Winston Industries CA8522, CA8509 Owner's Manual

CA85 Series

CA8509

CA8522

COOK & HOLD CABINET

Owner’s Manual

DOC080408B Rev8 wp 10-18-17

COOK & HOLD CABINET

WELCOME

Thank you for your purchase of a Winston CVap CA85 series Cook & Hold cabinet. The benefits

you will enjoy from this cabinet include precise doneness temperatures, greater yields, safer

foods, reduced labor, and superior food quality.

This cabinet utilizes Controlled Vapor Technology (CVap). Using a combination of dry and

moist heat, CVap cabinets are capable of producing foods at the precise temperature and

moist or crisp texture desired.

If you have any questions, or if anything cooked in your CVap Cook & Hold doesn’t meet your

satisfaction, please call our Customer Service Center at 1.800.234.5286, or email us at

customerservice@winstonind.com.

TABLE OF CONTENTS

Welcome 2

Safety 3

Receiving Your Equipment 4

Ventilation Requirements 5

Water Supply 5

Auto Water Fill 6

Electrical Information 7

Component Identication 8

NEED TO CONTACT US? CHOOSE THE MOST CONVENIENT METHOD.

Internet: www.winstonfoodservice.com

Email: customerservice@winstonind.com

Phone: 1.800.234.5286 | 1.502.495.5400 | 1.502.495.5458

Mail: 2345 Carton Drive | Louisville, KY 40299 USA

Controls 9

Daily Operating Instructions 10-13

Cooking Reference Chart 14-16

Roasting Guidelines 17

Daily Cleaning 18-19

Troubleshooting 20-21

Warranty and Terms & Conditions 22

MISSION

Transforming the world’s

kitchens through innovation.

VALUES

We operate with the

highest integrity.

We are passionate,

focused, and driven.

We celebrate one

another’s achievements.

We respect one another

and work as a team.

We invest in the

betterment of the global

community.

We innovate through

continuous improvement

and discovery.

FOUNDER’S PHILOSOPHY

“We are a family

business. We believe

in the entrepreneurial

spirit, strong drive, and

initiatives of individuals.

The company was founded

on the idea of an individual

and ourished through

the energy and sacrice

of family members and

countless other individuals.

Our commitment to

those individuals is

indistinguishable from that

of our own family members.

Together, we shall share the

work, sacrices, challenges,

and triumphs of the

business.”

– Winston Shelton

Copyright© 2017 Winston Industries, LLC. All rights reserved. CVap is a registered trademark of Winston Industries, LLC. The CVap logo is a trademark of Winston Industries, LLC. All other company and

product names may be trademarks of their respective companies.

2

www.winstonfoodservice.com | 1.800.234.5286

Models CA8509, CA8522

COOK & HOLD CABINET

Please read this entire owner's manual before operating

your CVap Cook & Hold cabinet. The manual contains

important safety information and operating instructions.

As is the case with all cooking appliances, your CVap

Cook and Hold should be used with caution. Please

read the following warnings to avoid potential

injuries.

!

DANGER: Electrical Hazard – Can cause

serious injury or death. Do not attempt to install or

service this equipment unless you are a licensed

electrician or trained servicer.

1. Because this equipment utilizes high voltage, it

should only be installed and serviced by a licensed

electrician or trained servicer. Attempting to install or

service the equipment yourself could result in

serious, potentially fatal injuries.

2. If an electrical shock is felt when touching

equipment, shut o power immediately (pull cord or

turn o circuit breaker) and call a trained servicer for

repair. Failure to do so could result in serious,

potentially fatal injuries.

6. Prior to using equipment for the rst time, perform

the daily cleaning procedure found on pages 18

and 19.

!

CAUTION: Burn Hazard – Can cause

injury. Allow 30 minutes for equipment to cool

before attempting to clean.

7. Always allow equipment to cool before cleaning.

!

CAUTION: High Temperature and Grease

Hazard – Can cause damage to equipment. Avoid

placing equipment near high heat or grease-laden

atmosphere.

Do not place equipment in an area where air

temperatures exceed 100˚F (38˚C). A heat shield

may be required to prevent heat exposure and

grease-laden vapors from aecting the unit if

adjacent to heat, vapor, or grease-generating

devices (such as grills, steamers, ovens, etc.). Excess

heat and grease inside the equipment cavities may

cause electrical components to fail.

3. Always turn power switch o any time equipment is

not in use.

!

CAUTION: Burn Hazard – Can cause

injury. Avoid heated vapor when opening or

closing unit door.

