Winston Industries CAC507 Use & Care Manual

Cook & Hold

All Models

Use & Care Manual

In this manual

Description 2

Safety 3

Installation 4-6

Nomenclature 7-8

Operating Instructions 9-13

Guidelines 14

Daily Cleaning 15-16

Troubleshooting 17-19

Circuit Diagram 20

ZAP Warranty 21

Terms & Conditions 22

MANUAL REORDER: LIT 4275V275 REV. 20 1-31-06

CAC507

(Shown with optional window)

WARNING

DAILY CLEANING

REQUIRED OR

W ARRANTY WILL

BE V OIDED.

SEE USE AND CARE

MANUAL FOR INSTRUCTIONS

Congratulations on your purchase of the Winston CVap®cook & hold, from the

manufacturer that developed the Science of Food Thermoisturization. CVap

(Controlled Vapor) technology, arising from that science, is the fundamental principle

on which the CVap cook & hold is based!

The benefits you will experience are precision doneness temperatures, greater

yields, safer foods, reduced human disciplines to manage high food quality - to

name a few. Five years in development; this appliance combines the science of

thermalizing and moisturizing of foods with a microprocessor control that has

embedded in it the knowledge of the skilled chef, and the requirements of FDA

regulations relative to food safety.

The operating section is all that you need to understand in order to prepare foods to

the precise doneness temperature and degree of browning you desire. After only

three inputs, the microprocessor takes charge of the dual heat system – to process

the High Yield cook cycle, the FDA Hold cycle, then the Serve and Sell cycle.

We want you to be as proud of your purchase as we are of the design of the CVap

cook & hold. If you have any question, comments or criticisms, please call our

Customer Service Center at 1-800-234-5286. If you would like to communicate with

me by Email, my address is Winston@Winstonind.com.

Thank you for your business.

Dr.Winston L. Shelton (Hon.)

Chairman of the Board

2 CVap®Cook & Hold

WARNING: Daily cleaning required or warranty will be voided.See Daily Cleaning instructions in this manual

DESCRIPTION

Copyright© 2005 Winston Industries LLC. All rights reserved. CVap is a registered trademark of Winston Industries LLC. The CVap logo is a trademark of Winston

Industries LLC. All other company and product names may be trademarks of their respective companies.

Read and understand this entire use and care manual before operating your

CVap®cook & hold.

WARNING:

Operating this appliance can be dangerous.

Read, understand, and obey the following warnings. If you do not you could be

burned, badly hurt, or killed!

• Have appliance installed and serviced ONLY by a licensed electrician or trained

servicer. Installation and service of appliance involves electrical and high

temperature hazards which can cause death, personal injury or property

damage.

• If an electrical shock is felt when touching appliance, disconnect power cord

immediately and call a trained servicer for repair. If you don't, you could

be electrocuted!

• Always turn power switch off any time appliance is not in use. If you don't,

electric shock can cause death, personal injury or property damage.

• Always perform daily cleaning procedures for this appliance. Build up of food

residues high in acid or chlorides can cause permanent damage to the stain-

less steel and can contaminate foods!

• Always allow appliance to cool before cleaning. If you don't, you could be

badly burned!

CAUTION: Clean evaporator daily to prevent chlorides (salts) from accumulating,

causing the evaporator tank to corrode to the extent that leaks will occur. Experience

has shown that leaks will occur only through failure to clean and rinse the evaporator

daily. LEAKING EVAPORATORS ARE NOT COVERED UNDER WARRANTY.

3

CVap®Cook & Hold

WARNING: Daily cleaning required or warranty will be voided.See Daily Cleaning instructions in this manual

SAFETY

INSTALLATION

4 CVap®Cook & Hold

WARNING: Daily cleaning required or warranty will be voided.See Daily Cleaning instructions in this manual

