Winston foodservice Collectrmatic ANNUAL SAFETY INSPECTION CHECKLIST

ANNUAL SAFETY INSPECTION CHECKLIST

This Annual Safety Inspection Checklist ( “Inspection” ) applies to all Collectramatic® Fryers.

The inspection performs an important safety function. It provides for an annual inspection

of each fryer. Each inspected fryer will be designated as either:

A) Pass

B) Fail & Decommission

C) Fail & Remove Fryer from Use until Repaired

D) Fail & Repair Promptly

The inspection does not replace any other recommended inspections, maintenance or repairs

of Collectramatic Fryers. See Owner's Manual for details.

Instructions

Step 1- Inspect for 25 Year Useful Life

The dened useful life of a Collectramatic Pressure Fryer is 25 years from date of manufacture. Any

Collectramatic Pressure Fryer that has reached its useful life is to be decommissioned immediately,

either through physical destruction or transformation of the pressure fryer into an open fryer through

the use of the dened process. If any of the following criteria apply to the Collectramatic Pressure

Fryer during inspection, the fryer will be designated as Fail & Decommission:

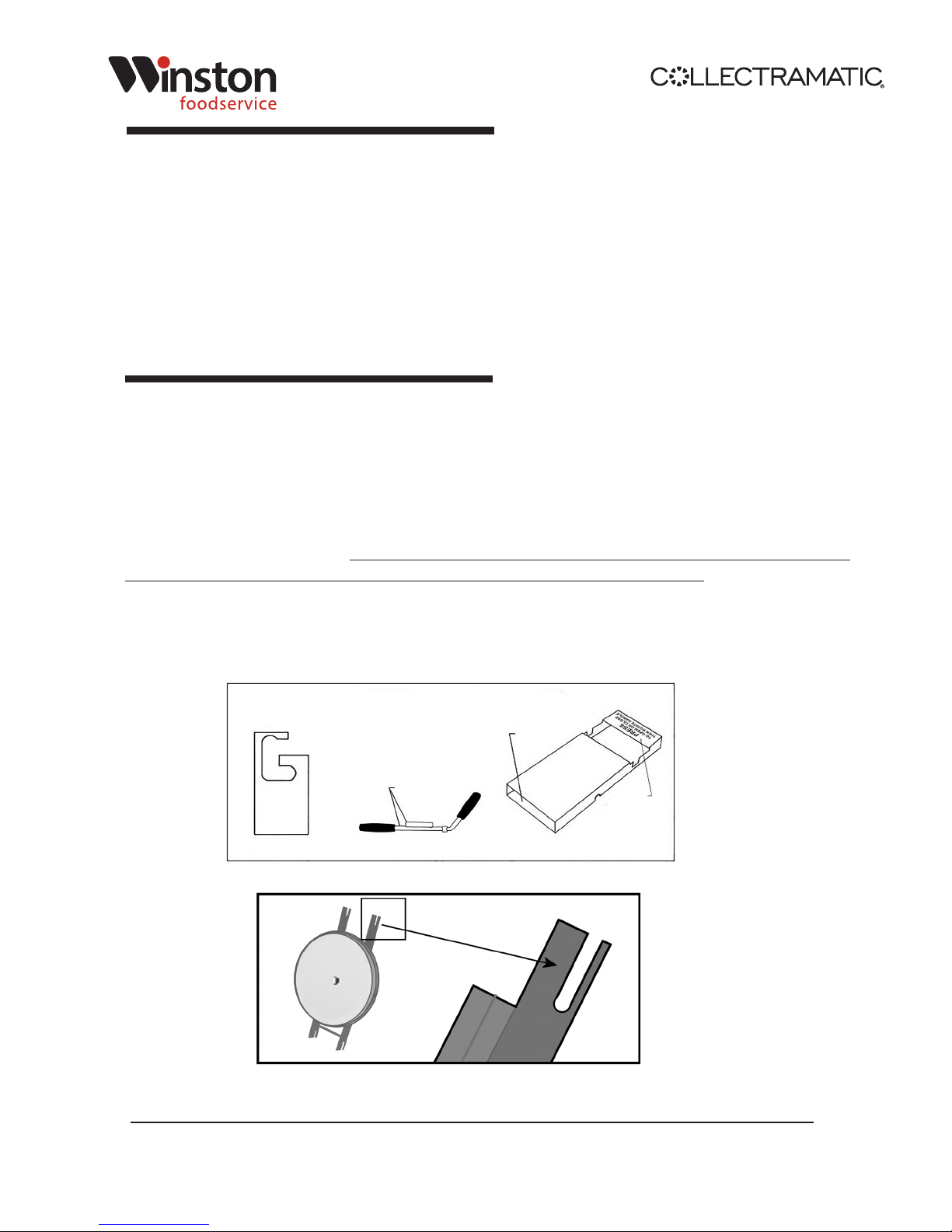

1. Fryer Lid or Front Block include any Cam Lock components (Fig. A and Fig. B)

2. Fryer Lid includes Pressure Lock components (Fig. B)

3. Fryer Serial Number to show an age of 25 years or more (Fig. C)

4. No identication of valid Serial Number found on fryer