4. This equipment utilizes heated water vapor, which

transfers heat much more quickly and eciently

than dry air of the same temperature. Use caution

when opening doors or reaching into the

equipment, as heated vapor can quickly cause burns.

!

DANGER: Contamination Hazard – Can

cause serious illness or damage to equipment. Clean

unit daily to avoid potential contamination hazard.

5. Clean equipment daily to prevent buildup of food

residue or chlorides, which can damage stainless

steel and contaminate food. Failure to follow proper

cleaning procedures can void your warranty.

!

WARNING: Safety Hazard,

Intended Use

Can cause serious injury or damage to equipment >>

Supervise untrained, young, or handicapped persons.

1. This equipment is not intended for use by persons

(including children) with reduced physical, sensory,

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the equipment by a

person

responsible for their safety.

2. Children should be supervised to ensure that they do

not play with the equipment.

3. This equipment is intended to be used for commercial

applications, for example in kitchens of restaurants,

canteens, hospitals and in commercial enterprises such

as bakeries, butcheries, etc., but not for continuous mass

production of food.

Email customerservice@winstonind.com • Phone 1.800.234.5286 | 1.502.495.5400 | 1.502.495.5458 • Mail 2345 Carton Drive | Louisville, KY 40299 USA

Models CA8509, CA8522

3

COOK & HOLD CABINET

CUSTOMER FREIGHT RESPONSIBILITIES

Thank you for your recent order. For your convenience,

we have summarized your responsibilities for receiving

a shipment and suggest procedures to follow if there is

freight damage. Once an order has left the factory, all

inspection responsibilities for the shipment passes on to

you.

If Merchandise Is Delivered in Damaged

Condition, You Must:

1. Have the driver note the damage and sign all

copies of the freight bill.

2. Examine for concealed damaged as soon

as possible.

3. Notify carrier of the freight claim immediately

(You have a 24-hour window).

4. Retain damaged merchandise and all original

packaging until inspected by carrier.

Steps to Take at Time of Delivery to Protect

Against Loss or Damage

1. Verify Count - Make sure you receive as many

cartons as are listed on the delivery receipt. Note any

shortage on carrier’s delivery receipt and have the

driver note the shortage on your copy.

2. Carefully Examine Each Carton for Damage - If

damage is visible, note this fact on the delivery

receipt and have the driver clearly note the same

on your copy. If the carton appears to have internal

damage, insist that the package be opened. You

and the driver should make joint inspection of

the contents. Any concealed damage discovered

should be noted on the receipt and on your copy.

3. Immediately After Delivery, Open All Cartons and

Inspect for Concealed Damage.

2. Call Carrier to Report Damage and Request

Inspection - The call should be placed immediately

upon discovery of the damage. Claims will be denied

if not reported within 24/48 hours.

3. Conrm Call in Writing - For your own protection,

conrm your telephone claim in writing using

certied, return receipt requested mail.

Steps to Take When Carrier Makes Inspection

of Damaged Items

1. Have Damaged Items in Receiving Area - The

damaged items should have not been moved from

the receiving area. Allow the carrier inspector to

inspect cartons, inner packing materials, and freight

bill. Show your copy of the delivery receipt.

2. Carefully Read the Inspection Report Before Signing If you do not agree with the report, do not sign it.

Steps to Take When Visible or Concealed

Damage Is Discovered

1. Retain Damaged Items - The damaged items,

shipping cartons, and all inner packing materials

must be held in the receiving area until a carrier

representative inspects them or waives the

opportunity to inspect.

4

www.winstonfoodservice.com | 1.800.234.5286

Models CA8509, CA8522

COOK & HOLD CABINET

VENTILATION REQUIREMENTS

!

CAUTION: High Temperature and Grease

Hazard – Can cause damage to equipment. Avoid

placing equipment near high heat or grease-laden

atmosphere.

Do not place equipment in an area where air

temperatures around the equipment exceed 100°F

(38˚C). A heat shield may be required to prevent

excessive heat exposure and grease-laden vapors from

affecting the equipment if adjacent to heat, vapor, or

grease-generating devices (such as grills, steamers,

cabinets, etc.). Excess heat and grease inside the

equipment cavities may cause electrical components to

fail.

Ventilation clearances - To operate properly, the Cook &

Hold will need sufficient space for air circulation. Allow

at least 2" (51mm) clearance on all sides of the cabinet,

particularly around ventilation holes. Care should be

taken to prevent placing the cabinet close to anything

combustible. It must be installed with its supplied legs,

feet, or casters. Half-size units may be stacked upon

each other using only a Winston supplied stacking kit

and following the instructions enclosed with the kit.