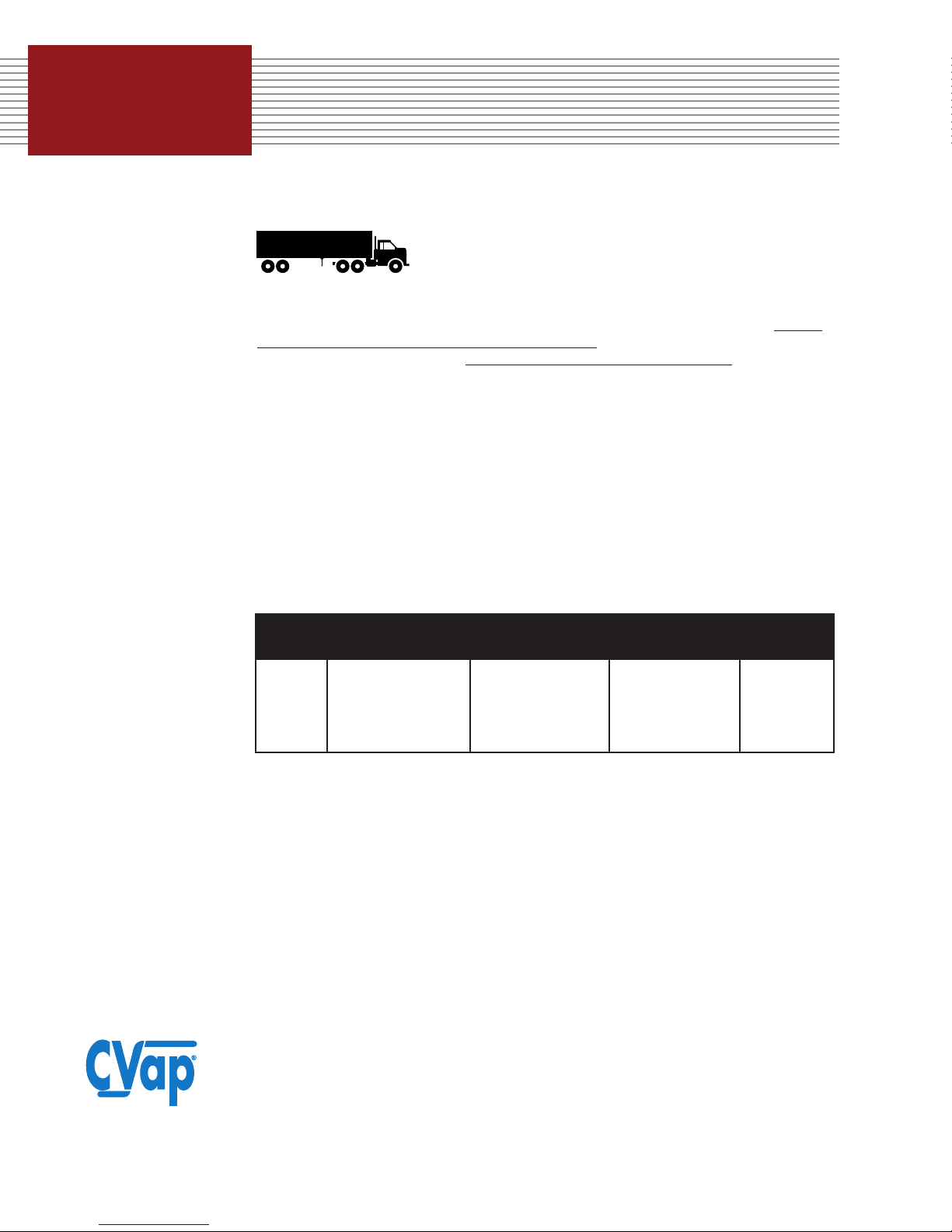

SHIPPING DAMAGE

All equipment should be thoroughly examined for shipping damage before, during

and after unloading. It has been carefully inspected at our factory and the carrier

has assumed responsibility for its safe arrival. If the equipment is damaged,

either apparent or concealed, a claim must be made to the carrier.

APPARENT LOSS OR DAMAGE

If there is any obvious loss or damage, it must be noted on the freight bill or express

receipt and signed by the carrier’s agent;otherwise, the carrier may refuse the

claim. The carrier will supply the necessary forms.

CONCEALED LOSS OR DAMAGE

When loss or damage is not apparent until after the equipment is uncrated, a claim

for concealed damage must be made. Upon discovering damage, make a request

in writing to the carrier for inspection within 15 days, and retain all packing. The

carrier will supply an inspection report and the required claim forms.

PHYSICAL

Casters are non-marking; back casters are non-locking, front are locking.

WATER SUPPLY

The evaporator of this appliance must be filled each day and during use from a

potable water supply. In that regard, an automatic fill system is provided that is to

be connected to a potable water supply. Hardware is included with each unit to

allow connection to a copper line.

NOTE: When installing the automatic water fill plumbing, make sure to remove the

plastic plug from the water inlet connector before hooking up the water line.