CAM LOCK LID PARTS ( >25 YEARS)

No Metal Tab

Sticking Out

Round Bar

PRESS

To Open or Close

Then Rotate Handle

1. Front Block 2. Handle Bar 3. Lid Lock

Fig. A - Cam Lock Lid Components

NO CUT OUT

Fig. B - Cam Lock or Pressure Lock Lid

Winston Foodservice | 2345 Carton Drive | Louisville, Kentucky 40299

800.234.5286 | +1.502.495.5400 | www.kfcfryers.com

Page 1 of 8 4272y185rev13_01-20-17_instructions_fryer_maintenance_kfc

Serial Number Range ( original ) Max Year of Useful Life for PF Models

37701-40187 2017

40188-40187 2018

41488-42605 2019

42606-42464 2020

>43465 or 12 digit SN w/ rst 6 digits of

063098 and ending in 96

12 digit SN with digits 5 and 6 as 97 2022

12 digit SN with digits 5 and 6 as 98 2023

12 digit SN with digits 5 and 6 as 99 2024

12 digit SN with digits 5 and 6 as 00 2025

12 digit SN with digits 5 and 6 as 01 or

11 digit SN with 2001 as rst four digits

11 digit SN with 2002 as rst four digits 2027

Fig. C - Serial Number Key for Useful Life

Serial numbers may be listed on the ID tag of the front panel of the fryer. If no ID tag is present or

the ID tag was replaced with an upgrade control kit, the original serial number is etched onto the front

right side of the fryer pot rim. A serial tag from an upgrade control kit can NOT be used to determine

useful life.

2021

2026

Step 2 - Inspect Pressure Components

Fryer should be emptied of oil and cooled to room temperature prior to inspection.

