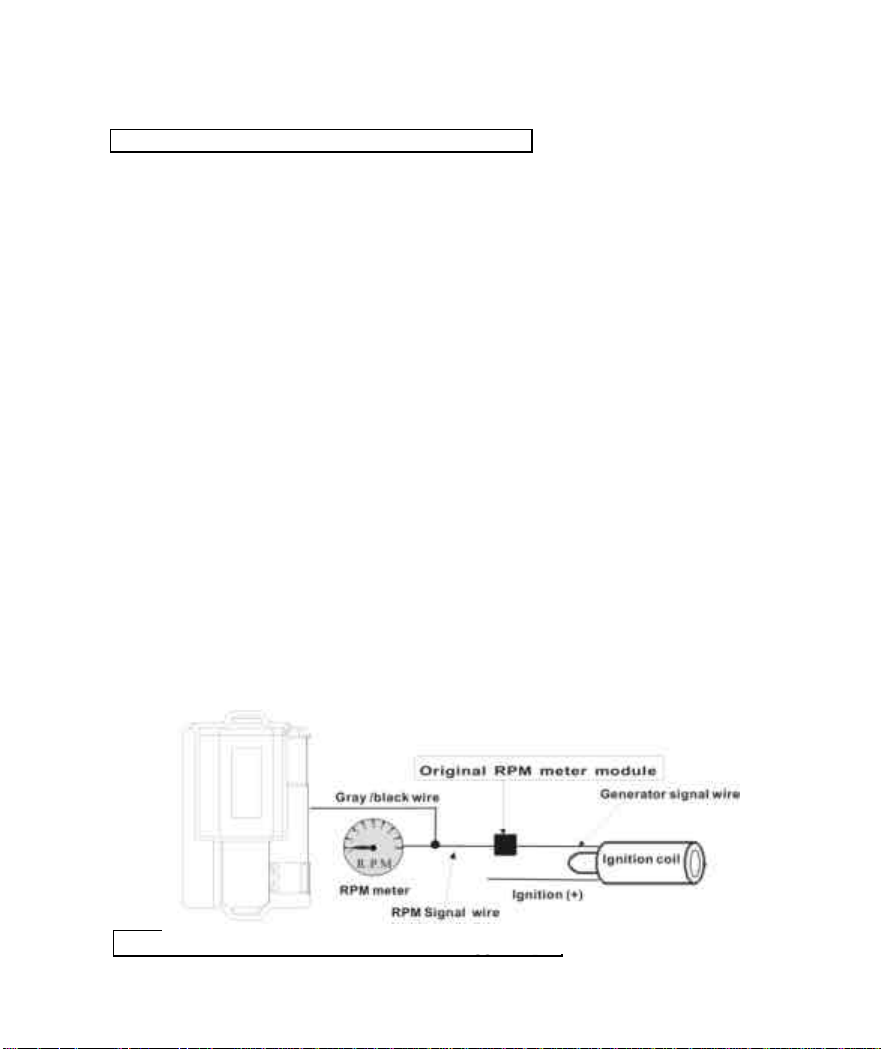

6 Grey w/ Black trace wire: tachmeter input singal

This wire diagnoses the success of engine start done by the remote control unit. Locate the

signal wire of the tachometer .[ Use the multi-meter adjusting for the measurement DC voltage.

Locate the tach wire which shows 0, 5, 12 V while the ignition key is turned “ ON” , and shows

2~12v when the engine is running. connect this wire with Grey w/ Black trace wire In case the

tach wire is hardly located, it is suggested to have the Grey w/ Black trace wire connect

grounded. In this case, the diagnosis for the engine running is detected by means of the noise in

voltage】.

※

to the 3th line of the RF program table for setting at the maximum 3000 ms.

※ For the installer to verify the main system diagnosing success of engine run by RPM signal,

it is recommended to observe the LED status indicator to be sure of proper RPM wire

connection. The LED status will indicate differently depending on the wire connection

modes.

※【

LED might have 3 indication modes within 5 sec at the end of cranking

(1) The LED stays on : Engine cranking stops immediately after engine run success,

neglecting the remaining rank time. This confirms the proper RPM wire connection.

(2) The LED stays on :After engine success engine ranking goes on through the maximum

to the generator.

(3) The LED does not light on:After engine success engine cranking goes on through the

maximum crank time of 3000ms ( = 3 sec). This indicates that the RPM wire is improperly

connected. In such case, the main system diagnoses engine run by means of noises in

voltage.

】

7 Blue w/ Red trace wire: door switch (+) trigger input

6

Loading...

Loading...