Your warranty may be void if you do not adhere to these

ventilation requirements.

Vent hood - Generally this equipment does not need to

be installed under a mechanical ventilation system (vent

hood). Check local health and fire codes for specific

requirements.

WATER SUPPLY

In order to operate properly, the evaporator in this

cabinet must be filled with clean, potable water.

Hardware is included to connect the cabinet to a

copper line in your facility's water system. If your

facility has plastic or galvanized pipes, contact a

licensed plumber to connect the water supply.

Equipment should be installed to comply with

applicable federal, state, or local plumbing codes.

Units with automatic water fill systems are to be

installed with adequate backflow protection to

comply with federal, state, and local codes.

As water evaporates, minerals in the water will

deposit on the surface of the evaporator. These

mineral deposits will inhibit the transfer of heat.

Deposits can also degrade and damage stainless

steel. To avoid mineral deposits, clean the

equipment daily. It is advisable to contact your

water utility for advice on minimizing deposit

buildup.

Experience has shown that leaks occur by failing

to clean and rinse evaporator daily. Leaking

evaporators are not covered under warranty.

!

CAUTION: High Temperature

Hazard – Can cause damage to unit. Fill

evaporator with water prior to turning

power on, and do not allow evaporator to

run dry.

Email customerservice@winstonind.com • Phone 1.800.234.5286 | 1.502.495.5400 | 1.502.495.5458 • Mail 2345 Carton Drive | Louisville, KY 40299 USA

Models CA8509, CA8522

!

CAUTION: Corrosion Hazard – Can

cause damage to equipment. Clean

equipment daily to avoid corrosion damage.