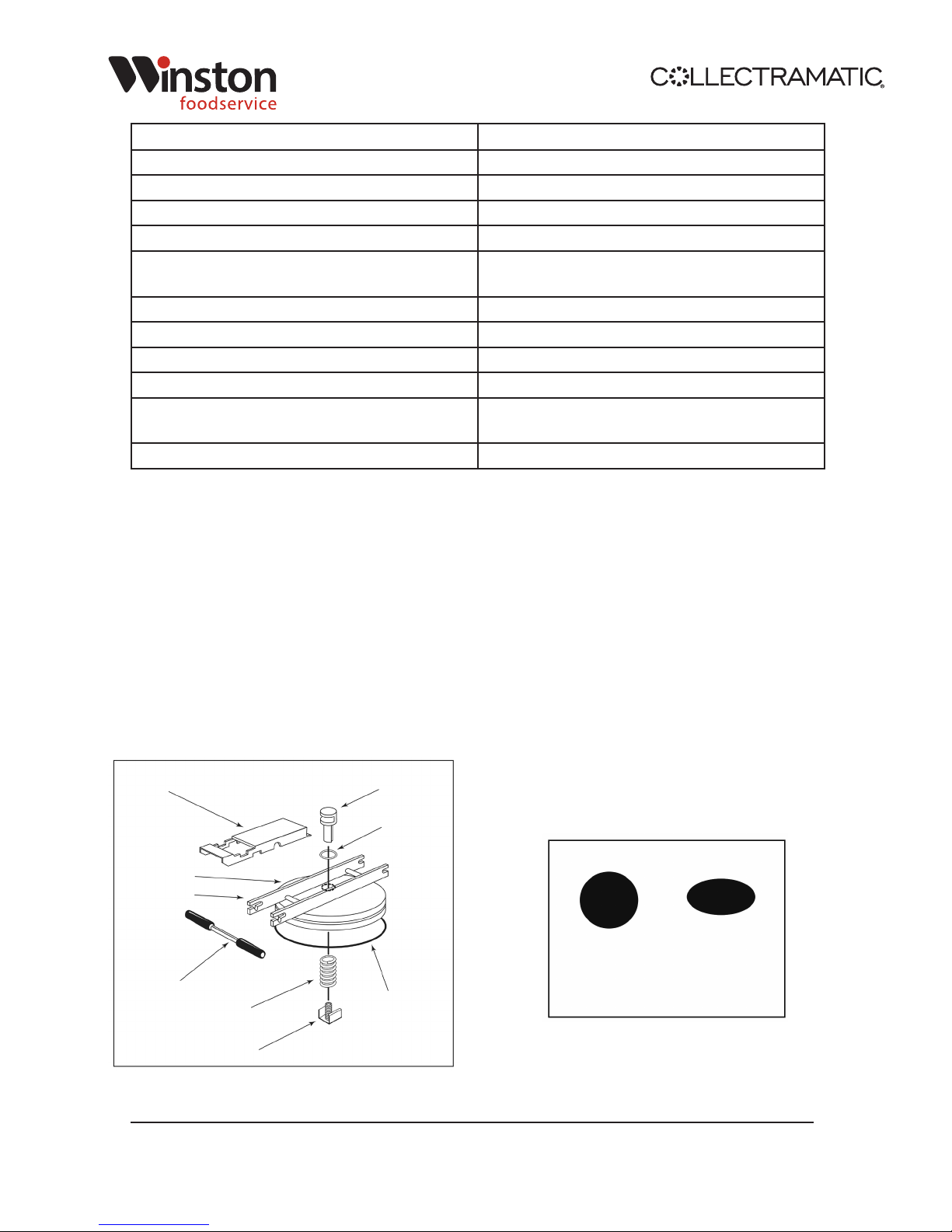

1. Lid Inspection - Examine all lid components for damage such as bends, cracks, or broken

welds (Fig. D). Open and Close lid with gasket installed to ensure proper function.

Remove lid valve (Fig. D #8) to verify O-Ring (Fig. D #9) is not attened,

frayed, or torn. Inspect Lid Gasket (Fig. E) to verify it is not attened, frayed, or torn.

1. LID LOCK

2. LID

3. LID SUPPORT BAR

4. HANDLEBAR

6. SPRING

8. LID VALVE

9. O-RING

5. LID GASKET

ROUND

OK

FLATTENED

DO NOT USE

GASKET CROSS SECTION

Fig. E - Lid Gasket

7. RETAINER

Fig. D - Lid Components

Winston Foodservice | 2345 Carton Drive | Louisville, Kentucky 40299

800.234.5286 | +1.502.495.5400 | www.kfcfryers.com

Page 2 of 8 4272y185rev13_01-20-17_instructions_fryer_maintenance_kfc

All components acceptable = Pass Lid Inspection

All components acceptable except at lid or lid valve gasket = Fail and Repair Promptly

Any components damaged = Fail and Remove Fryer from Use Until Repaired

Lid or lid valve gasket are frayed or torn = Fail and Remove Fryer from Use until Repaired

Lid does not open and/or close properly = Fail and Remove Fryer from use until Repaired

