WINSTON GROUP EAGLE V42-DD Operating Instructions Manual

OPERATING INSTRUCTIONS FOR THE

EAGLE V42-DD HOT-AIR WELDING TOOL

CONGRATULATIONS! You have purchased an Eagle, a tool that is designed and manufactured to assist

you with a quality seam weld. NOTE: The Winston Group does not warrant seam performance. We supply

a tool which provides heat, speed, and pressure. You, as the operator, select the correct combination of

these three components and, like all tools, the most important factor to a quality seam is your skill and

experience in setting up and using the Eagle.

WARRANTY CARD. A postage-paid warranty card is included in the shipping box. Please fill it out so that

we can provide you any new product information or "tips" for better welding. The serial number of your unit

is located on the handle of the gun assembly.

READ THESE INSTRUCTIONS

Any new tool requires familiarity. Take

fifteen minutes of time to get

acquainted with your purchase. These

instructions are intended to guide you

through connection, operation, trouble

shooting, and maintenance. If you have

any questions or problems in start-up,

give us a call at:

1-630-231-0419

sales@winstongroup.com

THE WINSTON GROUP LTD

1092 Carolina Drive, Suite 1 Phone:1-630-231-0419

West Chicago, Illinois 60185 Fax: 630-231-0429

www.winstongroup.com

COOL DOWN 10 MINUTES

CAUTION AS V42DD MOVES BACKWARD

Fig. #1

I. UNPACKING, ASSEMBLY AND CONNECTION .

A. UNPACKING.

Your new V42DD Hot Air Welder is delivered to you in a sturdy, reuseable polymer tool box. The custom

designed foam base and spacers assure that your machine is protected and arrives ready to assemble

and use.

Remove the machine by lifiting it straight up and out and set it on a horizontal surface. The 2 additional

10 lb. weights are packed in cut-outs under the machine with foam covers on top.

Remove the foam covers from the weights and place them into the cut-outs for reuse after removing the

weights. Return all of the foam pieces to the box for later use during transportation and storage.

The only assembly required is to thread the handle into its base on the frame and tighten it down with the

lock nut, and attach an appropriate twist-lock plug to the end of the cord as described below.

B. ELECTRICAL POWER REQUIREMENTS.

Rating: 230VAC at 20 AMP The Eagle will operate within a range of 210VAC to 250VAC. Checking the

voltage at the point of unit plug-in is critical to the performance of your welder. You can perform the

voltage check with built in voltmeter.

Caution: YOU ARE WORKING WITH HIGH VOLTAGE EQUIPMENT. DEATH OR SERIOUS INJURY

MAY OCCUR DURING OR AFTER EQUIPMENT CONNECTION. UTILIZE A QUALIFIED

ELECTRICIAN.

Generators: Minimum 7,500 Watt Portable Generators should be used as a power source for each Eagle

V42DD automatic unit in use. Building electrical outlets are a poor source of voltage because they are too

unpredictable. Even when they are dedicated circuits, power spikes and drops can occur, resulting in

sub-standard equipment operation.

A Minimum 7,500 Watt watt capacity for the generator provides a measure of protection against

insufficient voltage. Remember, the Eagle utilizes 4,200 watts so the guage and length of your extension

cord will affect the wattage requirement.

Extension Cords: Extension cord should be at least 10 Gauge, 3 wire, grounded cable.

Do not splice lengths of cable together. This is a serious safety hazard, and can cause a poor connection,

resulting in sub-standard machine performance. Maximum Extension Cord Lengths:

Voltage @ power source 10 Gauge, 3 wire 12 Gauge, 3 wire

208VAC 100 Feet 50 Feet

220VAC 300 Feet 100 Feet

230VAC 400 Feet 200 Feet

240VAC 500 Feet 300 Feet

C. PLUG CONNECTION.

A Three-prong(L6-30) Twist Lock plug with a rating of 30 Amps and 250VAC is required.

Eagle is shipped with a L6-30 plug (Part#HBL2621). An extension cord is required between generator

and eagle. A plug and receptacle with a rating of 30 Amps and 250VAC must be purchased and properly

installed. The purchased plug must fit the generator outlet (usually L14-30).

100 feet 10 gauge, 3wires extension cord furnished with L14-30 Plug and L6-30 Receptacle can be

purchased with the Eagle Unit. (Part#10-3-100)

The white and black wires from the cord set of the welder must be connected to the appropriate "X" and

"Y" terminals in the plug to obtain the proper voltage. The green wire must be connected to the ground

terminal of the purchased plug.

The voltmeter on the control box must read 210 Volts as a minimum and 250 Volts as a maximum

for proper operation.

-2-

D. ADDING THE WEIGHT KIT, AND CHECKING THE NOZZLE.

If recommended by the membrane manufacturer, add the 20 pound weight kit. Most membrane

manufacturers require the weights for welding. The amount of weight is a function of the type of

membrane, the type of insulation material and its thickness.

Weight Kit:To add the weight kit, simply slide the two weights over the preinstalled pins on the platform

over the pressure wheel. A third 10 pound weight (Part# 8622) may be added if required.