5

COOK & HOLD CABINET

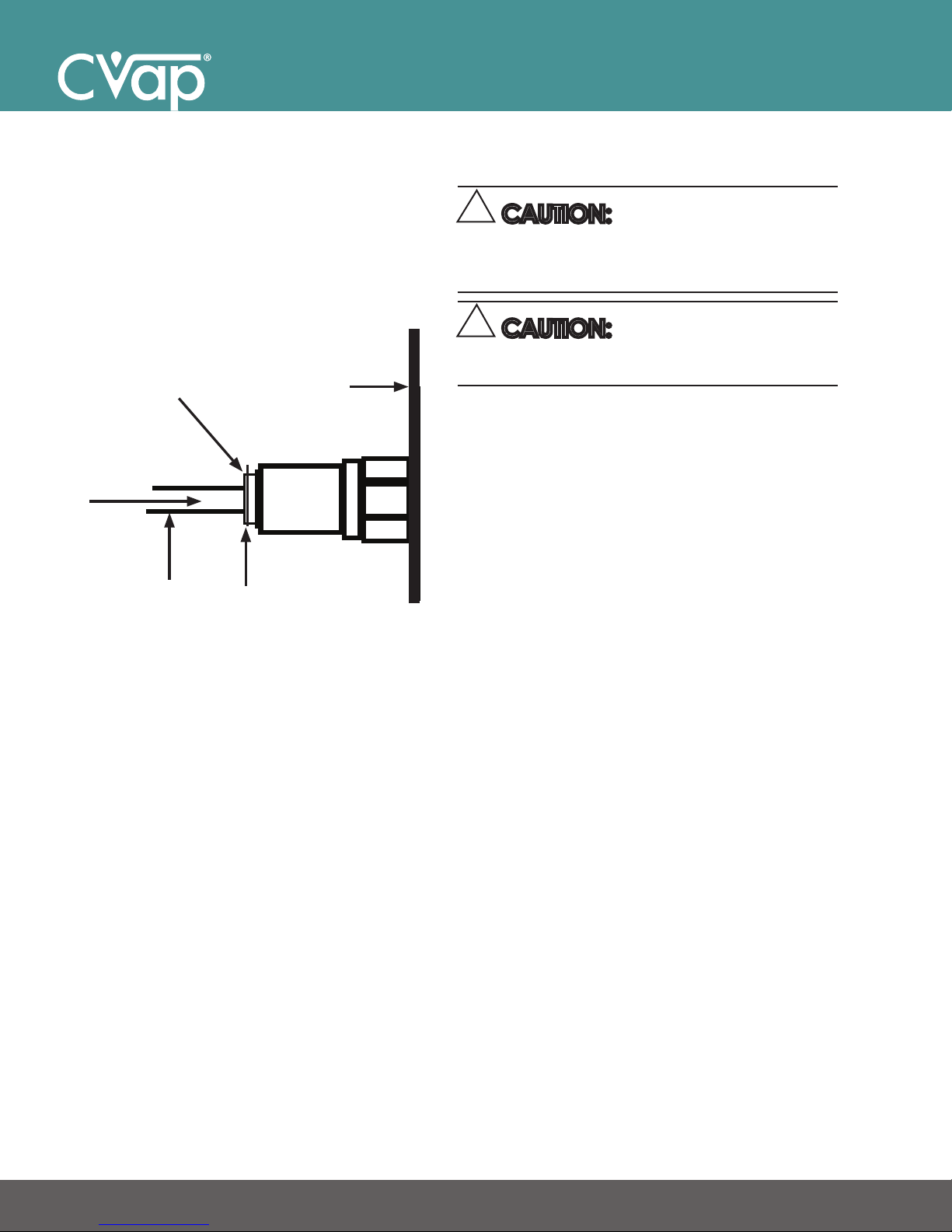

INSTALLING AUTO WATER FILL

Insert tubing and push fully into the connector.

(Reference drawing on this page.) Once seated, try

to pull the tubing out of the connector so that the

capture ring comes out (about 1/16” (1.6mm)) and

the tubing cannot be removed.

PUSH

HERE

TUBING

The maximum incoming water temperature may

not exceed 140˚F (60˚C) and the incoming water

pressure must be between 20 and 150 psi

(1.4 Kgf/cm2 to 10.5 Kgf/cm2 (kilogram-force

per sq. centimeter)).

APPLIANCE

WALL

CAPTURE RING

!

CAUTION: High Temperature Hazard –

Can cause damage to unit. Fill evaporator with

water prior to turning power on, and do not allow

evaporator to run dry.

!

CAUTION: Corrosion Hazard – Can

cause damage to equipment. Clean equipment

daily to avoid corrosion damage.

Regardless of whether the evaporator is lled with

water manually or automatically, as water evaporates

from the dual heat surface of the evaporator, any

minerals in the water will deposit on those surfaces.

The mineral deposits on the surfaces inhibit the ability

to transfer heat through the deposits, and the stainless

steel on which they are deposited can be degraded

and destroyed. The rst protection against this is the

daily cleaning procedure. It is also recommended that

your supplier of potable water be contacted for advice

to minimize mineral deposit build-up. Experience has

shown that leaks will occur only through failure to clean

and rinse the evaporator daily. LEAKING EVAPORATORS

ARE NOT COVERED UNDER WARRANTY. This unit is to be

installed to comply with the applicable federal, state,

or local plumbing codes.

6

www.winstonfoodservice.com | 1.800.234.5286

Models CA8509, CA8522

ELECTRICAL

The equipment is shipped from the factory with an 84"

(2134mm) (minimum) power cord and plug. Refer to the

table below to determine the correct electrical outlet. It

may be necessary to hire a licensed electrician to install

the correct outlet or wiring. Winston does not

recommend hard wiring the equipment direct.