If plastic or galvanized piping is encountered, a licensed plumber should be called

to make the installation. This equipment is to be installed to comply with the

applicable federal, state, or local plumbing codes.

As water evaporates from the dual heat surface of the evaporator, any minerals in

the water will deposit on those surfaces. Consequently, the mineral deposits on the

surfaces inhibit the ability to transfer heat through the deposits, and the stainless

steel on which they are deposited can be degraded and destroyed. The first

protection against this is the daily cleaning procedure. It is also recommended that

your supplier of potable water be contacted for advice to minimize mineral deposit

build-up.

Model Height with 3” Width Depth Weight

Caster (IN/MM) (IN/MM) (IN/MM) (LBS/KG)

CAC503 36.1/917 19.9/505 27.1/688 145/66

CAC507 36.2/919 27.6/701 34.5/876 215/98

CAC509 43.2/1097 27.6/701 34.5/876 235/107

INSTALLATION

5

CVap®Cook & Hold

WARNING: Daily cleaning required or warranty will be voided.See Daily Cleaning instructions in this manual

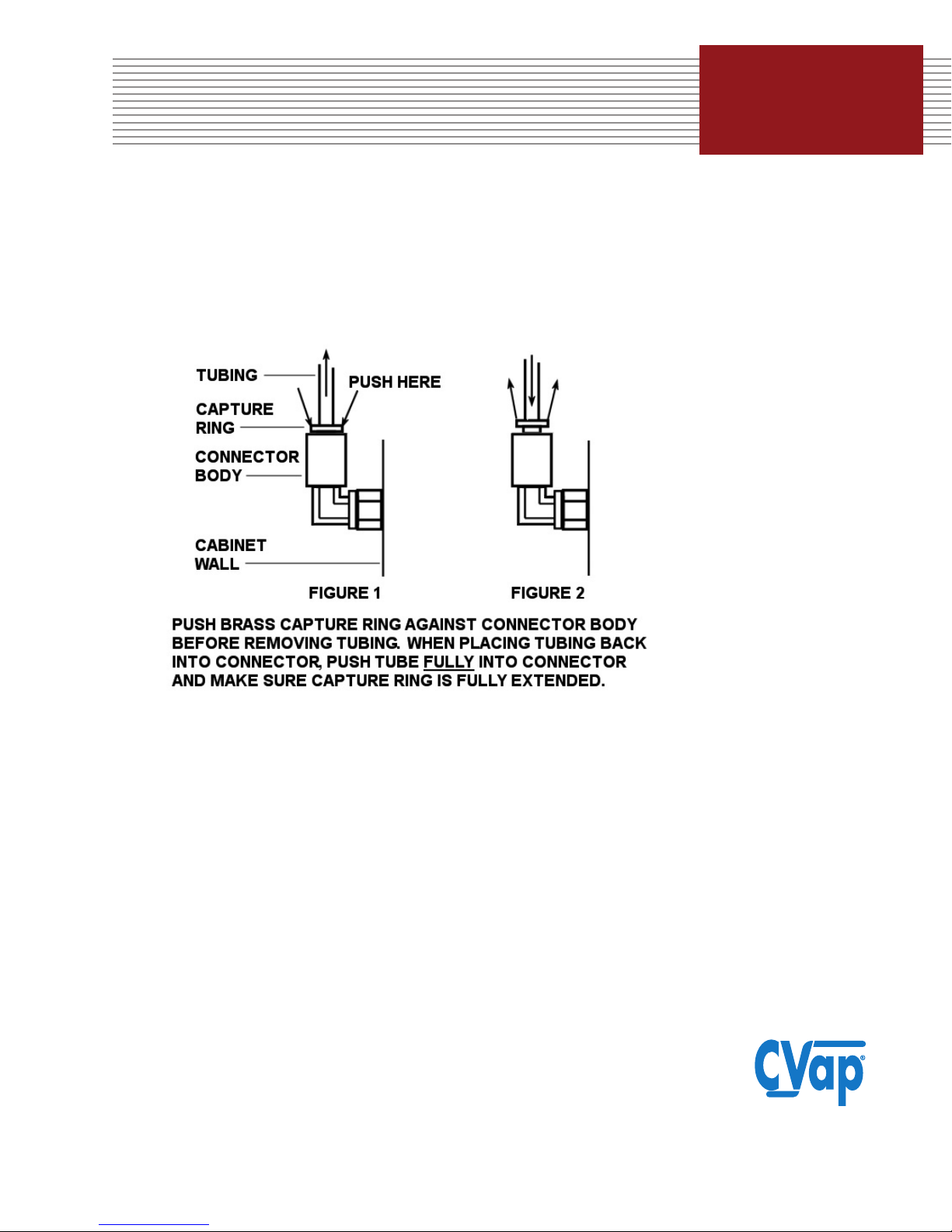

To remove the plastic tubing from the water line connector, using your fingers,

carefully press the small brass capture ring in toward the body of the connector.