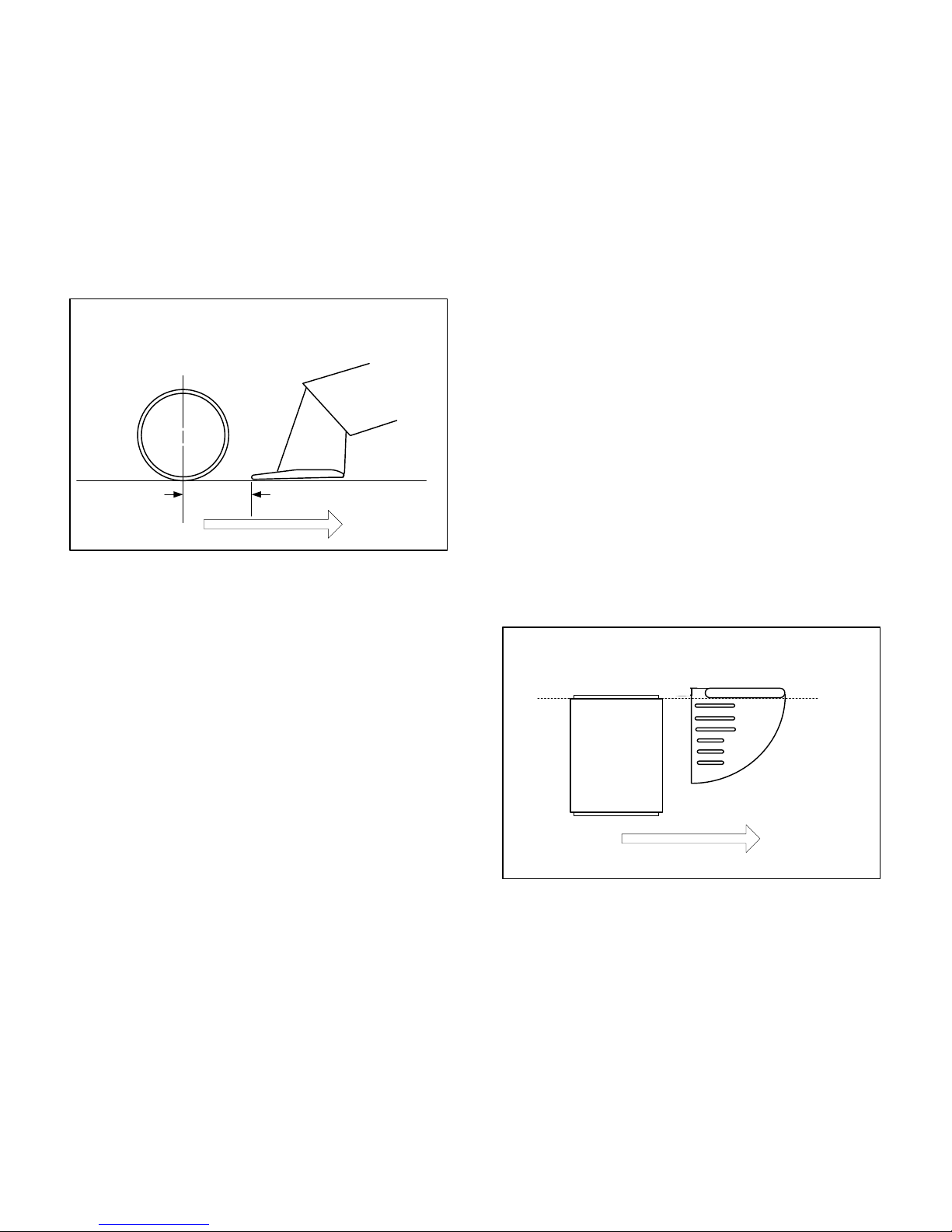

A- Welding Nozzle-Offset Alignment. Check

the distance between the vertical centerline of

the compression roller and the tip of the nozzle.

The distance should normally be 21/4"-21/2" (5560mm) from the centerline of the roller.

-3-

21/4" - 21/2"

Compression

Wheel

Nozzle

Nozzle

Compression

Wheel

B- Welding Nozzle In-line Alignment: Check the

alignment of the welding nozzle to the compression

wheel as shown in Fig. #2A. The inside edge of the

compression wheel should be in line with the inside

edge of the throat of the welding nozzle as shown

in Figure #2B. Proper alignment of the welding

nozzle to the compression wheel is accomplished

by adjusting the thumb wheel (Illustration #23 on

the part sheet) on the frame of the unit.

Fig. #2A

Fig. #2B

COOL DOWN 10 MINUTES

Fig. #3

Checking The Control Box Plugs

Each connector is "keyed" or "indexed" for proper alignment when attached.

The drive motor plug should be securely connected to the lower outlet on the left side of the control

box.

-4-

Drive Motor

connection

Speed Control

Knob

Main Power Input

30A 250V (L6-30)Twist-Lock Plug Furnished

II. OPERATION

A. POSITIONING OF WELDER

(For modified Bitumens APP or SBS)

The pressure roller should be positioned so that it

rolls fully on the surface of the top sheet, about 1/4"

inside the edge of the shelf. The edge of the roller

should not hang over the edge to keep it from

picking up the liquefied asphalt. (See Fig. #4).

THREADING THE HANDLE.

Thread the handle to the back of the welder. Tighten down the locking bolt so that the handle is firmly

bolted to the unit.

Put gear lever to drive to move the welder.

(CAUTION) - Lifting the welder by the lever can break off the lever.

Fig. #4

Drive Motor

Lever

Main Power

Switch

AC Input

Voltage

Indicator

Handle

COMPRESSION

WHEEL

0.25"

Bleed-Out

Loading...

Loading...