COOK & HOLD CABINET

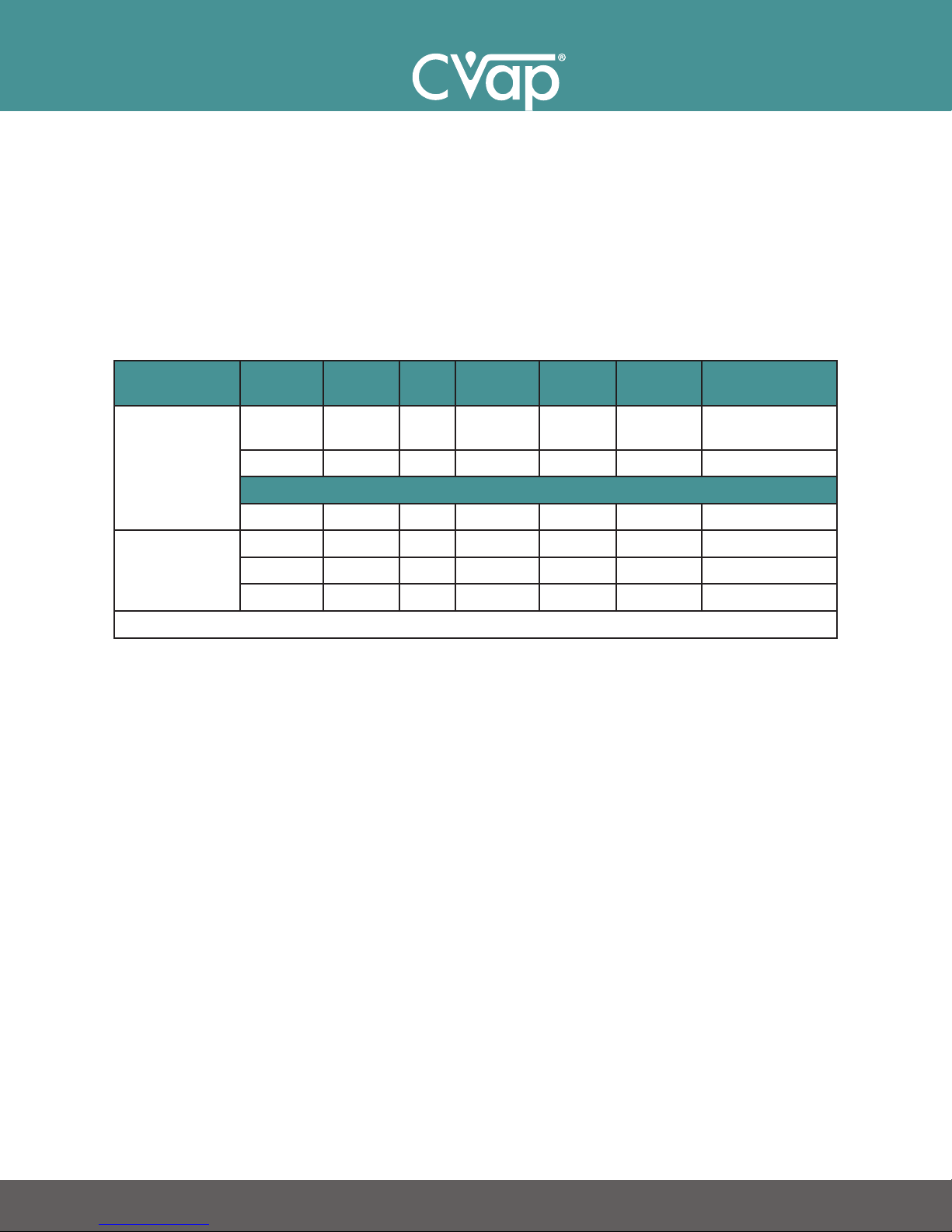

Model Volts Hertz PH Amps Watts Circuit

Plug Type

Amps

CA8509 208 60 1 27.9 5805 30 US/CAN 6-30P

240 60 1 24.2 5805 20 US/CAN 6-20P

International

230 50 1 25.3 5805 N/A N/A

CA8522 208 60 1 37.1 7716 50 US/CAN 6-50P

208 60 3 23.7 7716 30 US/CAN 15-30P

240 60 1 32.2 7716 50 US/CAN 6-50P

Not available for the international market at this time.

Email customerservice@winstonind.com • Phone 1.800.234.5286 | 1.502.495.5400 | 1.502.495.5458 • Mail 2345 Carton Drive | Louisville, KY 40299 USA

Models CA8509, CA8522

7

COOK & HOLD CABINET

COMPONENT IDENTIFICATION

9

10

1 2

3

4

10

11

1. Power Switch allows operator to turn electrical

power on and o.

2. Microprocessor Controller allows operator to select

one of eight multi-interval programmable cycles

and is removable for servicing or replacement.

3. Food Chamber cooking cavity where the dual heat

system combines to create the perfect cooking

environment.

4. Adjustable Rack Support supports racks onto

which food is placed.

13

5. Evaporator and Heater (not visible) supply vapor

atmosphere to the food chamber by heating water

within the evaporator.

12

5

6

7

8

Note: Equipment shown with optional rail supports.

Standard unit comes with wire rack supports.

Model shown is CA8522. Highlighted features are

common to all models.

12

15

6. Drain Trough carries water that has condensed onto

door back to evaporator.

7. Drain Valve enables operator to drain evaporator, to

perform daily cleaning.

14

8. Bottom Cover (not visible) provides service access.

9. Top Cover provides service access.

10. Side Panels support insulation and form outside of

cabinet.

11. Rack Support Bracket receives rack support.

12. Air Heaters (not visible) supply air heat for food

texture control.

13. Door & Latch can be reversed on site.

14. Door Gasket seals food chamber against heat or

vapor loss.

15. Name Plate identies model and serial number —

important for servicing and parts orders. Plate also

displays electrical data.

8

www.winstonfoodservice.com | 1.800.234.5286

Models CA8509, CA8522

Loading...

Loading...