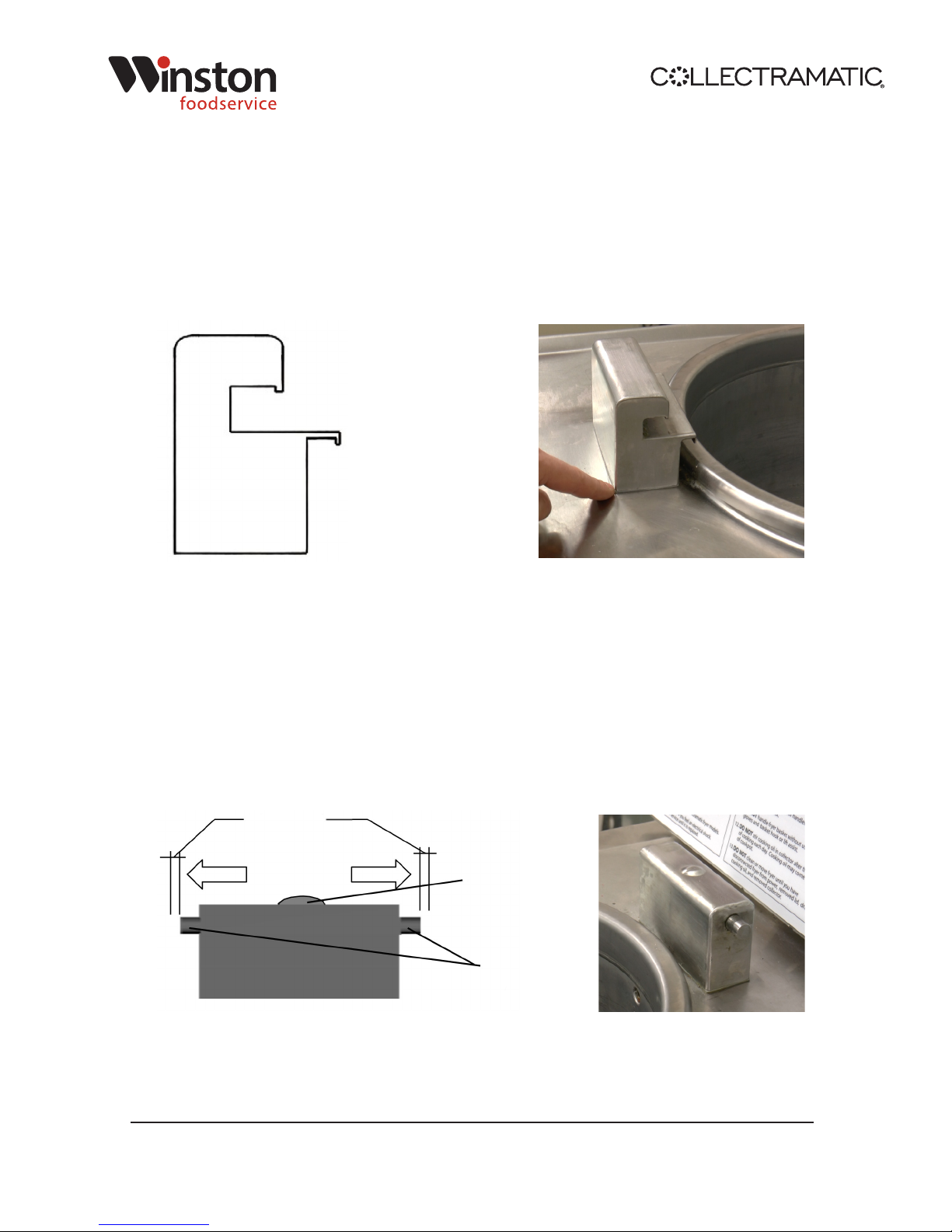

2. Front Latch Block Inspection - Inspect Front Latch Block (Fig. F) to ensure that there are no cracks or

broken welds. Ensure that there is a gasket or food-grade silicone caulk between the fryer top and

Fig. F - Front Latch Block Fig. G - Front Block Gasket

Front Latch acceptable = Pass Front Latch Inspection

Silicone/Gasket missing = Fail and Repair Promptly

Front Latch not acceptable = Fail and Remove Fryer from Use until Repaired

3. Rear Block Inspection - Inspect Rear Block (Fig. H & I) to ensure that the block has a bump on the top.

Inspect to ensure that there are no cracks or broken welds. Inspect pins to ensure they are not bent or

loose. While pins may spin or slide side to side, they may not move more than 1/16th of an inch. Ensure

that there is a gasket or food-grade silicone between the fryer top and the base of the block.

1/16" MAX

BUMP

PINS

Fig. I - Rear Hinge Block

Fig. H - Rear Hinge Block

Winston Foodservice | 2345 Carton Drive | Louisville, Kentucky 40299

800.234.5286 | +1.502.495.5400 | www.kfcfryers.com

Page 3 of 8 4272y185rev13_01-20-17_instructions_fryer_maintenance_kfc

Loading...

Loading...