Then gently pull the tubing out of the connector. To insert tubing back into

connector, push the tubing fully into the connector. Once seated, try to pull the

tubing out of the connector so that the capture ring comes out (about 1/16”) and the

tubing cannot be removed. See drawing below.

If an Auto Water Fill System is supplied with (or added to) this appliance, then it

must be hooked up to a potable water supply line. Winston RECOMMENDS that the

tap valve included with the kit be attached to a cold water, copper, brass or steel

line (the valve can handle any size line from 3/8" to 1").The maximum incoming

water temperature may not exceed 140°F (60°C) and the incoming water

pressure must be between 20 and 150 psi. CAUTION: Appliances with auto

water fill systems MUST NOT BE ALLOWED TO RUN DRY. Heat damage to the

water valve may result.

Regardless of whether the evaporator is filled with water manually or

automatically, as water evaporates from the dual heat surface of the evaporator,

any minerals in the water will deposit on those surfaces. Consequently, the mineral

deposits on the surfaces inhibit the ability to transfer heat through the deposits, and

the stainless steel on which they are deposited can be degraded and destroyed.The

first protection against this is the daily cleaning procedure. It is also recommended

that your supplier of potable water be contacted for advice to minimize mineral

deposit build-up.Experience has shown that leaks will occur only through failure to

clean and rinse the evaporator daily. LEAKING EVAPORATORS ARE NOT COVERED

UNDER WARRANTY. This appliance is to be installed to comply with the

applicable federal, state, or local plumbing codes.

INSTALLATION

6 CVap®Cook & Hold

WARNING: Daily cleaning required or warranty will be voided.See Daily Cleaning instructions in this manual

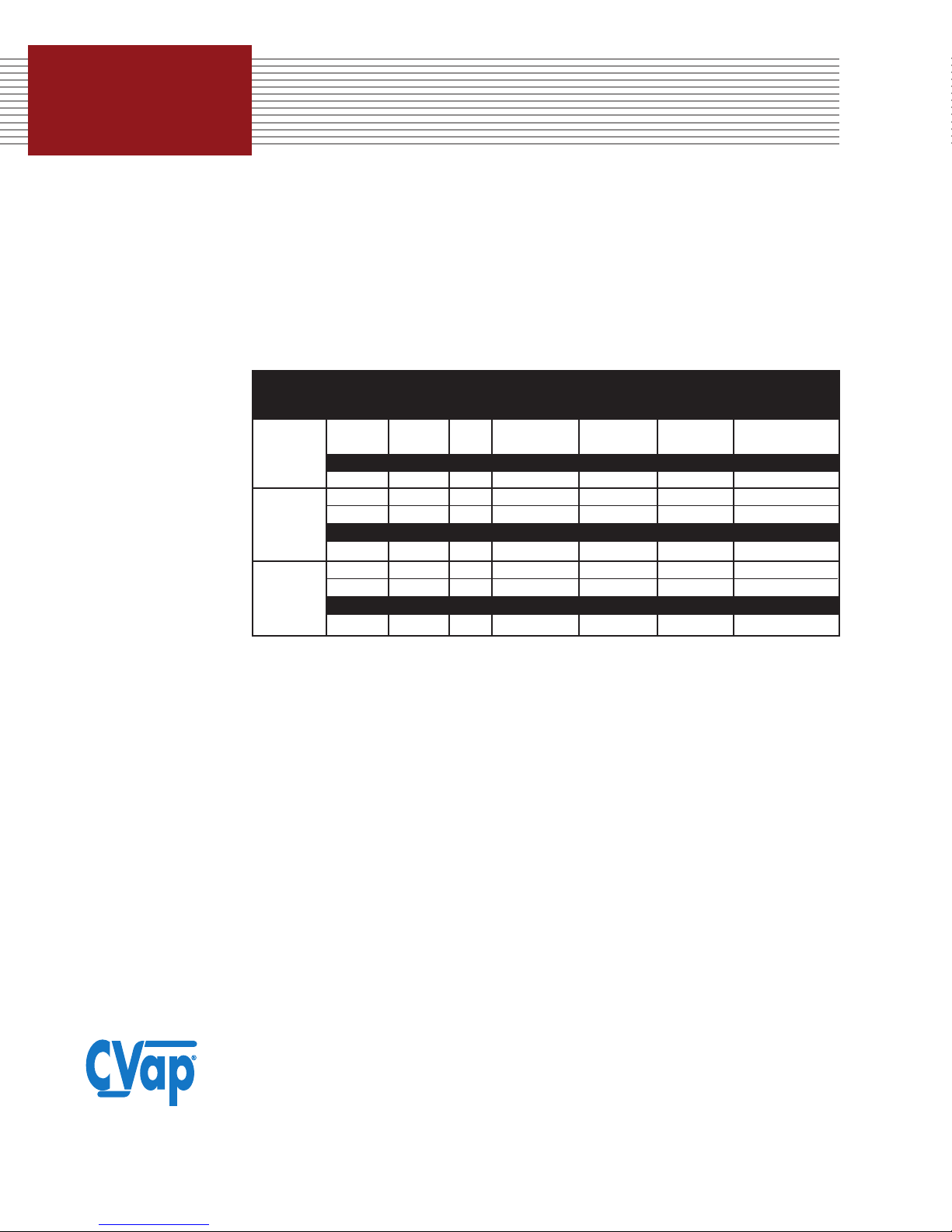

ELECTRIC

The appliance is shipped from the factory with an 8-foot-long power cord and plug.

Provide an electrical outlet by a licensed electrician to match plugs identified in the

following table. For the convenience of servicer and operators, do not wire direct.

Following is a copy of the electrical information on the name plate for various

models of Winston’s CVap®cook & hold.

VENTING AND VENTILATION REQUIREMENTS

Ventilation clearances - Allow space around appliance for good air circulation.

Installation of this appliance requires that a minimum 2” clearance from any

obstruction or combustible material be maintained at all locations where there are

ventilation holes in the appliance. The appliance must be installed with its supplied

legs, feet, or casters. Countertop appliances specifically supplied without legs or

casters may be set directly upon a countertop of non-combustible material. In this

situation, the appliance may have to be sealed to the countertop with a food-grade

silicone sealant (check local health codes). Half size appliances may be stacked

upon each other using only a Winston supplied stacking kit and following the

instructions enclosed with the kit. Your warranty may be void if you do not adhere to

the instructions above.

Vent hood - Generally this appliance does not need to be installed under a

mechanical ventilation system (vent hood). Check local health and fire codes for

requirements specific to your location.

Model Volts Hertz PH Amps Watts Circuit Plug

Amps Type

US 15 US 5-15P

CAC503 208 60 1 12.3 2400 CAN 20 CAN 5-15P

230 50 1 11.3 2400 20 N/A

CAC507 208 60 1 19.0 3942 30 US/CAN 6-30P

240 60 1 16.0 2842 20 US/CAN 6-20P

230 50 1 16.4 3762 20 N/A

CAC509 208 60 1 19.0 3942 30 US/CAN 6-30P

240 60 1 16.0 3842 20 US/CAN 6-20P

230 50 1 16.4 3762 20 6-20P

International

International

International

NOMENCLATURE

7

CVap®Cook & Hold

WARNING: Daily cleaning required or warranty will be voided.See Daily Cleaning instructions in this manual

1. Microprocessor Controller inter prets inputs as to Doneness, Browning, Time,

and High Yield Cook; then selects the optimum values of the dual heat system

to sequentialize Cook, Hold, and Sell processes.

2. Power Switch allows operator to turn electrical power on and off.

3. Food Chamber isolates CVap®dual heat food environment.

4. Adjustable Rack Support supports racks onto which food is placed

5. Rack Support Bracket receives rack support.

6. Air Heaters (not visible in photo) supply air heat for food texture control.

7. Evaporator supplies vapor to atmosphere to control food temperature.

8. Drain T rough carr ies water back to evaporator that has condensed onto door.

9. Evaporator Heater (not shown) supplies heat to the evaporator.

10. Drain Valve for draining evaporator during daily cleaning procedure.

11. Bottom Cover (not shown) provides service access.

12. Top Cover provides service access

1

2

3

4

7

8

16

17

18

15

Component ID

17

18

19

6

5

12

13

14

10

9

11

Loading...

Loading...